DODGE RAM 2003 Service Workshop Manual

Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 51 of 2895

NOTE: Do not allow the upper control arm and

steering knuckle to rebound downwards they must

be supported.Support the upper control arm and

steering knuckle out of the way.

(11) Remove the lower control arm support.

(12) Tighten the spring compressor tool to allow

clearance for the lower ball joint to be removed out of

the knuckle.

NOTE: It may necessary to loosen the control arm

pivot bolt to allow downward swing.

(13) Loosen the tension on the spring compressor

tool slowly allowing the lower suspension arm to

pivot downward.

(14) Remove the spring compressor tool.

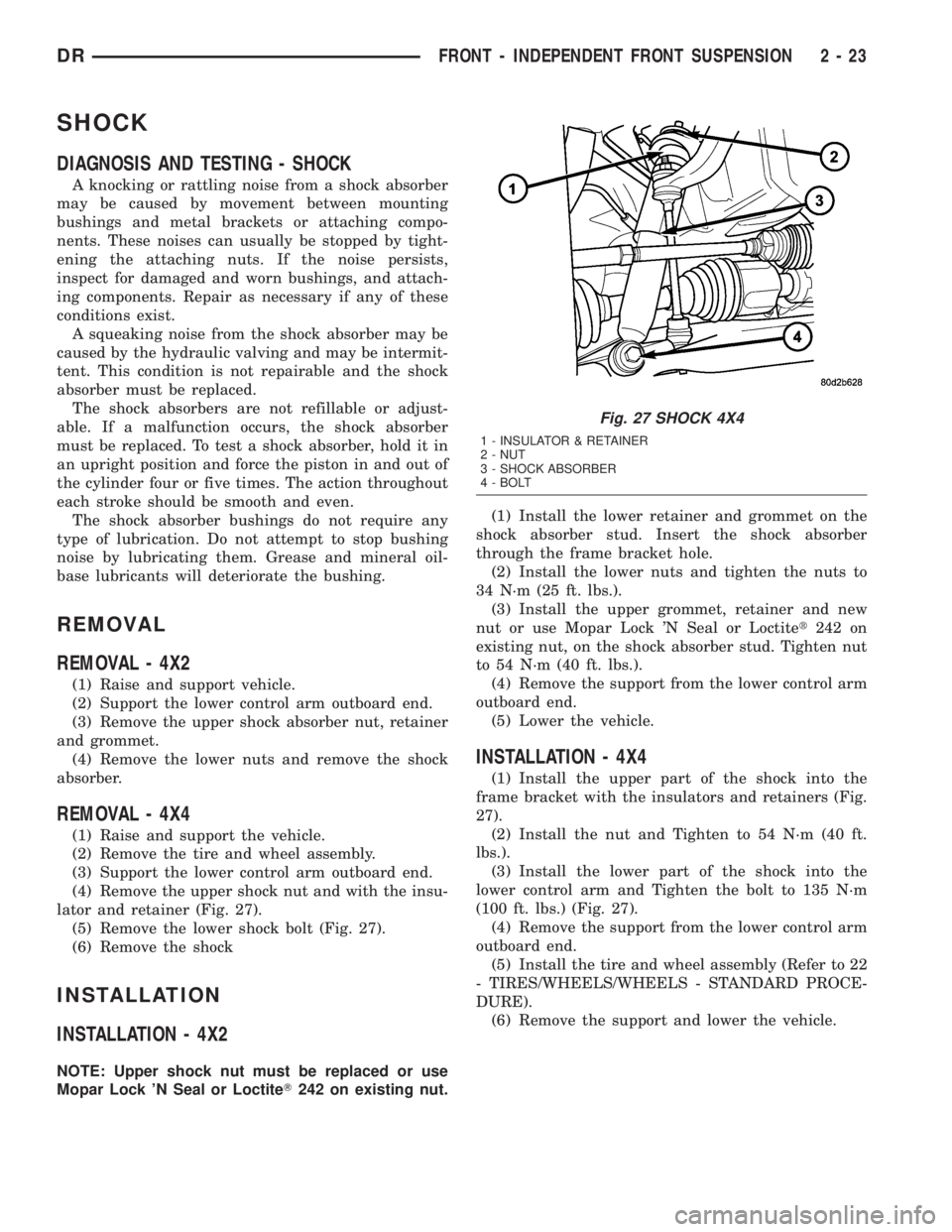

(15) Remove coil spring and isolator pad from the

vehicle (Fig. 26).

INSTALLATION

(1) Tape the isolator pad to the top of the coil

spring. Position the spring in the lower suspension

arm well. Be sure that the coil spring is seated in the

well.

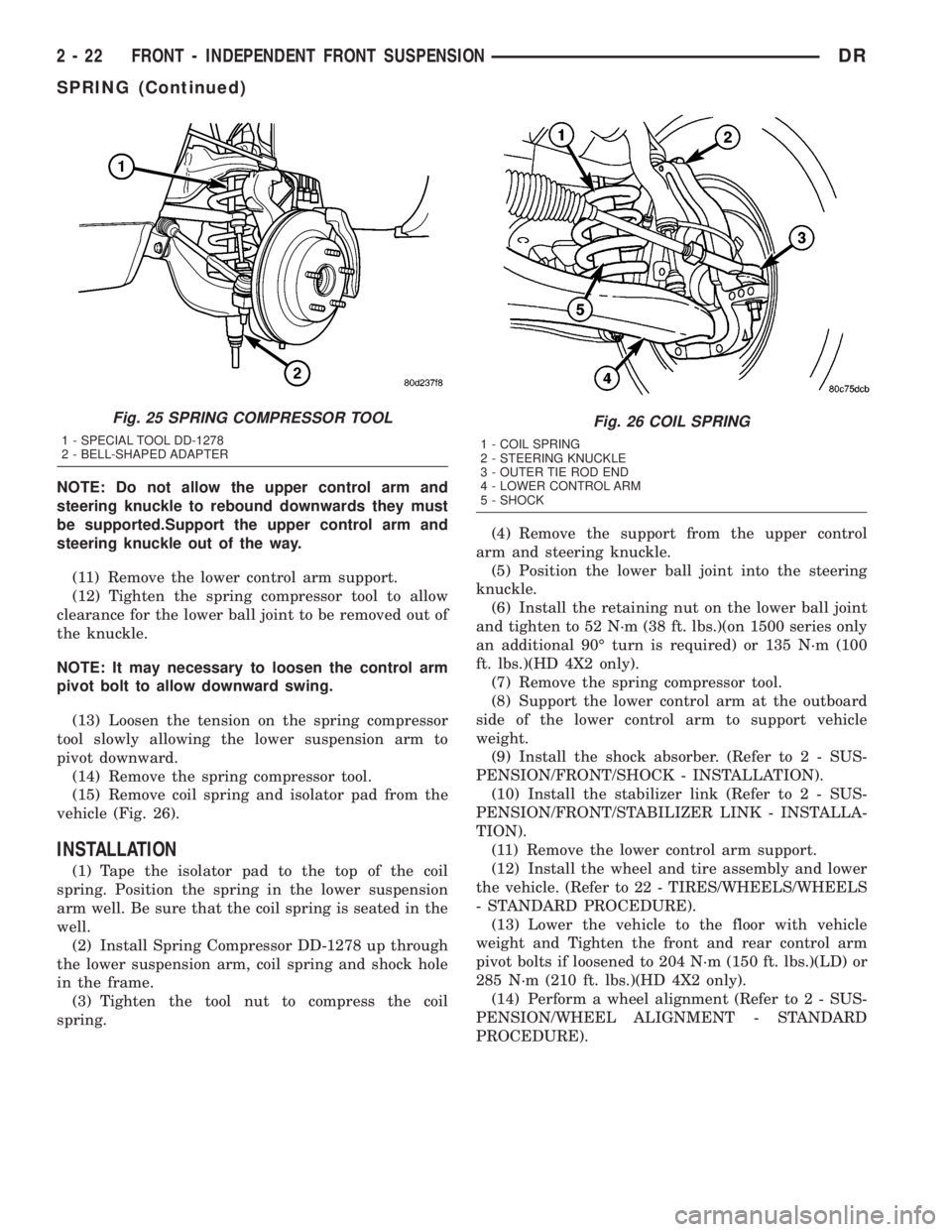

(2) Install Spring Compressor DD-1278 up through

the lower suspension arm, coil spring and shock hole

in the frame.

(3) Tighten the tool nut to compress the coil

spring.(4) Remove the support from the upper control

arm and steering knuckle.

(5) Position the lower ball joint into the steering

knuckle.

(6) Install the retaining nut on the lower ball joint

and tighten to 52 N´m (38 ft. lbs.)(on 1500 series only

an additional 90É turn is required) or 135 N´m (100

ft. lbs.)(HD 4X2 only).

(7) Remove the spring compressor tool.

(8) Support the lower control arm at the outboard

side of the lower control arm to support vehicle

weight.

(9) Install the shock absorber. (Refer to 2 - SUS-

PENSION/FRONT/SHOCK - INSTALLATION).

(10) Install the stabilizer link (Refer to 2 - SUS-

PENSION/FRONT/STABILIZER LINK - INSTALLA-

TION).

(11) Remove the lower control arm support.

(12) Install the wheel and tire assembly and lower

the vehicle. (Refer to 22 - TIRES/WHEELS/WHEELS

- STANDARD PROCEDURE).

(13) Lower the vehicle to the floor with vehicle

weight and Tighten the front and rear control arm

pivot bolts if loosened to 204 N´m (150 ft. lbs.)(LD) or

285 N´m (210 ft. lbs.)(HD 4X2 only).

(14) Perform a wheel alignment (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

Fig. 25 SPRING COMPRESSOR TOOL

1 - SPECIAL TOOL DD-1278

2 - BELL-SHAPED ADAPTER

Fig. 26 COIL SPRING

1 - COIL SPRING

2 - STEERING KNUCKLE

3 - OUTER TIE ROD END

4 - LOWER CONTROL ARM

5 - SHOCK

2 - 22 FRONT - INDEPENDENT FRONT SUSPENSIONDR

SPRING (Continued)

Page 52 of 2895

SHOCK

DIAGNOSIS AND TESTING - SHOCK

A knocking or rattling noise from a shock absorber

may be caused by movement between mounting

bushings and metal brackets or attaching compo-

nents. These noises can usually be stopped by tight-

ening the attaching nuts. If the noise persists,

inspect for damaged and worn bushings, and attach-

ing components. Repair as necessary if any of these

conditions exist.

A squeaking noise from the shock absorber may be

caused by the hydraulic valving and may be intermit-

tent. This condition is not repairable and the shock

absorber must be replaced.

The shock absorbers are not refillable or adjust-

able. If a malfunction occurs, the shock absorber

must be replaced. To test a shock absorber, hold it in

an upright position and force the piston in and out of

the cylinder four or five times. The action throughout

each stroke should be smooth and even.

The shock absorber bushings do not require any

type of lubrication. Do not attempt to stop bushing

noise by lubricating them. Grease and mineral oil-

base lubricants will deteriorate the bushing.

REMOVAL

REMOVAL - 4X2

(1) Raise and support vehicle.

(2) Support the lower control arm outboard end.

(3) Remove the upper shock absorber nut, retainer

and grommet.

(4) Remove the lower nuts and remove the shock

absorber.

REMOVAL - 4X4

(1) Raise and support the vehicle.

(2) Remove the tire and wheel assembly.

(3) Support the lower control arm outboard end.

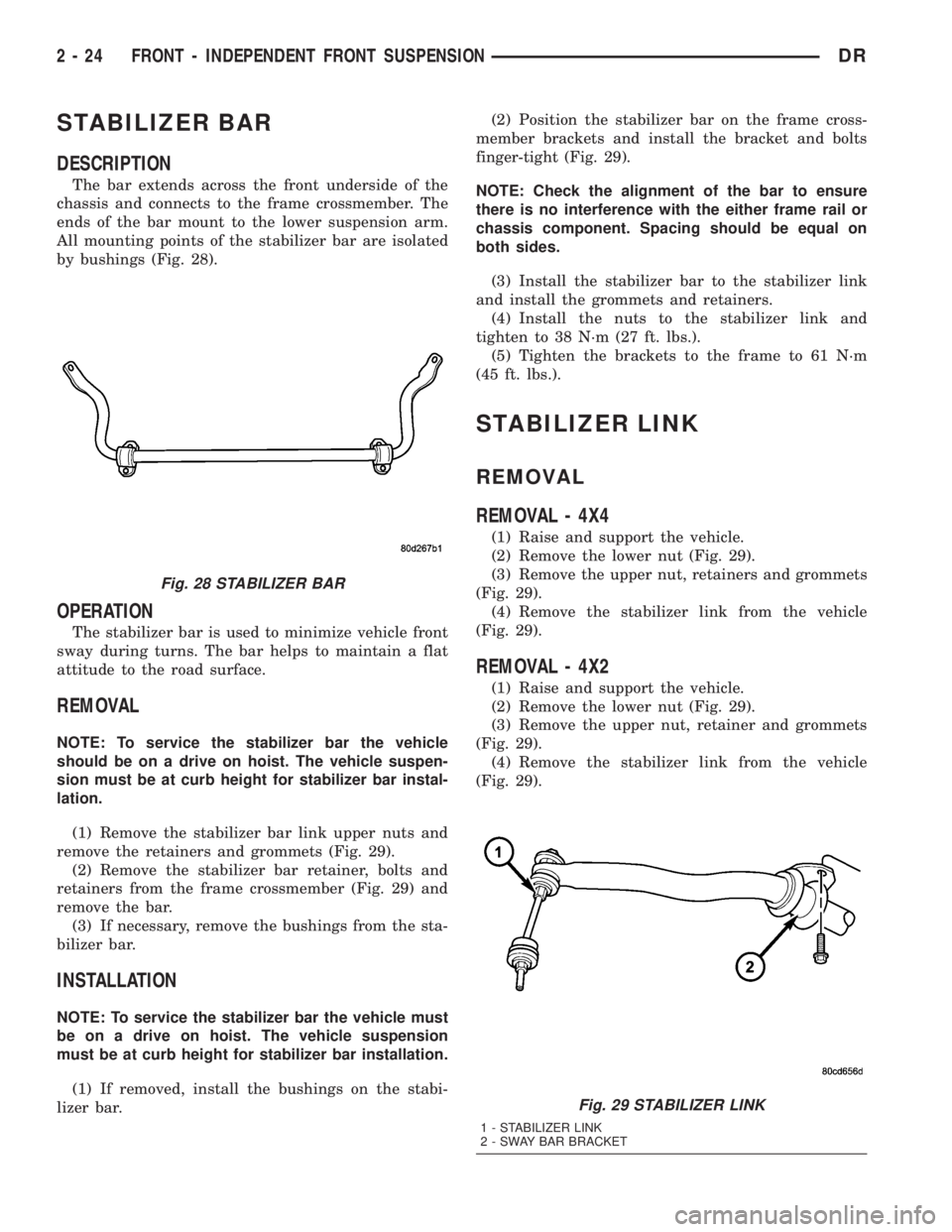

(4) Remove the upper shock nut and with the insu-

lator and retainer (Fig. 27).

(5) Remove the lower shock bolt (Fig. 27).

(6) Remove the shock

INSTALLATION

INSTALLATION - 4X2

NOTE: Upper shock nut must be replaced or use

Mopar Lock 'N Seal or LoctiteT242 on existing nut.(1) Install the lower retainer and grommet on the

shock absorber stud. Insert the shock absorber

through the frame bracket hole.

(2) Install the lower nuts and tighten the nuts to

34 N´m (25 ft. lbs.).

(3) Install the upper grommet, retainer and new

nut or use Mopar Lock 'N Seal or Loctitet242 on

existing nut, on the shock absorber stud. Tighten nut

to 54 N´m (40 ft. lbs.).

(4) Remove the support from the lower control arm

outboard end.

(5) Lower the vehicle.

INSTALLATION - 4X4

(1) Install the upper part of the shock into the

frame bracket with the insulators and retainers (Fig.

27).

(2) Install the nut and Tighten to 54 N´m (40 ft.

lbs.).

(3) Install the lower part of the shock into the

lower control arm and Tighten the bolt to 135 N´m

(100 ft. lbs.) (Fig. 27).

(4) Remove the support from the lower control arm

outboard end.

(5) Install the tire and wheel assembly (Refer to 22

- TIRES/WHEELS/WHEELS - STANDARD PROCE-

DURE).

(6) Remove the support and lower the vehicle.

Fig. 27 SHOCK 4X4

1 - INSULATOR & RETAINER

2 - NUT

3 - SHOCK ABSORBER

4 - BOLT

DRFRONT - INDEPENDENT FRONT SUSPENSION 2 - 23

Page 53 of 2895

STABILIZER BAR

DESCRIPTION

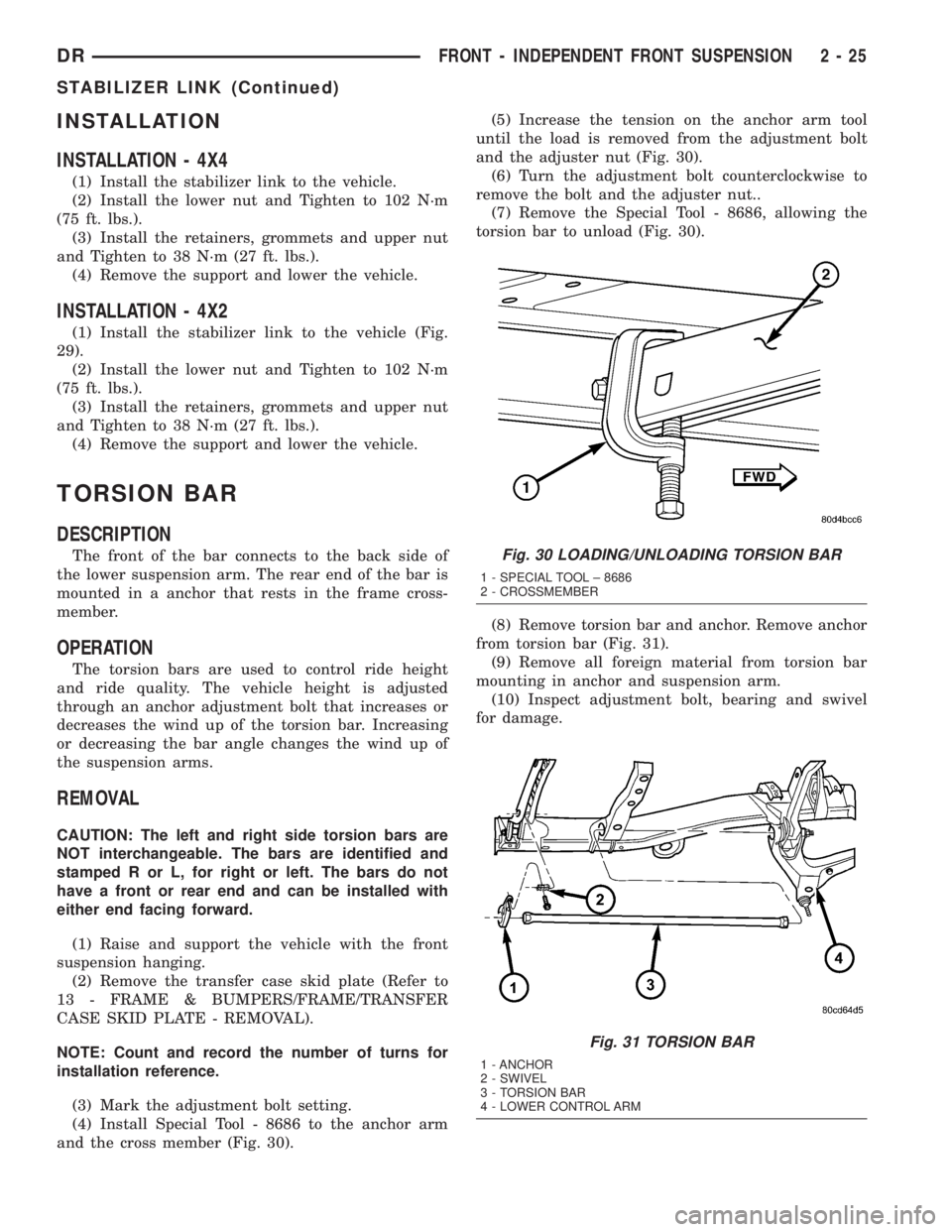

The bar extends across the front underside of the

chassis and connects to the frame crossmember. The

ends of the bar mount to the lower suspension arm.

All mounting points of the stabilizer bar are isolated

by bushings (Fig. 28).

OPERATION

The stabilizer bar is used to minimize vehicle front

sway during turns. The bar helps to maintain a flat

attitude to the road surface.

REMOVAL

NOTE: To service the stabilizer bar the vehicle

should be on a drive on hoist. The vehicle suspen-

sion must be at curb height for stabilizer bar instal-

lation.

(1) Remove the stabilizer bar link upper nuts and

remove the retainers and grommets (Fig. 29).

(2) Remove the stabilizer bar retainer, bolts and

retainers from the frame crossmember (Fig. 29) and

remove the bar.

(3) If necessary, remove the bushings from the sta-

bilizer bar.

INSTALLATION

NOTE: To service the stabilizer bar the vehicle must

be on a drive on hoist. The vehicle suspension

must be at curb height for stabilizer bar installation.

(1) If removed, install the bushings on the stabi-

lizer bar.(2) Position the stabilizer bar on the frame cross-

member brackets and install the bracket and bolts

finger-tight (Fig. 29).

NOTE: Check the alignment of the bar to ensure

there is no interference with the either frame rail or

chassis component. Spacing should be equal on

both sides.

(3) Install the stabilizer bar to the stabilizer link

and install the grommets and retainers.

(4) Install the nuts to the stabilizer link and

tighten to 38 N´m (27 ft. lbs.).

(5) Tighten the brackets to the frame to 61 N´m

(45 ft. lbs.).

STABILIZER LINK

REMOVAL

REMOVAL - 4X4

(1) Raise and support the vehicle.

(2) Remove the lower nut (Fig. 29).

(3) Remove the upper nut, retainers and grommets

(Fig. 29).

(4) Remove the stabilizer link from the vehicle

(Fig. 29).

REMOVAL - 4X2

(1) Raise and support the vehicle.

(2) Remove the lower nut (Fig. 29).

(3) Remove the upper nut, retainer and grommets

(Fig. 29).

(4) Remove the stabilizer link from the vehicle

(Fig. 29).

Fig. 28 STABILIZER BAR

Fig. 29 STABILIZER LINK

1 - STABILIZER LINK

2 - SWAY BAR BRACKET

2 - 24 FRONT - INDEPENDENT FRONT SUSPENSIONDR

Page 54 of 2895

INSTALLATION

INSTALLATION - 4X4

(1) Install the stabilizer link to the vehicle.

(2) Install the lower nut and Tighten to 102 N´m

(75 ft. lbs.).

(3) Install the retainers, grommets and upper nut

and Tighten to 38 N´m (27 ft. lbs.).

(4) Remove the support and lower the vehicle.

INSTALLATION - 4X2

(1) Install the stabilizer link to the vehicle (Fig.

29).

(2) Install the lower nut and Tighten to 102 N´m

(75 ft. lbs.).

(3) Install the retainers, grommets and upper nut

and Tighten to 38 N´m (27 ft. lbs.).

(4) Remove the support and lower the vehicle.

TORSION BAR

DESCRIPTION

The front of the bar connects to the back side of

the lower suspension arm. The rear end of the bar is

mounted in a anchor that rests in the frame cross-

member.

OPERATION

The torsion bars are used to control ride height

and ride quality. The vehicle height is adjusted

through an anchor adjustment bolt that increases or

decreases the wind up of the torsion bar. Increasing

or decreasing the bar angle changes the wind up of

the suspension arms.

REMOVAL

CAUTION: The left and right side torsion bars are

NOT interchangeable. The bars are identified and

stamped R or L, for right or left. The bars do not

have a front or rear end and can be installed with

either end facing forward.

(1) Raise and support the vehicle with the front

suspension hanging.

(2) Remove the transfer case skid plate (Refer to

13 - FRAME & BUMPERS/FRAME/TRANSFER

CASE SKID PLATE - REMOVAL).

NOTE: Count and record the number of turns for

installation reference.

(3) Mark the adjustment bolt setting.

(4) Install Special Tool - 8686 to the anchor arm

and the cross member (Fig. 30).(5) Increase the tension on the anchor arm tool

until the load is removed from the adjustment bolt

and the adjuster nut (Fig. 30).

(6) Turn the adjustment bolt counterclockwise to

remove the bolt and the adjuster nut..

(7) Remove the Special Tool - 8686, allowing the

torsion bar to unload (Fig. 30).

(8) Remove torsion bar and anchor. Remove anchor

from torsion bar (Fig. 31).

(9) Remove all foreign material from torsion bar

mounting in anchor and suspension arm.

(10) Inspect adjustment bolt, bearing and swivel

for damage.

Fig. 30 LOADING/UNLOADING TORSION BAR

1 - SPECIAL TOOL ± 8686

2 - CROSSMEMBER

Fig. 31 TORSION BAR

1 - ANCHOR

2 - SWIVEL

3 - TORSION BAR

4 - LOWER CONTROL ARM

DRFRONT - INDEPENDENT FRONT SUSPENSION 2 - 25

STABILIZER LINK (Continued)

Page 55 of 2895

INSTALLATION

CAUTION: The left and right side torsion bars are

NOT interchangeable. The bars are identified and

stamped R or L, for right or left. The bars do not

have a front or rear end and can be installed with

either end facing forward.

(1) Insert torsion bar ends into anchor and suspen-

sion arm.

(2) Position the anchor in the frame crossmember.

(3) Install Special Tool - 8686 to the anchor and

the crossmember (Fig. 30).

(4) Increase the tension on the anchor in order to

load the torsion bar.

(5) Install the adjustment bolt and the adjuster

nut.

(6) Turn adjustment bolt clockwise the recorded

amount of turns.

(7) Remove tool - 8686 from the torsion bar cross-

member (Fig. 30).

(8) Install the transfer case skid plate (Refer to 13

- FRAME & BUMPERS/FRAME/TRANSFER CASE

SKID PLATE - INSTALLATION).

(9) Lower vehicle and adjust the front suspension

height (Refer to 2 - SUSPENSION/WHEEL ALIGN-

MENT - STANDARD PROCEDURE).

(10) Perform a wheel alignment (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

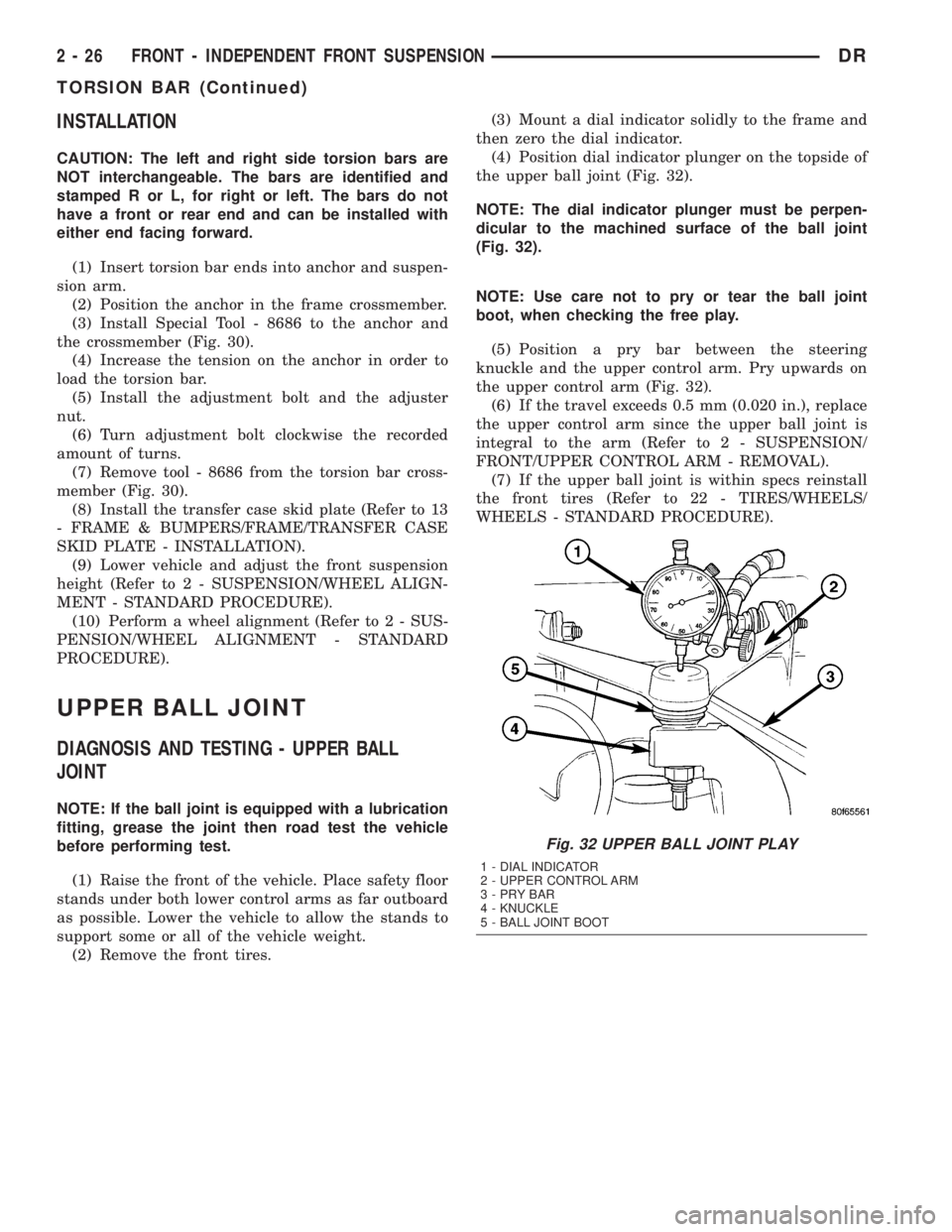

UPPER BALL JOINT

DIAGNOSIS AND TESTING - UPPER BALL

JOINT

NOTE: If the ball joint is equipped with a lubrication

fitting, grease the joint then road test the vehicle

before performing test.

(1) Raise the front of the vehicle. Place safety floor

stands under both lower control arms as far outboard

as possible. Lower the vehicle to allow the stands to

support some or all of the vehicle weight.

(2) Remove the front tires.(3) Mount a dial indicator solidly to the frame and

then zero the dial indicator.

(4) Position dial indicator plunger on the topside of

the upper ball joint (Fig. 32).

NOTE: The dial indicator plunger must be perpen-

dicular to the machined surface of the ball joint

(Fig. 32).

NOTE: Use care not to pry or tear the ball joint

boot, when checking the free play.

(5) Position a pry bar between the steering

knuckle and the upper control arm. Pry upwards on

the upper control arm (Fig. 32).

(6) If the travel exceeds 0.5 mm (0.020 in.), replace

the upper control arm since the upper ball joint is

integral to the arm (Refer to 2 - SUSPENSION/

FRONT/UPPER CONTROL ARM - REMOVAL).

(7) If the upper ball joint is within specs reinstall

the front tires (Refer to 22 - TIRES/WHEELS/

WHEELS - STANDARD PROCEDURE).

Fig. 32 UPPER BALL JOINT PLAY

1 - DIAL INDICATOR

2 - UPPER CONTROL ARM

3-PRYBAR

4 - KNUCKLE

5 - BALL JOINT BOOT

2 - 26 FRONT - INDEPENDENT FRONT SUSPENSIONDR

TORSION BAR (Continued)

Page 56 of 2895

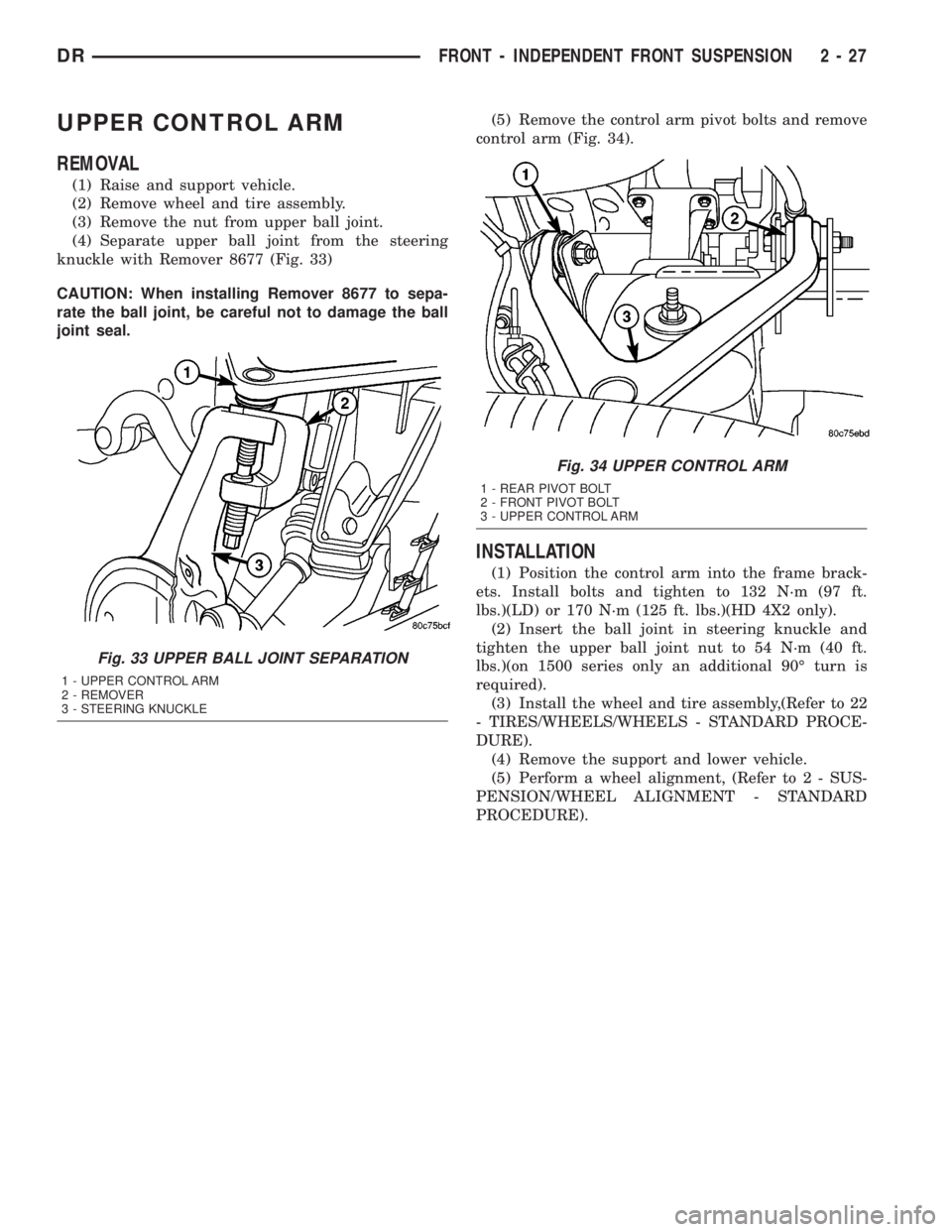

UPPER CONTROL ARM

REMOVAL

(1) Raise and support vehicle.

(2) Remove wheel and tire assembly.

(3) Remove the nut from upper ball joint.

(4) Separate upper ball joint from the steering

knuckle with Remover 8677 (Fig. 33)

CAUTION: When installing Remover 8677 to sepa-

rate the ball joint, be careful not to damage the ball

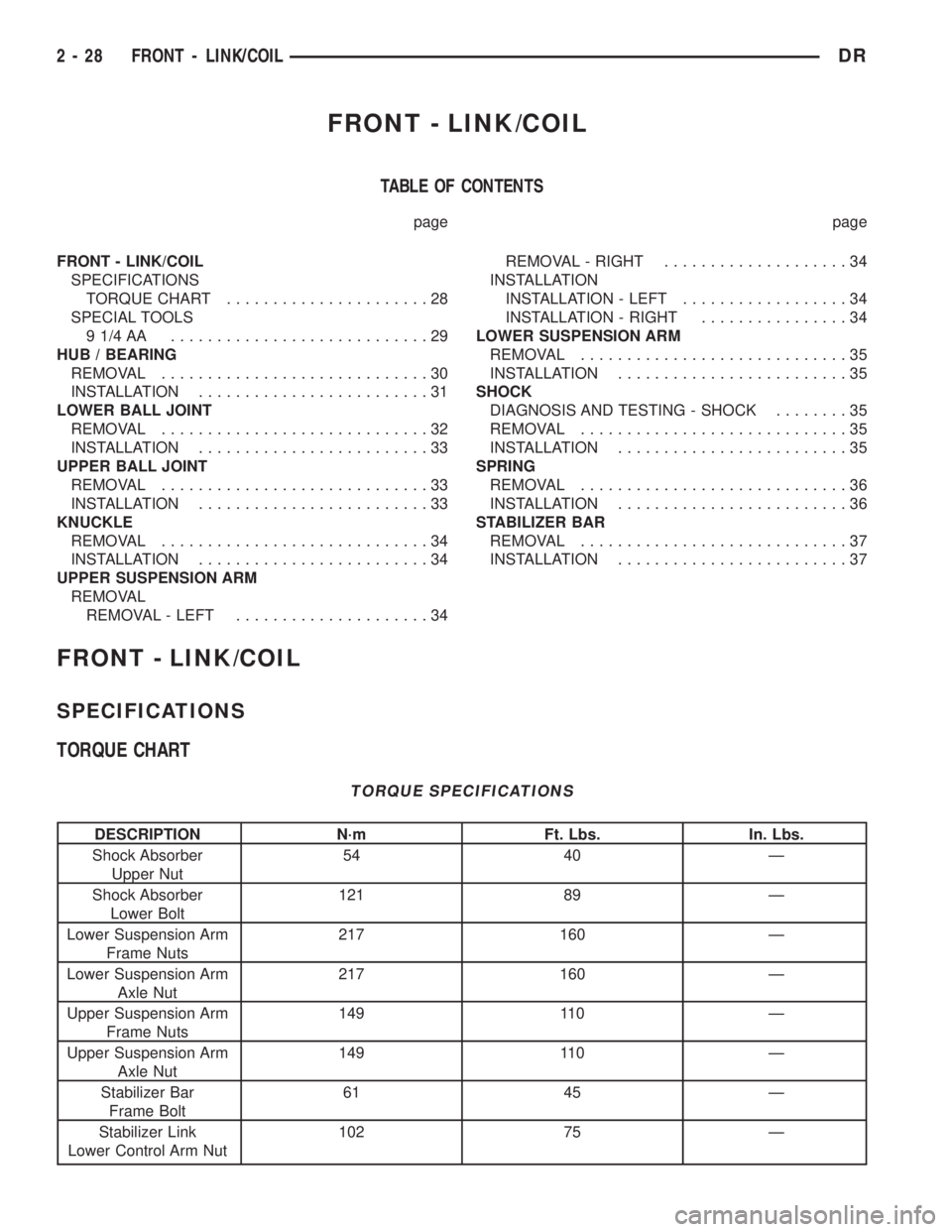

joint seal.(5) Remove the control arm pivot bolts and remove

control arm (Fig. 34).

INSTALLATION

(1) Position the control arm into the frame brack-

ets. Install bolts and tighten to 132 N´m (97 ft.

lbs.)(LD) or 170 N´m (125 ft. lbs.)(HD 4X2 only).

(2) Insert the ball joint in steering knuckle and

tighten the upper ball joint nut to 54 N´m (40 ft.

lbs.)(on 1500 series only an additional 90É turn is

required).

(3) Install the wheel and tire assembly,(Refer to 22

- TIRES/WHEELS/WHEELS - STANDARD PROCE-

DURE).

(4) Remove the support and lower vehicle.

(5) Perform a wheel alignment, (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

Fig. 33 UPPER BALL JOINT SEPARATION

1 - UPPER CONTROL ARM

2 - REMOVER

3 - STEERING KNUCKLE

Fig. 34 UPPER CONTROL ARM

1 - REAR PIVOT BOLT

2 - FRONT PIVOT BOLT

3 - UPPER CONTROL ARM

DRFRONT - INDEPENDENT FRONT SUSPENSION 2 - 27

Page 57 of 2895

FRONT - LINK/COIL

TABLE OF CONTENTS

page page

FRONT - LINK/COIL

SPECIFICATIONS

TORQUE CHART......................28

SPECIAL TOOLS

91/4AA ............................29

HUB / BEARING

REMOVAL.............................30

INSTALLATION.........................31

LOWER BALL JOINT

REMOVAL.............................32

INSTALLATION.........................33

UPPER BALL JOINT

REMOVAL.............................33

INSTALLATION.........................33

KNUCKLE

REMOVAL.............................34

INSTALLATION.........................34

UPPER SUSPENSION ARM

REMOVAL

REMOVAL - LEFT.....................34REMOVAL - RIGHT....................34

INSTALLATION

INSTALLATION - LEFT..................34

INSTALLATION - RIGHT................34

LOWER SUSPENSION ARM

REMOVAL.............................35

INSTALLATION.........................35

SHOCK

DIAGNOSIS AND TESTING - SHOCK........35

REMOVAL.............................35

INSTALLATION.........................35

SPRING

REMOVAL.............................36

INSTALLATION.........................36

STABILIZER BAR

REMOVAL.............................37

INSTALLATION.........................37

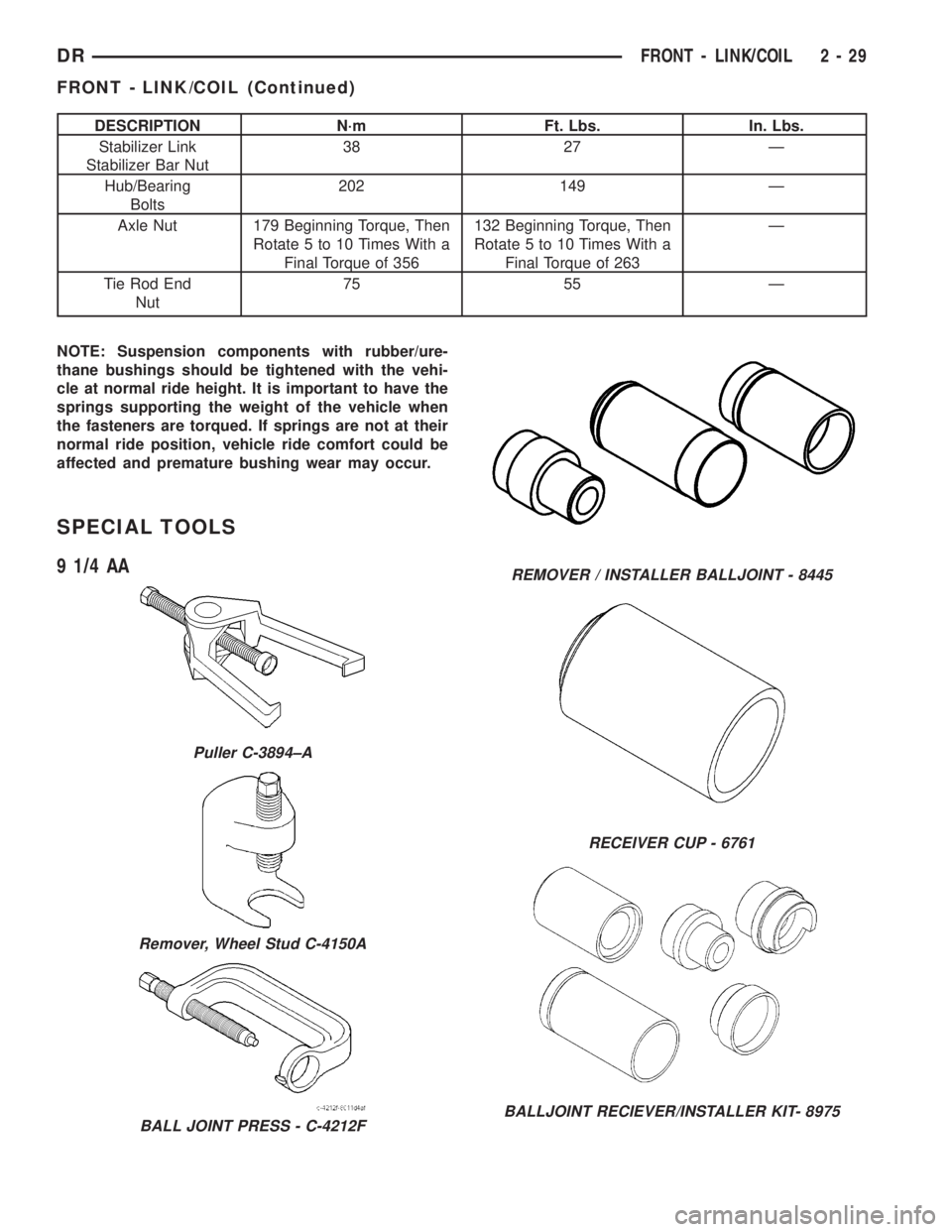

FRONT - LINK/COIL

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Shock Absorber

Upper Nut54 40 Ð

Shock Absorber

Lower Bolt121 89 Ð

Lower Suspension Arm

Frame Nuts217 160 Ð

Lower Suspension Arm

Axle Nut217 160 Ð

Upper Suspension Arm

Frame Nuts149 110 Ð

Upper Suspension Arm

Axle Nut149 110 Ð

Stabilizer Bar

Frame Bolt61 45 Ð

Stabilizer Link

Lower Control Arm Nut102 75 Ð

2 - 28 FRONT - LINK/COILDR

Page 58 of 2895

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Stabilizer Link

Stabilizer Bar Nut38 27 Ð

Hub/Bearing

Bolts202 149 Ð

Axle Nut 179 Beginning Torque, Then

Rotate 5 to 10 Times With a

Final Torque of 356132 Beginning Torque, Then

Rotate 5 to 10 Times With a

Final Torque of 263Ð

Tie Rod End

Nut75 55 Ð

NOTE: Suspension components with rubber/ure-

thane bushings should be tightened with the vehi-

cle at normal ride height. It is important to have the

springs supporting the weight of the vehicle when

the fasteners are torqued. If springs are not at their

normal ride position, vehicle ride comfort could be

affected and premature bushing wear may occur.

SPECIAL TOOLS

9 1/4 AA

Puller C-3894±A

Remover, Wheel Stud C-4150A

BALL JOINT PRESS - C-4212F

REMOVER / INSTALLER BALLJOINT - 8445

RECEIVER CUP - 6761

BALLJOINT RECIEVER/INSTALLER KIT- 8975

DRFRONT - LINK/COIL 2 - 29

FRONT - LINK/COIL (Continued)

Page 59 of 2895

HUB / BEARING

REMOVAL

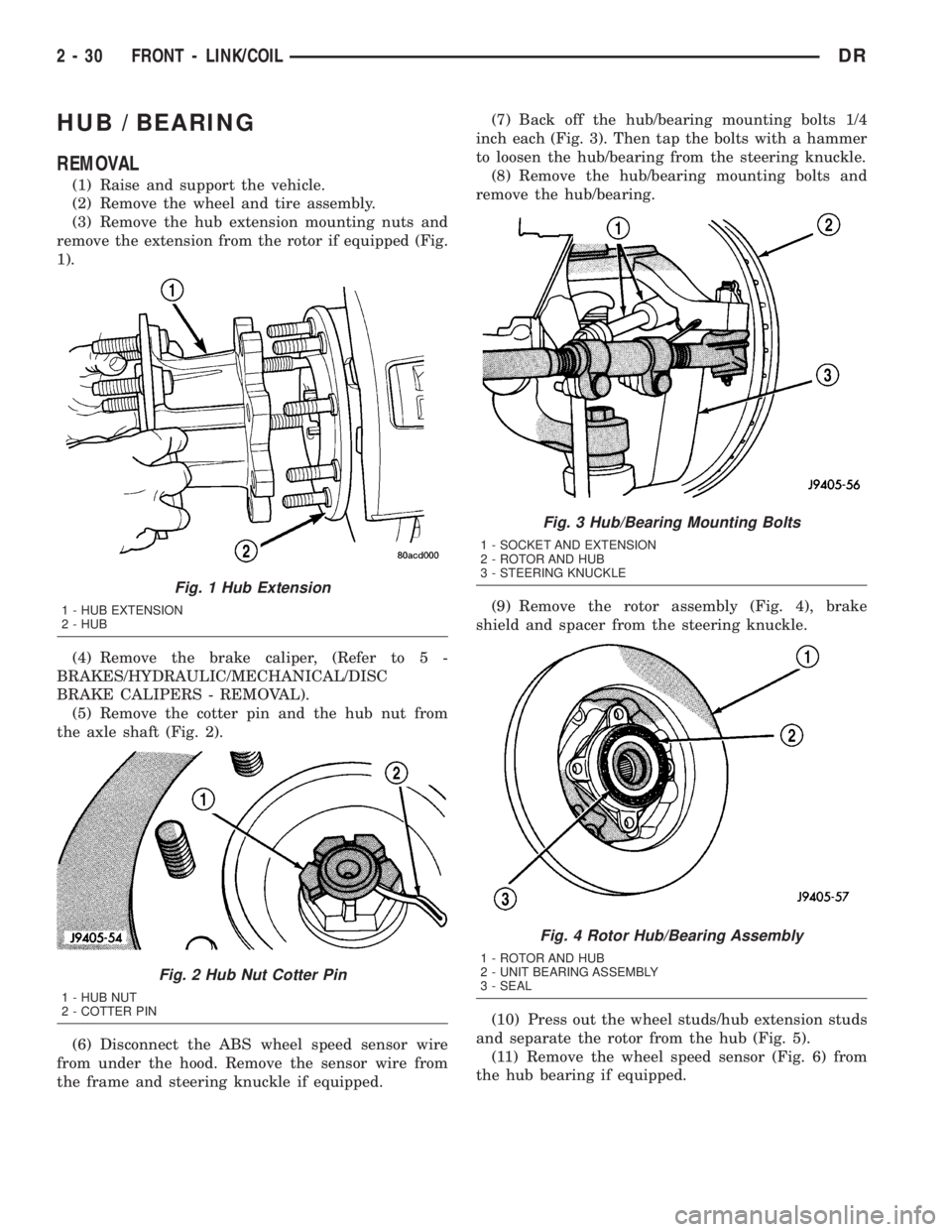

(1) Raise and support the vehicle.

(2) Remove the wheel and tire assembly.

(3) Remove the hub extension mounting nuts and

remove the extension from the rotor if equipped (Fig.

1).

(4) Remove the brake caliper, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - REMOVAL).

(5) Remove the cotter pin and the hub nut from

the axle shaft (Fig. 2).

(6) Disconnect the ABS wheel speed sensor wire

from under the hood. Remove the sensor wire from

the frame and steering knuckle if equipped.(7) Back off the hub/bearing mounting bolts 1/4

inch each (Fig. 3). Then tap the bolts with a hammer

to loosen the hub/bearing from the steering knuckle.

(8) Remove the hub/bearing mounting bolts and

remove the hub/bearing.

(9) Remove the rotor assembly (Fig. 4), brake

shield and spacer from the steering knuckle.

(10) Press out the wheel studs/hub extension studs

and separate the rotor from the hub (Fig. 5).

(11) Remove the wheel speed sensor (Fig. 6) from

the hub bearing if equipped.

Fig. 1 Hub Extension

1 - HUB EXTENSION

2 - HUB

Fig. 2 Hub Nut Cotter Pin

1 - HUB NUT

2 - COTTER PIN

Fig. 3 Hub/Bearing Mounting Bolts

1 - SOCKET AND EXTENSION

2 - ROTOR AND HUB

3 - STEERING KNUCKLE

Fig. 4 Rotor Hub/Bearing Assembly

1 - ROTOR AND HUB

2 - UNIT BEARING ASSEMBLY

3 - SEAL

2 - 30 FRONT - LINK/COILDR

Page 60 of 2895

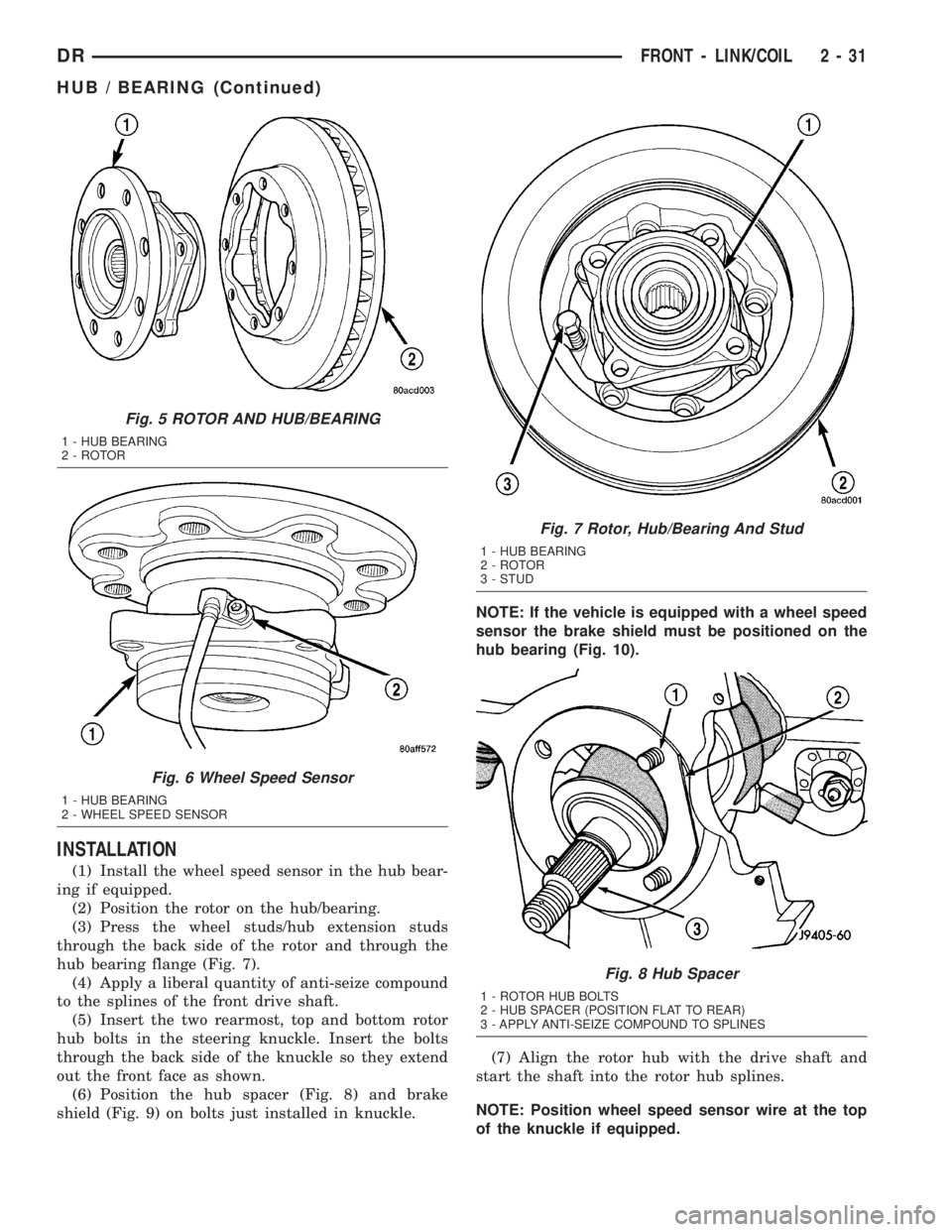

INSTALLATION

(1) Install the wheel speed sensor in the hub bear-

ing if equipped.

(2) Position the rotor on the hub/bearing.

(3) Press the wheel studs/hub extension studs

through the back side of the rotor and through the

hub bearing flange (Fig. 7).

(4) Apply a liberal quantity of anti-seize compound

to the splines of the front drive shaft.

(5) Insert the two rearmost, top and bottom rotor

hub bolts in the steering knuckle. Insert the bolts

through the back side of the knuckle so they extend

out the front face as shown.

(6) Position the hub spacer (Fig. 8) and brake

shield (Fig. 9) on bolts just installed in knuckle.NOTE: If the vehicle is equipped with a wheel speed

sensor the brake shield must be positioned on the

hub bearing (Fig. 10).

(7) Align the rotor hub with the drive shaft and

start the shaft into the rotor hub splines.

NOTE: Position wheel speed sensor wire at the top

of the knuckle if equipped.

Fig. 5 ROTOR AND HUB/BEARING

1 - HUB BEARING

2 - ROTOR

Fig. 6 Wheel Speed Sensor

1 - HUB BEARING

2 - WHEEL SPEED SENSOR

Fig. 7 Rotor, Hub/Bearing And Stud

1 - HUB BEARING

2 - ROTOR

3 - STUD

Fig. 8 Hub Spacer

1 - ROTOR HUB BOLTS

2 - HUB SPACER (POSITION FLAT TO REAR)

3 - APPLY ANTI-SEIZE COMPOUND TO SPLINES

DRFRONT - LINK/COIL 2 - 31

HUB / BEARING (Continued)