dash DODGE RAM 2003 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2678 of 2895

SEALER LOCATIONS

SPECIFICATIONS

INDEX

DESCRIPTION FIGURE

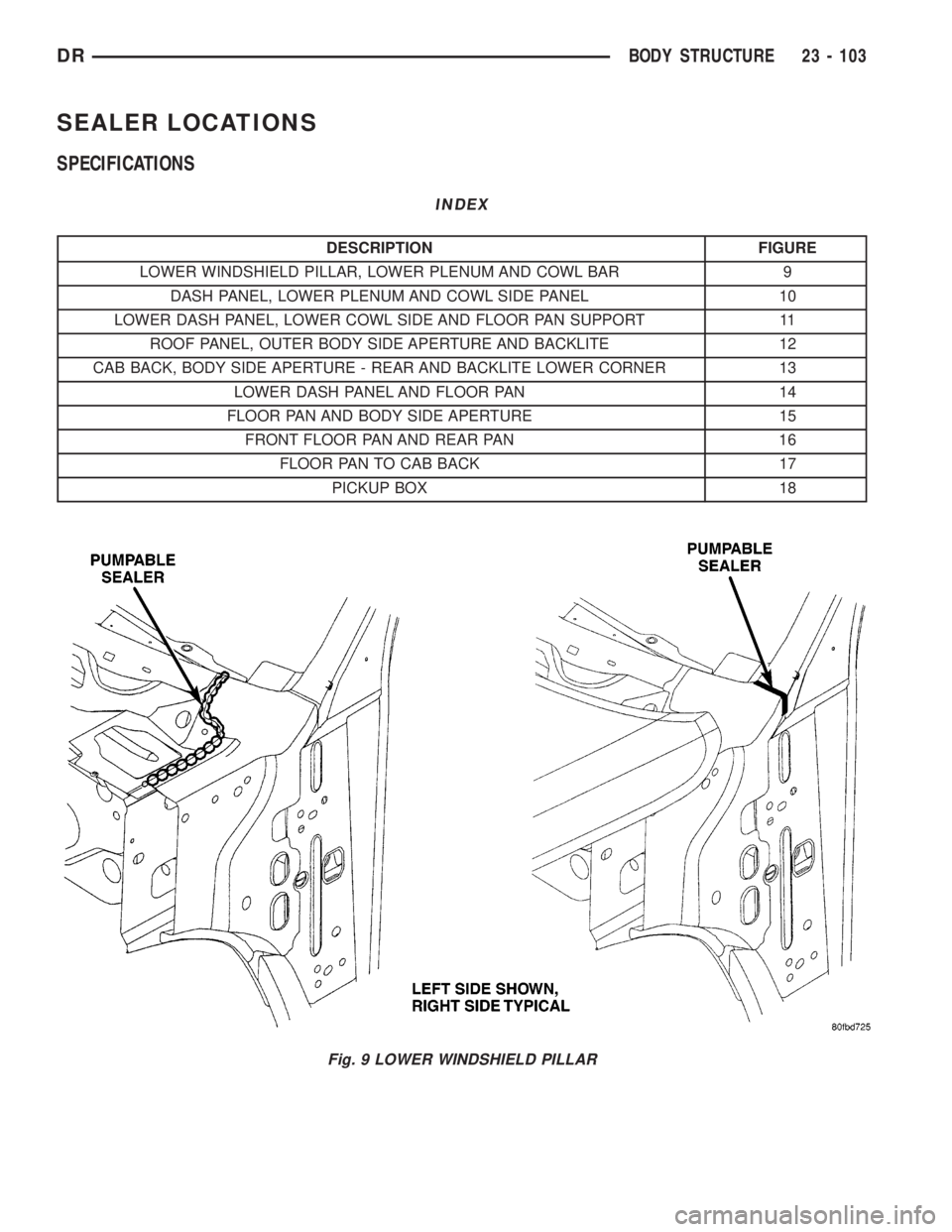

LOWER WINDSHIELD PILLAR, LOWER PLENUM AND COWL BAR 9

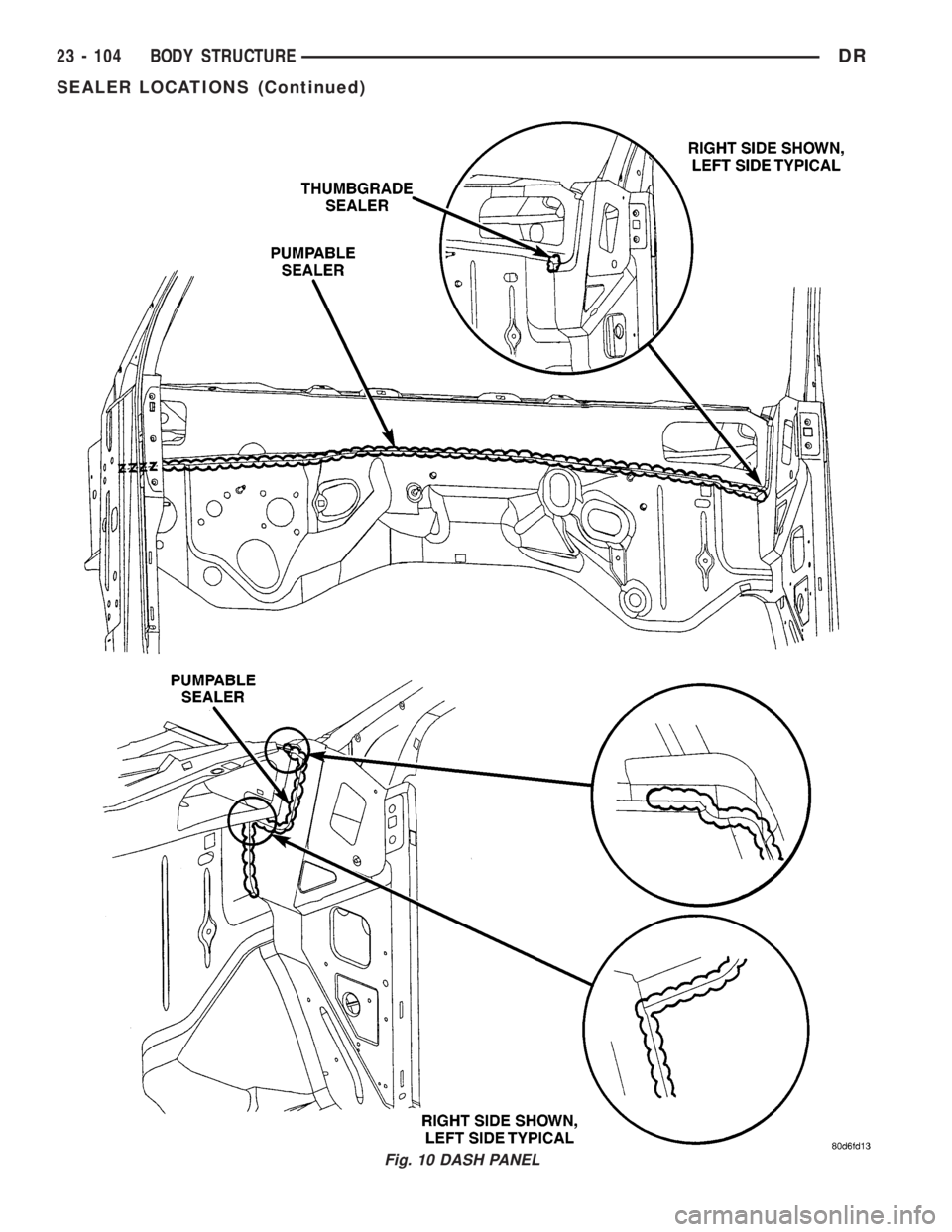

DASH PANEL, LOWER PLENUM AND COWL SIDE PANEL 10

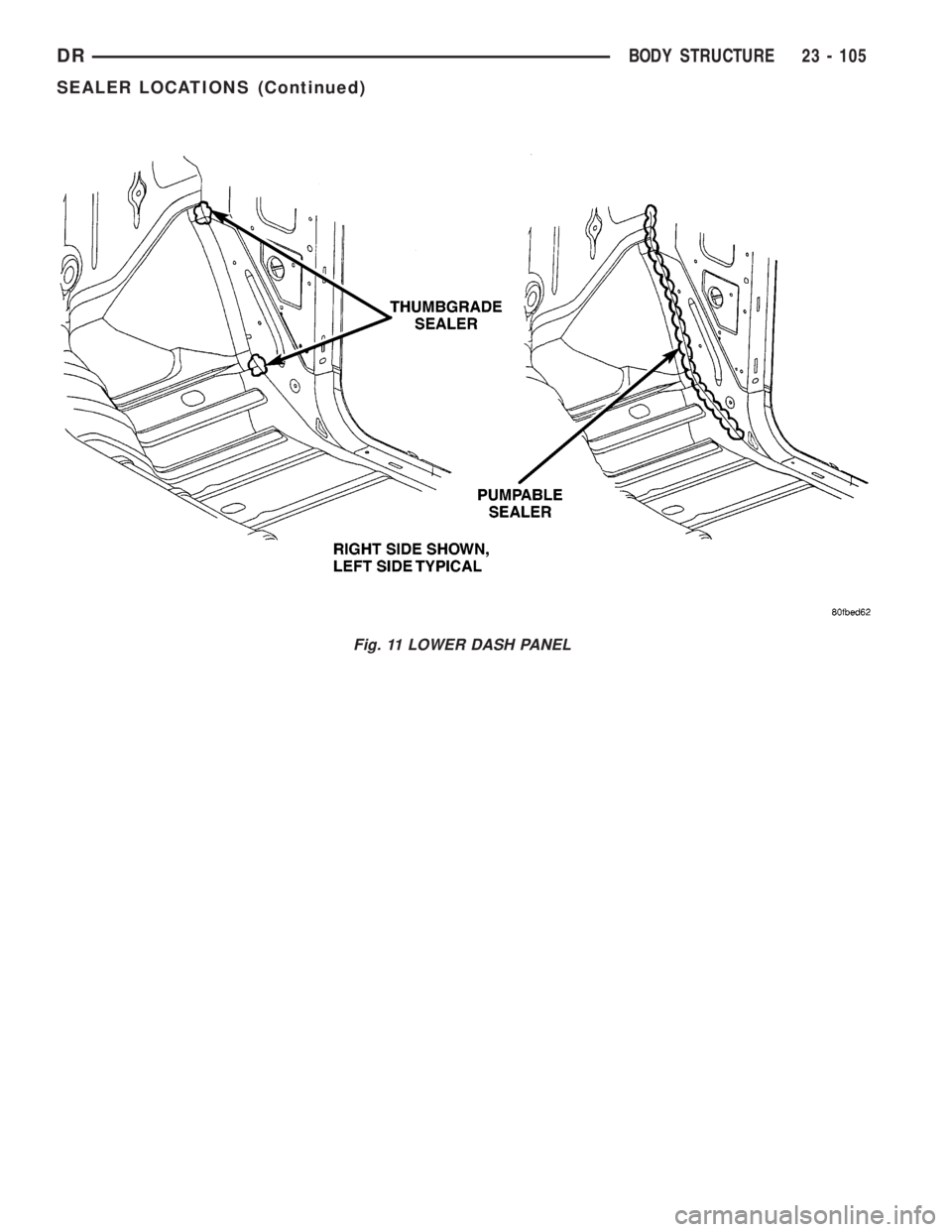

LOWER DASH PANEL, LOWER COWL SIDE AND FLOOR PAN SUPPORT 11

ROOF PANEL, OUTER BODY SIDE APERTURE AND BACKLITE 12

CAB BACK, BODY SIDE APERTURE - REAR AND BACKLITE LOWER CORNER 13

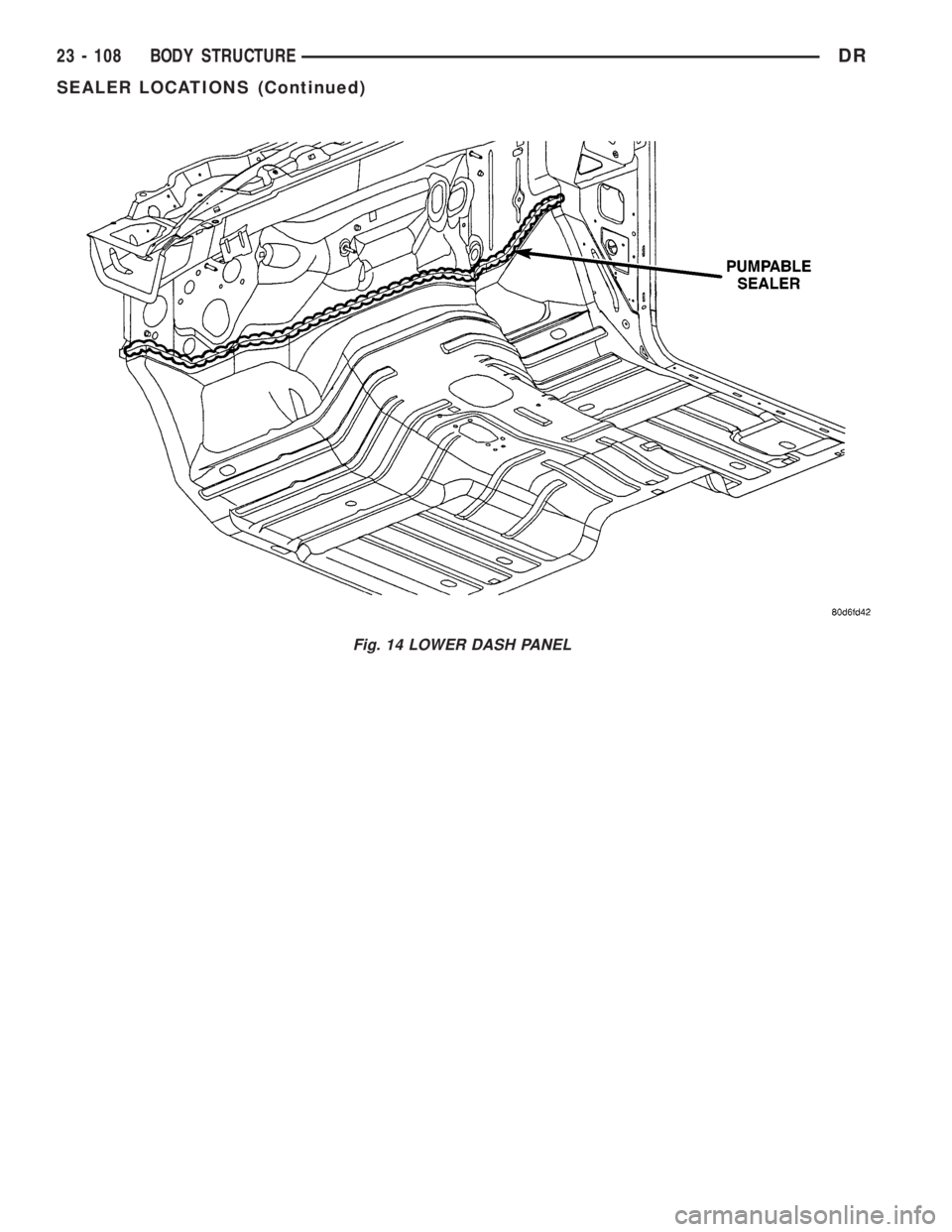

LOWER DASH PANEL AND FLOOR PAN 14

FLOOR PAN AND BODY SIDE APERTURE 15

FRONT FLOOR PAN AND REAR PAN 16

FLOOR PAN TO CAB BACK 17

PICKUP BOX 18

Fig. 9 LOWER WINDSHIELD PILLAR

DRBODY STRUCTURE 23 - 103

Page 2679 of 2895

Fig. 10 DASH PANEL

23 - 104 BODY STRUCTUREDR

SEALER LOCATIONS (Continued)

Page 2680 of 2895

Fig. 11 LOWER DASH PANEL

DRBODY STRUCTURE 23 - 105

SEALER LOCATIONS (Continued)

Page 2683 of 2895

Fig. 14 LOWER DASH PANEL

23 - 108 BODY STRUCTUREDR

SEALER LOCATIONS (Continued)

Page 2697 of 2895

WELD LOCATIONS

SPECIFICATIONS

INDEX

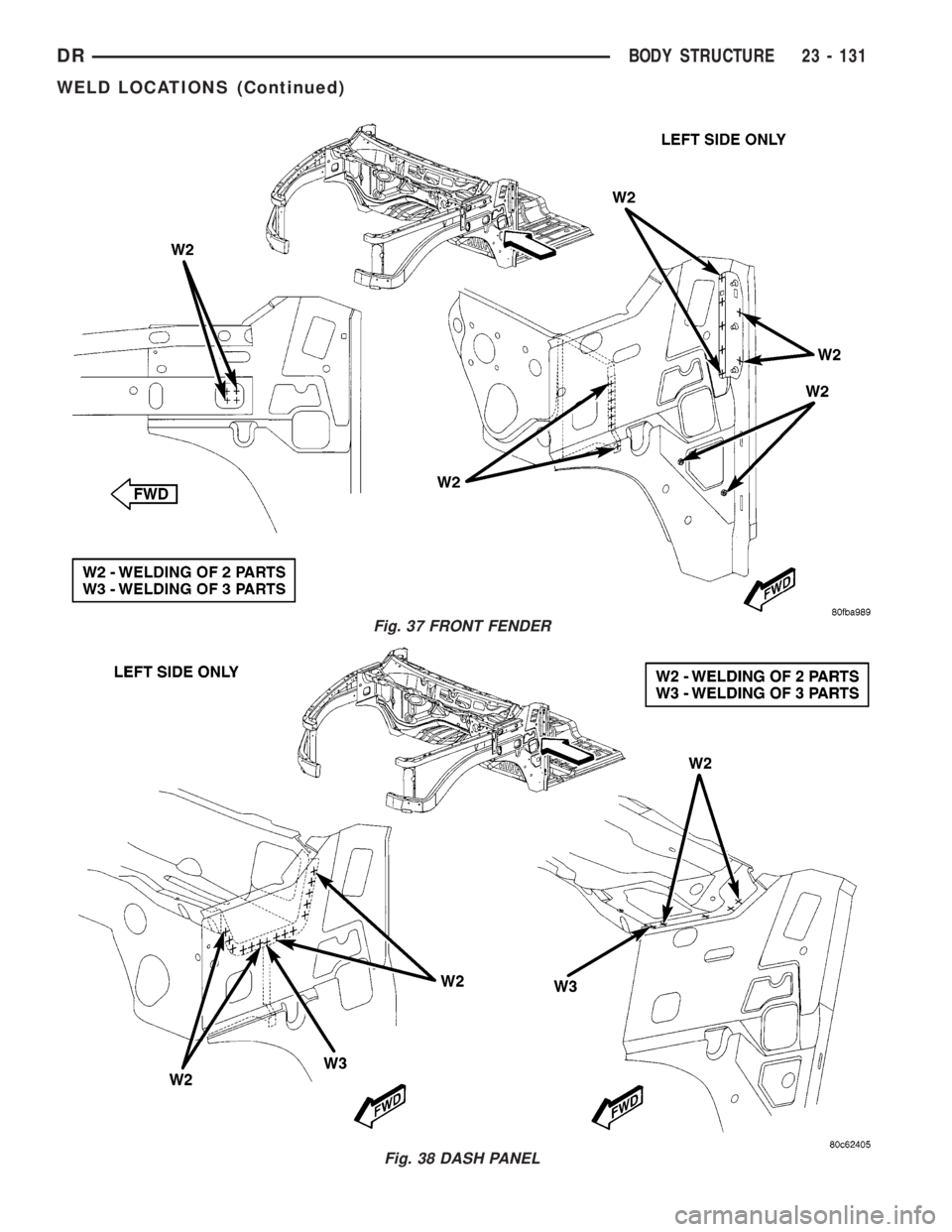

DESCRIPTION FIGURE

FENDER BRACE, CLOSURE TUBE AND FRAME MOUNTING BRACKET TO FRONT

FENDER SUPPORT, FRONT FENDER AND RADIATOR TUBE31

STEERING COLUMN SUPPORT, CONNECTOR WIRING BRACKET AND WELD NUTS

TO LOWER PLENUM PANEL32

WIPER ATTACHING WELD NUTS AND VACUUM RESERVOIR ATTACHING STUDS TO

COWL PAR PANEL33

DASH PANEL TO FRONT FLOOR PAN 34

DASH PANEL TO LOWER PLENUM PANEL 35

LOWER PLENUM PANEL TO COWL BACK PANEL 36

FRONT FENDER AND RADIATOR TUBE DASH PANEL, INSTRUMENT PANEL

MOUNTING BRACKET, AND WELD NUTS TO COWL SIDE PANEL - LEFT SIDE37

DASH PANEL, LOWER PLENUM PANEL AND COWL PANEL BAR TO COWL SIDE

PANEL - LEFT SIDE38

FRONT FENDER AND RADIATOR TUBE DASH PANEL, INSTRUMENT PANEL

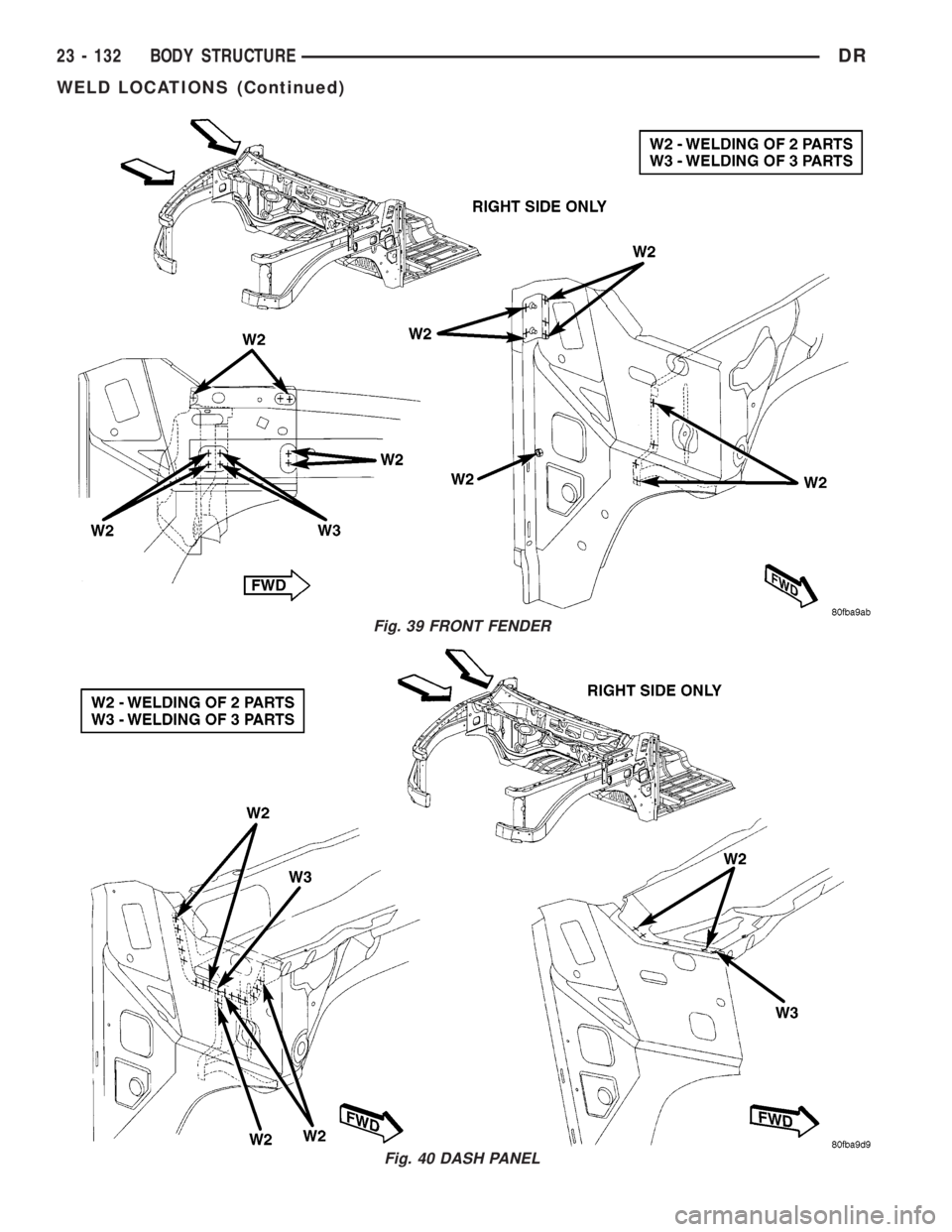

MOUNTING BRACKET AND WELD NUTS TO COWL SIDE PANEL - RIGHT SIDE39

DASH PANEL, LOWER PLENUM PANEL AND COWL PANEL BAR TO COWL SIDE

PANEL - RIGHT SIDE40

REINFORCEMENT AND HEADLAMP MOUNTING PANEL TO OUTER FENDER PANEL 41

SEAT MOUNTING FRONT BRACKETS TO SEAT MOUNTING FRONT CROSSMEMBER

TO FRONT FLOOR PAN42

AIR BAG MODULE BRACKET SHIFTER MOUNTING PLATE AND REAR FLOOR PANE

TO FRONT FLOOR PAN43

RIGHT TO LEFT REAR FLOOR CROSSMEMBER AND RIGHT TO LEFT SEAT

MOUNTING CROSSMEMBER44

REAR FLOOR CROSSMEMBER, SEAT MOUNTING CROSSMEMBER AND

UNDERBODY SUPPORT TO FLOOR SILL45

SEAT MOUNTING FRONT CROSSMEMBER TO FRONT FLOOR PAN TO UNDERBODY

SUPPORT46

FRONT SEAT MOUNTING CROSSMEMBERS TO FRONT SEAT MOUNTING BRACKET

TO FRONT FLOOR PAN47

REAR FLOOR CROSSMEMBERS TO REAR FLOOR PAN 48

FLOOR SILL TO FRONT SEAT MOUNTING CROSSMEMBER, FRONT AND REAR

FLOOR PAN49

AIR BAG MODULE BRACKET, SHIFTER MOUNTING PLATE AND FRONT SEAT

MOUNTING CROSSMEMBER TO FRONT FLOOR PAN50

REAR SEAT MIDDLE MOUNTING PLATE TO REAR FLOOR PAN TO FRONT FLOOR

PA N51

REAR FLOOR CROSSMEMBER, SEAT MOUNTING CROSSMEMBER AND

UNDERBODY SUPPORT TO FLOOR SILL52

LEFT REAR CROSSMEMBER TO RIGHT REAR CROSSMEMBER TO REAR FLOOR

PA N53

23 - 122 BODY STRUCTUREDR

Page 2703 of 2895

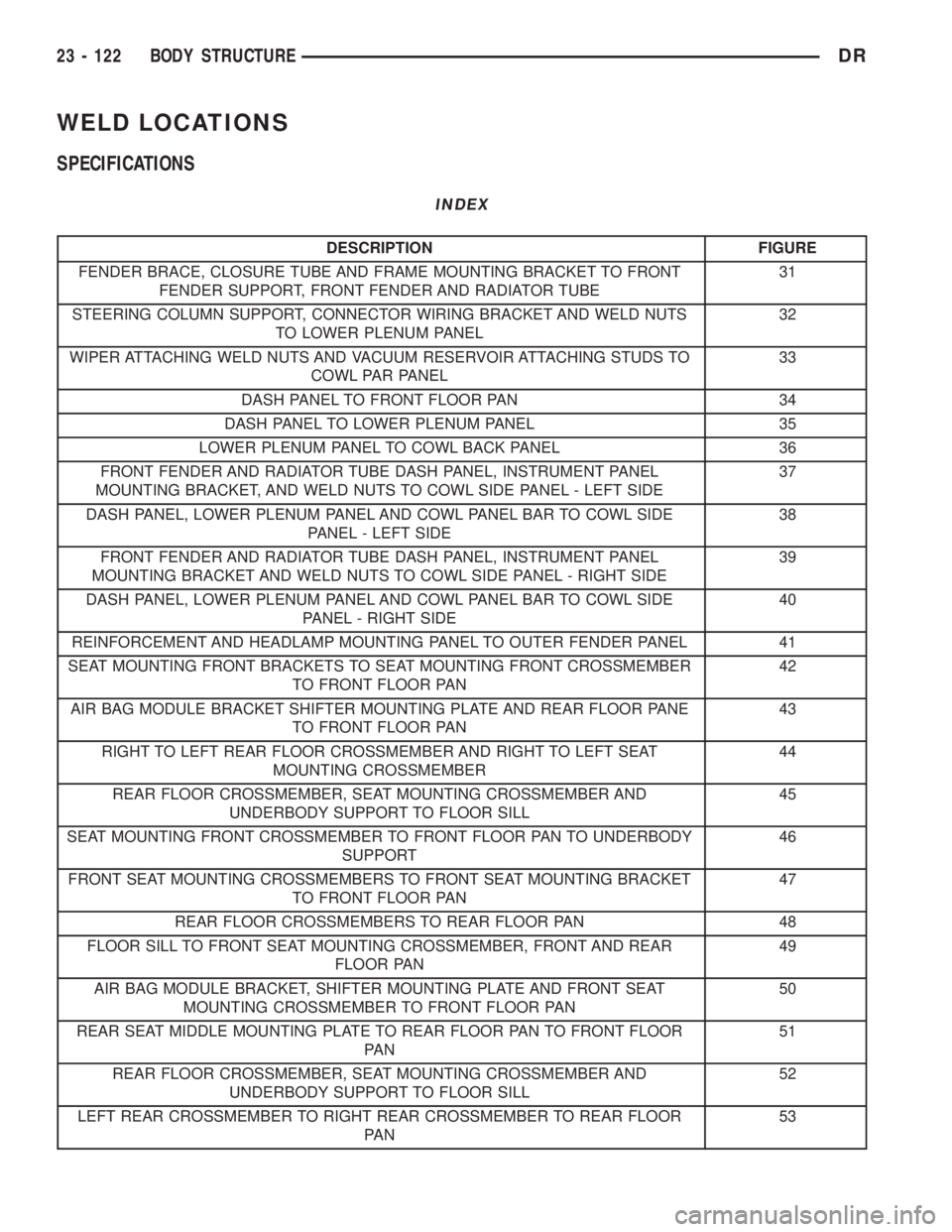

Fig. 33 WIPER ATTACHING WELD NUTS

Fig. 34 DASH PANEL

23 - 128 BODY STRUCTUREDR

WELD LOCATIONS (Continued)

Page 2704 of 2895

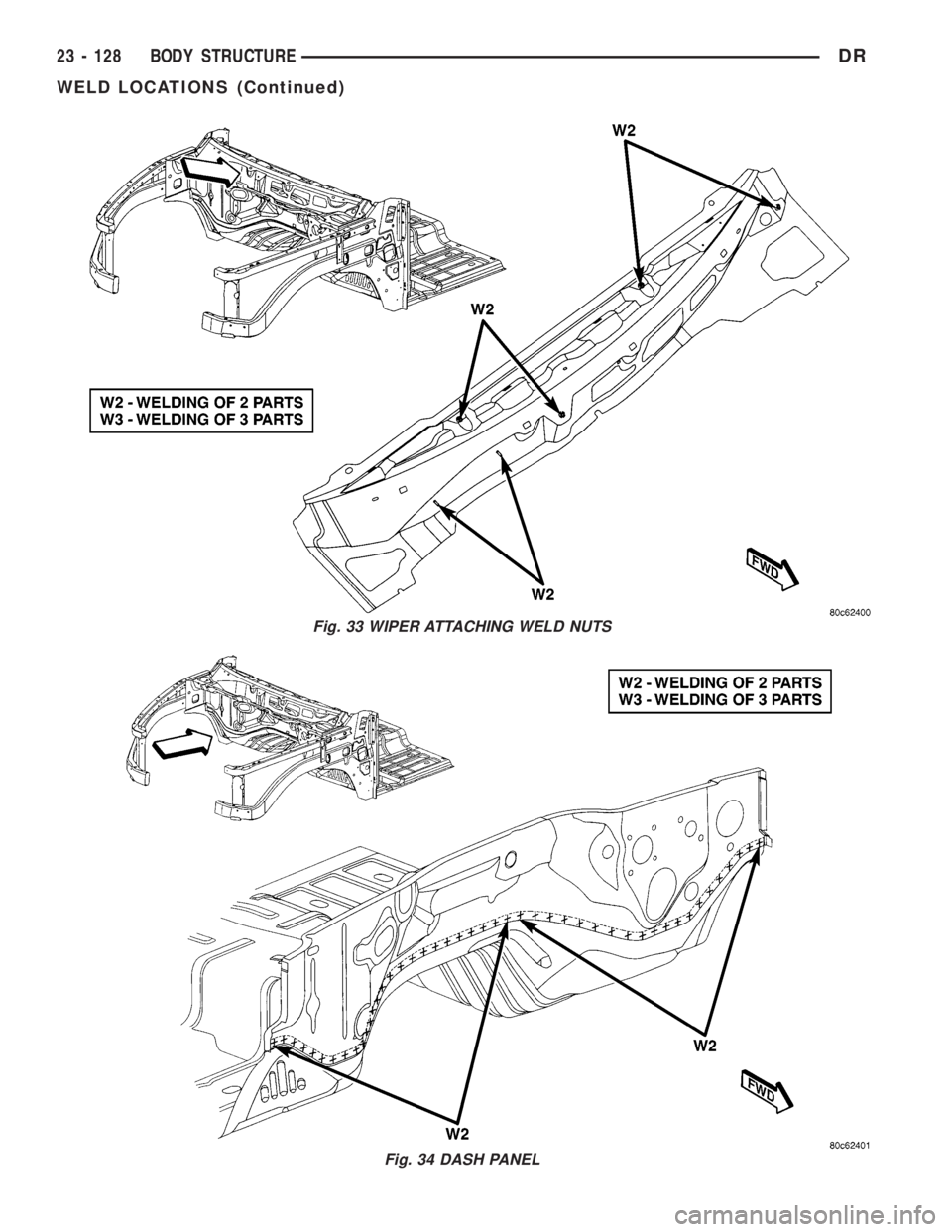

Fig. 35 DASH PANEL

DRBODY STRUCTURE 23 - 129

WELD LOCATIONS (Continued)

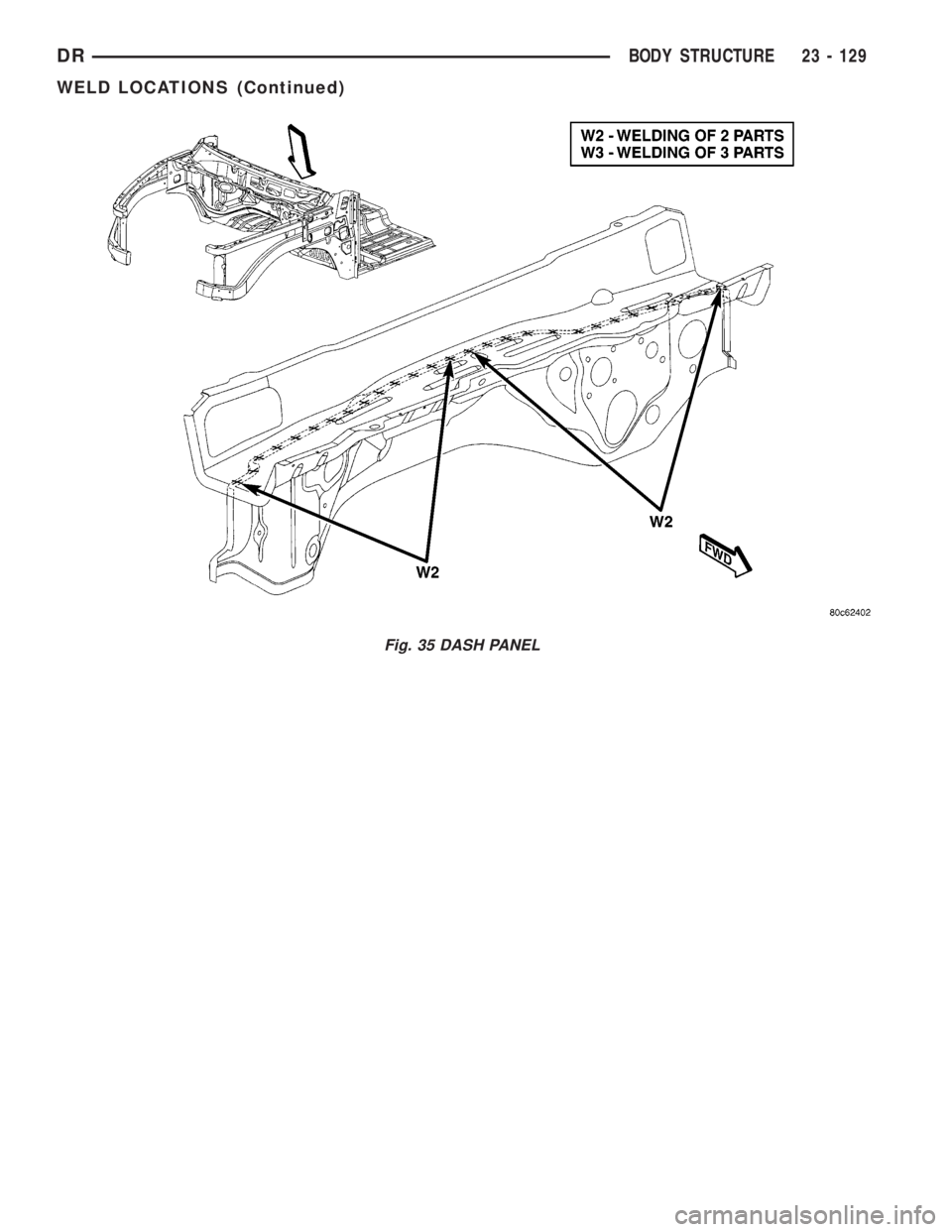

Page 2706 of 2895

Fig. 37 FRONT FENDER

Fig. 38 DASH PANEL

DRBODY STRUCTURE 23 - 131

WELD LOCATIONS (Continued)

Page 2707 of 2895

Fig. 39 FRONT FENDER

Fig. 40 DASH PANEL

23 - 132 BODY STRUCTUREDR

WELD LOCATIONS (Continued)

Page 2777 of 2895

coil. To maintain minimum evaporator temperature

and prevent evaporator freezing, the A/C Fin Probe

which is located in the evaporator cycles the com-

pressor clutch by sending an A/C request to the

JTEC which in turn processes this piece of informa-

tion and if all conditions are met cycles the compres-

sor clutch.

OPERATION - REFRIGERANT SYSTEM SERVICE

PORT

The low pressure service port is located on the suc-

tion refrigerant line, near the accumulator. The high

pressure service port is located on the liquid line at

the passenger side of the engine compartment, near

the condenser.

Each of the service ports has a threaded plastic

protective cap installed over it from the factory. After

servicing the refrigerant system, always reinstall

both of the service port caps.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - A/C

PERFORMANCE

The air conditioning system is designed to provide

the passenger compartment with low temperature

and low humidity air. The evaporator, located in the

HVAC housing on the dash panel below the instru-

ment panel, is cooled to temperatures near the freez-

ing point. As warm damp air passes through the

cooled evaporator, the air transfers its heat to the

refrigerant in the evaporator and the moisture in the

air condenses on the evaporator fins. During periods

of high heat and humidity, an air conditioning sys-

tem will be more effective in the Recirculation Mode.

With the system in the Recirculation Mode, only air

from the passenger compartment passes through the

evaporator. As the passenger compartment air dehu-

midifies, the air conditioning system performance

levels improve.

Humidity has an important bearing on the temper-

ature of the air delivered to the interior of the vehi-

cle. It is important to understand the effect that

humidity has on the performance of the air condition-

ing system. When humidity is high, the evaporator

has to perform a double duty. It must lower the air

temperature, and it must lower the temperature of

the moisture in the air that condenses on the evapo-

rator fins. Condensing the moisture in the air trans-

fers heat energy into the evaporator fins and tubing.

This reduces the amount of heat the evaporator can

absorb from the air. High humidity greatly reduces

the ability of the evaporator to lower the temperature

of the air.

However, evaporator capacity used to reduce the

amount of moisture in the air is not wasted. Remov-

ing some of the moisture out of the air entering the

vehicle adds to the comfort of the passengers.

Although, an owner may expect too much from the

air conditioning system on humid days. A perfor-

mance test is the best way to determine whether the

system is performing up to standard. This test also

provides valuable clues as to the possible cause of

trouble with the air conditioning system.

Before proceeding, (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - WARNING) and

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - CAUTION). The air temperature in

the test room and in the vehicle must be a minimum

of 21É C (70É F) for this test.

(1) Connect a tachometer and a manifold gauge set

or A/C recycling/charging station.

(2) Set the A/C Heater mode control switch knob in

the Recirculation Mode position, the temperature

control knob in the full cool position, and the blower

motor switch knob in the highest speed position.

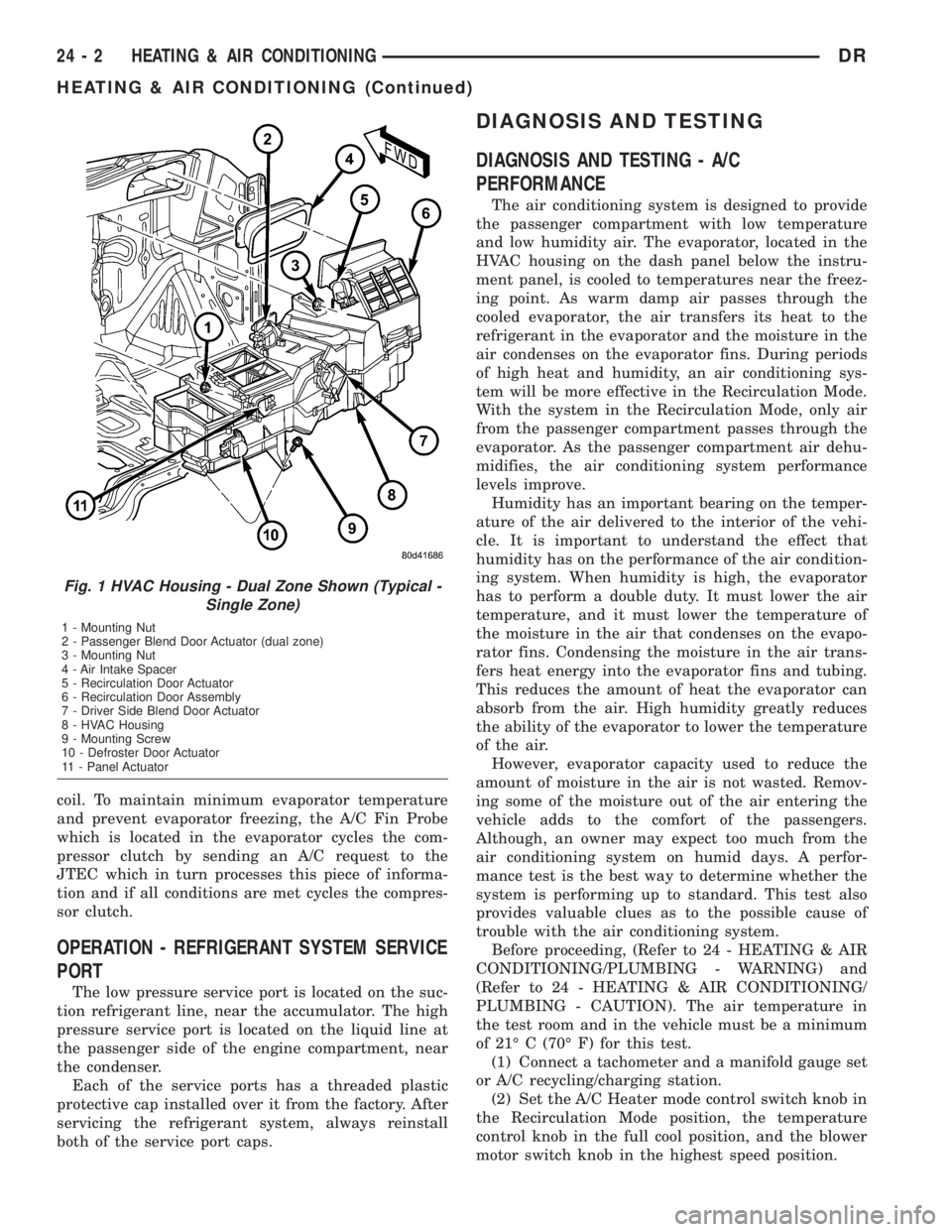

Fig. 1 HVAC Housing - Dual Zone Shown (Typical -

Single Zone)

1 - Mounting Nut

2 - Passenger Blend Door Actuator (dual zone)

3 - Mounting Nut

4 - Air Intake Spacer

5 - Recirculation Door Actuator

6 - Recirculation Door Assembly

7 - Driver Side Blend Door Actuator

8 - HVAC Housing

9 - Mounting Screw

10 - Defroster Door Actuator

11 - Panel Actuator

24 - 2 HEATING & AIR CONDITIONINGDR

HEATING & AIR CONDITIONING (Continued)