Transmission DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1502 of 2895

(8) To align the bearing cap, use cap slot, align-

ment dowel and cap bolts. DO NOT remove excess

material after assembly. DO NOT strike rear cap

more than 2 times for proper engagement.

(9) Clean and oil all cap bolts. Install all main

bearing caps. Install all cap bolts and alternately

tighten to 115 N´m (85 ft. lbs.) torque.

(10) Install oil pump (Refer to 9 - ENGINE/LU-

BRICATION/OIL PUMP - INSTALLATION).

(11) Install the timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(12) Install the vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION).

(13) Position the connecting rods onto the crank-

shaft and install the rod bearing caps. Tighten the

nuts to 61 N´m (45 ft. lbs.).

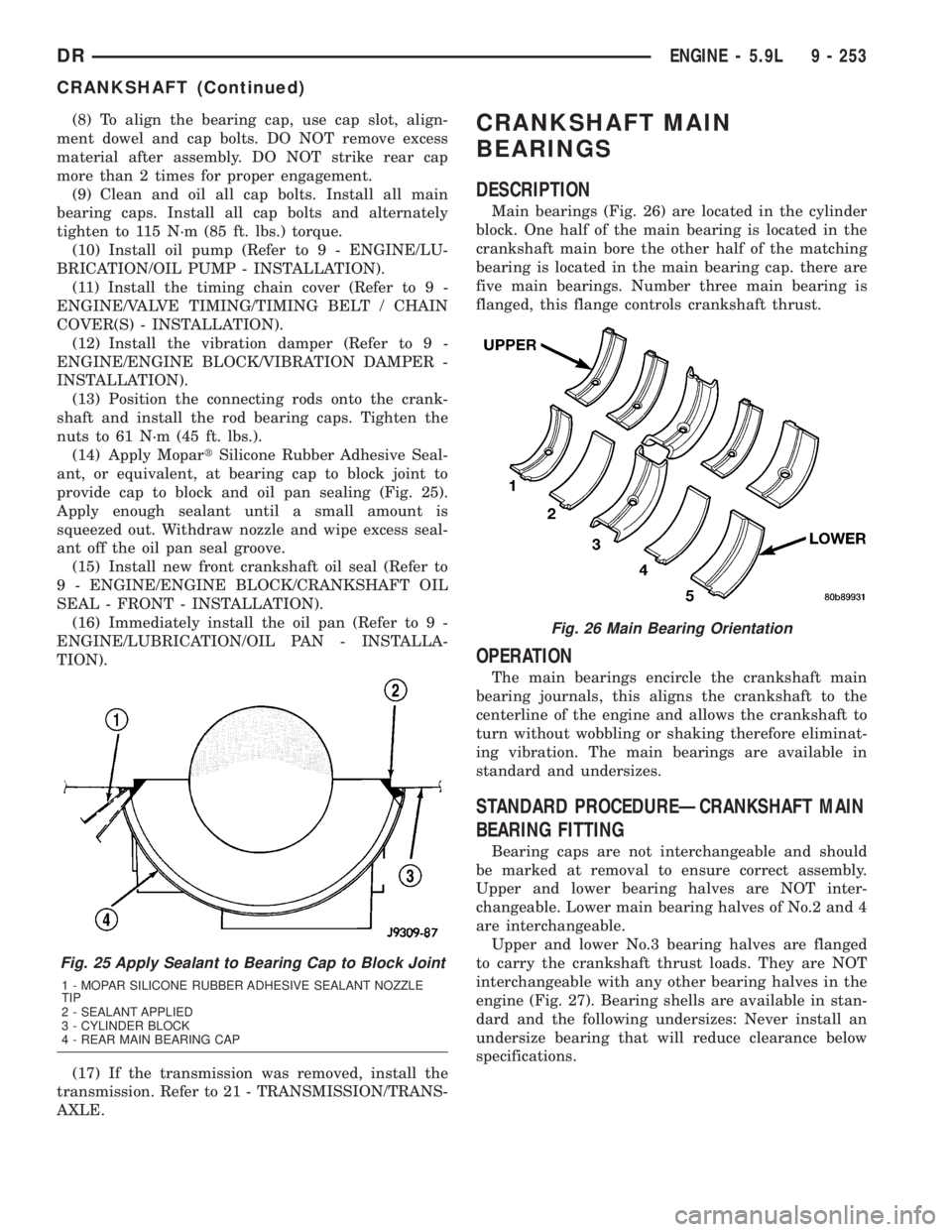

(14) Apply MopartSilicone Rubber Adhesive Seal-

ant, or equivalent, at bearing cap to block joint to

provide cap to block and oil pan sealing (Fig. 25).

Apply enough sealant until a small amount is

squeezed out. Withdraw nozzle and wipe excess seal-

ant off the oil pan seal groove.

(15) Install new front crankshaft oil seal (Refer to

9 - ENGINE/ENGINE BLOCK/CRANKSHAFT OIL

SEAL - FRONT - INSTALLATION).

(16) Immediately install the oil pan (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - INSTALLA-

TION).

(17) If the transmission was removed, install the

transmission. Refer to 21 - TRANSMISSION/TRANS-

AXLE.CRANKSHAFT MAIN

BEARINGS

DESCRIPTION

Main bearings (Fig. 26) are located in the cylinder

block. One half of the main bearing is located in the

crankshaft main bore the other half of the matching

bearing is located in the main bearing cap. there are

five main bearings. Number three main bearing is

flanged, this flange controls crankshaft thrust.

OPERATION

The main bearings encircle the crankshaft main

bearing journals, this aligns the crankshaft to the

centerline of the engine and allows the crankshaft to

turn without wobbling or shaking therefore eliminat-

ing vibration. The main bearings are available in

standard and undersizes.

STANDARD PROCEDUREÐCRANKSHAFT MAIN

BEARING FITTING

Bearing caps are not interchangeable and should

be marked at removal to ensure correct assembly.

Upper and lower bearing halves are NOT inter-

changeable. Lower main bearing halves of No.2 and 4

are interchangeable.

Upper and lower No.3 bearing halves are flanged

to carry the crankshaft thrust loads. They are NOT

interchangeable with any other bearing halves in the

engine (Fig. 27). Bearing shells are available in stan-

dard and the following undersizes: Never install an

undersize bearing that will reduce clearance below

specifications.

Fig. 25 Apply Sealant to Bearing Cap to Block Joint

1 - MOPAR SILICONE RUBBER ADHESIVE SEALANT NOZZLE

TIP

2 - SEALANT APPLIED

3 - CYLINDER BLOCK

4 - REAR MAIN BEARING CAP

Fig. 26 Main Bearing Orientation

DRENGINE - 5.9L 9 - 253

CRANKSHAFT (Continued)

Page 1515 of 2895

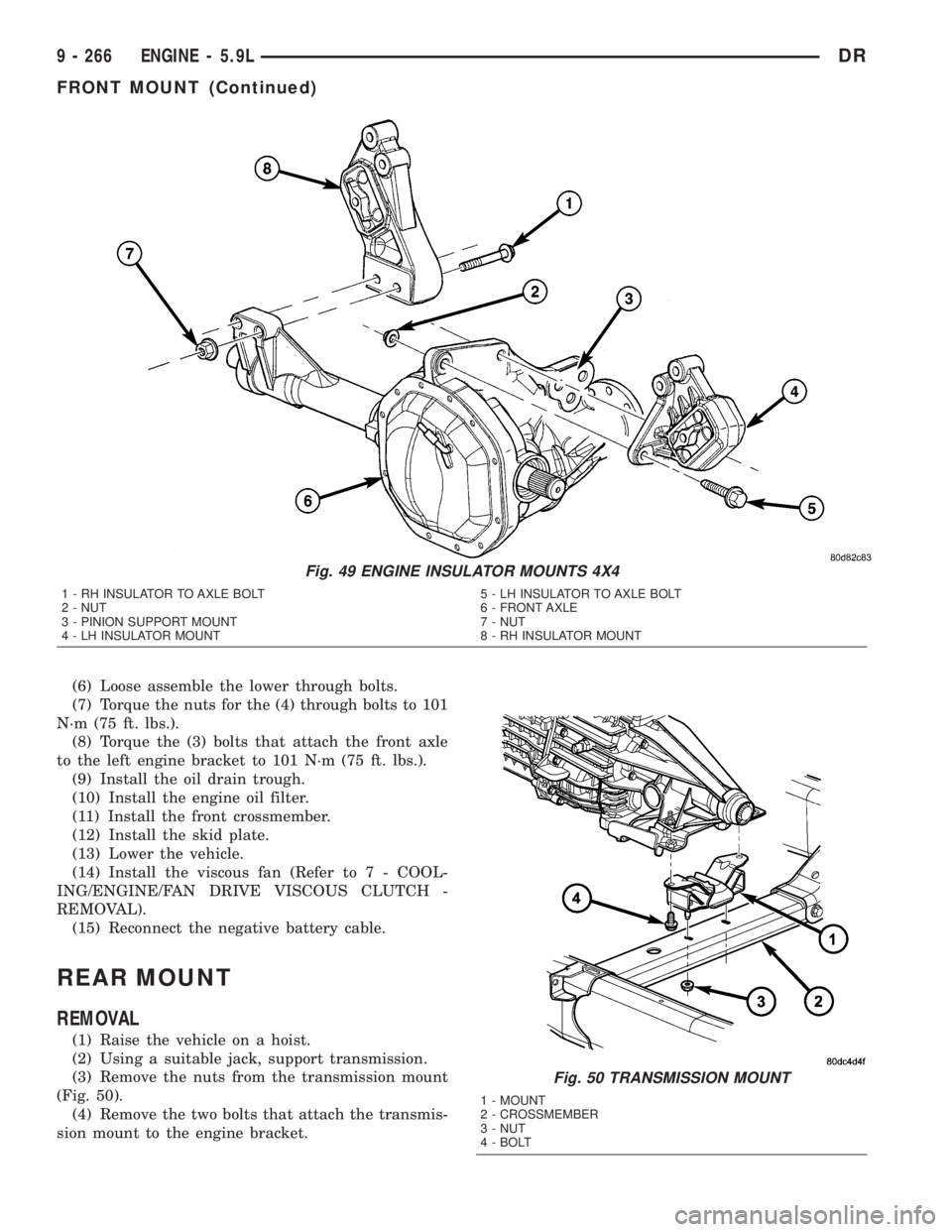

(6) Loose assemble the lower through bolts.

(7) Torque the nuts for the (4) through bolts to 101

N´m (75 ft. lbs.).

(8) Torque the (3) bolts that attach the front axle

to the left engine bracket to 101 N´m (75 ft. lbs.).

(9) Install the oil drain trough.

(10) Install the engine oil filter.

(11) Install the front crossmember.

(12) Install the skid plate.

(13) Lower the vehicle.

(14) Install the viscous fan (Refer to 7 - COOL-

ING/ENGINE/FAN DRIVE VISCOUS CLUTCH -

REMOVAL).

(15) Reconnect the negative battery cable.

REAR MOUNT

REMOVAL

(1) Raise the vehicle on a hoist.

(2) Using a suitable jack, support transmission.

(3) Remove the nuts from the transmission mount

(Fig. 50).

(4) Remove the two bolts that attach the transmis-

sion mount to the engine bracket.

Fig. 49 ENGINE INSULATOR MOUNTS 4X4

1 - RH INSULATOR TO AXLE BOLT

2 - NUT

3 - PINION SUPPORT MOUNT

4 - LH INSULATOR MOUNT5 - LH INSULATOR TO AXLE BOLT

6 - FRONT AXLE

7 - NUT

8 - RH INSULATOR MOUNT

Fig. 50 TRANSMISSION MOUNT

1 - MOUNT

2 - CROSSMEMBER

3 - NUT

4 - BOLT

9 - 266 ENGINE - 5.9LDR

FRONT MOUNT (Continued)

Page 1516 of 2895

(5) Raise the transmission enough to remove the

mount from the crossmember.

(6) Remove the mount.

INSTALLATION

NOTE: Threadlocking compound must be applied to

the bolts before installation.

(1) Install the two bolts that attach the transmis-

sion mount to the transmission bracket.

(2) Torque the bolts to 61N´m (45 ft.lbs.) torque.

(3) Lower the transmission so the transmission

mount rests on the crossmember, and the studs of

the transmission mount are aligned in the slots in

the crossmember.

(4) Install the nuts onto the transmission mount

studs through the crossmember access slot.

(5) Torque the nuts to 54N´m (40 ft. lbs.).

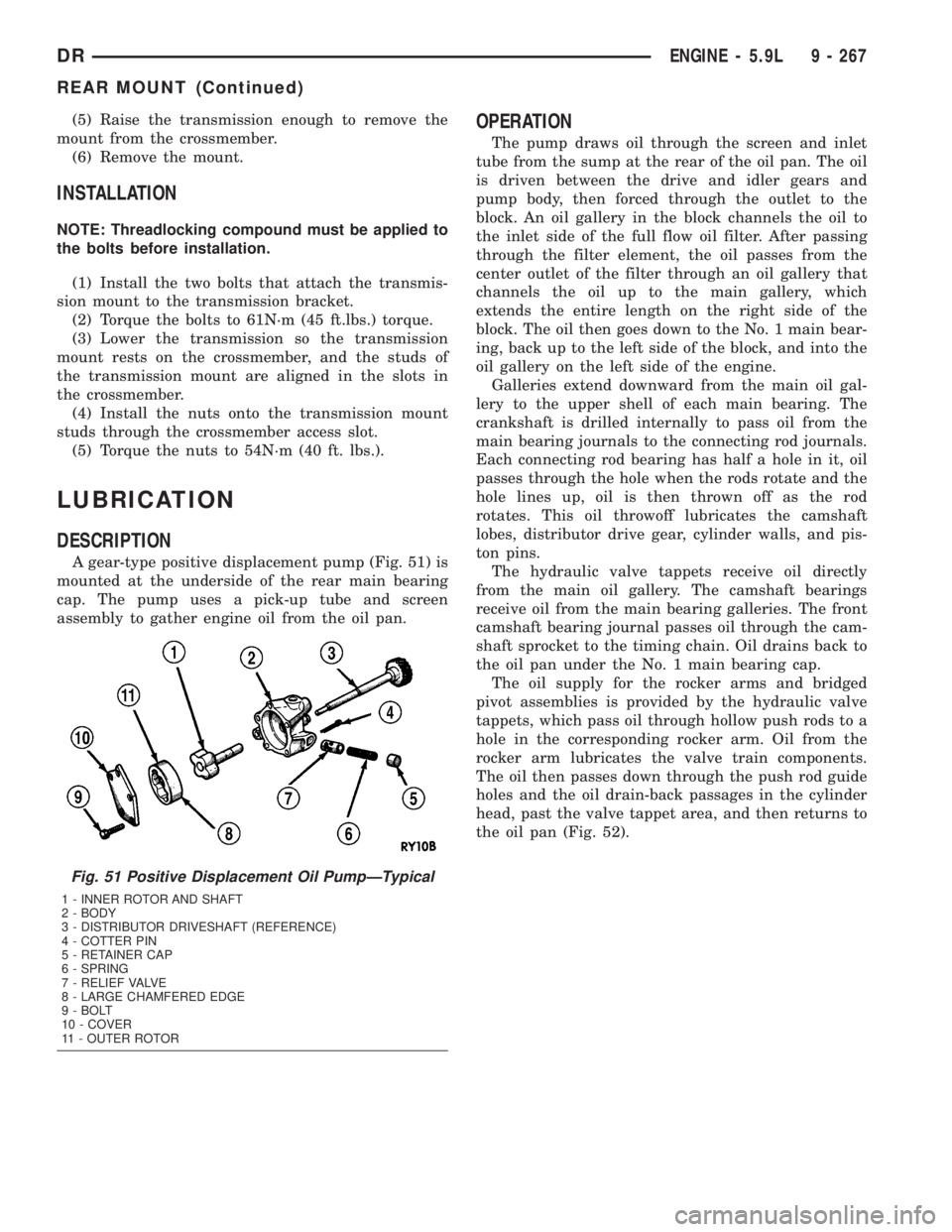

LUBRICATION

DESCRIPTION

A gear-type positive displacement pump (Fig. 51) is

mounted at the underside of the rear main bearing

cap. The pump uses a pick-up tube and screen

assembly to gather engine oil from the oil pan.

OPERATION

The pump draws oil through the screen and inlet

tube from the sump at the rear of the oil pan. The oil

is driven between the drive and idler gears and

pump body, then forced through the outlet to the

block. An oil gallery in the block channels the oil to

the inlet side of the full flow oil filter. After passing

through the filter element, the oil passes from the

center outlet of the filter through an oil gallery that

channels the oil up to the main gallery, which

extends the entire length on the right side of the

block. The oil then goes down to the No. 1 main bear-

ing, back up to the left side of the block, and into the

oil gallery on the left side of the engine.

Galleries extend downward from the main oil gal-

lery to the upper shell of each main bearing. The

crankshaft is drilled internally to pass oil from the

main bearing journals to the connecting rod journals.

Each connecting rod bearing has half a hole in it, oil

passes through the hole when the rods rotate and the

hole lines up, oil is then thrown off as the rod

rotates. This oil throwoff lubricates the camshaft

lobes, distributor drive gear, cylinder walls, and pis-

ton pins.

The hydraulic valve tappets receive oil directly

from the main oil gallery. The camshaft bearings

receive oil from the main bearing galleries. The front

camshaft bearing journal passes oil through the cam-

shaft sprocket to the timing chain. Oil drains back to

the oil pan under the No. 1 main bearing cap.

The oil supply for the rocker arms and bridged

pivot assemblies is provided by the hydraulic valve

tappets, which pass oil through hollow push rods to a

hole in the corresponding rocker arm. Oil from the

rocker arm lubricates the valve train components.

The oil then passes down through the push rod guide

holes and the oil drain-back passages in the cylinder

head, past the valve tappet area, and then returns to

the oil pan (Fig. 52).

Fig. 51 Positive Displacement Oil PumpÐTypical

1 - INNER ROTOR AND SHAFT

2 - BODY

3 - DISTRIBUTOR DRIVESHAFT (REFERENCE)

4 - COTTER PIN

5 - RETAINER CAP

6 - SPRING

7 - RELIEF VALVE

8 - LARGE CHAMFERED EDGE

9 - BOLT

10 - COVER

11 - OUTER ROTOR

DRENGINE - 5.9L 9 - 267

REAR MOUNT (Continued)

Page 1519 of 2895

(6) Add oil only if level is below the ADD mark on

dipstick.

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals

described in the Maintenance Schedule. This infor-

mation can be found in the owner's manual.

TO CHANGE ENGINE OIL

Run engine until achieving normal operating tem-

perature.

(1) Position the vehicle on a level surface and turn

engine off.

(2) Hoist vehicle.

(3) Remove oil fill cap.

(4) Place a suitable drain pan under crankcase

drain.

(5) Remove drain plug from crankcase and allow

oil to drain into pan. Inspect drain plug threads for

stretching or other damage. Replace drain plug and

gasket if damaged.

(6) Install drain plug in crankcase.

(7) Change oil filter (Refer to 9 - ENGINE/LUBRI-

CATION/OIL FILTER - REMOVAL).

(8) Lower vehicle and fill crankcase with specified

type (Refer to LUBRICATION & MAINTENANCE/

FLUID TYPES - DESCRIPTION) and amount of

engine oil (Refer to LUBRICATION & MAINTE-

NANCE - SPECIFICATIONS).

(9) Install oil fill cap.

(10) Start engine and inspect for leaks.

(11) Stop engine and inspect oil level.

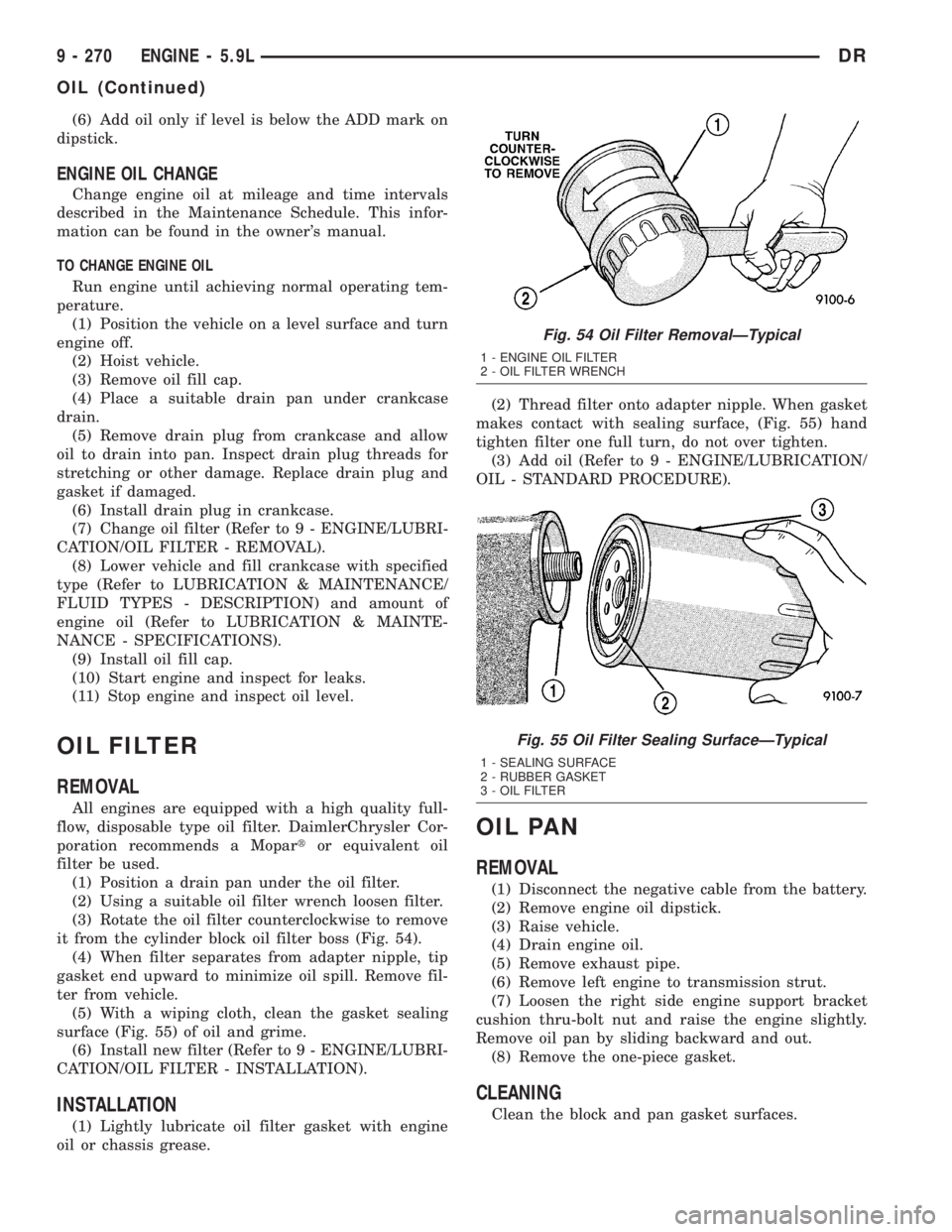

OIL FILTER

REMOVAL

All engines are equipped with a high quality full-

flow, disposable type oil filter. DaimlerChrysler Cor-

poration recommends a Mopartor equivalent oil

filter be used.

(1) Position a drain pan under the oil filter.

(2) Using a suitable oil filter wrench loosen filter.

(3) Rotate the oil filter counterclockwise to remove

it from the cylinder block oil filter boss (Fig. 54).

(4) When filter separates from adapter nipple, tip

gasket end upward to minimize oil spill. Remove fil-

ter from vehicle.

(5) With a wiping cloth, clean the gasket sealing

surface (Fig. 55) of oil and grime.

(6) Install new filter (Refer to 9 - ENGINE/LUBRI-

CATION/OIL FILTER - INSTALLATION).

INSTALLATION

(1) Lightly lubricate oil filter gasket with engine

oil or chassis grease.(2) Thread filter onto adapter nipple. When gasket

makes contact with sealing surface, (Fig. 55) hand

tighten filter one full turn, do not over tighten.

(3) Add oil (Refer to 9 - ENGINE/LUBRICATION/

OIL - STANDARD PROCEDURE).

OIL PAN

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Remove engine oil dipstick.

(3) Raise vehicle.

(4) Drain engine oil.

(5) Remove exhaust pipe.

(6) Remove left engine to transmission strut.

(7) Loosen the right side engine support bracket

cushion thru-bolt nut and raise the engine slightly.

Remove oil pan by sliding backward and out.

(8) Remove the one-piece gasket.

CLEANING

Clean the block and pan gasket surfaces.

Fig. 54 Oil Filter RemovalÐTypical

1 - ENGINE OIL FILTER

2 - OIL FILTER WRENCH

Fig. 55 Oil Filter Sealing SurfaceÐTypical

1 - SEALING SURFACE

2 - RUBBER GASKET

3 - OIL FILTER

9 - 270 ENGINE - 5.9LDR

OIL (Continued)

Page 1520 of 2895

Trim or remove excess sealant film in the rear

main cap oil pan gasket groove.DO NOT remove

the sealant inside the rear main cap slots.

If present, trim excess sealant from inside the

engine.

Clean oil pan in solvent and wipe dry with a clean

cloth.

Clean oil screen and pipe thoroughly in clean sol-

vent. Inspect condition of screen.

INSPECTION

Inspect oil drain plug and plug hole for stripped or

damaged threads. Repair as necessary.

Inspect oil pan mounting flange for bends or distor-

tion. Straighten flange, if necessary.

INSTALLATION

(1) Clean the block and pan gasket surfaces.

(2) Trim or remove excess sealant film in the rear

main cap oil pan gasket groove.DO NOT remove

the sealant inside the rear main cap slots.

(3) If present, trim excess sealant from inside the

engine.

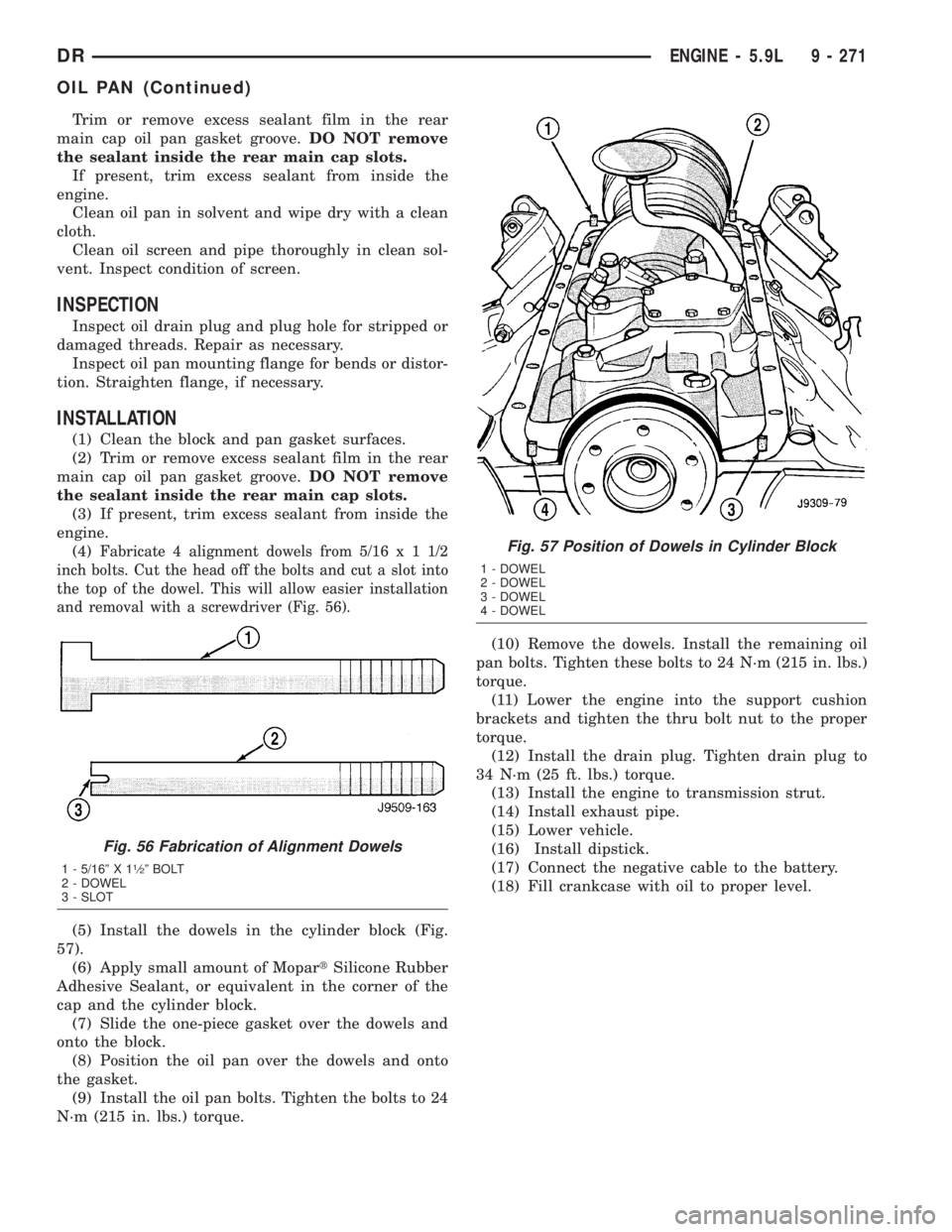

(4)

Fabricate 4 alignment dowels from 5/16x11/2

inch bolts. Cut the head off the bolts and cut a slot into

the top of the dowel. This will allow easier installation

and removal with a screwdriver (Fig. 56).

(5) Install the dowels in the cylinder block (Fig.

57).

(6) Apply small amount of MopartSilicone Rubber

Adhesive Sealant, or equivalent in the corner of the

cap and the cylinder block.

(7) Slide the one-piece gasket over the dowels and

onto the block.

(8) Position the oil pan over the dowels and onto

the gasket.

(9) Install the oil pan bolts. Tighten the bolts to 24

N´m (215 in. lbs.) torque.(10) Remove the dowels. Install the remaining oil

pan bolts. Tighten these bolts to 24 N´m (215 in. lbs.)

torque.

(11) Lower the engine into the support cushion

brackets and tighten the thru bolt nut to the proper

torque.

(12) Install the drain plug. Tighten drain plug to

34 N´m (25 ft. lbs.) torque.

(13) Install the engine to transmission strut.

(14) Install exhaust pipe.

(15) Lower vehicle.

(16) Install dipstick.

(17) Connect the negative cable to the battery.

(18) Fill crankcase with oil to proper level.

Fig. 56 Fabrication of Alignment Dowels

1 - 5/16º X 11¤2º BOLT

2 - DOWEL

3 - SLOT

Fig. 57 Position of Dowels in Cylinder Block

1 - DOWEL

2 - DOWEL

3 - DOWEL

4 - DOWEL

DRENGINE - 5.9L 9 - 271

OIL PAN (Continued)

Page 1524 of 2895

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS, OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water at the suspected

leak area.

(3) If a change in RPMs occur, the area of the sus-

pected leak has been found.

(4) Repair as required.

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Drain the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(3) Remove the A/C compressor (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/A/C

COMPRESSOR - REMOVAL).

(4) Remove the generator (Refer to 8 - ELECTRI-

CAL/CHARGING/GENERATOR - REMOVAL).

(5) Remove the accessory drive bracket.

(6) Remove the air cleaner.

(7) Perform the Fuel System Pressure release pro-

cedure (Refer to 14 - FUEL SYSTEM/FUEL DELIV-

ERY - STANDARD PROCEDURE). Disconnect the

fuel lines (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY/QUICK CONNECT FITTING - STAN-

DARD PROCEDURE).

(8) Disconnect the accelerator linkage (Refer to 14

- FUEL SYSTEM/FUEL INJECTION/THROTTLE

CONTROL CABLE - REMOVAL) and if so equipped,

the speed control and transmission kickdown cables.

(9) Remove the return spring.

(10) Remove the distributor cap and wires.

(11) Disconnect the coil wires.

(12) Disconnect the heat indicator sending unit

wire.

(13) Disconnect the heater hoses and bypass hose.

(14) Remove the closed crankcase ventilation and

evaporation control systems.

(15) Remove intake manifold bolts.

(16) Lift the intake manifold and throttle body out

of the engine compartment as an assembly.

(17) Remove and discard the flange side gaskets

and the front and rear end seals.

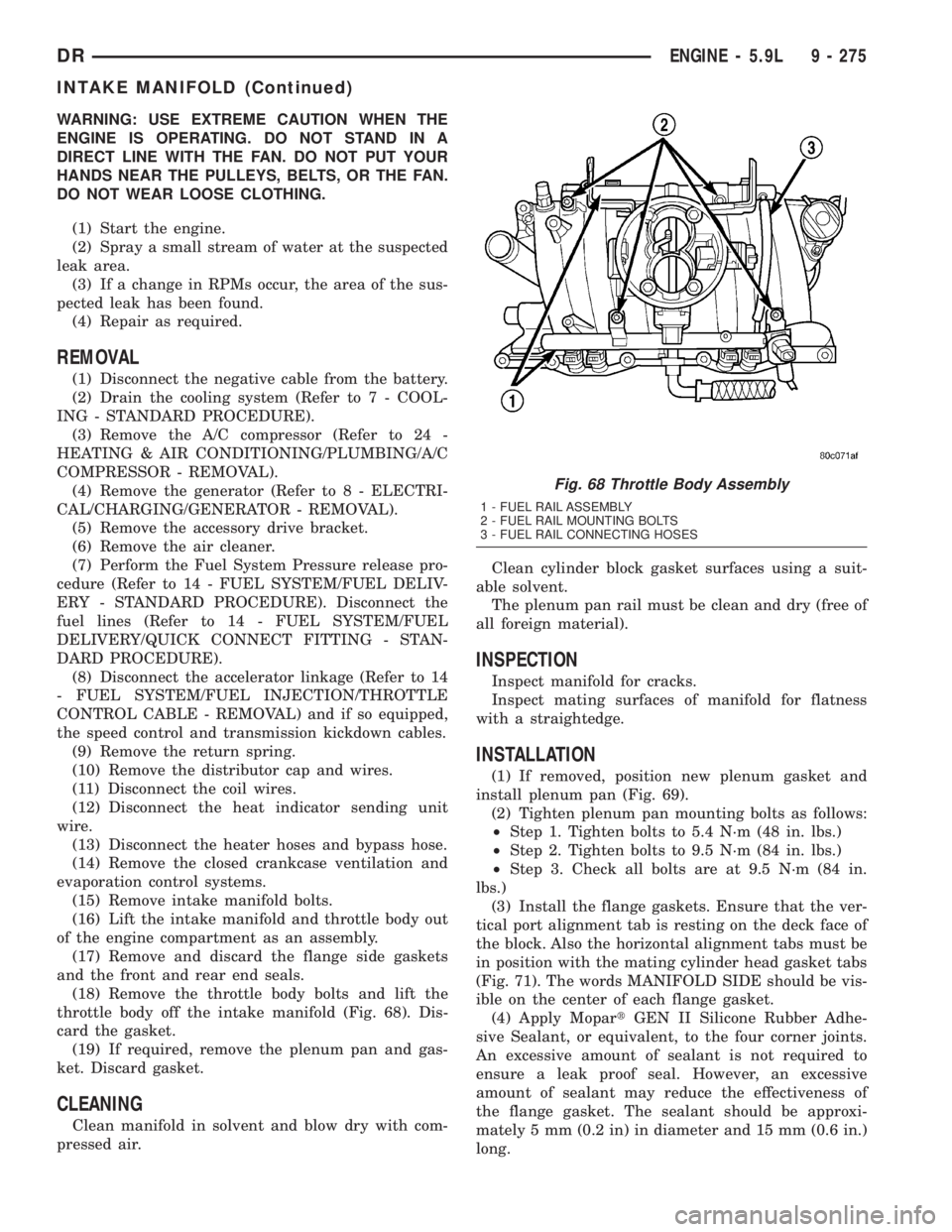

(18) Remove the throttle body bolts and lift the

throttle body off the intake manifold (Fig. 68). Dis-

card the gasket.

(19) If required, remove the plenum pan and gas-

ket. Discard gasket.

CLEANING

Clean manifold in solvent and blow dry with com-

pressed air.Clean cylinder block gasket surfaces using a suit-

able solvent.

The plenum pan rail must be clean and dry (free of

all foreign material).

INSPECTION

Inspect manifold for cracks.

Inspect mating surfaces of manifold for flatness

with a straightedge.

INSTALLATION

(1) If removed, position new plenum gasket and

install plenum pan (Fig. 69).

(2) Tighten plenum pan mounting bolts as follows:

²Step 1. Tighten bolts to 5.4 N´m (48 in. lbs.)

²Step 2. Tighten bolts to 9.5 N´m (84 in. lbs.)

²Step 3. Check all bolts are at 9.5 N´m (84 in.

lbs.)

(3) Install the flange gaskets. Ensure that the ver-

tical port alignment tab is resting on the deck face of

the block. Also the horizontal alignment tabs must be

in position with the mating cylinder head gasket tabs

(Fig. 71). The words MANIFOLD SIDE should be vis-

ible on the center of each flange gasket.

(4) Apply MopartGEN II Silicone Rubber Adhe-

sive Sealant, or equivalent, to the four corner joints.

An excessive amount of sealant is not required to

ensure a leak proof seal. However, an excessive

amount of sealant may reduce the effectiveness of

the flange gasket. The sealant should be approxi-

mately 5 mm (0.2 in) in diameter and 15 mm (0.6 in.)

long.

Fig. 68 Throttle Body Assembly

1 - FUEL RAIL ASSEMBLY

2 - FUEL RAIL MOUNTING BOLTS

3 - FUEL RAIL CONNECTING HOSES

DRENGINE - 5.9L 9 - 275

INTAKE MANIFOLD (Continued)

Page 1526 of 2895

equipped, the speed control and transmission kick-

down cables.

(16) Install the fuel lines (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY/QUICK CONNECT FIT-

TING - STANDARD PROCEDURE).

(17) Install the accessory drive bracket and A/C

compressor (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING/A/C COMPRESSOR -

INSTALLATION).

(18) Install the generator and drive belt (Refer to 7

- COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION). Tighten generator mounting bolt

to 41 N´m (30 ft. lbs.) torque.

(19) Install the air cleaner.

(20) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(21) Connect the negative cable to the battery.

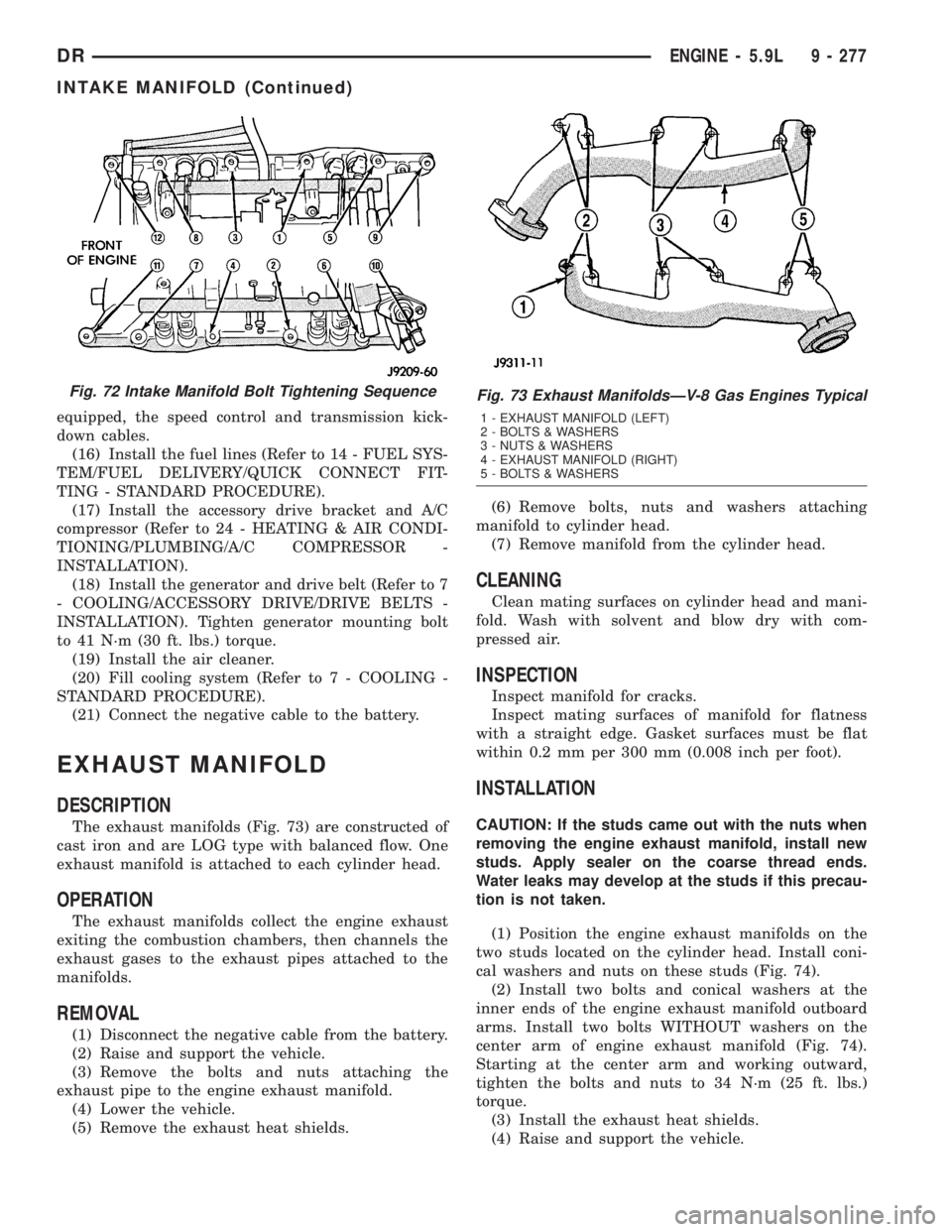

EXHAUST MANIFOLD

DESCRIPTION

The exhaust manifolds (Fig. 73) are constructed of

cast iron and are LOG type with balanced flow. One

exhaust manifold is attached to each cylinder head.

OPERATION

The exhaust manifolds collect the engine exhaust

exiting the combustion chambers, then channels the

exhaust gases to the exhaust pipes attached to the

manifolds.

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Raise and support the vehicle.

(3) Remove the bolts and nuts attaching the

exhaust pipe to the engine exhaust manifold.

(4) Lower the vehicle.

(5) Remove the exhaust heat shields.(6) Remove bolts, nuts and washers attaching

manifold to cylinder head.

(7) Remove manifold from the cylinder head.

CLEANING

Clean mating surfaces on cylinder head and mani-

fold. Wash with solvent and blow dry with com-

pressed air.

INSPECTION

Inspect manifold for cracks.

Inspect mating surfaces of manifold for flatness

with a straight edge. Gasket surfaces must be flat

within 0.2 mm per 300 mm (0.008 inch per foot).

INSTALLATION

CAUTION: If the studs came out with the nuts when

removing the engine exhaust manifold, install new

studs. Apply sealer on the coarse thread ends.

Water leaks may develop at the studs if this precau-

tion is not taken.

(1) Position the engine exhaust manifolds on the

two studs located on the cylinder head. Install coni-

cal washers and nuts on these studs (Fig. 74).

(2) Install two bolts and conical washers at the

inner ends of the engine exhaust manifold outboard

arms. Install two bolts WITHOUT washers on the

center arm of engine exhaust manifold (Fig. 74).

Starting at the center arm and working outward,

tighten the bolts and nuts to 34 N´m (25 ft. lbs.)

torque.

(3) Install the exhaust heat shields.

(4) Raise and support the vehicle.

Fig. 72 Intake Manifold Bolt Tightening SequenceFig. 73 Exhaust ManifoldsÐV-8 Gas Engines Typical

1 - EXHAUST MANIFOLD (LEFT)

2 - BOLTS & WASHERS

3 - NUTS & WASHERS

4 - EXHAUST MANIFOLD (RIGHT)

5 - BOLTS & WASHERS

DRENGINE - 5.9L 9 - 277

INTAKE MANIFOLD (Continued)

Page 1538 of 2895

(9) Use Tool 9010 to remove the injector and cop-

per sealing washer.

(10) Install compression test Tool 9007 into the

injector bore.

(11) Connect the leakage tester and perform the

leakage test procedure on each cylinder according to

the tester manufacturer's instructions.

(12) Upon completion of the test check and erase

any engine related fault codes.

STANDARD PROCEDURE

STANDARD PROCEDURE - FORM-IN-PLACE

GASKETS AND SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Too

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and Mopart

Gasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN II

MopartEngine RTV GEN II is used to seal com-

ponents exposed to engine oil. This material is a spe-

cially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

material to cure. This material is available in three

ounce tubes and has a shelf life of one year. After one

year this material will not properly cure. Always

inspect the package for the expiration date before

use.

MOPARtATF RTV

MopartATF RTV is a specifically designed black

silicone rubber RTV that retains adhesion and seal-

ing properties to seal components exposed to auto-

matic transmission fluid, engine coolants, and

moisture. This material is available in three ounce

tubes and has a shelf life of one year. After one year

this material will not properly cure. Always inspect

the package for the expiration date before use.

MOPARtGASKET MAKER

MopartGasket Maker is an anaerobic type gasket

material. The material cures in the absence of air

when squeezed between two metallic surfaces. It will

not cure if left in the uncovered tube. The anaerobicmaterial is for use between two machined surfaces.

Do not use on flexible metal flanges.

MOPARtGASKET SEALANT

MopartGasket Sealant is a slow drying, perma-

nently soft sealer. This material is recommended for

sealing threaded fittings and gaskets against leakage

of oil and coolant. Can be used on threaded and

machined parts under all temperatures. This mate-

rial is used on engines with multi-layer steel (MLS)

cylinder head gaskets. This material also will pre-

vent corrosion. MopartGasket Sealant is available in

a 13 oz. aerosol can or 4oz./16 oz. can w/applicator.

FORM-IN-PLACE GASKET AND SEALER

APPLICATION

Assembling parts using a form-in-place gasket

requires care but it's easier than using precut gas-

kets.

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 in.) diameter or less of sealant

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

MopartEngine RTV GEN II or ATF RTV gasket

material should be applied in a continuous bead

approximately 3 mm (0.120 in.) in diameter. All

mounting holes must be circled. For corner sealing, a

3.17 or 6.35 mm (1/8 or 1/4 in.) drop is placed in the

center of the gasket contact area. Uncured sealant

may be removed with a shop towel. Components

should be torqued in place while the sealant is still

wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to

prevent smearing material off the location.

MopartGasket Sealant in an aerosol can should be

applied using a thin, even coat sprayed completely

over both surfaces to be joined, and both sides of a

gasket. Then proceed with assembly. Material in a

can w/applicator can be brushed on evenly over the

sealing surfaces. Material in an aerosol can should be

used on engines with multi-layer steel gaskets.

STANDARD PROCEDURE - REPAIR DAMAGED

OR WORN THREADS

CAUTION: Be sure that the tapped holes maintain

the original center line.

Damaged or worn threads can be repaired. Essen-

tially, this repair consists of:

²Drilling out worn or damaged threads.

²Tapping the hole with a special Heli-Coil Tap, or

equivalent.

DRENGINE 5.9L DIESEL 9 - 289

ENGINE 5.9L DIESEL (Continued)

Page 1539 of 2895

²Installing an insert into the tapped hole to bring

the hole back to its original thread size.

STANDARD PROCEDUREÐHYDROSTATIC

LOCK

CAUTION: DO NOT use the starter motor to rotate

the crankshaft. Severe damage could occur.

When an engine is suspected of hydrostatic lock

(regardless of what caused the problem), follow the

steps below.

(1) Disconnect the negative cable(s) from the bat-

tery.

(2) Inspect air cleaner, induction system, and

intake manifold to ensure system is dry and clear of

foreign material.

(3) Place a shop towel around the fuel injectors to

catch any fluid that may possibly be under pressure

in the cylinder head. Remove the fuel injectors (Refer

to 14 - FUEL SYSTEM/FUEL INJECTION/FUEL

INJECTOR - REMOVAL).

(4) With all injectors removed, rotate the crank-

shaft using the crankshaft barring tool (PN 7471±B).

(5) Identify the fluid in the cylinders (coolant, fuel,

oil, etc.).

(6) Be sure all fluid has been removed from the

cylinders.

(7) Repair engine or components as necessary to

prevent this problem from occurring again.

(8) Squirt a small amount of engine oil into the

cylinders to lubricate the walls. This will prevent

damage on restart.

(9) Install fuel injectors (Refer to 14 - FUEL SYS-

TEM/FUEL INJECTION/FUEL INJECTOR -

INSTALLATION).

(10) Drain engine oil. Remove and discard the oil

filter (Refer to 9 - ENGINE/LUBRICATION/OIL FIL-

TER - REMOVAL).

(11) Install the drain plug. Tighten the plug to 50

N´m (37 ft. lbs.) torque.

(12) Install a new oil filter (Refer to 9 - ENGINE/

LUBRICATION/OIL FILTER - INSTALLATION).

(13) Fill engine crankcase with the specified

amount and grade of oil (Refer to LUBRICATION &

MAINTENANCE/FLUID TYPES - SPECIFICA-

TIONS).

(14) Connect the negative cable(s) to the battery.

(15) Start the engine and check for any leaks.

REMOVAL

REMOVALÐENGINE

(1) Disconnect both battery negative cables.

(2) Disconnect engine grid heater harness at grid

heater relays.(3) Disconnect electrical connections from rear of

alternator.

(4) Recover A/C refrigerant. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - STAN-

DARD PROCEDURE).

(5) Raise vehicle on a hoist.

(6) Drain engine coolant (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(7) Remove engine oil drain plug and drain engine

oil.

(8) Remove fan/drive assembly. Refer to Section 7

± Fan/Drive Removal

(9) Remove radiator upper hose.

(10) Remove upper fan shroud mounting bolts.

(11) Disconnect the coolant recovery bottle hose

from the radiator fill neck and remove bottle.

(12) Using a 36mm wrench, remove viscous fan/

drive assembly. (Refer to 7 - COOLING/ENGINE/RA-

DIATOR FAN - REMOVAL).

(13) Remove cooling fan and shroud together.

(14) Disconnect heater core supply and return

hoses from the cylinder head fitting and coolant pipe.

(15) Raise vehicle on a hoist.

(16) Remove transmission and transfer case (if

equipped).

(17) Disconnect exhaust pipe from turbocharger

extension pipe.

(18) Disconnect engine harness to vehicle harness

connectors.

(19) Remove starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL).

(20) Remove flywheel/flexplate.

(21) Remove transmission adapter

(22) Disconnect A/C suction/discharge hose from

the rear of the A/C compressor.

(23) Lower vehicle.

(24) Disconnect lower radiator hose from radiator

outlet.

(25) Automatic transmission models:

(26) Disconnect transmission oil cooler lines from

in front of radiator using special tool #6931

(27) Remove radiator. (Refer to 7 - COOLING/EN-

GINE/RADIATOR - REMOVAL).

(28) If A/C equipped, disconnect A/C condenser

refrigerant lines.

(29) Disconnect charge air cooler piping.

(30) Remove charge air cooler mounting bolts.

(31) Remove charge air cooler (and A/C condenser

if equipped) from vehicle.

(32) Remove damper and speed indicator ring from

front of engine.

(33) Disconnect engine block heater connector.

(34) Disconnect A/C compressor and pressure sen-

sor electrical connectors.

9 - 290 ENGINE 5.9L DIESELDR

ENGINE 5.9L DIESEL (Continued)

Page 1541 of 2895

(2) Lower engine into the engine compartment and

install the engine the engine mount through bolts

and nuts.

(3) Tighten the mount through bolts and nuts to

88 N-m (65 ft-lbs) torque.

(4) Remove the engine lifting device (Tool 9009).

(5) Check cylinder head capscrew length and

install into cylinder head.

(6) Torque alternately to 70 N-m (52 ft-lbs). Torque

alternately to 105 N-m (77 ft-lbs). Rotate 90 degrees.

(7) Install rocker housing. Torque to 24 N-m (18 ft-

lbs). Refer to Section 9 Rocker Housing Installation

(8) Replace injector o-ring and sealing washer on

injectors #5 and #6. Install injectors and alternately

tighten hold-down capscrews to 10 N-m (89 in-lbs).

(9) Install fuel connector tube and fuel connector

tube nut. Torque to 50 N-m (37 ft-lb). 10.

(10) Install #5 and #6 high pressure fuel lines. Fol-

low correct torque sequence per section 14. Torque

fuel line fittings to 30 N-m (22 ft-lb). Torque brace

capscrew to 24 N-m (18 ft-lb).

(11) Install rear engine lift bracket. Torque to 77

N-m (57 ft-lb).

(12) Install push tubes, rocker arms, and pedestals

for cylinders #4, #5, and #6. Torque the mounting

bolts to 36 N-m (27 ft-lbs).

(13) Reset valve lash on cylinders #4, #5, and #6.

Torque adjusting nuts to 24 N-m (18 ft-lbs).

(14) Install cylinder head cover. Torque to 24 N-m

(18 ft-lbs).(Refer to 9 - ENGINE/CYLINDER HEAD -

INSTALLATION).

(15) Connect breather tube and lube oil drain tube

to breather housing. Install breather housing. Torque

capscrews to 24 N-m (18 ft-lbs)

(16) Connect fuel supply and return hoses.

(17) Connect ECM ground to hydroform screw.

Connect ECM power connector.

(18) Install the APPS cable(s) to the APPS. Install

the throttle linkage cover.

(19) Install the power steering pump.

(20) Install the damper and speed indicator ring.

Torque to 40 N-m (30 ft-lb) plus 60 degrees.

(21) Connect the engine block heater connection.

(22) Connect the A/C compressor and pressure sen-

sor connectors

(23) Install the charge air cooler and a/c condenser

(if equipped). Install and tighten the charge air

cooler mounting bolts to 2 N-m (17 in-lbs).

(24) Connect the charge air cooler piping. Torque

all clamps to 8 N-m (72 in-lbs).

(25) Connect the a/c refrigerant lines to the a/c

condenser (if equipped).

(26) Install the radiator upper support panel.

(27) Install radiator.

(28) Connect the transmission quick-connect oil

cooler lines.(29) Raise vehicle.

(30) Connect a/c compressor suction/discharge hose

(if equipped).

(31) Install the radiator lower hose and clamps.

(32) Install the battery negative cables to the

engine block on the driver and passenger side.

(33) Install the transmission adapter with a new

camshaft rectangular ring seal. Torque to 77 N-m (57

ft-lb).

(34) Install the flywheel/flexplate. Torque to 137

N-m (101 ft-lb).

(35) Install the starter motor. Torque to 43 N-m

(32 ft-lb). (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - INSTALLATION).

(36) Connect engine to vehicle harness connectors.

(37) Install transmission and transfer case (if

equipped).

(38) Connect the exhaust pipe to the turbocharger

elbow.

(39) Connect the transmission auxiliary oil cooler

lines (if equipped).

(40) Lower the vehicle.

(41)

Connect the heater core supply and return hoses.

(42) Install the cooling fan and upper fan shroud

at the same time. (Refer to 7 - COOLING/ENGINE/

RADIATOR FAN - INSTALLATION).

(43) Install the coolant recovery bottle.

(44) Install the windshield washer bottle.

(45) Install the upper radiator hose and clamps.

(46) Raise vehicle.

(47) Connect electronically controlled fan drive

wire harness. Install lower radiator fan shroud.

(48) Change oil filter and install new engine oil.

(49) Fill the cooling system with coolant. (Refer to

7 - COOLING - STANDARD PROCEDURE).

(50) Connect grid heater harness at grid heater

relays.

(51) Connect electrical connections to rear of alter-

nator.

(52) Start the engine and inspect for engine oil,

coolant, and fuel leaks.

INSTALLATIONÐCRANKCASE BREATHER

(1) Install a new o-ring onto the breather element.

(2) Lubricate o-ring and install into cylinder head

cover. Torque capscrews to 10 N´m (89 in. lbs.).

(3) Connect breather tube and lube oil drain tube.

(4) Install breather cover (Fig. 4). Torque to 24

N´m (18 ft. lbs.)

(5) Install oil fill cap.

9 - 292 ENGINE 5.9L DIESELDR

ENGINE 5.9L DIESEL (Continued)