DODGE RAM 2003 Service Repair Manual

Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 501 of 2895

dles at several predetermined calibration points

across the gauge faces, and illuminating all segments

of the odometer/trip odometer and gear selector indi-

cator Vacuum-Fluorescent Display (VFD) units.

(Refer to 8 - ELECTRICAL/INSTRUMENT CLUS-

TER - DIAGNOSIS AND TESTING). See the owner's

manual in the vehicle glove box for more information

on the features, use and operation of the EMIC.

GAUGES

All gauges receive battery current through the

EMIC circuitry only when the ignition switch is in

the On or Start positions. With the ignition switch in

the Off position battery current is not supplied to

any gauges, and the EMIC circuitry is programmed

to move all of the gauge needles back to the low end

of their respective scales. Therefore, the gauges do

not accurately indicate any vehicle condition unless

the ignition switch is in the On or Start positions.

All of the EMIC gauges are air core magnetic

units. Two fixed electromagnetic coils are located

within each gauge. These coils are wrapped at right

angles to each other around a movable permanent

magnet. The movable magnet is suspended within

the coils on one end of a pivot shaft, while the gauge

needle is attached to the other end of the shaft. One

of the coils has a fixed current flowing through it to

maintain a constant magnetic field strength. Current

flow through the second coil changes, which causes

changes in its magnetic field strength. The current

flowing through the second coil is changed by the

EMIC circuitry in response to messages received over

the PCI data bus. The gauge needle moves as the

movable permanent magnet aligns itself to the

changing magnetic fields created around it by the

electromagnets.

The gauges are diagnosed using the EMIC self-di-

agnostic actuator test. (Refer to 8 - ELECTRICAL/

INSTRUMENT CLUSTER - DIAGNOSIS AND

TESTING). Proper testing of the PCI data bus and

the electronic data bus message inputs to the EMIC

that control each gauge require the use of a DRBIIIt

scan tool. Refer to the appropriate diagnostic infor-

mation. Specific operation details for each gauge may

be found elsewhere in this service information.

VACUUM-FLUORESCENT DISPLAYS

The Vacuum-Fluorescent Display (VFD) units are

soldered to the EMIC electronic circuit board. With

the ignition switch in the Off or Accessory positions,

the odometer display is activated when the driver

door is opened (Rental Car mode) and is deactivated

when the driver door is closed. Otherwise, both dis-

play units are active when the ignition switch is in

the On or Start positions, and inactive when the igni-

tion switch is in the Off or Accessory positions.The illumination intensity of the VFD units is con-

trolled by the EMIC circuitry based upon an input

from the headlamp switch and a dimming level input

received from the headlamp dimmer switch. The

EMIC synchronizes the illumination intensity of

other VFD units with that of the units in the EMIC

by sending electronic dimming level messages to

other electronic modules in the vehicle over the PCI

data bus.

The EMIC VFD units have several display capabil-

ities including odometer, trip odometer, engine hours,

gear selector indication (PRNDL) for models with an

automatic transmission, several warning or reminder

indications, and various diagnostic information when

certain fault conditions exist. An odometer/trip odom-

eter switch on the EMIC circuit board is used to con-

trol some of the display modes. This switch is

actuated manually by depressing the odometer/trip

odometer switch button that extends through the

lower edge of the cluster lens, just left of the tachom-

eter. Actuating this switch momentarily with the

ignition switch in the On position will toggle the

VFD between the odometer and trip odometer modes.

Depressing the switch button for about two seconds

while the VFD is in the trip odometer mode will

reset the trip odometer value to zero. While in the

odometer mode with the ignition switch in the On

position and the engine not running, depressing this

switch for about six seconds will display the engine

hours information. Holding this switch depressed

while turning the ignition switch from the Off posi-

tion to the On position will initiate the EMIC self-di-

agnostic actuator test. Refer to the appropriate

diagnostic information for additional details on this

VFD function. The EMIC microprocessor remembers

which display mode is active when the ignition

switch is turned to the Off position, and returns the

VFD display to that mode when the ignition switch is

turned On again.

The VFD units are diagnosed using the EMIC self-

diagnostic actuator test. (Refer to 8 - ELECTRICAL/

INSTRUMENT CLUSTER - DIAGNOSIS AND

TESTING). Proper testing of the PCI data bus and

the electronic data bus message inputs to the EMIC

that control some of the VFD functions requires the

use of a DRBIIItscan tool. Refer to the appropriate

diagnostic information. Specific operation details for

the odometer, the trip odometer, the gear selector

indicator and the various warning and reminder indi-

cator functions of the VFD may be found elsewhere

in this service information.

INDICATORS

Indicators are located in various positions within

the EMIC and are all connected to the EMIC elec-

tronic circuit board. The cargo lamp indicator, door

8J - 8 INSTRUMENT CLUSTERDR

INSTRUMENT CLUSTER (Continued)

Page 502 of 2895

ajar indicator, high beam indicator, and turn signal

indicators operate based upon hard wired inputs to

the EMIC. The brake indicator is controlled by PCI

data bus messages from the Controller Antilock

Brake (CAB) as well as by hard wired park brake

switch inputs to the EMIC. The seatbelt indicator is

controlled by the EMIC programming, PCI data bus

messages from the Airbag Control Module (ACM),

and a hard wired seat belt switch input to the EMIC.

The Malfunction Indicator Lamp (MIL) is normally

controlled by PCI data bus messages from the Pow-

ertrain Control Module (PCM); however, if the EMIC

loses PCI data bus communication, the EMIC cir-

cuitry will automatically turn the MIL on until PCI

data bus communication is restored. The EMIC uses

PCI data bus messages from the Front Control Mod-

ule (FCM), the PCM, the diesel engine only Engine

Control Module (ECM), the ACM, the CAB, and the

Sentry Key Immobilizer Module (SKIM) to control all

of the remaining indicators.

The various EMIC indicators are controlled by dif-

ferent strategies; some receive fused ignition switch

output from the EMIC circuitry and have a switched

ground, while others are grounded through the EMIC

circuitry and have a switched battery feed. However,

all indicators are completely controlled by the EMIC

microprocessor based upon various hard wired and

electronic message inputs. All indicators are illumi-

nated at a fixed intensity, which is not affected by

the selected illumination intensity of the EMIC gen-

eral illumination lamps.

In addition, certain indicators in this instrument

cluster are automatically configured or self-config-

ured. This feature allows the configurable indicators

to be enabled by the EMIC circuitry for compatibility

with certain optional equipment. The EMIC defaults

for the ABS indicator and airbag indicator are

enabled, and these configuration settings must be

programmatically disabled in the EMIC using a

DRBIIItscan tool for vehicles that do not have this

equipment. The automatically configured or self-con-

figured indicators remain latent in each EMIC at all

times and will be active only when the EMIC

receives the appropriate PCI message inputs for that

optional system or equipment.

The hard wired indicator inputs may be diagnosed

using conventional diagnostic methods. However, the

EMIC circuitry and PCI bus message controlled indi-

cators are diagnosed using the EMIC self-diagnostic

actuator test. (Refer to 8 - ELECTRICAL/INSTRU-

MENT CLUSTER - DIAGNOSIS AND TESTING).

Proper testing of the PCI data bus and the electronic

message inputs to the EMIC that control an indicator

requires the use of a DRBIIItscan tool. Refer to the

appropriate diagnostic information. Specific details ofthe operation for each indicator may be found else-

where in this service information.

CLUSTER ILLUMINATION

The EMIC has several illumination lamps that are

illuminated when the exterior lighting is turned on

with the headlamp switch. The illumination intensity

of these lamps is adjusted when the interior lighting

thumbwheel on the headlamp switch is rotated (down

to dim, up to brighten) to one of six available minor

detent positions. The EMIC monitors a resistor mul-

tiplexed input from the headlamp switch on a dim-

mer input circuit. In response to that input, the

EMIC electronic circuitry converts a 12-volt input it

receives from a fuse in the Integrated Power Module

(IPM) on a hard wired panel lamps dimmer switch

signal circuit into a 12-volt Pulse Width Modulated

(PWM) output. The EMIC uses this PWM output to

power the cluster illumination lamps and the VFD

units on the EMIC circuit board, then provides a syn-

chronized PWM output on the various hard wired

fused panel lamps dimmer switch signal circuits to

control and synchronize the illumination intensity of

other incandescent illumination lamps in the vehicle.

The cluster illumination lamps are grounded at all

times.

The EMIC also sends electronic dimming level

messages over the PCI data bus to other electronic

modules in the vehicle to control and synchronize the

illumination intensity of their VFD units to that of

the EMIC VFD units. In addition, the thumbwheel

on the headlamp switch has a Parade Mode position

to provide a parade mode. The EMIC monitors the

request for this mode from the headlamp switch,

then sends an electronic dimming level message over

the PCI data bus to illuminate all VFD units in the

vehicle at full (daytime) intensity for easier visibility

when driving in daylight with the exterior lighting

turned on.

The hard wired headlamp switch and EMIC panel

lamps dimmer inputs and outputs may be diagnosed

using conventional diagnostic methods. However,

proper testing of the PWM output of the EMIC and

the electronic dimming level messages sent by the

EMIC over the PCI data bus requires the use of a

DRBIIItscan tool. Refer to the appropriate diagnos-

tic information.

INPUT AND OUTPUT CIRCUITS

HARD WIRED INPUTS

The hard wired inputs to the EMIC include the fol-

lowing:

²Brake Lamp Switch Output

²Driver Cylinder Lock Switch Sense

²Driver Door Ajar Switch Sense

DRINSTRUMENT CLUSTER 8J - 9

INSTRUMENT CLUSTER (Continued)

Page 503 of 2895

²Driver Door Lock Switch MUX - with

Power Locks

²Fused B(+) - Ignition-Off Draw

²Fused B(+) - Power Lock Feed - with Power

Locks

²Fused Ignition Switch Output (Accessory-

Run)

²Fused Ignition Switch Output (Off-Run-

Start)

²Fused Ignition Switch Output (Run-Start)

²Headlamp Dimmer Switch MUX

²Headlamp Switch MUX

²Horn Relay Control

²Key-In Ignition Switch Sense

²Left Rear Door Ajar Switch Sense

²Panel Lamps Dimmer Switch Signal

²Park Brake Switch Sense

²Passenger Door Ajar Switch Sense

²Passenger Door Lock Switch MUX - with

Power Locks

²Radio Control MUX

²Right Rear Door Ajar Switch Sense

²RKE Supply - with RKE

²Seat Belt Switch Sense

²Transmission Range Sensor MUX - with

Auto Trans

²Turn/Hazard Switch MUX

²Washer/Beam Select Switch MUX

²Wiper Switch MUX

Refer to the appropriate wiring information for

additional details.

HARD WIRED OUTPUTS

The hard wired outputs of the EMIC include the

following:

²Accessory Switch Bank Illumination Driver

²BTSI Driver - with Auto Trans

²Cargo Lamp Driver

²Dome/Overhead Lamp Driver

²Driver Door Unlock Driver - with Power

Locks

²Headlamp Switch Illumination Driver

²Heated Seat Switch Indicator Driver - with

Heated Seats

²Heater-A/C Control Illumination Driver

²Left Door Lock Driver - with Power Locks

²Left Rear Door Unlock Driver - with Power

Locks

²Map/Glove Box Lamp Driver²Radio Illumination Driver

²Right Door Lock Driver - with Power Locks

²Right Door Unlock Driver - with Power

Locks

²Transfer Case Switch Illumination Driver -

with Four-Wheel Drive

Refer to the appropriate wiring information for

additional details.

GROUNDS

The EMIC receives and supplies a ground path to

several switches and sensors through the following

hard wired circuits:

²Ground - Illumination (2 Circuits)

²Ground - Power Lock - with Power Locks

²Ground - Signal

²Headlamp Switch Return

²Multi-Function Switch Return

²Transmission Range Sensor Return - with

Auto Trans

Refer to the appropriate wiring information for

additional details.

COMMUNICATION

The EMIC has provisions for the following commu-

nication circuits:

²PCI Data Bus

²RKE Program Serial Data - with RKE

²RKE Transmit Serial Data - with RKE

Refer to the appropriate wiring information for

additional details.

DIAGNOSIS AND TESTING - INSTRUMENT

CLUSTER

If all of the instrument cluster gauges and/or indi-

cators are inoperative, refer to PRELIMINARY

DIAGNOSIS. If an individual gauge or Programma-

ble Communications Interface (PCI) data bus mes-

sage-controlled indicator is inoperative, refer to

ACTUATOR TEST. If an individual hard wired indi-

cator is inoperative, refer to the diagnosis and testing

information for that specific indicator.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

8J - 10 INSTRUMENT CLUSTERDR

INSTRUMENT CLUSTER (Continued)

Page 504 of 2895

CAUTION: Instrument clusters used in this model

automatically configure themselves for compatibil-

ity with the features and optional equipment in the

vehicle in which they are initially installed. The

instrument cluster is programmed to do this by

embedding the Vehicle Identification Number (VIN)

and other information critical to proper cluster

operation into electronic memory. This embedded

information is learned through electronic messages

received from other electronic modules in the vehi-

cle over the Programmable Communications Inter-

face (PCI) data bus, and through certain hard wired

inputs received when the cluster is connected to

the vehicle electrically. Once configured, the instru-

ment cluster memory may be irreparably damaged

and certain irreversible configuration errors may

occur if the cluster is connected electrically to

another vehicle; or, if an electronic module from

another vehicle is connected that provides data to

the instrument cluster (including odometer values)

that conflicts with that which was previously

learned and stored. Therefore, the practice of

exchanging (swapping) instrument clusters and

other electronic modules in this vehicle with those

removed from another vehicle must always be

avoided. Failure to observe this caution may result

in instrument cluster damage, which is not reim-

bursable under the terms of the product warranty.

Service replacement instrument clusters are pro-

vided with the correct VIN, and the certified odom-

eter and engine hours values embedded into cluster

memory, but will otherwise be automatically config-

ured for compatibility with the features and optional

equipment in the vehicle in which they are initially

installed.

NOTE: Certain indicators in this instrument cluster

are automatically configured. This feature allows

those indicators to be activated or deactivated for

compatibility with certain optional equipment. If the

problem being diagnosed involves improper illumi-

nation of the cruise indicator, the electronic throttle

control indicator, the overdrive-off indicator, the

service four-wheel drive indicator, the transmission

overtemp indicator, the upshift indicator, the secu-

rity indicator or the gear selector indicator, discon-

nect and isolate the battery negative cable. After

about five minutes, reconnect the battery negative

cable and turn the ignition switch to the On posi-

tion. The instrument cluster should automatically

relearn the equipment in the vehicle and properly

configure the configurable indicators accordingly.PRELIMINARY DIAGNOSIS

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

SIDE CURTAIN AIRBAG, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE SYSTEM CAPACITOR TO DISCHARGE BEFORE

PERFORMING FURTHER DIAGNOSIS OR SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

SUPPLEMENTAL RESTRAINT SYSTEM. FAILURE TO

TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Check the fused B(+) fuse (Fuse 28 - 10

ampere) in the Integrated Power Module (IPM). If

OK, go to Step 2. If not OK, repair the shorted circuit

or component as required and replace the faulty fuse.

(2) Check for battery voltage at the fused B(+) fuse

(Fuse 28 - 10 ampere) in the IPM. If OK, go to Step

3. If not OK, repair the open fused B(+) circuit

between the IPM and the battery as required.

(3) Disconnect and isolate the battery negative

cable. Remove the instrument cluster. Reconnect the

battery negative cable. Check for battery voltage at

the fused B(+) circuit cavity of the instrument panel

wire harness connector (Connector C1) for the instru-

ment cluster. If OK, go to Step 4. If not OK, repair

the open fused B(+) circuit between the instrument

cluster and the IPM as required.

(4) Check for continuity between the signal ground

circuit cavity of the instrument panel wire harness

connector (Connector C1) for the instrument cluster

and a good ground. There should be continuity. If

OK, refer to ACTUATOR TEST. If not OK, repair the

open ground circuit to ground (G202) as required.

DRINSTRUMENT CLUSTER 8J - 11

INSTRUMENT CLUSTER (Continued)

Page 505 of 2895

ACTUATOR TEST

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

SIDE CURTAIN AIRBAG, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE SYSTEM CAPACITOR TO DISCHARGE BEFORE

PERFORMING FURTHER DIAGNOSIS OR SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

SUPPLEMENTAL RESTRAINT SYSTEM. FAILURE TO

TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

The instrument cluster actuator test will put the

instrument cluster into its self-diagnostic mode. In

this mode the instrument cluster can perform a self-

diagnostic test that will confirm that the instrument

cluster circuitry, the gauges, and the indicators are

capable of operating as designed. During the actuator

test the instrument cluster circuitry will position

each of the gauge needles at various calibration

points, illuminate all of the segments in the Vacuum

Fluorescent Display (VFD) units, turn all of the indi-

cators on and off again, display any Diagnostic Trou-

ble Code (DTC) information, and display the number

of ignition key cycles that have occurred since the

DTC was detected. It is suggested that a note pad

and pencil be used to write down any fault informa-

tion that is displayed during the test for reference.

Successful completion of the actuator test will con-

firm that the instrument cluster is operational. How-

ever, there may still be a problem with the PCI data

bus, the Powertrain Control Module (PCM), the

Engine Control Module (ECM), the Front Control

Module (FCM), the Transmission Control Module

(TCM), the Transfer Case Control Module (TCCM),

the Airbag Control Module (ACM), the Controller

Anti-lock Brake (CAB), or the inputs to one of these

electronic control modules. Use a DRBIIItscan toolto diagnose these components. Refer to the appropri-

ate diagnostic information.

(1) Begin the test with the ignition switch in the

Off position.

(2) Depress the odometer/trip odometer switch but-

ton.

(3) While still holding the odometer/trip odometer

switch button depressed, turn the ignition switch to

the On position, but do not start the engine.

(4) Release the odometer/trip odometer switch but-

ton.

(5) The instrument cluster will simultaneously

illuminate all of the operational segments in both

VFD units, perform a bulb check of each operational

LED indicator. The VFD segments and LED indica-

tors remain illuminated as each gauge needle is

swept to several calibration points and back. If a

VFD segment or an LED indicator fails to illuminate,

or if a gauge needle fails to sweep through the cali-

bration points and back during this test, the instru-

ment cluster must be replaced. Following these tests,

the actuator test will proceed as described in Step 6.

(6) The text ªC Codeº is displayed in the odometer

VFD for about three seconds. If there is no stored

fault information, the display will show two pairs of

zeroes in the format ª00º ª00º, which indicate that

the display of fault information is done. If there is

stored fault information, two sets of two-digit alpha

and alpha-numeric fault codes will appear in the

odometer display for a three second interval. The

first pair of digits represents a Diagnostic Trouble

Code (DTC), or fault code for the instrument cluster.

The second pair of digits is a counter for the number

of ignition key cycles that have occurred since the

displayed DTC was set. The instrument cluster will

continue to display additional sets of two pairs of dig-

its at three second intervals until all of the stored

codes have been displayed, which is again signaled

by a code of ª00º ª00º. Refer to the Instrument Clus-

ter Failure Message table for a description of each

fault code that the instrument cluster displays. If an

instrument cluster fault is displayed, use a DRBIIIt

scan tool to diagnose the problem. Refer to the appro-

priate diagnostic information.

INSTRUMENT CLUSTER FAILURE MESSAGE

Fault Code Description Correction

01 Airbag warning indicator output circuit shorted. Refer to the appropriate diagnostic information.

02 Airbag warning indicator output circuit open. Refer to the appropriate diagnostic information.

03 ABS indicator output circuit shorted. Refer to the appropriate diagnostic information.

04 ABS indicator output circuit open. Refer to the appropriate diagnostic information.

05 MIL indicator output circuit shorted. Refer to the appropriate diagnostic information.

06 MIL indicator output circuit open. Refer to the appropriate diagnostic information.

8J - 12 INSTRUMENT CLUSTERDR

INSTRUMENT CLUSTER (Continued)

Page 506 of 2895

INSTRUMENT CLUSTER FAILURE MESSAGE

Fault Code Description Correction

07 Wait to start indicator circuit shorted. Refer to the appropriate diagnostic information.

08 Wait to start indicator circuit open. Refer to the appropriate diagnostic information.

0B BTSI output circuit shorted or open. Refer to the appropriate diagnostic information.

22 Headlamp switch input circuit shorted. Refer to the appropriate diagnostic information.

23 Headlamp switch input circuit open. Refer to the appropriate diagnostic information.

24 Turn hazard switch input circuit shorted. Refer to the appropriate diagnostic information.

25 Turn hazard swiitch inpot circuit open. Refer to the appropriate diagnostic information.

27 Courtesy/dome output circuit shorted or open. Refer to the appropriate diagnostic information.

28 Glovebox/map lamp output circuit shorted or

open.Refer to the appropriate diagnostic information.

29 Cargo lamp output circuit shorted or open. Refer to the appropriate diagnostic information.

40 Wiper switch input circuit shorted. Refer to the appropriate diagnostic information.

41 Wiper switch input circuit open. Refer to the appropriate diagnostic information.

42 Wash/beam input circuit shorted. Refer to the appropriate diagnostic information.

60 Passenger door lock switch input circuit shorted. Refer to the appropriate diagnostic information.

61 Passenger door lock switch input circuit open. Refer to the appropriate diagnostic information.

62 Passenger door lock switch input circuit stuck. Refer to the appropriate diagnostic information.

63 Driver door lock switch input circuit shorted. Refer to the appropriate diagnostic information.

64 Driver door lock switch input circuit open. Refer to the appropriate diagnostic information.

65 Driver door lock switch input circuit stuck. Refer to the appropriate diagnostic information.

66 All door lock output circuit shorted to ground or

voltage.Refer to the appropriate diagnostic information.

67 All door unlock output circuit shorted to ground

or voltage.Refer to the appropriate diagnostic information.

68 Driver door unlock output circuit shorted to

ground or voltage.Refer to the appropriate diagnostic information.

6C Driver cylinder lock switch input circuit shorted. Refer to the appropriate diagnostic information.

6E Driver cylinder lock switch input circuit stuck. Refer to the appropriate diagnostic information.

80 Incorrect odometer value found. Refer to the appropriate diagnostic information.

81 Remote radio switch input circuit high. Refer to the appropriate diagnostic information.

82 Remote radio switch stuck. Refer to the appropriate diagnostic information.

A0 Internal module FLASH memory checksum

failure.Refer to the appropriate diagnostic information.

A1 Internal module bootloader failure. Refer to the appropriate diagnostic information.

A3 Battery voltage open. Refer to the appropriate diagnostic information.

A5 TCCM messages not received. Refer to the appropriate diagnostic information.

A7 VIN checksum error. Refer to the appropriate diagnostic information.

A8 VIN previously stored. Refer to the appropriate diagnostic information.

A9 PCI bus internal failure. Refer to the appropriate diagnostic information.

AA PCM messages not received. Refer to the appropriate diagnostic information.

AB TCM messages not received. Refer to the appropriate diagnostic information.

AC ABS messages not received. Refer to the appropriate diagnostic information.

DRINSTRUMENT CLUSTER 8J - 13

INSTRUMENT CLUSTER (Continued)

Page 507 of 2895

INSTRUMENT CLUSTER FAILURE MESSAGE

Fault Code Description Correction

AD FCM messages not received. Refer to the appropriate diagnostic information.

AE ACM messages not received. Refer to the appropriate diagnostic information.

AF SKIM messages not received. Refer to the appropriate diagnostic information.

B0 RKE fob batteries low. Refer to the appropriate diagnostic information.

B1 RKE module communication link. Refer to the appropriate diagnostic information.

00 Done All Diagnostic Trouble Codes (DTC) have been

displayed.

(7) The actuator test is now completed. The instru-

ment cluster will automatically exit the self-diagnos-

tic mode and return to normal operation at the

completion of the test, if the ignition switch is turned

to the Off position during the test, or if a vehicle

speed message indicating that the vehicle is moving

is received from the PCM over the PCI data bus dur-

ing the test.

(8)

Go back to Step 1 to repeat the test, if necessary.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

SIDE CURTAIN AIRBAG, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE SYSTEM CAPACITOR TO DISCHARGE BEFORE

PERFORMING FURTHER DIAGNOSIS OR SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

SUPPLEMENTAL RESTRAINT SYSTEM. FAILURE TO

TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cluster bezel from the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

CLUSTER BEZEL - REMOVAL).

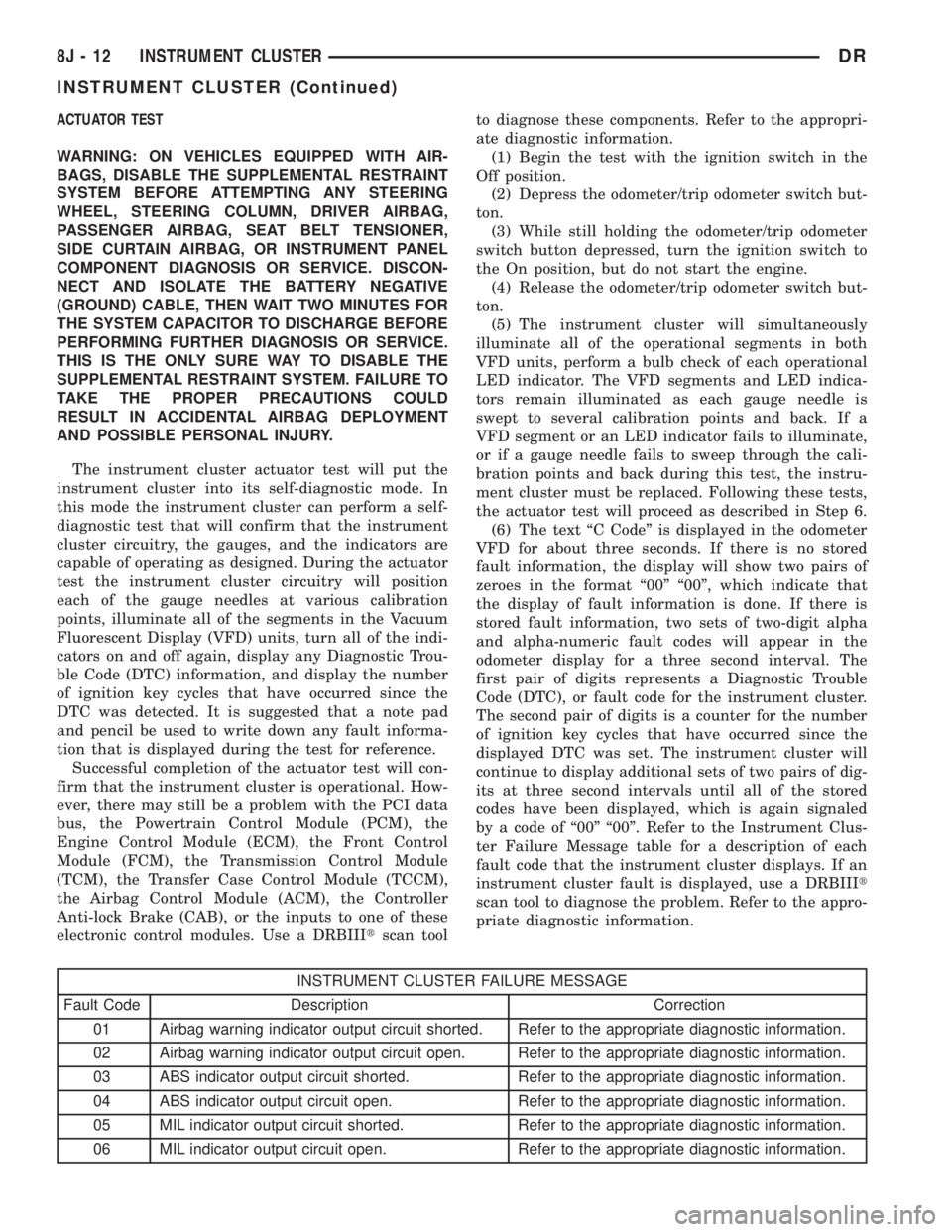

(3) Remove the four screws that secure the instru-

ment cluster to the instrument panel structural sup-

port (Fig. 5).(4) Pull the instrument cluster rearward far

enough to access and disconnect the instrument

panel wire harness connectors for the cluster from

the connector receptacles on the back of the cluster

housing.

(5) Remove the instrument cluster from the instru-

ment panel.

DISASSEMBLY

Some of the components for the instrument cluster

used in this vehicle are serviced individually. The

serviced components include the incandescent instru-

ment cluster illumination lamp bulbs (including the

integral bulb holders), and the cluster lens, hood and

mask unit. Following are the procedures for disas-

sembling these components from the instrument clus-

ter unit.

Fig. 5 Instrument Cluster Remove/Install

1 - WIRE HARNESS CONNECTOR (3)

2 - INSTRUMENT CLUSTER

3 - SCREW (4)

4 - INSTRUMENT PANEL STRUCTURAL SUPPORT

8J - 14 INSTRUMENT CLUSTERDR

INSTRUMENT CLUSTER (Continued)

Page 508 of 2895

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

SIDE CURTAIN AIRBAG, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE SYSTEM CAPACITOR TO DISCHARGE BEFORE

PERFORMING FURTHER DIAGNOSIS OR SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

SUPPLEMENTAL RESTRAINT SYSTEM. FAILURE TO

TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

CLUSTER BULB

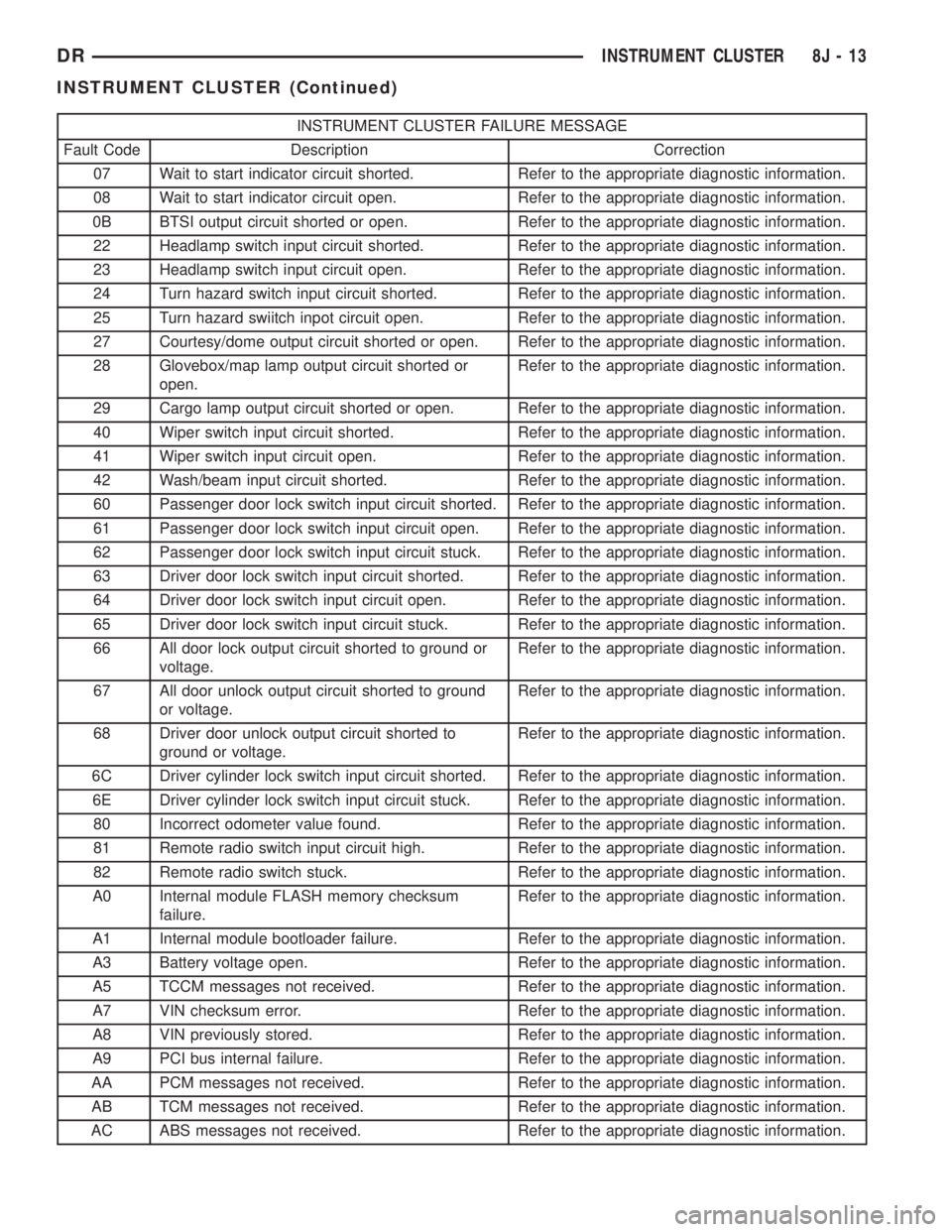

This procedure applies to each of the incandescent

cluster illumination lamp bulb and bulb holder units.

If the vehicle is equipped with the optional Remote

Keyless Entry (RKE) system, the RKE receiver mod-

ule must be removed from the instrument cluster

rear cover to access the lower center cluster illumi-

nation lamp, which is located on the circuit board

directly behind the RKE module. (Refer to 8 - ELEC-

TRICAL/POWER LOCKS/REMOTE KEYLESS

ENTRY MODULE - REMOVAL).

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument cluster from the instru-

ment panel. (Refer to 8 - ELECTRICAL/INSTRU-

MENT CLUSTER - REMOVAL).

(3) Turn the bulb holder counterclockwise about

sixty degrees on the cluster electronic circuit board

(Fig. 6).(4) Pull the bulb and bulb holder unit straight

back to remove it from the bulb mounting hole in the

cluster electronic circuit board.

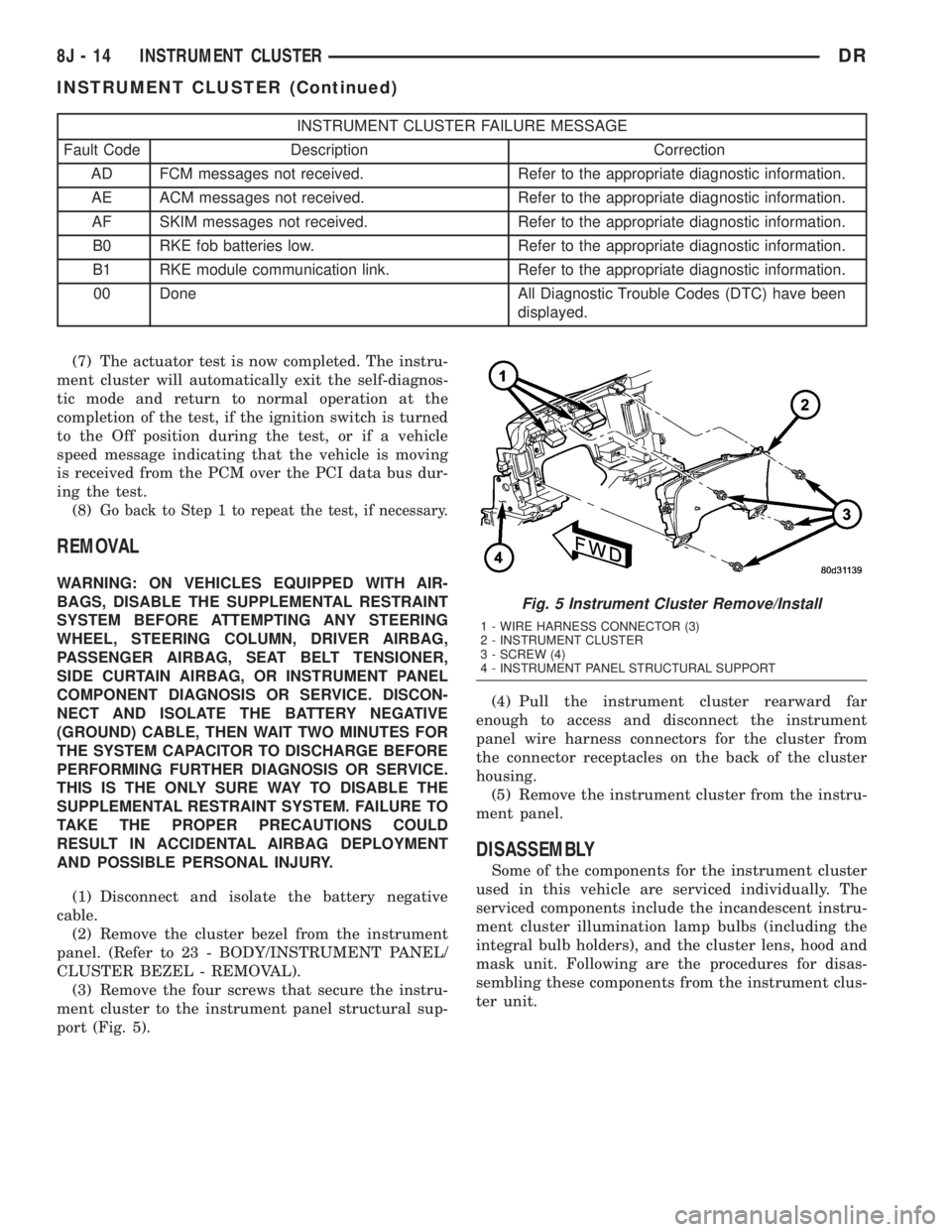

CLUSTER LENS, HOOD, AND MASK

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument cluster from the instru-

ment panel. (Refer to 8 - ELECTRICAL/INSTRU-

MENT CLUSTER - REMOVAL).

(3) From the back of the instrument cluster,

remove the eight screws around the outer perimeter

of the rear cover that secure the lens, hood, and

mask unit to the cluster housing (Fig. 7).

(4) Remove the lens, hood, and mask unit from the

face of the instrument cluster.

ASSEMBLY

Some of the components for the instrument cluster

used in this vehicle are serviced individually. The

serviced components include the incandescent instru-

ment cluster illumination lamp bulbs (including the

integral bulb holders), and the cluster lens, hood and

mask unit. Following are the procedures for assem-

bling these components to the instrument cluster

unit.

Fig. 6 Cluster Bulb Remove/Install

1 - INSTRUMENT CLUSTER

2 - BULB & HOLDER (11)

Fig. 7 Instrument Cluster Components

1 - SCREW (9)

2 - REAR COVER

3 - CLUSTER HOUSING

4 - LENS, HOOD & MASK

DRINSTRUMENT CLUSTER 8J - 15

INSTRUMENT CLUSTER (Continued)

Page 509 of 2895

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

SIDE CURTAIN AIRBAG, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE SYSTEM CAPACITOR TO DISCHARGE BEFORE

PERFORMING FURTHER DIAGNOSIS OR SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

SUPPLEMENTAL RESTRAINT SYSTEM. FAILURE TO

TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

CLUSTER BULB

This procedure applies to each of the incandescent

cluster illumination lamp bulb and bulb holder units.

If the vehicle is equipped with the optional Remote

Keyless Entry (RKE) system, and the RKE receiver

module was removed from the instrument cluster

rear cover to access the lower center cluster illumi-

nation lamp, reinstall the RKE module after the bulb

is replaced on the circuit board. (Refer to 8 - ELEC-

TRICAL/POWER LOCKS/REMOTE KEYLESS

ENTRY MODULE - INSTALLATION).

CAUTION: Always use the correct bulb size and

type for replacement. An incorrect bulb size or type

may overheat and cause damage to the instrument

cluster, the electronic circuit board and/or the

gauges.

(1) Insert the bulb and bulb holder unit straight

into the correct bulb mounting hole in the cluster

electronic circuit board (Fig. 6).

(2) With the bulb holder fully seated against the

cluster electronic circuit board, turn the bulb holder

clockwise about sixty degrees to lock it into place.

(3) Reinstall the instrument cluster onto the

instrument panel. (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - INSTALLATION).

(4) Reconnect the battery negative cable.CLUSTER LENS, HOOD, AND MASK

(1) Position the cluster lens, hood, and mask unit

over the face of the instrument cluster (Fig. 7). Be

certain that the odometer/trip odometer switch but-

ton is inserted through the proper clearance holes in

the mask and the lens.

(2) From the back of the instrument cluster, install

and tighten the eight screws around the outer perim-

eter of the rear cover that secure the lens, hood, and

mask unit to the cluster housing. Tighten the screws

to 1 N´m (10 in. lbs.).

(3) Reinstall the instrument cluster onto the

instrument panel. (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - INSTALLATION).

(4) Reconnect the battery negative cable.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

SIDE CURTAIN AIRBAG, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE SYSTEM CAPACITOR TO DISCHARGE BEFORE

PERFORMING FURTHER DIAGNOSIS OR SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

SUPPLEMENTAL RESTRAINT SYSTEM. FAILURE TO

TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Position the instrument cluster to the instru-

ment panel.

(2) Reconnect the instrument panel wire harness

connectors for the cluster to the connector receptacles

on the back of the cluster housing.

(3) Position the instrument cluster into the instru-

ment panel.

(4) Install and tighten the four screws that secure

the instrument cluster to the instrument panel struc-

tural support (Fig. 5). Tighten the screws to 4 N´m

(31 in. lbs.).

(5) Reinstall the cluster bezel onto the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

CLUSTER BEZEL - INSTALLATION).

(6) Reconnect the battery negative cable.

8J - 16 INSTRUMENT CLUSTERDR

INSTRUMENT CLUSTER (Continued)

Page 510 of 2895

NOTE: Certain indicators in this instrument cluster

are automatically configured. This feature allows

those indicators to be activated or deactivated for

compatibility with certain optional equipment. If the

problem being diagnosed involves improper illumi-

nation of the cruise indicator, the electronic throttle

control indicator, the overdrive-off indicator, the

service four-wheel drive indicator, the transmission

overtemp indicator, the upshift indicator, the secu-

rity indicator or the gear selector indicator, discon-

nect and isolate the battery negative cable. After

about five minutes, reconnect the battery negative

cable and turn the ignition switch to the On posi-

tion. The instrument cluster should automatically

relearn the equipment in the vehicle and properly

configure the configurable indicators accordingly.

ABS INDICATOR

DESCRIPTION

An Antilock Brake System (ABS) indicator is stan-

dard equipment on all instrument clusters. However,

the instrument cluster can be programmed to disable

this indicator on vehicles that are not equipped with

the ABS or Rear Wheel Anti-Lock (RWAL) brake sys-

tems, which are not available in some markets. On

vehicles equipped with a gasoline engine, the ABS

indicator is located near the lower edge of the instru-

ment cluster, between the tachometer and the speed-

ometer. On vehicles equipped with a diesel engine,

the ABS indicator is located on the right side of the

instrument cluster, to the right of the engine temper-

ature gauge. The ABS indicator consists of a stencil-

like cutout of the International Control and Display

Symbol icon for ªFailure of Anti-lock Braking Sys-

temº in the opaque layer of the instrument cluster

overlay. The dark outer layer of the overlay prevents

the indicator from being clearly visible when it is not

illuminated. An amber Light Emitting Diode (LED)

behind the cutout in the opaque layer of the overlay

causes the icon to appear in amber through the

translucent outer layer of the overlay when the indi-

cator is illuminated from behind by the LED, which

is soldered onto the instrument cluster electronic cir-

cuit board. The ABS indicator is serviced as a unit

with the instrument cluster.

OPERATION

The ABS indicator gives an indication to the vehi-

cle operator when the ABS system is faulty or inop-

erative. This indicator is controlled by a transistor on

the instrument cluster circuit board based upon clus-

ter programming and electronic messages received by

the cluster from the Controller Antilock Brake (CAB)over the Programmable Communications Interface

(PCI) data bus. The ABS indicator Light Emitting

Diode (LED) is completely controlled by the instru-

ment cluster logic circuit, and that logic will only

allow this indicator to operate when the instrument

cluster receives a battery current input on the fused

ignition switch output (run-start) circuit. Therefore,

the LED will always be off when the ignition switch

is in any position except On or Start. The LED only

illuminates when it is provided a path to ground by

the instrument cluster transistor. The instrument

cluster will turn on the ABS indicator for the follow-

ing reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the ABS indicator is illu-

minated by the cluster for about two seconds as a

bulb test.

²ABS Lamp-On Message- Each time the clus-

ter receives a lamp-on message from the CAB, the

ABS indicator will be illuminated. The indicator

remains illuminated until the cluster receives a

lamp-off message from the CAB, or until the ignition

switch is turned to the Off position, whichever occurs

first.

²Communication Error- If the cluster receives

no lamp-on or lamp-off messages from the CAB for

three consecutive seconds, the ABS indicator is illu-

minated. The indicator remains illuminated until the

cluster receives a valid message from the CAB, or

until the ignition switch is turned to the Off position,

whichever occurs first.

²Actuator Test- Each time the instrument clus-

ter is put through the actuator test, the ABS indica-

tor will be turned on, then off again during the bulb

check portion of the test to confirm the functionality

of the LED and the cluster control circuitry.

²ABS Diagnostic Test- The ABS indicator is

blinked on and off by lamp-on and lamp-off messages

from the CAB during the performance of the ABS

diagnostic tests.

The CAB continually monitors the ABS circuits

and sensors to decide whether the system is in good

operating condition. The CAB then sends the proper

lamp-on or lamp-off messages to the instrument clus-

ter. If the CAB sends a lamp-on message after the

bulb test, it indicates that the CAB has detected a

system malfunction and/or that the ABS system has

become inoperative. The CAB will store a Diagnostic

Trouble Code (DTC) for any malfunction it detects.

Each time the ABS indicator fails to light due to an

open or short in the cluster ABS indicator circuit, the

cluster sends a message notifying the CAB of the

condition, then the instrument cluster and the CAB

will each store a DTC. For proper diagnosis of the

antilock brake system, the CAB, the PCI data bus, or

the electronic message inputs to the instrument clus-

DRINSTRUMENT CLUSTER 8J - 17

INSTRUMENT CLUSTER (Continued)