service DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2781 of 2895

If the floor outlet air temperature is too low, refer

to Cooling to check the engine coolant temperature

specifications. Both of the heater hoses should be hot

to the touch. The coolant return heater hose should

be slightly cooler than the coolant supply heater

hose. If the return hose is much cooler than the sup-

ply hose, locate and repair the engine coolant flow

obstruction in the cooling system. Refer to Cooling

for the procedures.

An alternate method of checking heater perfor-

mance is to use a DRBIIItscan tool to monitor the

engine coolant temperature. The floor outlet air tem-

perature reading should be no more than 4.5É C (40É

F) lower than the engine coolant temperature read-

ing.

OBSTRUCTED COOLANT FLOW Possible loca-

tions or causes of obstructed coolant flow:

²Faulty water pump.

²Faulty thermostat.

²Pinched or kinked heater hoses.

²Improper heater hose routing.

²Plugged heater hoses or supply and return ports

at the cooling system connections.

²A plugged heater core.If proper coolant flow through the cooling system is

verified, and heater outlet air temperature is still

low, a mechanical problem may exist.

MECHANICAL PROBLEMS Possible locations or

causes of insufficient heat:

²An obstructed cowl air intake.

²Obstructed heater system outlets.

²A faulty, obstructed or improperly installed

blend door.

²A faulty blower system.

²A faulty a/c heater control.

TEMPERATURE CONTROL

If the heater outlet air temperature cannot be

adjusted with the temperature control knob on the

a/c heater control panel, the following could require

service:

²A faulty a/c heater control.

²A faulty blend door actuator.

²A faulty, obstructed or improperly installed

blend door.

²An obstructed cowl air intake.

²The engine cooling system.

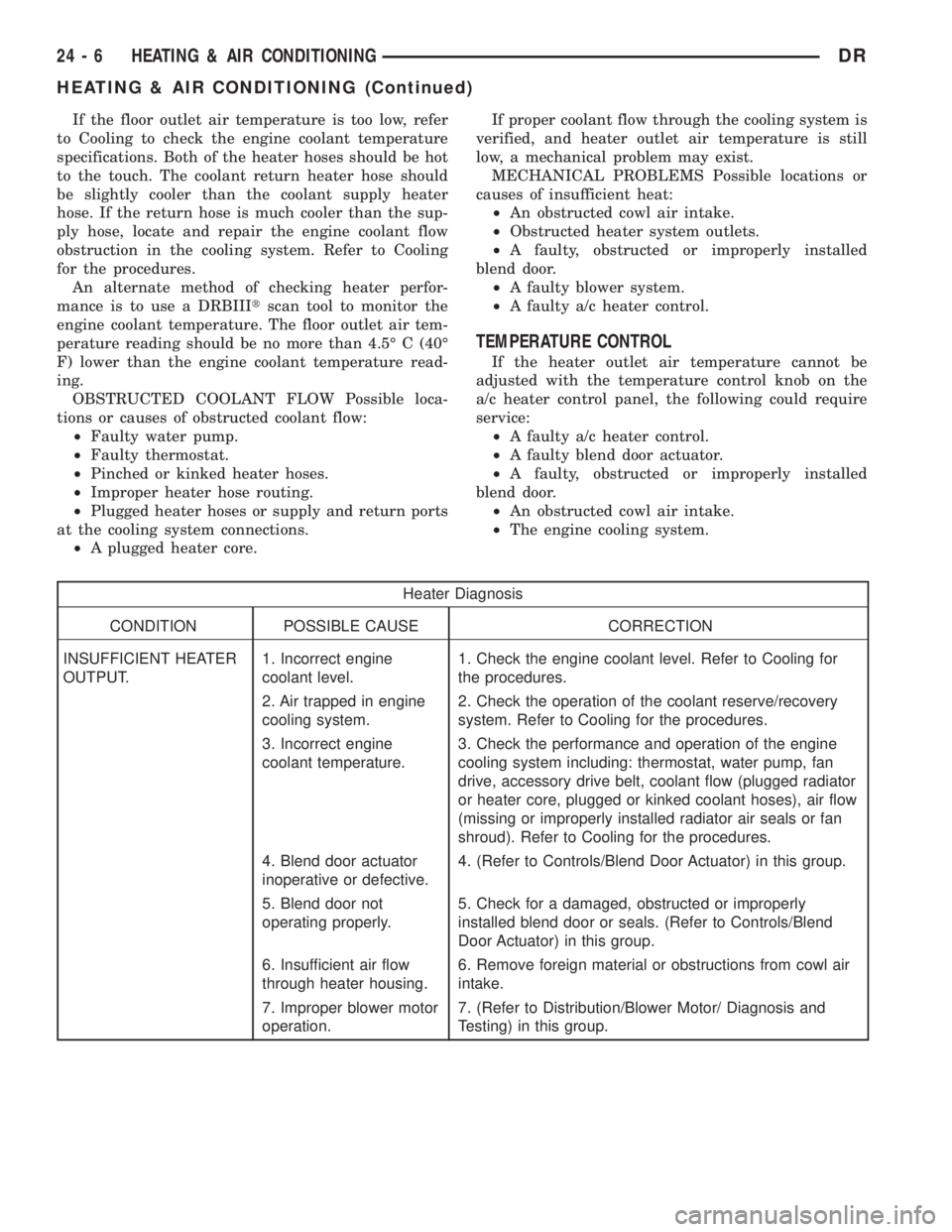

Heater Diagnosis

CONDITION POSSIBLE CAUSE CORRECTION

INSUFFICIENT HEATER

OUTPUT.1. Incorrect engine

coolant level.1. Check the engine coolant level. Refer to Cooling for

the procedures.

2. Air trapped in engine

cooling system.2. Check the operation of the coolant reserve/recovery

system. Refer to Cooling for the procedures.

3. Incorrect engine

coolant temperature.3. Check the performance and operation of the engine

cooling system including: thermostat, water pump, fan

drive, accessory drive belt, coolant flow (plugged radiator

or heater core, plugged or kinked coolant hoses), air flow

(missing or improperly installed radiator air seals or fan

shroud). Refer to Cooling for the procedures.

4. Blend door actuator

inoperative or defective.4. (Refer to Controls/Blend Door Actuator) in this group.

5. Blend door not

operating properly.5. Check for a damaged, obstructed or improperly

installed blend door or seals. (Refer to Controls/Blend

Door Actuator) in this group.

6. Insufficient air flow

through heater housing.6. Remove foreign material or obstructions from cowl air

intake.

7. Improper blower motor

operation.7. (Refer to Distribution/Blower Motor/ Diagnosis and

Testing) in this group.

24 - 6 HEATING & AIR CONDITIONINGDR

HEATING & AIR CONDITIONING (Continued)

Page 2784 of 2895

CONTROLS

TABLE OF CONTENTS

page page

A/C COMPRESSOR CLUTCH

DESCRIPTION..........................9

OPERATION............................9

DIAGNOSIS AND TESTING - A/C

COMPRESSOR CLUTCH COIL...........10

STANDARD PROCEDURE - A/C

COMPRESSOR CLUTCH BREAK-IN.......10

REMOVAL.............................10

INSPECTION..........................12

INSTALLATION.........................12

A/C COMPRESSOR CLUTCH RELAY

DESCRIPTION.........................13

OPERATION...........................13

DIAGNOSIS AND TESTING - COMPRESSOR

CLUTCH RELAY......................13

REMOVAL.............................14

INSTALLATION.........................14

A/C HEATER CONTROL

DESCRIPTION.........................14

REMOVAL.............................14

INSTALLATION.........................15

A/C PRESSURE TRANSDUCER

DESCRIPTION - A/C PRESSURE

TRANSDUCER.......................15

OPERATION...........................15

DIAGNOSIS AND TESTING - A/C PRESSURE

TRANSDUCER.......................15

REMOVAL.............................16

INSTALLATION.........................16

BLEND DOOR ACTUATOR

DESCRIPTION.........................16

OPERATION...........................16REMOVAL.............................17

INSTALLATION.........................17

BLOWER MOTOR RESISTOR BLOCK

DESCRIPTION.........................17

OPERATION...........................17

DIAGNOSIS AND TESTING - BLOWER

MOTOR RESISTOR....................18

REMOVAL.............................18

INSTALLATION.........................18

BLOWER MOTOR SWITCH

DESCRIPTION.........................18

OPERATION...........................18

DIAGNOSIS AND TESTING - BLOWER

MOTOR SWITCH......................18

REMOVAL.............................19

INSTALLATION.........................19

DEFROST DOOR ACTUATOR

REMOVAL - FLOOR - DEFROST DOOR

ACTUATOR..........................19

INSTALLATION - FLOOR - DEFROST DOOR

ACTUATOR..........................20

MODE DOOR ACTUATOR

DESCRIPTION.........................20

OPERATION...........................21

REMOVAL.............................21

INSTALLATION.........................22

RECIRCULATION DOOR ACTUATOR

DESCRIPTION.........................22

OPERATION...........................22

REMOVAL.............................22

INSTALLATION.........................23

A/C COMPRESSOR CLUTCH

DESCRIPTION

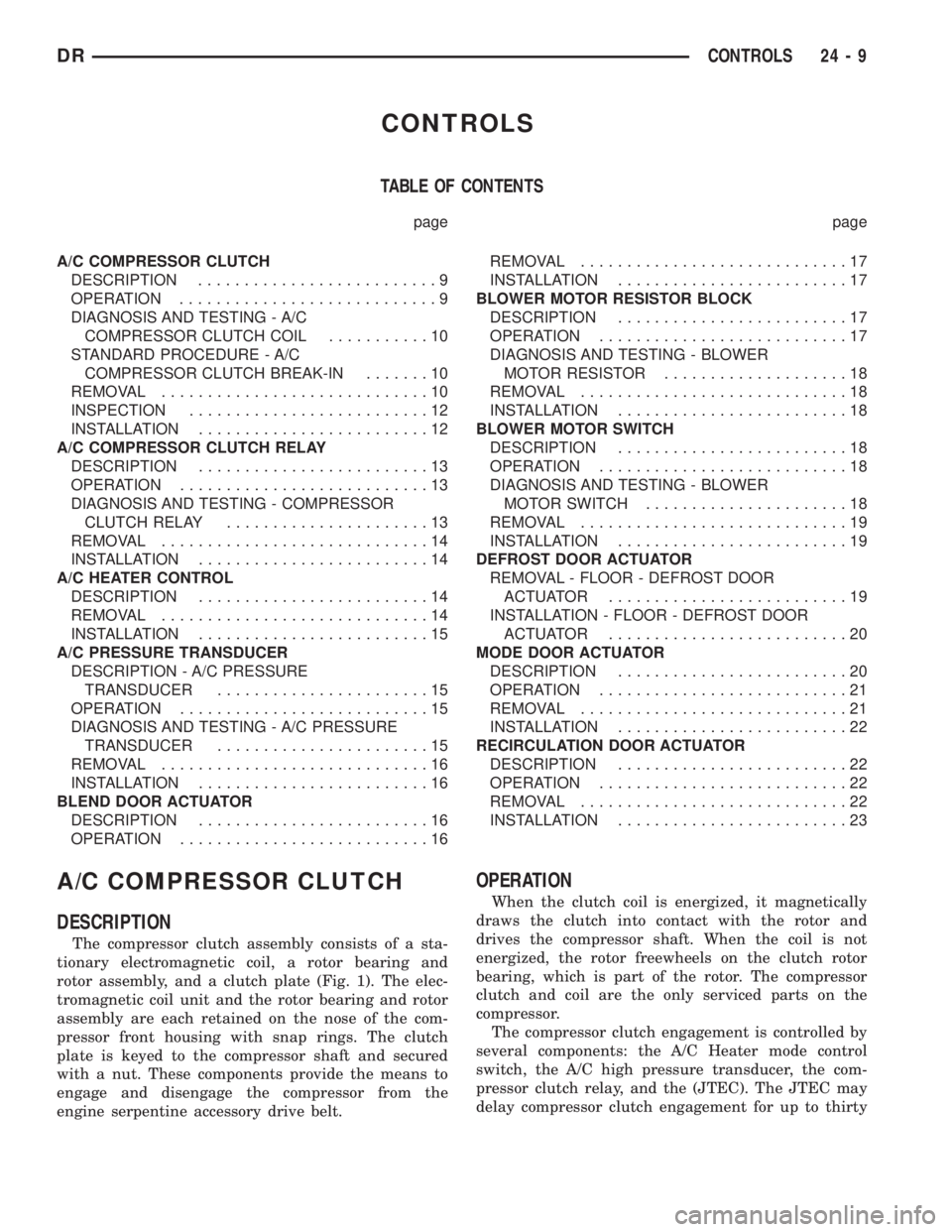

The compressor clutch assembly consists of a sta-

tionary electromagnetic coil, a rotor bearing and

rotor assembly, and a clutch plate (Fig. 1). The elec-

tromagnetic coil unit and the rotor bearing and rotor

assembly are each retained on the nose of the com-

pressor front housing with snap rings. The clutch

plate is keyed to the compressor shaft and secured

with a nut. These components provide the means to

engage and disengage the compressor from the

engine serpentine accessory drive belt.

OPERATION

When the clutch coil is energized, it magnetically

draws the clutch into contact with the rotor and

drives the compressor shaft. When the coil is not

energized, the rotor freewheels on the clutch rotor

bearing, which is part of the rotor. The compressor

clutch and coil are the only serviced parts on the

compressor.

The compressor clutch engagement is controlled by

several components: the A/C Heater mode control

switch, the A/C high pressure transducer, the com-

pressor clutch relay, and the (JTEC). The JTEC may

delay compressor clutch engagement for up to thirty

DRCONTROLS 24 - 9

Page 2785 of 2895

seconds. Refer to Electronic Control Modules for

more information on the JTEC controls.

DIAGNOSIS AND TESTING - A/C COMPRESSOR

CLUTCH COIL

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information). The battery must

be fully-charged before performing the following

tests. Refer to Battery for more information.

(1) Connect an ammeter (0 to 10 ampere scale) in

series with the clutch coil terminal. Use a voltmeter

(0 to 20 volt scale) with clip-type leads for measuring

the voltage across the battery and the compressor

clutch coil.

(2) With the A/C Heater mode control switch in

any A/C mode, and the blower motor switch in the

lowest speed position, start the engine and run it at

normal idle.

(3) The compressor clutch coil voltage should read

within 0.2 volts of the battery voltage. If there is

voltage at the clutch coil, but the reading is not

within 0.2 volts of the battery voltage, test the clutch

coil feed circuit for excessive voltage drop and repair

as required. If there is no voltage reading at the

clutch coil, use a DRB IIItscan tool and (Refer to

Appropriate Diagnostic Information) for testing of the

compressor clutch circuit and PCM control. The fol-

lowing components must be checked and repaired as

required before you can complete testing of the clutch

coil:

²Fuses in the junction block and the Power Dis-

tribution Center (PDC)

²A/C heater mode control switch

²Compressor clutch relay

²A/C high pressure transducer switch²JTEC

(4) The compressor clutch coil is acceptable if the

current draw measured at the clutch coil is 2.0 to 3.9

amperes with the electrical system voltage at 11.5 to

12.5 volts. This should only be checked with the work

area temperature at 21É C (70É F). If system voltage

is more than 12.5 volts, add electrical loads by turn-

ing on electrical accessories until the system voltage

drops below 12.5 volts.

(a) If the clutch coil current reading is four

amperes or more, the coil is shorted and should be

replaced.

(b) If the clutch coil current reading is zero, the

coil is open and should be replaced.

STANDARD PROCEDURE - A/C COMPRESSOR

CLUTCH BREAK-IN

After a new compressor clutch has been installed,

cycle the compressor clutch approximately twenty

times (five seconds on, then five seconds off). During

this procedure, set the A/C Heater control to the

Recirculation Mode, the blower motor switch in the

highest speed position, and the engine speed at 1500

to 2000 rpm. This procedure (burnishing) will seat

the opposing friction surfaces and provide a higher

compressor clutch torque capability.

REMOVAL

The refrigerant system can remain fully-charged

during compressor clutch, rotor, or coil replacement.

The compressor clutch can be serviced in the vehicle.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the serpentine drive belt(Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(3) Unplug the compressor clutch coil wire harness

connector.

(4) Remove the bolts that secure the compressor to

the mounting bracket.

(5) Remove the compressor from the mounting

bracket. Support the compressor in the engine com-

partment while servicing the clutch.

(6) Insert the two pins of the spanner wrench

(Special Tool C-4489 or equivalent) into the holes of

the clutch plate. Hold the clutch plate stationary and

remove the hex nut (Fig. 2).

(7) Remove the clutch plate.

(8) Remove the compressor clutch shims.

(9) Remove the external front housing snap ring

with snap ring pliers (Fig. 3).

(10)

Install the lip of the rotor puller (Special Tool

C-6141-1 or equivalent) into the snap ring groove

exposed in the previous step, and install the shaft pro-

tector (Special Tool C-6141-2 or equivalent) (Fig. 4).

Fig. 1 COMPRESSOR CLUTCH - TYPICAL

1 - CLUTCH PLATE

2 - SHAFT KEY (not used on KJ)

3 - ROTOR

4 - COIL

5 - CLUTCH SHIMS

6 - SNAP RING

7 - SNAP RING

24 - 10 CONTROLSDR

A/C COMPRESSOR CLUTCH (Continued)

Page 2789 of 2895

for relay terminal 86 with the ignition switch in the

On position. If OK, go to Step 5. If not OK, repair the

open circuit to the fuse in the junction block as

required.

(5) The coil ground terminal cavity (85) is switched

to ground through the Powertrain Control Module

(PCM). There should be continuity between this cav-

ity and the A/C compressor clutch relay control cir-

cuit cavity of the PCM wire harness connector C

(gray) at all times. If not OK, repair the open circuit

as required.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cover from the Power Distribution

Center (PDC).

(3) Refer to the label on the PDC for compressor

clutch relay identification and location.

(4) Unplug the compressor clutch relay from the

PDC.

INSTALLATION

(1) Install the compressor clutch relay by aligning

the relay terminals with the cavities in the PDC and

pushing the relay firmly into place.

(2) Install the PDC cover.

(3) Connect the battery negative cable.

(4) Test the relay operation.

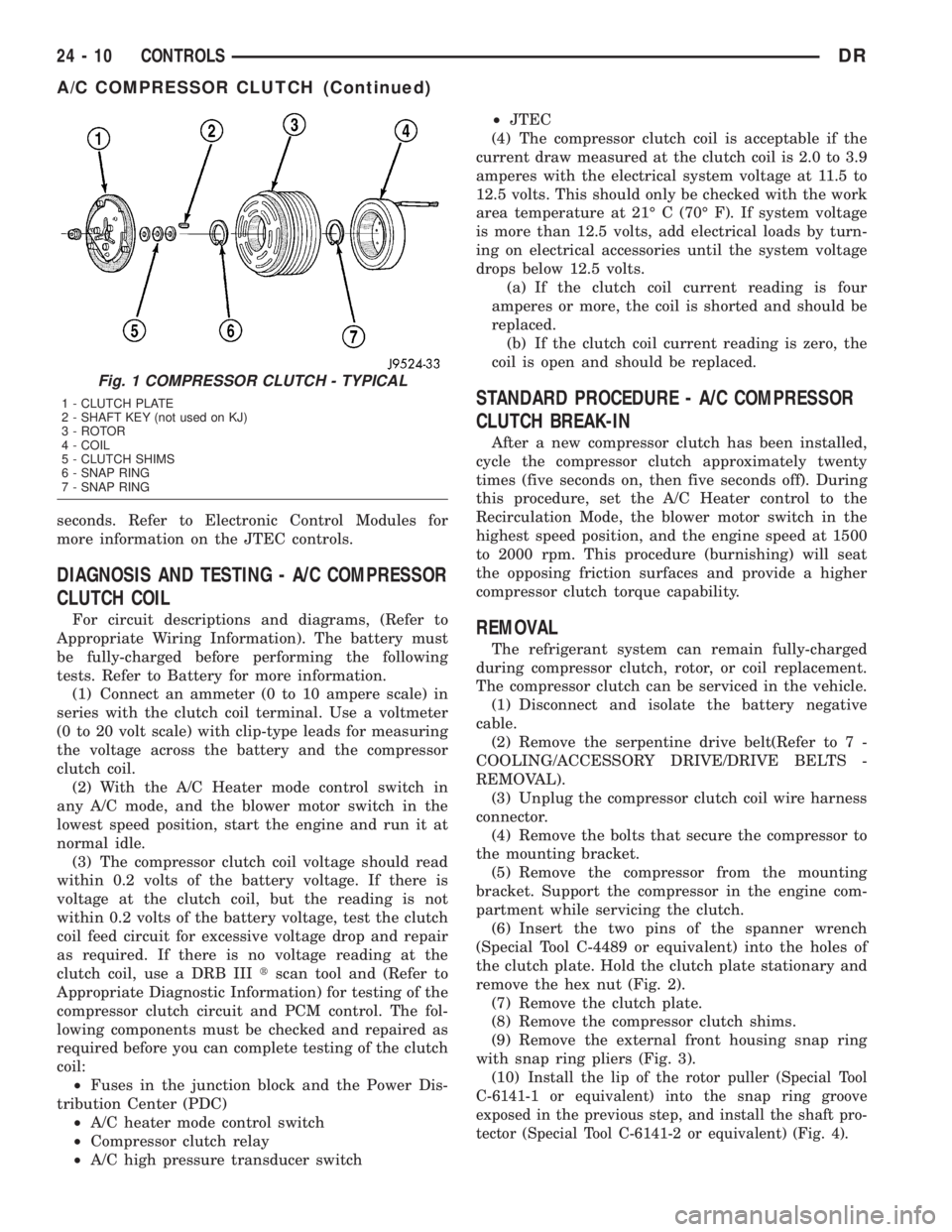

A/C HEATER CONTROL

DESCRIPTION

The A/C heater system uses a seriers of electrical

controls. These controls provide the vehicle operator

with a number of setting options to help control the

climate and comfort within the vehicle. Refer to the

owner's manual in the vehicle glove box for more

information on the features, use, and suggested oper-

ation of these controls.

The A/C heater control - (Single Zone) or (Dual

Zone) panel is located to the right of the instrument

cluster on the instrument panel.

The control panel contains a rotary-type tempera-

ture control, a rotary-type mode control switch knob,

and a rotary-type blower motor speed switch knob.

The control also has a push button to activate the

Optional side view mirrors defroster elements and to

turn the A/C on.

The Dual Zone HVAC control panel contains a pair

of slider-type temperature controls, a rotary-type

mode control switch knob and a rotary-type blower

motor speed switch knob. The control also has but-

tons to turn the A/C ON, Set it on Max A/C and for

the Optional Heated Sideview Mirrors.The A/C heater control panel cannot be repaired. If

faulty or damaged, the entire unit must be replaced.

The illumination lamps are available for service

replacement.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the center bezel from the instrument

panel(Refer to 23 - BODY/INSTRUMENT PANEL/IN-

STRUMENT PANEL CENTER BEZEL - REMOVAL).

(3) Remove the screws that secure the A/C Heater

control to the instrument panel (Fig. 11) or (Fig. 12).

(4) Pull the A/C Heater control assembly away

from the instrument panel far enough to access the

connections on the back of the control.

(5) Unplug the wire harness connectors from the

back of the A/C Heater control (Fig. 13).

Fig. 11 Single Zone HVAC Control

1 - Mounting Tab (4)

2 - A/C Button

3 - Sideview Mirror Defroster Button (if equiped)

4 - Mode Control

5 - Blend Air Control

6 - Blower Motor Speed Control

24 - 14 CONTROLSDR

A/C COMPRESSOR CLUTCH RELAY (Continued)

Page 2792 of 2895

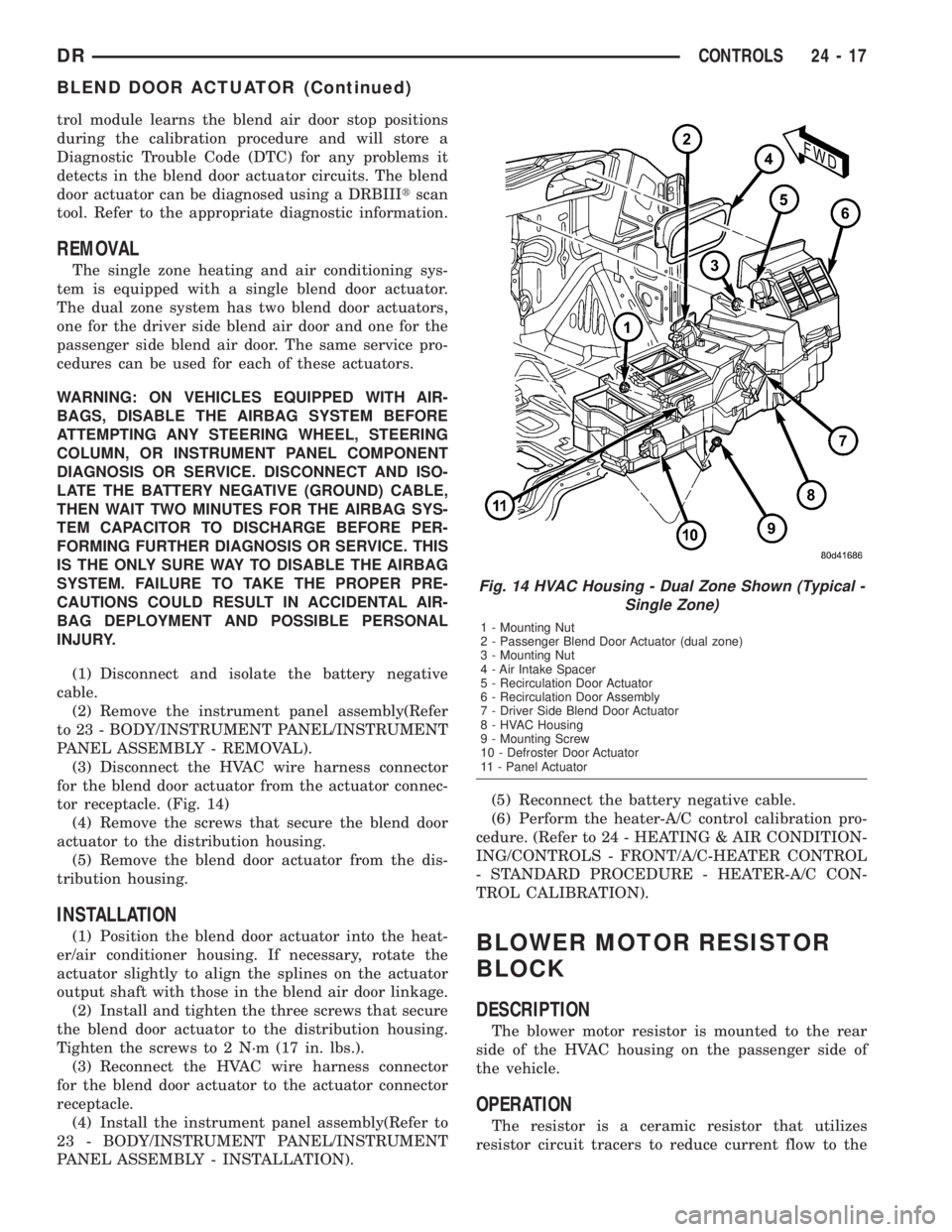

trol module learns the blend air door stop positions

during the calibration procedure and will store a

Diagnostic Trouble Code (DTC) for any problems it

detects in the blend door actuator circuits. The blend

door actuator can be diagnosed using a DRBIIItscan

tool. Refer to the appropriate diagnostic information.

REMOVAL

The single zone heating and air conditioning sys-

tem is equipped with a single blend door actuator.

The dual zone system has two blend door actuators,

one for the driver side blend air door and one for the

passenger side blend air door. The same service pro-

cedures can be used for each of these actuators.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument panel assembly(Refer

to 23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - REMOVAL).

(3) Disconnect the HVAC wire harness connector

for the blend door actuator from the actuator connec-

tor receptacle. (Fig. 14)

(4) Remove the screws that secure the blend door

actuator to the distribution housing.

(5) Remove the blend door actuator from the dis-

tribution housing.

INSTALLATION

(1) Position the blend door actuator into the heat-

er/air conditioner housing. If necessary, rotate the

actuator slightly to align the splines on the actuator

output shaft with those in the blend air door linkage.

(2) Install and tighten the three screws that secure

the blend door actuator to the distribution housing.

Tighten the screws to 2 N´m (17 in. lbs.).

(3) Reconnect the HVAC wire harness connector

for the blend door actuator to the actuator connector

receptacle.

(4) Install the instrument panel assembly(Refer to

23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - INSTALLATION).(5) Reconnect the battery negative cable.

(6) Perform the heater-A/C control calibration pro-

cedure. (Refer to 24 - HEATING & AIR CONDITION-

ING/CONTROLS - FRONT/A/C-HEATER CONTROL

- STANDARD PROCEDURE - HEATER-A/C CON-

TROL CALIBRATION).BLOWER MOTOR RESISTOR

BLOCK

DESCRIPTION

The blower motor resistor is mounted to the rear

side of the HVAC housing on the passenger side of

the vehicle.

OPERATION

The resistor is a ceramic resistor that utilizes

resistor circuit tracers to reduce current flow to the

Fig. 14 HVAC Housing - Dual Zone Shown (Typical -

Single Zone)

1 - Mounting Nut

2 - Passenger Blend Door Actuator (dual zone)

3 - Mounting Nut

4 - Air Intake Spacer

5 - Recirculation Door Actuator

6 - Recirculation Door Assembly

7 - Driver Side Blend Door Actuator

8 - HVAC Housing

9 - Mounting Screw

10 - Defroster Door Actuator

11 - Panel Actuator

DRCONTROLS 24 - 17

BLEND DOOR ACTUATOR (Continued)

Page 2793 of 2895

blower. The blower motor switch directs the ground

path through the correct resistor circuit to obtain the

selected speed.

The blower motor resistor cannot be repaired and,

if faulty or damaged, it must be replaced.

DIAGNOSIS AND TESTING - BLOWER MOTOR

RESISTOR

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information).

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Reach under the passenger side bottom of the

HVAC unit and unplug the wire harness connector

from the blower motor resistor.

(3) Check for continuity between each of the

blower motor switch input terminals of the resistor

and the resistor output terminal. In each case there

should be continuity. If OK, repair the wire harness

circuits between the blower motor switch and the

blower motor resistor or blower motor relay as

required. If not OK, replace the faulty blower motor

resistor.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.(1) Disconnect and isolate the battery negative

cable.

(2) The blower motor resistor is accessable from

the passenger side of the HVAC unit and is located

on the bottom of the HVAC unit.

(3) Pull out the lock on the blower motor resistor

wire harness connector to unlock the connector latch.

(4) Depress the latch on the blower motor resistor

wire harness connector and unplug the connector

from the resistor.

(5) Remove the two screws that secure the resistor

to the HVAC housing.

(6) Remove the resistor from the HVAC housing.

INSTALLATION

(1) Install the new resistor in the HVAC housing.

(2) Install the two screws that secure the resistor

to the HVAC housing and tighten to 2.2 N´m (20 in.

lbs.).

(3) Plug in the blower motor harness connector.

(4) Push in the lock on the blower motor resistor

harness connector.

(5) Close the glove box door.

(6) Connect the battery negative cable.

BLOWER MOTOR SWITCH

DESCRIPTION

The A/C Heater blower motor is controlled by a

four position rotary-type blower motor switch,

mounted in the A/C Heater control panel. The switch

allows the selection of one of four blower motor

speeds, but can only be turned off by selecting the

Off position on the blower motor switch.

OPERATION

The blower motor switch directs the blower motor

ground path through the mode control switch to the

blower motor resistor, or directly to ground, as

required to achieve the selected blower motor speed.

The blower motor switch cannot be repaired and, if

faulty or damaged, the entire A/C Heater control unit

must be replaced.

DIAGNOSIS AND TESTING - BLOWER MOTOR

SWITCH

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information).

24 - 18 CONTROLSDR

BLOWER MOTOR RESISTOR BLOCK (Continued)

Page 2794 of 2895

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Check for battery voltage at the fuse in the

Power Distribution Center (PDC). If OK, go to Step

2. If not OK, repair the shorted circuit or component

as required and replace the faulty fuse.

(2) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the A/C Heater control from the instrument

panel. Check for continuity between the ground cir-

cuit cavity of the A/C Heater control wire harness

connector and a good ground. There should be conti-

nuity. If OK, go to Step 3. If not OK, repair the open

circuit to ground as required.

(3) With the A/C Heater control wire harness con-

nector unplugged, place the A/C Heater mode control

switch knob in any position except the Off position.

Check for continuity between the ground circuit ter-

minal and each of the blower motor driver circuit ter-

minals of the A/C Heater control as you move the

blower motor switch knob to each of the four speed

positions. There should be continuity at each driver

circuit terminal in only one blower motor switch

speed position. If OK, test and repair the blower

driver circuits between the A/C Heater control con-

nector and the blower motor resistor as required. If

not OK, replace the faulty A/C Heater control unit.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.The blower motor switch cannot be repaired and, if

faulty or damaged, the entire A/C Heater control unit

must be replaced. (Refer to 24 - HEATING & AIR

CONDITIONING/CONTROLS/A/C HEATER CON-

TROL - REMOVAL)

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) The blower motor switch cannot be repaired

and, if faulty or damaged the entire A/C heater con-

trol unit must be replaced(Refer to 24 - HEATING &

AIR CONDITIONING/CONTROLS/A/C HEATER

CONTROL - INSTALLATION).

DEFROST DOOR ACTUATOR

REMOVAL - FLOOR - DEFROST DOOR

ACTUATOR

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument panel assembly from

the vehicle(Refer to 23 - BODY/INSTRUMENT

PANEL - REMOVAL).

(3) Remove the electrical connector from the actua-

tor (Fig. 15).

DRCONTROLS 24 - 19

BLOWER MOTOR SWITCH (Continued)

Page 2796 of 2895

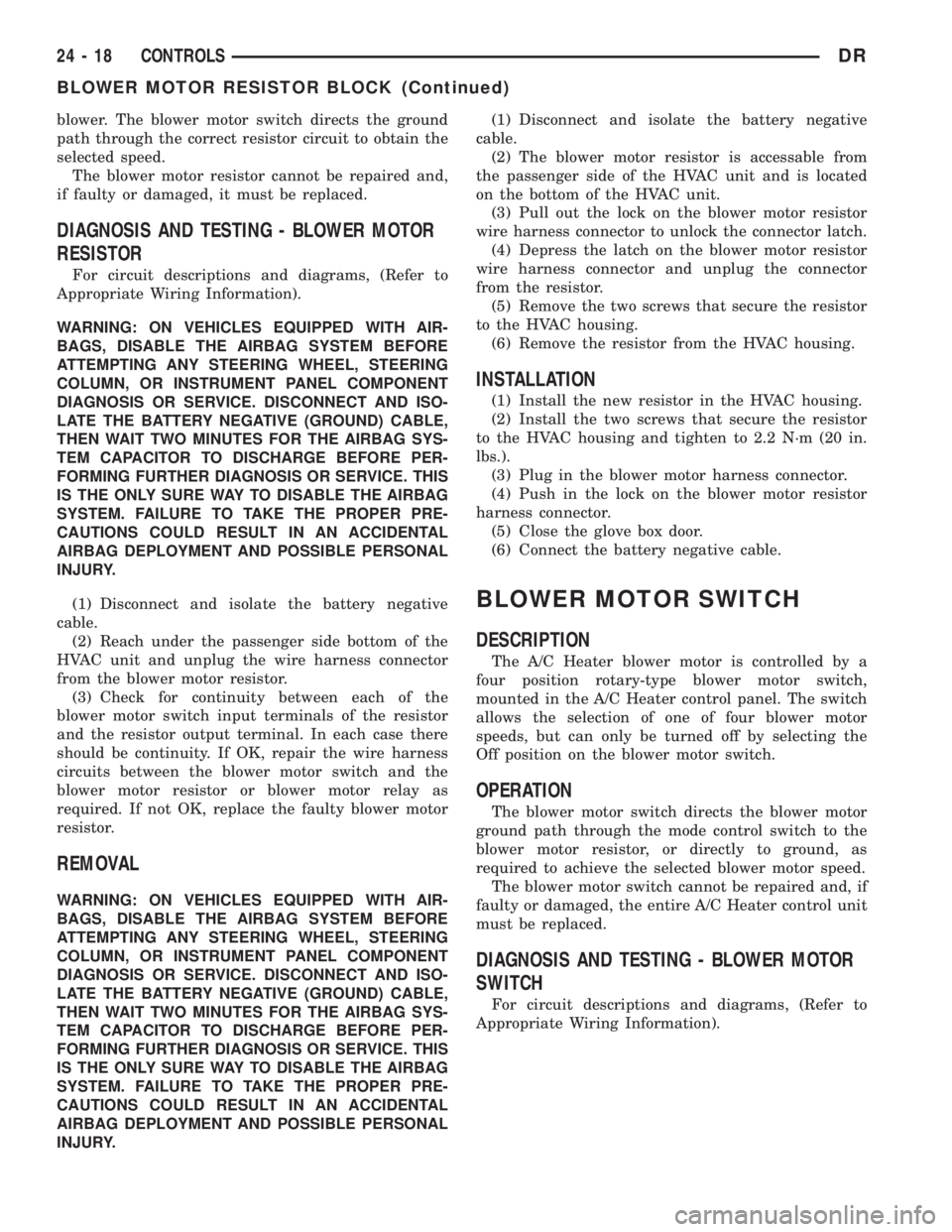

to the mode door linkage, as it is electronically cali-

brated by the heater-A/C control module. The mode

door actuator cannot be adjusted or repaired and, if

damaged or faulty, it must be replaced.

OPERATION

The mode door actuator is connected to the heater-

A/C control module through the vehicle electrical sys-

tem by a dedicated two-wire take out and connector

of the HVAC wire harness. The mode door actuator

can move the mode door in two directions. When the

heater-A/C control module pulls the voltage on one

side of the motor connection high and the other con-

nection low, the mode door will move in one direction.

When the module reverses the polarity of the voltage

to the motor, the mode door moves in the opposite

direction. When the module makes the voltage to

both connections high or both connections low, the

mode door stops and will not move. These same

motor connections also provide a feedback signal to

the heater-A/C control module. This feedback signal

allows the module to monitor the operation and rela-

tive position of the mode door actuator and the mode

door. The heater-A/C control module learns the mode

door stop positions during the calibration procedure

and will store a Diagnostic Trouble Code (DTC) for

any problems it detects in the mode door actuator

circuits. The mode door actuator can be diagnosed

using a DRBIIItscan tool. Refer to the appropriate

diagnostic information.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument panel assembly(Refer

to 23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - REMOVAL).

(3) Disconnect the electricial connector from the

actuator (single or dual zone as required).

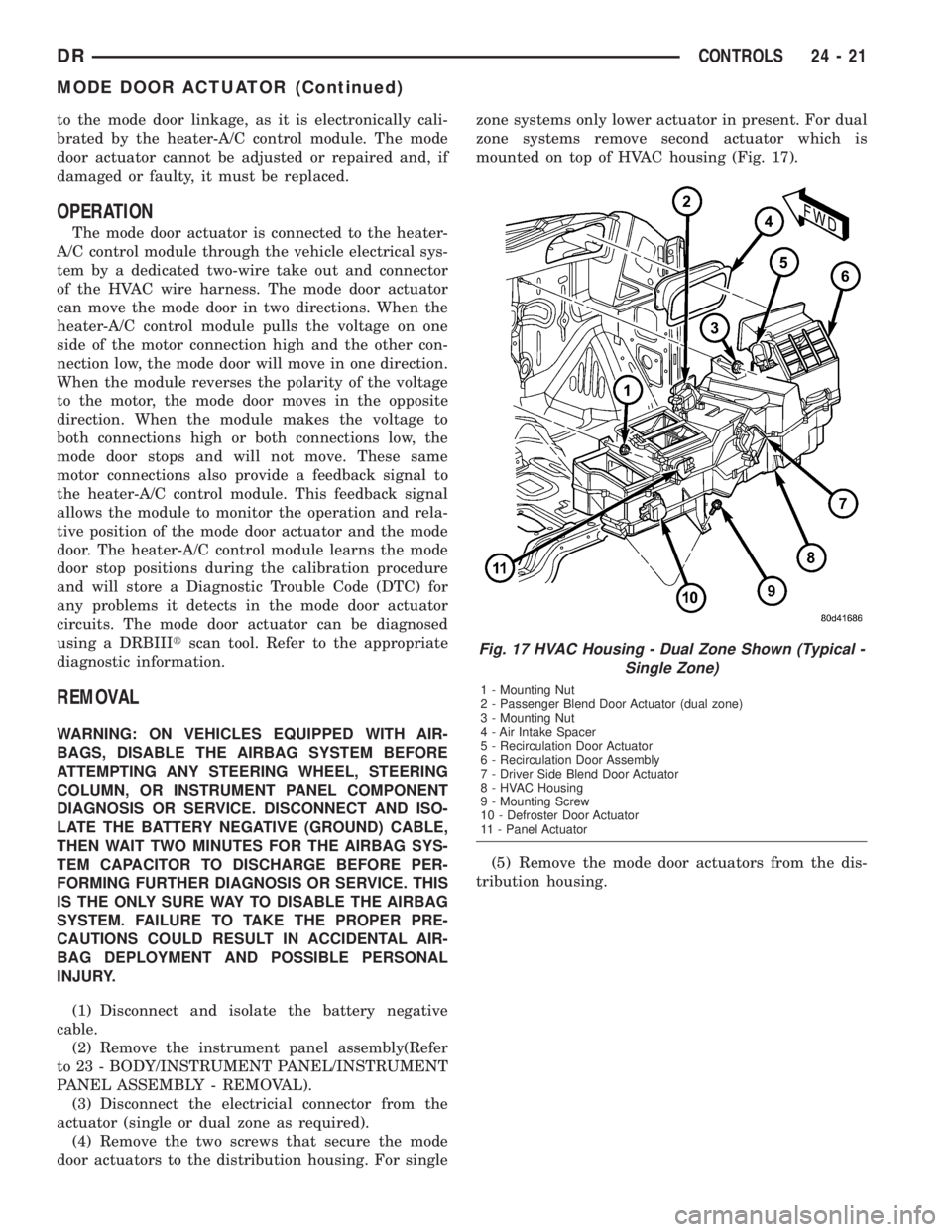

(4) Remove the two screws that secure the mode

door actuators to the distribution housing. For singlezone systems only lower actuator in present. For dual

zone systems remove second actuator which is

mounted on top of HVAC housing (Fig. 17).

(5) Remove the mode door actuators from the dis-

tribution housing.

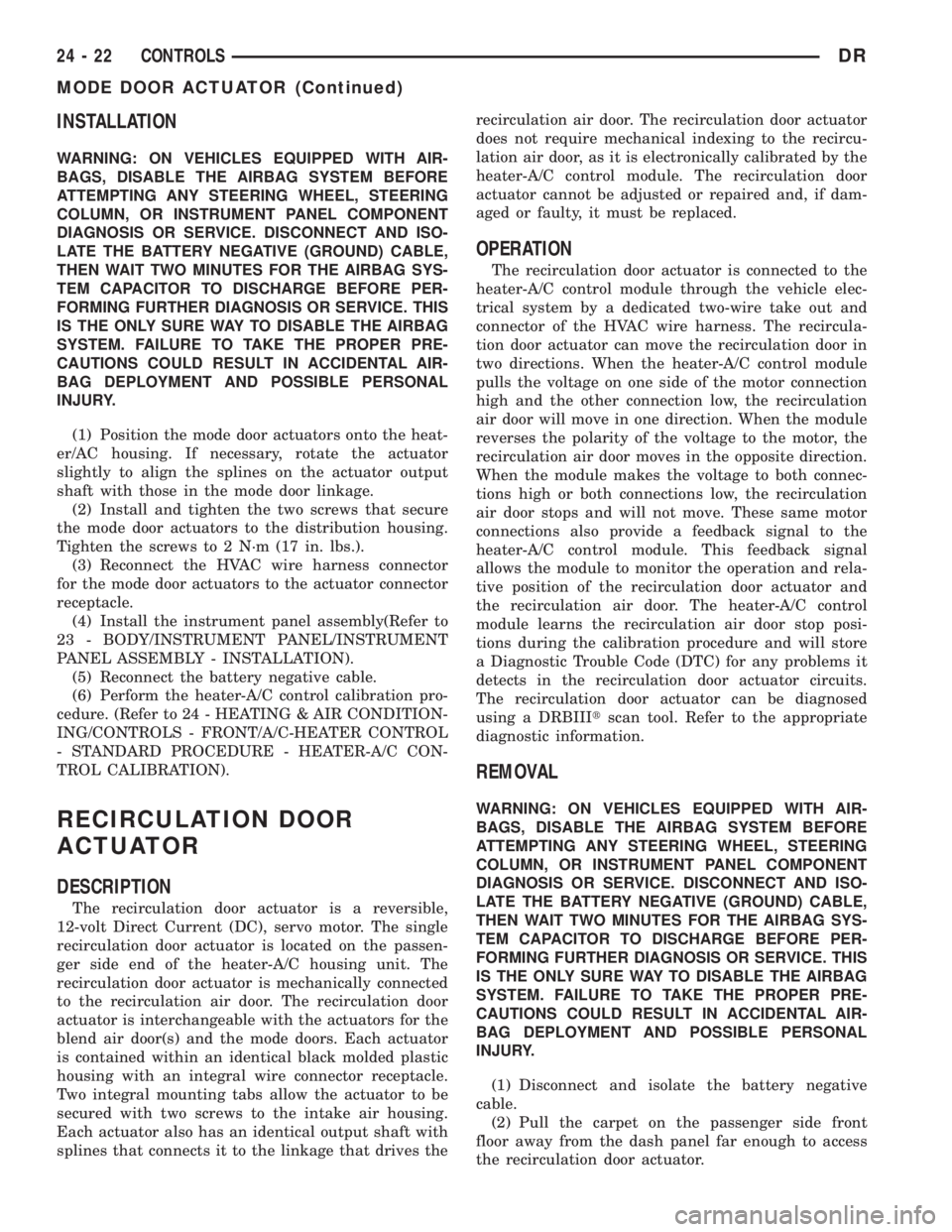

Fig. 17 HVAC Housing - Dual Zone Shown (Typical -

Single Zone)

1 - Mounting Nut

2 - Passenger Blend Door Actuator (dual zone)

3 - Mounting Nut

4 - Air Intake Spacer

5 - Recirculation Door Actuator

6 - Recirculation Door Assembly

7 - Driver Side Blend Door Actuator

8 - HVAC Housing

9 - Mounting Screw

10 - Defroster Door Actuator

11 - Panel Actuator

DRCONTROLS 24 - 21

MODE DOOR ACTUATOR (Continued)

Page 2797 of 2895

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Position the mode door actuators onto the heat-

er/AC housing. If necessary, rotate the actuator

slightly to align the splines on the actuator output

shaft with those in the mode door linkage.

(2) Install and tighten the two screws that secure

the mode door actuators to the distribution housing.

Tighten the screws to 2 N´m (17 in. lbs.).

(3) Reconnect the HVAC wire harness connector

for the mode door actuators to the actuator connector

receptacle.

(4) Install the instrument panel assembly(Refer to

23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - INSTALLATION).

(5) Reconnect the battery negative cable.

(6) Perform the heater-A/C control calibration pro-

cedure. (Refer to 24 - HEATING & AIR CONDITION-

ING/CONTROLS - FRONT/A/C-HEATER CONTROL

- STANDARD PROCEDURE - HEATER-A/C CON-

TROL CALIBRATION).

RECIRCULATION DOOR

ACTUATOR

DESCRIPTION

The recirculation door actuator is a reversible,

12-volt Direct Current (DC), servo motor. The single

recirculation door actuator is located on the passen-

ger side end of the heater-A/C housing unit. The

recirculation door actuator is mechanically connected

to the recirculation air door. The recirculation door

actuator is interchangeable with the actuators for the

blend air door(s) and the mode doors. Each actuator

is contained within an identical black molded plastic

housing with an integral wire connector receptacle.

Two integral mounting tabs allow the actuator to be

secured with two screws to the intake air housing.

Each actuator also has an identical output shaft with

splines that connects it to the linkage that drives therecirculation air door. The recirculation door actuator

does not require mechanical indexing to the recircu-

lation air door, as it is electronically calibrated by the

heater-A/C control module. The recirculation door

actuator cannot be adjusted or repaired and, if dam-

aged or faulty, it must be replaced.

OPERATION

The recirculation door actuator is connected to the

heater-A/C control module through the vehicle elec-

trical system by a dedicated two-wire take out and

connector of the HVAC wire harness. The recircula-

tion door actuator can move the recirculation door in

two directions. When the heater-A/C control module

pulls the voltage on one side of the motor connection

high and the other connection low, the recirculation

air door will move in one direction. When the module

reverses the polarity of the voltage to the motor, the

recirculation air door moves in the opposite direction.

When the module makes the voltage to both connec-

tions high or both connections low, the recirculation

air door stops and will not move. These same motor

connections also provide a feedback signal to the

heater-A/C control module. This feedback signal

allows the module to monitor the operation and rela-

tive position of the recirculation door actuator and

the recirculation air door. The heater-A/C control

module learns the recirculation air door stop posi-

tions during the calibration procedure and will store

a Diagnostic Trouble Code (DTC) for any problems it

detects in the recirculation door actuator circuits.

The recirculation door actuator can be diagnosed

using a DRBIIItscan tool. Refer to the appropriate

diagnostic information.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Pull the carpet on the passenger side front

floor away from the dash panel far enough to access

the recirculation door actuator.

24 - 22 CONTROLSDR

MODE DOOR ACTUATOR (Continued)

Page 2798 of 2895

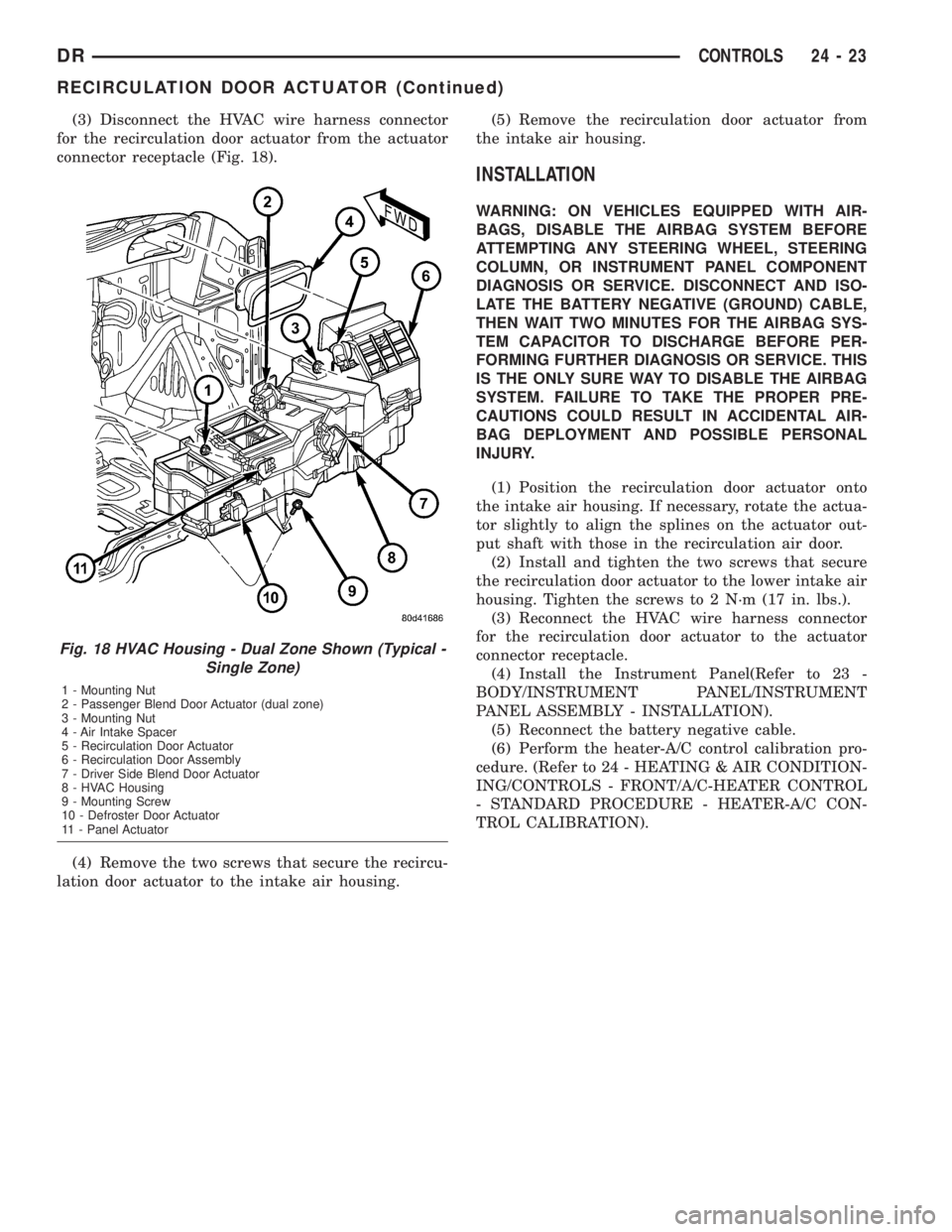

(3) Disconnect the HVAC wire harness connector

for the recirculation door actuator from the actuator

connector receptacle (Fig. 18).

(4) Remove the two screws that secure the recircu-

lation door actuator to the intake air housing.(5) Remove the recirculation door actuator from

the intake air housing.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Position the recirculation door actuator onto

the intake air housing. If necessary, rotate the actua-

tor slightly to align the splines on the actuator out-

put shaft with those in the recirculation air door.

(2) Install and tighten the two screws that secure

the recirculation door actuator to the lower intake air

housing. Tighten the screws to 2 N´m (17 in. lbs.).

(3) Reconnect the HVAC wire harness connector

for the recirculation door actuator to the actuator

connector receptacle.

(4) Install the Instrument Panel(Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - INSTALLATION).

(5) Reconnect the battery negative cable.

(6) Perform the heater-A/C control calibration pro-

cedure. (Refer to 24 - HEATING & AIR CONDITION-

ING/CONTROLS - FRONT/A/C-HEATER CONTROL

- STANDARD PROCEDURE - HEATER-A/C CON-

TROL CALIBRATION).

Fig. 18 HVAC Housing - Dual Zone Shown (Typical -

Single Zone)

1 - Mounting Nut

2 - Passenger Blend Door Actuator (dual zone)

3 - Mounting Nut

4 - Air Intake Spacer

5 - Recirculation Door Actuator

6 - Recirculation Door Assembly

7 - Driver Side Blend Door Actuator

8 - HVAC Housing

9 - Mounting Screw

10 - Defroster Door Actuator

11 - Panel Actuator

DRCONTROLS 24 - 23

RECIRCULATION DOOR ACTUATOR (Continued)