Diesel DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1597 of 2895

(8) Install the oil drain tube and a new gasket to

the turbocharger. Tighten the drain tube bolts to 24

N´m (18 ft. lbs.) torque.

(9)Pre-lube the turbocharger.Pour 50 to 60 cc

(2 to 3 oz.) clean engine oil in the oil supply line fit-

ting on the turbo. Rotate the turbocharger impeller

by hand to distrubute the oil thoroughly.

(10) Install and tighten the oil supply line fitting

nut to 24 N´m (18 ft. lbs.) torque.

(11) Position the charge air cooler inlet pipe to the

turbocharger. With the clamp in position, tighten the

clamp nut to 8 N´m (72 in. lbs.) torque.

(12) Position the air inlet hose to the turbocharger.

Tighten the clamp to 8 N´m (72 in. lbs.) torque.

(13) Raise vehicle on hoist.

(14) Connect the exhaust pipe to the turbocharger

and tighten the bolts to 34 N´m (25 ft. lbs.) torque.

(15) Lower the vehicle.

(16) Connect the battery negative cables.

(17) Start the engine to check for leaks.

VALVE TIMING

STANDARD PROCEDURE - TIMING

VERIFICATION

(1) Remove the cylinder head cover(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(2) Remove fuel injector from cylinder number

1(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

FUEL INJECTOR - REMOVAL).

(3) Using Special Tool 7471B rotate the engine

until the TDC mark on the damper is at 12 o'clock.

(4) Using a 8 in.x 1/4 in. dowel rod inserted into

cylinder number 1, rock the crankshaft back and

forth to verify piston number 1 is at TDC.

(5) With cylinder number still at TDC, inspect the

keyway on the crankshaft gear for proper alignment

(12 o'clock position).

(6) If the keyway is not at 12 o'clock position

replace the crankshaft gear assembly.

(7) If the keyway is at 12 o'clock position, remove

front gear cover and verify timing mark alignment

between the camshaft gear and crankshaft gear, if

not aligned inspect keyway on camshaft gear.

(8) Inspect keyway on camshaft gear for proper

alignment with the key in the camshaft, if alignment

is off replace the camshaft/gear assembly.

(9) If timing marks alignment is off and no dam-

age is found at either the crankshaft or camshaft

gear keyways, realign timing marks as necessary.

GEAR HOUSING

REMOVAL

(1) Disconnect the battery negative cables.

(2) Raise vehicle on hoist.

(3) Partially drain engine coolant into container

suitable for re-use (Refer to 7 - COOLING - STAN-

DARD PROCEDURE).

(4) Lower vehicle.

(5) Remove radiator upper hose.

(6) Disconnect coolant recovery bottle hose from

radiator filler neck and lift bottle off of fan shroud.

(7) Disconnect windshield washer pump supply

hose and electrical connections and lift washer bottle

off of fan shroud.

(8) Remove lower fan shroud fasteners. Disconnect

fan drive wire harness.

(9) Remove the upper fan shroud-to-radiator

mounting bolts.

(10) Remove viscous fan/drive assembly (Refer to 7

- COOLING/ENGINE/RADIATOR FAN - REMOVAL).

(11) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(12) Remove the cooling fan support/hub from the

front of the engine.

(13) Raise the vehicle on hoist.

(14) Remove the crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL) and speed indicator ring.

(15) Lower the vehicle.

(16) Remove the hydraulic pump.

(17) Remove the accessory drive belt tensioner.

(18) Remove the gear cover-to-housing bolts and

gently pry the cover away from the housing, taking

care not to mar the gasket surfaces.

(19) Remove the fuel injection pump (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/FUEL INJEC-

TION PUMP - REMOVAL).

(20) Disconnect the camshaft position sensor con-

nector.

(21) Disconnect and remove engine speed sensor.

(22) Remove the camshaft (Refer to 9 - ENGINE/

ENGINE BLOCK/CAMSHAFT & BEARINGS (IN

BLOCK) - REMOVAL).

(23) Remove the six front oil pan fasteners.

(24) Remove the gear housing fasteners.

NOTE: Use care when removing the gear housing,

to avoid damage to the oil pan gasket, as the gas-

ket will be reused if it is not damaged.

(25) Slide a feeler gauge between the gear housing

and oil pan gasket, to break the gasket seal.

(26) Remove the gear housing and gasket.

9 - 348 ENGINE 5.9L DIESELDR

EXHAUST MANIFOLD (Continued)

Page 1598 of 2895

(27) Clean the gasket material from the cylinder

block and gear housing.

INSTALLATION

(1) Inspect oil pan gasket. If torn, gasket must be

replaced.

(2) Install a new gasket and the gear housing.

Torque bolts to 24 N´m (18 ft. lbs.). Follow torque

sequence.

(3) If a new housing is installed, the camshaft

position sensor, and engine speed sensor must be

transferred to the new housing.

(4) Connect the camshaft position sensor connec-

tor.

(5) Install and connect engine speed sensor.

(6) Install the injection pump (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY/FUEL INJECTION

PUMP - INSTALLATION).

(7) Install the camshaft (Refer to 9 - ENGINE/EN-

GINE BLOCK/CAMSHAFT & BEARINGS (IN

BLOCK) - INSTALLATION). Align the crankshaft

and camshaft gear marks as shown in.

(8) Install a new front crankshaft seal into the

gear cover.

(9) Apply a bead of MopartSilicone Rubber Adhe-

sive Sealant or equivalent to the gear housing cover.

Be sure to surround all through holes.

(10) Using the seal pilot to align the cover, install

the cover to the housing and install the bolts.

Tighten the bolts to 24 N´m (18 ft. lbs.) torque.

(11) Remove the seal pilot. Install front seal dust

shield.

(12) Raise the vehicle.

(13) Trim any excess gear housing gasket to make

it flush with the oil pan rail.

(14) Install the crankshaft damper and speed indi-

cator ring (Refer to 9 - ENGINE/ENGINE BLOCK/

VIBRATION DAMPER - INSTALLATION). Torque

bolts to 40 Nm (30 ft. lbs.), plus an additional 60É.

(15) Lower vehicle.

(16) Install the fan support/hub assembly and

tighten bolts to 32 N´m (24 ft. lbs.) torque.

(17) Install the hydraulic pump.

(18) Install the accessory drive belt tensioner.

Torque bolt to 43 N´m (32 ft. lbs.) torque.

(19) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(20) Install the upper cooling fan and shroud

together (Refer to 7 - COOLING/ENGINE/RADIA-

TOR FAN - INSTALLATION).(21) Install lower shroud and connect fan drive

harness connector.

(22) Install the windshield washer reservoir to the

fan shroud and connect the washer pump supply

hose and electrical connection.

(23) Install the coolant recovery bottle to the fan

shroud and connect the hose to the radiator filler

neck.

(24) Install the radiator upper hose and clamps.

(25) Add engine oil.

(26) Add coolant (Refer to 7 - COOLING - STAN-

DARD PROCEDURE).

(27) Connect the battery cables.

(28) Start engine and inspect for leaks.

GEAR HOUSING COVER

REMOVAL

(1) Disconnect both battery negative cables.

(2) Raise vehicle on hoist.

(3) Partially drain engine coolant into container

suitable for re-use (Refer to 7 - COOLING - STAN-

DARD PROCEDURE).

(4) Lower vehicle.

(5) Remove radiator upper hose.

(6) Disconnect coolant recovery bottle hose from

radiator filler neck and lift bottle off of fan shroud.

(7) Disconnect windshield washer pump supply

hose and electrical connections and lift washer bottle

off of fan shroud.

(8) Remove viscous fan/drive assembly (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - REMOVAL).

(9) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(10) Remove the cooling fan support/hub from the

front of the engine.

(11) Raise the vehicle on hoist.

(12) Remove power steering pump.

(13) Remove accessory drive belt tensioner.

(14) Remove the crankshaft damper and speed

indicator ring (Refer to 9 - ENGINE/ENGINE

BLOCK/VIBRATION DAMPER - REMOVAL).

(15) Lower the vehicle.

(16) Remove the gear cover-to-housing bolts and

gently pry the cover away from the housing, taking

care not to mar the gasket surfaces.

DRENGINE 5.9L DIESEL 9 - 349

GEAR HOUSING (Continued)

Page 1599 of 2895

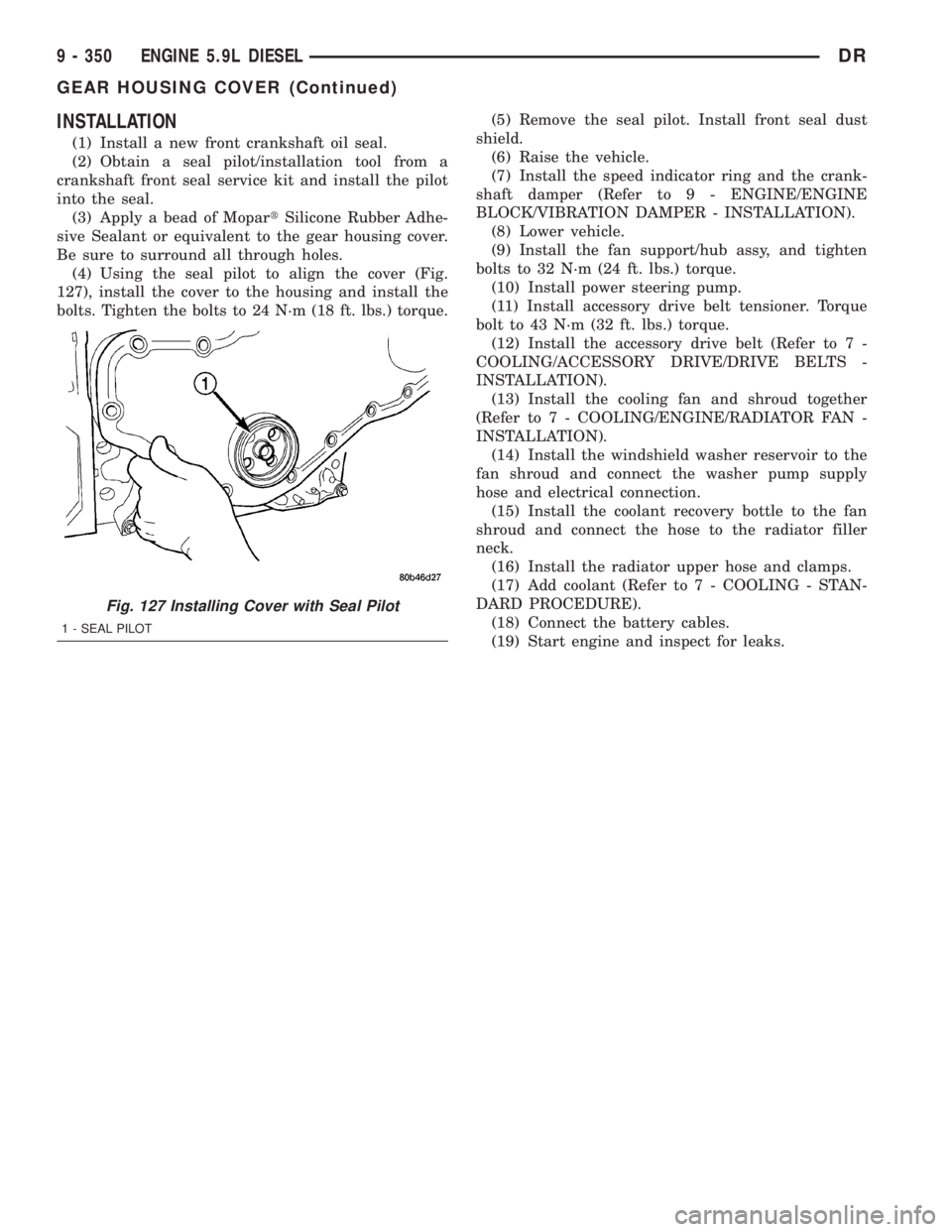

INSTALLATION

(1) Install a new front crankshaft oil seal.

(2) Obtain a seal pilot/installation tool from a

crankshaft front seal service kit and install the pilot

into the seal.

(3) Apply a bead of MopartSilicone Rubber Adhe-

sive Sealant or equivalent to the gear housing cover.

Be sure to surround all through holes.

(4) Using the seal pilot to align the cover (Fig.

127), install the cover to the housing and install the

bolts. Tighten the bolts to 24 N´m (18 ft. lbs.) torque.(5) Remove the seal pilot. Install front seal dust

shield.

(6) Raise the vehicle.

(7) Install the speed indicator ring and the crank-

shaft damper (Refer to 9 - ENGINE/ENGINE

BLOCK/VIBRATION DAMPER - INSTALLATION).

(8) Lower vehicle.

(9) Install the fan support/hub assy, and tighten

bolts to 32 N´m (24 ft. lbs.) torque.

(10) Install power steering pump.

(11) Install accessory drive belt tensioner. Torque

bolt to 43 N´m (32 ft. lbs.) torque.

(12) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(13) Install the cooling fan and shroud together

(Refer to 7 - COOLING/ENGINE/RADIATOR FAN -

INSTALLATION).

(14) Install the windshield washer reservoir to the

fan shroud and connect the washer pump supply

hose and electrical connection.

(15) Install the coolant recovery bottle to the fan

shroud and connect the hose to the radiator filler

neck.

(16) Install the radiator upper hose and clamps.

(17) Add coolant (Refer to 7 - COOLING - STAN-

DARD PROCEDURE).

(18) Connect the battery cables.

(19) Start engine and inspect for leaks.

Fig. 127 Installing Cover with Seal Pilot

1 - SEAL PILOT

9 - 350 ENGINE 5.9L DIESELDR

GEAR HOUSING COVER (Continued)

Page 1656 of 2895

EXHAUST SYSTEM

TABLE OF CONTENTS

page page

EXHAUST SYSTEM

DESCRIPTION

DESCRIPTION........................1

DESCRIPTION ± 5.9L DIESEL.............2

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - GAS ENGINE . . . 2

DIAGNOSIS AND TESTING - DIESEL

ENGINE..............................3

SPECIFICATIONS - TORQUE...............4

SPECIAL TOOLS........................4

CATALYTIC CONVERTER

DESCRIPTION - CATALYTIC CONVERTER.....4

OPERATION............................4

REMOVAL

REMOVAL............................5

REMOVAL............................5

INSPECTION...........................5

INSTALLATION

INSTALLATION........................5

INSTALLATION........................5

EXHAUST PIPE

REMOVAL

REMOVAL Ð 5.9L......................5

REMOVAL............................5

INSPECTION...........................6

INSTALLATION

INSTALLATION Ð 5.9L..................6

INSTALLATION........................7

EXHAUST PIPE

REMOVAL.............................7

INSPECTION...........................7

INSTALLATION..........................7

HEAT SHIELDS

DESCRIPTION..........................7

REMOVAL.............................7INSTALLATION..........................8

MUFFLER

REMOVAL.............................8

INSTALLATION..........................8

MUFFLER - 5.9L DIESEL

REMOVAL.............................9

INSTALLATION..........................9

TAILPIPE - 5.9L DIESEL

REMOVAL.............................9

INSPECTION...........................9

INSTALLATION..........................9

TAILPIPE

REMOVAL.............................10

INSPECTION..........................10

INSTALLATION.........................10

TURBOCHARGER SYSTEM

DIAGNOSIS AND TESTING -

TURBOCHARGER BOOST PRESSURE.....10

TURBOCHARGER

DESCRIPTION.........................11

OPERATION...........................11

REMOVAL.............................13

CLEANING............................14

INSPECTION..........................14

INSTALLATION.........................14

CHARGE AIR COOLER AND PLUMBING

DESCRIPTION.........................15

OPERATION...........................15

DIAGNOSIS AND TESTING - CHARGE AIR

COOLER SYSTEM - LEAKS..............15

REMOVAL.............................15

CLEANING............................16

INSPECTION..........................16

INSTALLATION.........................16

EXHAUST SYSTEM

DESCRIPTION

DESCRIPTION

CAUTION: Avoid application of rust prevention com-

pounds or undercoating materials to exhaust sys-

tem floor pan exhaust heat shields. Light overspray

near the edges is permitted. Application of coating

will result in excessive floor pan temperatures and

objectionable fumes.The federal gasoline engine exhaust system con-

sists of engine exhaust manifolds, exhaust pipes, cat-

alytic converter(s), extension pipe (if needed),

exhaust heat shields, muffler and exhaust tailpipe.

The California emission vehicles exhaust system

also contains the above components as well as mini

catalytic converters added to the exhaust pipe.

The exhaust system must be properly aligned to

prevent stress, leakage and body contact. Minimum

clearance between any exhaust component and the

body or frame is 25.4 mm (1.0 in.). If the system con-

tacts any body panel, it may amplify objectionable

noises from the engine or body.

DREXHAUST SYSTEM 11 - 1

Page 1657 of 2895

DESCRIPTION ± 5.9L DIESEL

CAUTION: Avoid application of rust prevention com-

pounds or undercoating materials to exhaust sys-

tem floor pan exhaust heat shields. Light overspray

near the edges is permitted. Application of coating

will result in excessive floor pan temperatures and

objectionable fumes.

The diesel engine exhaust system consists of an

engine exhaust manifold, turbocharger, exhaust pipe,resonator, extension pipe (if needed), muffler and

exhaust tailpipe.

California emission vehicales include a catalytic

converter.

The exhaust system must be properly aligned to

prevent stress, leakage and body contact. The

exhaust components should be kept a minimum of

25.4 mm (1.0 in.) away from the body and frame. If

the system contacts any body panel, it may amplify

objectionable noises from the engine or body.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - GAS ENGINE

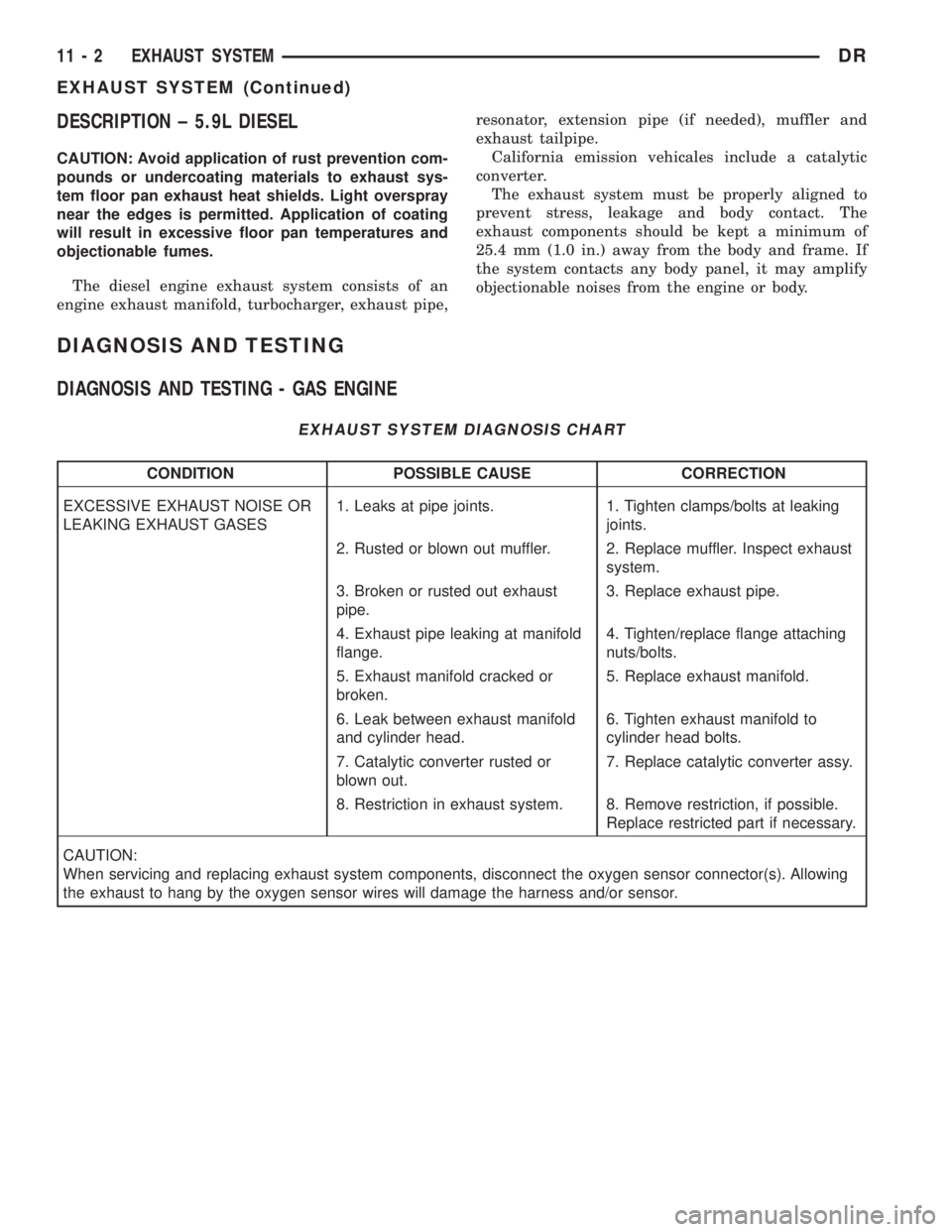

EXHAUST SYSTEM DIAGNOSIS CHART

CONDITION POSSIBLE CAUSE CORRECTION

EXCESSIVE EXHAUST NOISE OR

LEAKING EXHAUST GASES1. Leaks at pipe joints. 1. Tighten clamps/bolts at leaking

joints.

2. Rusted or blown out muffler. 2. Replace muffler. Inspect exhaust

system.

3. Broken or rusted out exhaust

pipe.3. Replace exhaust pipe.

4. Exhaust pipe leaking at manifold

flange.4. Tighten/replace flange attaching

nuts/bolts.

5. Exhaust manifold cracked or

broken.5. Replace exhaust manifold.

6. Leak between exhaust manifold

and cylinder head.6. Tighten exhaust manifold to

cylinder head bolts.

7. Catalytic converter rusted or

blown out.7. Replace catalytic converter assy.

8. Restriction in exhaust system. 8. Remove restriction, if possible.

Replace restricted part if necessary.

CAUTION:

When servicing and replacing exhaust system components, disconnect the oxygen sensor connector(s). Allowing

the exhaust to hang by the oxygen sensor wires will damage the harness and/or sensor.

11 - 2 EXHAUST SYSTEMDR

EXHAUST SYSTEM (Continued)

Page 1658 of 2895

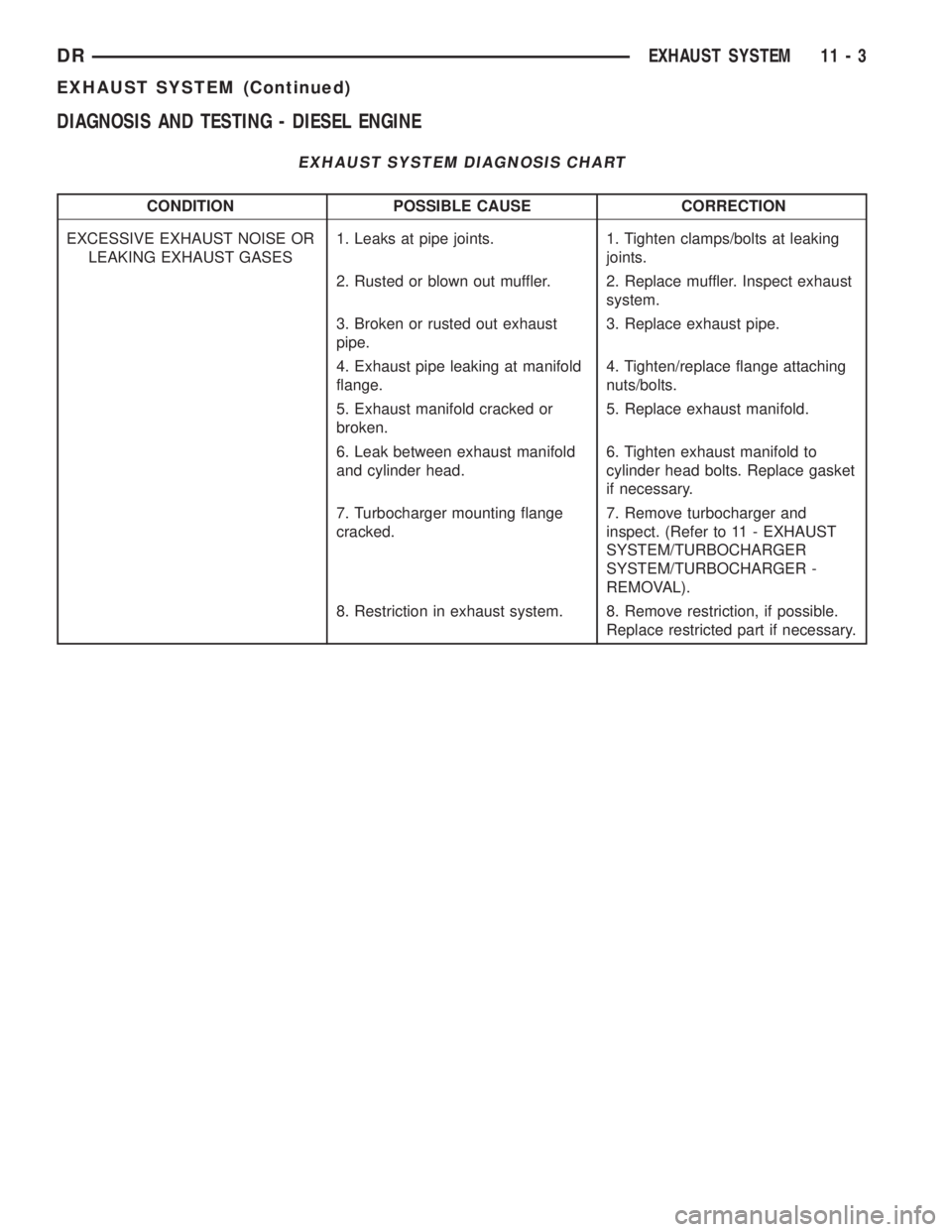

DIAGNOSIS AND TESTING - DIESEL ENGINE

EXHAUST SYSTEM DIAGNOSIS CHART

CONDITION POSSIBLE CAUSE CORRECTION

EXCESSIVE EXHAUST NOISE OR

LEAKING EXHAUST GASES1. Leaks at pipe joints. 1. Tighten clamps/bolts at leaking

joints.

2. Rusted or blown out muffler. 2. Replace muffler. Inspect exhaust

system.

3. Broken or rusted out exhaust

pipe.3. Replace exhaust pipe.

4. Exhaust pipe leaking at manifold

flange.4. Tighten/replace flange attaching

nuts/bolts.

5. Exhaust manifold cracked or

broken.5. Replace exhaust manifold.

6. Leak between exhaust manifold

and cylinder head.6. Tighten exhaust manifold to

cylinder head bolts. Replace gasket

if necessary.

7. Turbocharger mounting flange

cracked.7. Remove turbocharger and

inspect. (Refer to 11 - EXHAUST

SYSTEM/TURBOCHARGER

SYSTEM/TURBOCHARGER -

REMOVAL).

8. Restriction in exhaust system. 8. Remove restriction, if possible.

Replace restricted part if necessary.

DREXHAUST SYSTEM 11 - 3

EXHAUST SYSTEM (Continued)

Page 1659 of 2895

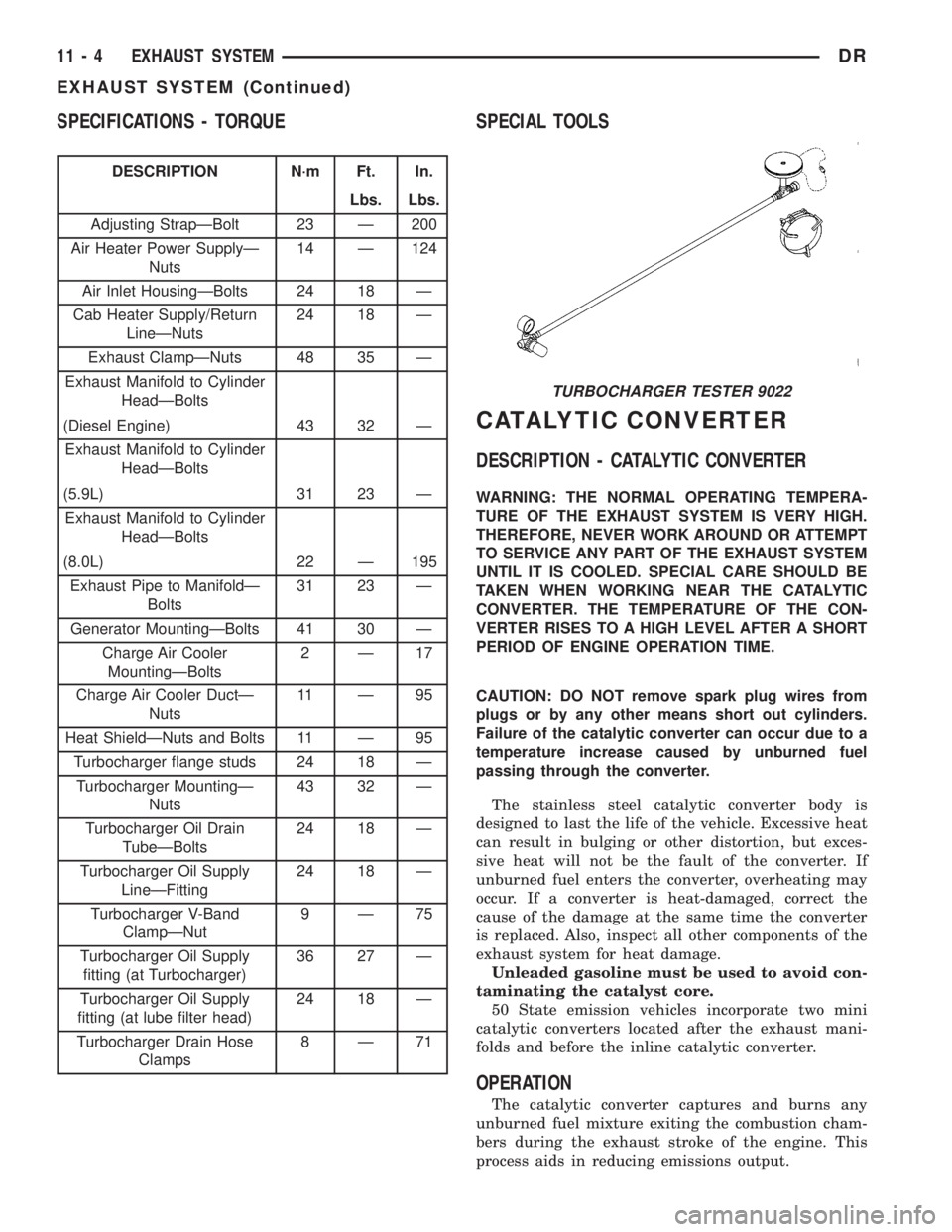

SPECIFICATIONS - TORQUE

DESCRIPTION N´m Ft. In.

Lbs. Lbs.

Adjusting StrapÐBolt 23 Ð 200

Air Heater Power SupplyÐ

Nuts14 Ð 124

Air Inlet HousingÐBolts 24 18 Ð

Cab Heater Supply/Return

LineÐNuts24 18 Ð

Exhaust ClampÐNuts 48 35 Ð

Exhaust Manifold to Cylinder

HeadÐBolts

(Diesel Engine) 43 32 Ð

Exhaust Manifold to Cylinder

HeadÐBolts

(5.9L) 31 23 Ð

Exhaust Manifold to Cylinder

HeadÐBolts

(8.0L) 22 Ð 195

Exhaust Pipe to ManifoldÐ

Bolts31 23 Ð

Generator MountingÐBolts 41 30 Ð

Charge Air Cooler

MountingÐBolts2Ð17

Charge Air Cooler DuctÐ

Nuts11 Ð 9 5

Heat ShieldÐNuts and Bolts 11 Ð 95

Turbocharger flange studs 24 18 Ð

Turbocharger MountingÐ

Nuts43 32 Ð

Turbocharger Oil Drain

TubeÐBolts24 18 Ð

Turbocharger Oil Supply

LineÐFitting24 18 Ð

Turbocharger V-Band

ClampÐNut9Ð75

Turbocharger Oil Supply

fitting (at Turbocharger)36 27 Ð

Turbocharger Oil Supply

fitting (at lube filter head)24 18 Ð

Turbocharger Drain Hose

Clamps8Ð71

SPECIAL TOOLS

CATALYTIC CONVERTER

DESCRIPTION - CATALYTIC CONVERTER

WARNING: THE NORMAL OPERATING TEMPERA-

TURE OF THE EXHAUST SYSTEM IS VERY HIGH.

THEREFORE, NEVER WORK AROUND OR ATTEMPT

TO SERVICE ANY PART OF THE EXHAUST SYSTEM

UNTIL IT IS COOLED. SPECIAL CARE SHOULD BE

TAKEN WHEN WORKING NEAR THE CATALYTIC

CONVERTER. THE TEMPERATURE OF THE CON-

VERTER RISES TO A HIGH LEVEL AFTER A SHORT

PERIOD OF ENGINE OPERATION TIME.

CAUTION: DO NOT remove spark plug wires from

plugs or by any other means short out cylinders.

Failure of the catalytic converter can occur due to a

temperature increase caused by unburned fuel

passing through the converter.

The stainless steel catalytic converter body is

designed to last the life of the vehicle. Excessive heat

can result in bulging or other distortion, but exces-

sive heat will not be the fault of the converter. If

unburned fuel enters the converter, overheating may

occur. If a converter is heat-damaged, correct the

cause of the damage at the same time the converter

is replaced. Also, inspect all other components of the

exhaust system for heat damage.

Unleaded gasoline must be used to avoid con-

taminating the catalyst core.

50 State emission vehicles incorporate two mini

catalytic converters located after the exhaust mani-

folds and before the inline catalytic converter.

OPERATION

The catalytic converter captures and burns any

unburned fuel mixture exiting the combustion cham-

bers during the exhaust stroke of the engine. This

process aids in reducing emissions output.

TURBOCHARGER TESTER 9022

11 - 4 EXHAUST SYSTEMDR

EXHAUST SYSTEM (Continued)

Page 1664 of 2895

MUFFLER - 5.9L DIESEL

REMOVAL

(1) Disconnect the battery negative cables.

(2) Raise and support the vehicle.

(3) Remove the muffler to tail pipe and extension

pipe clamps (Fig. 10).

(4) Disconnect the muffler from the hanger isola-

tors (Fig. 10).

(5) Disconnect the muffler from the tailpipe.

(6) Disconnect the muffler from the extension pipe

and remove from the vehicle.

INSTALLATION

(1) Install the muffler hanger rods into the isola-

tors (Fig. 10).

(2) Install the muffler into the extension pipe.

(3) Install the muffler into the tail pipe.

(4) Install the exhaust clamps, align the exhaust

system, and tighten the exhaust clamps to 48 N´m

(35 ft. lbs.) torque.

(5) Lower the vehicle.

(6) Connect the battery negative cables.

(7) Start the engine and inspect for exhaust leaks

and exhaust system contact with the body panels. A

minimum of 25.4 mm (1.0 in.) is required between

exhaust system components and body/frame parts.

Adjust the alignment, if needed.

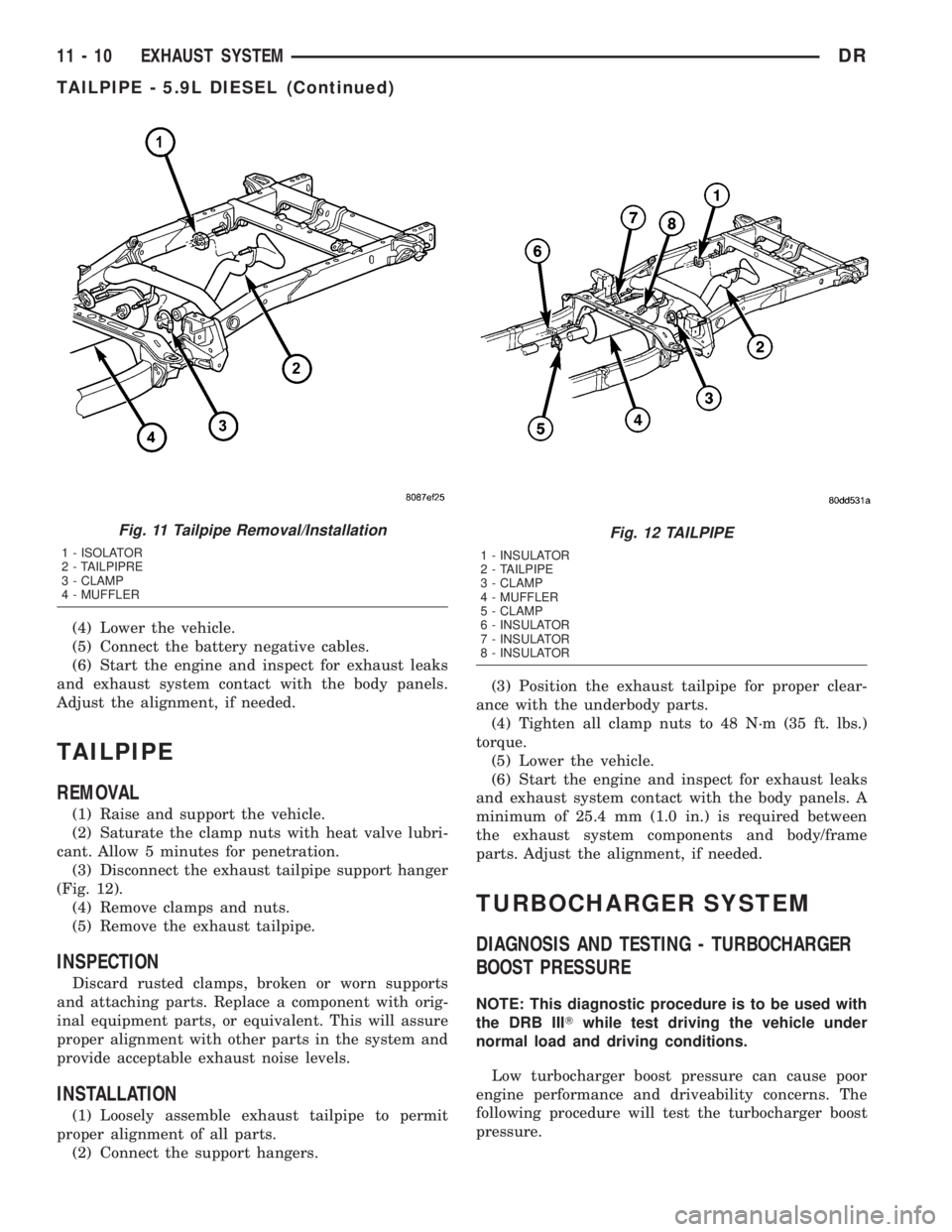

TAILPIPE - 5.9L DIESEL

REMOVAL

(1) Disconnect the battery negative cables.

(2) Raise and support the vehicle.

(3) Saturate the clamp nuts with heat valve lubri-

cant. Allow 5 minutes for penetration.

(4) Disconnect the exhaust tailpipe support hanger

isolators (Fig. 11).

(5) Remove the muffler-to-tailpipe clamps (Fig. 11).

(6) Remove the tailpipe from the vehicle.

INSPECTION

Discard rusted clamps, broken or worn supports

and attaching parts. Replace a component with orig-

inal equipment parts, or equivalent. This will assure

proper alignment with other parts in the system and

provide acceptable exhaust noise levels.

INSTALLATION

(1) Install the tailpipe into the muffler.

(2) Install the tailpipe hanger rods into the isola-

tors (Fig. 11)

(3) Install the exhaust clamp, align the exhaust

system, and tighten the clamp 48 N´m (35 ft. lbs.)

torque.

Fig. 9 MUFFLER

1 - INSULATOR

2 - INSULATOR

3 - MUFFLER

4 - INSULATOR

Fig. 10 Muffler Removal/Installation

1 - INSULATOR

2 - ISOLATOR

3 - TAILPIPE

4 - CLAMP

5 - MUFFLER

6 - CLAMP

7 - EXTENSION PIPE

DREXHAUST SYSTEM 11 - 9

MUFFLER (Continued)

Page 1665 of 2895

(4) Lower the vehicle.

(5) Connect the battery negative cables.

(6) Start the engine and inspect for exhaust leaks

and exhaust system contact with the body panels.

Adjust the alignment, if needed.

TAILPIPE

REMOVAL

(1) Raise and support the vehicle.

(2) Saturate the clamp nuts with heat valve lubri-

cant. Allow 5 minutes for penetration.

(3) Disconnect the exhaust tailpipe support hanger

(Fig. 12).

(4) Remove clamps and nuts.

(5) Remove the exhaust tailpipe.

INSPECTION

Discard rusted clamps, broken or worn supports

and attaching parts. Replace a component with orig-

inal equipment parts, or equivalent. This will assure

proper alignment with other parts in the system and

provide acceptable exhaust noise levels.

INSTALLATION

(1) Loosely assemble exhaust tailpipe to permit

proper alignment of all parts.

(2) Connect the support hangers.(3) Position the exhaust tailpipe for proper clear-

ance with the underbody parts.

(4) Tighten all clamp nuts to 48 N´m (35 ft. lbs.)

torque.

(5) Lower the vehicle.

(6) Start the engine and inspect for exhaust leaks

and exhaust system contact with the body panels. A

minimum of 25.4 mm (1.0 in.) is required between

the exhaust system components and body/frame

parts. Adjust the alignment, if needed.

TURBOCHARGER SYSTEM

DIAGNOSIS AND TESTING - TURBOCHARGER

BOOST PRESSURE

NOTE: This diagnostic procedure is to be used with

the DRB IIITwhile test driving the vehicle under

normal load and driving conditions.

Low turbocharger boost pressure can cause poor

engine performance and driveability concerns. The

following procedure will test the turbocharger boost

pressure.

Fig. 11 Tailpipe Removal/Installation

1 - ISOLATOR

2 - TAILPIPRE

3 - CLAMP

4 - MUFFLER

Fig. 12 TAILPIPE

1 - INSULATOR

2 - TAILPIPE

3 - CLAMP

4 - MUFFLER

5 - CLAMP

6 - INSULATOR

7 - INSULATOR

8 - INSULATOR

11 - 10 EXHAUST SYSTEMDR

TAILPIPE - 5.9L DIESEL (Continued)

Page 1698 of 2895

FUEL SYSTEM

TABLE OF CONTENTS

page page

FUEL DELIVERY - GAS....................1

FUEL INJECTION - GAS...................24FUEL DELIVERY - DIESEL.................56

FUEL INJECTION - DIESEL................79

FUEL DELIVERY - GAS

TABLE OF CONTENTS

page page

FUEL DELIVERY - GAS

DESCRIPTION..........................1

OPERATION............................2

STANDARD PROCEDURE - FUEL SYSTEM

PRESSURE RELEASE...................2

SPECIFICATIONS

FUEL SYSTEM PRESSURE..............3

TORQUE - FUEL SYSTEM...............3

SPECIAL TOOLS

FUEL SYSTEM........................5

FUEL FILTER/PRESSURE REGULATOR

DESCRIPTION..........................6

OPERATION............................6

FUEL LEVEL SENDING UNIT / SENSOR

DESCRIPTION..........................7

OPERATION............................7

REMOVAL.............................7

INSTALLATION..........................8

FUEL LINES

DESCRIPTION..........................8

QUICK CONNECT FITTING

DESCRIPTION..........................8

STANDARD PROCEDURE - QUICK-CONNECT

FITTINGS............................8FUEL PUMP

DESCRIPTION.........................12

OPERATION...........................12

FUEL PUMP MODULE

DESCRIPTION.........................12

OPERATION...........................12

REMOVAL.............................12

INSTALLATION.........................13

FUEL RAIL

DESCRIPTION.........................13

OPERATION...........................13

REMOVAL.............................13

INSTALLATION.........................18

FUEL TANK

DESCRIPTION.........................20

OPERATION...........................20

REMOVAL- EXCEPT DIESEL..............20

INSTALLATION - EXCEPT DIESEL..........22

INLET FILTER

REMOVAL.............................23

INSTALLATION.........................23

FUEL DELIVERY - GAS

DESCRIPTION

The fuel delivery system consists of:

²a fuel pump module containing the electric fuel

pump, fuel filter/fuel pressure regulator, fuel gauge

sending unit (fuel level sensor) and a secondary fuel

filter located at the bottom of the pump module

²fuel tubes/lines/hoses

²a combination fuel filter/fuel pressure regulator²quick-connect fittings

²fuel injector rail

²fuel tank

²fuel tank filler/vent tube assembly

²fuel tank filler tube cap

²accelerator pedal

²throttle cable

Certain fuel delivery components can be found in

(Fig. 1).

DRFUEL SYSTEM 14 - 1