DODGE RAM 2003 Service Manual PDF

Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 61 of 2895

(8) Align the bolt holes in the hub bearing flange

with the bolts installed in the knuckle. Then thread

the bolts into the bearing flange far enough to hold

the assembly in place.(9) Install the remaining bolts. Tighten the hub/

bearing bolts to 202 N´m (149 ft. lbs.

(10) Install the washer and axle nut and tighten a

beginning torque of 179 N´m (132 ft. lbs.).

(11) Rotate the axle 5 to 10 times to seat the hub

bearing.

(12) Tighten to a final torque of 356 N´m (263 ft.

lbs.).

(13) Align the axle nut to the next forward cotter

pin hole and install a new cotter pin in the axle nut.

(14) Install the brake caliper, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - INSTALLATION).

(15) Install the sensor wire to the steering knuckle

and frame and if equipped. Connect the wheel speed

sensor wire under the hood.

(16) Install the wheel and tire assemblies, (Refer

to 22 - TIRES/WHEELS/WHEELS - STANDARD

PROCEDURE).

(17) Remove the support and lower the vehicle.

(18) Apply the brakes several times to seat the

brake shoes and caliper piston. Do not move the vehi-

cle until a firm brake pedal is obtained.

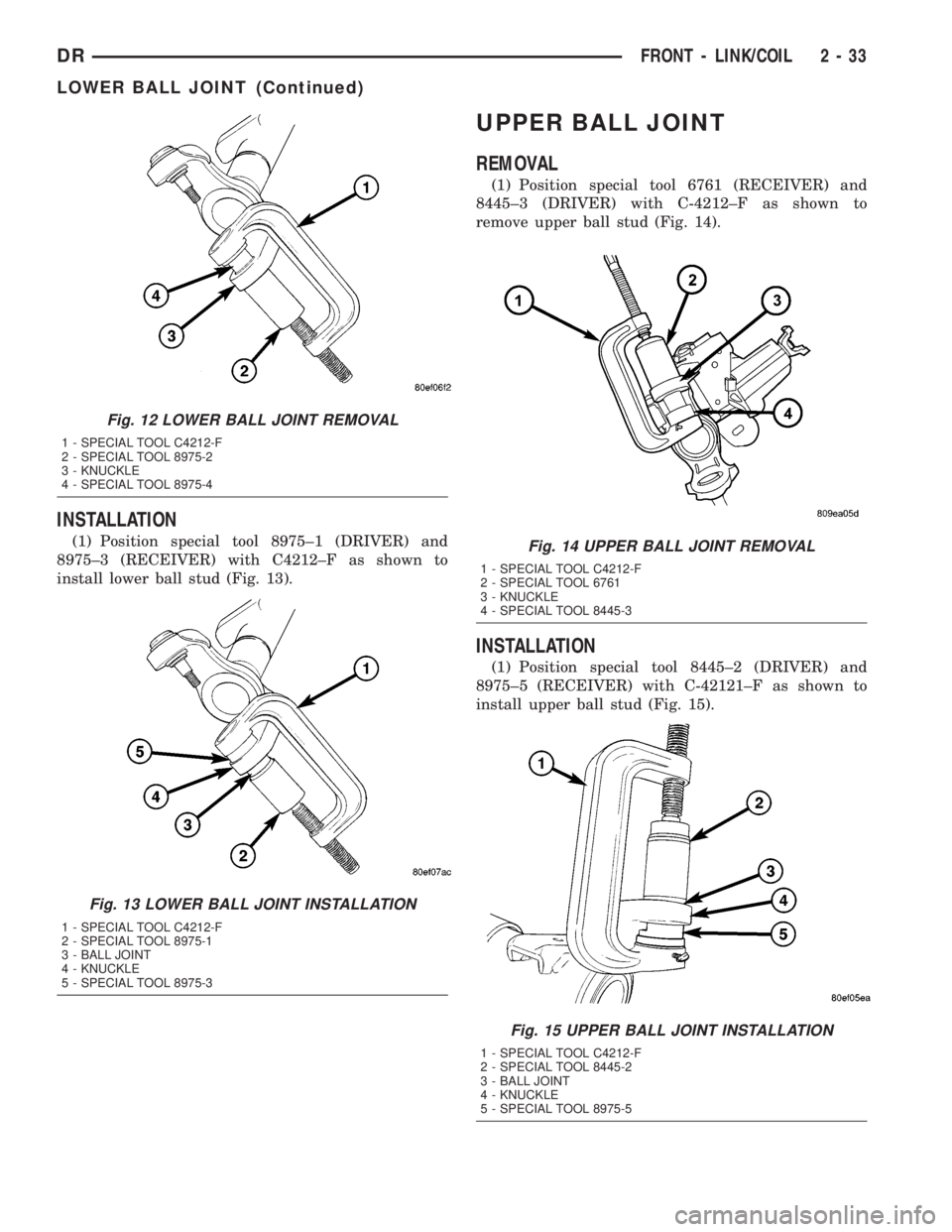

LOWER BALL JOINT

REMOVAL

(1) Remove lower snap ring from the lower ball

joint (Fig. 11).

(2) Position special tool 8975±2 (RECEIVER) and

8975±4 (DRIVER) with tool C4212±F as shown to

remove lower ball stud (Fig. 12).

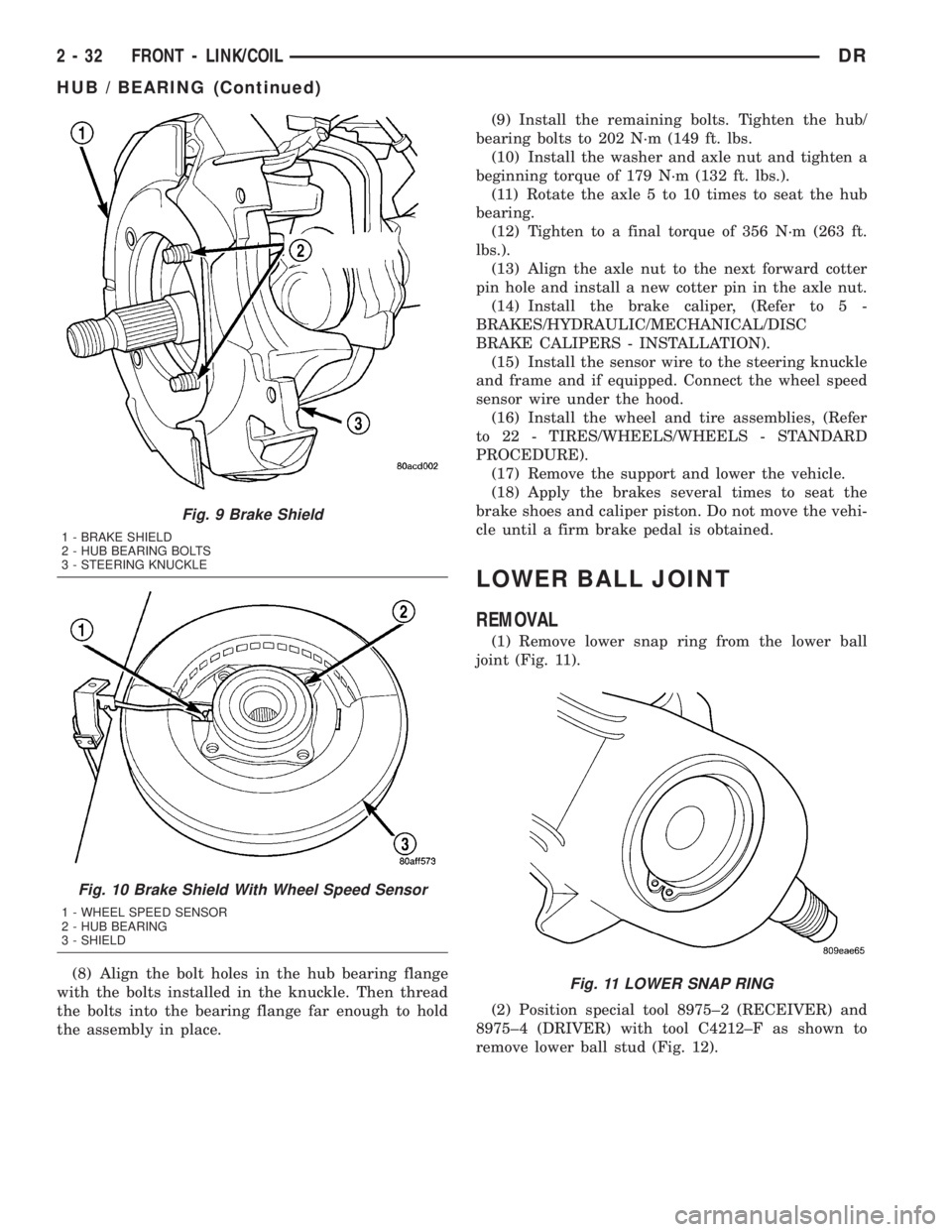

Fig. 9 Brake Shield

1 - BRAKE SHIELD

2 - HUB BEARING BOLTS

3 - STEERING KNUCKLE

Fig. 10 Brake Shield With Wheel Speed Sensor

1 - WHEEL SPEED SENSOR

2 - HUB BEARING

3 - SHIELD

Fig. 11 LOWER SNAP RING

2 - 32 FRONT - LINK/COILDR

HUB / BEARING (Continued)

Page 62 of 2895

INSTALLATION

(1) Position special tool 8975±1 (DRIVER) and

8975±3 (RECEIVER) with C4212±F as shown to

install lower ball stud (Fig. 13).

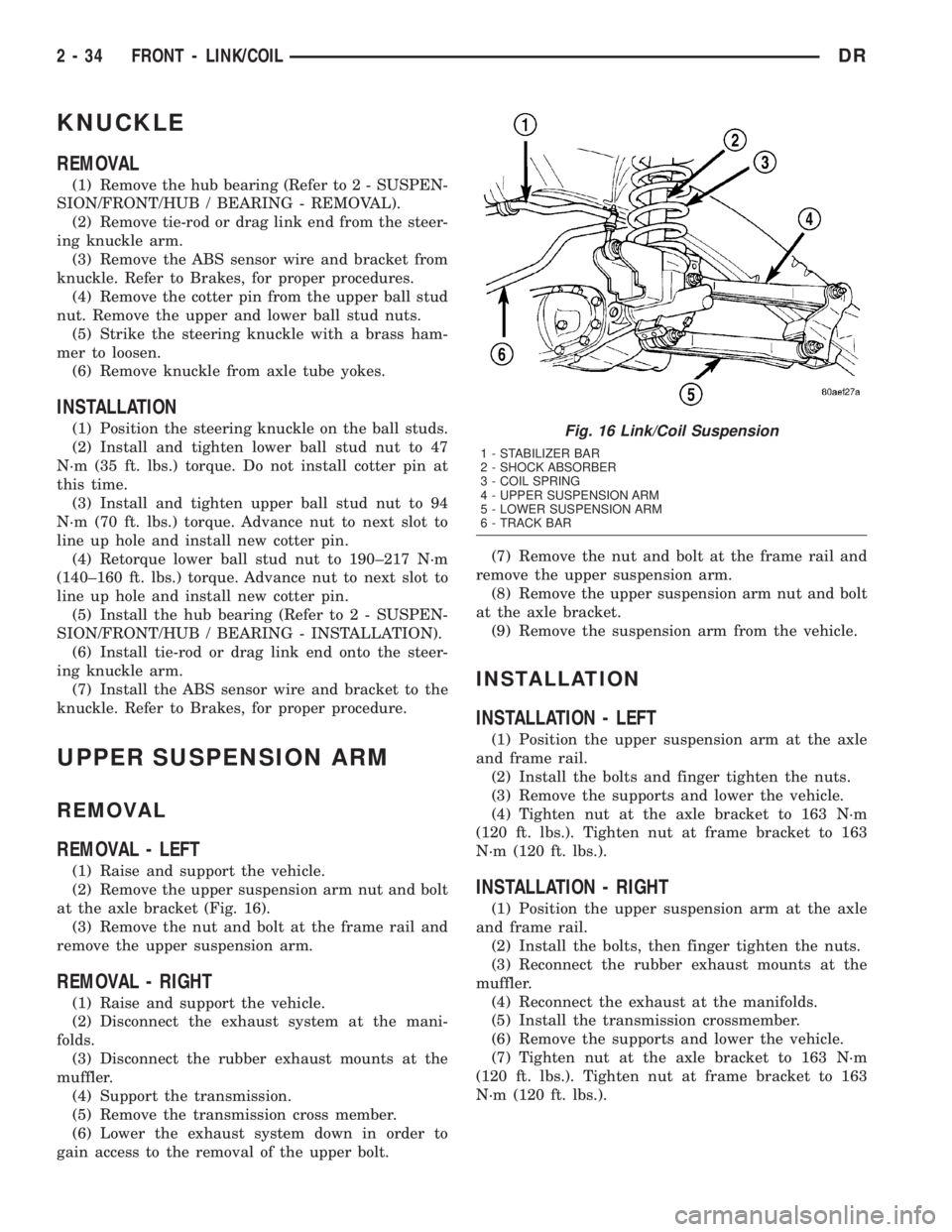

UPPER BALL JOINT

REMOVAL

(1) Position special tool 6761 (RECEIVER) and

8445±3 (DRIVER) with C-4212±F as shown to

remove upper ball stud (Fig. 14).

INSTALLATION

(1) Position special tool 8445±2 (DRIVER) and

8975±5 (RECEIVER) with C-42121±F as shown to

install upper ball stud (Fig. 15).

Fig. 12 LOWER BALL JOINT REMOVAL

1 - SPECIAL TOOL C4212-F

2 - SPECIAL TOOL 8975-2

3 - KNUCKLE

4 - SPECIAL TOOL 8975-4

Fig. 13 LOWER BALL JOINT INSTALLATION

1 - SPECIAL TOOL C4212-F

2 - SPECIAL TOOL 8975-1

3 - BALL JOINT

4 - KNUCKLE

5 - SPECIAL TOOL 8975-3

Fig. 14 UPPER BALL JOINT REMOVAL

1 - SPECIAL TOOL C4212-F

2 - SPECIAL TOOL 6761

3 - KNUCKLE

4 - SPECIAL TOOL 8445-3

Fig. 15 UPPER BALL JOINT INSTALLATION

1 - SPECIAL TOOL C4212-F

2 - SPECIAL TOOL 8445-2

3 - BALL JOINT

4 - KNUCKLE

5 - SPECIAL TOOL 8975-5

DRFRONT - LINK/COIL 2 - 33

LOWER BALL JOINT (Continued)

Page 63 of 2895

KNUCKLE

REMOVAL

(1) Remove the hub bearing (Refer to 2 - SUSPEN-

SION/FRONT/HUB / BEARING - REMOVAL).

(2) Remove tie-rod or drag link end from the steer-

ing knuckle arm.

(3) Remove the ABS sensor wire and bracket from

knuckle. Refer to Brakes, for proper procedures.

(4) Remove the cotter pin from the upper ball stud

nut. Remove the upper and lower ball stud nuts.

(5) Strike the steering knuckle with a brass ham-

mer to loosen.

(6) Remove knuckle from axle tube yokes.

INSTALLATION

(1) Position the steering knuckle on the ball studs.

(2) Install and tighten lower ball stud nut to 47

N´m (35 ft. lbs.) torque. Do not install cotter pin at

this time.

(3) Install and tighten upper ball stud nut to 94

N´m (70 ft. lbs.) torque. Advance nut to next slot to

line up hole and install new cotter pin.

(4) Retorque lower ball stud nut to 190±217 N´m

(140±160 ft. lbs.) torque. Advance nut to next slot to

line up hole and install new cotter pin.

(5) Install the hub bearing (Refer to 2 - SUSPEN-

SION/FRONT/HUB / BEARING - INSTALLATION).

(6) Install tie-rod or drag link end onto the steer-

ing knuckle arm.

(7) Install the ABS sensor wire and bracket to the

knuckle. Refer to Brakes, for proper procedure.

UPPER SUSPENSION ARM

REMOVAL

REMOVAL - LEFT

(1) Raise and support the vehicle.

(2) Remove the upper suspension arm nut and bolt

at the axle bracket (Fig. 16).

(3) Remove the nut and bolt at the frame rail and

remove the upper suspension arm.

REMOVAL - RIGHT

(1) Raise and support the vehicle.

(2) Disconnect the exhaust system at the mani-

folds.

(3) Disconnect the rubber exhaust mounts at the

muffler.

(4) Support the transmission.

(5) Remove the transmission cross member.

(6) Lower the exhaust system down in order to

gain access to the removal of the upper bolt.(7) Remove the nut and bolt at the frame rail and

remove the upper suspension arm.

(8) Remove the upper suspension arm nut and bolt

at the axle bracket.

(9) Remove the suspension arm from the vehicle.

INSTALLATION

INSTALLATION - LEFT

(1) Position the upper suspension arm at the axle

and frame rail.

(2) Install the bolts and finger tighten the nuts.

(3) Remove the supports and lower the vehicle.

(4) Tighten nut at the axle bracket to 163 N´m

(120 ft. lbs.). Tighten nut at frame bracket to 163

N´m (120 ft. lbs.).

INSTALLATION - RIGHT

(1) Position the upper suspension arm at the axle

and frame rail.

(2) Install the bolts, then finger tighten the nuts.

(3) Reconnect the rubber exhaust mounts at the

muffler.

(4) Reconnect the exhaust at the manifolds.

(5) Install the transmission crossmember.

(6) Remove the supports and lower the vehicle.

(7) Tighten nut at the axle bracket to 163 N´m

(120 ft. lbs.). Tighten nut at frame bracket to 163

N´m (120 ft. lbs.).

Fig. 16 Link/Coil Suspension

1 - STABILIZER BAR

2 - SHOCK ABSORBER

3 - COIL SPRING

4 - UPPER SUSPENSION ARM

5 - LOWER SUSPENSION ARM

6 - TRACK BAR

2 - 34 FRONT - LINK/COILDR

Page 64 of 2895

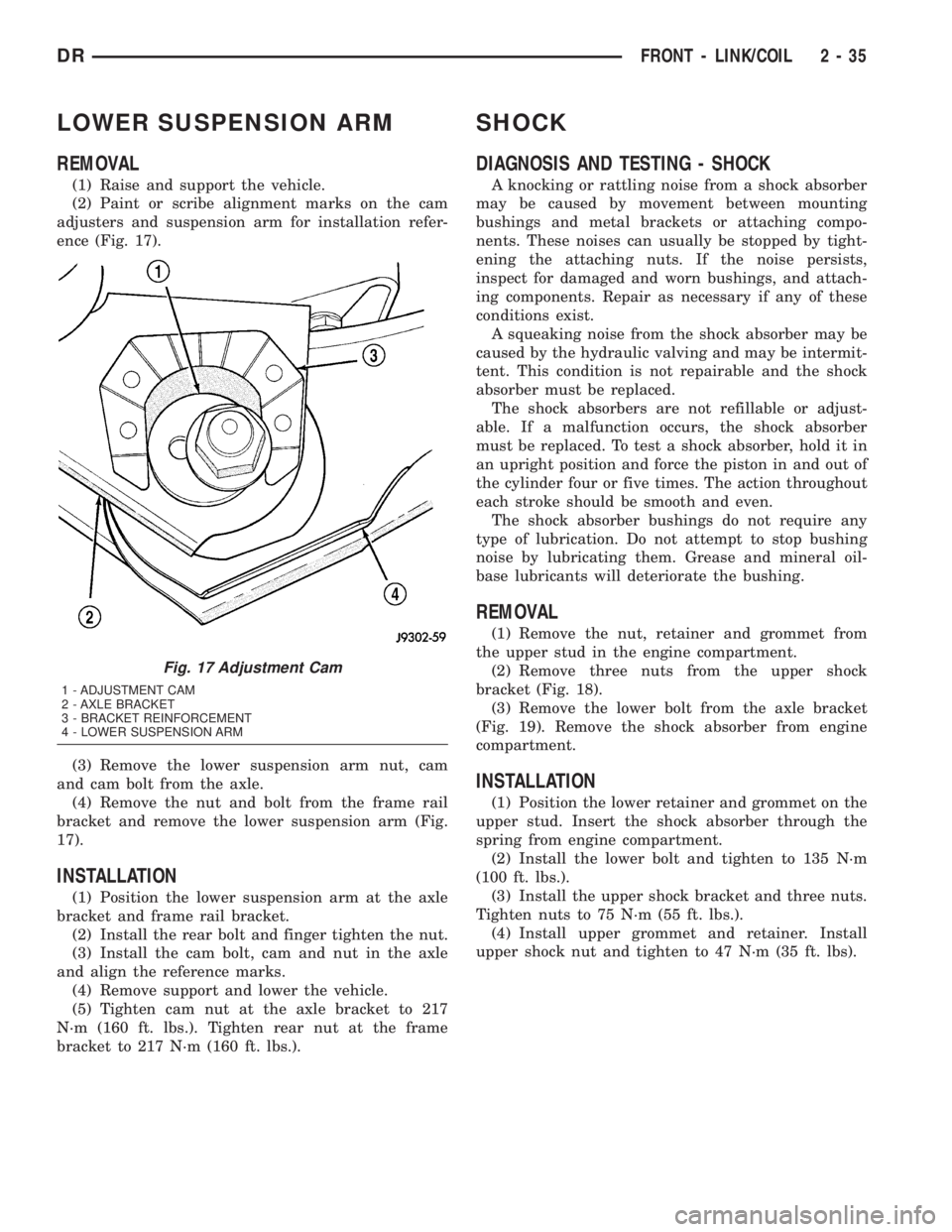

LOWER SUSPENSION ARM

REMOVAL

(1) Raise and support the vehicle.

(2) Paint or scribe alignment marks on the cam

adjusters and suspension arm for installation refer-

ence (Fig. 17).

(3) Remove the lower suspension arm nut, cam

and cam bolt from the axle.

(4) Remove the nut and bolt from the frame rail

bracket and remove the lower suspension arm (Fig.

17).

INSTALLATION

(1) Position the lower suspension arm at the axle

bracket and frame rail bracket.

(2) Install the rear bolt and finger tighten the nut.

(3) Install the cam bolt, cam and nut in the axle

and align the reference marks.

(4) Remove support and lower the vehicle.

(5) Tighten cam nut at the axle bracket to 217

N´m (160 ft. lbs.). Tighten rear nut at the frame

bracket to 217 N´m (160 ft. lbs.).

SHOCK

DIAGNOSIS AND TESTING - SHOCK

A knocking or rattling noise from a shock absorber

may be caused by movement between mounting

bushings and metal brackets or attaching compo-

nents. These noises can usually be stopped by tight-

ening the attaching nuts. If the noise persists,

inspect for damaged and worn bushings, and attach-

ing components. Repair as necessary if any of these

conditions exist.

A squeaking noise from the shock absorber may be

caused by the hydraulic valving and may be intermit-

tent. This condition is not repairable and the shock

absorber must be replaced.

The shock absorbers are not refillable or adjust-

able. If a malfunction occurs, the shock absorber

must be replaced. To test a shock absorber, hold it in

an upright position and force the piston in and out of

the cylinder four or five times. The action throughout

each stroke should be smooth and even.

The shock absorber bushings do not require any

type of lubrication. Do not attempt to stop bushing

noise by lubricating them. Grease and mineral oil-

base lubricants will deteriorate the bushing.

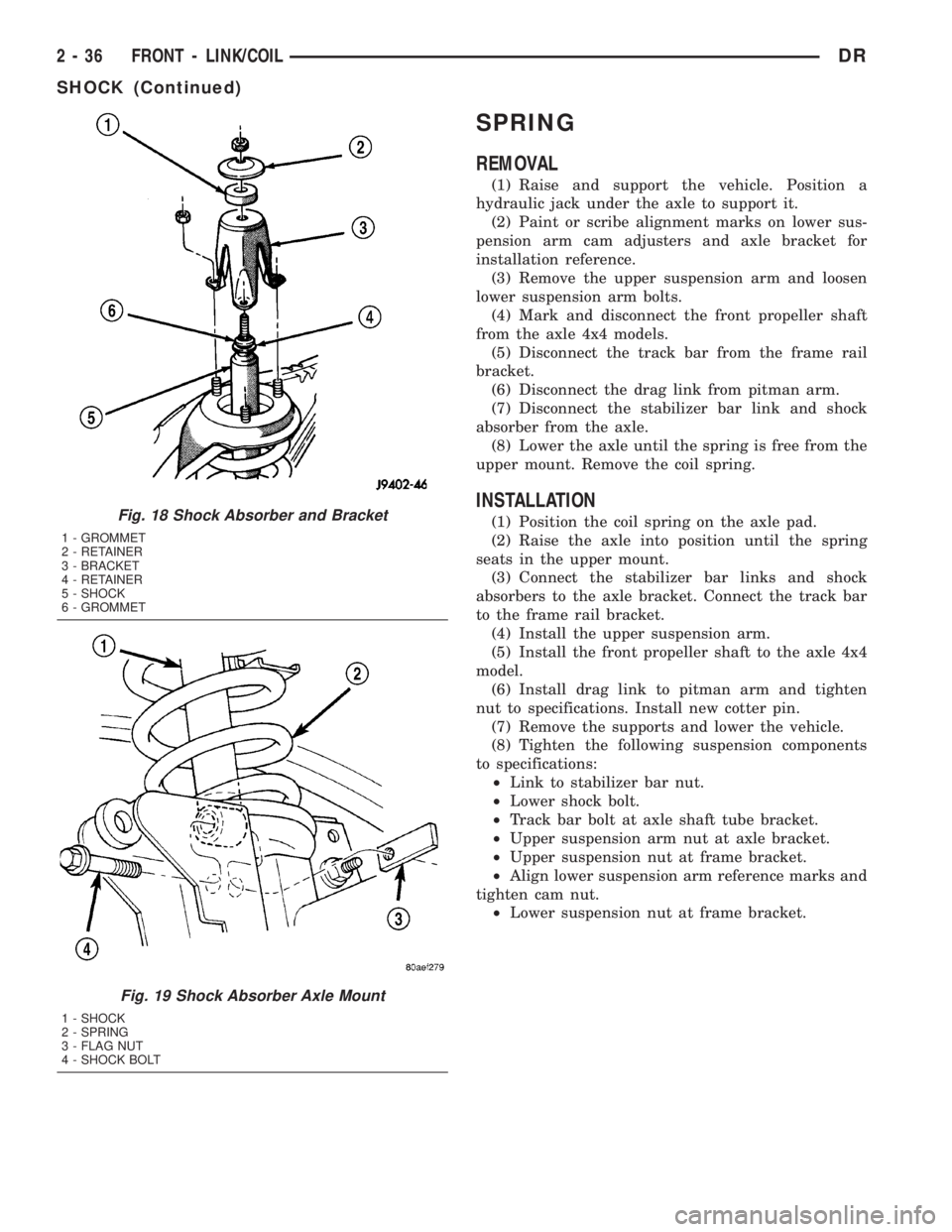

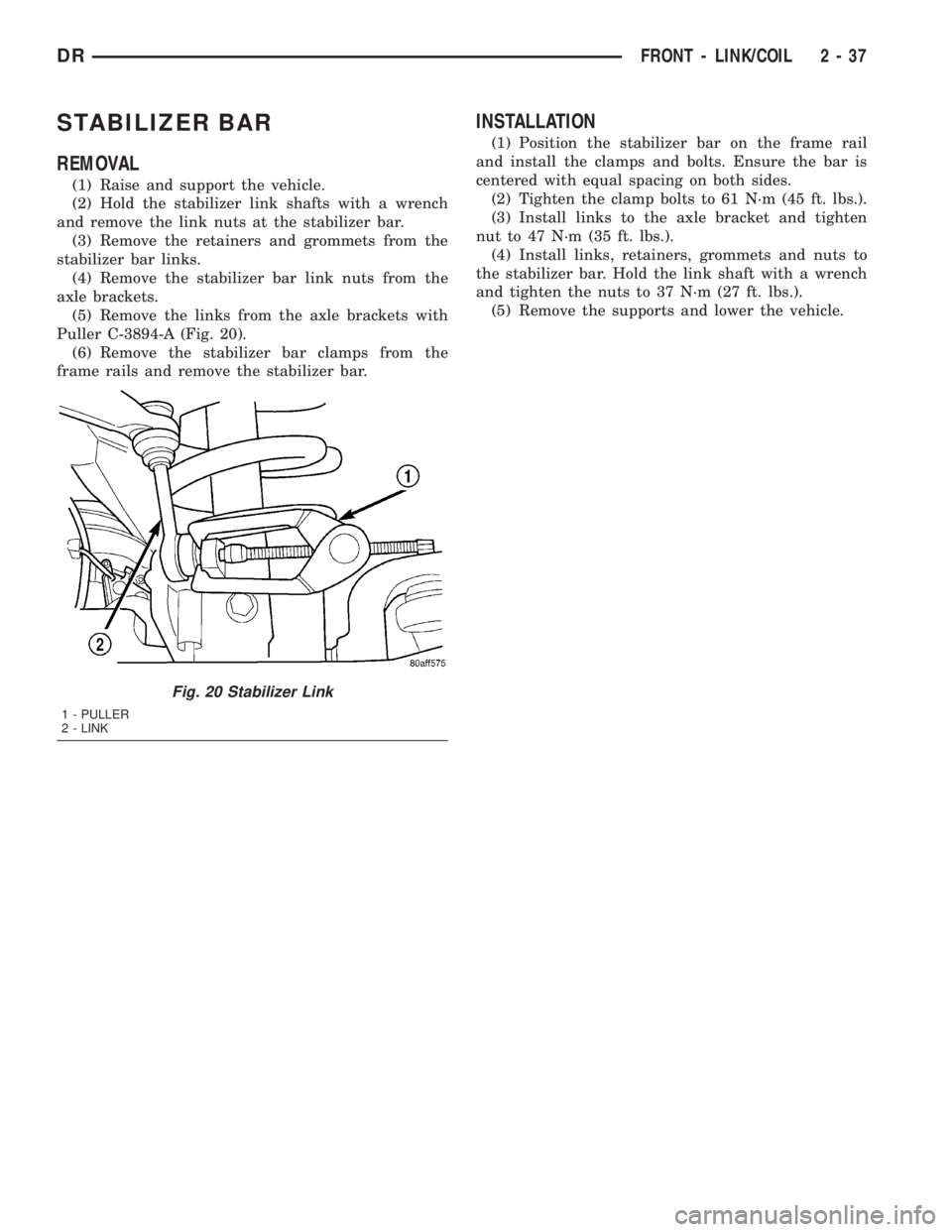

REMOVAL

(1) Remove the nut, retainer and grommet from

the upper stud in the engine compartment.

(2) Remove three nuts from the upper shock

bracket (Fig. 18).

(3) Remove the lower bolt from the axle bracket

(Fig. 19). Remove the shock absorber from engine

compartment.

INSTALLATION

(1) Position the lower retainer and grommet on the

upper stud. Insert the shock absorber through the

spring from engine compartment.

(2) Install the lower bolt and tighten to 135 N´m

(100 ft. lbs.).

(3) Install the upper shock bracket and three nuts.

Tighten nuts to 75 N´m (55 ft. lbs.).

(4) Install upper grommet and retainer. Install

upper shock nut and tighten to 47 N´m (35 ft. lbs).

Fig. 17 Adjustment Cam

1 - ADJUSTMENT CAM

2 - AXLE BRACKET

3 - BRACKET REINFORCEMENT

4 - LOWER SUSPENSION ARM

DRFRONT - LINK/COIL 2 - 35

Page 65 of 2895

SPRING

REMOVAL

(1) Raise and support the vehicle. Position a

hydraulic jack under the axle to support it.

(2) Paint or scribe alignment marks on lower sus-

pension arm cam adjusters and axle bracket for

installation reference.

(3) Remove the upper suspension arm and loosen

lower suspension arm bolts.

(4) Mark and disconnect the front propeller shaft

from the axle 4x4 models.

(5) Disconnect the track bar from the frame rail

bracket.

(6) Disconnect the drag link from pitman arm.

(7) Disconnect the stabilizer bar link and shock

absorber from the axle.

(8) Lower the axle until the spring is free from the

upper mount. Remove the coil spring.

INSTALLATION

(1) Position the coil spring on the axle pad.

(2) Raise the axle into position until the spring

seats in the upper mount.

(3) Connect the stabilizer bar links and shock

absorbers to the axle bracket. Connect the track bar

to the frame rail bracket.

(4) Install the upper suspension arm.

(5) Install the front propeller shaft to the axle 4x4

model.

(6) Install drag link to pitman arm and tighten

nut to specifications. Install new cotter pin.

(7) Remove the supports and lower the vehicle.

(8) Tighten the following suspension components

to specifications:

²Link to stabilizer bar nut.

²Lower shock bolt.

²Track bar bolt at axle shaft tube bracket.

²Upper suspension arm nut at axle bracket.

²Upper suspension nut at frame bracket.

²Align lower suspension arm reference marks and

tighten cam nut.

²Lower suspension nut at frame bracket.Fig. 18 Shock Absorber and Bracket

1 - GROMMET

2 - RETAINER

3 - BRACKET

4 - RETAINER

5 - SHOCK

6 - GROMMET

Fig. 19 Shock Absorber Axle Mount

1 - SHOCK

2 - SPRING

3 - FLAG NUT

4 - SHOCK BOLT

2 - 36 FRONT - LINK/COILDR

SHOCK (Continued)

Page 66 of 2895

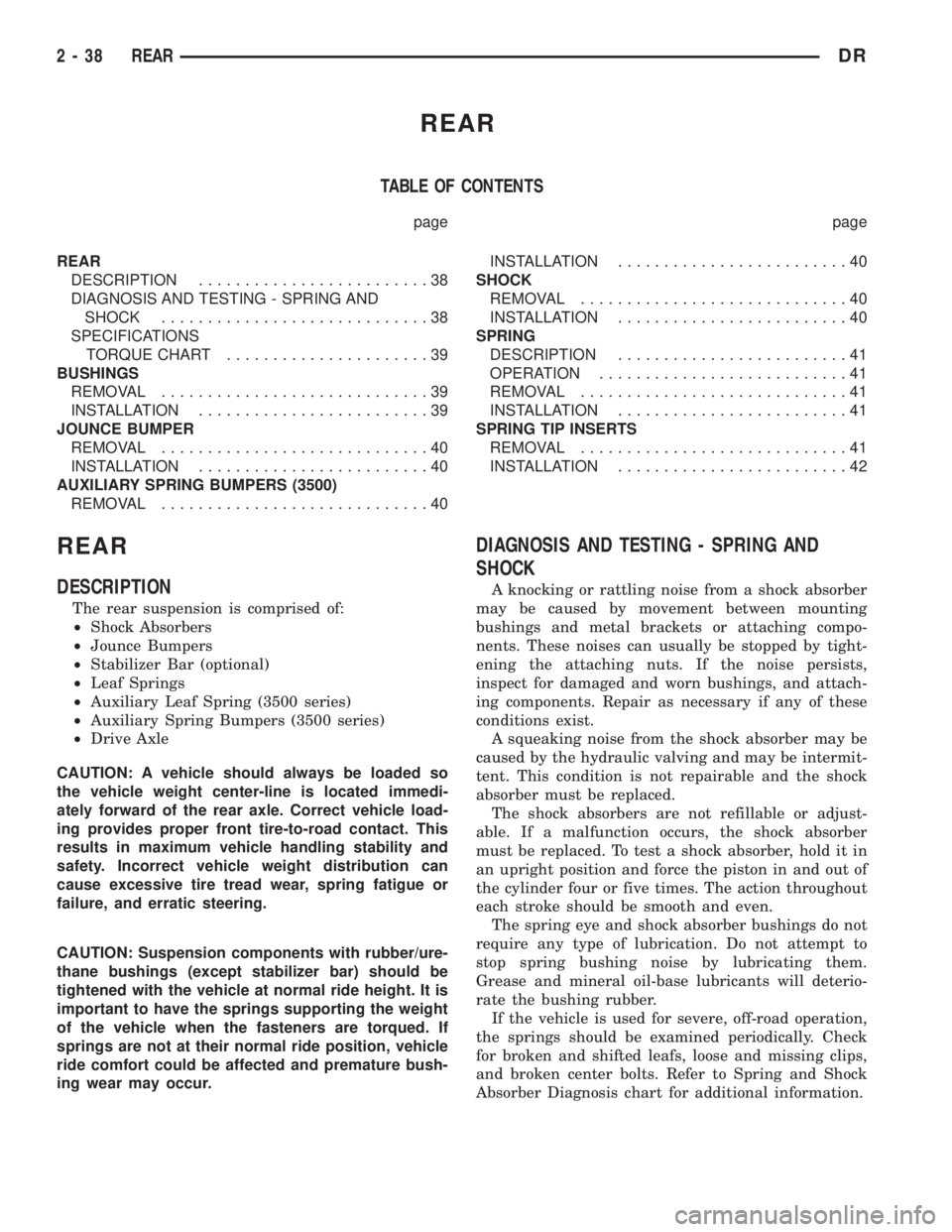

STABILIZER BAR

REMOVAL

(1) Raise and support the vehicle.

(2) Hold the stabilizer link shafts with a wrench

and remove the link nuts at the stabilizer bar.

(3) Remove the retainers and grommets from the

stabilizer bar links.

(4) Remove the stabilizer bar link nuts from the

axle brackets.

(5) Remove the links from the axle brackets with

Puller C-3894-A (Fig. 20).

(6) Remove the stabilizer bar clamps from the

frame rails and remove the stabilizer bar.

INSTALLATION

(1) Position the stabilizer bar on the frame rail

and install the clamps and bolts. Ensure the bar is

centered with equal spacing on both sides.

(2) Tighten the clamp bolts to 61 N´m (45 ft. lbs.).

(3) Install links to the axle bracket and tighten

nut to 47 N´m (35 ft. lbs.).

(4) Install links, retainers, grommets and nuts to

the stabilizer bar. Hold the link shaft with a wrench

and tighten the nuts to 37 N´m (27 ft. lbs.).

(5) Remove the supports and lower the vehicle.

Fig. 20 Stabilizer Link

1 - PULLER

2 - LINK

DRFRONT - LINK/COIL 2 - 37

Page 67 of 2895

REAR

TABLE OF CONTENTS

page page

REAR

DESCRIPTION.........................38

DIAGNOSIS AND TESTING - SPRING AND

SHOCK.............................38

SPECIFICATIONS

TORQUE CHART......................39

BUSHINGS

REMOVAL.............................39

INSTALLATION.........................39

JOUNCE BUMPER

REMOVAL.............................40

INSTALLATION.........................40

AUXILIARY SPRING BUMPERS (3500)

REMOVAL.............................40INSTALLATION.........................40

SHOCK

REMOVAL.............................40

INSTALLATION.........................40

SPRING

DESCRIPTION.........................41

OPERATION...........................41

REMOVAL.............................41

INSTALLATION.........................41

SPRING TIP INSERTS

REMOVAL.............................41

INSTALLATION.........................42

REAR

DESCRIPTION

The rear suspension is comprised of:

²Shock Absorbers

²Jounce Bumpers

²Stabilizer Bar (optional)

²Leaf Springs

²Auxiliary Leaf Spring (3500 series)

²Auxiliary Spring Bumpers (3500 series)

²Drive Axle

CAUTION: A vehicle should always be loaded so

the vehicle weight center-line is located immedi-

ately forward of the rear axle. Correct vehicle load-

ing provides proper front tire-to-road contact. This

results in maximum vehicle handling stability and

safety. Incorrect vehicle weight distribution can

cause excessive tire tread wear, spring fatigue or

failure, and erratic steering.

CAUTION: Suspension components with rubber/ure-

thane bushings (except stabilizer bar) should be

tightened with the vehicle at normal ride height. It is

important to have the springs supporting the weight

of the vehicle when the fasteners are torqued. If

springs are not at their normal ride position, vehicle

ride comfort could be affected and premature bush-

ing wear may occur.

DIAGNOSIS AND TESTING - SPRING AND

SHOCK

A knocking or rattling noise from a shock absorber

may be caused by movement between mounting

bushings and metal brackets or attaching compo-

nents. These noises can usually be stopped by tight-

ening the attaching nuts. If the noise persists,

inspect for damaged and worn bushings, and attach-

ing components. Repair as necessary if any of these

conditions exist.

A squeaking noise from the shock absorber may be

caused by the hydraulic valving and may be intermit-

tent. This condition is not repairable and the shock

absorber must be replaced.

The shock absorbers are not refillable or adjust-

able. If a malfunction occurs, the shock absorber

must be replaced. To test a shock absorber, hold it in

an upright position and force the piston in and out of

the cylinder four or five times. The action throughout

each stroke should be smooth and even.

The spring eye and shock absorber bushings do not

require any type of lubrication. Do not attempt to

stop spring bushing noise by lubricating them.

Grease and mineral oil-base lubricants will deterio-

rate the bushing rubber.

If the vehicle is used for severe, off-road operation,

the springs should be examined periodically. Check

for broken and shifted leafs, loose and missing clips,

and broken center bolts. Refer to Spring and Shock

Absorber Diagnosis chart for additional information.

2 - 38 REARDR

Page 68 of 2895

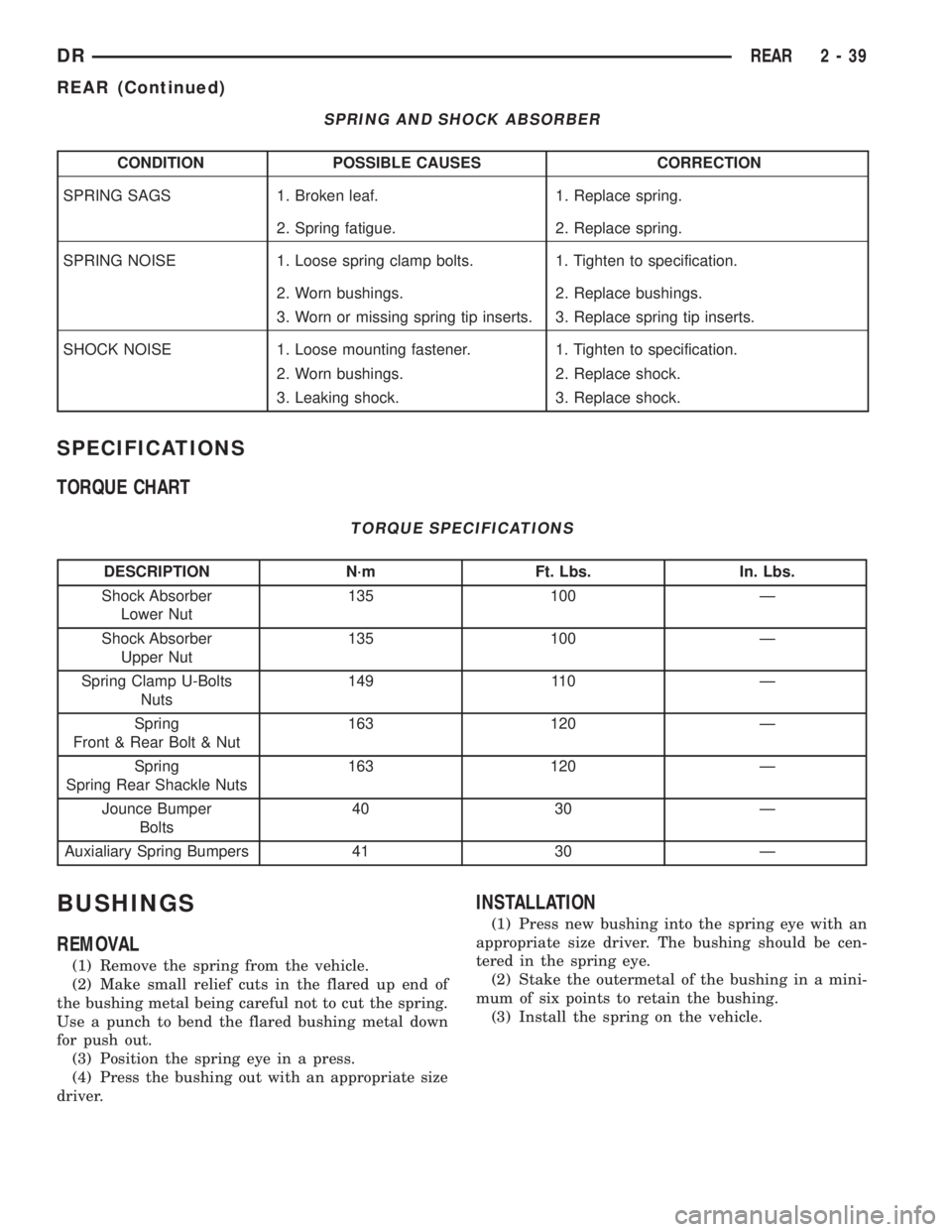

SPRING AND SHOCK ABSORBER

CONDITION POSSIBLE CAUSES CORRECTION

SPRING SAGS 1. Broken leaf. 1. Replace spring.

2. Spring fatigue. 2. Replace spring.

SPRING NOISE 1. Loose spring clamp bolts. 1. Tighten to specification.

2. Worn bushings. 2. Replace bushings.

3. Worn or missing spring tip inserts. 3. Replace spring tip inserts.

SHOCK NOISE 1. Loose mounting fastener. 1. Tighten to specification.

2. Worn bushings. 2. Replace shock.

3. Leaking shock. 3. Replace shock.

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Shock Absorber

Lower Nut135 100 Ð

Shock Absorber

Upper Nut135 100 Ð

Spring Clamp U-Bolts

Nuts149 110 Ð

Spring

Front & Rear Bolt & Nut163 120 Ð

Spring

Spring Rear Shackle Nuts163 120 Ð

Jounce Bumper

Bolts40 30 Ð

Auxialiary Spring Bumpers 41 30 Ð

BUSHINGS

REMOVAL

(1) Remove the spring from the vehicle.

(2) Make small relief cuts in the flared up end of

the bushing metal being careful not to cut the spring.

Use a punch to bend the flared bushing metal down

for push out.

(3) Position the spring eye in a press.

(4) Press the bushing out with an appropriate size

driver.

INSTALLATION

(1) Press new bushing into the spring eye with an

appropriate size driver. The bushing should be cen-

tered in the spring eye.

(2) Stake the outermetal of the bushing in a mini-

mum of six points to retain the bushing.

(3) Install the spring on the vehicle.

DRREAR 2 - 39

REAR (Continued)

Page 69 of 2895

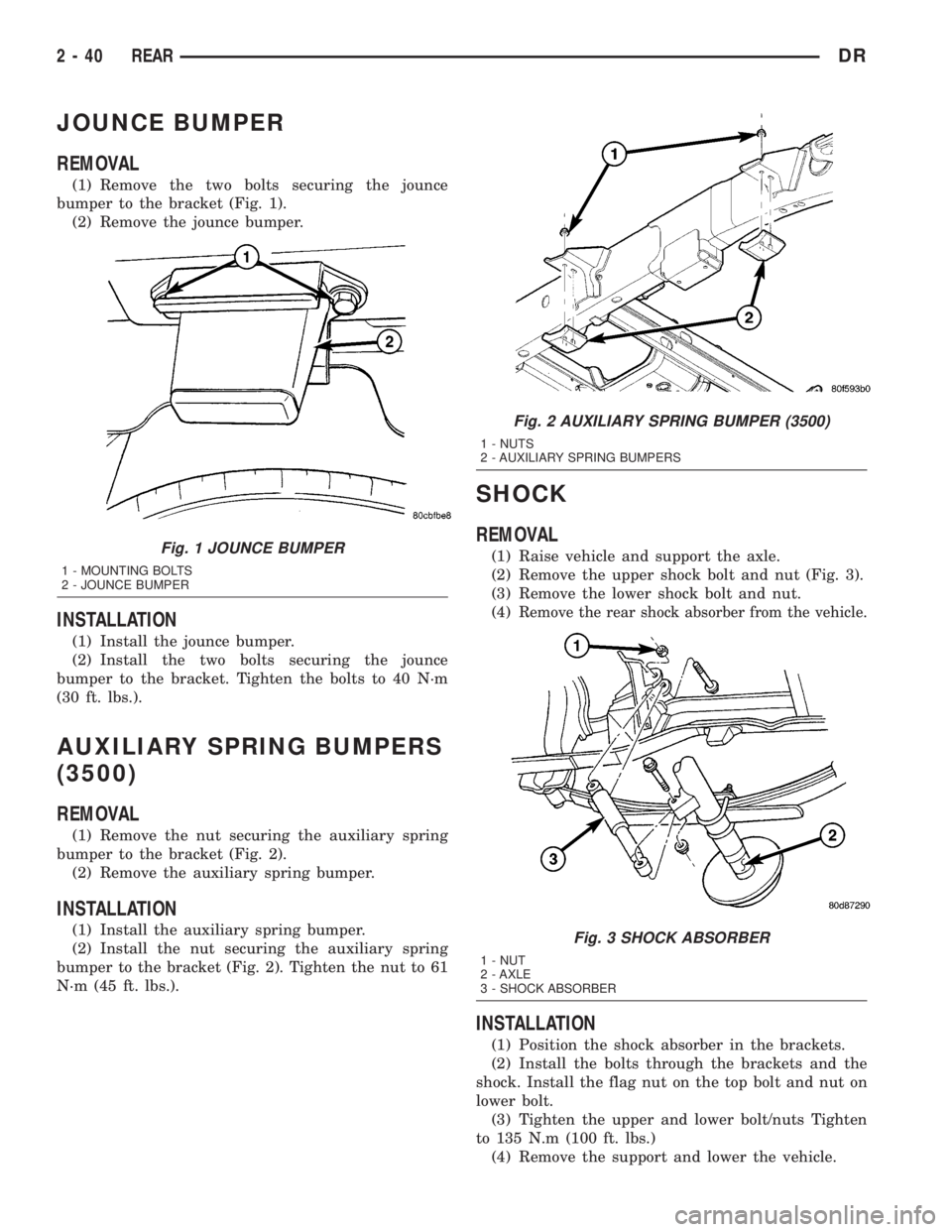

JOUNCE BUMPER

REMOVAL

(1) Remove the two bolts securing the jounce

bumper to the bracket (Fig. 1).

(2) Remove the jounce bumper.

INSTALLATION

(1) Install the jounce bumper.

(2) Install the two bolts securing the jounce

bumper to the bracket. Tighten the bolts to 40 N´m

(30 ft. lbs.).

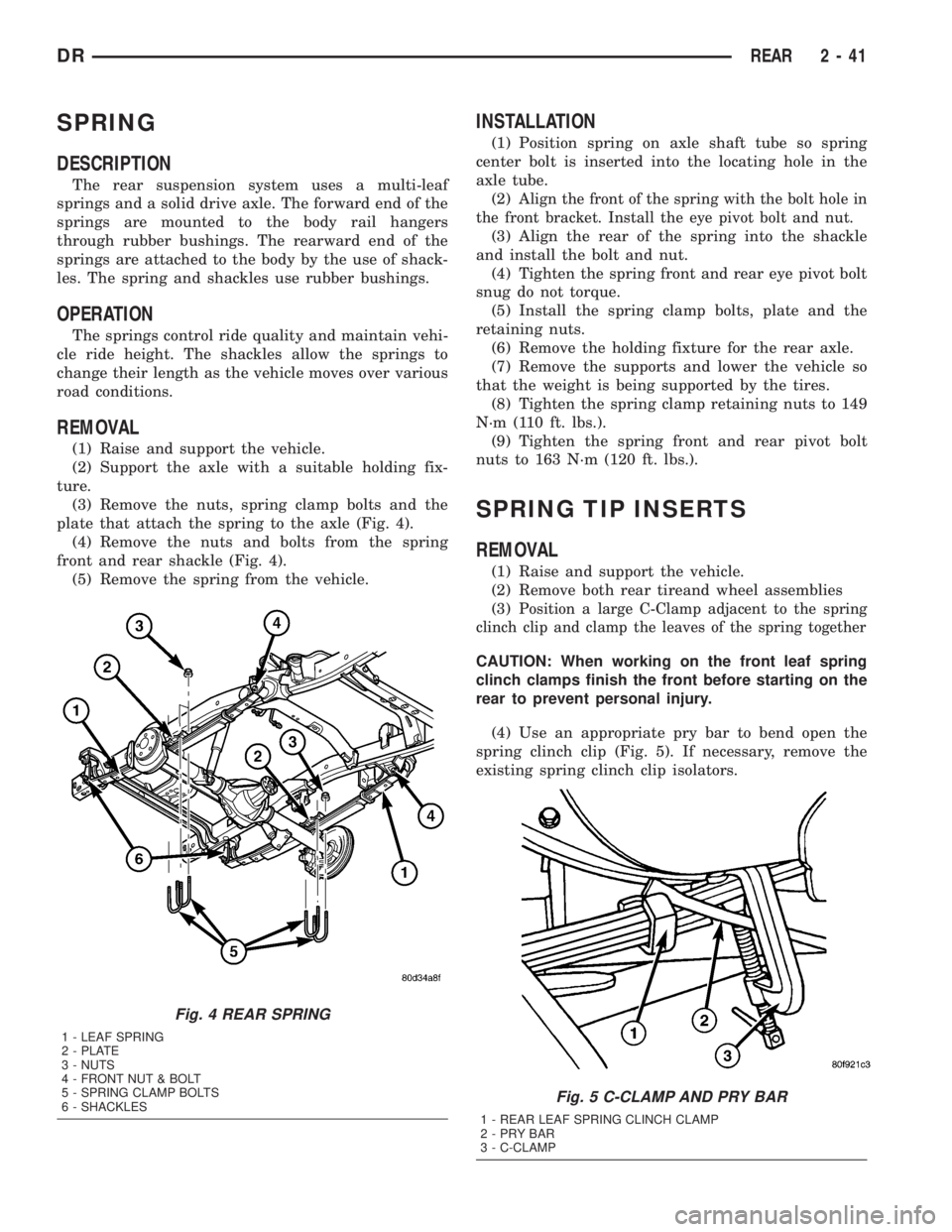

AUXILIARY SPRING BUMPERS

(3500)

REMOVAL

(1) Remove the nut securing the auxiliary spring

bumper to the bracket (Fig. 2).

(2) Remove the auxiliary spring bumper.

INSTALLATION

(1) Install the auxiliary spring bumper.

(2) Install the nut securing the auxiliary spring

bumper to the bracket (Fig. 2). Tighten the nut to 61

N´m (45 ft. lbs.).

SHOCK

REMOVAL

(1) Raise vehicle and support the axle.

(2) Remove the upper shock bolt and nut (Fig. 3).

(3) Remove the lower shock bolt and nut.

(4)

Remove the rear shock absorber from the vehicle.

INSTALLATION

(1) Position the shock absorber in the brackets.

(2) Install the bolts through the brackets and the

shock. Install the flag nut on the top bolt and nut on

lower bolt.

(3) Tighten the upper and lower bolt/nuts Tighten

to 135 N.m (100 ft. lbs.)

(4) Remove the support and lower the vehicle.

Fig. 1 JOUNCE BUMPER

1 - MOUNTING BOLTS

2 - JOUNCE BUMPER

Fig. 2 AUXILIARY SPRING BUMPER (3500)

1 - NUTS

2 - AUXILIARY SPRING BUMPERS

Fig. 3 SHOCK ABSORBER

1 - NUT

2 - AXLE

3 - SHOCK ABSORBER

2 - 40 REARDR

Page 70 of 2895

SPRING

DESCRIPTION

The rear suspension system uses a multi-leaf

springs and a solid drive axle. The forward end of the

springs are mounted to the body rail hangers

through rubber bushings. The rearward end of the

springs are attached to the body by the use of shack-

les. The spring and shackles use rubber bushings.

OPERATION

The springs control ride quality and maintain vehi-

cle ride height. The shackles allow the springs to

change their length as the vehicle moves over various

road conditions.

REMOVAL

(1) Raise and support the vehicle.

(2) Support the axle with a suitable holding fix-

ture.

(3) Remove the nuts, spring clamp bolts and the

plate that attach the spring to the axle (Fig. 4).

(4) Remove the nuts and bolts from the spring

front and rear shackle (Fig. 4).

(5) Remove the spring from the vehicle.

INSTALLATION

(1) Position spring on axle shaft tube so spring

center bolt is inserted into the locating hole in the

axle tube.

(2)

Align the front of the spring with the bolt hole in

the front bracket. Install the eye pivot bolt and nut.

(3) Align the rear of the spring into the shackle

and install the bolt and nut.

(4) Tighten the spring front and rear eye pivot bolt

snug do not torque.

(5) Install the spring clamp bolts, plate and the

retaining nuts.

(6) Remove the holding fixture for the rear axle.

(7) Remove the supports and lower the vehicle so

that the weight is being supported by the tires.

(8) Tighten the spring clamp retaining nuts to 149

N´m (110 ft. lbs.).

(9) Tighten the spring front and rear pivot bolt

nuts to 163 N´m (120 ft. lbs.).

SPRING TIP INSERTS

REMOVAL

(1) Raise and support the vehicle.

(2) Remove both rear tireand wheel assemblies

(3)

Position a large C-Clamp adjacent to the spring

clinch clip and clamp the leaves of the spring together

CAUTION: When working on the front leaf spring

clinch clamps finish the front before starting on the

rear to prevent personal injury.

(4) Use an appropriate pry bar to bend open the

spring clinch clip (Fig. 5). If necessary, remove the

existing spring clinch clip isolators.

Fig. 4 REAR SPRING

1 - LEAF SPRING

2 - PLATE

3 - NUTS

4 - FRONT NUT & BOLT

5 - SPRING CLAMP BOLTS

6 - SHACKLES

Fig. 5 C-CLAMP AND PRY BAR

1 - REAR LEAF SPRING CLINCH CLAMP

2-PRYBAR

3 - C-CLAMP

DRREAR 2 - 41