Throttle Position Sensor DODGE RAM 2003 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2035 of 2895

(8) With shifter lever in the:

²PARK position - Apply upward force on the shift

arm and remove pressure. Engine starts must be

possible.

²PARK position - Apply downward force on the

shift arm and remove pressure. Engine starts must

be possible.

²NEUTRAL position - Normal position. Engine

starts must be possible.

²NEUTRAL position - Engine running and brakes

applied, apply upward force on the shift arm. Trans-

mission shall not be able to shift from neutral to

reverse.

ELECTRONIC GOVERNOR

DESCRIPTION

Governor pressure is controlled electronically. Com-

ponents used for governor pressure control include:

²Governor body

²Valve body transfer plate

²Governor pressure solenoid valve

²Governor pressure sensor

²Fluid temperature thermistor

²Throttle position sensor (TPS)

²Transmission speed sensor

²Powertrain control module (PCM)

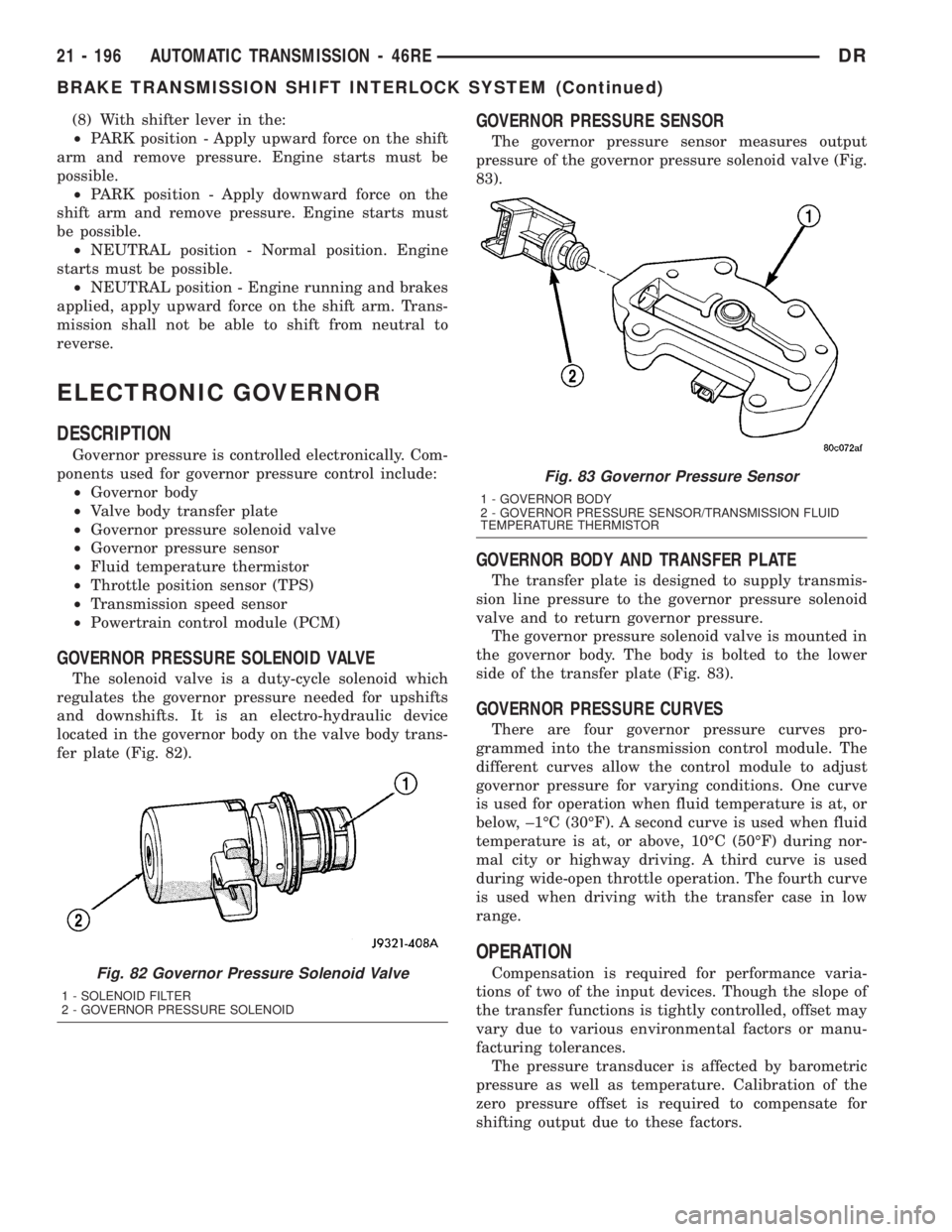

GOVERNOR PRESSURE SOLENOID VALVE

The solenoid valve is a duty-cycle solenoid which

regulates the governor pressure needed for upshifts

and downshifts. It is an electro-hydraulic device

located in the governor body on the valve body trans-

fer plate (Fig. 82).

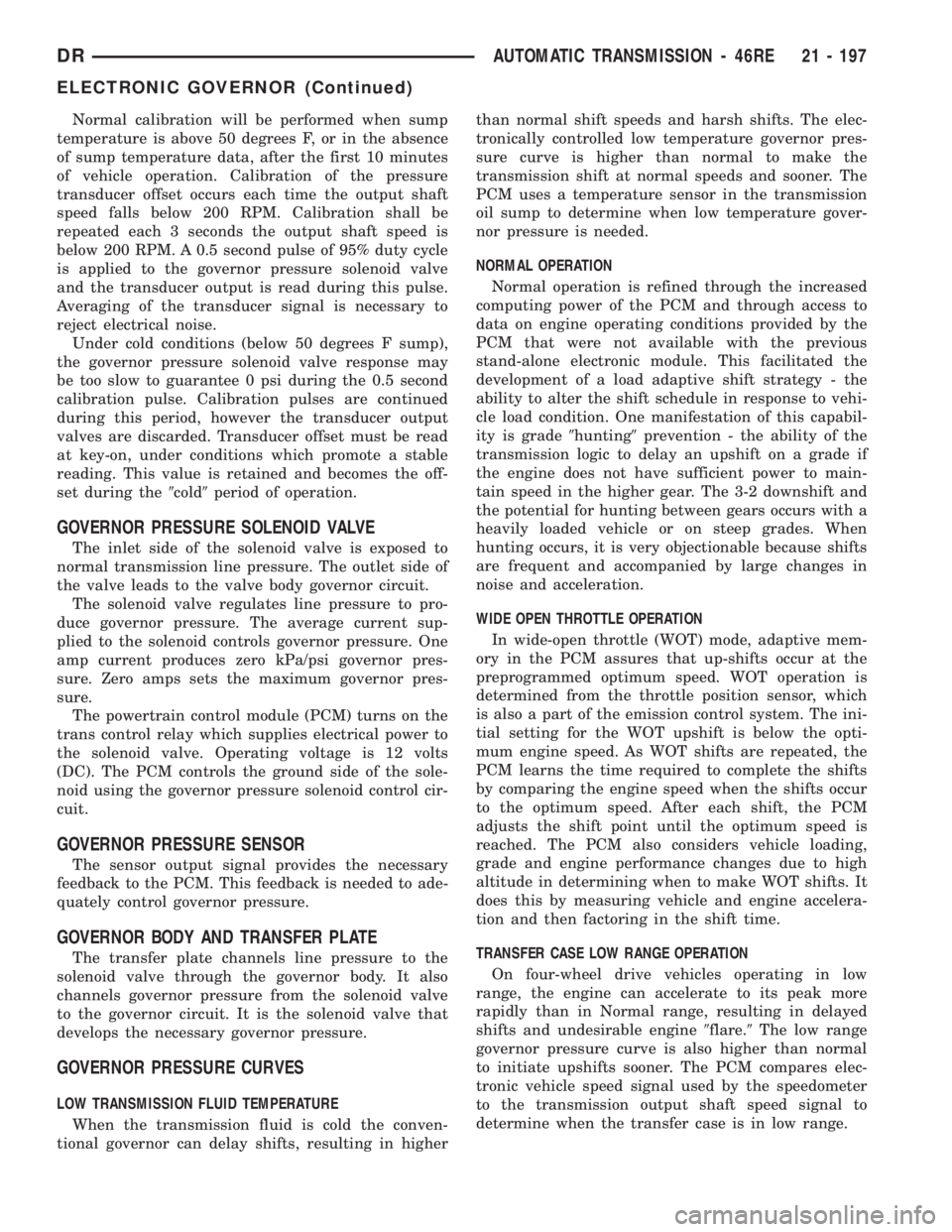

GOVERNOR PRESSURE SENSOR

The governor pressure sensor measures output

pressure of the governor pressure solenoid valve (Fig.

83).

GOVERNOR BODY AND TRANSFER PLATE

The transfer plate is designed to supply transmis-

sion line pressure to the governor pressure solenoid

valve and to return governor pressure.

The governor pressure solenoid valve is mounted in

the governor body. The body is bolted to the lower

side of the transfer plate (Fig. 83).

GOVERNOR PRESSURE CURVES

There are four governor pressure curves pro-

grammed into the transmission control module. The

different curves allow the control module to adjust

governor pressure for varying conditions. One curve

is used for operation when fluid temperature is at, or

below, ±1ÉC (30ÉF). A second curve is used when fluid

temperature is at, or above, 10ÉC (50ÉF) during nor-

mal city or highway driving. A third curve is used

during wide-open throttle operation. The fourth curve

is used when driving with the transfer case in low

range.

OPERATION

Compensation is required for performance varia-

tions of two of the input devices. Though the slope of

the transfer functions is tightly controlled, offset may

vary due to various environmental factors or manu-

facturing tolerances.

The pressure transducer is affected by barometric

pressure as well as temperature. Calibration of the

zero pressure offset is required to compensate for

shifting output due to these factors.Fig. 82 Governor Pressure Solenoid Valve

1 - SOLENOID FILTER

2 - GOVERNOR PRESSURE SOLENOID

Fig. 83 Governor Pressure Sensor

1 - GOVERNOR BODY

2 - GOVERNOR PRESSURE SENSOR/TRANSMISSION FLUID

TEMPERATURE THERMISTOR

21 - 196 AUTOMATIC TRANSMISSION - 46REDR

BRAKE TRANSMISSION SHIFT INTERLOCK SYSTEM (Continued)

Page 2036 of 2895

Normal calibration will be performed when sump

temperature is above 50 degrees F, or in the absence

of sump temperature data, after the first 10 minutes

of vehicle operation. Calibration of the pressure

transducer offset occurs each time the output shaft

speed falls below 200 RPM. Calibration shall be

repeated each 3 seconds the output shaft speed is

below 200 RPM. A 0.5 second pulse of 95% duty cycle

is applied to the governor pressure solenoid valve

and the transducer output is read during this pulse.

Averaging of the transducer signal is necessary to

reject electrical noise.

Under cold conditions (below 50 degrees F sump),

the governor pressure solenoid valve response may

be too slow to guarantee 0 psi during the 0.5 second

calibration pulse. Calibration pulses are continued

during this period, however the transducer output

valves are discarded. Transducer offset must be read

at key-on, under conditions which promote a stable

reading. This value is retained and becomes the off-

set during the9cold9period of operation.

GOVERNOR PRESSURE SOLENOID VALVE

The inlet side of the solenoid valve is exposed to

normal transmission line pressure. The outlet side of

the valve leads to the valve body governor circuit.

The solenoid valve regulates line pressure to pro-

duce governor pressure. The average current sup-

plied to the solenoid controls governor pressure. One

amp current produces zero kPa/psi governor pres-

sure. Zero amps sets the maximum governor pres-

sure.

The powertrain control module (PCM) turns on the

trans control relay which supplies electrical power to

the solenoid valve. Operating voltage is 12 volts

(DC). The PCM controls the ground side of the sole-

noid using the governor pressure solenoid control cir-

cuit.

GOVERNOR PRESSURE SENSOR

The sensor output signal provides the necessary

feedback to the PCM. This feedback is needed to ade-

quately control governor pressure.

GOVERNOR BODY AND TRANSFER PLATE

The transfer plate channels line pressure to the

solenoid valve through the governor body. It also

channels governor pressure from the solenoid valve

to the governor circuit. It is the solenoid valve that

develops the necessary governor pressure.

GOVERNOR PRESSURE CURVES

LOW TRANSMISSION FLUID TEMPERATURE

When the transmission fluid is cold the conven-

tional governor can delay shifts, resulting in higherthan normal shift speeds and harsh shifts. The elec-

tronically controlled low temperature governor pres-

sure curve is higher than normal to make the

transmission shift at normal speeds and sooner. The

PCM uses a temperature sensor in the transmission

oil sump to determine when low temperature gover-

nor pressure is needed.

NORMAL OPERATION

Normal operation is refined through the increased

computing power of the PCM and through access to

data on engine operating conditions provided by the

PCM that were not available with the previous

stand-alone electronic module. This facilitated the

development of a load adaptive shift strategy - the

ability to alter the shift schedule in response to vehi-

cle load condition. One manifestation of this capabil-

ity is grade9hunting9prevention - the ability of the

transmission logic to delay an upshift on a grade if

the engine does not have sufficient power to main-

tain speed in the higher gear. The 3-2 downshift and

the potential for hunting between gears occurs with a

heavily loaded vehicle or on steep grades. When

hunting occurs, it is very objectionable because shifts

are frequent and accompanied by large changes in

noise and acceleration.

WIDE OPEN THROTTLE OPERATION

In wide-open throttle (WOT) mode, adaptive mem-

ory in the PCM assures that up-shifts occur at the

preprogrammed optimum speed. WOT operation is

determined from the throttle position sensor, which

is also a part of the emission control system. The ini-

tial setting for the WOT upshift is below the opti-

mum engine speed. As WOT shifts are repeated, the

PCM learns the time required to complete the shifts

by comparing the engine speed when the shifts occur

to the optimum speed. After each shift, the PCM

adjusts the shift point until the optimum speed is

reached. The PCM also considers vehicle loading,

grade and engine performance changes due to high

altitude in determining when to make WOT shifts. It

does this by measuring vehicle and engine accelera-

tion and then factoring in the shift time.

TRANSFER CASE LOW RANGE OPERATION

On four-wheel drive vehicles operating in low

range, the engine can accelerate to its peak more

rapidly than in Normal range, resulting in delayed

shifts and undesirable engine9flare.9The low range

governor pressure curve is also higher than normal

to initiate upshifts sooner. The PCM compares elec-

tronic vehicle speed signal used by the speedometer

to the transmission output shaft speed signal to

determine when the transfer case is in low range.

DRAUTOMATIC TRANSMISSION - 46RE 21 - 197

ELECTRONIC GOVERNOR (Continued)

Page 2093 of 2895

stant ON, or duty cycle. The variable force and pulse-

width modulated versions utilize similar methods to

control the current flow through the solenoid to posi-

tion the solenoid plunger at a desired position some-

where between full ON and full OFF. The constant

ON and duty cycled versions control the voltage

across the solenoid to allow either full flow or no flow

through the solenoid's valve.

OPERATION

When an electrical current is applied to the sole-

noid coil, a magnetic field is created which produces

an attraction to the plunger, causing the plunger to

move and work against the spring pressure and the

load applied by the fluid the valve is controlling. The

plunger is normally directly attached to the valve

which it is to operate. When the current is removed

from the coil, the attraction is removed and the

plunger will return to its original position due to

spring pressure.

The plunger is made of a conductive material and

accomplishes this movement by providing a path for

the magnetic field to flow. By keeping the air gap

between the plunger and the coil to the minimum

necessary to allow free movement of the plunger, the

magnetic field is maximized.

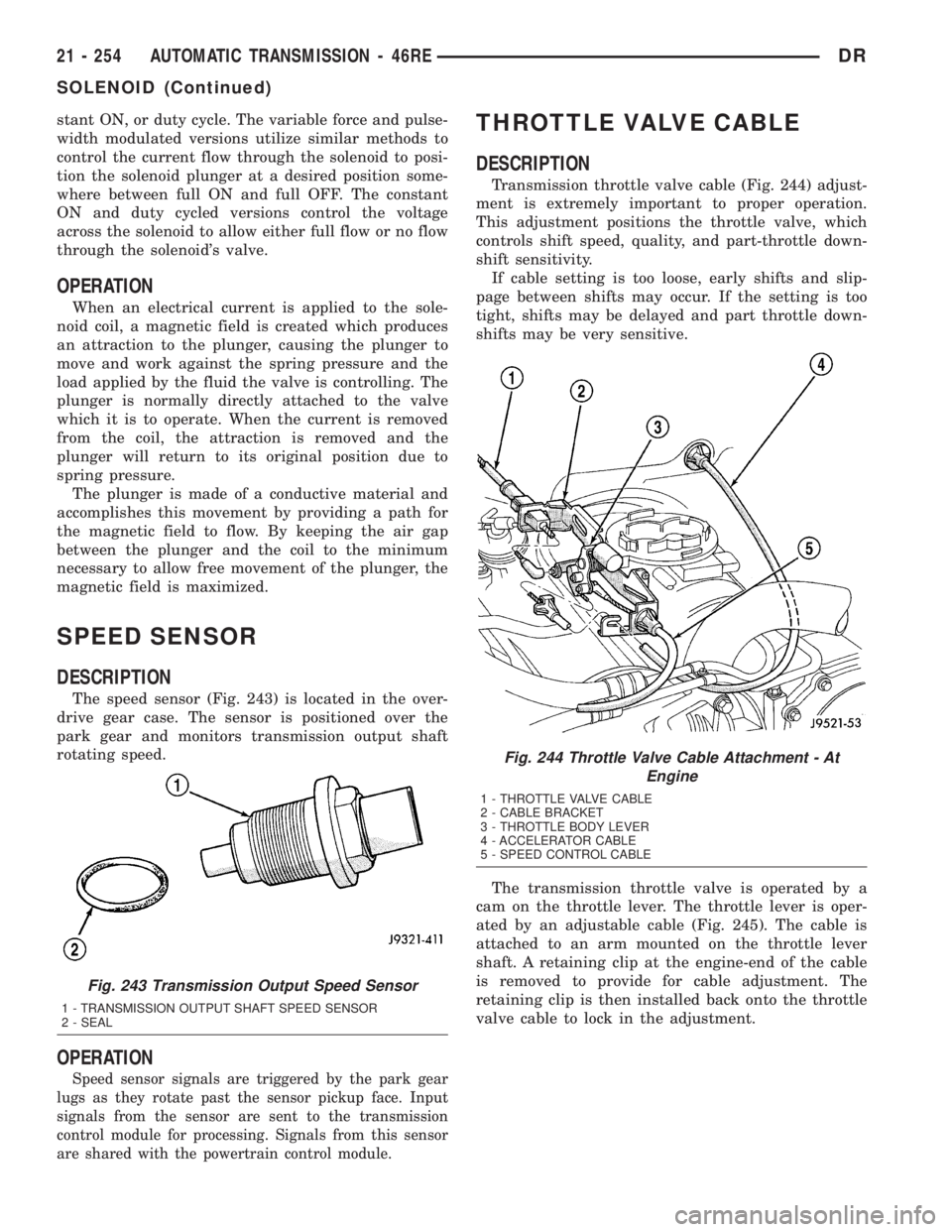

SPEED SENSOR

DESCRIPTION

The speed sensor (Fig. 243) is located in the over-

drive gear case. The sensor is positioned over the

park gear and monitors transmission output shaft

rotating speed.

OPERATION

Speed sensor signals are triggered by the park gear

lugs as they rotate past the sensor pickup face. Input

signals from the sensor are sent to the transmission

control module for processing. Signals from this sensor

are shared with the powertrain control module.

THROTTLE VALVE CABLE

DESCRIPTION

Transmission throttle valve cable (Fig. 244) adjust-

ment is extremely important to proper operation.

This adjustment positions the throttle valve, which

controls shift speed, quality, and part-throttle down-

shift sensitivity.

If cable setting is too loose, early shifts and slip-

page between shifts may occur. If the setting is too

tight, shifts may be delayed and part throttle down-

shifts may be very sensitive.

The transmission throttle valve is operated by a

cam on the throttle lever. The throttle lever is oper-

ated by an adjustable cable (Fig. 245). The cable is

attached to an arm mounted on the throttle lever

shaft. A retaining clip at the engine-end of the cable

is removed to provide for cable adjustment. The

retaining clip is then installed back onto the throttle

valve cable to lock in the adjustment.

Fig. 243 Transmission Output Speed Sensor

1 - TRANSMISSION OUTPUT SHAFT SPEED SENSOR

2 - SEAL

Fig. 244 Throttle Valve Cable Attachment - At

Engine

1 - THROTTLE VALVE CABLE

2 - CABLE BRACKET

3 - THROTTLE BODY LEVER

4 - ACCELERATOR CABLE

5 - SPEED CONTROL CABLE

21 - 254 AUTOMATIC TRANSMISSION - 46REDR

SOLENOID (Continued)

Page 2125 of 2895

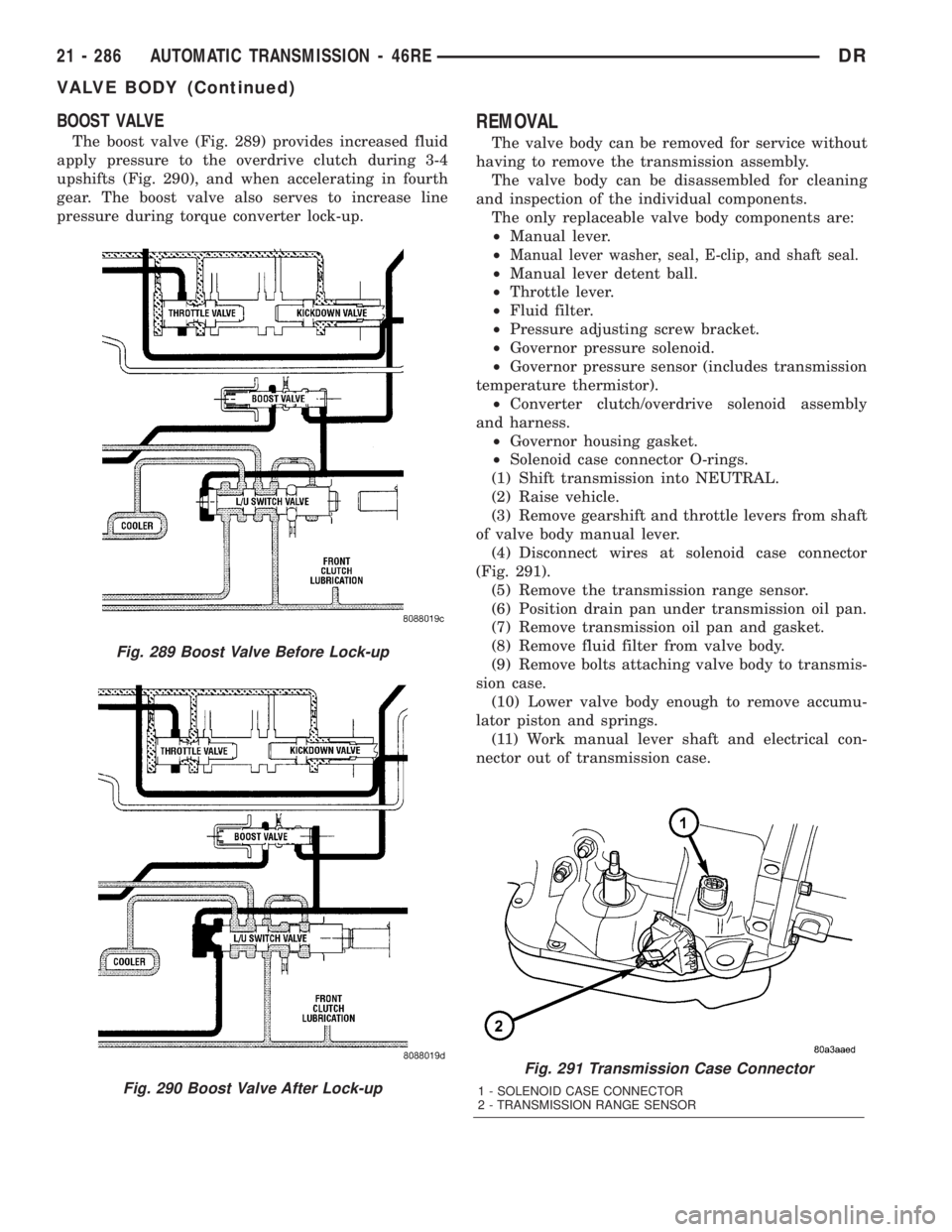

BOOST VALVE

The boost valve (Fig. 289) provides increased fluid

apply pressure to the overdrive clutch during 3-4

upshifts (Fig. 290), and when accelerating in fourth

gear. The boost valve also serves to increase line

pressure during torque converter lock-up.

REMOVAL

The valve body can be removed for service without

having to remove the transmission assembly.

The valve body can be disassembled for cleaning

and inspection of the individual components.

The only replaceable valve body components are:

²Manual lever.

²

Manual lever washer, seal, E-clip, and shaft seal.

²Manual lever detent ball.

²Throttle lever.

²Fluid filter.

²Pressure adjusting screw bracket.

²Governor pressure solenoid.

²Governor pressure sensor (includes transmission

temperature thermistor).

²Converter clutch/overdrive solenoid assembly

and harness.

²Governor housing gasket.

²Solenoid case connector O-rings.

(1) Shift transmission into NEUTRAL.

(2) Raise vehicle.

(3) Remove gearshift and throttle levers from shaft

of valve body manual lever.

(4) Disconnect wires at solenoid case connector

(Fig. 291).

(5) Remove the transmission range sensor.

(6) Position drain pan under transmission oil pan.

(7) Remove transmission oil pan and gasket.

(8) Remove fluid filter from valve body.

(9) Remove bolts attaching valve body to transmis-

sion case.

(10) Lower valve body enough to remove accumu-

lator piston and springs.

(11) Work manual lever shaft and electrical con-

nector out of transmission case.

Fig. 291 Transmission Case Connector

1 - SOLENOID CASE CONNECTOR

2 - TRANSMISSION RANGE SENSOR

Fig. 289 Boost Valve Before Lock-up

Fig. 290 Boost Valve After Lock-up

21 - 286 AUTOMATIC TRANSMISSION - 46REDR

VALVE BODY (Continued)

Page 2137 of 2895

CLEANING

Clean the valve housings, valves, plugs, springs,

and separator plates with a standard parts cleaning

solution only. Do not use gasoline, kerosene, or any

type of caustic solution.

Do not immerse any of the electrical components in

cleaning solution. Clean the governor solenoid and

sensor and the dual solenoid and harness assembly

by wiping them off with dry shop towels only.

Dry all except the electrical parts with compressed

air. Make sure all passages are clean and free from

obstructions.Do not use rags or shop towels to

dry or wipe off valve body components. Lint

from these materials can stick to valve body

parts, interfere with valve operation, and clog

filters and fluid passages.

Wipe the governor pressure sensor and solenoid

valve with dry, lint free shop towels only. The O-rings

on the sensor and solenoid valve are the only service-

able components. Be sure the vent ports in the sole-

noid valve are open and not blocked by dirt or debris.

Replace the valve and/or sensor only when DRB scan

tool diagnosis indicates this is necessary. Or, if either

part has sustained physical damage (dented,

deformed, broken, etc.).

CAUTION: Do not turn the small screw at the end of

the solenoid valve for any reason. Turning the

screw in either direction will ruin solenoid calibra-

tion and result in solenoid failure. In addition, thefilter on the solenoid valve is NOT serviceable. Do

not try to remove the filter as this will damage the

valve housing.

INSPECTION

Inspect the throttle and manual valve levers and

shafts. Do not attempt to straighten a bent shaft or

correct a loose lever. Replace these components if

worn, bent, loose or damaged in any way.

Inspect all of the valve body mating surfaces for

scratches, nicks, burrs, or distortion. Use a straight-

edge to check surface flatness. Minor scratches may

be removed with crocus cloth using only very light

pressure.

Minor distortion of a valve body mating surface

may be corrected by smoothing the surface with a

sheet of crocus cloth. Position the crocus cloth on a

surface plate, sheet of plate glass or equally flat sur-

face. If distortion is severe or any surfaces are

heavily scored, the valve body will have to be

replaced.

CAUTION: Many of the valves and plugs, such as

the throttle valve, shuttle valve plug, 1-2 shift valve

and 1-2 governor plug, are made of coated alumi-

num. Aluminum components are identified by the

dark color of the special coating applied to the sur-

face (or by testing with a magnet). Do not sand alu-

minum valves or plugs under any circumstances.

This practice could damage the special coating

causing the valves/plugs to stick and bind.

Inspect the valves and plugs for scratches, burrs,

nicks, or scores. Minor surface scratches on steel

valves and plugs can be removed with crocus cloth

butdo not round off the edges of the valve or

plug lands.Maintaining sharpness of these edges is

vitally important. The edges prevent foreign matter

from lodging between the valves and plugs and the

bore.

Inspect all the valve and plug bores in the valve

body. Use a penlight to view the bore interiors.

Replace the valve body if any bores are distorted or

scored. Inspect all of the valve body springs. The

springs must be free of distortion, warpage or broken

coils.

Check the two separator plates for distortion or

damage of any kind. Inspect the upper housing,

lower housing, 3-4 accumulator housing, and transfer

plate carefully. Be sure all fluid passages are clean

and clear. Check condition of the upper housing and

transfer plate check balls as well. The check balls

and ball seats must not be worn or damaged.

Trial fit each valve and plug in its bore to check

freedom of operation. When clean and dry, the valves

and plugs should drop freely into the bores.

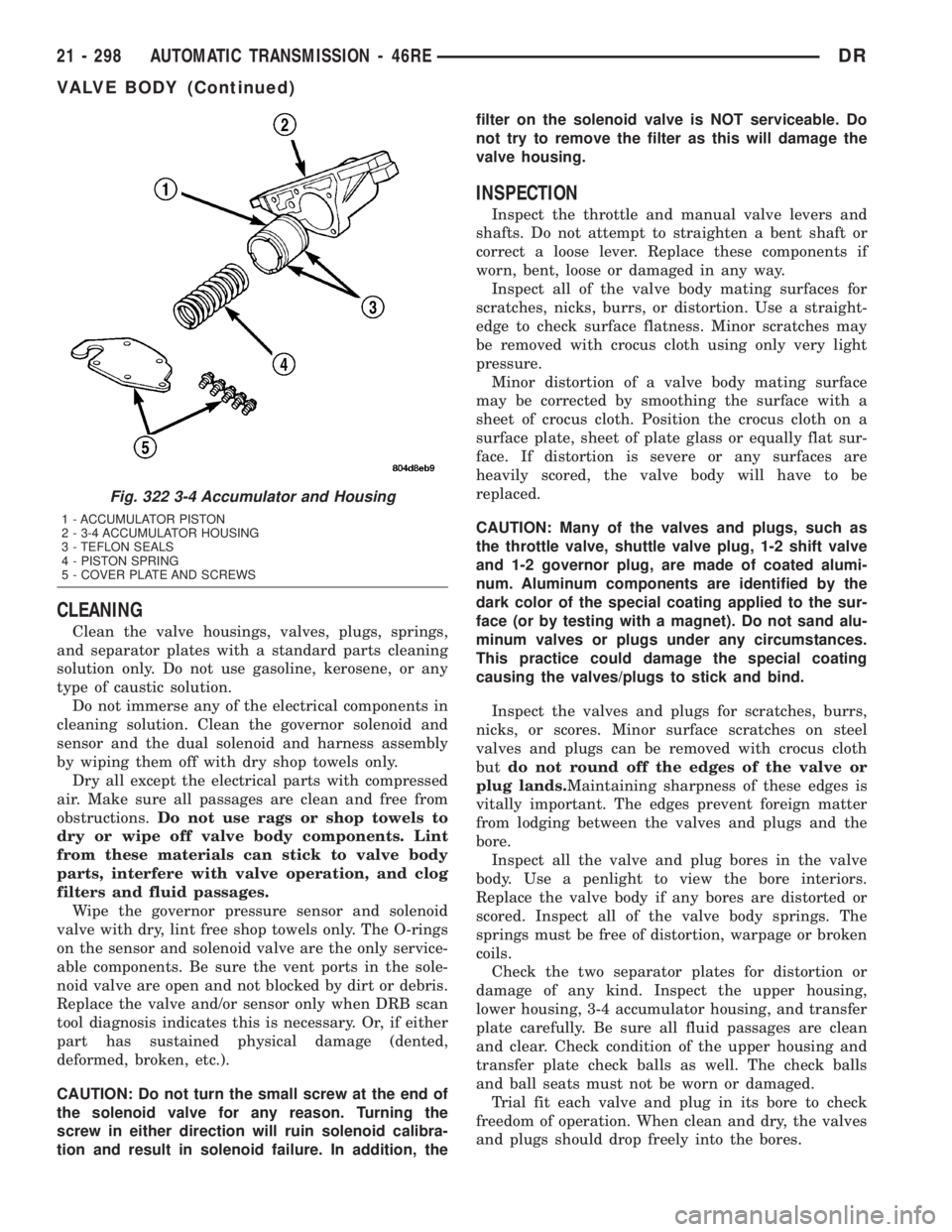

Fig. 322 3-4 Accumulator and Housing

1 - ACCUMULATOR PISTON

2 - 3-4 ACCUMULATOR HOUSING

3 - TEFLON SEALS

4 - PISTON SPRING

5 - COVER PLATE AND SCREWS

21 - 298 AUTOMATIC TRANSMISSION - 46REDR

VALVE BODY (Continued)

Page 2146 of 2895

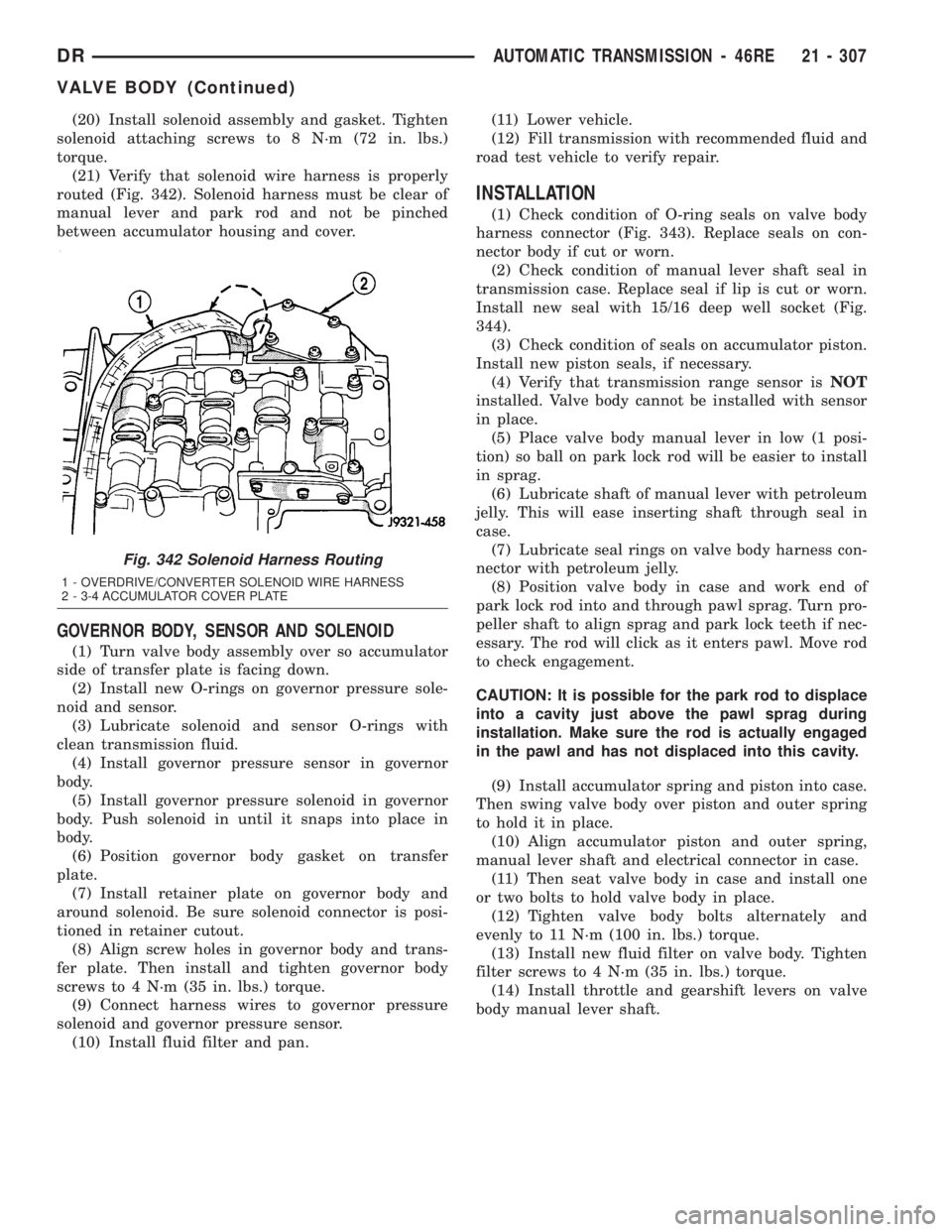

(20) Install solenoid assembly and gasket. Tighten

solenoid attaching screws to 8 N´m (72 in. lbs.)

torque.

(21) Verify that solenoid wire harness is properly

routed (Fig. 342). Solenoid harness must be clear of

manual lever and park rod and not be pinched

between accumulator housing and cover.

GOVERNOR BODY, SENSOR AND SOLENOID

(1) Turn valve body assembly over so accumulator

side of transfer plate is facing down.

(2) Install new O-rings on governor pressure sole-

noid and sensor.

(3) Lubricate solenoid and sensor O-rings with

clean transmission fluid.

(4) Install governor pressure sensor in governor

body.

(5) Install governor pressure solenoid in governor

body. Push solenoid in until it snaps into place in

body.

(6) Position governor body gasket on transfer

plate.

(7) Install retainer plate on governor body and

around solenoid. Be sure solenoid connector is posi-

tioned in retainer cutout.

(8) Align screw holes in governor body and trans-

fer plate. Then install and tighten governor body

screws to 4 N´m (35 in. lbs.) torque.

(9) Connect harness wires to governor pressure

solenoid and governor pressure sensor.

(10) Install fluid filter and pan.(11) Lower vehicle.

(12) Fill transmission with recommended fluid and

road test vehicle to verify repair.

INSTALLATION

(1) Check condition of O-ring seals on valve body

harness connector (Fig. 343). Replace seals on con-

nector body if cut or worn.

(2) Check condition of manual lever shaft seal in

transmission case. Replace seal if lip is cut or worn.

Install new seal with 15/16 deep well socket (Fig.

344).

(3) Check condition of seals on accumulator piston.

Install new piston seals, if necessary.

(4) Verify that transmission range sensor isNOT

installed. Valve body cannot be installed with sensor

in place.

(5) Place valve body manual lever in low (1 posi-

tion) so ball on park lock rod will be easier to install

in sprag.

(6) Lubricate shaft of manual lever with petroleum

jelly. This will ease inserting shaft through seal in

case.

(7) Lubricate seal rings on valve body harness con-

nector with petroleum jelly.

(8) Position valve body in case and work end of

park lock rod into and through pawl sprag. Turn pro-

peller shaft to align sprag and park lock teeth if nec-

essary. The rod will click as it enters pawl. Move rod

to check engagement.

CAUTION: It is possible for the park rod to displace

into a cavity just above the pawl sprag during

installation. Make sure the rod is actually engaged

in the pawl and has not displaced into this cavity.

(9) Install accumulator spring and piston into case.

Then swing valve body over piston and outer spring

to hold it in place.

(10) Align accumulator piston and outer spring,

manual lever shaft and electrical connector in case.

(11) Then seat valve body in case and install one

or two bolts to hold valve body in place.

(12) Tighten valve body bolts alternately and

evenly to 11 N´m (100 in. lbs.) torque.

(13) Install new fluid filter on valve body. Tighten

filter screws to 4 N´m (35 in. lbs.) torque.

(14) Install throttle and gearshift levers on valve

body manual lever shaft.

Fig. 342 Solenoid Harness Routing

1 - OVERDRIVE/CONVERTER SOLENOID WIRE HARNESS

2 - 3-4 ACCUMULATOR COVER PLATE

DRAUTOMATIC TRANSMISSION - 46RE 21 - 307

VALVE BODY (Continued)

Page 2159 of 2895

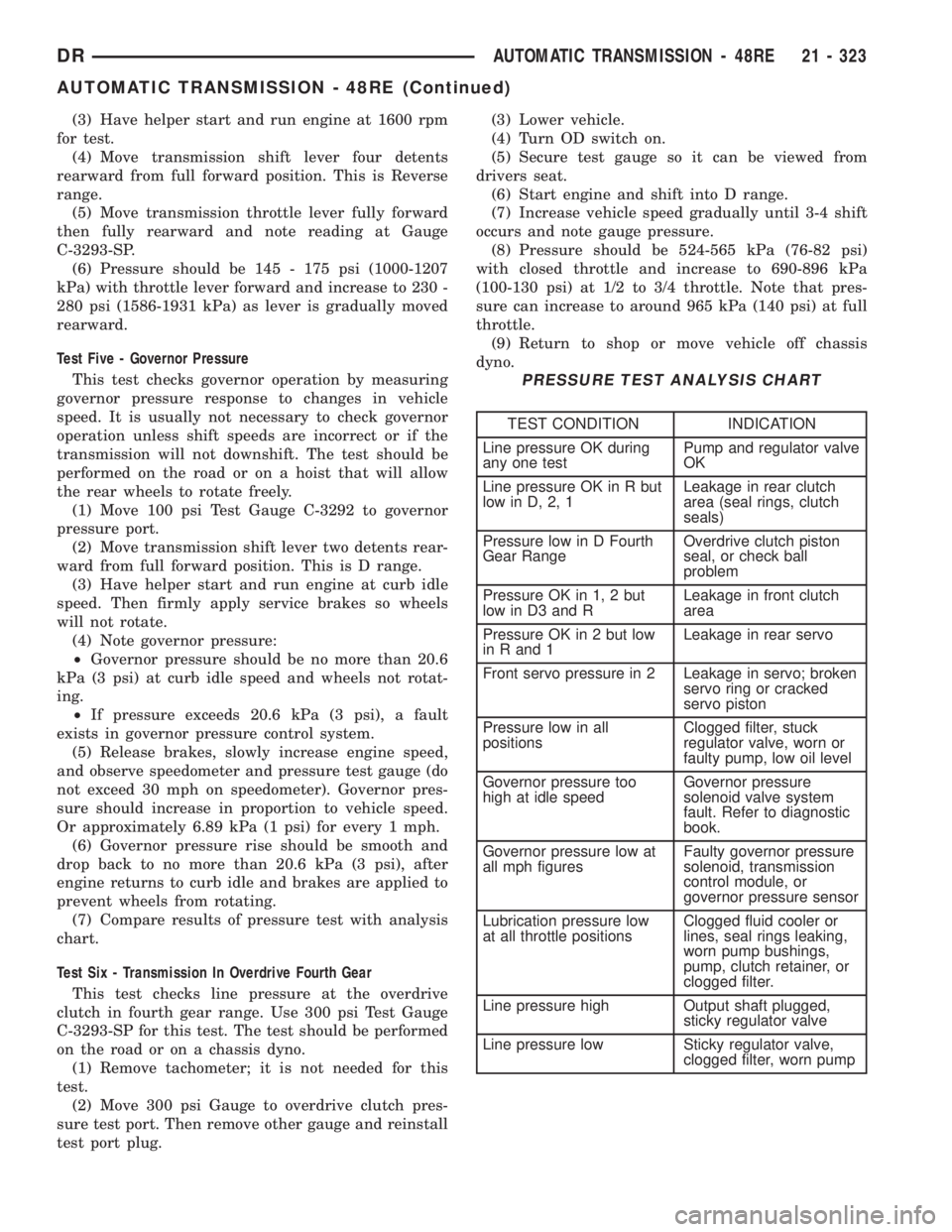

FOURTH GEAR POWERFLOW

Fourth gear overdrive range is electronically con-

trolled and hydraulically activated. Various sensor

inputs are supplied to the powertrain control module

to operate the overdrive solenoid on the valve body.

The solenoid contains a check ball that opens and

closes a vent port in the 3-4 shift valve feed passage.

The overdrive solenoid (and check ball) are not ener-

gized in first, second, third, or reverse gear. The vent

port remains open, diverting line pressure from the

2-3 shift valve away from the 3-4 shift valve. The

overdrive control switch must be in the ON position

to transmit overdrive status to the PCM. A 3-4

upshift occurs only when the overdrive solenoid is

energized by the PCM. The PCM energizes the over-

drive solenoid during the 3-4 upshift. This causes the

solenoid check ball to close the vent port allowing

line pressure from the 2-3 shift valve to act directly

on the 3-4 upshift valve. Line pressure on the 3-4

shift valve overcomes valve spring pressure moving

the valve to the upshift position. This action exposes

the feed passages to the 3-4 timing valve, 3-4 quick

fill valve, 3-4 accumulator, and ultimately to the

overdrive piston. Line pressure through the timing

valve moves the overdrive piston into contact with

the overdrive clutch. The direct clutch is disengaged

before the overdrive clutch is engaged. The boost

valve provides increased fluid apply pressure to the

overdrive clutch during 3-4 upshifts, and when accel-

erating in fourth gear. The 3-4 accumulator cushions

overdrive clutch engagement to smooth 3-4 upshifts.

The accumulator is charged at the same time as

apply pressure acts against the overdrive piston.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AUTOMATIC

TRANSMISSION

Automatic transmission problems can be a result of

poor engine performance, incorrect fluid level, incor-

rect linkage or cable adjustment, band or hydraulic

control pressure adjustments, hydraulic system mal-

functions or electrical/mechanical component mal-

functions. Begin diagnosis by checking the easily

accessible items such as: fluid level and condition,

linkage adjustments and electrical connections. A

road test will determine if further diagnosis is neces-

sary.

DIAGNOSIS AND TESTING - PRELIMINARY

Two basic procedures are required. One procedure

for vehicles that are drivable and an alternate proce-

dure for disabled vehicles (will not back up or move

forward).

VEHICLE IS DRIVEABLE

(1) Check for transmission fault codes using DRBt

scan tool.

(2) Check fluid level and condition.

(3) Adjust throttle and gearshift linkage if com-

plaint was based on delayed, erratic, or harsh shifts.

(4) Road test and note how transmission upshifts,

downshifts, and engages.

(5) Perform hydraulic pressure test if shift prob-

lems were noted during road test.

(6) Perform air-pressure test to check clutch-band

operation.

VEHICLE IS DISABLED

(1) Check fluid level and condition.

(2) Check for broken or disconnected gearshift or

throttle linkage.

(3) Check for cracked, leaking cooler lines, or loose

or missing pressure-port plugs.

(4) Raise and support vehicle on safety stands,

start engine, shift transmission into gear, and note

following:

(a) If propeller shaft turns but wheels do not,

problem is with differential or axle shafts.

(b) If propeller shaft does not turn and transmis-

sion is noisy, stop engine. Remove oil pan, and

check for debris. If pan is clear, remove transmis-

sion and check for damaged drive plate, converter,

oil pump, or input shaft.

(c) If propeller shaft does not turn and transmis-

sion is not noisy, perform hydraulic-pressure test to

determine if problem is hydraulic or mechanical.

DIAGNOSIS AND TESTING - ROAD TESTING

Before road testing, be sure the fluid level and con-

trol cable adjustments have been checked and

adjusted if necessary. Verify that diagnostic trouble

codes have been resolved.

Observe engine performance during the road test.

A poorly tuned engine will not allow accurate analy-

sis of transmission operation.

Operate the transmission in all gear ranges. Check

for shift variations and engine flare which indicates

slippage. Note if shifts are harsh, spongy, delayed,

early, or if part throttle downshifts are sensitive.

Slippage indicated by engine flare, usually means

clutch, band or overrunning clutch problems. If the

condition is advanced, an overhaul will be necessary

to restore normal operation.

A slipping clutch or band can often be determined

by comparing which internal units are applied in the

various gear ranges. The Clutch and Band Applica-

tion chart provides a basis for analyzing road test

results.

21 - 320 AUTOMATIC TRANSMISSION - 48REDR

AUTOMATIC TRANSMISSION - 48RE (Continued)

Page 2162 of 2895

(3) Have helper start and run engine at 1600 rpm

for test.

(4) Move transmission shift lever four detents

rearward from full forward position. This is Reverse

range.

(5) Move transmission throttle lever fully forward

then fully rearward and note reading at Gauge

C-3293-SP.

(6) Pressure should be 145 - 175 psi (1000-1207

kPa) with throttle lever forward and increase to 230 -

280 psi (1586-1931 kPa) as lever is gradually moved

rearward.

Test Five - Governor Pressure

This test checks governor operation by measuring

governor pressure response to changes in vehicle

speed. It is usually not necessary to check governor

operation unless shift speeds are incorrect or if the

transmission will not downshift. The test should be

performed on the road or on a hoist that will allow

the rear wheels to rotate freely.

(1) Move 100 psi Test Gauge C-3292 to governor

pressure port.

(2) Move transmission shift lever two detents rear-

ward from full forward position. This is D range.

(3) Have helper start and run engine at curb idle

speed. Then firmly apply service brakes so wheels

will not rotate.

(4) Note governor pressure:

²Governor pressure should be no more than 20.6

kPa (3 psi) at curb idle speed and wheels not rotat-

ing.

²If pressure exceeds 20.6 kPa (3 psi), a fault

exists in governor pressure control system.

(5) Release brakes, slowly increase engine speed,

and observe speedometer and pressure test gauge (do

not exceed 30 mph on speedometer). Governor pres-

sure should increase in proportion to vehicle speed.

Or approximately 6.89 kPa (1 psi) for every 1 mph.

(6) Governor pressure rise should be smooth and

drop back to no more than 20.6 kPa (3 psi), after

engine returns to curb idle and brakes are applied to

prevent wheels from rotating.

(7) Compare results of pressure test with analysis

chart.

Test Six - Transmission In Overdrive Fourth Gear

This test checks line pressure at the overdrive

clutch in fourth gear range. Use 300 psi Test Gauge

C-3293-SP for this test. The test should be performed

on the road or on a chassis dyno.

(1) Remove tachometer; it is not needed for this

test.

(2) Move 300 psi Gauge to overdrive clutch pres-

sure test port. Then remove other gauge and reinstall

test port plug.(3) Lower vehicle.

(4) Turn OD switch on.

(5) Secure test gauge so it can be viewed from

drivers seat.

(6) Start engine and shift into D range.

(7) Increase vehicle speed gradually until 3-4 shift

occurs and note gauge pressure.

(8) Pressure should be 524-565 kPa (76-82 psi)

with closed throttle and increase to 690-896 kPa

(100-130 psi) at 1/2 to 3/4 throttle. Note that pres-

sure can increase to around 965 kPa (140 psi) at full

throttle.

(9) Return to shop or move vehicle off chassis

dyno.

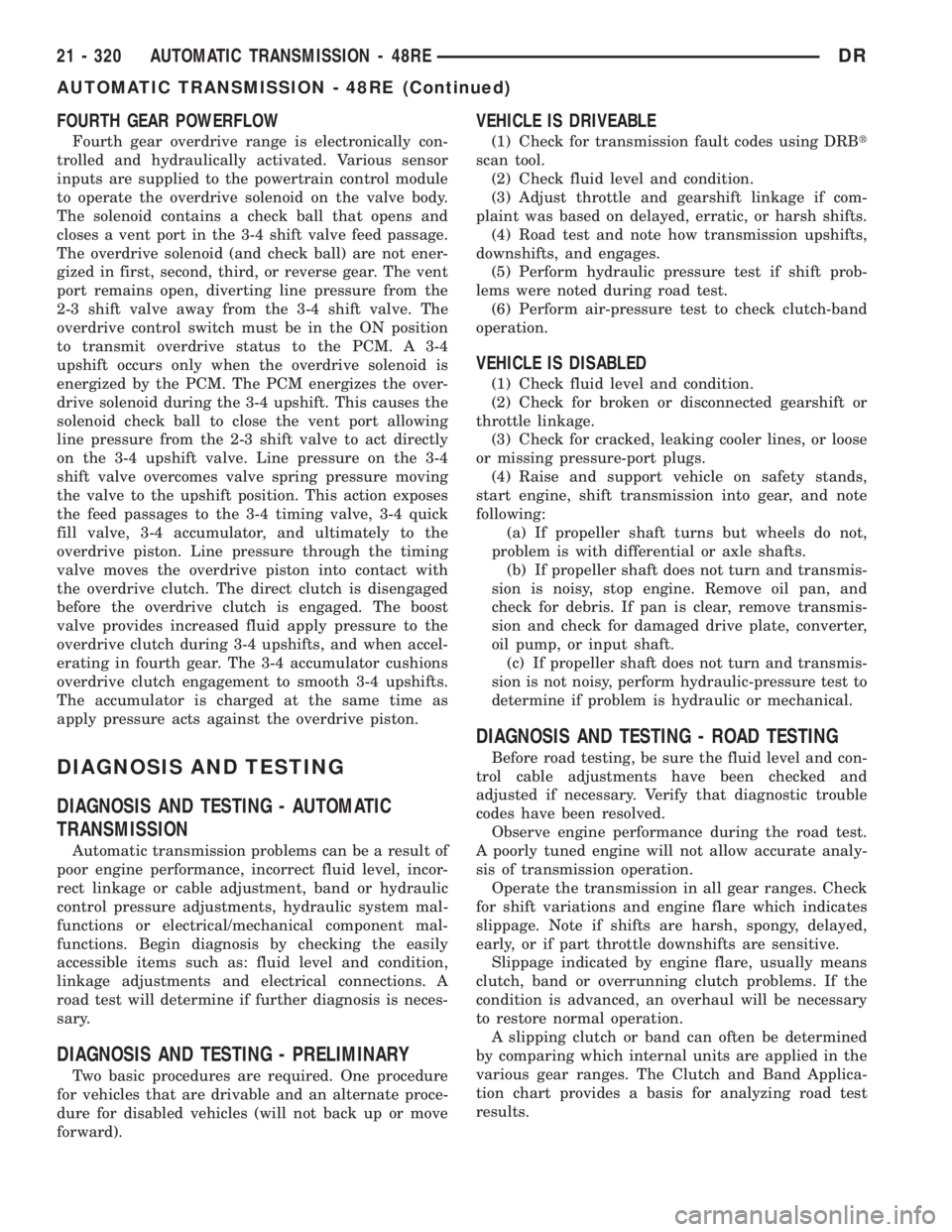

PRESSURE TEST ANALYSIS CHART

TEST CONDITION INDICATION

Line pressure OK during

any one testPump and regulator valve

OK

Line pressure OK in R but

low in D, 2, 1Leakage in rear clutch

area (seal rings, clutch

seals)

Pressure low in D Fourth

Gear RangeOverdrive clutch piston

seal, or check ball

problem

Pressure OK in 1, 2 but

low in D3 and RLeakage in front clutch

area

Pressure OK in 2 but low

in R and 1Leakage in rear servo

Front servo pressure in 2 Leakage in servo; broken

servo ring or cracked

servo piston

Pressure low in all

positionsClogged filter, stuck

regulator valve, worn or

faulty pump, low oil level

Governor pressure too

high at idle speedGovernor pressure

solenoid valve system

fault. Refer to diagnostic

book.

Governor pressure low at

all mph figuresFaulty governor pressure

solenoid, transmission

control module, or

governor pressure sensor

Lubrication pressure low

at all throttle positionsClogged fluid cooler or

lines, seal rings leaking,

worn pump bushings,

pump, clutch retainer, or

clogged filter.

Line pressure high Output shaft plugged,

sticky regulator valve

Line pressure low Sticky regulator valve,

clogged filter, worn pump

DRAUTOMATIC TRANSMISSION - 48RE 21 - 323

AUTOMATIC TRANSMISSION - 48RE (Continued)

Page 2192 of 2895

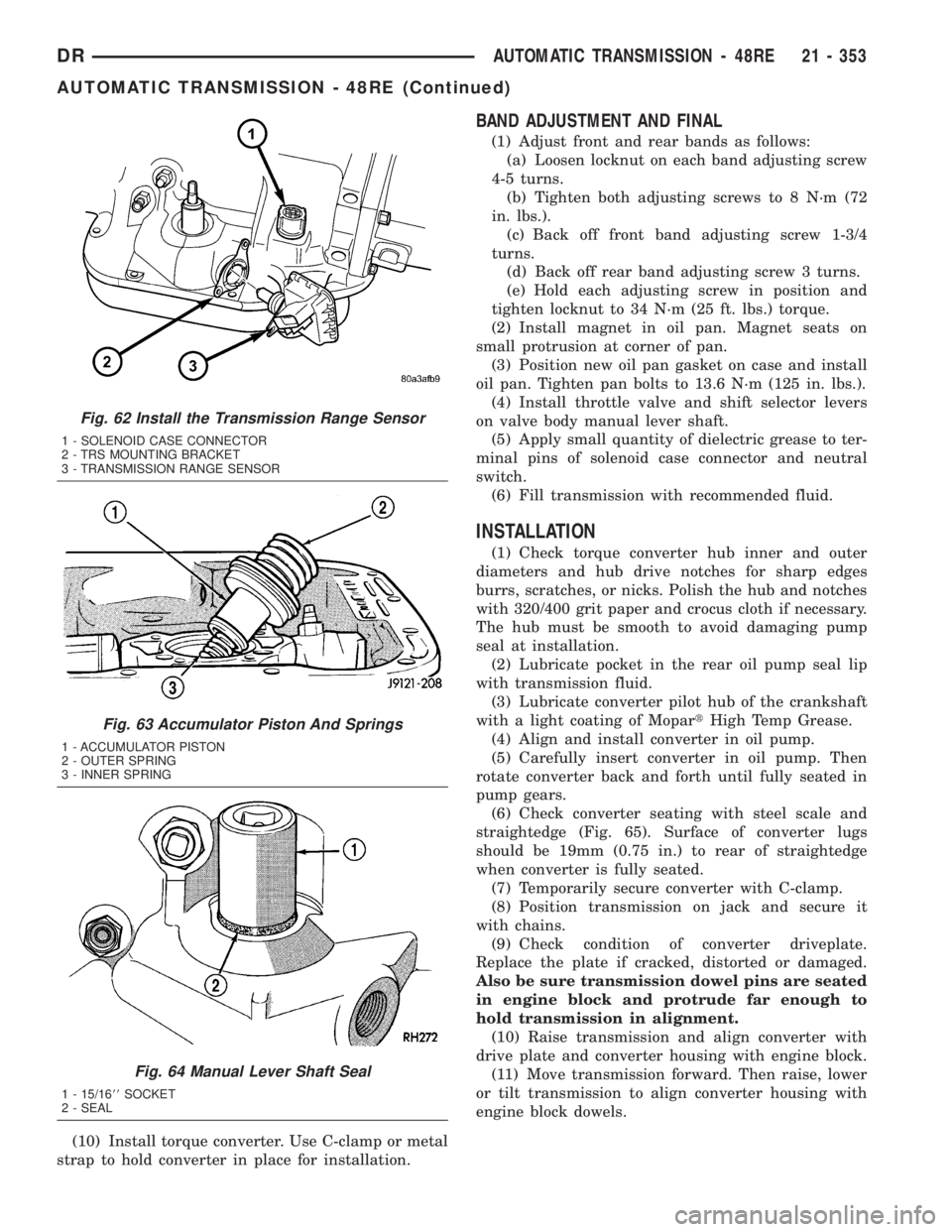

(10) Install torque converter. Use C-clamp or metal

strap to hold converter in place for installation.

BAND ADJUSTMENT AND FINAL

(1) Adjust front and rear bands as follows:

(a) Loosen locknut on each band adjusting screw

4-5 turns.

(b) Tighten both adjusting screws to 8 N´m (72

in. lbs.).

(c) Back off front band adjusting screw 1-3/4

turns.

(d) Back off rear band adjusting screw 3 turns.

(e) Hold each adjusting screw in position and

tighten locknut to 34 N´m (25 ft. lbs.) torque.

(2) Install magnet in oil pan. Magnet seats on

small protrusion at corner of pan.

(3) Position new oil pan gasket on case and install

oil pan. Tighten pan bolts to 13.6 N´m (125 in. lbs.).

(4) Install throttle valve and shift selector levers

on valve body manual lever shaft.

(5) Apply small quantity of dielectric grease to ter-

minal pins of solenoid case connector and neutral

switch.

(6) Fill transmission with recommended fluid.

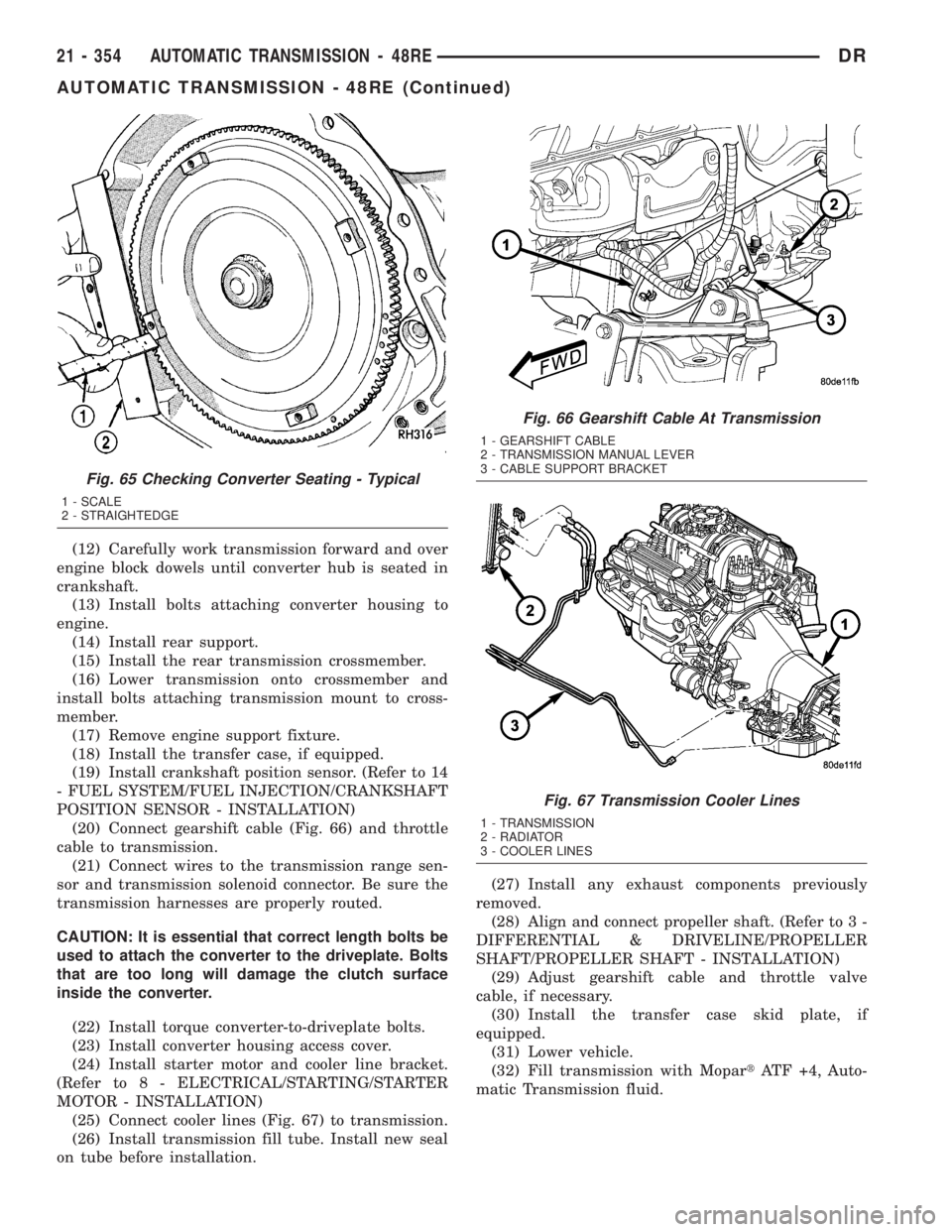

INSTALLATION

(1) Check torque converter hub inner and outer

diameters and hub drive notches for sharp edges

burrs, scratches, or nicks. Polish the hub and notches

with 320/400 grit paper and crocus cloth if necessary.

The hub must be smooth to avoid damaging pump

seal at installation.

(2) Lubricate pocket in the rear oil pump seal lip

with transmission fluid.

(3) Lubricate converter pilot hub of the crankshaft

with a light coating of MopartHigh Temp Grease.

(4) Align and install converter in oil pump.

(5) Carefully insert converter in oil pump. Then

rotate converter back and forth until fully seated in

pump gears.

(6) Check converter seating with steel scale and

straightedge (Fig. 65). Surface of converter lugs

should be 19mm (0.75 in.) to rear of straightedge

when converter is fully seated.

(7) Temporarily secure converter with C-clamp.

(8) Position transmission on jack and secure it

with chains.

(9) Check condition of converter driveplate.

Replace the plate if cracked, distorted or damaged.

Also be sure transmission dowel pins are seated

in engine block and protrude far enough to

hold transmission in alignment.

(10) Raise transmission and align converter with

drive plate and converter housing with engine block.

(11) Move transmission forward. Then raise, lower

or tilt transmission to align converter housing with

engine block dowels.

Fig. 62 Install the Transmission Range Sensor

1 - SOLENOID CASE CONNECTOR

2 - TRS MOUNTING BRACKET

3 - TRANSMISSION RANGE SENSOR

Fig. 63 Accumulator Piston And Springs

1 - ACCUMULATOR PISTON

2 - OUTER SPRING

3 - INNER SPRING

Fig. 64 Manual Lever Shaft Seal

1 - 15/1688SOCKET

2 - SEAL

DRAUTOMATIC TRANSMISSION - 48RE 21 - 353

AUTOMATIC TRANSMISSION - 48RE (Continued)

Page 2193 of 2895

(12) Carefully work transmission forward and over

engine block dowels until converter hub is seated in

crankshaft.

(13) Install bolts attaching converter housing to

engine.

(14) Install rear support.

(15) Install the rear transmission crossmember.

(16) Lower transmission onto crossmember and

install bolts attaching transmission mount to cross-

member.

(17) Remove engine support fixture.

(18) Install the transfer case, if equipped.

(19) Install crankshaft position sensor. (Refer to 14

- FUEL SYSTEM/FUEL INJECTION/CRANKSHAFT

POSITION SENSOR - INSTALLATION)

(20) Connect gearshift cable (Fig. 66) and throttle

cable to transmission.

(21) Connect wires to the transmission range sen-

sor and transmission solenoid connector. Be sure the

transmission harnesses are properly routed.

CAUTION: It is essential that correct length bolts be

used to attach the converter to the driveplate. Bolts

that are too long will damage the clutch surface

inside the converter.

(22) Install torque converter-to-driveplate bolts.

(23) Install converter housing access cover.

(24) Install starter motor and cooler line bracket.

(Refer to 8 - ELECTRICAL/STARTING/STARTER

MOTOR - INSTALLATION)

(25) Connect cooler lines (Fig. 67) to transmission.

(26) Install transmission fill tube. Install new seal

on tube before installation.(27) Install any exhaust components previously

removed.

(28) Align and connect propeller shaft. (Refer to 3 -

DIFFERENTIAL & DRIVELINE/PROPELLER

SHAFT/PROPELLER SHAFT - INSTALLATION)

(29) Adjust gearshift cable and throttle valve

cable, if necessary.

(30) Install the transfer case skid plate, if

equipped.

(31) Lower vehicle.

(32) Fill transmission with MopartATF +4, Auto-

matic Transmission fluid.

Fig. 65 Checking Converter Seating - Typical

1 - SCALE

2 - STRAIGHTEDGE

Fig. 66 Gearshift Cable At Transmission

1 - GEARSHIFT CABLE

2 - TRANSMISSION MANUAL LEVER

3 - CABLE SUPPORT BRACKET

Fig. 67 Transmission Cooler Lines

1 - TRANSMISSION

2 - RADIATOR

3 - COOLER LINES

21 - 354 AUTOMATIC TRANSMISSION - 48REDR

AUTOMATIC TRANSMISSION - 48RE (Continued)