Throttle Position Sensor DODGE RAM 2003 Service Manual Online

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2215 of 2895

ADJUSTMENTS - BRAKE TRANSMISSION

SHIFT INTERLOCK

Correct cable adjustment is important to proper

interlock operation. The gearshift cable must be cor-

rectly adjusted in order to shift out of PARK.

ADJUSTMENT PROCEDURE

(1) Remove the steering column trim as necessary

for access to the brake transmission shift interlock.

(2) Shift the transmission into the PARK position.

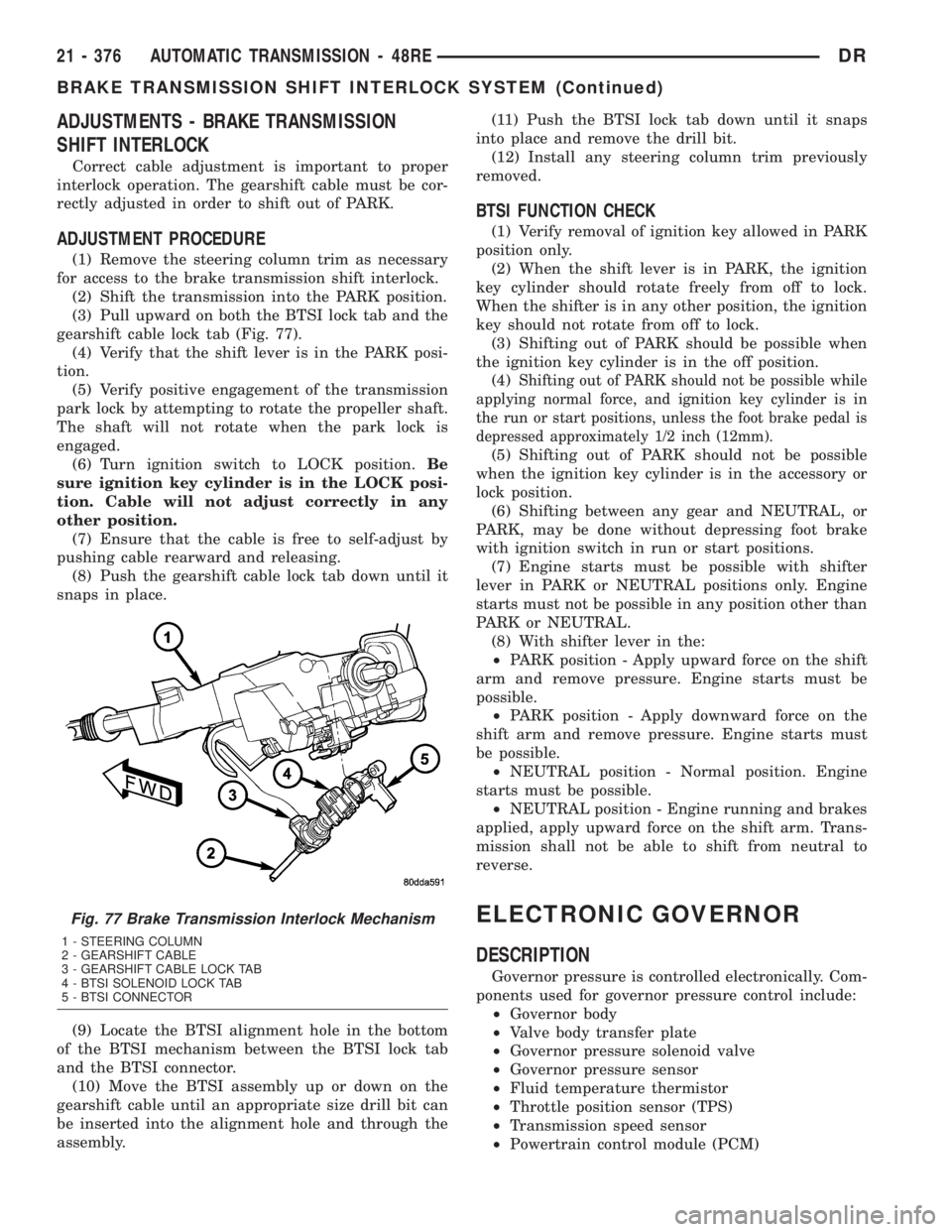

(3) Pull upward on both the BTSI lock tab and the

gearshift cable lock tab (Fig. 77).

(4) Verify that the shift lever is in the PARK posi-

tion.

(5) Verify positive engagement of the transmission

park lock by attempting to rotate the propeller shaft.

The shaft will not rotate when the park lock is

engaged.

(6) Turn ignition switch to LOCK position.Be

sure ignition key cylinder is in the LOCK posi-

tion. Cable will not adjust correctly in any

other position.

(7) Ensure that the cable is free to self-adjust by

pushing cable rearward and releasing.

(8) Push the gearshift cable lock tab down until it

snaps in place.

(9) Locate the BTSI alignment hole in the bottom

of the BTSI mechanism between the BTSI lock tab

and the BTSI connector.

(10) Move the BTSI assembly up or down on the

gearshift cable until an appropriate size drill bit can

be inserted into the alignment hole and through the

assembly.(11) Push the BTSI lock tab down until it snaps

into place and remove the drill bit.

(12) Install any steering column trim previously

removed.

BTSI FUNCTION CHECK

(1) Verify removal of ignition key allowed in PARK

position only.

(2) When the shift lever is in PARK, the ignition

key cylinder should rotate freely from off to lock.

When the shifter is in any other position, the ignition

key should not rotate from off to lock.

(3) Shifting out of PARK should be possible when

the ignition key cylinder is in the off position.

(4)

Shifting out of PARK should not be possible while

applying normal force, and ignition key cylinder is in

the run or start positions, unless the foot brake pedal is

depressed approximately 1/2 inch (12mm).

(5) Shifting out of PARK should not be possible

when the ignition key cylinder is in the accessory or

lock position.

(6) Shifting between any gear and NEUTRAL, or

PARK, may be done without depressing foot brake

with ignition switch in run or start positions.

(7) Engine starts must be possible with shifter

lever in PARK or NEUTRAL positions only. Engine

starts must not be possible in any position other than

PARK or NEUTRAL.

(8) With shifter lever in the:

²PARK position - Apply upward force on the shift

arm and remove pressure. Engine starts must be

possible.

²PARK position - Apply downward force on the

shift arm and remove pressure. Engine starts must

be possible.

²NEUTRAL position - Normal position. Engine

starts must be possible.

²NEUTRAL position - Engine running and brakes

applied, apply upward force on the shift arm. Trans-

mission shall not be able to shift from neutral to

reverse.

ELECTRONIC GOVERNOR

DESCRIPTION

Governor pressure is controlled electronically. Com-

ponents used for governor pressure control include:

²Governor body

²Valve body transfer plate

²Governor pressure solenoid valve

²Governor pressure sensor

²Fluid temperature thermistor

²Throttle position sensor (TPS)

²Transmission speed sensor

²Powertrain control module (PCM)

Fig. 77 Brake Transmission Interlock Mechanism

1 - STEERING COLUMN

2 - GEARSHIFT CABLE

3 - GEARSHIFT CABLE LOCK TAB

4 - BTSI SOLENOID LOCK TAB

5 - BTSI CONNECTOR

21 - 376 AUTOMATIC TRANSMISSION - 48REDR

BRAKE TRANSMISSION SHIFT INTERLOCK SYSTEM (Continued)

Page 2217 of 2895

GOVERNOR PRESSURE SENSOR

The sensor output signal provides the necessary

feedback to the PCM. This feedback is needed to ade-

quately control governor pressure.

GOVERNOR BODY AND TRANSFER PLATE

The transfer plate channels line pressure to the

solenoid valve through the governor body. It also

channels governor pressure from the solenoid valve

to the governor circuit. It is the solenoid valve that

develops the necessary governor pressure.

GOVERNOR PRESSURE CURVES

LOW TRANSMISSION FLUID TEMPERATURE

When the transmission fluid is cold the conven-

tional governor can delay shifts, resulting in higher

than normal shift speeds and harsh shifts. The elec-

tronically controlled low temperature governor pres-

sure curve is higher than normal to make the

transmission shift at normal speeds and sooner. The

PCM uses a temperature sensor in the transmission

oil sump to determine when low temperature gover-

nor pressure is needed.

NORMAL OPERATION

Normal operation is refined through the increased

computing power of the PCM and through access to

data on engine operating conditions provided by the

PCM that were not available with the previous

stand-alone electronic module. This facilitated the

development of a load adaptive shift strategy - the

ability to alter the shift schedule in response to vehi-

cle load condition. One manifestation of this capabil-

ity is grade9hunting9prevention - the ability of the

transmission logic to delay an upshift on a grade if

the engine does not have sufficient power to main-

tain speed in the higher gear. The 3-2 downshift and

the potential for hunting between gears occurs with a

heavily loaded vehicle or on steep grades. When

hunting occurs, it is very objectionable because shifts

are frequent and accompanied by large changes in

noise and acceleration.

WIDE OPEN THROTTLE OPERATION

In wide-open throttle (WOT) mode, adaptive mem-

ory in the PCM assures that up-shifts occur at the

preprogrammed optimum speed. WOT operation is

determined from the throttle position sensor, which

is also a part of the emission control system. The ini-tial setting for the WOT upshift is below the opti-

mum engine speed. As WOT shifts are repeated, the

PCM learns the time required to complete the shifts

by comparing the engine speed when the shifts occur

to the optimum speed. After each shift, the PCM

adjusts the shift point until the optimum speed is

reached. The PCM also considers vehicle loading,

grade and engine performance changes due to high

altitude in determining when to make WOT shifts. It

does this by measuring vehicle and engine accelera-

tion and then factoring in the shift time.

TRANSFER CASE LOW RANGE OPERATION

On four-wheel drive vehicles operating in low

range, the engine can accelerate to its peak more

rapidly than in Normal range, resulting in delayed

shifts and undesirable engine9flare.9The low range

governor pressure curve is also higher than normal

to initiate upshifts sooner. The PCM compares elec-

tronic vehicle speed signal used by the speedometer

to the transmission output shaft speed signal to

determine when the transfer case is in low range.

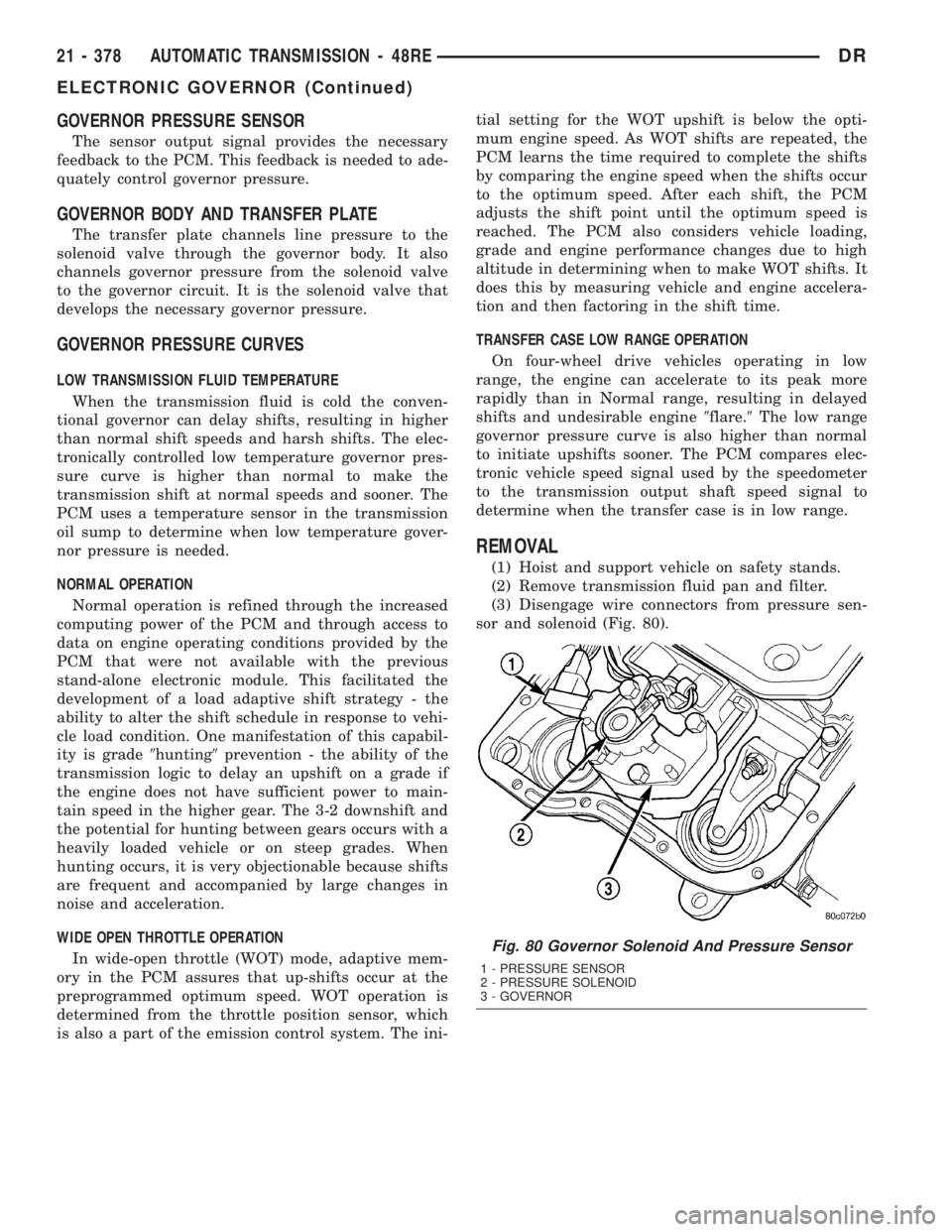

REMOVAL

(1) Hoist and support vehicle on safety stands.

(2) Remove transmission fluid pan and filter.

(3) Disengage wire connectors from pressure sen-

sor and solenoid (Fig. 80).

Fig. 80 Governor Solenoid And Pressure Sensor

1 - PRESSURE SENSOR

2 - PRESSURE SOLENOID

3 - GOVERNOR

21 - 378 AUTOMATIC TRANSMISSION - 48REDR

ELECTRONIC GOVERNOR (Continued)

Page 2303 of 2895

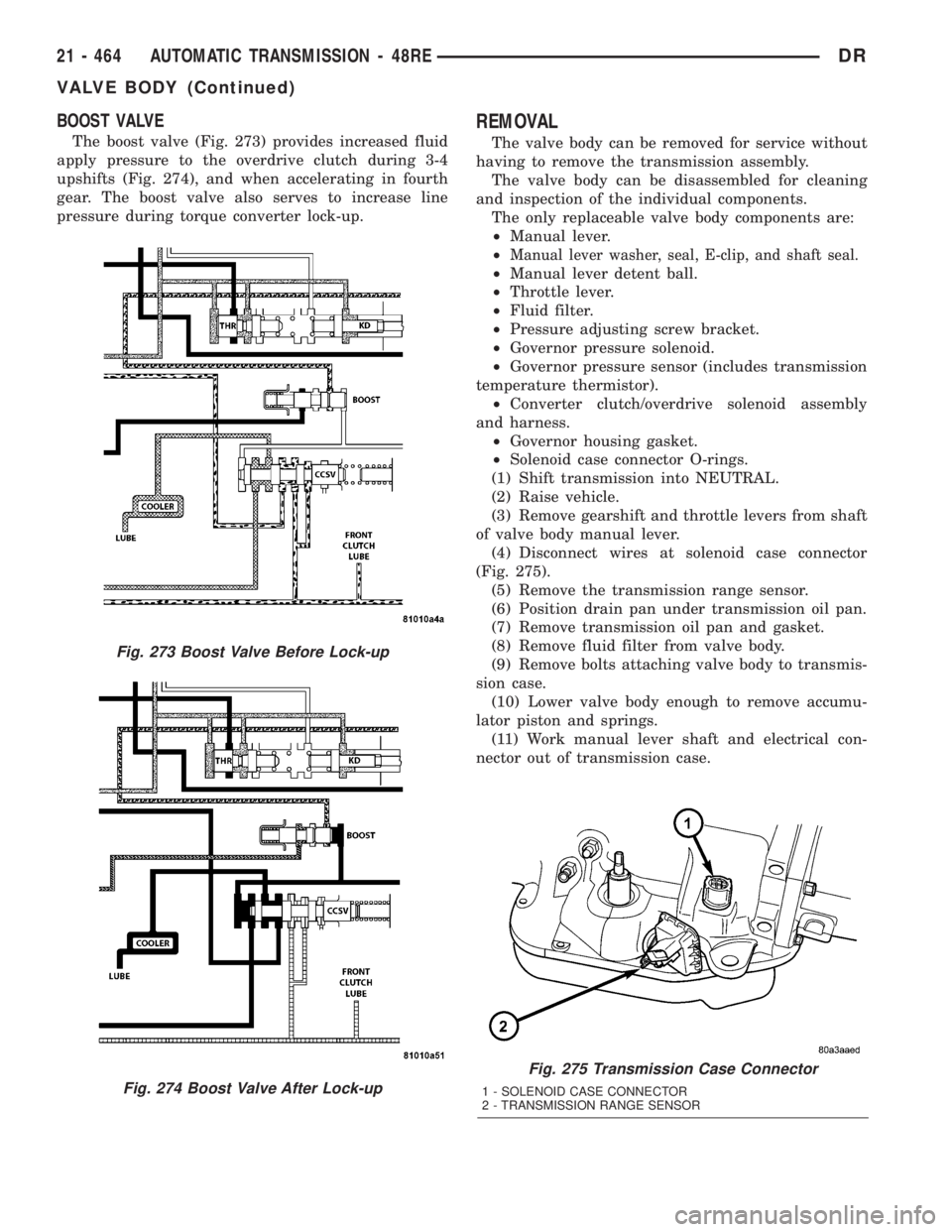

BOOST VALVE

The boost valve (Fig. 273) provides increased fluid

apply pressure to the overdrive clutch during 3-4

upshifts (Fig. 274), and when accelerating in fourth

gear. The boost valve also serves to increase line

pressure during torque converter lock-up.

REMOVAL

The valve body can be removed for service without

having to remove the transmission assembly.

The valve body can be disassembled for cleaning

and inspection of the individual components.

The only replaceable valve body components are:

²Manual lever.

²

Manual lever washer, seal, E-clip, and shaft seal.

²Manual lever detent ball.

²Throttle lever.

²Fluid filter.

²Pressure adjusting screw bracket.

²Governor pressure solenoid.

²Governor pressure sensor (includes transmission

temperature thermistor).

²Converter clutch/overdrive solenoid assembly

and harness.

²Governor housing gasket.

²Solenoid case connector O-rings.

(1) Shift transmission into NEUTRAL.

(2) Raise vehicle.

(3) Remove gearshift and throttle levers from shaft

of valve body manual lever.

(4) Disconnect wires at solenoid case connector

(Fig. 275).

(5) Remove the transmission range sensor.

(6) Position drain pan under transmission oil pan.

(7) Remove transmission oil pan and gasket.

(8) Remove fluid filter from valve body.

(9) Remove bolts attaching valve body to transmis-

sion case.

(10) Lower valve body enough to remove accumu-

lator piston and springs.

(11) Work manual lever shaft and electrical con-

nector out of transmission case.

Fig. 275 Transmission Case Connector

1 - SOLENOID CASE CONNECTOR

2 - TRANSMISSION RANGE SENSOR

Fig. 273 Boost Valve Before Lock-up

Fig. 274 Boost Valve After Lock-up

21 - 464 AUTOMATIC TRANSMISSION - 48REDR

VALVE BODY (Continued)

Page 2315 of 2895

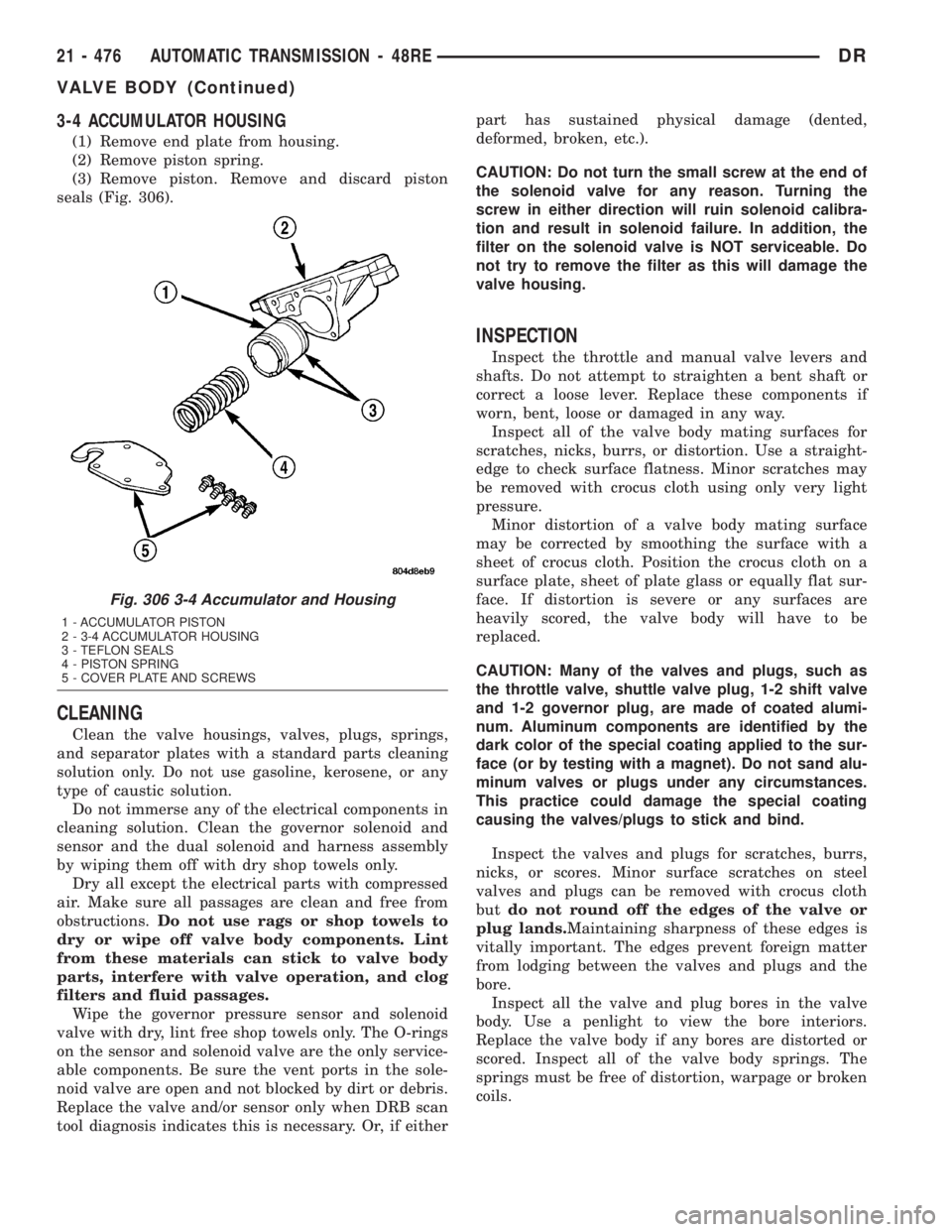

3-4 ACCUMULATOR HOUSING

(1) Remove end plate from housing.

(2) Remove piston spring.

(3) Remove piston. Remove and discard piston

seals (Fig. 306).

CLEANING

Clean the valve housings, valves, plugs, springs,

and separator plates with a standard parts cleaning

solution only. Do not use gasoline, kerosene, or any

type of caustic solution.

Do not immerse any of the electrical components in

cleaning solution. Clean the governor solenoid and

sensor and the dual solenoid and harness assembly

by wiping them off with dry shop towels only.

Dry all except the electrical parts with compressed

air. Make sure all passages are clean and free from

obstructions.Do not use rags or shop towels to

dry or wipe off valve body components. Lint

from these materials can stick to valve body

parts, interfere with valve operation, and clog

filters and fluid passages.

Wipe the governor pressure sensor and solenoid

valve with dry, lint free shop towels only. The O-rings

on the sensor and solenoid valve are the only service-

able components. Be sure the vent ports in the sole-

noid valve are open and not blocked by dirt or debris.

Replace the valve and/or sensor only when DRB scan

tool diagnosis indicates this is necessary. Or, if eitherpart has sustained physical damage (dented,

deformed, broken, etc.).

CAUTION: Do not turn the small screw at the end of

the solenoid valve for any reason. Turning the

screw in either direction will ruin solenoid calibra-

tion and result in solenoid failure. In addition, the

filter on the solenoid valve is NOT serviceable. Do

not try to remove the filter as this will damage the

valve housing.

INSPECTION

Inspect the throttle and manual valve levers and

shafts. Do not attempt to straighten a bent shaft or

correct a loose lever. Replace these components if

worn, bent, loose or damaged in any way.

Inspect all of the valve body mating surfaces for

scratches, nicks, burrs, or distortion. Use a straight-

edge to check surface flatness. Minor scratches may

be removed with crocus cloth using only very light

pressure.

Minor distortion of a valve body mating surface

may be corrected by smoothing the surface with a

sheet of crocus cloth. Position the crocus cloth on a

surface plate, sheet of plate glass or equally flat sur-

face. If distortion is severe or any surfaces are

heavily scored, the valve body will have to be

replaced.

CAUTION: Many of the valves and plugs, such as

the throttle valve, shuttle valve plug, 1-2 shift valve

and 1-2 governor plug, are made of coated alumi-

num. Aluminum components are identified by the

dark color of the special coating applied to the sur-

face (or by testing with a magnet). Do not sand alu-

minum valves or plugs under any circumstances.

This practice could damage the special coating

causing the valves/plugs to stick and bind.

Inspect the valves and plugs for scratches, burrs,

nicks, or scores. Minor surface scratches on steel

valves and plugs can be removed with crocus cloth

butdo not round off the edges of the valve or

plug lands.Maintaining sharpness of these edges is

vitally important. The edges prevent foreign matter

from lodging between the valves and plugs and the

bore.

Inspect all the valve and plug bores in the valve

body. Use a penlight to view the bore interiors.

Replace the valve body if any bores are distorted or

scored. Inspect all of the valve body springs. The

springs must be free of distortion, warpage or broken

coils.

Fig. 306 3-4 Accumulator and Housing

1 - ACCUMULATOR PISTON

2 - 3-4 ACCUMULATOR HOUSING

3 - TEFLON SEALS

4 - PISTON SPRING

5 - COVER PLATE AND SCREWS

21 - 476 AUTOMATIC TRANSMISSION - 48REDR

VALVE BODY (Continued)

Page 2325 of 2895

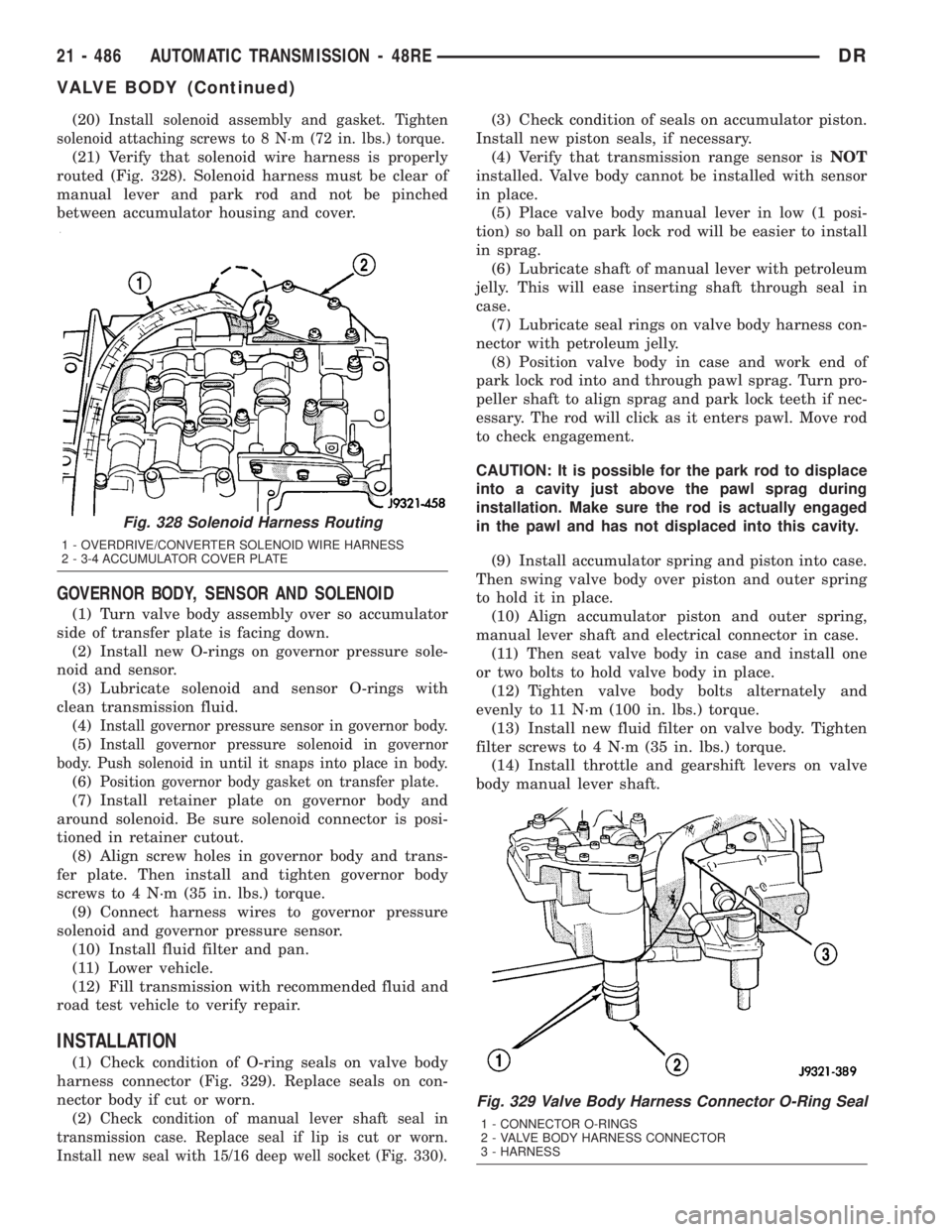

(20)Install solenoid assembly and gasket. Tighten

solenoid attaching screws to 8 N´m (72 in. lbs.) torque.

(21) Verify that solenoid wire harness is properly

routed (Fig. 328). Solenoid harness must be clear of

manual lever and park rod and not be pinched

between accumulator housing and cover.

GOVERNOR BODY, SENSOR AND SOLENOID

(1) Turn valve body assembly over so accumulator

side of transfer plate is facing down.

(2) Install new O-rings on governor pressure sole-

noid and sensor.

(3) Lubricate solenoid and sensor O-rings with

clean transmission fluid.

(4)

Install governor pressure sensor in governor body.

(5)Install governor pressure solenoid in governor

body. Push solenoid in until it snaps into place in body.

(6)Position governor body gasket on transfer plate.

(7) Install retainer plate on governor body and

around solenoid. Be sure solenoid connector is posi-

tioned in retainer cutout.

(8) Align screw holes in governor body and trans-

fer plate. Then install and tighten governor body

screws to 4 N´m (35 in. lbs.) torque.

(9) Connect harness wires to governor pressure

solenoid and governor pressure sensor.

(10) Install fluid filter and pan.

(11) Lower vehicle.

(12) Fill transmission with recommended fluid and

road test vehicle to verify repair.

INSTALLATION

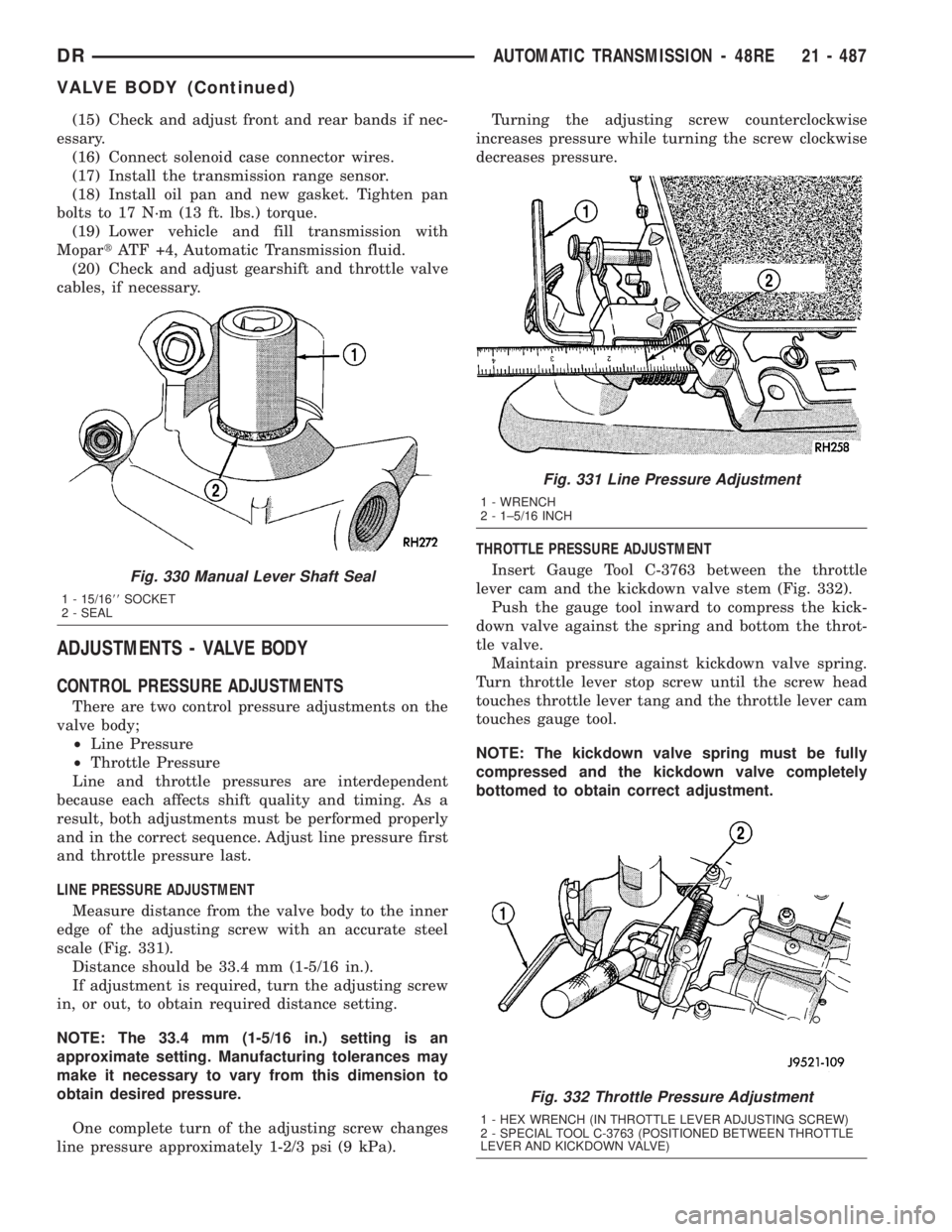

(1) Check condition of O-ring seals on valve body

harness connector (Fig. 329). Replace seals on con-

nector body if cut or worn.

(2)

Check condition of manual lever shaft seal in

transmission case. Replace seal if lip is cut or worn.

Install new seal with 15/16 deep well socket (Fig. 330).

(3) Check condition of seals on accumulator piston.

Install new piston seals, if necessary.

(4) Verify that transmission range sensor isNOT

installed. Valve body cannot be installed with sensor

in place.

(5) Place valve body manual lever in low (1 posi-

tion) so ball on park lock rod will be easier to install

in sprag.

(6) Lubricate shaft of manual lever with petroleum

jelly. This will ease inserting shaft through seal in

case.

(7) Lubricate seal rings on valve body harness con-

nector with petroleum jelly.

(8) Position valve body in case and work end of

park lock rod into and through pawl sprag. Turn pro-

peller shaft to align sprag and park lock teeth if nec-

essary. The rod will click as it enters pawl. Move rod

to check engagement.

CAUTION: It is possible for the park rod to displace

into a cavity just above the pawl sprag during

installation. Make sure the rod is actually engaged

in the pawl and has not displaced into this cavity.

(9) Install accumulator spring and piston into case.

Then swing valve body over piston and outer spring

to hold it in place.

(10) Align accumulator piston and outer spring,

manual lever shaft and electrical connector in case.

(11) Then seat valve body in case and install one

or two bolts to hold valve body in place.

(12) Tighten valve body bolts alternately and

evenly to 11 N´m (100 in. lbs.) torque.

(13) Install new fluid filter on valve body. Tighten

filter screws to 4 N´m (35 in. lbs.) torque.

(14) Install throttle and gearshift levers on valve

body manual lever shaft.

Fig. 329 Valve Body Harness Connector O-Ring Seal

1 - CONNECTOR O-RINGS

2 - VALVE BODY HARNESS CONNECTOR

3 - HARNESS

Fig. 328 Solenoid Harness Routing

1 - OVERDRIVE/CONVERTER SOLENOID WIRE HARNESS

2 - 3-4 ACCUMULATOR COVER PLATE

21 - 486 AUTOMATIC TRANSMISSION - 48REDR

VALVE BODY (Continued)

Page 2326 of 2895

(15) Check and adjust front and rear bands if nec-

essary.

(16) Connect solenoid case connector wires.

(17) Install the transmission range sensor.

(18) Install oil pan and new gasket. Tighten pan

bolts to 17 N´m (13 ft. lbs.) torque.

(19) Lower vehicle and fill transmission with

MopartATF +4, Automatic Transmission fluid.

(20) Check and adjust gearshift and throttle valve

cables, if necessary.

ADJUSTMENTS - VALVE BODY

CONTROL PRESSURE ADJUSTMENTS

There are two control pressure adjustments on the

valve body;

²Line Pressure

²Throttle Pressure

Line and throttle pressures are interdependent

because each affects shift quality and timing. As a

result, both adjustments must be performed properly

and in the correct sequence. Adjust line pressure first

and throttle pressure last.

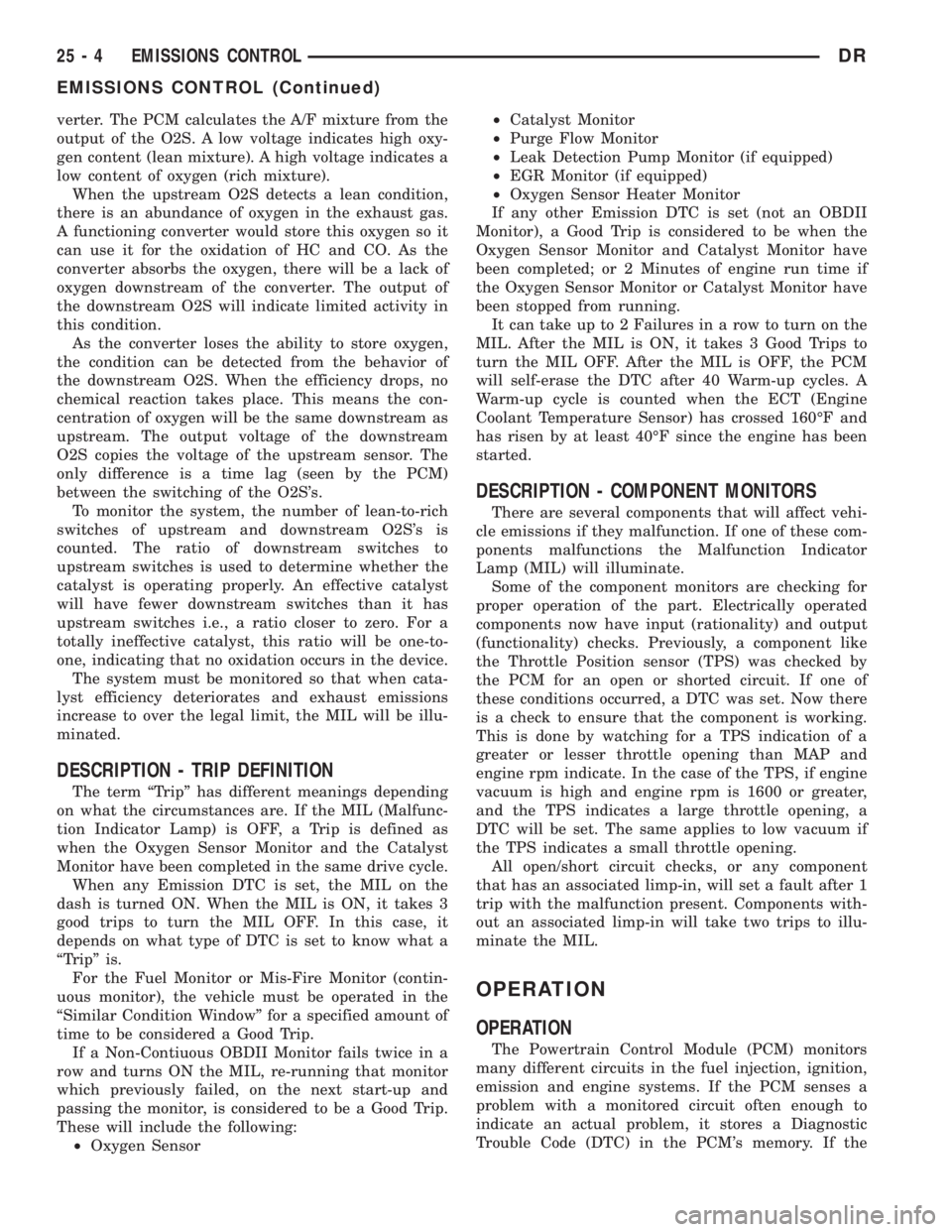

LINE PRESSURE ADJUSTMENT

Measure distance from the valve body to the inner

edge of the adjusting screw with an accurate steel

scale (Fig. 331).

Distance should be 33.4 mm (1-5/16 in.).

If adjustment is required, turn the adjusting screw

in, or out, to obtain required distance setting.

NOTE: The 33.4 mm (1-5/16 in.) setting is an

approximate setting. Manufacturing tolerances may

make it necessary to vary from this dimension to

obtain desired pressure.

One complete turn of the adjusting screw changes

line pressure approximately 1-2/3 psi (9 kPa).Turning the adjusting screw counterclockwise

increases pressure while turning the screw clockwise

decreases pressure.

THROTTLE PRESSURE ADJUSTMENT

Insert Gauge Tool C-3763 between the throttle

lever cam and the kickdown valve stem (Fig. 332).

Push the gauge tool inward to compress the kick-

down valve against the spring and bottom the throt-

tle valve.

Maintain pressure against kickdown valve spring.

Turn throttle lever stop screw until the screw head

touches throttle lever tang and the throttle lever cam

touches gauge tool.

NOTE: The kickdown valve spring must be fully

compressed and the kickdown valve completely

bottomed to obtain correct adjustment.

Fig. 330 Manual Lever Shaft Seal

1 - 15/1688SOCKET

2 - SEAL

Fig. 331 Line Pressure Adjustment

1 - WRENCH

2 - 1±5/16 INCH

Fig. 332 Throttle Pressure Adjustment

1 - HEX WRENCH (IN THROTTLE LEVER ADJUSTING SCREW)

2 - SPECIAL TOOL C-3763 (POSITIONED BETWEEN THROTTLE

LEVER AND KICKDOWN VALVE)

DRAUTOMATIC TRANSMISSION - 48RE 21 - 487

VALVE BODY (Continued)

Page 2833 of 2895

verter. The PCM calculates the A/F mixture from the

output of the O2S. A low voltage indicates high oxy-

gen content (lean mixture). A high voltage indicates a

low content of oxygen (rich mixture).

When the upstream O2S detects a lean condition,

there is an abundance of oxygen in the exhaust gas.

A functioning converter would store this oxygen so it

can use it for the oxidation of HC and CO. As the

converter absorbs the oxygen, there will be a lack of

oxygen downstream of the converter. The output of

the downstream O2S will indicate limited activity in

this condition.

As the converter loses the ability to store oxygen,

the condition can be detected from the behavior of

the downstream O2S. When the efficiency drops, no

chemical reaction takes place. This means the con-

centration of oxygen will be the same downstream as

upstream. The output voltage of the downstream

O2S copies the voltage of the upstream sensor. The

only difference is a time lag (seen by the PCM)

between the switching of the O2S's.

To monitor the system, the number of lean-to-rich

switches of upstream and downstream O2S's is

counted. The ratio of downstream switches to

upstream switches is used to determine whether the

catalyst is operating properly. An effective catalyst

will have fewer downstream switches than it has

upstream switches i.e., a ratio closer to zero. For a

totally ineffective catalyst, this ratio will be one-to-

one, indicating that no oxidation occurs in the device.

The system must be monitored so that when cata-

lyst efficiency deteriorates and exhaust emissions

increase to over the legal limit, the MIL will be illu-

minated.

DESCRIPTION - TRIP DEFINITION

The term ªTripº has different meanings depending

on what the circumstances are. If the MIL (Malfunc-

tion Indicator Lamp) is OFF, a Trip is defined as

when the Oxygen Sensor Monitor and the Catalyst

Monitor have been completed in the same drive cycle.

When any Emission DTC is set, the MIL on the

dash is turned ON. When the MIL is ON, it takes 3

good trips to turn the MIL OFF. In this case, it

depends on what type of DTC is set to know what a

ªTripº is.

For the Fuel Monitor or Mis-Fire Monitor (contin-

uous monitor), the vehicle must be operated in the

ªSimilar Condition Windowº for a specified amount of

time to be considered a Good Trip.

If a Non-Contiuous OBDII Monitor fails twice in a

row and turns ON the MIL, re-running that monitor

which previously failed, on the next start-up and

passing the monitor, is considered to be a Good Trip.

These will include the following:

²Oxygen Sensor²Catalyst Monitor

²Purge Flow Monitor

²Leak Detection Pump Monitor (if equipped)

²EGR Monitor (if equipped)

²Oxygen Sensor Heater Monitor

If any other Emission DTC is set (not an OBDII

Monitor), a Good Trip is considered to be when the

Oxygen Sensor Monitor and Catalyst Monitor have

been completed; or 2 Minutes of engine run time if

the Oxygen Sensor Monitor or Catalyst Monitor have

been stopped from running.

It can take up to 2 Failures in a row to turn on the

MIL. After the MIL is ON, it takes 3 Good Trips to

turn the MIL OFF. After the MIL is OFF, the PCM

will self-erase the DTC after 40 Warm-up cycles. A

Warm-up cycle is counted when the ECT (Engine

Coolant Temperature Sensor) has crossed 160ÉF and

has risen by at least 40ÉF since the engine has been

started.

DESCRIPTION - COMPONENT MONITORS

There are several components that will affect vehi-

cle emissions if they malfunction. If one of these com-

ponents malfunctions the Malfunction Indicator

Lamp (MIL) will illuminate.

Some of the component monitors are checking for

proper operation of the part. Electrically operated

components now have input (rationality) and output

(functionality) checks. Previously, a component like

the Throttle Position sensor (TPS) was checked by

the PCM for an open or shorted circuit. If one of

these conditions occurred, a DTC was set. Now there

is a check to ensure that the component is working.

This is done by watching for a TPS indication of a

greater or lesser throttle opening than MAP and

engine rpm indicate. In the case of the TPS, if engine

vacuum is high and engine rpm is 1600 or greater,

and the TPS indicates a large throttle opening, a

DTC will be set. The same applies to low vacuum if

the TPS indicates a small throttle opening.

All open/short circuit checks, or any component

that has an associated limp-in, will set a fault after 1

trip with the malfunction present. Components with-

out an associated limp-in will take two trips to illu-

minate the MIL.

OPERATION

OPERATION

The Powertrain Control Module (PCM) monitors

many different circuits in the fuel injection, ignition,

emission and engine systems. If the PCM senses a

problem with a monitored circuit often enough to

indicate an actual problem, it stores a Diagnostic

Trouble Code (DTC) in the PCM's memory. If the

25 - 4 EMISSIONS CONTROLDR

EMISSIONS CONTROL (Continued)

Page 2860 of 2895

BRAKE SYSTEM - DIAGNOSIS AND

TESTING, BASE........................5-2

BRAKE TRANSMISSION SHIFT

INTERLOCK - ADJUSTMENTS . . . 21-195,21-376,

21-540

BRAKE TRANSMISSION SHIFT

INTERLOCK - DIAGNOSIS AND

TESTING..............21-195,21-375,21-540

BRAKE TRANSMISSION SHIFT

INTERLOCK SYSTEM - DESCRIPTION . . . 21-194,

21-375,21-540

BRAKE TRANSMISSION SHIFT

INTERLOCK SYSTEM - OPERATION.....21-194,

21-375,21-540

BRAKE/PARK BRAKE INDICATOR -

DESCRIPTION.......................8J-18

BRAKE/PARK BRAKE INDICATOR -

OPERATION.........................8J-19

BRAKES - ABS - DESCRIPTION...........5-39

BRAKES - ABS - OPERATION............5-39

BRAKES, SPECIAL TOOLS - BASE.........5-5

BREAK-IN - STANDARD PROCEDURE,

A/C COMPRESSOR CLUTCH............24-10

BREATHER - INSTALLATION,

CRANKCASE........................9-292

BREATHER - REMOVAL, CRANKCASE.....9-291

BUCKLE - INSTALLATION, FRONT

OUTBOARD SEAT BELT................8O-34

BUCKLE - REMOVAL, FRONT OUTBOARD

SEAT BELT .........................8O-33

BUILT-IN INDICATOR TEST - STANDARD

PROCEDURE........................8F-10

BUMPER - INSTALLATION, FRONT........13-2

BUMPER - INSTALLATION, JOUNCE.......2-40

BUMPER - INSTALLATION, REAR.........13-4

BUMPER - REMOVAL, FRONT............13-2

BUMPER - REMOVAL, JOUNCE...........2-40

BUMPER - REMOVAL, REAR.............13-4

BUMPERS (3500) - INSTALLATION,

AUXILIARY SPRING....................2-40

BUMPERS (3500) - REMOVAL,

AUXILIARY SPRING....................2-40

BURNT FLUID - DIAGNOSIS AND

TESTING, CAUSES OF....21-201,21-381,21-541

BUSHING - INSTALLATION.............19-18

BUSHING - INSTALLATION,

DISTRIBUTOR.......................9-258

BUSHING - INSTALLATION, EXTENSION

HOUSING..........................21-200

BUSHING - INSTALLATION, TORSION

BAR CROSS MEMBER..................2-14

BUSHING - REMOVAL.................19-18

BUSHING - REMOVAL, DISTRIBUTOR.....9-258

BUSHING - REMOVAL, EXTENSION

HOUSING..........................21-200

BUSHING - REMOVAL, TORSION BAR

CROSSMEMBER......................2-12

BUSHING AND SEAL - INSTALLATION,

EXTENSION HOUSING..........21-616,21-682

BUSHING AND SEAL - REMOVAL,

EXTENSION HOUSING..........21-616,21-682

BUSHINGS - 2WD (LD) - INSTALLATION,

LOWER CONTROL ARM................2-14

BUSHINGS - 2WD (LD) - REMOVAL,

LOWER CONTROL ARM................2-12

BUSHINGS - 4WD (LD) - INSTALLATION,

LOWER CONTROL ARM

................2-13

BUSHINGS - 4WD (LD) - REMOVAL,

LOWER CONTROL ARM

................2-12

BUSHINGS - INSTALLATION

.............2-39

BUSHINGS - REMOVAL

.................2-39

BUZZ, SQUEAK & RATTLE - STANDARD

PROCEDURE

........................23-11

BYPASS - DESCRIPTION, WATER PUMP

. . . 7-64

BYPASS - OPERATION, WATER PUMP

.....7-65

BYPASS HOSE WITH AIR CONDITIONING

- INSTALLATION, WATER PUMP

..........7-70

BYPASS HOSE WITH AIR CONDITIONING

- REMOVAL, WATER PUMP

..............7-68

BYPASS HOSE WITHOUT AIR

CONDITIONING - INSTALLATION,

WATER PUMP

........................7-70

BYPASS HOSE WITHOUT AIR

CONDITIONING - REMOVAL, WATER

PUMP

..............................7-69

C205F - ADJUSTMENTS, FRONT AXLE

.....3-21

C205F - DESCRIPTION, FRONT AXLE

......3-18C205F - DIAGNOSIS AND TESTING,

FRONT AXLE.........................3-18

C205F - INSTALLATION, FRONT AXLE.....3-21

C205F - OPERATION, FRONT AXLE........3-18

C205F - REMOVAL, FRONT AXLE.........3-21

C205F - SPECIAL TOOLS, FRONT AXLE....3-30

C205F - SPECIFICATIONS, FRONT AXLE....3-29

CAB - INSTALLATION, QUAD...........8O-32

CAB - INSTALLATION, STANDARD.......8O-31

CAB - REMOVAL, QUAD...............8O-29

CAB - REMOVAL, STANDARD...........8O-28

CAB BACK PANEL TRIM -

INSTALLATION, REAR.................23-70

CAB BACK PANEL TRIM - REMOVAL,

REAR..............................23-70

CAB CLEARANCE LAMP - INSTALLATION . . 8L-10

CAB CLEARANCE LAMP - REMOVAL.....8L-10

CABLE - ADJUSTMENTS, THROTTLE

VALVE ......................21-255,21-432

CABLE - DESCRIPTION.................8P-3

CABLE - DESCRIPTION, ANTENNA BODY . . . 8A-4

CABLE - DESCRIPTION, SPARK PLUG.....8I-33

CABLE - DESCRIPTION, THROTTLE

VALVE ......................21-254,21-432

CABLE - DIAGNOSIS AND TESTING,

ANTENNA BODY......................8A-4

CABLE - DIAGNOSIS AND TESTING,

GEARSHIFT............21-209,21-389,21-544

CABLE - INSTALLATION..................8P-6

CABLE - INSTALLATION, ANTENNA BODY . . 8A-6

CABLE - INSTALLATION, CHECK.........23-15

CABLE - INSTALLATION, FRONT

PARKING BRAKE......................5-32

CABLE - INSTALLATION, GEARSHIFT....21-210,

21-390,21-545

CABLE - INSTALLATION, INSTRUMENT

PANEL ANTENNA......................8A-7

CABLE - INSTALLATION, LEFT REAR......5-33

CABLE - INSTALLATION, REAR PARK

BRAKE..............................5-32

CABLE - INSTALLATION, RIGHT REAR.....5-32

CABLE - INSTALLATION, SPARK PLUG....8I-35

CABLE - INSTALLATION, THROTTLE

CONTROL.....................14-51,14-96

CABLE - OPERATION...................8P-3

CABLE - OPERATION, ANTENNA BODY.....8A-4

CABLE - OPERATION, SPARK PLUG.......8I-33

CABLE - REMOVAL....................8P-3

CABLE - REMOVAL, ANTENNA BODY......8A-6

CABLE - REMOVAL, CHECK.............23-15

CABLE - REMOVAL, FRONT PARKING

BRAKE..............................5-31

CABLE - REMOVAL, GEARSHIFT . 21-209,21-389,

21-544

CABLE - REMOVAL, INSTRUMENT PANEL

ANTENNA...........................8A-6

CABLE - REMOVAL, LEFT REAR..........5-32

CABLE - REMOVAL, REAR PARK BRAKE . . . 5-31

CABLE - REMOVAL, RIGHT REAR.........5-31

CABLE - REMOVAL, SPARK PLUG........8I-34

CABLE - REMOVAL, THROTTLE

CONTROL.....................14-49,14-94

CABLE, ADJUSTMENTS - GEARSHIFT . . . 21-211,

21-391,21-546

CABLE ORDER, 8.0L V-10 ENGINE -

SPARK PLUG.........................8I-5

CABLE RESISTANCE, SPECIFICATIONS -

SPARK PLUG.........................8I-5

CABLE ROUTING, 5.7L V-8 ENGINE -

FIRING ORDER........................8I-4

CABLE/HANDLE ASSEMBLY -

INSTALLATION, LATCH RELEASE........23-47

CABLE/HANDLE ASSEMBLY - REMOVAL,

LATCH RELEASE.....................23-47

CABLES - DESCRIPTION, BATTERY.......8F-14

CABLES - DIAGNOSIS AND TESTING,

BATTERY...........................8F-15

CABLES - DIAGNOSIS AND TESTING,

SPARK PLUG........................8I-33

CABLES - INSTALLATION, BATTERY......8F-17

CABLES - OPERATION, BATTERY........8F-14

CABLES - REMOVAL, BATTERY

..........8F-16

CALIBRATION - STANDARD PROCEDURE,

COMPASS

...........................8M-3

CALIPER ADAPTER MOUNT -

INSTALLATION, DISC BRAKE

............5-17

CALIPERS - DESCRIPTION, DISC BRAKE

. . . 5-11

CALIPERS - OPERATION, DISC BRAKE

.....5-12CAM BORE REPAIR - STANDARD

PROCEDURE........................9-315

CAMBER AND CASTER ADJUSTMENT -

STANDARD PROCEDURE.................2-4

CAMBER, CASTER AND TOE

ADJUSTMENT - STANDARD

PROCEDURE..........................2-4

CAM/OVERDRIVE PISTON RETAINER -

ASSEMBLY, OVERRUNNING CLUTCH....21-239,

21-416

CAM/OVERDRIVE PISTON RETAINER -

CLEANING, OVERRUNNING CLUTCH....21-238,

21-416

CAM/OVERDRIVE PISTON RETAINER -

DESCRIPTION, OVERRUNNING CLUTCH . 21-237,

21-415

CAM/OVERDRIVE PISTON RETAINER -

DISASSEMBLY, OVERRUNNING

CLUTCH.....................21-238,21-415

CAM/OVERDRIVE PISTON RETAINER -

INSPECTION, OVERRUNNING CLUTCH . . 21-238,

21-416

CAM/OVERDRIVE PISTON RETAINER -

OPERATION, OVERRUNNING CLUTCH . . . 21-237,

21-415

CAMSHAFT - INSTALLATION . 9-201,9-250,9-320,

9-381

CAMSHAFT - REMOVAL.....9-200,9-250,9-317,

9-380

CAMSHAFT BEARINGS - INSTALLATION . . 9-320,

9-381

CAMSHAFT BEARINGS - REMOVAL . 9-317,9-380

CAMSHAFT CORE HOLE PLUG -

INSTALLATION.......................9-201

CAMSHAFT CORE HOLE PLUG -

REMOVAL............................9-200

CAMSHAFT POSITION SENSOR -

DESCRIPTION.......................14-82

CAMSHAFT POSITION SENSOR -

DESCRIPTION.........................8I-8

CAMSHAFT POSITION SENSOR -

INSTALLATION.......................14-83

CAMSHAFT POSITION SENSOR -

INSTALLATION.......................8I-14

CAMSHAFT POSITION SENSOR -

OPERATION.........................14-82

CAMSHAFT POSITION SENSOR -

OPERATION..........................8I-8

CAMSHAFT POSITION SENSOR -

REMOVAL..........................14-83

CAMSHAFT POSITION SENSOR -

REMOVAL...........................8I-11

CAMSHAFT(S) - DESCRIPTION.......9-24,9-34

CAMSHAFT(S) - INSTALLATION......9-25,9-35

CAMSHAFT(S) - LEFT - DESCRIPTION....9-113

CAMSHAFT(S) - LEFT - INSTALLATION....9-114

CAMSHAFT(S) - LEFT - REMOVAL.......9-113

CAMSHAFT(S) - REMOVAL..........9-24,9-34

CAMSHAFT(S) - RIGHT - DESCRIPTION . . . 9-117

CAMSHAFT(S) - RIGHT - INSTALLATION . . 9-118

CAMSHAFT(S) - RIGHT - REMOVAL......9-117

CANISTER - DESCRIPTION, VAPOR......25-22

CANISTER - INSTALLATION, VAPOR......25-23

CANISTER - OPERATION, VAPOR........25-22

CANISTER - REMOVAL, VAPOR..........25-22

CAP - 5.9L V-8 - DIAGNOSIS AND

TESTING, DISTRIBUTOR...............8I-18

CAP - DESCRIPTION, FUEL FILLER.......25-13

CAP - DESCRIPTION, RADIATOR

PRESSURE..........................7-60

CAP - DIAGNOSIS AND TESTING,

RADIATOR...........................7-61

CAP - OPERATION, FUEL FILLER........25-13

CAP - OPERATION, RADIATOR

PRESSURE..........................7-61

CAPACITIES, SPECIFICATIONS - FLUID......0-5

CAPACITOR - DESCRIPTION, IGNITION

COIL...............................8I-33

CAPACITOR - INSTALLATION, IGNITION

COIL...............................8I-33

CAPACITOR - OPERATION, IGNITION

COIL

...............................8I-33

CAPACITOR - REMOVAL, IGNITION COIL

. . . 8I-33

CAPACITY - SPECIFICATIONS, CHARGE

. . . 24-35

CAP-TO-FILLER NECK SEAL -

DIAGNOSIS AND TESTING, RADIATOR

.....7-61

CARDAN UNIVERSAL JOINTS -

ASSEMBLY, SINGLE

.....................3-9

DRINDEX 5

Description Group-Page Description Group-Page Description Group-Page

Page 2880 of 2895

PLANETARY GEARTRAIN/OUTPUT SHAFT

- INSPECTION................21-245,21-422

PLANETARY GEARTRAIN/OUTPUT SHAFT

- OPERATION.................21-243,21-420

PLASTIC BODY PANEL REPAIR -

STANDARD PROCEDURE................23-3

PLATE - DESCRIPTION, BODY CODE....Intro.-4

PLATE - DESCRIPTION, ENGINE DATA....9-297

PLATE - INSTALLATION, FLEX . . 9-137,9-205,9-47

PLATE - INSTALLATION, FRONT SKID.....13-24

PLATE - INSTALLATION, SUPPORT........5-29

PLATE - INSTALLATION, TRANSFER

CASE SKID.........................13-26

PLATE - REMOVAL, FLEX.....9-137,9-205,9-47

PLATE - REMOVAL, FRONT SKID........13-24

PLATE - REMOVAL, SUPPORT...........5-29

PLATE - REMOVAL, TRANSFER CASE

SKID..............................13-26

PLATE LAMP - INSTALLATION, LICENSE . . 8L-16

PLATE LAMP - REMOVAL, LICENSE......8L-16

PLATE LAMP UNIT - INSTALLATION,

LICENSE...........................8L-16

PLATE LAMP UNIT - REMOVAL, LICENSE . . 8L-16

PLATES - INSTALLATION, EXTERIOR

NAME.............................23-38

PLATES - REMOVAL, EXTERIOR NAME....23-38

PLUG - DESCRIPTION, SPARK...........8I-27

PLUG - INSTALLATION, CAMSHAFT

CORE HOLE.........................9-201

PLUG - REMOVAL, CAMSHAFT CORE

HOLE..............................9-200

PLUG - REMOVAL, SPARK..............8I-30

PLUG CABLE - DESCRIPTION, SPARK.....8I-33

PLUG CABLE - INSTALLATION, SPARK....8I-35

PLUG CABLE - OPERATION, SPARK.......8I-33

PLUG CABLE - REMOVAL, SPARK........8I-34

PLUG CABLE ORDER, 8.0L V-10 ENGINE

- SPARK .............................8I-5

PLUG CABLE RESISTANCE,

SPECIFICATIONS - SPARK...............8I-5

PLUG CABLES - DIAGNOSIS AND

TESTING, SPARK.....................8I-33

PLUG CONDITIONS - DIAGNOSIS AND

TESTING, SPARK.....................8I-27

PLUGS - INSTALLATION, CORE..........9-130

PLUGS - REMOVAL, CORE.............9-129

PLUGS, SPECIFICATIONS - SPARK........8I-5

PLUMBING - CLEANING, CHARGE AIR

COOLER............................11-16

PLUMBING - DESCRIPTION, CHARGE

AIR COOLER........................11-15

PLUMBING - INSPECTION, CHARGE AIR

COOLER............................11-16

PLUMBING - INSTALLATION, CHARGE

AIR COOLER........................11-16

PLUMBING - OPERATION, CHARGE AIR

COOLER............................11-15

PLUMBING - REMOVAL, CHARGE AIR

COOLER............................11-15

PLY TIRES - DESCRIPTION, RADIAL.......22-6

POLISHING - DESCRIPTION, FINESSE

SANDING/BUFFING...................23-75

PORT - DESCRIPTION, REFRIGERANT

SYSTEM SERVICE.....................24-1

PORT - OPERATION, REFRIGERANT

SYSTEM SERVICE.....................24-2

POSITION SENSOR - DESCRIPTION.....21-618,

21-654

POSITION SENSOR - DESCRIPTION,

ACCELERATOR PEDAL.................14-25

POSITION SENSOR - DESCRIPTION,

CAMSHAFT.........................14-82

POSITION SENSOR - DESCRIPTION,

CAMSHAFT...........................8I-8

POSITION SENSOR - DESCRIPTION,

CRANKSHAFT..................14-26,14-83

POSITION SENSOR - DESCRIPTION,

THROTTLE..........................14-52

POSITION SENSOR - INSTALLATION

....21-619,

21-654

POSITION SENSOR - INSTALLATION,

ACCELERATOR PEDAL

.................14-25

POSITION SENSOR - INSTALLATION,

CAMSHAFT

.........................14-83

POSITION SENSOR - INSTALLATION,

CAMSHAFT

..........................8I-14

POSITION SENSOR - INSTALLATION,

CRANKSHAFT

..................14-30,14-84POSITION SENSOR - INSTALLATION,

THROTTLE..........................14-54

POSITION SENSOR - OPERATION . 21-619,21-654

POSITION SENSOR - OPERATION,

ACCELERATOR PEDAL.................14-25

POSITION SENSOR - OPERATION,

CAMSHAFT.........................14-82

POSITION SENSOR - OPERATION,

CAMSHAFT...........................8I-8

POSITION SENSOR - OPERATION,

CRANKSHAFT..................14-26,14-83

POSITION SENSOR - OPERATION,

THROTTLE..........................14-52

POSITION SENSOR - REMOVAL . . 21-619,21-654

POSITION SENSOR - REMOVAL,

ACCELERATOR PEDAL.................14-25

POSITION SENSOR - REMOVAL,

CAMSHAFT.........................14-83

POSITION SENSOR - REMOVAL,

CAMSHAFT..........................8I-11

POSITION SENSOR - REMOVAL,

CRANKSHAFT..................14-29,14-84

POSITION SENSOR - REMOVAL,

THROTTLE..........................14-53

POSITION SWITCH - DESCRIPTION,

CLUTCH PEDAL.......................6-14

POSITION SWITCH - DIAGNOSIS AND

TESTING, CLUTCH PEDAL...............6-14

POSITION SWITCH - OPERATION,

CLUTCH PEDAL.......................6-14

POTENTIAL - STANDARD PROCEDURE,

TESTING OF VOLTAGE..............8W-01-9

POWER - INSTALLATION, WINDOW

REGULATOR...................23-25,23-34

POWER - REMOVAL, WINDOW

REGULATOR...................23-25,23-34

POWER BRAKE BOOSTER -

DESCRIPTION........................5-25

POWER BRAKE BOOSTER -

INSTALLATION........................5-25

POWER BRAKE BOOSTER - OPERATION . . . 5-25

POWER BRAKE BOOSTER - REMOVAL.....5-25

POWER DISTRIBUTION - DESCRIPTION . 8W-97-1

POWER DISTRIBUTION - OPERATION . . 8W-97-1

POWER DISTRIBUTION SYSTEMS,

SPECIAL TOOLS...................8W-97-2

POWER GROUNDS - DESCRIPTION......8E-10

POWER LOCK SWITCH - DIAGNOSIS

AND TESTING........................8N-4

POWER LOCK SWITCH - INSTALLATION . . . 8N-4

POWER LOCK SWITCH - REMOVAL.......8N-4

POWER LOCKS - DESCRIPTION..........8N-1

POWER LOCKS - DIAGNOSIS AND

TESTING............................8N-3

POWER LOCKS - OPERATION............8N-2

POWER MIRROR SWITCH - DIAGNOSIS

AND TESTING.......................8N-13

POWER MIRROR SWITCH - REMOVAL

. . . 8N-13

POWER MIRRORS - DESCRIPTION

......8N-11

POWER MIRRORS - DIAGNOSIS AND

TESTING

...........................8N-11

POWER MIRRORS - OPERATION

........8N-11

POWER MODULE - DESCRIPTION,

INTEGRATED

......................8W-97-3

POWER MODULE - INSTALLATION,

INTEGRATED

......................8W-97-4

POWER MODULE - OPERATION,

INTEGRATED

......................8W-97-3

POWER MODULE - REMOVAL,

INTEGRATED

......................8W-97-3

POWER OUTLET - DESCRIPTION

......8W-97-7

POWER OUTLET - DIAGNOSIS AND

TESTING

.........................8W-97-7

POWER OUTLET - INSTALLATION

.....8W-97-7

POWER OUTLET - OPERATION

........8W-97-7

POWER OUTLET - REMOVAL

.........8W-97-7

POWER SEAT SYSTEM - DIAGNOSIS

AND TESTING

.......................8N-14

POWER SEAT TRACK - DESCRIPTION

....8N-18

POWER SEAT TRACK - DIAGNOSIS AND

TESTING

...........................8N-18

POWER SEAT TRACK - INSTALLATION

....8N-19

POWER SEAT TRACK - OPERATION

......8N-18

POWER SEAT TRACK - REMOVAL

.......8N-19

POWER SEATS - DESCRIPTION

.........8N-14

POWER SEATS - OPERATION

...........8N-14POWER STEERING FLOW AND

PRESSURE - DIAGNOSIS AND

TESTING............................19-4

POWER STEERING FLUID -

DESCRIPTION.........................0-3

POWER STEERING FLUID LEVEL

CHECKING - STANDARD PROCEDURE....19-42

POWER STEERING GEAR, SPECIAL

TOOLS.............................19-22

POWER STEERING GEAR,

SPECIFICATIONS.....................19-21

POWER STEERING PRESSURE SWITCH -

DESCRIPTION.......................19-45

POWER STEERING PRESSURE SWITCH -

OPERATION.........................19-45

POWER STEERING PUMP - INITIAL

OPERATION - STANDARD PROCEDURE . . . 19-39

POWER STEERING SYSTEM -

DIAGNOSIS AND TESTING..............19-2

POWER STEERING SYSTEM -

STANDARD PROCEDURE, FLUSHING.....19-39

POWER WINDOWS - DESCRIPTION......8N-21

POWER WINDOWS - DIAGNOSIS AND

TESTING...........................8N-21

POWER WINDOWS - OPERATION........8N-21

POWERING SEVERAL LOADS -

STANDARD PROCEDURE, TESTING

FOR A SHORT TO GROUND ON FUSES . 8W-01-10

PRE-ALIGNMENT INSPECTION -

DIAGNOSIS AND TESTING...............2-2

PRECAUTIONS - CAUTION,

REFRIGERANT HOSES/LINES/TUBES......24-33

PRECAUTIONS AND WARNINGS,

WARNING - SAFETY.....................23-1

PRECAUTIONS, STANDARD PROCEDURE

- SAFETY............................8L-7

PRECAUTIONS, WARNING -

WINDSHIELD SAFETY.................23-88

PREFERENCES - STANDARD

PROCEDURE, RKE TRANSMITTER

CUSTOMER..........................8N-9

PRELIMINARY - DIAGNOSIS AND

TESTING..............21-139,21-320,21-491

PRELIMINARY CHECKS - DIAGNOSIS

AND TESTING........................7-10

PREPARATION - STANDARD

PROCEDURE, ENGINE GASKET

SURFACE............................9-10

PRESSURE - DIAGNOSIS AND TESTING,

CHECKING ENGINE OIL.......9-150,9-214,9-64

PRESSURE - DIAGNOSIS AND TESTING,

CYLINDER COMPRESSION . . . 9-182,9-231,9-359,

9-8,9-92

PRESSURE - DIAGNOSIS AND TESTING,

ENGINE OIL...............9-269,9-338,9-396

PRESSURE - DIAGNOSIS AND TESTING,

POWER STEERING FLOW...............19-4

PRESSURE - DIAGNOSIS AND TESTING,

TURBOCHARGER BOOST...............11-10

PRESSURE BLEEDING - STANDARD

PROCEDURE..........................5-5

PRESSURE CAP - DESCRIPTION,

RADIATOR...........................7-60

PRESSURE CAP - OPERATION,

RADIATOR...........................7-61

PRESSURE, DIESEL - FUEL SYSTEM

.....14-60

PRESSURE FOR HIGH SPEEDS -

DESCRIPTION, TIRE

...................22-6

PRESSURE GAUGE - DESCRIPTION, OIL

. . 8J-32

PRESSURE GAUGE - OPERATION, OIL

....8J-32

PRESSURE GAUGES - DIAGNOSIS AND

TESTING

............................22-7

PRESSURE HOSE - INSTALLATION

. . 19-43,19-44

PRESSURE HOSE - REMOVAL

.....19-43,19-44

PRESSURE LEAKAGE - DIAGNOSIS AND

TESTING, CYLINDER COMBUSTION

. 9-182,9-231,

9-359,9-8,9-92

PRESSURE LIMITING VALVE -

DESCRIPTION, FUEL

..................14-72

PRESSURE LIMITING VALVE -

INSTALLATION, FUEL

.................14-73

PRESSURE LIMITING VALVE -

OPERATION, FUEL

....................14-72

PRESSURE LIMITING VALVE - REMOVAL,

FUEL

..............................14-72

PRESSURE (LP) SENSOR -

DESCRIPTION, LINE

.................21-559

DRINDEX 25

Description Group-Page Description Group-Page Description Group-Page

Page 2885 of 2895

SEAT BELT & RETRACTOR - REMOVAL,

REAR OUTBOARD....................8O-41

SEAT BELT BUCKLE - INSTALLATION,

FRONT OUTBOARD...................8O-34

SEAT BELT BUCKLE - REMOVAL, FRONT

OUTBOARD.........................8O-33

SEAT BELT SWITCH - DESCRIPTION.....8O-46

SEAT BELT SWITCH - DIAGNOSIS AND

TESTING...........................8O-47

SEAT BELT SWITCH - OPERATION.......8O-46

SEAT BELT TENSION REDUCER -

DESCRIPTION.......................8O-48

SEAT BELT TENSION REDUCER -

DIAGNOSIS AND TESTING.............8O-49

SEAT BELT TENSION REDUCER -

OPERATION.........................8O-49

SEAT BELT TENSIONER - DESCRIPTION . . . 8O-47

SEAT BELT TENSIONER - OPERATION....8O-48

SEAT BELT TURNING LOOP ADJUSTER -

INSTALLATION......................8O-50

SEAT BELT TURNING LOOP ADJUSTER -

REMOVAL..........................8O-50

SEAT CUSHION / COVER - FRONT -

INSTALLATION.......................23-83

SEAT CUSHION / COVER - FRONT -

REMOVAL..........................23-83

SEAT CUSHION / COVER - REAR -

INSTALLATION.......................23-85

SEAT CUSHION / COVER - REAR -

REMOVAL..........................23-85

SEAT CUSHION - INSTALLATION,

CENTER............................23-80

SEAT CUSHION - REMOVAL, CENTER.....23-80

SEAT CUSHION COVER - INSTALLATION,

CENTER............................23-81

SEAT CUSHION COVER - REMOVAL,

CENTER............................23-81

SEAT CUSHION FRAME - REAR -

INSTALLATION.......................23-85

SEAT CUSHION FRAME - REAR -

REMOVAL..........................23-85

SEAT ELEMENT - DESCRIPTION, HEATED . . 8G-5

SEAT ELEMENT - DIAGNOSIS AND

TESTING, HEATED.....................8G-6

SEAT ELEMENT - INSTALLATION,

HEATED.............................8G-6

SEAT ELEMENT - OPERATION, HEATED....8G-6

SEAT ELEMENT - REMOVAL, HEATED.....8G-6

SEAT MODULE - DESCRIPTION, HEATED . . . 8E-6

SEAT MODULE - DIAGNOSIS AND

TESTING, HEATED.....................8E-7

SEAT MODULE - INSTALLATION, HEATED . . . 8E-7

SEAT MODULE - OPERATION, HEATED.....8E-6

SEAT MODULE - REMOVAL, HEATED......8E-7

SEAT SENSOR - DESCRIPTION, HEATED . . . 8G-7

SEAT SENSOR - DIAGNOSIS AND

TESTING, HEATED.....................8G-7

SEAT SENSOR - OPERATION, HEATED.....8G-7

SEAT SENSOR - REMOVAL, HEATED......8G-7

SEAT STORAGE BIN - INSTALLATION,

UNDER............................23-81

SEAT STORAGE BIN - REMOVAL, UNDER . . 23-81

SEAT STORAGE BIN COVERING -

INSTALLATION, UNDER................23-81

SEAT STORAGE BIN COVERING -

REMOVAL, UNDER...................23-81

SEAT STORAGE BIN LATCH -

INSTALLATION, UNDER................23-81

SEAT STORAGE BIN LATCH - REMOVAL,

UNDER............................23-81

SEAT SWITCH - DESCRIPTION, DRIVER . . . 8N-15

SEAT SWITCH - DESCRIPTION, HEATED . . . 8G-7

SEAT SWITCH - DESCRIPTION,

PASSENGER........................8N-16

SEAT SWITCH - DIAGNOSIS AND

TESTING, DRIVER....................8N-15

SEAT SWITCH - DIAGNOSIS AND

TESTING, HEATED.....................8G-8

SEAT SWITCH - DIAGNOSIS AND

TESTING, PASSENGER................8N-17

SEAT SWITCH - INSTALLATION, DRIVER . . 8N-16

SEAT SWITCH - INSTALLATION, HEATED

. . . 8G-9

SEAT SWITCH - INSTALLATION,

PASSENGER

........................8N-18

SEAT SWITCH - OPERATION, DRIVER

....8N-15

SEAT SWITCH - OPERATION, HEATED

.....8G-8

SEAT SWITCH - OPERATION,

PASSENGER

........................8N-17SEAT SWITCH - REMOVAL, DRIVER......8N-16

SEAT SWITCH - REMOVAL, HEATED.......8G-9

SEAT SWITCH - REMOVAL, PASSENGER . . 8N-17

SEAT SYSTEM - DESCRIPTION, HEATED . . . 8G-3

SEAT SYSTEM - DIAGNOSIS AND

TESTING, HEATED.....................8G-4

SEAT SYSTEM - DIAGNOSIS AND

TESTING, POWER....................8N-14

SEAT SYSTEM - OPERATION, HEATED.....8G-4

SEAT TRACK - DESCRIPTION, POWER....8N-18

SEAT TRACK - DIAGNOSIS AND

TESTING, POWER....................8N-18

SEAT TRACK - INSTALLATION...........23-83

SEAT TRACK - INSTALLATION, POWER . . . 8N-19

SEAT TRACK - OPERATION, POWER.....8N-18

SEAT TRACK - REMOVAL..............23-83

SEAT TRACK - REMOVAL, POWER.......8N-19

SEATBELT INDICATOR - DESCRIPTION....8J-34

SEATBELT INDICATOR - OPERATION......8J-34

SEATS - CLEANING, INTAKE/EXHAUST

VALVES ............................9-248

SEATS - DESCRIPTION, INTAKE/

EXHAUST VALVES . 9-122,9-246,9-27,9-305,9-375

SEATS - DESCRIPTION, POWER.........8N-14

SEATS - INSPECTION, INTAKE/EXHAUST

VALVES ............................9-248

SEATS - INSTALLATION, INTAKE/

EXHAUST VALVES...........9-123,9-248,9-29

SEATS - OPERATION, POWER............8N-14

SEATS - REMOVAL, INTAKE/EXHAUST

VALVES ...................9-122,9-248,9-28

SECONDARY CATCH - INSTALLATION,

LATCH STRIKER.....................23-48

SECONDARY CATCH - REMOVAL, LATCH

STRIKER...........................23-48

SECTION IDENTIFICATION AND

INFORMATION - DESCRIPTION........8W-01-6

SECURITY INDICATOR - DESCRIPTION....8J-34

SECURITY INDICATOR - OPERATION.....8J-35

SECURITY SYSTEM, DIAGNOSIS AND

TESTING - VEHICLE THEFT..............8Q-3

SELECTION - STANDARD PROCEDURE,

HEAD GASKET.......................9-330

SELECTOR INDICATOR - DESCRIPTION,

GEAR..............................8J-26

SELECTOR INDICATOR - OPERATION,

GEAR..............................8J-27

SELECTOR SWITCH - DESCRIPTION....21-685,

21-719

SELECTOR SWITCH - OPERATION......21-685,

21-719

SENDING UNIT / SENSOR -

DESCRIPTION, FUEL LEVEL........14-68,14-7

SENDING UNIT / SENSOR -

INSTALLATION, FUEL LEVEL.............14-8

SENDING UNIT / SENSOR - OPERATION,

FUEL LEVEL.....................14-68,14-7

SENDING UNIT / SENSOR - REMOVAL,

FUEL LEVEL..........................14-7

SENSE - DESCRIPTION, IGNITION

CIRCUIT............................8E-10

SENSE - OPERATION, IGNITION CIRCUIT . . 8E-12

SENSE - PCM INPUT - OPERATION, ASD

. . . 8I-6

SENSITIVE DEVICES - STANDARD

PROCEDURE, ELECTROSTATIC

DISCHARGE (ESD)

.................8W-01-8

SENSOR - DESCRIPTION, ACCELERATOR

PEDAL POSITION

....................14-25

SENSOR - DESCRIPTION, AMBIENT

TEMP

.............................8M-10

SENSOR - DESCRIPTION, BATTERY

TEMPERATURE

......................8F-21

SENSOR - DESCRIPTION, CAMSHAFT

POSITION

..........................14-82

SENSOR - DESCRIPTION, CAMSHAFT

POSITION

............................8I-8

SENSOR - DESCRIPTION, CRANKSHAFT

POSITION

.....................14-26,14-83

SENSOR - DESCRIPTION, ENGINE

COOLANT TEMPERATURE

...............7-44

SENSOR - DESCRIPTION, FRONT WHEEL

SPEED

..............................5-41

SENSOR - DESCRIPTION, FUEL LEVEL

SENDING UNIT

..................14-68,14-7

SENSOR - DESCRIPTION, FUEL

PRESSURE

.........................14-72

SENSOR - DESCRIPTION, HEATED SEAT

. . . 8G-7SENSOR - DESCRIPTION, INLET AIR

TEMPERATURE SENSOR/PRESSURE......14-90

SENSOR - DESCRIPTION, INPUT SPEED . 21-558

SENSOR - DESCRIPTION, INTAKE AIR

TEMPERATURE......................14-36

SENSOR - DESCRIPTION, INTAKE AIR

TEMPERATURE SENSOR/MAP...........14-93

SENSOR - DESCRIPTION, KNOCK........8I-25

SENSOR - DESCRIPTION, LINE

PRESSURE (LP)....................21-559

SENSOR - DESCRIPTION, MAP.....14-39,14-94

SENSOR - DESCRIPTION, MODE . . 21-684,21-718

SENSOR - DESCRIPTION, OUTPUT

SPEED............................21-567

SENSOR - DESCRIPTION, OXYGEN.......14-43

SENSOR - DESCRIPTION, POSITION....21-618,

21-654

SENSOR - DESCRIPTION, SPEED . 21-254,21-431

SENSOR - DESCRIPTION, THROTTLE

POSITION..........................14-52

SENSOR - DESCRIPTION,

TRANSMISSION RANGE . . 21-263,21-441,21-581

SENSOR - DESCRIPTION,

TRANSMISSION TEMPERATURE . 21-267,21-445,

21-583

SENSOR - DESCRIPTION, WATER IN

FUEL..............................14-77

SENSOR - DIAGNOSIS AND TESTING,

AMBIENT TEMPERATURE..............8M-11

SENSOR - DIAGNOSIS AND TESTING,

HEATED SEAT ........................8G-7

SENSOR - DIAGNOSIS AND TESTING,

REAR WHEEL SPEED..................5-43

SENSOR - INSTALLATION,

ACCELERATOR PEDAL POSITION........14-25

SENSOR - INSTALLATION, BATTERY

TEMPERATURE......................8F-21

SENSOR - INSTALLATION, CAMSHAFT

POSITION..........................14-83

SENSOR - INSTALLATION, CAMSHAFT

POSITION...........................8I-14

SENSOR - INSTALLATION, CRANKSHAFT

POSITION.....................14-30,14-84

SENSOR - INSTALLATION, ENGINE

COOLANT TEMPERATURE...............7-47

SENSOR - INSTALLATION, FRONT

WHEEL SPEED........................5-42

SENSOR - INSTALLATION, FUEL LEVEL

SENDING UNIT.......................14-8

SENSOR - INSTALLATION, FUEL

PRESSURE.........................14-72

SENSOR - INSTALLATION, INLET AIR

TEMPERATURE SENSOR/PRESSURE......14-90

SENSOR - INSTALLATION, INPUT SPEED . 21-559

SENSOR - INSTALLATION, INTAKE AIR

TEMPERATURE......................14-38

SENSOR - INSTALLATION, INTAKE AIR

TEMPERATURE SENSOR/MAP...........14-94

SENSOR - INSTALLATION, KNOCK........8I-26

SENSOR - INSTALLATION, LINE

PRESSURE (LP)....................21-560

SENSOR - INSTALLATION, MAP.........14-42

SENSOR - INSTALLATION, OUTPUT

SPEED............................21-567

SENSOR - INSTALLATION, OXYGEN......14-45

SENSOR - INSTALLATION, POSITION....21-619,

21-654

SENSOR - INSTALLATION, REAR WHEEL

SPEED..............................5-43

SENSOR - INSTALLATION, THROTTLE

POSITION..........................14-54

SENSOR - INSTALLATION,

TRANSMISSION RANGE........21-266,21-444

SENSOR - OPERATION, ACCELERATOR

PEDAL POSITION....................14-25

SENSOR - OPERATION, AMBIENT TEMP . . 8M-10

SENSOR - OPERATION, BATTERY

TEMPERATURE......................8F-21

SENSOR - OPERATION, CAMSHAFT

POSITION

..........................14-82

SENSOR - OPERATION, CAMSHAFT

POSITION

............................8I-8

SENSOR - OPERATION, CRANKSHAFT

POSITION

.....................14-26,14-83

SENSOR - OPERATION, ENGINE

COOLANT TEMPERATURE

...............7-44

SENSOR - OPERATION, FRONT WHEEL

SPEED

..............................5-41

30 INDEXDR

Description Group-Page Description Group-Page Description Group-Page