refrigerant type DODGE RAM 2003 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2818 of 2895

NOTE: If the condenser is replaced, add 30 millili-

ters (1 fluid ounce) of refrigerant oil to the refriger-

ant system. Use only refrigerant oil of the type

recommended for the compressor in the vehicle(Re-

fer to 24 - HEATING & AIR CONDITIONING/PLUMB-

ING/REFRIGERANT OIL - DESCRIPTION).

(8) Charge the a/c system(Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING - STANDARD

PROCEDURE).

(9) Install the battery negative cable.

A/C CONDENSER FAN

REMOVAL - CONDENSER FAN (GAS ENGINE

ONLY - 3.7, 4.7 & 5.7L)

(1) Remove and isolate negative battery cable.

(2) Remove condenser assembly(Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/A/C

CONDENSER - REMOVAL).

(3) Place condenser assembly on a flat work area

and remove screws holding fan assembly to con-

denser.

(4) Separate fan assembly from condenser noting

location of all seals for reinstallation.

INSTALLATION - CONDENSER FAN (GAS

ENGINE ONLY - 3.7, 4.7 & 5.7L)

(1) Position fan assembly on to the condenser.

(2) Check all fan shroud seals and replace as

required then install retainer screws to hold fan

assembly to condenser.

(3) Install condenser and fan assembly to vehi-

cle(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/A/C CONDENSER - INSTALLATION).

(4) Install battery negative cable.

A/C DISCHARGE LINE

REMOVAL

REMOVAL

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

(1) Disconnect and isolate the battery negative

cable.

(2) Recover the refrigerant from the refrigerant

system. (Refer to 24 - HEATING & AIR CONDI-TIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY)

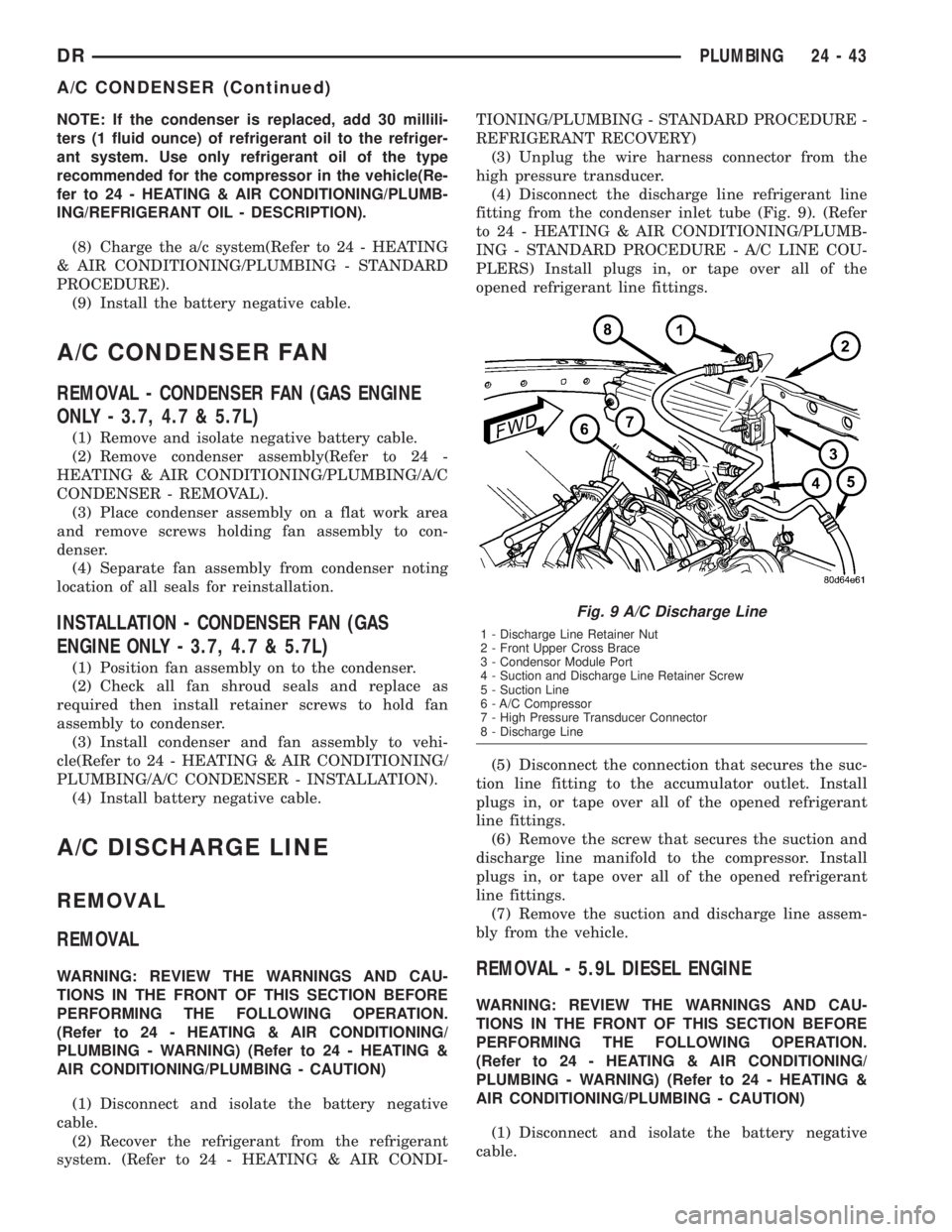

(3) Unplug the wire harness connector from the

high pressure transducer.

(4) Disconnect the discharge line refrigerant line

fitting from the condenser inlet tube (Fig. 9). (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMB-

ING - STANDARD PROCEDURE - A/C LINE COU-

PLERS) Install plugs in, or tape over all of the

opened refrigerant line fittings.

(5) Disconnect the connection that secures the suc-

tion line fitting to the accumulator outlet. Install

plugs in, or tape over all of the opened refrigerant

line fittings.

(6) Remove the screw that secures the suction and

discharge line manifold to the compressor. Install

plugs in, or tape over all of the opened refrigerant

line fittings.

(7) Remove the suction and discharge line assem-

bly from the vehicle.REMOVAL - 5.9L DIESEL ENGINE

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

(1) Disconnect and isolate the battery negative

cable.

Fig. 9 A/C Discharge Line

1 - Discharge Line Retainer Nut

2 - Front Upper Cross Brace

3 - Condensor Module Port

4 - Suction and Discharge Line Retainer Screw

5 - Suction Line

6 - A/C Compressor

7 - High Pressure Transducer Connector

8 - Discharge Line

DRPLUMBING 24 - 43

A/C CONDENSER (Continued)

Page 2825 of 2895

INSTALLATION

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)(Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING -

CAUTION - REFRIGERANT HOSES/LINES/TUBES

PRECAUTIONS)

(1) Install the accumulator to the bulkhead but do

not tighten yet.

(2) Remove the tape or plugs from the refrigerant

line fittings on the accumulator inlet and the evapo-

rator outlet. Connect the accumulator inlet refriger-

ant line coupler to the evaporator outlet. (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - A/C LINE COUPLERS)

(3) Remove the tape or plugs from the refrigerant

line fittings on the suction line and the accumulator

outlet. Connect the suction line refrigerant line cou-

pler to the accumulator outlet. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - A/C LINE COUPLERS)

(4) Tighten the accumulator fasteners to 4.5 N´m

(40 in. lbs.).

(5) Connect the battery negative cable.

(6) Evacuate the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE)

(7) Charge the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE)

NOTE: If the accumulator is replaced, add 60 milli-

liters (2 fluid ounces) of refrigerant oil to the refrig-

erant system. Use only refrigerant oil of the type

recommended for the compressor in the vehicle.

HEATER CORE

DESCRIPTION

The heater core is located in the HVAC housing,

under the instrument panel. It is a heat exchanger

made of rows of tubes and fins.

The heater core is not repairable and if damaged it

must be replaced.

OPERATION

Engine coolant is circulated through heater hoses

to the heater core at all times. As the coolant flowsthrough the heater core, heat removed from the

engine is transferred to the heater core fins and

tubes. Air directed through the heater core picks up

the heat from the heater core fins. The blend door

allows control of the heater output air temperature

by controlling how much of the air flowing through

the HVAC housing is directed through the heater

core. The blower motor speed controls the volume of

air flowing through the HVAC housing.

The heater core cannot be repaired and, if faulty or

damaged, it must be replaced.

REMOVAL

NOTE: Disassembly of the HVAC housing is not

required to remove heater core.

(1) Remove the HVAC housing from the vehicle.

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - REMOVAL)

(2) Remove the screws and retainers that secure

the heater core to the HVAC housing.

(3) Lift the heater core out of the heater-A/C hous-

ing.

(4) Inspect all seals and repair or replace as

required.

INSTALLATION

(1) Place the heater core into the HVAC housing.

(2) Snap the retainers for the heater core to the

housing. Install and tighten the screws that secure

the heater core to the HVAC housing (if equipped).

Tighten the screws to 2.2 N´m (20 in. lbs.).

(3) Reinstall the HVAC housing in the vehicle.

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - INSTALLA-

TION)

REFRIGERANT

DESCRIPTION

The refrigerant used in this air conditioning sys-

tem is a HydroFluoroCarbon (HFC), type R-134a.

Unlike R-12, which is a ChloroFluoroCarbon (CFC),

R-134a refrigerant does not contain ozone-depleting

chlorine. R-134a refrigerant is a non-toxic, non-flam-

mable, clear, and colorless liquefied gas.

Even though R-134a does not contain chlorine, it

must be reclaimed and recycled just like CFC-type

refrigerants. This is because R-134a is a greenhouse

gas and can contribute to global warming.

OPERATION

R-134a refrigerant is not compatible with R-12

refrigerant in an air conditioning system. Even a

24 - 50 PLUMBINGDR

ACCUMULATOR (Continued)

Page 2827 of 2895

air and boil the moisture out of the system at near

room temperature. To evacuate the refrigerant sys-

tem, use the following procedure:

(1) Connect a R-134a refrigerant recovery/recy-

cling/charging station that meets SAE Standard

J2210 and a manifold gauge set (if required) to the

refrigerant system of the vehicle and recover refrig-

erant.

(2) Open the low and high side valves and start

the charging station vacuum pump. When the suc-

tion gauge reads 88 kPa (26 in. Hg.) vacuum or

greater, close all of the valves and turn off the vac-

uum pump.

(a) If the refrigerant system fails to reach the

specified vacuum, the system has a leak that must

be corrected. See Refrigerant System Leaks in the

Diagnosis and Testing section of this group for the

procedures.

(b) If the refrigerant system maintains the spec-

ified vacuum for five minutes, restart the vacuum

pump, open the suction and discharge valves and

evacuate the system for an additional ten minutes.

(3) Close all of the valves, and turn off the charg-

ing station vacuum pump.

(4) The refrigerant system is now ready to be

charged with R-134a refrigerant(Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/REFRIG-

ERANT - STANDARD PROCEDURE).

STANDARD PROCEDURE- REFRIGERANT

RECOVERY

WARNING: (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - WARNING) AND (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING - CAU-

TION) BEFORE PERFORMING THE FOLLOWING

OPERATION.

A R-134a refrigerant recovery/recycling/charging

station that meets SAE Standard J2210 must be

used to recover the refrigerant from an R-134a refrig-

erant system. Refer to the operating instructions sup-

plied by the equipment manufacturer for the proper

care and use of this equipment.

STANDARD PROCEDURE- REFRIGERANT

SYSTEM CHARGE

WARNING: (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - WARNING) AND (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING - CAU-

TION) BEFORE PERFORMING THE FOLLOWING

OPERATION.

After the refrigerant system has been tested for

leaks and evacuated, a refrigerant charge can beinjected into the system. See Refrigerant Charge

Capacity in the Service Procedures section of this

group for the proper amount of the refrigerant

charge, this fill level can also be found on a label

attached under the hood of the vehicle..

A R-134a refrigerant recovery/recycling/charging

station that meets SAE Standard J2210 must be

used to charge the refrigerant system with R-134a

refrigerant. Refer to the operating instructions sup-

plied by the equipment manufacturer for the proper

care and use of this equipment.

The R-134a refrigerant system charge capacity for

this vehicle is:

²If equipped with a 3.7L or a 4.7L engine charge

to 0.6804 Kg. (24 oz.).

²If equipped with a 5.9L engine charge to 0.7371

Kg. ( 26 oz.).

REFRIGERANT LINE COUPLER

DESCRIPTION

Spring-lock type refrigerant line couplers are used

to connect many of the refrigerant lines and other

components to the refrigerant system. These couplers

require a special tool for disengaging the two coupler

halves.

OPERATION

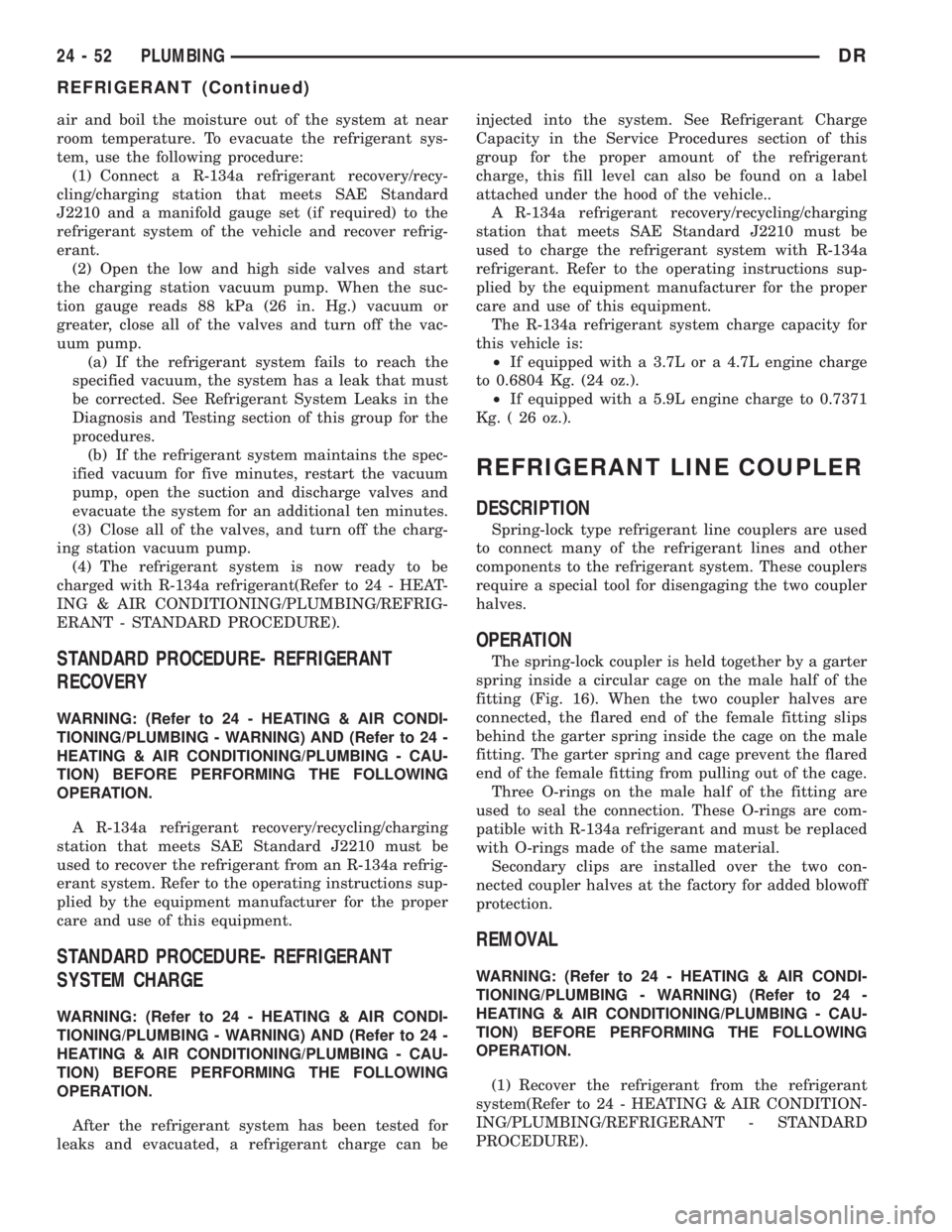

The spring-lock coupler is held together by a garter

spring inside a circular cage on the male half of the

fitting (Fig. 16). When the two coupler halves are

connected, the flared end of the female fitting slips

behind the garter spring inside the cage on the male

fitting. The garter spring and cage prevent the flared

end of the female fitting from pulling out of the cage.

Three O-rings on the male half of the fitting are

used to seal the connection. These O-rings are com-

patible with R-134a refrigerant and must be replaced

with O-rings made of the same material.

Secondary clips are installed over the two con-

nected coupler halves at the factory for added blowoff

protection.

REMOVAL

WARNING: (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - WARNING) (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING - CAU-

TION) BEFORE PERFORMING THE FOLLOWING

OPERATION.

(1) Recover the refrigerant from the refrigerant

system(Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING/REFRIGERANT - STANDARD

PROCEDURE).

24 - 52 PLUMBINGDR

REFRIGERANT (Continued)

Page 2828 of 2895

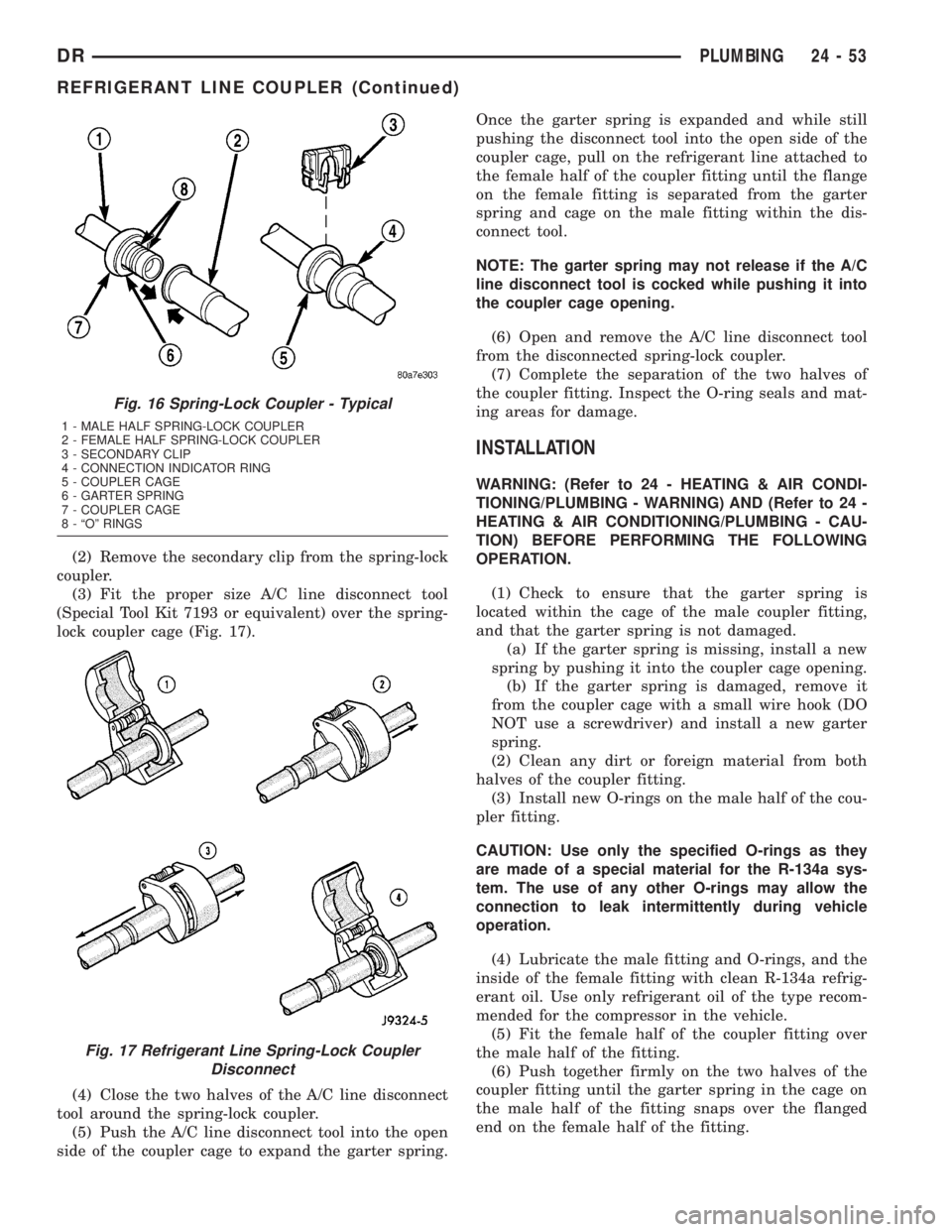

(2) Remove the secondary clip from the spring-lock

coupler.

(3) Fit the proper size A/C line disconnect tool

(Special Tool Kit 7193 or equivalent) over the spring-

lock coupler cage (Fig. 17).

(4) Close the two halves of the A/C line disconnect

tool around the spring-lock coupler.

(5) Push the A/C line disconnect tool into the open

side of the coupler cage to expand the garter spring.Once the garter spring is expanded and while still

pushing the disconnect tool into the open side of the

coupler cage, pull on the refrigerant line attached to

the female half of the coupler fitting until the flange

on the female fitting is separated from the garter

spring and cage on the male fitting within the dis-

connect tool.

NOTE: The garter spring may not release if the A/C

line disconnect tool is cocked while pushing it into

the coupler cage opening.

(6) Open and remove the A/C line disconnect tool

from the disconnected spring-lock coupler.

(7) Complete the separation of the two halves of

the coupler fitting. Inspect the O-ring seals and mat-

ing areas for damage.

INSTALLATION

WARNING: (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - WARNING) AND (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING - CAU-

TION) BEFORE PERFORMING THE FOLLOWING

OPERATION.

(1) Check to ensure that the garter spring is

located within the cage of the male coupler fitting,

and that the garter spring is not damaged.

(a) If the garter spring is missing, install a new

spring by pushing it into the coupler cage opening.

(b) If the garter spring is damaged, remove it

from the coupler cage with a small wire hook (DO

NOT use a screwdriver) and install a new garter

spring.

(2) Clean any dirt or foreign material from both

halves of the coupler fitting.

(3) Install new O-rings on the male half of the cou-

pler fitting.

CAUTION: Use only the specified O-rings as they

are made of a special material for the R-134a sys-

tem. The use of any other O-rings may allow the

connection to leak intermittently during vehicle

operation.

(4) Lubricate the male fitting and O-rings, and the

inside of the female fitting with clean R-134a refrig-

erant oil. Use only refrigerant oil of the type recom-

mended for the compressor in the vehicle.

(5) Fit the female half of the coupler fitting over

the male half of the fitting.

(6) Push together firmly on the two halves of the

coupler fitting until the garter spring in the cage on

the male half of the fitting snaps over the flanged

end on the female half of the fitting.

Fig. 16 Spring-Lock Coupler - Typical

1 - MALE HALF SPRING-LOCK COUPLER

2 - FEMALE HALF SPRING-LOCK COUPLER

3 - SECONDARY CLIP

4 - CONNECTION INDICATOR RING

5 - COUPLER CAGE

6 - GARTER SPRING

7 - COUPLER CAGE

8 - ªOº RINGS

Fig. 17 Refrigerant Line Spring-Lock Coupler

Disconnect

DRPLUMBING 24 - 53

REFRIGERANT LINE COUPLER (Continued)

Page 2829 of 2895

(7) Ensure that the spring-lock coupler is fully

engaged by trying to separate the two coupler halves.

This is done by pulling the refrigerant lines on either

side of the coupler away from each other.

(8) Reinstall the secondary clip over the spring-

lock coupler cage.

REFRIGERANT OIL

DESCRIPTION

The refrigerant oil used in R-134a refrigerant sys-

tems is a synthetic-based, PolyAlkylene Glycol (PAG),

wax-free lubricant. Mineral-based R-12 refrigerant

oils are not compatible with PAG oils, and should

never be introduced to an R-134a refrigerant system.

There are different PAG oils available, and each

contains a different additive package. The SD±7 com-

pressor used in this vehicle is designed to use an

SP-15 PAG refrigerant oil. Use only refrigerant oil of

this same type to service the refrigerant system.

OPERATION

After performing any refrigerant recovery or recy-

cling operation, always replenish the refrigerant sys-

tem with the same amount of the recommended

refrigerant oil as was removed. Too little refrigerant

oil can cause compressor damage, and too much can

reduce air conditioning system performance.

PAG refrigerant oil is much more hygroscopic than

mineral oil, and will absorb any moisture it comes

into contact with, even moisture in the air. The PAG

oil container should always be kept tightly capped

until it is ready to be used. After use, recap the oil

container immediately to prevent moisture contami-

nation.

STANDARD PROCEDURE - REFRIGERANT OIL

LEVEL

When an air conditioning system is assembled at

the factory, all components except the compressor are

refrigerant oil free. After the refrigerant system hasbeen charged and operated, the refrigerant oil in the

compressor is dispersed throughout the refrigerant

system. The accumulator, evaporator, condenser, and

compressor will each retain a significant amount of

the needed refrigerant oil.

It is important to have the correct amount of oil in

the refrigerant system. This ensures proper lubrica-

tion of the compressor. Too little oil will result in

damage to the compressor. Too much oil will reduce

the cooling capacity of the air conditioning system.

It will not be necessary to check the oil level in the

compressor or to add oil, unless there has been an oil

loss. An oil loss may occur due to a rupture or leak

from a refrigerant line, a connector fitting, a compo-

nent, or a component seal. If a leak occurs, add 30

milliliters (1 fluid ounce) of refrigerant oil to the

refrigerant system after the repair has been made.

Refrigerant oil loss will be evident at the leak point

by the presence of a wet, shiny surface around the

leak.

Refrigerant oil must be added when a accumulator,

evaporator coil or condenser are replaced. See the

Refrigerant Oil Capacities chart. When a compressor

is replaced, the refrigerant oil must be drained from

the old compressor and measured. Drain all of the

refrigerant oil from the new compressor, then fill the

new compressor with the same amount of refrigerant

oil that was drained out of the old compressor.

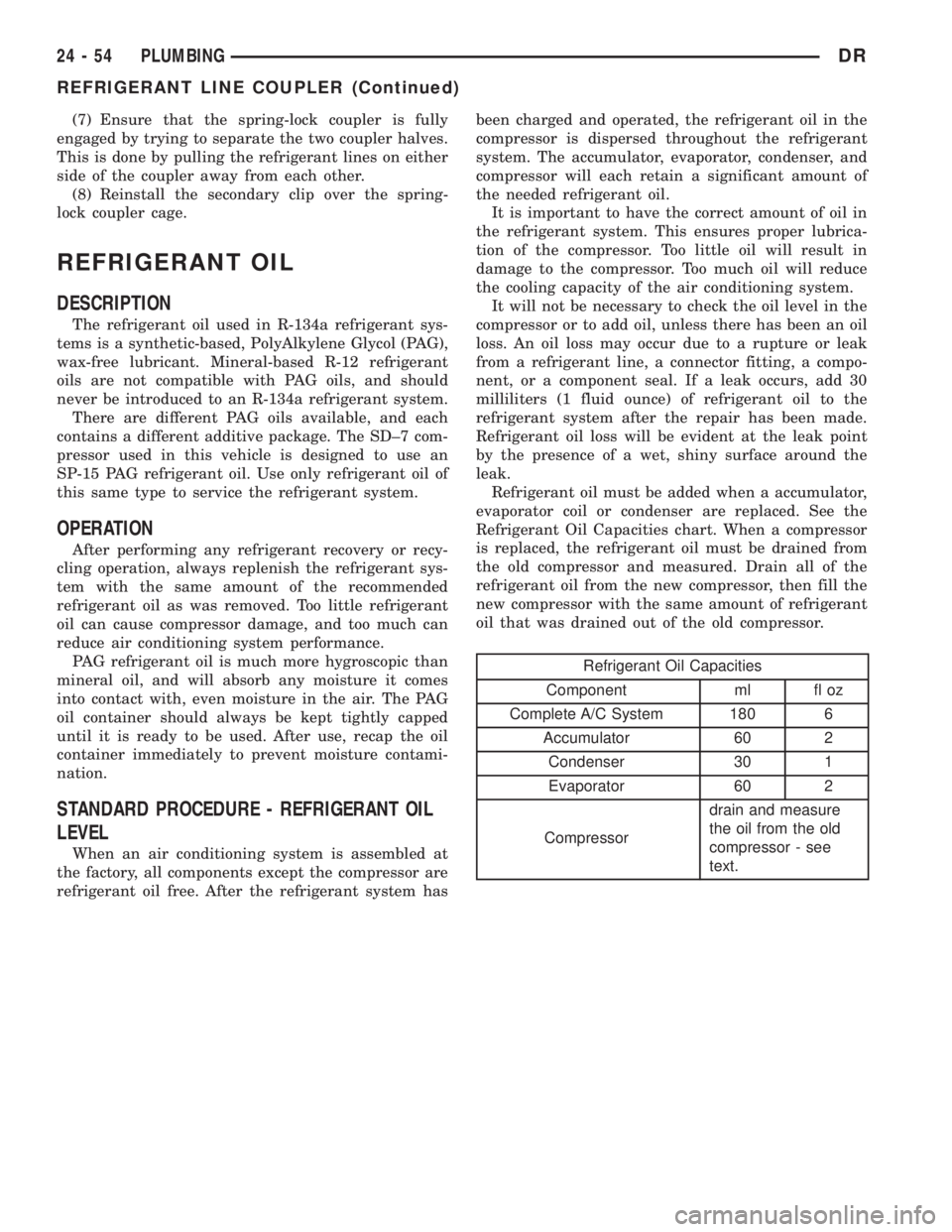

Refrigerant Oil Capacities

Component ml fl oz

Complete A/C System 180 6

Accumulator 60 2

Condenser 30 1

Evaporator 60 2

Compressordrain and measure

the oil from the old

compressor - see

text.

24 - 54 PLUMBINGDR

REFRIGERANT LINE COUPLER (Continued)