Engine DODGE RAM 2003 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 301 of 2895

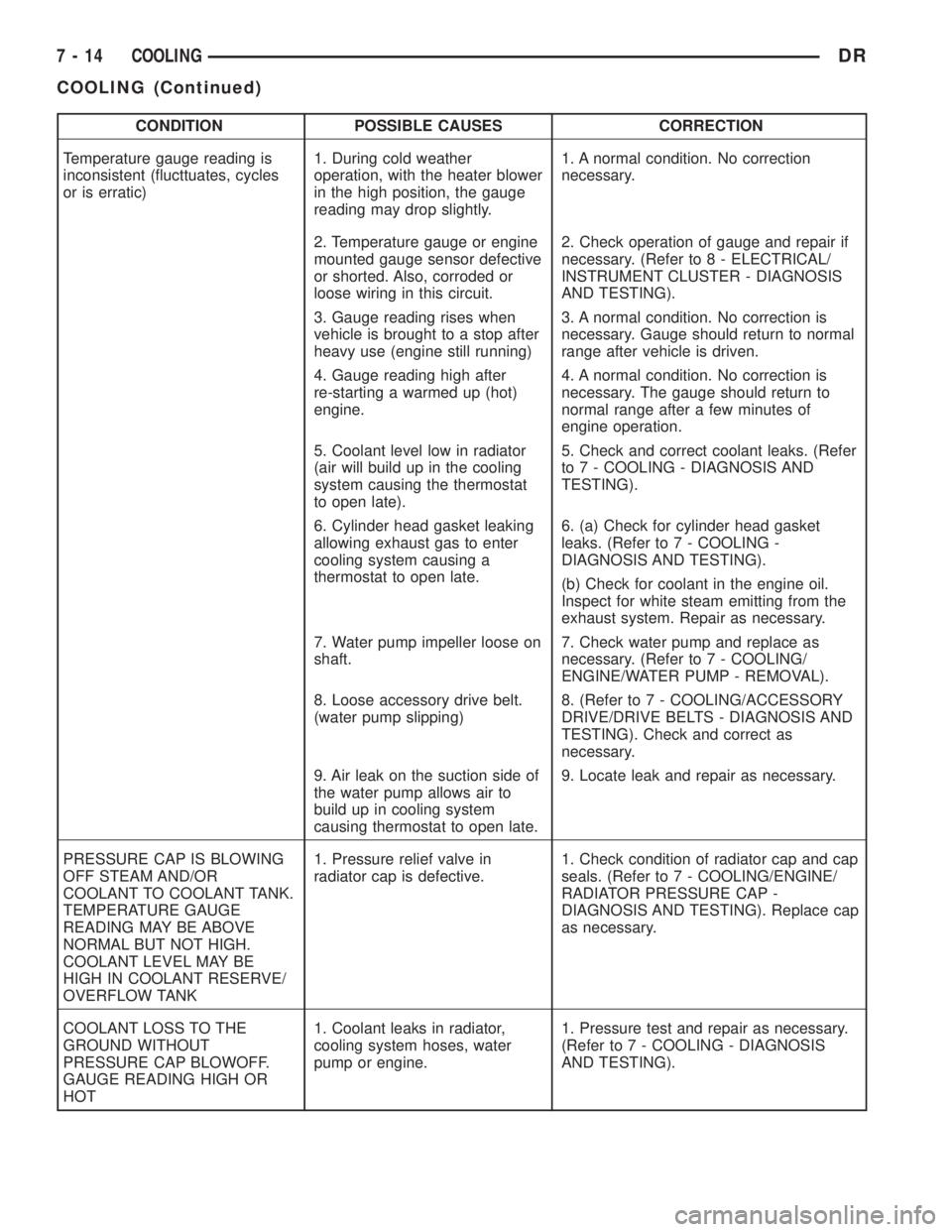

CONDITION POSSIBLE CAUSES CORRECTION

Temperature gauge reading is

inconsistent (flucttuates, cycles

or is erratic)1. During cold weather

operation, with the heater blower

in the high position, the gauge

reading may drop slightly.1. A normal condition. No correction

necessary.

2. Temperature gauge or engine

mounted gauge sensor defective

or shorted. Also, corroded or

loose wiring in this circuit.2. Check operation of gauge and repair if

necessary. (Refer to 8 - ELECTRICAL/

INSTRUMENT CLUSTER - DIAGNOSIS

AND TESTING).

3. Gauge reading rises when

vehicle is brought to a stop after

heavy use (engine still running)3. A normal condition. No correction is

necessary. Gauge should return to normal

range after vehicle is driven.

4. Gauge reading high after

re-starting a warmed up (hot)

engine.4. A normal condition. No correction is

necessary. The gauge should return to

normal range after a few minutes of

engine operation.

5. Coolant level low in radiator

(air will build up in the cooling

system causing the thermostat

to open late).5. Check and correct coolant leaks. (Refer

to 7 - COOLING - DIAGNOSIS AND

TESTING).

6. Cylinder head gasket leaking

allowing exhaust gas to enter

cooling system causing a

thermostat to open late.6. (a) Check for cylinder head gasket

leaks. (Refer to 7 - COOLING -

DIAGNOSIS AND TESTING).

(b) Check for coolant in the engine oil.

Inspect for white steam emitting from the

exhaust system. Repair as necessary.

7. Water pump impeller loose on

shaft.7. Check water pump and replace as

necessary. (Refer to 7 - COOLING/

ENGINE/WATER PUMP - REMOVAL).

8. Loose accessory drive belt.

(water pump slipping)8. (Refer to 7 - COOLING/ACCESSORY

DRIVE/DRIVE BELTS - DIAGNOSIS AND

TESTING). Check and correct as

necessary.

9. Air leak on the suction side of

the water pump allows air to

build up in cooling system

causing thermostat to open late.9. Locate leak and repair as necessary.

PRESSURE CAP IS BLOWING

OFF STEAM AND/OR

COOLANT TO COOLANT TANK.

TEMPERATURE GAUGE

READING MAY BE ABOVE

NORMAL BUT NOT HIGH.

COOLANT LEVEL MAY BE

HIGH IN COOLANT RESERVE/

OVERFLOW TANK1. Pressure relief valve in

radiator cap is defective.1. Check condition of radiator cap and cap

seals. (Refer to 7 - COOLING/ENGINE/

RADIATOR PRESSURE CAP -

DIAGNOSIS AND TESTING). Replace cap

as necessary.

COOLANT LOSS TO THE

GROUND WITHOUT

PRESSURE CAP BLOWOFF.

GAUGE READING HIGH OR

HOT1. Coolant leaks in radiator,

cooling system hoses, water

pump or engine.1. Pressure test and repair as necessary.

(Refer to 7 - COOLING - DIAGNOSIS

AND TESTING).

7 - 14 COOLINGDR

COOLING (Continued)

Page 302 of 2895

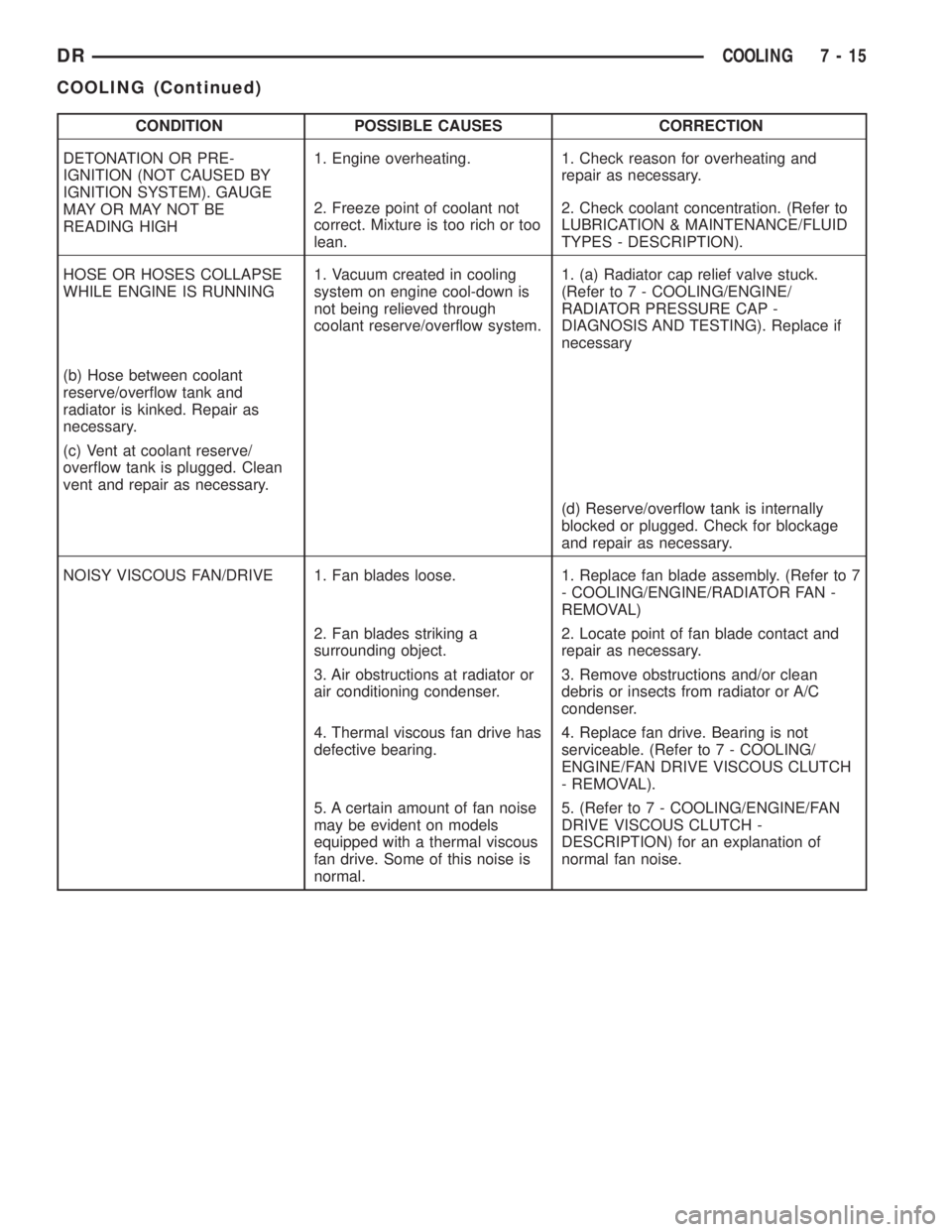

CONDITION POSSIBLE CAUSES CORRECTION

DETONATION OR PRE-

IGNITION (NOT CAUSED BY

IGNITION SYSTEM). GAUGE

MAY OR MAY NOT BE

READING HIGH1. Engine overheating. 1. Check reason for overheating and

repair as necessary.

2. Freeze point of coolant not

correct. Mixture is too rich or too

lean.2. Check coolant concentration. (Refer to

LUBRICATION & MAINTENANCE/FLUID

TYPES - DESCRIPTION).

HOSE OR HOSES COLLAPSE

WHILE ENGINE IS RUNNING1. Vacuum created in cooling

system on engine cool-down is

not being relieved through

coolant reserve/overflow system.1. (a) Radiator cap relief valve stuck.

(Refer to 7 - COOLING/ENGINE/

RADIATOR PRESSURE CAP -

DIAGNOSIS AND TESTING). Replace if

necessary

(b) Hose between coolant

reserve/overflow tank and

radiator is kinked. Repair as

necessary.

(c) Vent at coolant reserve/

overflow tank is plugged. Clean

vent and repair as necessary.

(d) Reserve/overflow tank is internally

blocked or plugged. Check for blockage

and repair as necessary.

NOISY VISCOUS FAN/DRIVE 1. Fan blades loose. 1. Replace fan blade assembly. (Refer to 7

- COOLING/ENGINE/RADIATOR FAN -

REMOVAL)

2. Fan blades striking a

surrounding object.2. Locate point of fan blade contact and

repair as necessary.

3. Air obstructions at radiator or

air conditioning condenser.3. Remove obstructions and/or clean

debris or insects from radiator or A/C

condenser.

4. Thermal viscous fan drive has

defective bearing.4. Replace fan drive. Bearing is not

serviceable. (Refer to 7 - COOLING/

ENGINE/FAN DRIVE VISCOUS CLUTCH

- REMOVAL).

5. A certain amount of fan noise

may be evident on models

equipped with a thermal viscous

fan drive. Some of this noise is

normal.5. (Refer to 7 - COOLING/ENGINE/FAN

DRIVE VISCOUS CLUTCH -

DESCRIPTION) for an explanation of

normal fan noise.

DRCOOLING 7 - 15

COOLING (Continued)

Page 303 of 2895

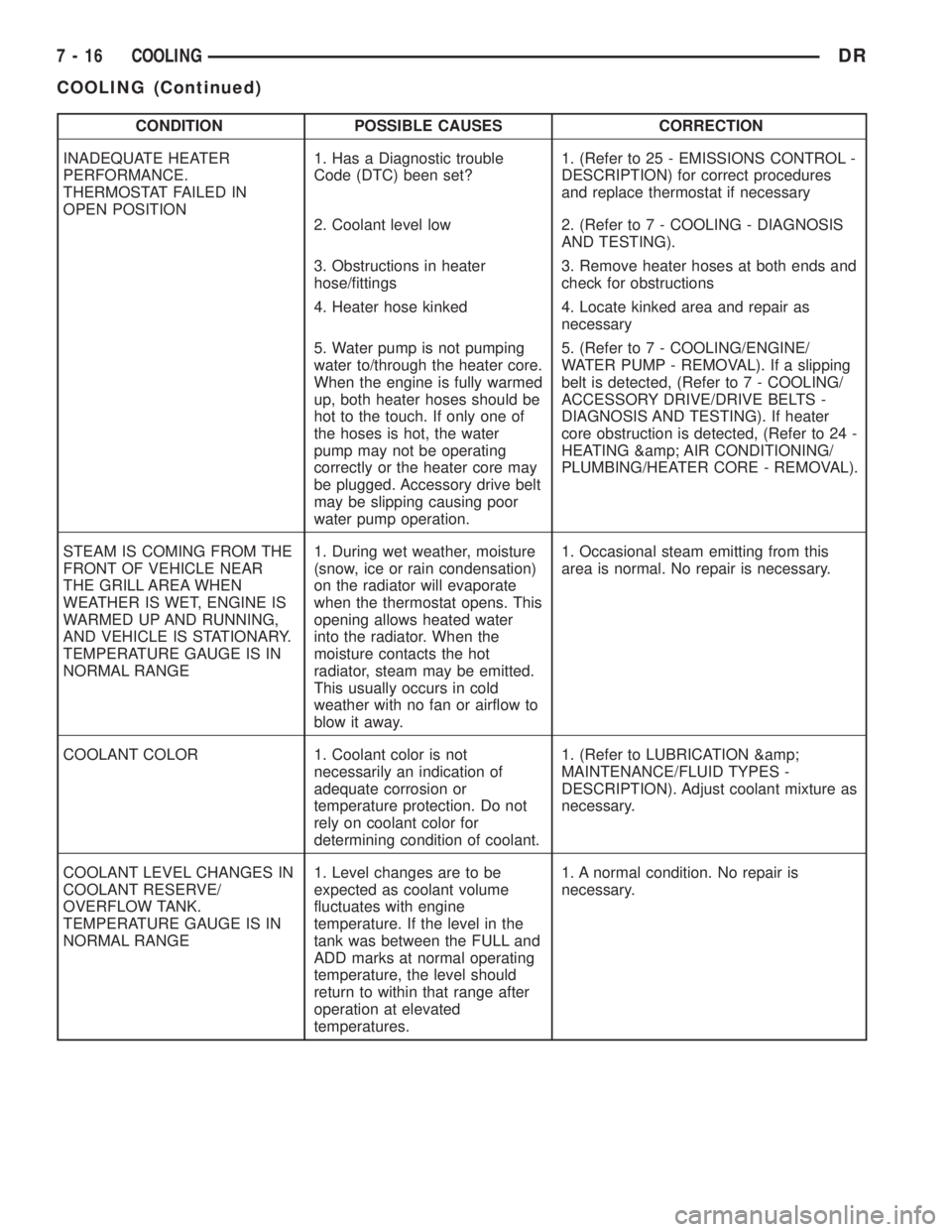

CONDITION POSSIBLE CAUSES CORRECTION

INADEQUATE HEATER

PERFORMANCE.

THERMOSTAT FAILED IN

OPEN POSITION1. Has a Diagnostic trouble

Code (DTC) been set?1. (Refer to 25 - EMISSIONS CONTROL -

DESCRIPTION) for correct procedures

and replace thermostat if necessary

2. Coolant level low 2. (Refer to 7 - COOLING - DIAGNOSIS

AND TESTING).

3. Obstructions in heater

hose/fittings3. Remove heater hoses at both ends and

check for obstructions

4. Heater hose kinked 4. Locate kinked area and repair as

necessary

5. Water pump is not pumping

water to/through the heater core.

When the engine is fully warmed

up, both heater hoses should be

hot to the touch. If only one of

the hoses is hot, the water

pump may not be operating

correctly or the heater core may

be plugged. Accessory drive belt

may be slipping causing poor

water pump operation.5. (Refer to 7 - COOLING/ENGINE/

WATER PUMP - REMOVAL). If a slipping

belt is detected, (Refer to 7 - COOLING/

ACCESSORY DRIVE/DRIVE BELTS -

DIAGNOSIS AND TESTING). If heater

core obstruction is detected, (Refer to 24 -

HEATING & AIR CONDITIONING/

PLUMBING/HEATER CORE - REMOVAL).

STEAM IS COMING FROM THE

FRONT OF VEHICLE NEAR

THE GRILL AREA WHEN

WEATHER IS WET, ENGINE IS

WARMED UP AND RUNNING,

AND VEHICLE IS STATIONARY.

TEMPERATURE GAUGE IS IN

NORMAL RANGE1. During wet weather, moisture

(snow, ice or rain condensation)

on the radiator will evaporate

when the thermostat opens. This

opening allows heated water

into the radiator. When the

moisture contacts the hot

radiator, steam may be emitted.

This usually occurs in cold

weather with no fan or airflow to

blow it away.1. Occasional steam emitting from this

area is normal. No repair is necessary.

COOLANT COLOR 1. Coolant color is not

necessarily an indication of

adequate corrosion or

temperature protection. Do not

rely on coolant color for

determining condition of coolant.1. (Refer to LUBRICATION &

MAINTENANCE/FLUID TYPES -

DESCRIPTION). Adjust coolant mixture as

necessary.

COOLANT LEVEL CHANGES IN

COOLANT RESERVE/

OVERFLOW TANK.

TEMPERATURE GAUGE IS IN

NORMAL RANGE1. Level changes are to be

expected as coolant volume

fluctuates with engine

temperature. If the level in the

tank was between the FULL and

ADD marks at normal operating

temperature, the level should

return to within that range after

operation at elevated

temperatures.1. A normal condition. No repair is

necessary.

7 - 16 COOLINGDR

COOLING (Continued)

Page 304 of 2895

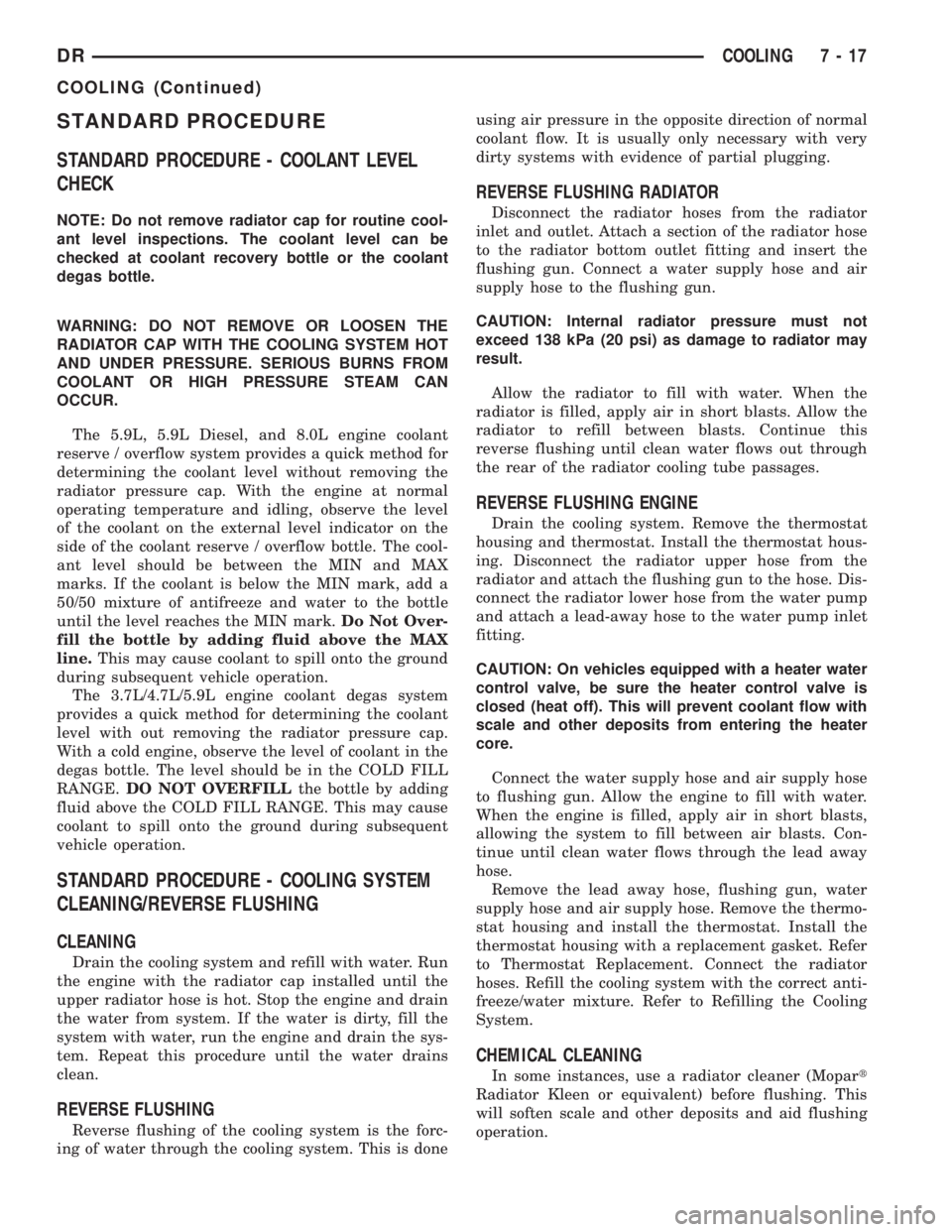

STANDARD PROCEDURE

STANDARD PROCEDURE - COOLANT LEVEL

CHECK

NOTE: Do not remove radiator cap for routine cool-

ant level inspections. The coolant level can be

checked at coolant recovery bottle or the coolant

degas bottle.

WARNING: DO NOT REMOVE OR LOOSEN THE

RADIATOR CAP WITH THE COOLING SYSTEM HOT

AND UNDER PRESSURE. SERIOUS BURNS FROM

COOLANT OR HIGH PRESSURE STEAM CAN

OCCUR.

The 5.9L, 5.9L Diesel, and 8.0L engine coolant

reserve / overflow system provides a quick method for

determining the coolant level without removing the

radiator pressure cap. With the engine at normal

operating temperature and idling, observe the level

of the coolant on the external level indicator on the

side of the coolant reserve / overflow bottle. The cool-

ant level should be between the MIN and MAX

marks. If the coolant is below the MIN mark, add a

50/50 mixture of antifreeze and water to the bottle

until the level reaches the MIN mark.Do Not Over-

fill the bottle by adding fluid above the MAX

line.This may cause coolant to spill onto the ground

during subsequent vehicle operation.

The 3.7L/4.7L/5.9L engine coolant degas system

provides a quick method for determining the coolant

level with out removing the radiator pressure cap.

With a cold engine, observe the level of coolant in the

degas bottle. The level should be in the COLD FILL

RANGE.DO NOT OVERFILLthe bottle by adding

fluid above the COLD FILL RANGE. This may cause

coolant to spill onto the ground during subsequent

vehicle operation.

STANDARD PROCEDURE - COOLING SYSTEM

CLEANING/REVERSE FLUSHING

CLEANING

Drain the cooling system and refill with water. Run

the engine with the radiator cap installed until the

upper radiator hose is hot. Stop the engine and drain

the water from system. If the water is dirty, fill the

system with water, run the engine and drain the sys-

tem. Repeat this procedure until the water drains

clean.

REVERSE FLUSHING

Reverse flushing of the cooling system is the forc-

ing of water through the cooling system. This is doneusing air pressure in the opposite direction of normal

coolant flow. It is usually only necessary with very

dirty systems with evidence of partial plugging.

REVERSE FLUSHING RADIATOR

Disconnect the radiator hoses from the radiator

inlet and outlet. Attach a section of the radiator hose

to the radiator bottom outlet fitting and insert the

flushing gun. Connect a water supply hose and air

supply hose to the flushing gun.

CAUTION: Internal radiator pressure must not

exceed 138 kPa (20 psi) as damage to radiator may

result.

Allow the radiator to fill with water. When the

radiator is filled, apply air in short blasts. Allow the

radiator to refill between blasts. Continue this

reverse flushing until clean water flows out through

the rear of the radiator cooling tube passages.

REVERSE FLUSHING ENGINE

Drain the cooling system. Remove the thermostat

housing and thermostat. Install the thermostat hous-

ing. Disconnect the radiator upper hose from the

radiator and attach the flushing gun to the hose. Dis-

connect the radiator lower hose from the water pump

and attach a lead-away hose to the water pump inlet

fitting.

CAUTION: On vehicles equipped with a heater water

control valve, be sure the heater control valve is

closed (heat off). This will prevent coolant flow with

scale and other deposits from entering the heater

core.

Connect the water supply hose and air supply hose

to flushing gun. Allow the engine to fill with water.

When the engine is filled, apply air in short blasts,

allowing the system to fill between air blasts. Con-

tinue until clean water flows through the lead away

hose.

Remove the lead away hose, flushing gun, water

supply hose and air supply hose. Remove the thermo-

stat housing and install the thermostat. Install the

thermostat housing with a replacement gasket. Refer

to Thermostat Replacement. Connect the radiator

hoses. Refill the cooling system with the correct anti-

freeze/water mixture. Refer to Refilling the Cooling

System.

CHEMICAL CLEANING

In some instances, use a radiator cleaner (Mopart

Radiator Kleen or equivalent) before flushing. This

will soften scale and other deposits and aid flushing

operation.

DRCOOLING 7 - 17

COOLING (Continued)

Page 305 of 2895

CAUTION: Follow manufacturers instructions when

using these products.

STANDARD PROCEDUREÐDRAINING COOLING

SYSTEM 3.7L/4.7L/5.7L ENGINE

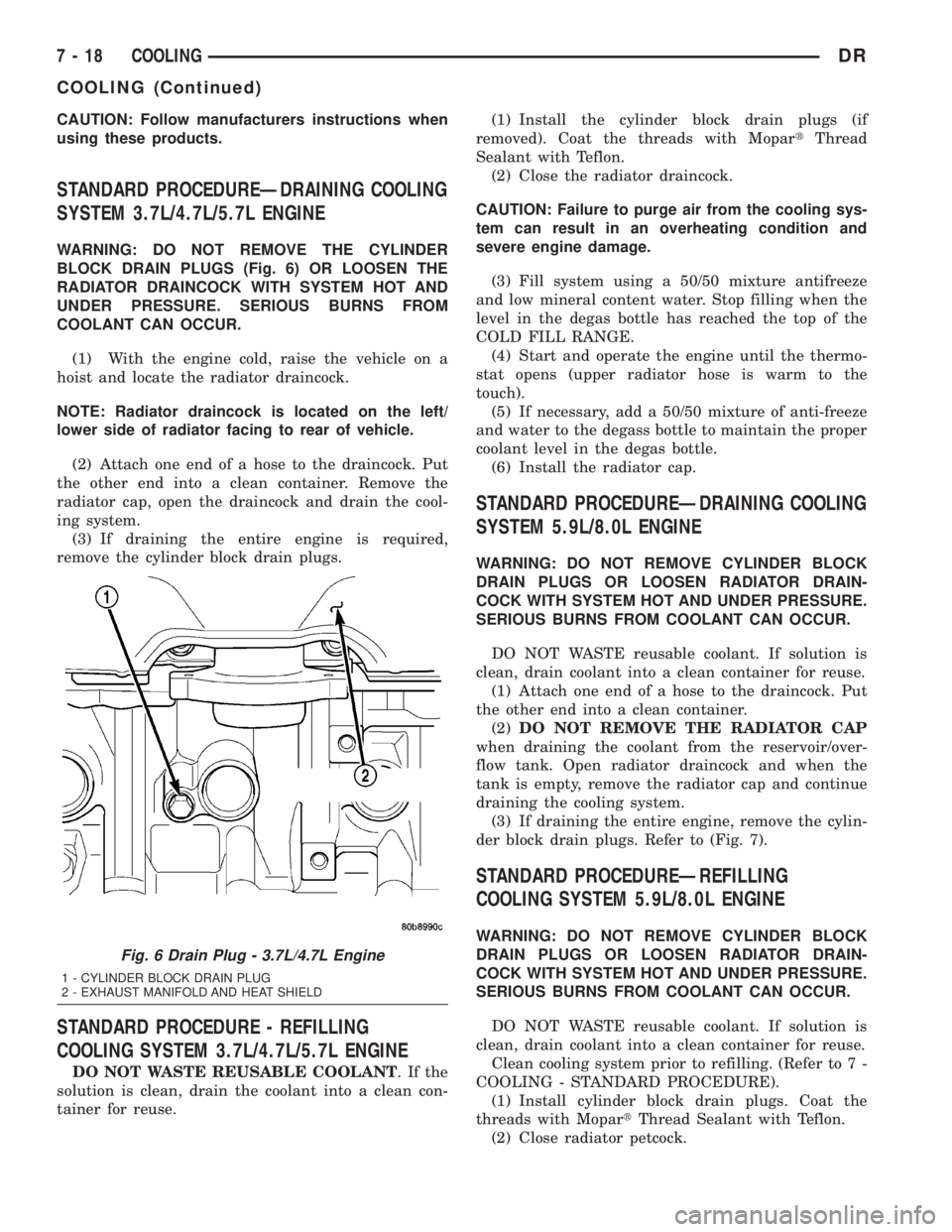

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS (Fig. 6) OR LOOSEN THE

RADIATOR DRAINCOCK WITH SYSTEM HOT AND

UNDER PRESSURE. SERIOUS BURNS FROM

COOLANT CAN OCCUR.

(1) With the engine cold, raise the vehicle on a

hoist and locate the radiator draincock.

NOTE: Radiator draincock is located on the left/

lower side of radiator facing to rear of vehicle.

(2) Attach one end of a hose to the draincock. Put

the other end into a clean container. Remove the

radiator cap, open the draincock and drain the cool-

ing system.

(3) If draining the entire engine is required,

remove the cylinder block drain plugs.

STANDARD PROCEDURE - REFILLING

COOLING SYSTEM 3.7L/4.7L/5.7L ENGINE

DO NOT WASTE REUSABLE COOLANT.Ifthe

solution is clean, drain the coolant into a clean con-

tainer for reuse.(1) Install the cylinder block drain plugs (if

removed). Coat the threads with MopartThread

Sealant with Teflon.

(2) Close the radiator draincock.

CAUTION: Failure to purge air from the cooling sys-

tem can result in an overheating condition and

severe engine damage.

(3) Fill system using a 50/50 mixture antifreeze

and low mineral content water. Stop filling when the

level in the degas bottle has reached the top of the

COLD FILL RANGE.

(4) Start and operate the engine until the thermo-

stat opens (upper radiator hose is warm to the

touch).

(5) If necessary, add a 50/50 mixture of anti-freeze

and water to the degass bottle to maintain the proper

coolant level in the degas bottle.

(6) Install the radiator cap.

STANDARD PROCEDUREÐDRAINING COOLING

SYSTEM 5.9L/8.0L ENGINE

WARNING: DO NOT REMOVE CYLINDER BLOCK

DRAIN PLUGS OR LOOSEN RADIATOR DRAIN-

COCK WITH SYSTEM HOT AND UNDER PRESSURE.

SERIOUS BURNS FROM COOLANT CAN OCCUR.

DO NOT WASTE reusable coolant. If solution is

clean, drain coolant into a clean container for reuse.

(1) Attach one end of a hose to the draincock. Put

the other end into a clean container.

(2)DO NOT REMOVE THE RADIATOR CAP

when draining the coolant from the reservoir/over-

flow tank. Open radiator draincock and when the

tank is empty, remove the radiator cap and continue

draining the cooling system.

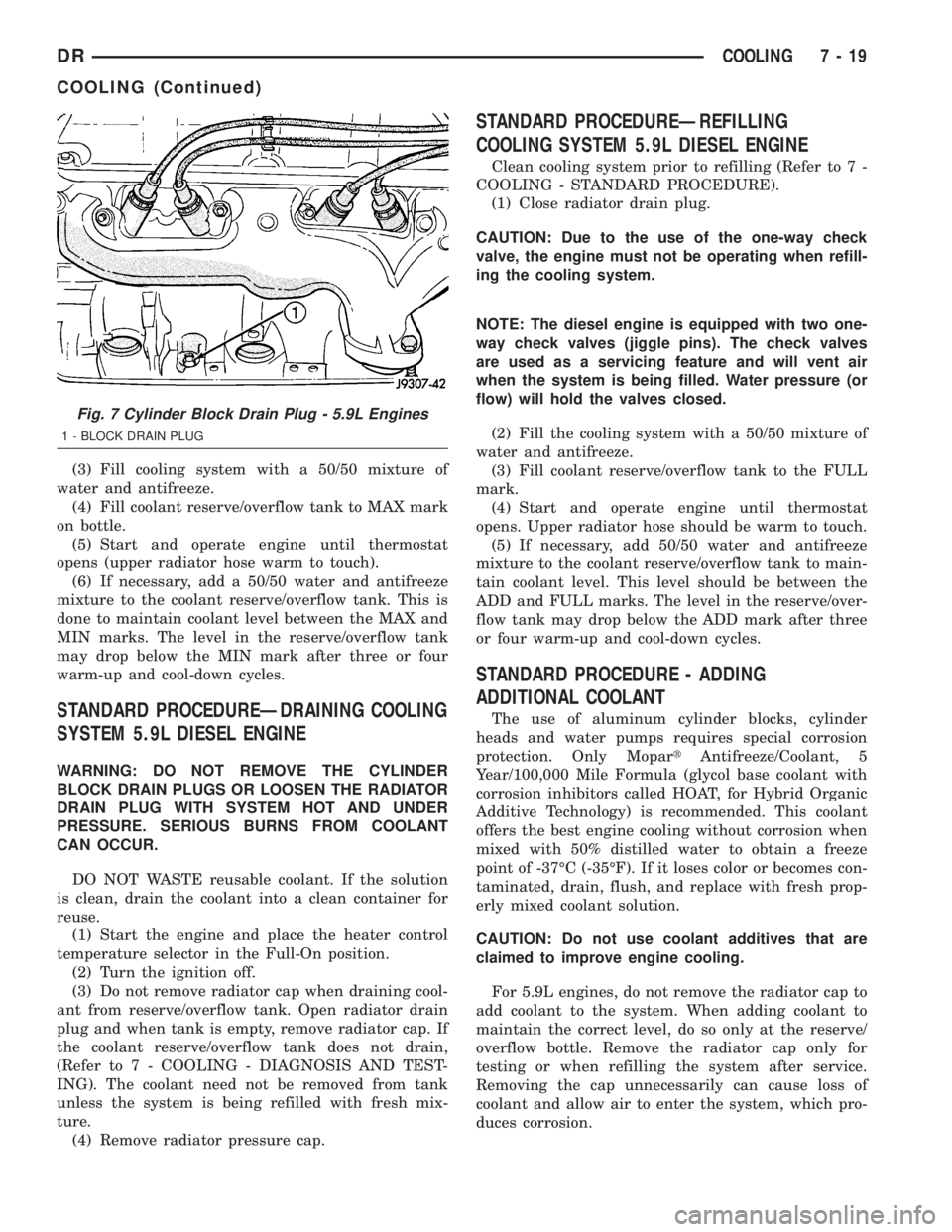

(3) If draining the entire engine, remove the cylin-

der block drain plugs. Refer to (Fig. 7).

STANDARD PROCEDUREÐREFILLING

COOLING SYSTEM 5.9L/8.0L ENGINE

WARNING: DO NOT REMOVE CYLINDER BLOCK

DRAIN PLUGS OR LOOSEN RADIATOR DRAIN-

COCK WITH SYSTEM HOT AND UNDER PRESSURE.

SERIOUS BURNS FROM COOLANT CAN OCCUR.

DO NOT WASTE reusable coolant. If solution is

clean, drain coolant into a clean container for reuse.

Clean cooling system prior to refilling. (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(1) Install cylinder block drain plugs. Coat the

threads with MopartThread Sealant with Teflon.

(2) Close radiator petcock.

Fig. 6 Drain Plug - 3.7L/4.7L Engine

1 - CYLINDER BLOCK DRAIN PLUG

2 - EXHAUST MANIFOLD AND HEAT SHIELD

7 - 18 COOLINGDR

COOLING (Continued)

Page 306 of 2895

(3) Fill cooling system with a 50/50 mixture of

water and antifreeze.

(4) Fill coolant reserve/overflow tank to MAX mark

on bottle.

(5) Start and operate engine until thermostat

opens (upper radiator hose warm to touch).

(6) If necessary, add a 50/50 water and antifreeze

mixture to the coolant reserve/overflow tank. This is

done to maintain coolant level between the MAX and

MIN marks. The level in the reserve/overflow tank

may drop below the MIN mark after three or four

warm-up and cool-down cycles.

STANDARD PROCEDUREÐDRAINING COOLING

SYSTEM 5.9L DIESEL ENGINE

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAIN PLUG WITH SYSTEM HOT AND UNDER

PRESSURE. SERIOUS BURNS FROM COOLANT

CAN OCCUR.

DO NOT WASTE reusable coolant. If the solution

is clean, drain the coolant into a clean container for

reuse.

(1) Start the engine and place the heater control

temperature selector in the Full-On position.

(2) Turn the ignition off.

(3) Do not remove radiator cap when draining cool-

ant from reserve/overflow tank. Open radiator drain

plug and when tank is empty, remove radiator cap. If

the coolant reserve/overflow tank does not drain,

(Refer to 7 - COOLING - DIAGNOSIS AND TEST-

ING). The coolant need not be removed from tank

unless the system is being refilled with fresh mix-

ture.

(4) Remove radiator pressure cap.

STANDARD PROCEDUREÐREFILLING

COOLING SYSTEM 5.9L DIESEL ENGINE

Clean cooling system prior to refilling (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(1) Close radiator drain plug.

CAUTION: Due to the use of the one-way check

valve, the engine must not be operating when refill-

ing the cooling system.

NOTE: The diesel engine is equipped with two one-

way check valves (jiggle pins). The check valves

are used as a servicing feature and will vent air

when the system is being filled. Water pressure (or

flow) will hold the valves closed.

(2) Fill the cooling system with a 50/50 mixture of

water and antifreeze.

(3) Fill coolant reserve/overflow tank to the FULL

mark.

(4) Start and operate engine until thermostat

opens. Upper radiator hose should be warm to touch.

(5) If necessary, add 50/50 water and antifreeze

mixture to the coolant reserve/overflow tank to main-

tain coolant level. This level should be between the

ADD and FULL marks. The level in the reserve/over-

flow tank may drop below the ADD mark after three

or four warm-up and cool-down cycles.

STANDARD PROCEDURE - ADDING

ADDITIONAL COOLANT

The use of aluminum cylinder blocks, cylinder

heads and water pumps requires special corrosion

protection. Only MopartAntifreeze/Coolant, 5

Year/100,000 Mile Formula (glycol base coolant with

corrosion inhibitors called HOAT, for Hybrid Organic

Additive Technology) is recommended. This coolant

offers the best engine cooling without corrosion when

mixed with 50% distilled water to obtain a freeze

point of -37ÉC (-35ÉF). If it loses color or becomes con-

taminated, drain, flush, and replace with fresh prop-

erly mixed coolant solution.

CAUTION: Do not use coolant additives that are

claimed to improve engine cooling.

For 5.9L engines, do not remove the radiator cap to

add coolant to the system. When adding coolant to

maintain the correct level, do so only at the reserve/

overflow bottle. Remove the radiator cap only for

testing or when refilling the system after service.

Removing the cap unnecessarily can cause loss of

coolant and allow air to enter the system, which pro-

duces corrosion.

Fig. 7 Cylinder Block Drain Plug - 5.9L Engines

1 - BLOCK DRAIN PLUG

DRCOOLING 7 - 19

COOLING (Continued)

Page 307 of 2895

WARNING: DO NOT REMOVE OR LOOSEN THE

RADIATOR CAP WITH THE COOLING SYSTEM HOT

AND UNDER PRESSURE. SERIOUS BURNS FROM

THE COOLANT OR HIGH PRESSURE STEAM CAN

OCCUR.

For 3.7L / 4.7L/5.9L engines, remove the radiator

cap from the coolant degas bottle to add coolant.

SPECIFICATIONS

TORQUE

DESCRIPTION N´m Ft. In.

Lbs. Lbs.

Automatic Belt Tensioner to

BlockÐBolts 41 30 Ð

Automatic Belt Tensioner

PulleyÐBolt 61 45 Ð

Block HeaterÐBolt 2 Ð 17

Generator/Compressor

Mounting BracketÐBolts

# 1 and 2 54 40 Ð

# 3 40 30 Ð

Fan Shroud to Radiator

MountingÐBolts6Ð55

Radiator to Support - Bolts 8.5 Ð 75

Fan Blade to Viscous Fan

DriveÐBolts24 18 Ð

Idler PulleyÐBolt 54 40 Ð

Thermostat HousingÐBolts

- All Except 5.9L13 Ð 112

Thermostat HousingÐBolts

- 5.9L23 16 Ð

Power Steering Oil Cooler

Ð Bolts6Ð55

Transmission Auxiliary Oil

CoolerÐBolts 6 Ð 55

Transmission Oil Cooler

Tube Nuts31.5 24 Ð

Coolant Bottle Ð Bolts 8.5 Ð 75

Transmission Oil Cooler to

Transmission - 5.9L/46RE -

Tube Nuts 31.5 24 Ð

Transmission Oil Cooler to

Transmission - 3.7L/4.7L/

45RFE - Tube Nuts20 18 Ð

Water PumpÐBolts 24 18 Ð

Water Pump Ð Bolts - 4.7L 58 43 Ð

SPECIFICATIONS -

SPECIFICATIONS

DESCRIPTION SPECIFICATION

3.7/4.7L Engine 15.4L (16.2 qts.)- to the

middle of the cold fill

range

5.7L Engine 15.4L (16.2 qts.)- to the

middle of the cold fill

range

5.9L Engine 15.5L (16.3 qts.)- to the

MIN mark after 3 warm

up, cool down cycles

8.0L Engine 24L (25.3 qts.)

5.9L Diesel Engine 28L (29.5 qts.)

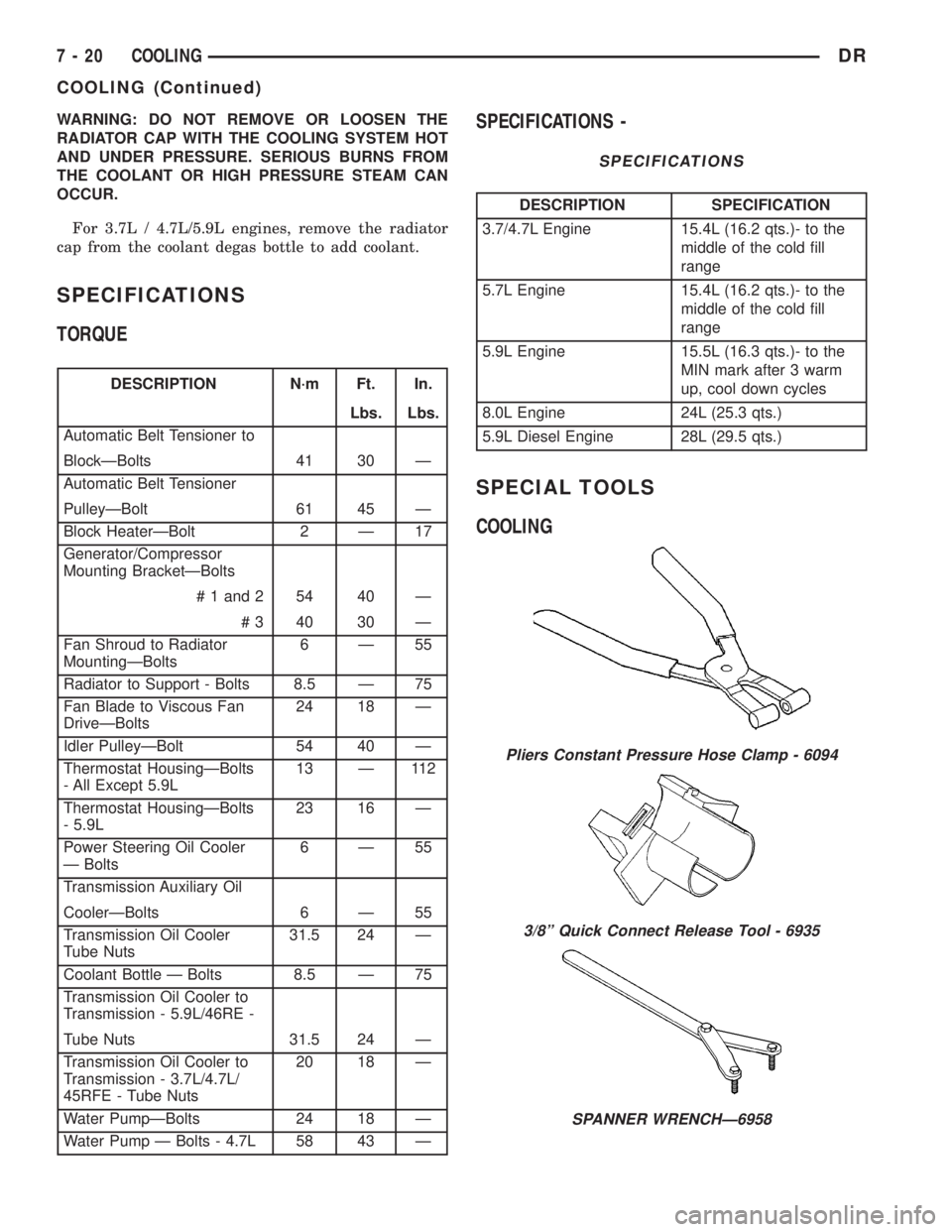

SPECIAL TOOLS

COOLING

Pliers Constant Pressure Hose Clamp - 6094

3/8º Quick Connect Release Tool - 6935

SPANNER WRENCHÐ6958

7 - 20 COOLINGDR

COOLING (Continued)

Page 309 of 2895

ACCESSORY DRIVE

TABLE OF CONTENTS

page page

BELT TENSIONERS - 3.7L / 4.7L

DESCRIPTION.........................22

OPERATION...........................22

REMOVAL.............................22

INSTALLATION.........................23

BELT TENSIONERS - 5.9L

DESCRIPTION.........................23

OPERATION...........................23

REMOVAL.............................23

INSTALLATION.........................24

BELT TENSIONERS - 5.9L DIESEL

DESCRIPTION.........................24

OPERATION...........................24

REMOVAL.............................25

INSTALLATION.........................25DRIVE BELTS - 3.7L / 4.7L

DIAGNOSIS AND TESTING - ACCESSORY

DRIVE BELT.........................25

REMOVAL.............................27

INSTALLATION.........................27

DRIVE BELTS - 5.9L

DIAGNOSIS AND TESTING - ACCESSORY

DRIVE BELT.........................28

REMOVAL.............................30

INSTALLATION.........................31

DRIVE BELTS - 5.9L DIESEL

DIAGNOSIS AND TESTINGÐACCESSORY

DRIVE BELT.........................31

REMOVAL.............................34

INSTALLATION.........................34

BELT TENSIONERS - 3.7L /

4.7L

DESCRIPTION

Correct drive belt tension is required to ensure

optimum performance of the belt driven engine acces-

sories. If specified tension is not maintained, belt

slippage may cause; engine overheating, lack of

power steering assist, loss of air conditioning capac-

ity, reduced generator output rate, and greatly

reduced belt life.

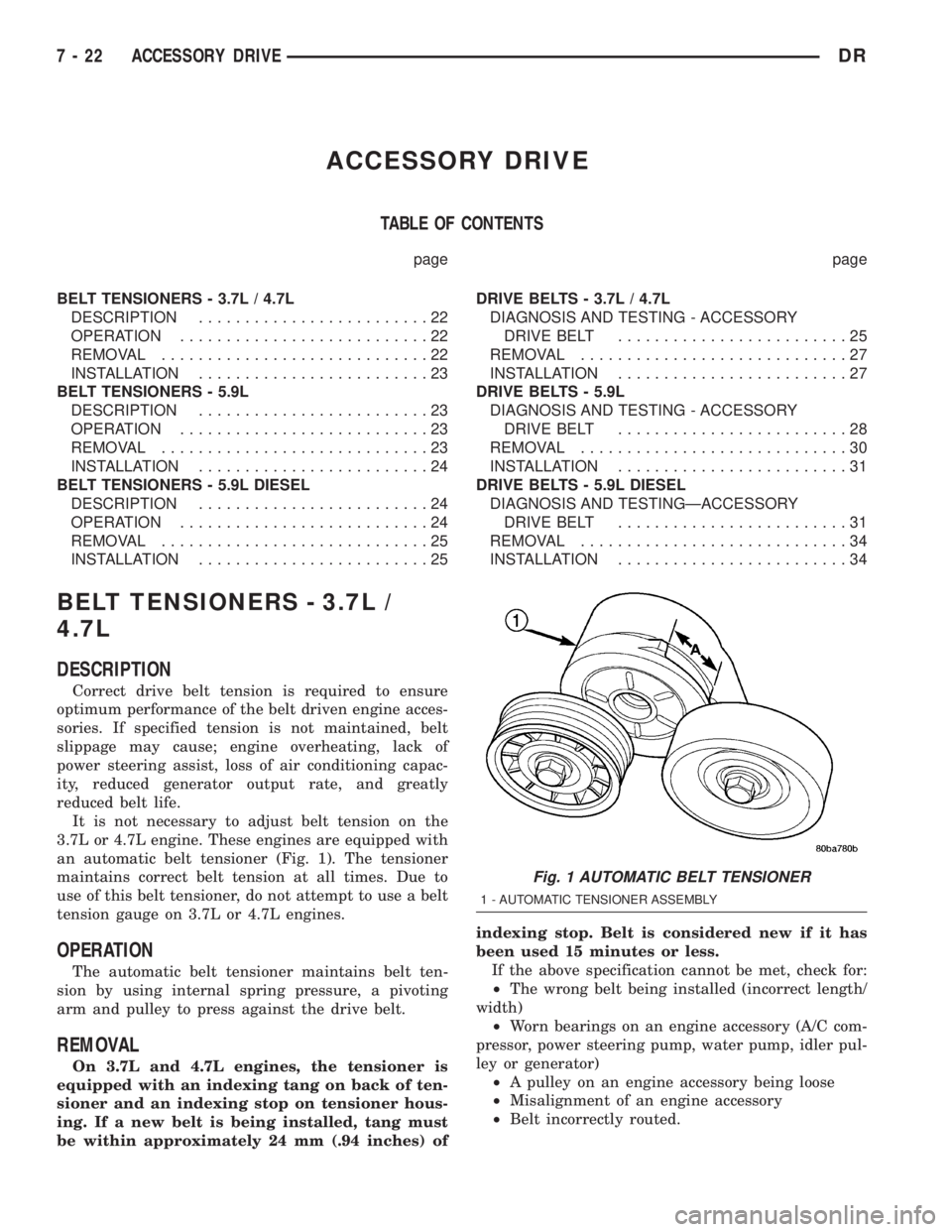

It is not necessary to adjust belt tension on the

3.7L or 4.7L engine. These engines are equipped with

an automatic belt tensioner (Fig. 1). The tensioner

maintains correct belt tension at all times. Due to

use of this belt tensioner, do not attempt to use a belt

tension gauge on 3.7L or 4.7L engines.

OPERATION

The automatic belt tensioner maintains belt ten-

sion by using internal spring pressure, a pivoting

arm and pulley to press against the drive belt.

REMOVAL

On 3.7L and 4.7L engines, the tensioner is

equipped with an indexing tang on back of ten-

sioner and an indexing stop on tensioner hous-

ing. If a new belt is being installed, tang must

be within approximately 24 mm (.94 inches) ofindexing stop. Belt is considered new if it has

been used 15 minutes or less.

If the above specification cannot be met, check for:

²The wrong belt being installed (incorrect length/

width)

²Worn bearings on an engine accessory (A/C com-

pressor, power steering pump, water pump, idler pul-

ley or generator)

²A pulley on an engine accessory being loose

²Misalignment of an engine accessory

²Belt incorrectly routed.

Fig. 1 AUTOMATIC BELT TENSIONER

1 - AUTOMATIC TENSIONER ASSEMBLY

7 - 22 ACCESSORY DRIVEDR

Page 310 of 2895

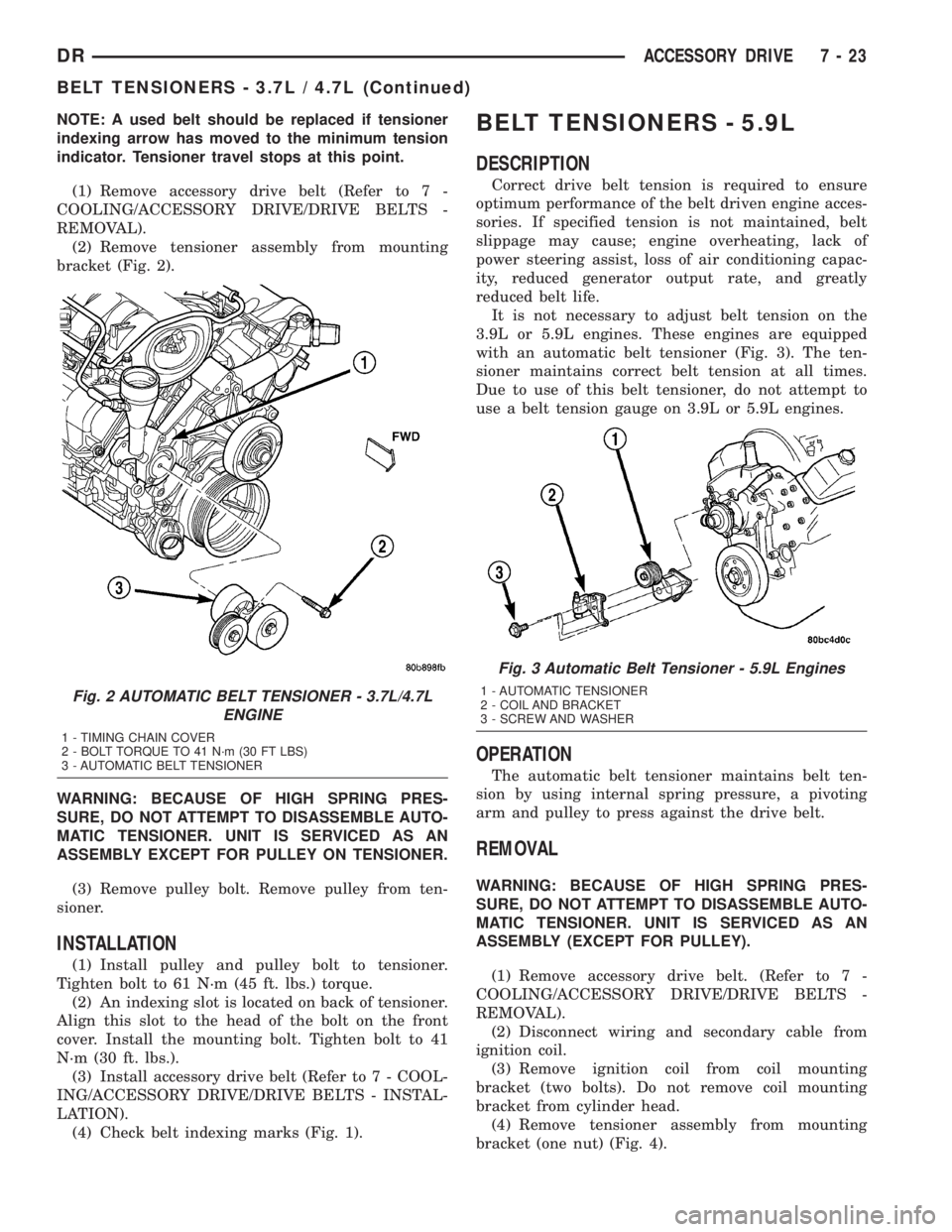

NOTE: A used belt should be replaced if tensioner

indexing arrow has moved to the minimum tension

indicator. Tensioner travel stops at this point.

(1) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(2) Remove tensioner assembly from mounting

bracket (Fig. 2).

WARNING: BECAUSE OF HIGH SPRING PRES-

SURE, DO NOT ATTEMPT TO DISASSEMBLE AUTO-

MATIC TENSIONER. UNIT IS SERVICED AS AN

ASSEMBLY EXCEPT FOR PULLEY ON TENSIONER.

(3) Remove pulley bolt. Remove pulley from ten-

sioner.

INSTALLATION

(1) Install pulley and pulley bolt to tensioner.

Tighten bolt to 61 N´m (45 ft. lbs.) torque.

(2) An indexing slot is located on back of tensioner.

Align this slot to the head of the bolt on the front

cover. Install the mounting bolt. Tighten bolt to 41

N´m (30 ft. lbs.).

(3) Install accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(4) Check belt indexing marks (Fig. 1).

BELT TENSIONERS - 5.9L

DESCRIPTION

Correct drive belt tension is required to ensure

optimum performance of the belt driven engine acces-

sories. If specified tension is not maintained, belt

slippage may cause; engine overheating, lack of

power steering assist, loss of air conditioning capac-

ity, reduced generator output rate, and greatly

reduced belt life.

It is not necessary to adjust belt tension on the

3.9L or 5.9L engines. These engines are equipped

with an automatic belt tensioner (Fig. 3). The ten-

sioner maintains correct belt tension at all times.

Due to use of this belt tensioner, do not attempt to

use a belt tension gauge on 3.9L or 5.9L engines.

OPERATION

The automatic belt tensioner maintains belt ten-

sion by using internal spring pressure, a pivoting

arm and pulley to press against the drive belt.

REMOVAL

WARNING: BECAUSE OF HIGH SPRING PRES-

SURE, DO NOT ATTEMPT TO DISASSEMBLE AUTO-

MATIC TENSIONER. UNIT IS SERVICED AS AN

ASSEMBLY (EXCEPT FOR PULLEY).

(1) Remove accessory drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(2) Disconnect wiring and secondary cable from

ignition coil.

(3) Remove ignition coil from coil mounting

bracket (two bolts). Do not remove coil mounting

bracket from cylinder head.

(4) Remove tensioner assembly from mounting

bracket (one nut) (Fig. 4).

Fig. 2 AUTOMATIC BELT TENSIONER - 3.7L/4.7L

ENGINE

1 - TIMING CHAIN COVER

2 - BOLT TORQUE TO 41 N´m (30 FT LBS)

3 - AUTOMATIC BELT TENSIONER

Fig. 3 Automatic Belt Tensioner - 5.9L Engines

1 - AUTOMATIC TENSIONER

2 - COIL AND BRACKET

3 - SCREW AND WASHER

DRACCESSORY DRIVE 7 - 23

BELT TENSIONERS - 3.7L / 4.7L (Continued)

Page 311 of 2895

(5) Remove pulley bolt. Remove pulley from ten-

sioner.

INSTALLATION

(1) Install pulley and pulley bolt to tensioner.

Tighten bolt to 61 N´m (45 ft. lbs.) torque.

(2) Install tensioner assembly to mounting

bracket. An indexing tab is located on back of ten-

sioner. Align this tab to slot in mounting bracket.

Tighten nut to 67 N´m (50 ft. lbs.) torque.

(3) Connect all wiring to ignition coil.

CAUTION: To prevent damage to coil case, coil

mounting bolts must be torqued.

(4) Install coil to coil bracket. If nuts and bolts are

used to secure coil to coil bracket, tighten to 11 N´m

(100 in. lbs.) torque. If coil mounting bracket has

been tapped for coil mounting bolts, tighten bolts to 5

N´m (50 in. lbs.) torque.

(5) Install drive belt. (Refer to 7 - COOLING/AC-

CESSORY DRIVE/DRIVE BELTS - INSTALLA-

TION).

(6) Check belt indexing marks (Fig. 4).

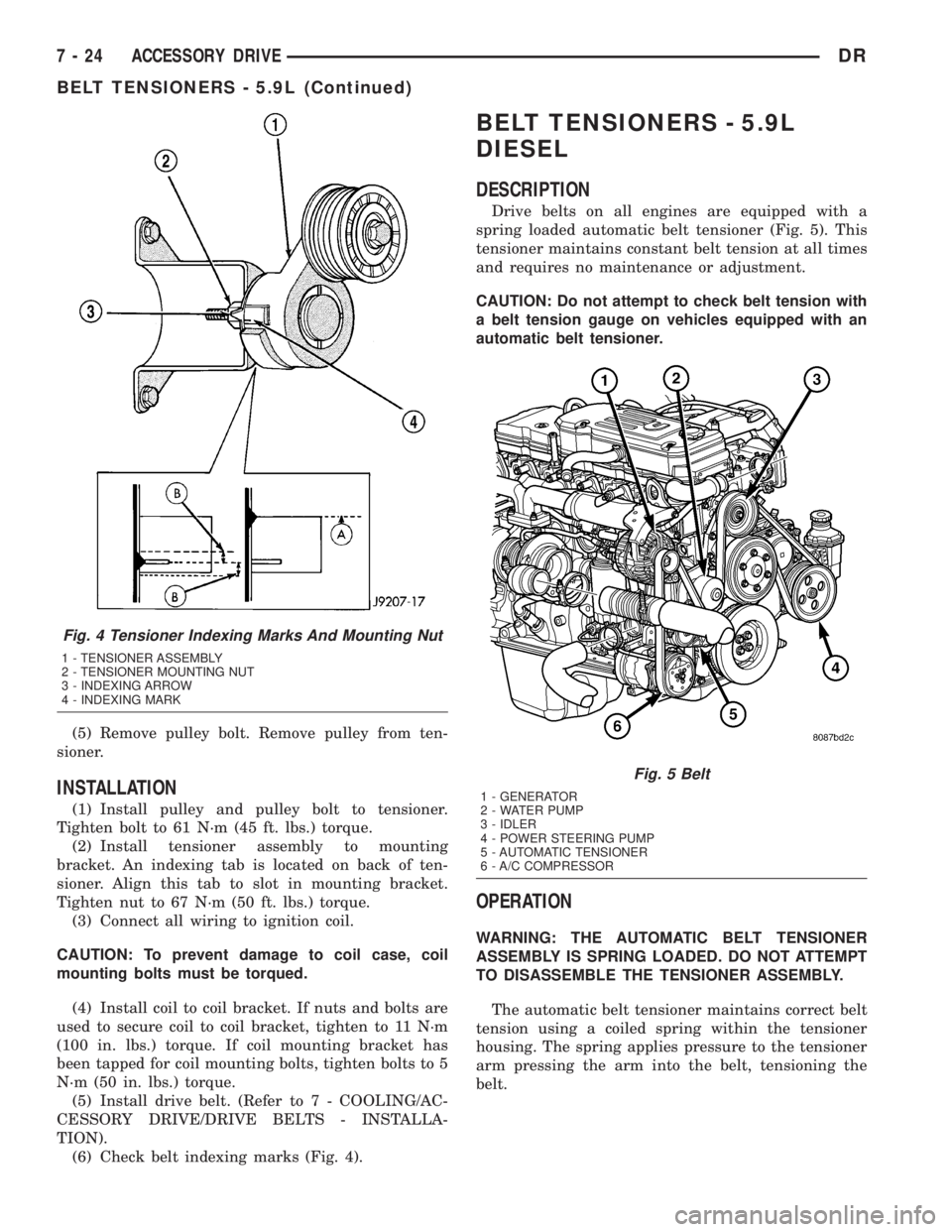

BELT TENSIONERS - 5.9L

DIESEL

DESCRIPTION

Drive belts on all engines are equipped with a

spring loaded automatic belt tensioner (Fig. 5). This

tensioner maintains constant belt tension at all times

and requires no maintenance or adjustment.

CAUTION: Do not attempt to check belt tension with

a belt tension gauge on vehicles equipped with an

automatic belt tensioner.

OPERATION

WARNING: THE AUTOMATIC BELT TENSIONER

ASSEMBLY IS SPRING LOADED. DO NOT ATTEMPT

TO DISASSEMBLE THE TENSIONER ASSEMBLY.

The automatic belt tensioner maintains correct belt

tension using a coiled spring within the tensioner

housing. The spring applies pressure to the tensioner

arm pressing the arm into the belt, tensioning the

belt.

Fig. 4 Tensioner Indexing Marks And Mounting Nut

1 - TENSIONER ASSEMBLY

2 - TENSIONER MOUNTING NUT

3 - INDEXING ARROW

4 - INDEXING MARK

Fig. 5 Belt

1 - GENERATOR

2 - WATER PUMP

3 - IDLER

4 - POWER STEERING PUMP

5 - AUTOMATIC TENSIONER

6 - A/C COMPRESSOR

7 - 24 ACCESSORY DRIVEDR

BELT TENSIONERS - 5.9L (Continued)