DODGE RAM 2003 Service Repair Manual

Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2321 of 2895

(d) Compress secondary spring and install E-clip

in groove at end of shuttle valve.

(e) Verify that spring and E-clip are properly

seated before proceeding.

(8) Install shuttle valve cover plate. Tighten cover

plate screws to 4 N´m (35 in. lbs.) torque.

(9) Install 1-2 and 2-3 valve governor plugs in

valve body.

(10) Install shuttle valve primary spring and

throttle plug.

(11) Align and install governor plug cover. Tighten

cover screws to 4 N´m (35 in. lbs.) torque.BOOST VALVE TUBE AND BRACE

(1) Position valve body assembly so lower housing

is facing upward (Fig. 320).

(2) Lubricate tube ends and housing ports with

transmission fluid or petroleum jelly.

(3) Start tube in lower housing port first. Then

swing tube downward and work opposite end of tube

into upper housing port (Fig. 320).

(4) Insert and seat each end of tube in housings.

(5) Slide tube brace under tube and into alignment

with valve body screw holes (Fig. 321).

(6) Install and finger tighten three screws that

secure tube brace to valve body housings (Fig. 321).

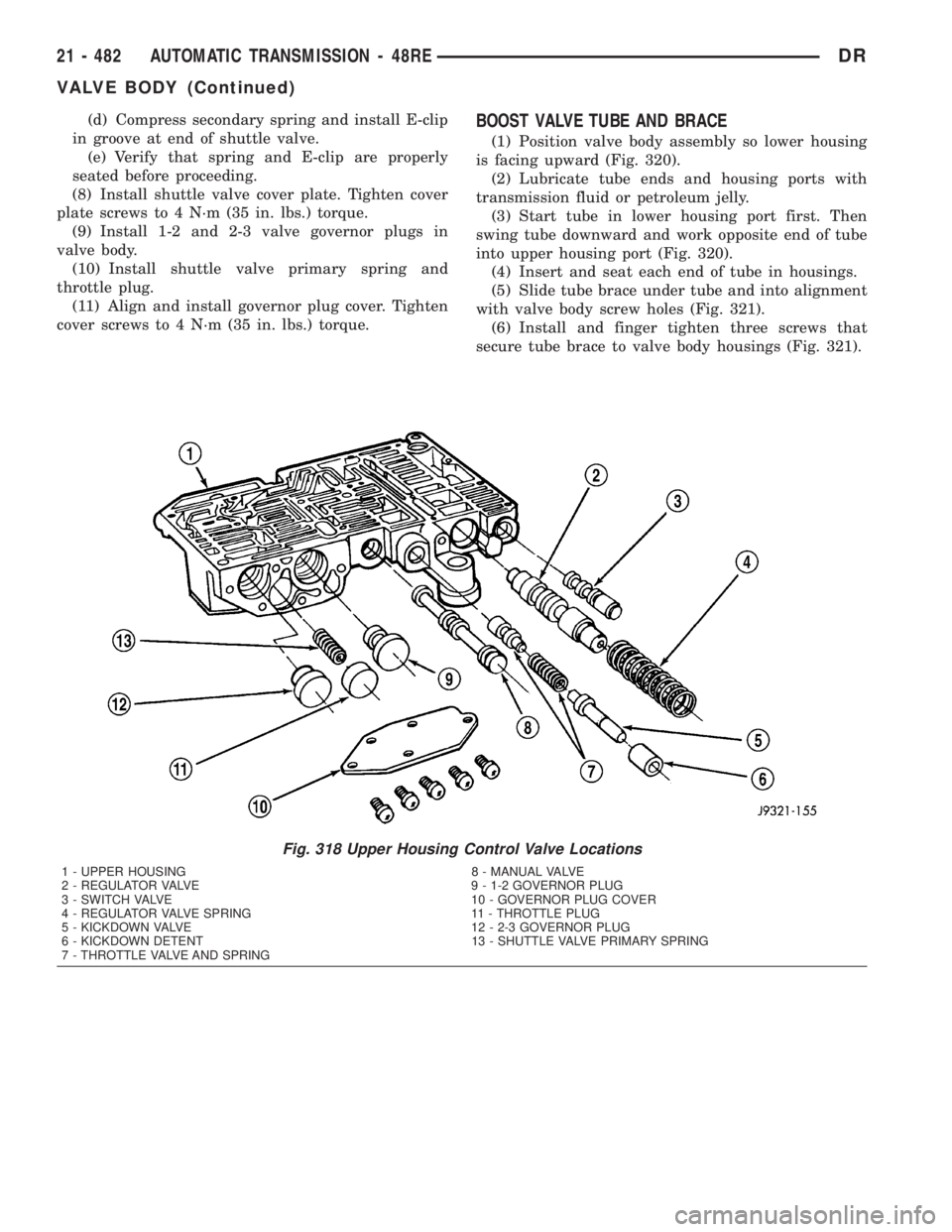

Fig. 318 Upper Housing Control Valve Locations

1 - UPPER HOUSING 8 - MANUAL VALVE

2 - REGULATOR VALVE 9 - 1-2 GOVERNOR PLUG

3 - SWITCH VALVE 10 - GOVERNOR PLUG COVER

4 - REGULATOR VALVE SPRING 11 - THROTTLE PLUG

5 - KICKDOWN VALVE 12 - 2-3 GOVERNOR PLUG

6 - KICKDOWN DETENT 13 - SHUTTLE VALVE PRIMARY SPRING

7 - THROTTLE VALVE AND SPRING

21 - 482 AUTOMATIC TRANSMISSION - 48REDR

VALVE BODY (Continued)

Page 2322 of 2895

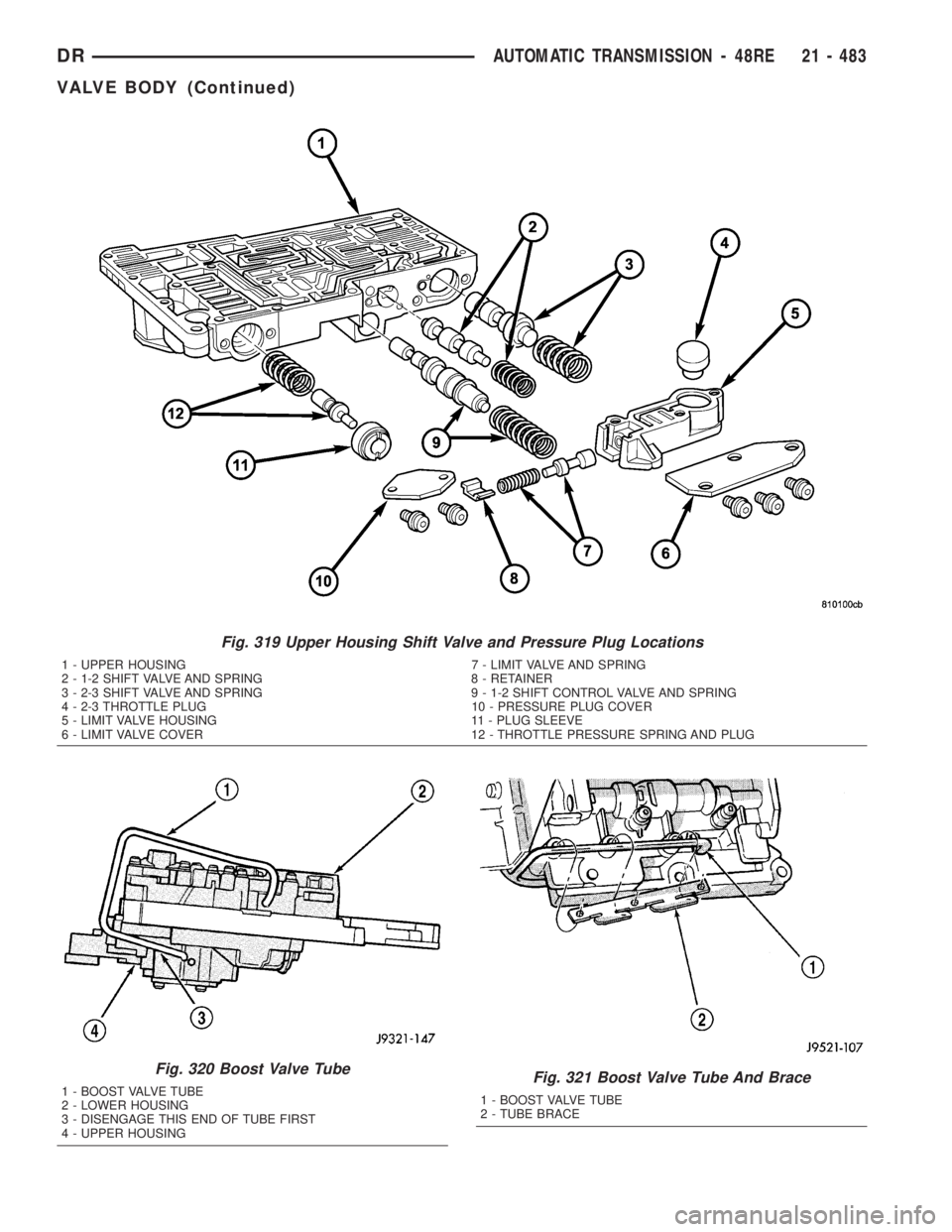

Fig. 319 Upper Housing Shift Valve and Pressure Plug Locations

1 - UPPER HOUSING 7 - LIMIT VALVE AND SPRING

2 - 1-2 SHIFT VALVE AND SPRING 8 - RETAINER

3 - 2-3 SHIFT VALVE AND SPRING 9 - 1-2 SHIFT CONTROL VALVE AND SPRING

4 - 2-3 THROTTLE PLUG 10 - PRESSURE PLUG COVER

5 - LIMIT VALVE HOUSING 11 - PLUG SLEEVE

6 - LIMIT VALVE COVER 12 - THROTTLE PRESSURE SPRING AND PLUG

Fig. 320 Boost Valve Tube

1 - BOOST VALVE TUBE

2 - LOWER HOUSING

3 - DISENGAGE THIS END OF TUBE FIRST

4 - UPPER HOUSINGFig. 321 Boost Valve Tube And Brace

1 - BOOST VALVE TUBE

2 - TUBE BRACE

DRAUTOMATIC TRANSMISSION - 48RE 21 - 483

VALVE BODY (Continued)

Page 2323 of 2895

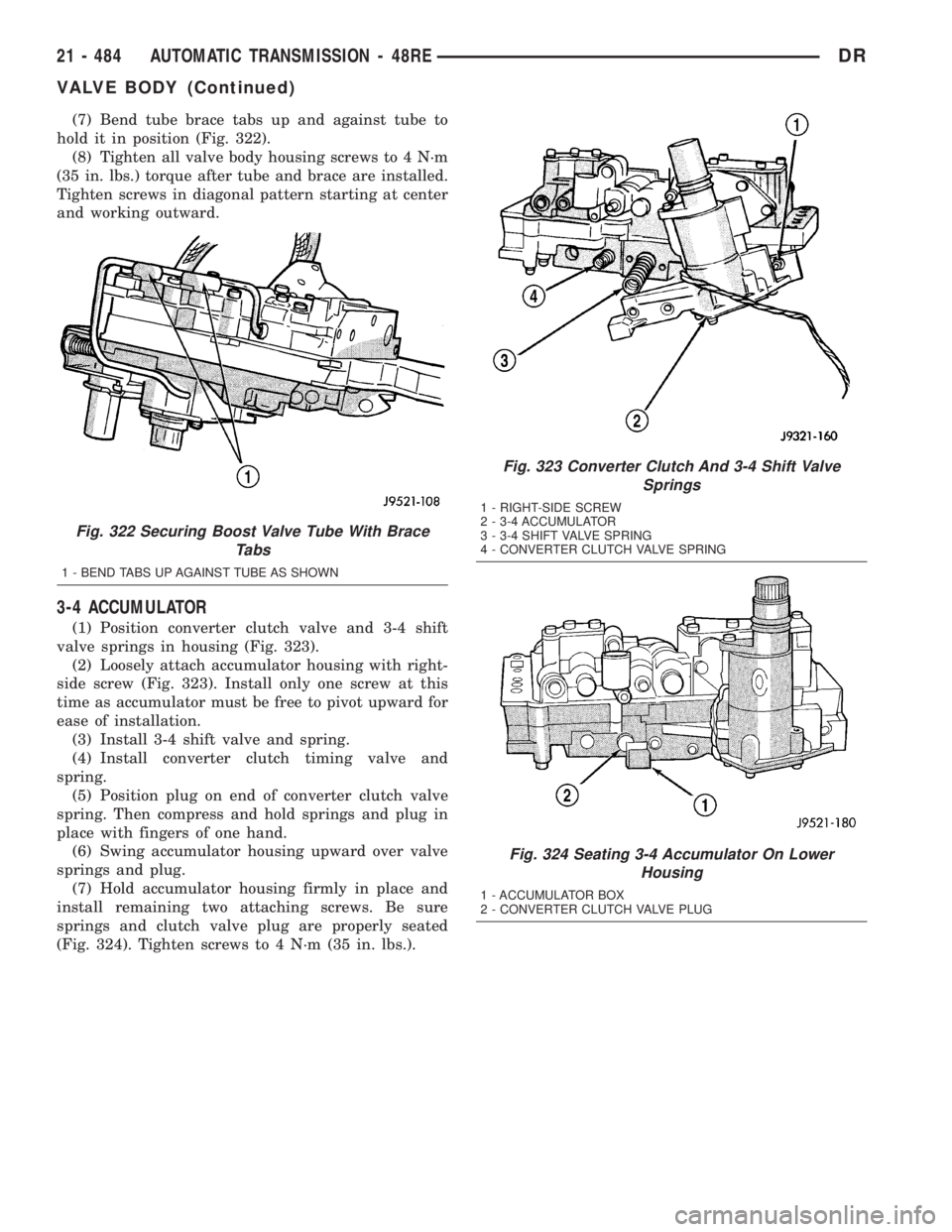

(7) Bend tube brace tabs up and against tube to

hold it in position (Fig. 322).

(8) Tighten all valve body housing screws to 4 N´m

(35 in. lbs.) torque after tube and brace are installed.

Tighten screws in diagonal pattern starting at center

and working outward.

3-4 ACCUMULATOR

(1) Position converter clutch valve and 3-4 shift

valve springs in housing (Fig. 323).

(2) Loosely attach accumulator housing with right-

side screw (Fig. 323). Install only one screw at this

time as accumulator must be free to pivot upward for

ease of installation.

(3) Install 3-4 shift valve and spring.

(4) Install converter clutch timing valve and

spring.

(5) Position plug on end of converter clutch valve

spring. Then compress and hold springs and plug in

place with fingers of one hand.

(6) Swing accumulator housing upward over valve

springs and plug.

(7) Hold accumulator housing firmly in place and

install remaining two attaching screws. Be sure

springs and clutch valve plug are properly seated

(Fig. 324). Tighten screws to 4 N´m (35 in. lbs.).

Fig. 322 Securing Boost Valve Tube With Brace

Tabs

1 - BEND TABS UP AGAINST TUBE AS SHOWN

Fig. 323 Converter Clutch And 3-4 Shift Valve

Springs

1 - RIGHT-SIDE SCREW

2 - 3-4 ACCUMULATOR

3 - 3-4 SHIFT VALVE SPRING

4 - CONVERTER CLUTCH VALVE SPRING

Fig. 324 Seating 3-4 Accumulator On Lower

Housing

1 - ACCUMULATOR BOX

2 - CONVERTER CLUTCH VALVE PLUG

21 - 484 AUTOMATIC TRANSMISSION - 48REDR

VALVE BODY (Continued)

Page 2324 of 2895

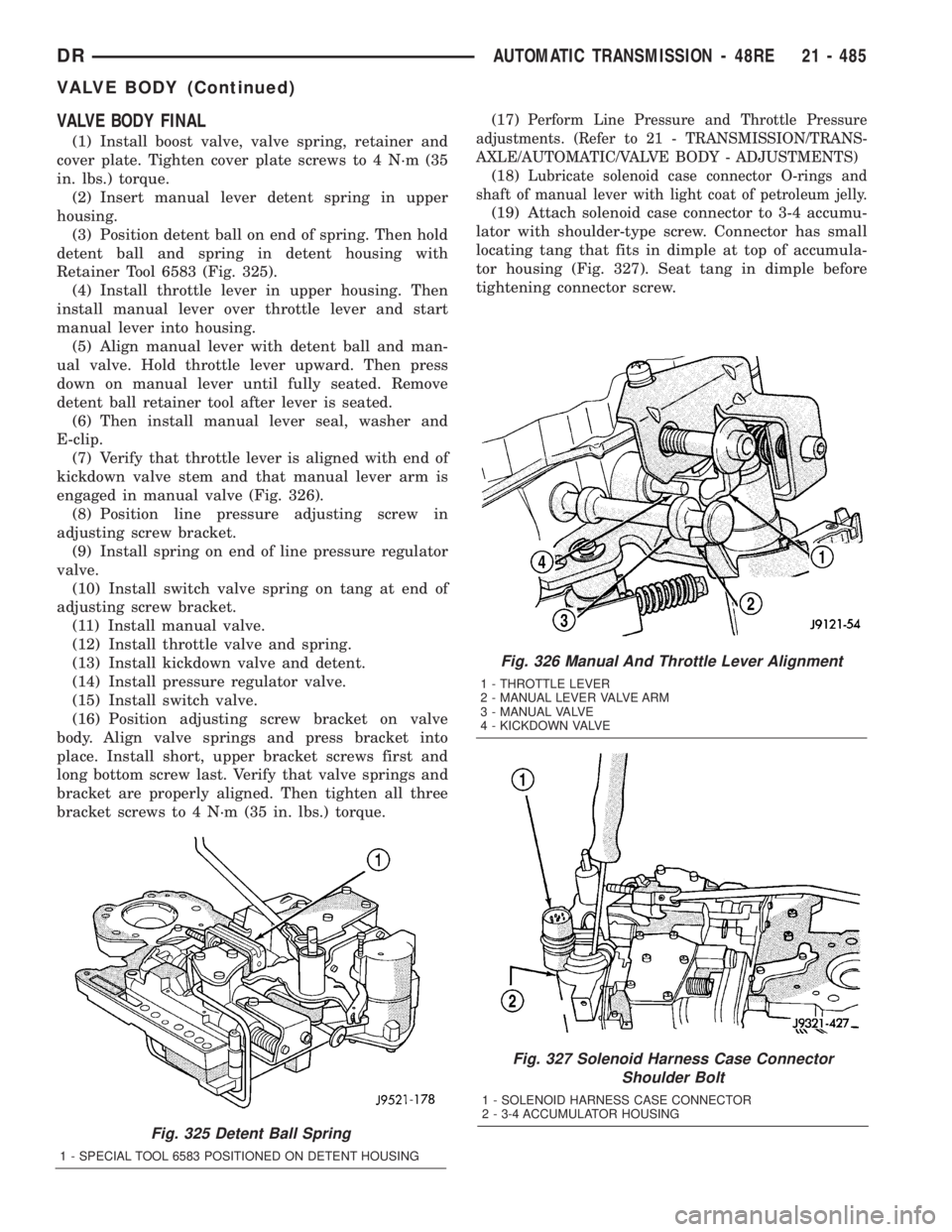

VALVE BODY FINAL

(1) Install boost valve, valve spring, retainer and

cover plate. Tighten cover plate screws to 4 N´m (35

in. lbs.) torque.

(2) Insert manual lever detent spring in upper

housing.

(3) Position detent ball on end of spring. Then hold

detent ball and spring in detent housing with

Retainer Tool 6583 (Fig. 325).

(4) Install throttle lever in upper housing. Then

install manual lever over throttle lever and start

manual lever into housing.

(5) Align manual lever with detent ball and man-

ual valve. Hold throttle lever upward. Then press

down on manual lever until fully seated. Remove

detent ball retainer tool after lever is seated.

(6) Then install manual lever seal, washer and

E-clip.

(7) Verify that throttle lever is aligned with end of

kickdown valve stem and that manual lever arm is

engaged in manual valve (Fig. 326).

(8) Position line pressure adjusting screw in

adjusting screw bracket.

(9) Install spring on end of line pressure regulator

valve.

(10) Install switch valve spring on tang at end of

adjusting screw bracket.

(11) Install manual valve.

(12) Install throttle valve and spring.

(13) Install kickdown valve and detent.

(14) Install pressure regulator valve.

(15) Install switch valve.

(16) Position adjusting screw bracket on valve

body. Align valve springs and press bracket into

place. Install short, upper bracket screws first and

long bottom screw last. Verify that valve springs and

bracket are properly aligned. Then tighten all three

bracket screws to 4 N´m (35 in. lbs.) torque.(17)

Perform Line Pressure and Throttle Pressure

adjustments. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC/VALVE BODY - ADJUSTMENTS)

(18)Lubricate solenoid case connector O-rings and

shaft of manual lever with light coat of petroleum jelly.

(19) Attach solenoid case connector to 3-4 accumu-

lator with shoulder-type screw. Connector has small

locating tang that fits in dimple at top of accumula-

tor housing (Fig. 327). Seat tang in dimple before

tightening connector screw.

Fig. 325 Detent Ball Spring

1 - SPECIAL TOOL 6583 POSITIONED ON DETENT HOUSING

Fig. 326 Manual And Throttle Lever Alignment

1 - THROTTLE LEVER

2 - MANUAL LEVER VALVE ARM

3 - MANUAL VALVE

4 - KICKDOWN VALVE

Fig. 327 Solenoid Harness Case Connector

Shoulder Bolt

1 - SOLENOID HARNESS CASE CONNECTOR

2 - 3-4 ACCUMULATOR HOUSING

DRAUTOMATIC TRANSMISSION - 48RE 21 - 485

VALVE BODY (Continued)

Page 2325 of 2895

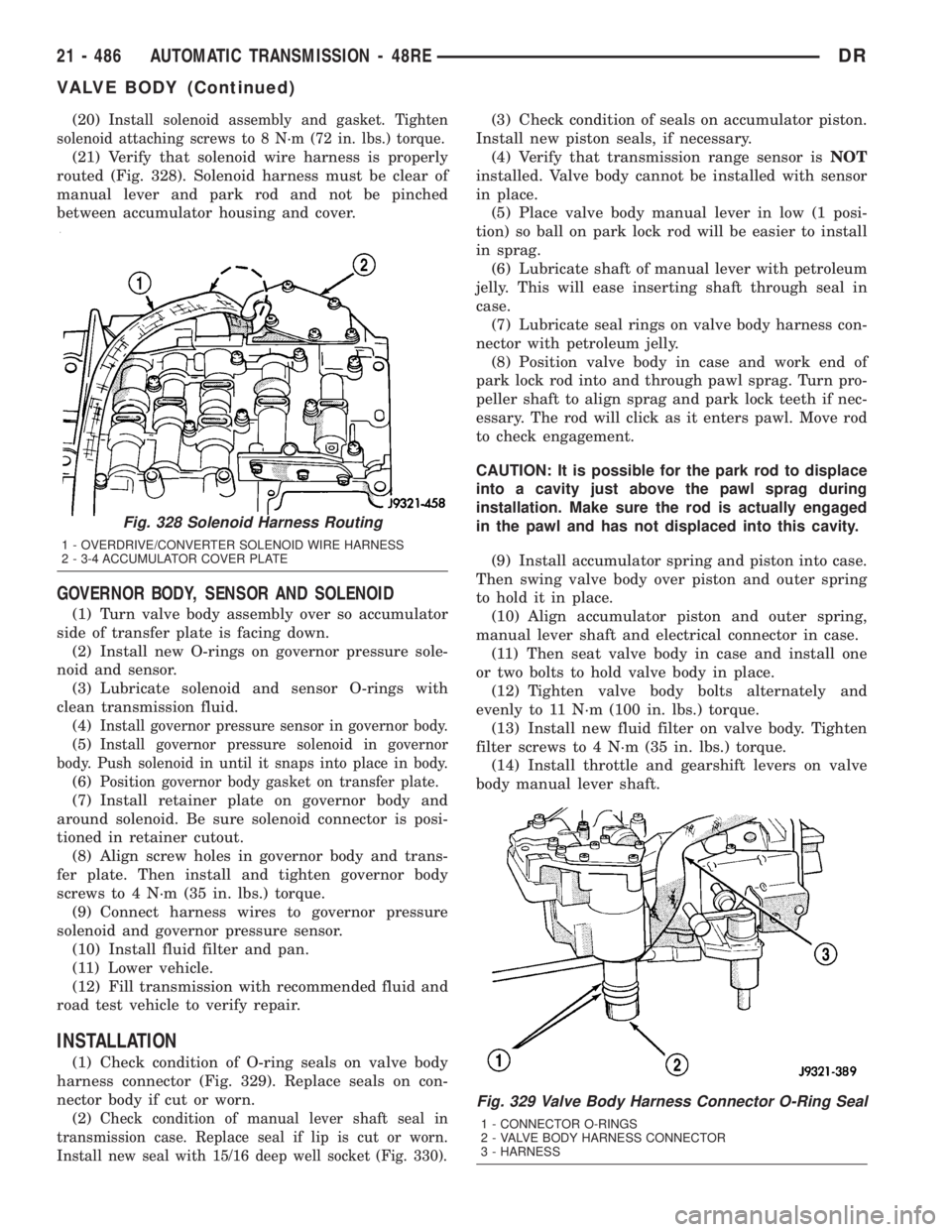

(20)Install solenoid assembly and gasket. Tighten

solenoid attaching screws to 8 N´m (72 in. lbs.) torque.

(21) Verify that solenoid wire harness is properly

routed (Fig. 328). Solenoid harness must be clear of

manual lever and park rod and not be pinched

between accumulator housing and cover.

GOVERNOR BODY, SENSOR AND SOLENOID

(1) Turn valve body assembly over so accumulator

side of transfer plate is facing down.

(2) Install new O-rings on governor pressure sole-

noid and sensor.

(3) Lubricate solenoid and sensor O-rings with

clean transmission fluid.

(4)

Install governor pressure sensor in governor body.

(5)Install governor pressure solenoid in governor

body. Push solenoid in until it snaps into place in body.

(6)Position governor body gasket on transfer plate.

(7) Install retainer plate on governor body and

around solenoid. Be sure solenoid connector is posi-

tioned in retainer cutout.

(8) Align screw holes in governor body and trans-

fer plate. Then install and tighten governor body

screws to 4 N´m (35 in. lbs.) torque.

(9) Connect harness wires to governor pressure

solenoid and governor pressure sensor.

(10) Install fluid filter and pan.

(11) Lower vehicle.

(12) Fill transmission with recommended fluid and

road test vehicle to verify repair.

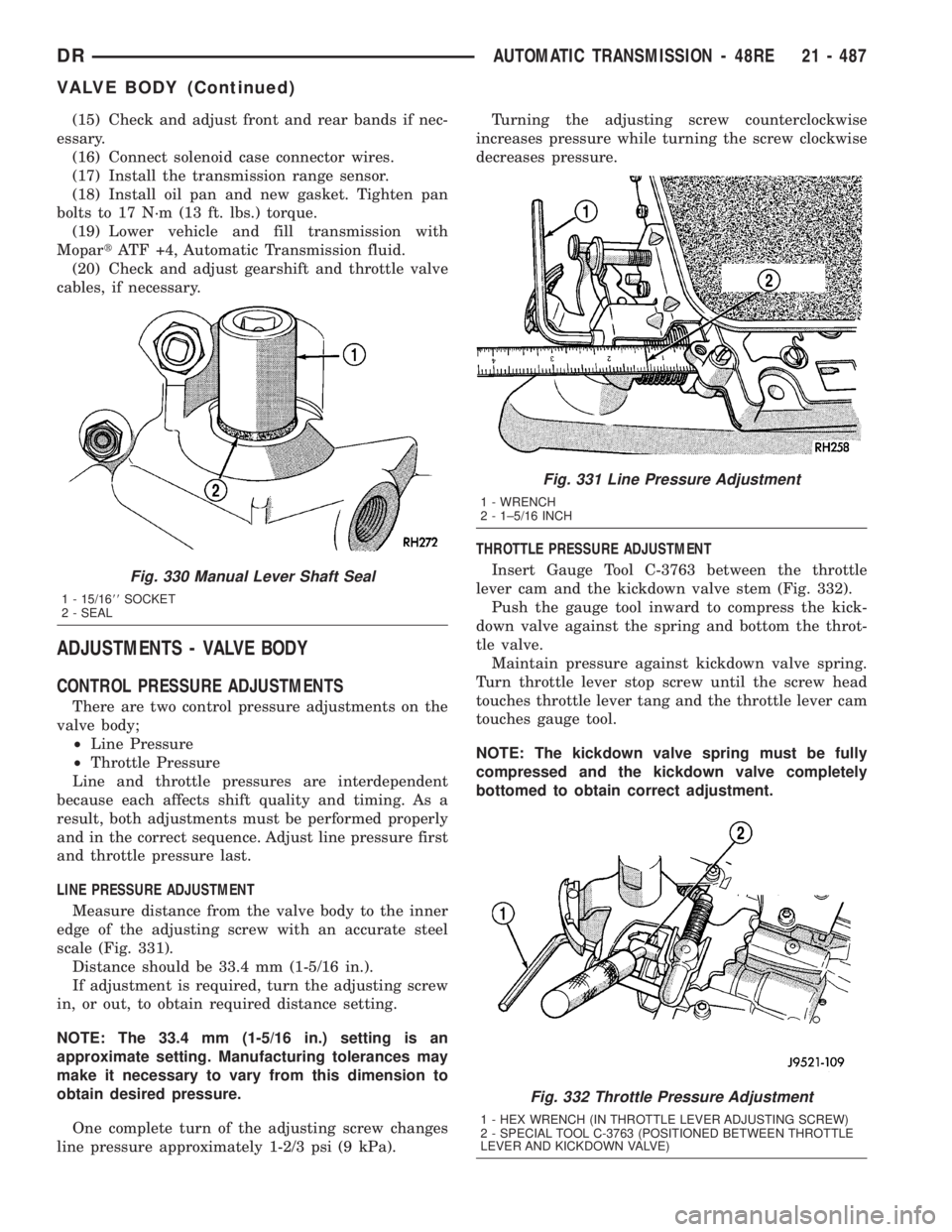

INSTALLATION

(1) Check condition of O-ring seals on valve body

harness connector (Fig. 329). Replace seals on con-

nector body if cut or worn.

(2)

Check condition of manual lever shaft seal in

transmission case. Replace seal if lip is cut or worn.

Install new seal with 15/16 deep well socket (Fig. 330).

(3) Check condition of seals on accumulator piston.

Install new piston seals, if necessary.

(4) Verify that transmission range sensor isNOT

installed. Valve body cannot be installed with sensor

in place.

(5) Place valve body manual lever in low (1 posi-

tion) so ball on park lock rod will be easier to install

in sprag.

(6) Lubricate shaft of manual lever with petroleum

jelly. This will ease inserting shaft through seal in

case.

(7) Lubricate seal rings on valve body harness con-

nector with petroleum jelly.

(8) Position valve body in case and work end of

park lock rod into and through pawl sprag. Turn pro-

peller shaft to align sprag and park lock teeth if nec-

essary. The rod will click as it enters pawl. Move rod

to check engagement.

CAUTION: It is possible for the park rod to displace

into a cavity just above the pawl sprag during

installation. Make sure the rod is actually engaged

in the pawl and has not displaced into this cavity.

(9) Install accumulator spring and piston into case.

Then swing valve body over piston and outer spring

to hold it in place.

(10) Align accumulator piston and outer spring,

manual lever shaft and electrical connector in case.

(11) Then seat valve body in case and install one

or two bolts to hold valve body in place.

(12) Tighten valve body bolts alternately and

evenly to 11 N´m (100 in. lbs.) torque.

(13) Install new fluid filter on valve body. Tighten

filter screws to 4 N´m (35 in. lbs.) torque.

(14) Install throttle and gearshift levers on valve

body manual lever shaft.

Fig. 329 Valve Body Harness Connector O-Ring Seal

1 - CONNECTOR O-RINGS

2 - VALVE BODY HARNESS CONNECTOR

3 - HARNESS

Fig. 328 Solenoid Harness Routing

1 - OVERDRIVE/CONVERTER SOLENOID WIRE HARNESS

2 - 3-4 ACCUMULATOR COVER PLATE

21 - 486 AUTOMATIC TRANSMISSION - 48REDR

VALVE BODY (Continued)

Page 2326 of 2895

(15) Check and adjust front and rear bands if nec-

essary.

(16) Connect solenoid case connector wires.

(17) Install the transmission range sensor.

(18) Install oil pan and new gasket. Tighten pan

bolts to 17 N´m (13 ft. lbs.) torque.

(19) Lower vehicle and fill transmission with

MopartATF +4, Automatic Transmission fluid.

(20) Check and adjust gearshift and throttle valve

cables, if necessary.

ADJUSTMENTS - VALVE BODY

CONTROL PRESSURE ADJUSTMENTS

There are two control pressure adjustments on the

valve body;

²Line Pressure

²Throttle Pressure

Line and throttle pressures are interdependent

because each affects shift quality and timing. As a

result, both adjustments must be performed properly

and in the correct sequence. Adjust line pressure first

and throttle pressure last.

LINE PRESSURE ADJUSTMENT

Measure distance from the valve body to the inner

edge of the adjusting screw with an accurate steel

scale (Fig. 331).

Distance should be 33.4 mm (1-5/16 in.).

If adjustment is required, turn the adjusting screw

in, or out, to obtain required distance setting.

NOTE: The 33.4 mm (1-5/16 in.) setting is an

approximate setting. Manufacturing tolerances may

make it necessary to vary from this dimension to

obtain desired pressure.

One complete turn of the adjusting screw changes

line pressure approximately 1-2/3 psi (9 kPa).Turning the adjusting screw counterclockwise

increases pressure while turning the screw clockwise

decreases pressure.

THROTTLE PRESSURE ADJUSTMENT

Insert Gauge Tool C-3763 between the throttle

lever cam and the kickdown valve stem (Fig. 332).

Push the gauge tool inward to compress the kick-

down valve against the spring and bottom the throt-

tle valve.

Maintain pressure against kickdown valve spring.

Turn throttle lever stop screw until the screw head

touches throttle lever tang and the throttle lever cam

touches gauge tool.

NOTE: The kickdown valve spring must be fully

compressed and the kickdown valve completely

bottomed to obtain correct adjustment.

Fig. 330 Manual Lever Shaft Seal

1 - 15/1688SOCKET

2 - SEAL

Fig. 331 Line Pressure Adjustment

1 - WRENCH

2 - 1±5/16 INCH

Fig. 332 Throttle Pressure Adjustment

1 - HEX WRENCH (IN THROTTLE LEVER ADJUSTING SCREW)

2 - SPECIAL TOOL C-3763 (POSITIONED BETWEEN THROTTLE

LEVER AND KICKDOWN VALVE)

DRAUTOMATIC TRANSMISSION - 48RE 21 - 487

VALVE BODY (Continued)

Page 2327 of 2895

AUTOMATIC TRANSMISSION - 45RFE/545RFE

TABLE OF CONTENTS

page page

AUTOMATIC TRANSMISSION - 45RFE/545RFE

DESCRIPTION........................489

OPERATION..........................490

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AUTOMATIC

TRANSMISSION.....................491

DIAGNOSIS AND TESTING - PRELIMINARY. . 491

DIAGNOSIS AND TESTING - ROAD

TESTING...........................491

DIAGNOSIS AND TESTING - HYDRAULIC

PRESSURE TEST....................493

DIAGNOSIS AND TESTING - AIR CHECKING

TRANSMISSION CLUTCH OPERATION....494

DIAGNOSIS AND TESTING - CONVERTER

HOUSING FLUID LEAK................495

STANDARD PROCEDURE - ALUMINUM

THREAD REPAIR.....................495

REMOVAL............................495

DISASSEMBLY........................497

CLEANING...........................502

INSPECTION.........................503

ASSEMBLY...........................503

INSTALLATION........................510

SCHEMATICS AND DIAGRAMS

HYDRAULIC SCHEMATICS.............513

SPECIFICATIONS

TRANSMISSION.....................534

SPECIAL TOOLS

RFE TRANSMISSION.................535

4C RETAINER/BULKHEAD

DISASSEMBLY........................538

ASSEMBLY...........................538

ADAPTER HOUSING SEAL

REMOVAL............................539

INSTALLATION........................539

BRAKE TRANSMISSION SHIFT INTERLOCK

SYSTEM

DESCRIPTION........................540

OPERATION..........................540

DIAGNOSIS AND TESTING - BRAKE

TRANSMISSION SHIFT INTERLOCK......540

ADJUSTMENTS - BRAKE TRANSMISSION

SHIFT INTERLOCK...................540

FLUID AND FILTER

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - EFFECTS OF

INCORRECT FLUID LEVEL.............541

DIAGNOSIS AND TESTING - CAUSES OF

BURNT FLUID.......................541DIAGNOSIS AND TESTING - FLUID

CONTAMINATION....................541

STANDARD PROCEDURE

STANDARD PROCEDURE - FLUID LEVEL

CHECK............................542

STANDARD PROCEDURE - FLUID AND

FILTER REPLACEMENT...............542

STANDARD PROCEDURE - TRANSMISSION

FILL...............................544

GEARSHIFT CABLE

DIAGNOSIS AND TESTING - GEARSHIFT

CABLE.............................544

REMOVAL............................544

INSTALLATION........................545

ADJUSTMENTS

GEARSHIFT CABLE..................546

HOLDING CLUTCHES

DESCRIPTION........................546

OPERATION..........................546

INPUT CLUTCH ASSEMBLY

DESCRIPTION........................549

OPERATION..........................549

DISASSEMBLY........................550

ASSEMBLY...........................552

INPUT SPEED SENSOR

DESCRIPTION........................558

OPERATION..........................558

REMOVAL............................559

INSTALLATION........................559

LINE PRESSURE (LP) SENSOR

DESCRIPTION........................559

OPERATION..........................559

REMOVAL............................559

INSTALLATION........................560

LOW/REVERSE CLUTCH

DISASSEMBLY........................560

CLEANING...........................561

INSPECTION.........................561

ASSEMBLY...........................561

OIL PUMP

DESCRIPTION........................562

OPERATION..........................562

STANDARD PROCEDURE - OIL PUMP

VOLUME CHECK.....................563

DISASSEMBLY........................564

CLEANING...........................566

INSPECTION.........................566

ASSEMBLY...........................566

21 - 488 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

Page 2328 of 2895

OIL PUMP FRONT SEAL

REMOVAL............................567

INSTALLATION........................567

OUTPUT SPEED SENSOR

DESCRIPTION........................567

OPERATION..........................567

REMOVAL............................567

INSTALLATION........................567

OVERDRIVE SWITCH

DESCRIPTION........................568

OPERATION..........................568

REMOVAL............................568

INSTALLATION........................569

PISTONS

DESCRIPTION........................569

OPERATION..........................569

PLANETARY GEARTRAIN

DESCRIPTION........................571

OPERATION..........................571

DISASSEMBLY........................573

CLEANING...........................573

INSPECTION.........................573

ASSEMBLY...........................573

SHIFT MECHANISM

DESCRIPTION........................574

OPERATION..........................574

SOLENOID SWITCH VALVE

DESCRIPTION........................574

OPERATION..........................574

SOLENOIDS

DESCRIPTION........................574OPERATION..........................575

TORQUE CONVERTER

DESCRIPTION........................575

OPERATION..........................579

REMOVAL............................580

INSTALLATION........................580

TRANSMISSION CONTROL RELAY

DESCRIPTION........................581

OPERATION..........................581

TRANSMISSION RANGE SENSOR

DESCRIPTION........................581

OPERATION..........................581

TRANSMISSION SOLENOID/TRS ASSEMBLY

DESCRIPTION........................582

OPERATION..........................582

REMOVAL............................583

INSTALLATION........................583

TRANSMISSION TEMPERATURE SENSOR

DESCRIPTION........................583

OPERATION..........................583

VALVE BODY

DESCRIPTION........................584

OPERATION..........................585

REMOVAL............................585

DISASSEMBLY........................586

CLEANING...........................588

INSPECTION.........................588

ASSEMBLY...........................590

INSTALLATION........................590

AUTOMATIC TRANSMISSION -

45RFE/545RFE

DESCRIPTION

The 45RFE/545RFE automatic transmissions is a

sophisticated, multi-range, electronically controlled

transmission which combines optimized gear ratios

for responsive performance, state of the art efficiency

features and low NVH. Other features include driver

adaptive shifting and three planetary gear sets to

provide wide ratio capability with precise ratio steps

for optimum driveability. The three planetary gear

sets also make available a unique alternate second

gear ratio. The primary 2nd gear ratio fits between

1st and 3rd gears for normal through-gear accelera-

tions. The alternate second gear ratio (2prime) allows

smoother 4-2 kickdowns at high speeds to provide

2nd gear passing performance over a wider highway

cruising range.

The hydraulic portion of the transmission consists

of the transmission fluid, fluid passages, hydraulic

valves, and various line pressure control components.The primary mechanical components of the trans-

mission consist of the following:

²Three multiple disc input clutches

²Three multiple disc holding clutches

²Five hydraulic accumulators

²Three planetary gear sets

²Dual Stage Hydraulic oil pump

²Valve body

²Solenoid pack

The TCM is the ªheartº or ªbrainº of the electronic

control system and relies on information from vari-

ous direct and indirect inputs (sensors, switches, etc.)

to determine driver demand and vehicle operating

conditions. With this information, the TCM can cal-

culate and perform timely and quality shifts through

various output or control devices (solenoid pack,

transmission control relay, etc.).

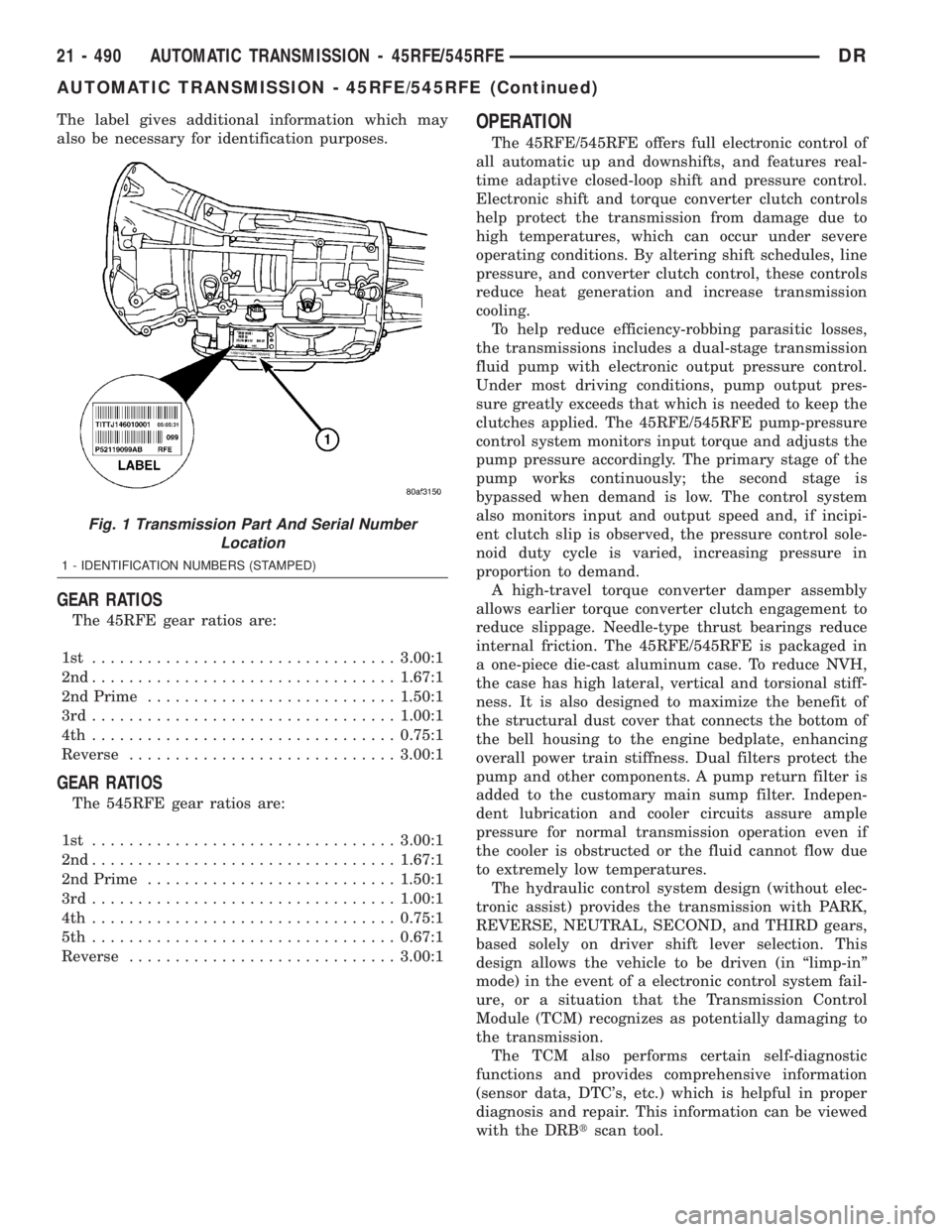

TRANSMISSION IDENTIFICATION

Transmission identification numbers are stamped

on the left side of the case just above the oil pan

sealing surface (Fig. 1). Refer to this information

when ordering replacement parts. A label is attached

to the transmission case above the stamped numbers.

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 489

Page 2329 of 2895

The label gives additional information which may

also be necessary for identification purposes.

GEAR RATIOS

The 45RFE gear ratios are:

1st .................................3.00:1

2nd.................................1.67:1

2nd Prime...........................1.50:1

3rd.................................1.00:1

4th .................................0.75:1

Reverse.............................3.00:1

GEAR RATIOS

The 545RFE gear ratios are:

1st .................................3.00:1

2nd.................................1.67:1

2nd Prime...........................1.50:1

3rd.................................1.00:1

4th .................................0.75:1

5th .................................0.67:1

Reverse.............................3.00:1

OPERATION

The 45RFE/545RFE offers full electronic control of

all automatic up and downshifts, and features real-

time adaptive closed-loop shift and pressure control.

Electronic shift and torque converter clutch controls

help protect the transmission from damage due to

high temperatures, which can occur under severe

operating conditions. By altering shift schedules, line

pressure, and converter clutch control, these controls

reduce heat generation and increase transmission

cooling.

To help reduce efficiency-robbing parasitic losses,

the transmissions includes a dual-stage transmission

fluid pump with electronic output pressure control.

Under most driving conditions, pump output pres-

sure greatly exceeds that which is needed to keep the

clutches applied. The 45RFE/545RFE pump-pressure

control system monitors input torque and adjusts the

pump pressure accordingly. The primary stage of the

pump works continuously; the second stage is

bypassed when demand is low. The control system

also monitors input and output speed and, if incipi-

ent clutch slip is observed, the pressure control sole-

noid duty cycle is varied, increasing pressure in

proportion to demand.

A high-travel torque converter damper assembly

allows earlier torque converter clutch engagement to

reduce slippage. Needle-type thrust bearings reduce

internal friction. The 45RFE/545RFE is packaged in

a one-piece die-cast aluminum case. To reduce NVH,

the case has high lateral, vertical and torsional stiff-

ness. It is also designed to maximize the benefit of

the structural dust cover that connects the bottom of

the bell housing to the engine bedplate, enhancing

overall power train stiffness. Dual filters protect the

pump and other components. A pump return filter is

added to the customary main sump filter. Indepen-

dent lubrication and cooler circuits assure ample

pressure for normal transmission operation even if

the cooler is obstructed or the fluid cannot flow due

to extremely low temperatures.

The hydraulic control system design (without elec-

tronic assist) provides the transmission with PARK,

REVERSE, NEUTRAL, SECOND, and THIRD gears,

based solely on driver shift lever selection. This

design allows the vehicle to be driven (in ªlimp-inº

mode) in the event of a electronic control system fail-

ure, or a situation that the Transmission Control

Module (TCM) recognizes as potentially damaging to

the transmission.

The TCM also performs certain self-diagnostic

functions and provides comprehensive information

(sensor data, DTC's, etc.) which is helpful in proper

diagnosis and repair. This information can be viewed

with the DRBtscan tool.

Fig. 1 Transmission Part And Serial Number

Location

1 - IDENTIFICATION NUMBERS (STAMPED)

21 - 490 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2330 of 2895

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AUTOMATIC

TRANSMISSION

CAUTION: Before attempting any repair on a RFE

automatic transmission, check for Diagnostic Trou-

ble Codes with the DRBTscan tool.

Transmission malfunctions may be caused by these

general conditions:

²Poor engine performance

²Improper adjustments

²Hydraulic malfunctions

²Mechanical malfunctions

²Electronic malfunctions

Diagnosis of these problems should always begin

by checking the easily accessible variables: fluid level

and condition, gearshift cable adjustment. Then per-

form a road test to determine if the problem has been

corrected or if more diagnosis is necessary. If the

problem persists after the preliminary tests and cor-

rections are completed, hydraulic pressure checks

should be performed.

DIAGNOSIS AND TESTING - PRELIMINARY

Two basic procedures are required. One procedure

for vehicles that are drivable and an alternate proce-

dure for disabled vehicles (will not back up or move

forward).

VEHICLE IS DRIVABLE

(1) Check for transmission fault codes using DRBt

scan tool.

(2) Check fluid level and condition.

(3) Adjust gearshift cable if complaint was based

on delayed, erratic, or harsh shifts.

(4) Road test and note how transmission upshifts,

downshifts, and engages.

(5) Perform hydraulic pressure test if shift prob-

lems were noted during road test.

(6) Perform air-pressure test to check clutch oper-

ation.

VEHICLE IS DISABLED

(1) Check fluid level and condition.

(2) Check for broken or disconnected gearshift

cable.

(3) Check for cracked, leaking cooler lines, or loose

or missing pressure-port plugs.

(4) Raise and support vehicle on safety stands,

start engine, shift transmission into gear, and note

following:

(a) If propeller shaft turns but wheels do not,

problem is with differential or axle shafts.

(b) If propeller shaft does not turn and transmis-

sion is noisy, stop engine. Remove oil pan, and

check for debris. If pan is clear, remove transmis-

sion and check for damaged driveplate, converter,

oil pump, or input shaft.

(c) If propeller shaft does not turn and transmis-

sion is not noisy, perform hydraulic-pressure test to

determine if problem is hydraulic or mechanical.

DIAGNOSIS AND TESTING - ROAD TESTING

Before road testing, be sure the fluid level and con-

trol cable adjustments have been checked and

adjusted if necessary. Verify that all diagnostic trou-

ble codes have been resolved.

Observe engine performance during the road test.

A poorly tuned engine will not allow accurate analy-

sis of transmission operation.

Operate the transmission in all gear ranges. Check

for shift variations and engine flare which indicates

slippage. Note if shifts are harsh, spongy, delayed,

early, or if part throttle downshifts are sensitive.

Slippage indicated by engine flare, usually means

clutch, overrunning clutch, or line pressure problems.

A slipping clutch can often be determined by com-

paring which internal units are applied in the vari-

ous gear ranges. The Clutch Application charts

provide a basis for analyzing road test results.

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 491

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)