Throttle Position Sensor DODGE RAM 2003 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1548 of 2895

(24) Remove the engine wire harness attaching

bolt and wire harness push-in fastener from air inlet

housing.

(25) Remove the air inlet housing and intake grid

heater from the intake manifold cover.

(26) Remove the two grid heater harness-to-cylin-

der head attaching bolts at front of cylinder head.(27) Remove the engine lift bracket from the rear

of the cylinder head.

(28)Remove the high pressure pump to fuel

rail fuel line as follows:

(a) Loosen fuel line nuts at fuel pump and at

fuel rail.

(b) Use a back-up wrench on the fitting at the

fuel pump to keep it from loosening.

(29) Remove the fuel rail to cylinder head fuel

lines as follows:

(a) Loosen No. 6 high pressure fuel line shield

and position out of way.

(b) Loosen the fuel line nuts at the fuel rail and

at the cylinder head.

(c) Remove the fuel line bracket bolts at the

intake manifold cover.

(30) Remove the fuel rail as follows:

(a) Remove fuel rail pressure sensor connector.

(b) Remove banjo fitting at pressure limiting

valve.

(c) Remove fuel rail bolts and fuel rail.

(31) Remove the low pressure lines as follows:

(a) Remove the fuel drain banjo fitting on the

front side of fuel filter housing.

(b) Remove the fuel drain banjo fitting on rear

side of fuel filter housing.

(c) Remove the fuel drain line support bracket

on rear side of filter housing.

(d) Remove fuel drain hose.

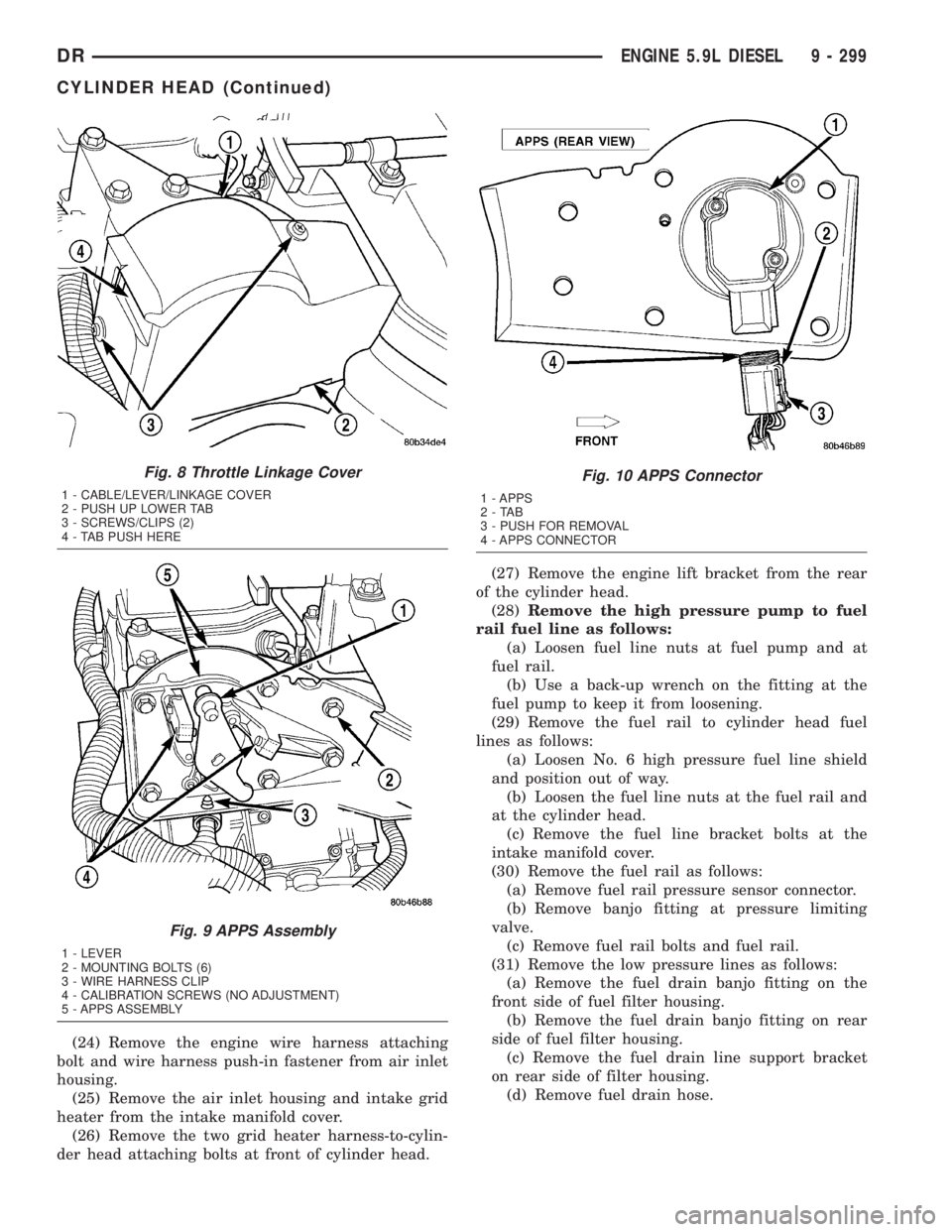

Fig. 8 Throttle Linkage Cover

1 - CABLE/LEVER/LINKAGE COVER

2 - PUSH UP LOWER TAB

3 - SCREWS/CLIPS (2)

4 - TAB PUSH HERE

Fig. 9 APPS Assembly

1 - LEVER

2 - MOUNTING BOLTS (6)

3 - WIRE HARNESS CLIP

4 - CALIBRATION SCREWS (NO ADJUSTMENT)

5 - APPS ASSEMBLY

Fig. 10 APPS Connector

1 - APPS

2-TAB

3 - PUSH FOR REMOVAL

4 - APPS CONNECTOR

DRENGINE 5.9L DIESEL 9 - 299

CYLINDER HEAD (Continued)

Page 1552 of 2895

(9) Install rocker housing and bolts. Tighten to 24

Nm (18 lb. ft.).

(10) Install fuel injector(Refer to 14 - FUEL SYS-

TEM/FUEL INJECTION/FUEL INJECTOR -

INSTALLATION).

(11) Install fuel injector tube and fuel injector tube

nut. Torqu to 50 N´m (37 ft. lbs.).

(12) Install injector harness nuts. Tighten to 1.5

Nm (13 lb. in.).

(13) Install cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(14) Install wire harness P-clip to cylinder head

behind filter housing 24 N´m (18 ft. lbs.).

(15) Connect the IAT and MAP sensor connector.

(16) Install the fuel filter canister assembly and

torque mounting bolts to 24 N´m (18 ft. lbs.).

(17) Connect fuel lift pump, WIF sensor, and fuel

heater.

(18) Remove the engine lift bracket at rear of cyl-

inder head.

CAUTION: Failure to follow procedure will result in

fuel leaks and/or fuel system failure.

(19)Install the fuel rail and high pressure

fuel lines as follows:

(a) Hand tighten fuel rail bolts.

(b) Hand tighten fuel drain line to pressure lim-

iting valve. Hand tighten at fuel filter housing.

(c) Hand tighten fuel rail-to-cylinder head lines.(d) Install fuel line brace bolts-to-intake mani-

fold finger tight.

(e) Hand tighten fuel pump to fuel rail line.

(f) Torque fuel line nuts at cylinder head to 30

Nm ( 22 ft. lbs.).

(g) Torque fuel line nuts at fuel rail to 30 Nm

(22 ft. lbs.)

(h) Torque fuel pump to fuel rail line to 30 Nm

(22 ft. lbs.).

(i) Torque fuel drain banjo bolt at pressure lim-

iting valve and front of fuel filter housing to 24 Nm

(18 ft. lbs.).

(j) Torque fuel line brace bolts to 24 N´m (18 ft.

lbs.).

(k) Torque rail bolts to 24 Nm (18 ft. lbs.).

(l) Connect fuel pressure sensor.

(20) Install the engine lift bracket at the rear of

cylinder head. Torque to 77 N´m (57 ft. lbs.).

(21) Reposition number 6 fuel line shield and

torque to 43 N´m (32 ft. lbs.).

(22) Install the fuel filter to injection pump low

pressure line. Inspect and replace sealing washers if

necessary. Torque banjo bolts to 24 N´m (18 ft. lbs.).

(23) Connect fuel return line at back of cylinder

head hand tight.

(24) Connect fuel return line at filter housing hand

tight.

(25) Torque banjo connections at cylinder head and

fuel filter housing to 24 Nm (18 ft. lbs.)

(26) Install bracket to rear of filter housing.

Torque to 24 Nm (18 ft. lbs.).

(27) Using new gaskets, install the intake grid

heater and air inlet housing. Torque bolts to 24 N´m

(18 ft. lbs.).

(28) Install wire harness P-clip and push on clip to

air inlet housing.

(29) Connect engine oil level indicator tube at fuel

filter housing and at air inlet housing.

(30) Connect the APPS connector.

(31) Install the APPS assembly to the cylinder

head bracket and torque bolts to 24 N´m (18 ft. lbs.).

(32) Install the throttle linkage cover.

(33) Install the charge air cooler-to-air inlet hous-

ing duct assembly. Torque all clamps to 11 N´m (100

in. lbs.).

(34) Connect intake grid heater wires.

(35) Secure engine harness to front of cylinder

head with bolt at four locations.

(36) Connect engine coolant temperature sensor

connector.

(37) Connect radiator upper hose to thermostat

housing.

(38) Rotate generator into position. Install upper

bolt and torque upper and lower bolts.

(39) Install wire harness push-on clip below

bracket.

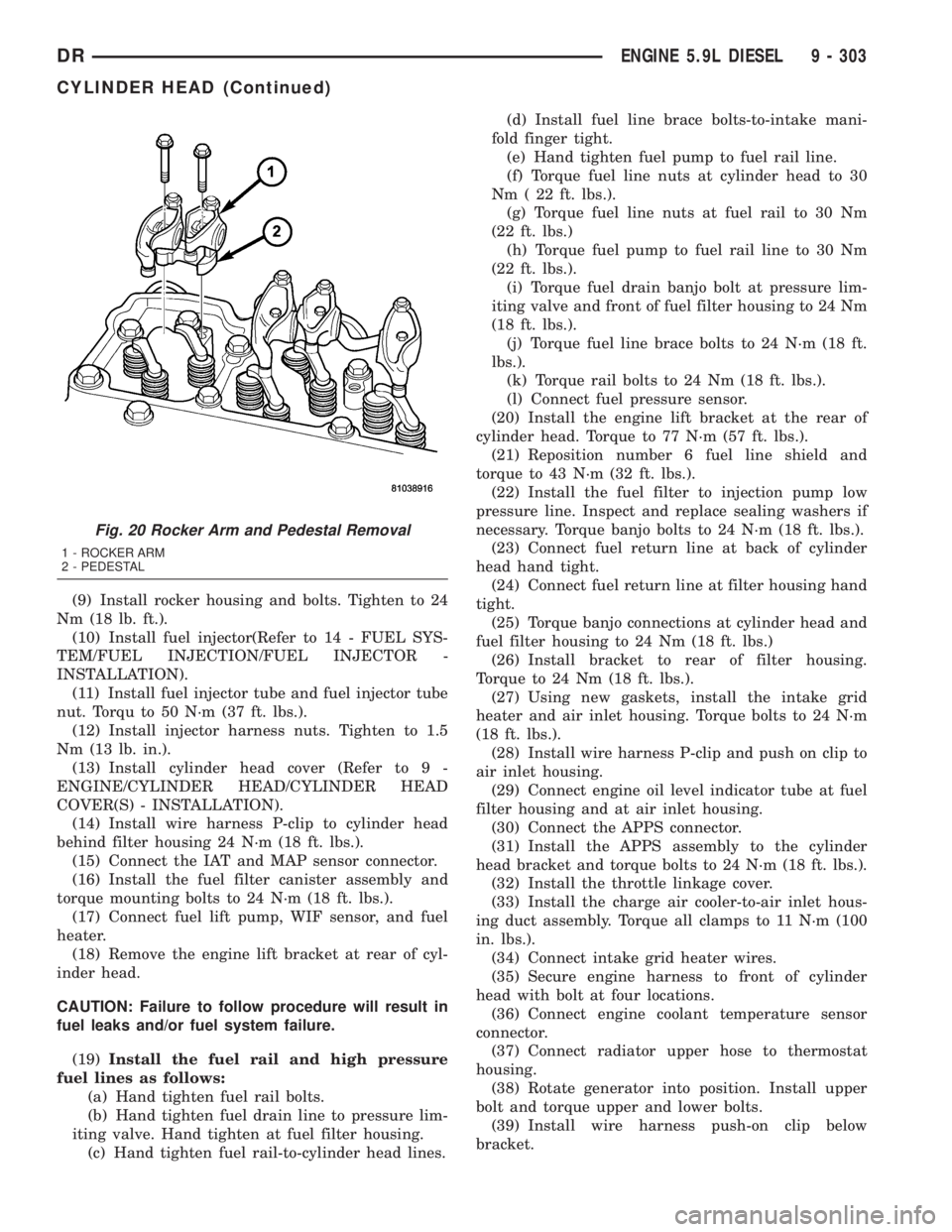

Fig. 20 Rocker Arm and Pedestal Removal

1 - ROCKER ARM

2 - PEDESTAL

DRENGINE 5.9L DIESEL 9 - 303

CYLINDER HEAD (Continued)

Page 1710 of 2895

INSTALLATION

CAUTION: Whenever the fuel pump module is ser-

viced, the rubber gasket must be replaced.

(1) Using a new gasket, position fuel pump module

into opening in fuel tank.

(2) Position locknut over top of fuel pump module.

Install locknut finger tight.

(3) Rotate module until embossed alignment arrow

(Fig. 15) points to center alignment mark. This step

must be performed to prevent float from contacting

side of fuel tank. Also be sure fitting on fuel filter/

fuel pressure regulator is pointed to drivers side of

vehicle.

(4) Install Special Tool 6856 (Fig. 16) to locknut.

(5) Tighten locknut. Refer to Torque Specifications.

(6) Install fuel tank. Refer to Fuel Tank Removal/

Installation.

FUEL RAIL

DESCRIPTION

The fuel injector rail is used to mount the fuel

injectors to the engine.

OPERATION

High pressure from the fuel pump is routed to the

fuel rail. The fuel rail then supplies the necessary

fuel to each individual fuel injector.

A quick-connect fitting with a safety latch clip is

used to attach the fuel line to the fuel rail.

The fuel rail is not repairable.

CAUTION: The left and right sections of the fuel rail

are connected with either a flexible connecting

hose, or joints. Do not attempt to separate the rail

halves at these connecting hose or joints. Due to

the design of the connecting hose or joint, it does

not use any clamps. Never attempt to install a

clamping device of any kind to the hose or joint.

When removing the fuel rail assembly for any rea-

son, be careful not to bend or kink the connecting

hose or joint.

REMOVAL

3.7L V-6

WARNING: THE FUEL SYSTEM IS UNDER CON-

STANT PRESSURE EVEN WITH ENGINE OFF.

BEFORE SERVICING FUEL RAIL, FUEL SYSTEM

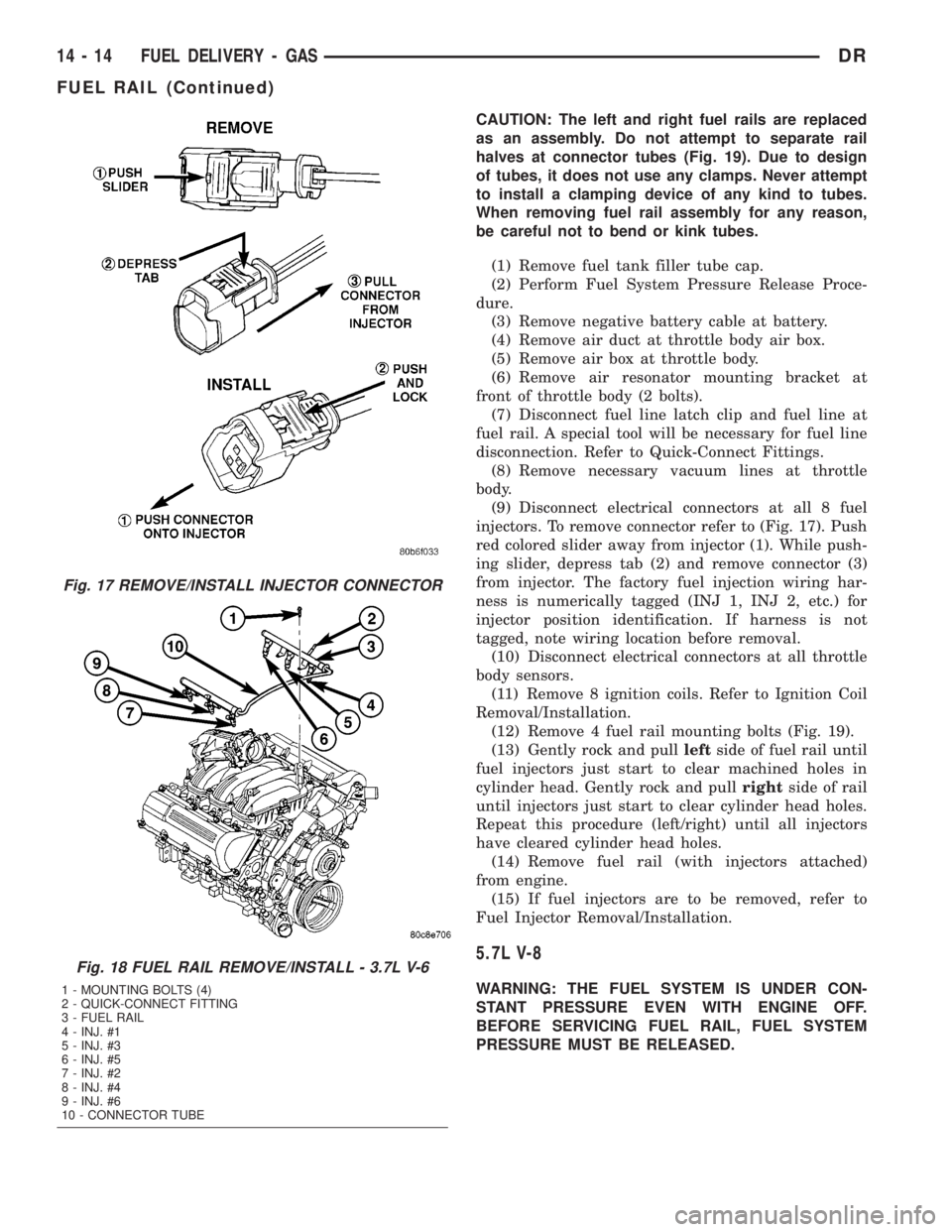

PRESSURE MUST BE RELEASED.CAUTION: The left and right fuel rails are replaced

as an assembly. Do not attempt to separate rail

halves at connector tubes (Fig. 18). Due to design

of tubes, it does not use any clamps. Never attempt

to install a clamping device of any kind to tubes.

When removing fuel rail assembly for any reason,

be careful not to bend or kink tubes.

(1) Remove fuel tank filler tube cap.

(2) Perform Fuel System Pressure Release Proce-

dure.

(3) Remove negative battery cable at battery.

(4) Remove air duct at throttle body air box.

(5) Remove air box at throttle body.

(6) Remove air resonator mounting bracket at

front of throttle body (2 bolts).

(7) Disconnect fuel line latch clip and fuel line at

fuel rail. A special tool will be necessary for fuel line

disconnection. Refer to Quick-Connect Fittings.

(8) Remove necessary vacuum lines at throttle

body.

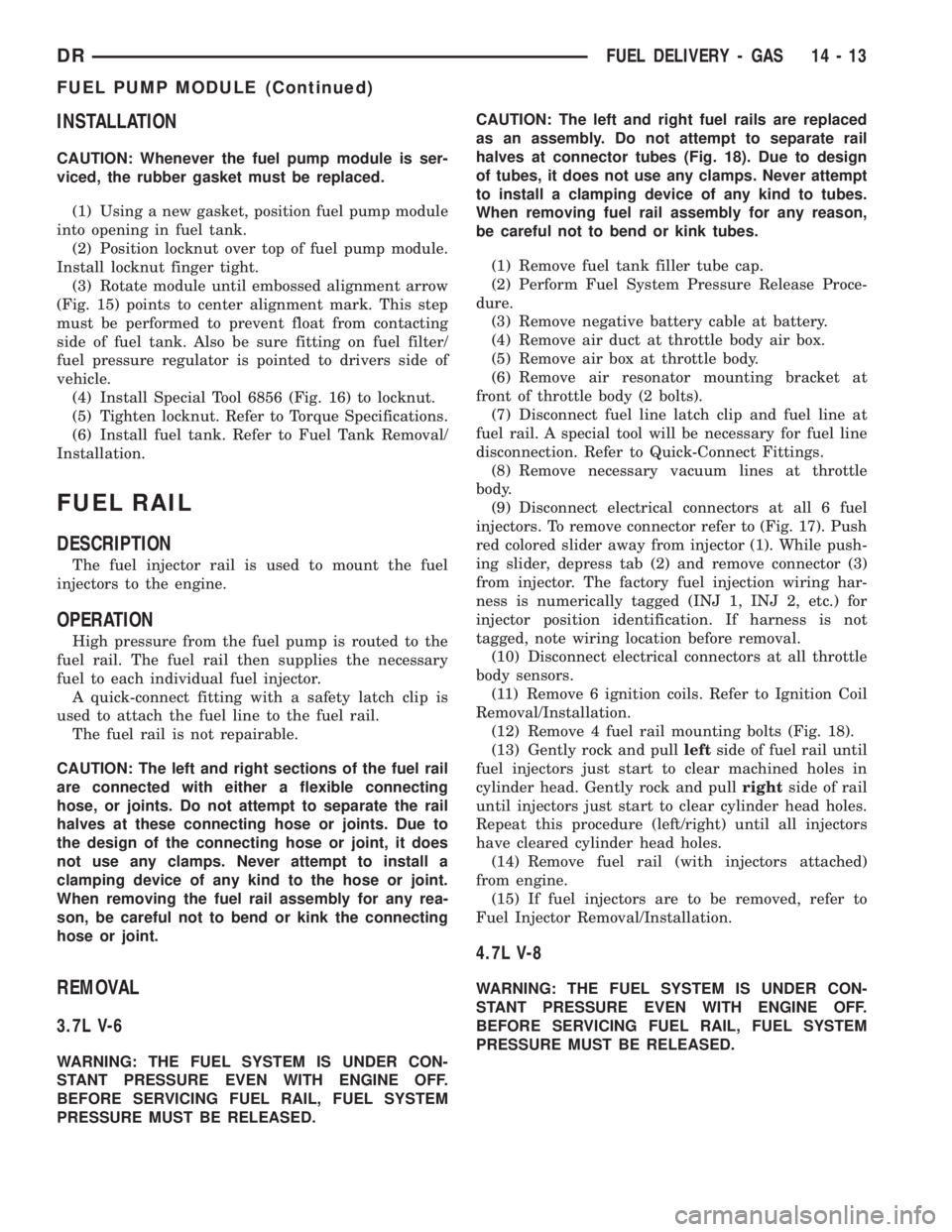

(9) Disconnect electrical connectors at all 6 fuel

injectors. To remove connector refer to (Fig. 17). Push

red colored slider away from injector (1). While push-

ing slider, depress tab (2) and remove connector (3)

from injector. The factory fuel injection wiring har-

ness is numerically tagged (INJ 1, INJ 2, etc.) for

injector position identification. If harness is not

tagged, note wiring location before removal.

(10) Disconnect electrical connectors at all throttle

body sensors.

(11) Remove 6 ignition coils. Refer to Ignition Coil

Removal/Installation.

(12) Remove 4 fuel rail mounting bolts (Fig. 18).

(13) Gently rock and pullleftside of fuel rail until

fuel injectors just start to clear machined holes in

cylinder head. Gently rock and pullrightside of rail

until injectors just start to clear cylinder head holes.

Repeat this procedure (left/right) until all injectors

have cleared cylinder head holes.

(14) Remove fuel rail (with injectors attached)

from engine.

(15) If fuel injectors are to be removed, refer to

Fuel Injector Removal/Installation.

4.7L V-8

WARNING: THE FUEL SYSTEM IS UNDER CON-

STANT PRESSURE EVEN WITH ENGINE OFF.

BEFORE SERVICING FUEL RAIL, FUEL SYSTEM

PRESSURE MUST BE RELEASED.

DRFUEL DELIVERY - GAS 14 - 13

FUEL PUMP MODULE (Continued)

Page 1711 of 2895

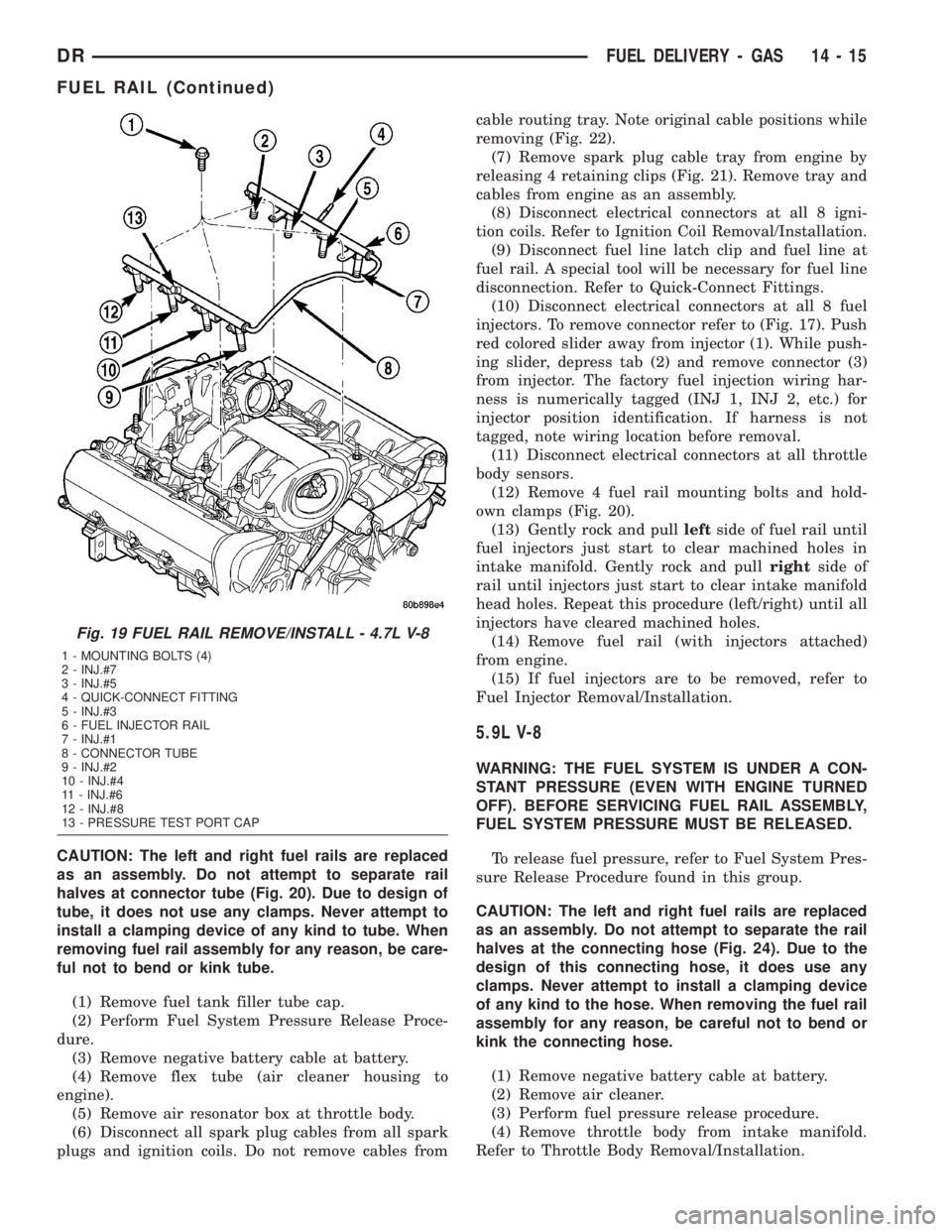

CAUTION: The left and right fuel rails are replaced

as an assembly. Do not attempt to separate rail

halves at connector tubes (Fig. 19). Due to design

of tubes, it does not use any clamps. Never attempt

to install a clamping device of any kind to tubes.

When removing fuel rail assembly for any reason,

be careful not to bend or kink tubes.

(1) Remove fuel tank filler tube cap.

(2) Perform Fuel System Pressure Release Proce-

dure.

(3) Remove negative battery cable at battery.

(4) Remove air duct at throttle body air box.

(5) Remove air box at throttle body.

(6) Remove air resonator mounting bracket at

front of throttle body (2 bolts).

(7) Disconnect fuel line latch clip and fuel line at

fuel rail. A special tool will be necessary for fuel line

disconnection. Refer to Quick-Connect Fittings.

(8) Remove necessary vacuum lines at throttle

body.

(9) Disconnect electrical connectors at all 8 fuel

injectors. To remove connector refer to (Fig. 17). Push

red colored slider away from injector (1). While push-

ing slider, depress tab (2) and remove connector (3)

from injector. The factory fuel injection wiring har-

ness is numerically tagged (INJ 1, INJ 2, etc.) for

injector position identification. If harness is not

tagged, note wiring location before removal.

(10) Disconnect electrical connectors at all throttle

body sensors.

(11) Remove 8 ignition coils. Refer to Ignition Coil

Removal/Installation.

(12) Remove 4 fuel rail mounting bolts (Fig. 19).

(13) Gently rock and pullleftside of fuel rail until

fuel injectors just start to clear machined holes in

cylinder head. Gently rock and pullrightside of rail

until injectors just start to clear cylinder head holes.

Repeat this procedure (left/right) until all injectors

have cleared cylinder head holes.

(14) Remove fuel rail (with injectors attached)

from engine.

(15) If fuel injectors are to be removed, refer to

Fuel Injector Removal/Installation.

5.7L V-8

WARNING: THE FUEL SYSTEM IS UNDER CON-

STANT PRESSURE EVEN WITH ENGINE OFF.

BEFORE SERVICING FUEL RAIL, FUEL SYSTEM

PRESSURE MUST BE RELEASED.

Fig. 17 REMOVE/INSTALL INJECTOR CONNECTOR

Fig. 18 FUEL RAIL REMOVE/INSTALL - 3.7L V-6

1 - MOUNTING BOLTS (4)

2 - QUICK-CONNECT FITTING

3 - FUEL RAIL

4 - INJ. #1

5 - INJ. #3

6 - INJ. #5

7 - INJ. #2

8 - INJ. #4

9 - INJ. #6

10 - CONNECTOR TUBE

14 - 14 FUEL DELIVERY - GASDR

FUEL RAIL (Continued)

Page 1712 of 2895

CAUTION: The left and right fuel rails are replaced

as an assembly. Do not attempt to separate rail

halves at connector tube (Fig. 20). Due to design of

tube, it does not use any clamps. Never attempt to

install a clamping device of any kind to tube. When

removing fuel rail assembly for any reason, be care-

ful not to bend or kink tube.

(1) Remove fuel tank filler tube cap.

(2) Perform Fuel System Pressure Release Proce-

dure.

(3) Remove negative battery cable at battery.

(4) Remove flex tube (air cleaner housing to

engine).

(5) Remove air resonator box at throttle body.

(6) Disconnect all spark plug cables from all spark

plugs and ignition coils. Do not remove cables fromcable routing tray. Note original cable positions while

removing (Fig. 22).

(7) Remove spark plug cable tray from engine by

releasing 4 retaining clips (Fig. 21). Remove tray and

cables from engine as an assembly.

(8) Disconnect electrical connectors at all 8 igni-

tion coils. Refer to Ignition Coil Removal/Installation.

(9) Disconnect fuel line latch clip and fuel line at

fuel rail. A special tool will be necessary for fuel line

disconnection. Refer to Quick-Connect Fittings.

(10) Disconnect electrical connectors at all 8 fuel

injectors. To remove connector refer to (Fig. 17). Push

red colored slider away from injector (1). While push-

ing slider, depress tab (2) and remove connector (3)

from injector. The factory fuel injection wiring har-

ness is numerically tagged (INJ 1, INJ 2, etc.) for

injector position identification. If harness is not

tagged, note wiring location before removal.

(11) Disconnect electrical connectors at all throttle

body sensors.

(12) Remove 4 fuel rail mounting bolts and hold-

own clamps (Fig. 20).

(13) Gently rock and pullleftside of fuel rail until

fuel injectors just start to clear machined holes in

intake manifold. Gently rock and pullrightside of

rail until injectors just start to clear intake manifold

head holes. Repeat this procedure (left/right) until all

injectors have cleared machined holes.

(14) Remove fuel rail (with injectors attached)

from engine.

(15) If fuel injectors are to be removed, refer to

Fuel Injector Removal/Installation.

5.9L V-8

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH ENGINE TURNED

OFF). BEFORE SERVICING FUEL RAIL ASSEMBLY,

FUEL SYSTEM PRESSURE MUST BE RELEASED.

To release fuel pressure, refer to Fuel System Pres-

sure Release Procedure found in this group.

CAUTION: The left and right fuel rails are replaced

as an assembly. Do not attempt to separate the rail

halves at the connecting hose (Fig. 24). Due to the

design of this connecting hose, it does use any

clamps. Never attempt to install a clamping device

of any kind to the hose. When removing the fuel rail

assembly for any reason, be careful not to bend or

kink the connecting hose.

(1) Remove negative battery cable at battery.

(2) Remove air cleaner.

(3) Perform fuel pressure release procedure.

(4) Remove throttle body from intake manifold.

Refer to Throttle Body Removal/Installation.

Fig. 19 FUEL RAIL REMOVE/INSTALL - 4.7L V-8

1 - MOUNTING BOLTS (4)

2 - INJ.#7

3 - INJ.#5

4 - QUICK-CONNECT FITTING

5 - INJ.#3

6 - FUEL INJECTOR RAIL

7 - INJ.#1

8 - CONNECTOR TUBE

9 - INJ.#2

10 - INJ.#4

11 - INJ.#6

12 - INJ.#8

13 - PRESSURE TEST PORT CAP

DRFUEL DELIVERY - GAS 14 - 15

FUEL RAIL (Continued)

Page 1716 of 2895

(11) Connect necessary vacuum lines to throttle

body.

(12) Install air resonator mounting bracket near

front of throttle body (2 bolts).

(13) Connect fuel line latch clip and fuel line to

fuel rail. Refer to Quick-Connect Fittings.

(14) Install air box to throttle body.

(15) Install air duct to air box.

(16) Connect battery cable to battery.

(17) Start engine and check for leaks.

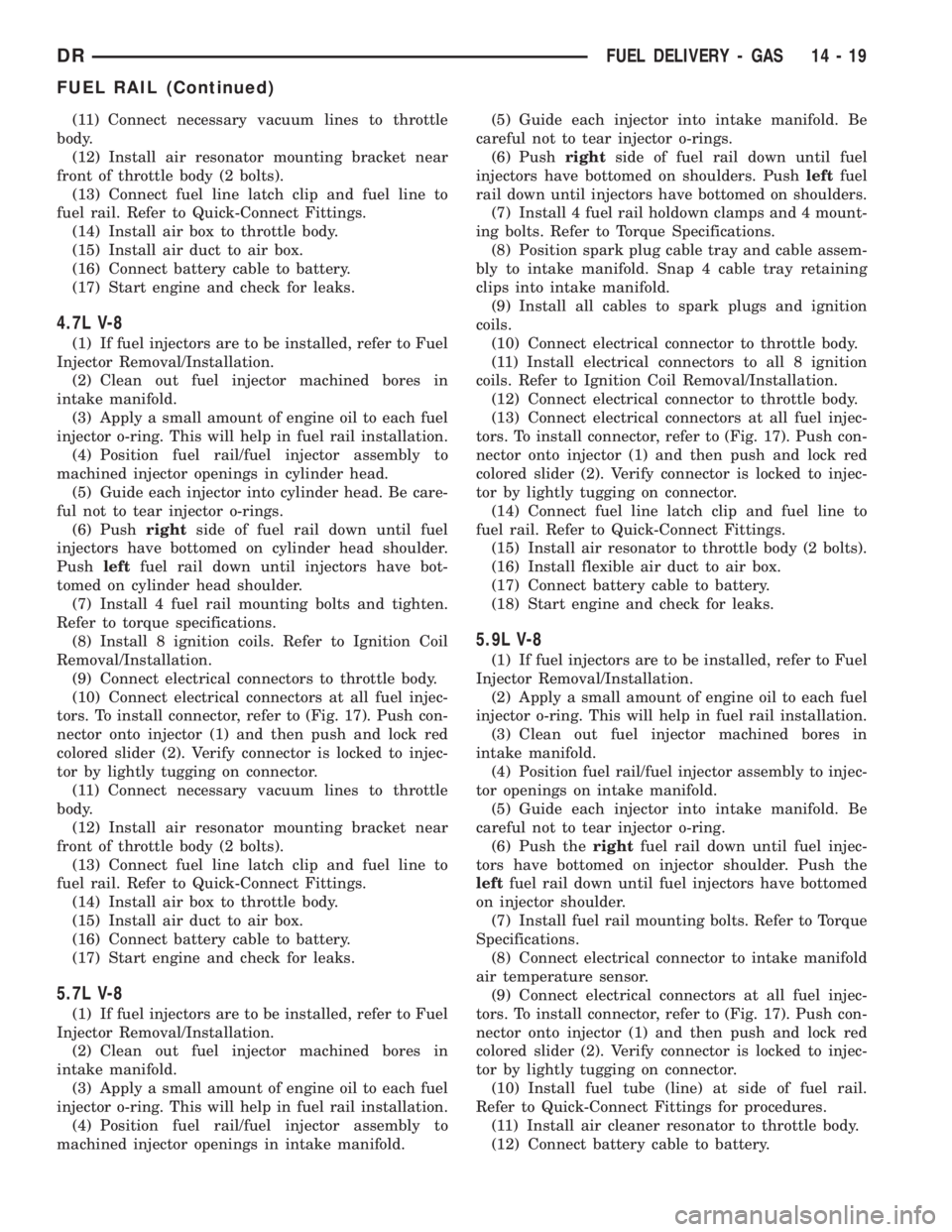

4.7L V-8

(1) If fuel injectors are to be installed, refer to Fuel

Injector Removal/Installation.

(2) Clean out fuel injector machined bores in

intake manifold.

(3) Apply a small amount of engine oil to each fuel

injector o-ring. This will help in fuel rail installation.

(4) Position fuel rail/fuel injector assembly to

machined injector openings in cylinder head.

(5) Guide each injector into cylinder head. Be care-

ful not to tear injector o-rings.

(6) Pushrightside of fuel rail down until fuel

injectors have bottomed on cylinder head shoulder.

Pushleftfuel rail down until injectors have bot-

tomed on cylinder head shoulder.

(7) Install 4 fuel rail mounting bolts and tighten.

Refer to torque specifications.

(8) Install 8 ignition coils. Refer to Ignition Coil

Removal/Installation.

(9) Connect electrical connectors to throttle body.

(10) Connect electrical connectors at all fuel injec-

tors. To install connector, refer to (Fig. 17). Push con-

nector onto injector (1) and then push and lock red

colored slider (2). Verify connector is locked to injec-

tor by lightly tugging on connector.

(11) Connect necessary vacuum lines to throttle

body.

(12) Install air resonator mounting bracket near

front of throttle body (2 bolts).

(13) Connect fuel line latch clip and fuel line to

fuel rail. Refer to Quick-Connect Fittings.

(14) Install air box to throttle body.

(15) Install air duct to air box.

(16) Connect battery cable to battery.

(17) Start engine and check for leaks.

5.7L V-8

(1) If fuel injectors are to be installed, refer to Fuel

Injector Removal/Installation.

(2) Clean out fuel injector machined bores in

intake manifold.

(3) Apply a small amount of engine oil to each fuel

injector o-ring. This will help in fuel rail installation.

(4) Position fuel rail/fuel injector assembly to

machined injector openings in intake manifold.(5) Guide each injector into intake manifold. Be

careful not to tear injector o-rings.

(6) Pushrightside of fuel rail down until fuel

injectors have bottomed on shoulders. Pushleftfuel

rail down until injectors have bottomed on shoulders.

(7) Install 4 fuel rail holdown clamps and 4 mount-

ing bolts. Refer to Torque Specifications.

(8) Position spark plug cable tray and cable assem-

bly to intake manifold. Snap 4 cable tray retaining

clips into intake manifold.

(9) Install all cables to spark plugs and ignition

coils.

(10) Connect electrical connector to throttle body.

(11) Install electrical connectors to all 8 ignition

coils. Refer to Ignition Coil Removal/Installation.

(12) Connect electrical connector to throttle body.

(13) Connect electrical connectors at all fuel injec-

tors. To install connector, refer to (Fig. 17). Push con-

nector onto injector (1) and then push and lock red

colored slider (2). Verify connector is locked to injec-

tor by lightly tugging on connector.

(14) Connect fuel line latch clip and fuel line to

fuel rail. Refer to Quick-Connect Fittings.

(15) Install air resonator to throttle body (2 bolts).

(16) Install flexible air duct to air box.

(17) Connect battery cable to battery.

(18) Start engine and check for leaks.

5.9L V-8

(1) If fuel injectors are to be installed, refer to Fuel

Injector Removal/Installation.

(2) Apply a small amount of engine oil to each fuel

injector o-ring. This will help in fuel rail installation.

(3) Clean out fuel injector machined bores in

intake manifold.

(4) Position fuel rail/fuel injector assembly to injec-

tor openings on intake manifold.

(5) Guide each injector into intake manifold. Be

careful not to tear injector o-ring.

(6) Push therightfuel rail down until fuel injec-

tors have bottomed on injector shoulder. Push the

leftfuel rail down until fuel injectors have bottomed

on injector shoulder.

(7) Install fuel rail mounting bolts. Refer to Torque

Specifications.

(8) Connect electrical connector to intake manifold

air temperature sensor.

(9) Connect electrical connectors at all fuel injec-

tors. To install connector, refer to (Fig. 17). Push con-

nector onto injector (1) and then push and lock red

colored slider (2). Verify connector is locked to injec-

tor by lightly tugging on connector.

(10) Install fuel tube (line) at side of fuel rail.

Refer to Quick-Connect Fittings for procedures.

(11) Install air cleaner resonator to throttle body.

(12) Connect battery cable to battery.

DRFUEL DELIVERY - GAS 14 - 19

FUEL RAIL (Continued)

Page 1721 of 2895

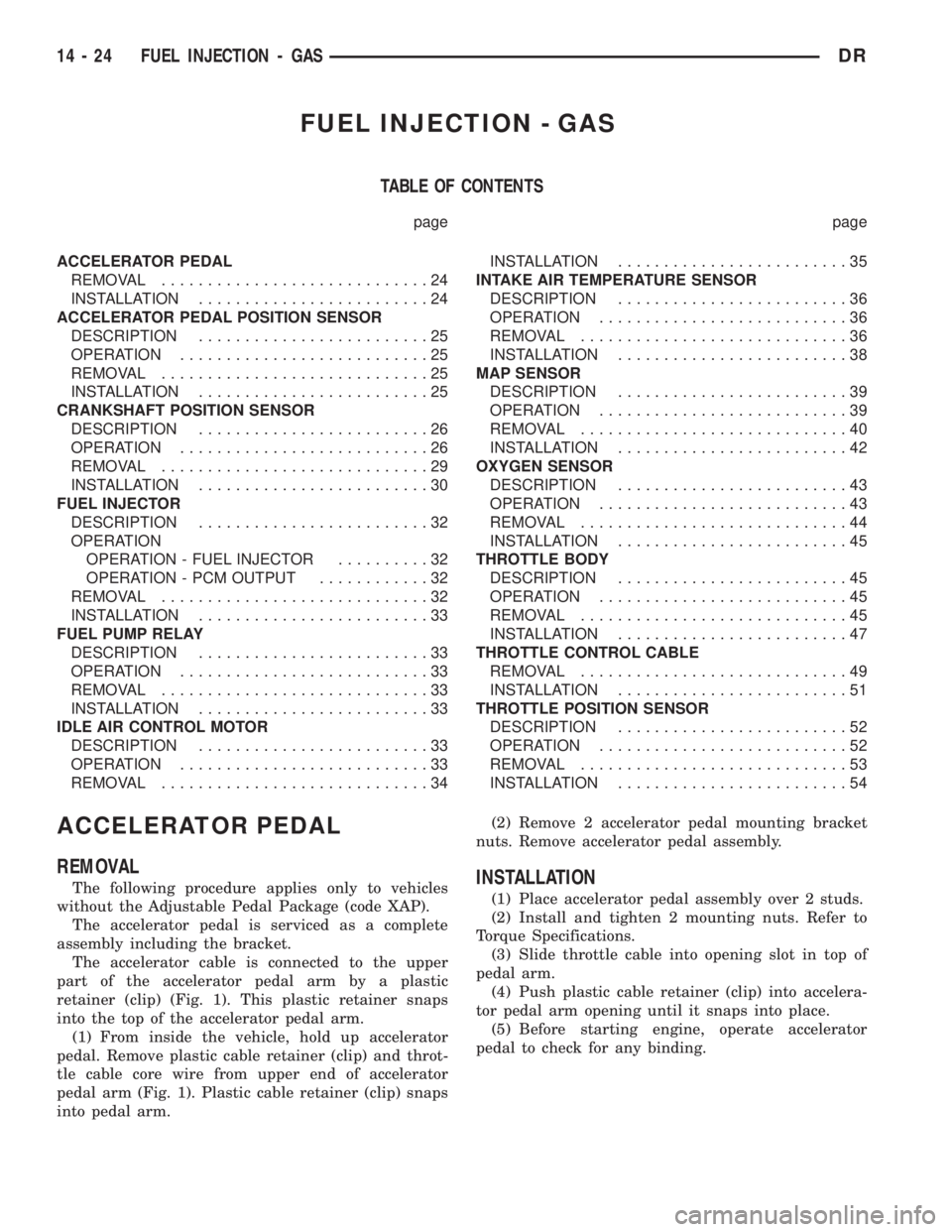

FUEL INJECTION - GAS

TABLE OF CONTENTS

page page

ACCELERATOR PEDAL

REMOVAL.............................24

INSTALLATION.........................24

ACCELERATOR PEDAL POSITION SENSOR

DESCRIPTION.........................25

OPERATION...........................25

REMOVAL.............................25

INSTALLATION.........................25

CRANKSHAFT POSITION SENSOR

DESCRIPTION.........................26

OPERATION...........................26

REMOVAL.............................29

INSTALLATION.........................30

FUEL INJECTOR

DESCRIPTION.........................32

OPERATION

OPERATION - FUEL INJECTOR..........32

OPERATION - PCM OUTPUT............32

REMOVAL.............................32

INSTALLATION.........................33

FUEL PUMP RELAY

DESCRIPTION.........................33

OPERATION...........................33

REMOVAL.............................33

INSTALLATION.........................33

IDLE AIR CONTROL MOTOR

DESCRIPTION.........................33

OPERATION...........................33

REMOVAL.............................34INSTALLATION.........................35

INTAKE AIR TEMPERATURE SENSOR

DESCRIPTION.........................36

OPERATION...........................36

REMOVAL.............................36

INSTALLATION.........................38

MAP SENSOR

DESCRIPTION.........................39

OPERATION...........................39

REMOVAL.............................40

INSTALLATION.........................42

OXYGEN SENSOR

DESCRIPTION.........................43

OPERATION...........................43

REMOVAL.............................44

INSTALLATION.........................45

THROTTLE BODY

DESCRIPTION.........................45

OPERATION...........................45

REMOVAL.............................45

INSTALLATION.........................47

THROTTLE CONTROL CABLE

REMOVAL.............................49

INSTALLATION.........................51

THROTTLE POSITION SENSOR

DESCRIPTION.........................52

OPERATION...........................52

REMOVAL.............................53

INSTALLATION.........................54

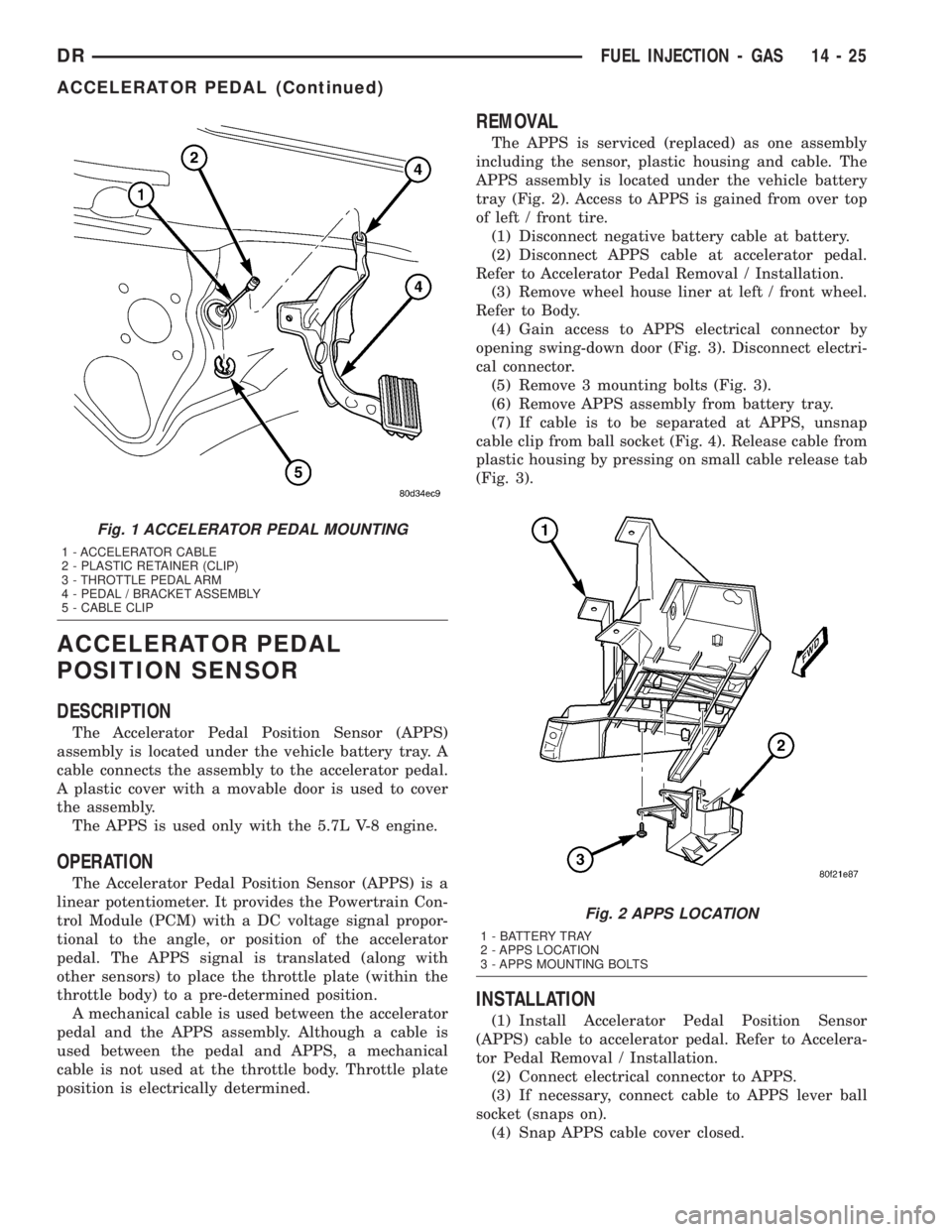

ACCELERATOR PEDAL

REMOVAL

The following procedure applies only to vehicles

without the Adjustable Pedal Package (code XAP).

The accelerator pedal is serviced as a complete

assembly including the bracket.

The accelerator cable is connected to the upper

part of the accelerator pedal arm by a plastic

retainer (clip) (Fig. 1). This plastic retainer snaps

into the top of the accelerator pedal arm.

(1) From inside the vehicle, hold up accelerator

pedal. Remove plastic cable retainer (clip) and throt-

tle cable core wire from upper end of accelerator

pedal arm (Fig. 1). Plastic cable retainer (clip) snaps

into pedal arm.(2) Remove 2 accelerator pedal mounting bracket

nuts. Remove accelerator pedal assembly.INSTALLATION

(1) Place accelerator pedal assembly over 2 studs.

(2) Install and tighten 2 mounting nuts. Refer to

Torque Specifications.

(3) Slide throttle cable into opening slot in top of

pedal arm.

(4) Push plastic cable retainer (clip) into accelera-

tor pedal arm opening until it snaps into place.

(5) Before starting engine, operate accelerator

pedal to check for any binding.

14 - 24 FUEL INJECTION - GASDR

Page 1722 of 2895

ACCELERATOR PEDAL

POSITION SENSOR

DESCRIPTION

The Accelerator Pedal Position Sensor (APPS)

assembly is located under the vehicle battery tray. A

cable connects the assembly to the accelerator pedal.

A plastic cover with a movable door is used to cover

the assembly.

The APPS is used only with the 5.7L V-8 engine.

OPERATION

The Accelerator Pedal Position Sensor (APPS) is a

linear potentiometer. It provides the Powertrain Con-

trol Module (PCM) with a DC voltage signal propor-

tional to the angle, or position of the accelerator

pedal. The APPS signal is translated (along with

other sensors) to place the throttle plate (within the

throttle body) to a pre-determined position.

A mechanical cable is used between the accelerator

pedal and the APPS assembly. Although a cable is

used between the pedal and APPS, a mechanical

cable is not used at the throttle body. Throttle plate

position is electrically determined.

REMOVAL

The APPS is serviced (replaced) as one assembly

including the sensor, plastic housing and cable. The

APPS assembly is located under the vehicle battery

tray (Fig. 2). Access to APPS is gained from over top

of left / front tire.

(1) Disconnect negative battery cable at battery.

(2) Disconnect APPS cable at accelerator pedal.

Refer to Accelerator Pedal Removal / Installation.

(3) Remove wheel house liner at left / front wheel.

Refer to Body.

(4) Gain access to APPS electrical connector by

opening swing-down door (Fig. 3). Disconnect electri-

cal connector.

(5) Remove 3 mounting bolts (Fig. 3).

(6) Remove APPS assembly from battery tray.

(7) If cable is to be separated at APPS, unsnap

cable clip from ball socket (Fig. 4). Release cable from

plastic housing by pressing on small cable release tab

(Fig. 3).

INSTALLATION

(1) Install Accelerator Pedal Position Sensor

(APPS) cable to accelerator pedal. Refer to Accelera-

tor Pedal Removal / Installation.

(2) Connect electrical connector to APPS.

(3) If necessary, connect cable to APPS lever ball

socket (snaps on).

(4) Snap APPS cable cover closed.

Fig. 1 ACCELERATOR PEDAL MOUNTING

1 - ACCELERATOR CABLE

2 - PLASTIC RETAINER (CLIP)

3 - THROTTLE PEDAL ARM

4 - PEDAL / BRACKET ASSEMBLY

5 - CABLE CLIP

Fig. 2 APPS LOCATION

1 - BATTERY TRAY

2 - APPS LOCATION

3 - APPS MOUNTING BOLTS

DRFUEL INJECTION - GAS 14 - 25

ACCELERATOR PEDAL (Continued)

Page 1731 of 2895

The IAC motor has 4 wires with 4 circuits. Two of

the wires are for 12 volts and ground to supply elec-

trical current to the motor windings to operate the

stepper motor in one direction. The other 2 wires are

also for 12 volts and ground to supply electrical cur-

rent to operate the stepper motor in the opposite

direction.

To make the IAC go in the opposite direction, the

PCM just reverses polarity on both windings. If only

1 wire is open, the IAC can only be moved 1 step

(increment) in either direction. To keep the IAC

motor in position when no movement is needed, the

PCM will energize both windings at the same time.

This locks the IAC motor in place.

In the IAC motor system, the PCM will count

every step that the motor is moved. This allows the

PCM to determine the motor pintle position. If the

memory is cleared, the PCM no longer knows the

position of the pintle. So at the first key ON, the

PCM drives the IAC motor closed, regardless of

where it was before. This zeros the counter. From

this point the PCM will back out the IAC motor and

keep track of its position again.

When engine rpm is above idle speed, the IAC is

used for the following:

²Off-idle dashpot (throttle blade will close quickly

but idle speed will not stop quickly)

²Deceleration air flow control

²A/C compressor load control (also opens the pas-

sage slightly before the compressor is engaged so

that the engine rpm does not dip down when the

compressor engages)

²Power steering load control

The PCM can control polarity of the circuit to con-

trol direction of the stepper motor.

IAC Stepper Motor Program:The PCM is also

equipped with a memory program that records the

number of steps the IAC stepper motor most recently

advanced to during a certain set of parameters. For

example: The PCM was attempting to maintain a

1000 rpm target during a cold start-up cycle. The last

recorded number of steps for that may have been

125. That value would be recorded in the memory

cell so that the next time the PCM recognizes the

identical conditions, the PCM recalls that 125 steps

were required to maintain the target. This program

allows for greater customer satisfaction due to

greater control of engine idle.

Another function of the memory program, which

occurs when the power steering switch (if equipped),

or the A/C request circuit, requires that the IAC step-

per motor control engine rpm, is the recording of the

last targeted steps into the memory cell. The PCM

can anticipate A/C compressor loads. This is accom-

plished by delaying compressor operation for approx-

imately 0.5 seconds until the PCM moves the IACstepper motor to the recorded steps that were loaded

into the memory cell. Using this program helps elim-

inate idle-quality changes as loads change. Finally,

the PCM incorporates a9No-Load9engine speed lim-

iter of approximately 1800 - 2000 rpm, when it rec-

ognizes that the TPS is indicating an idle signal and

IAC motor cannot maintain engine idle.

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the IAC motor through the PCM.

REMOVAL

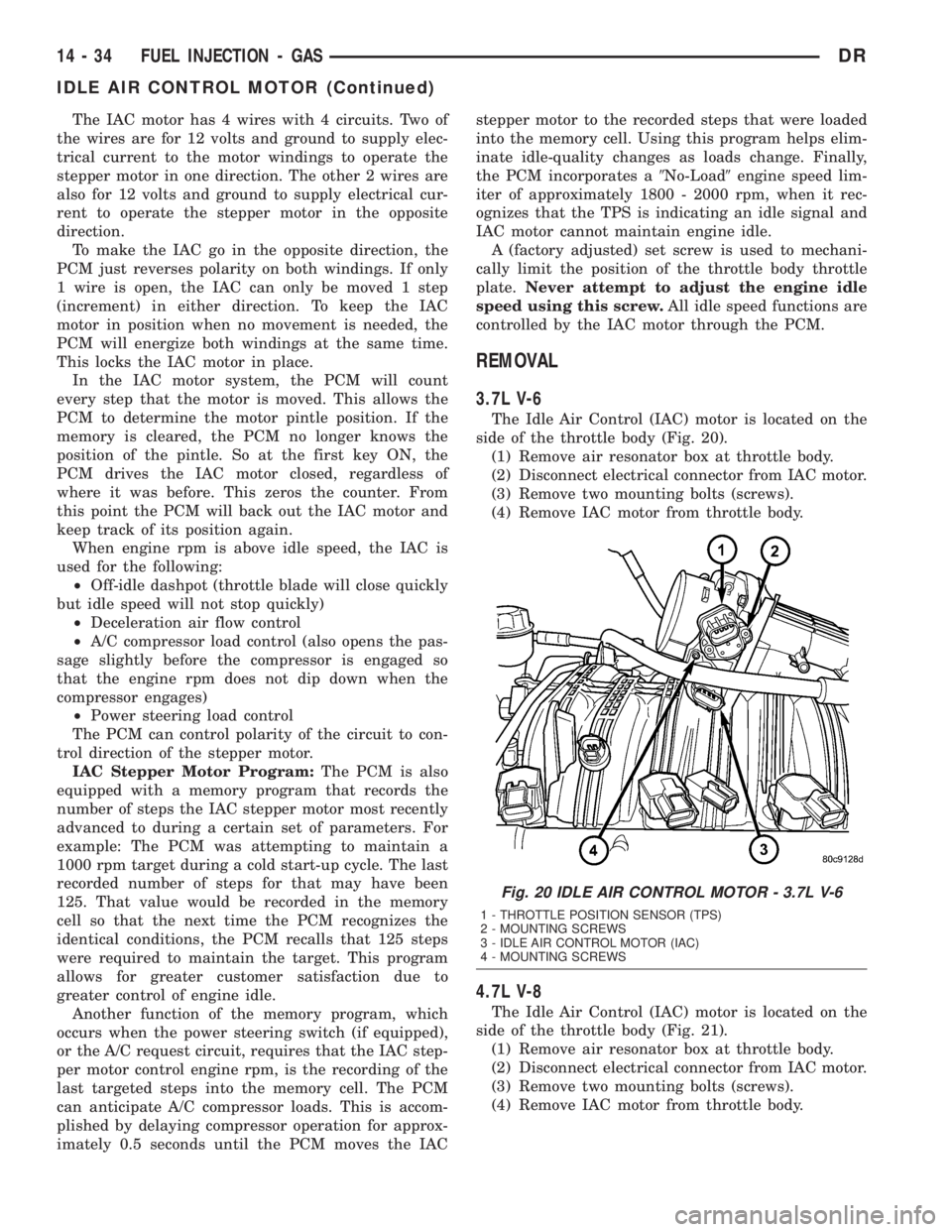

3.7L V-6

The Idle Air Control (IAC) motor is located on the

side of the throttle body (Fig. 20).

(1) Remove air resonator box at throttle body.

(2) Disconnect electrical connector from IAC motor.

(3) Remove two mounting bolts (screws).

(4) Remove IAC motor from throttle body.

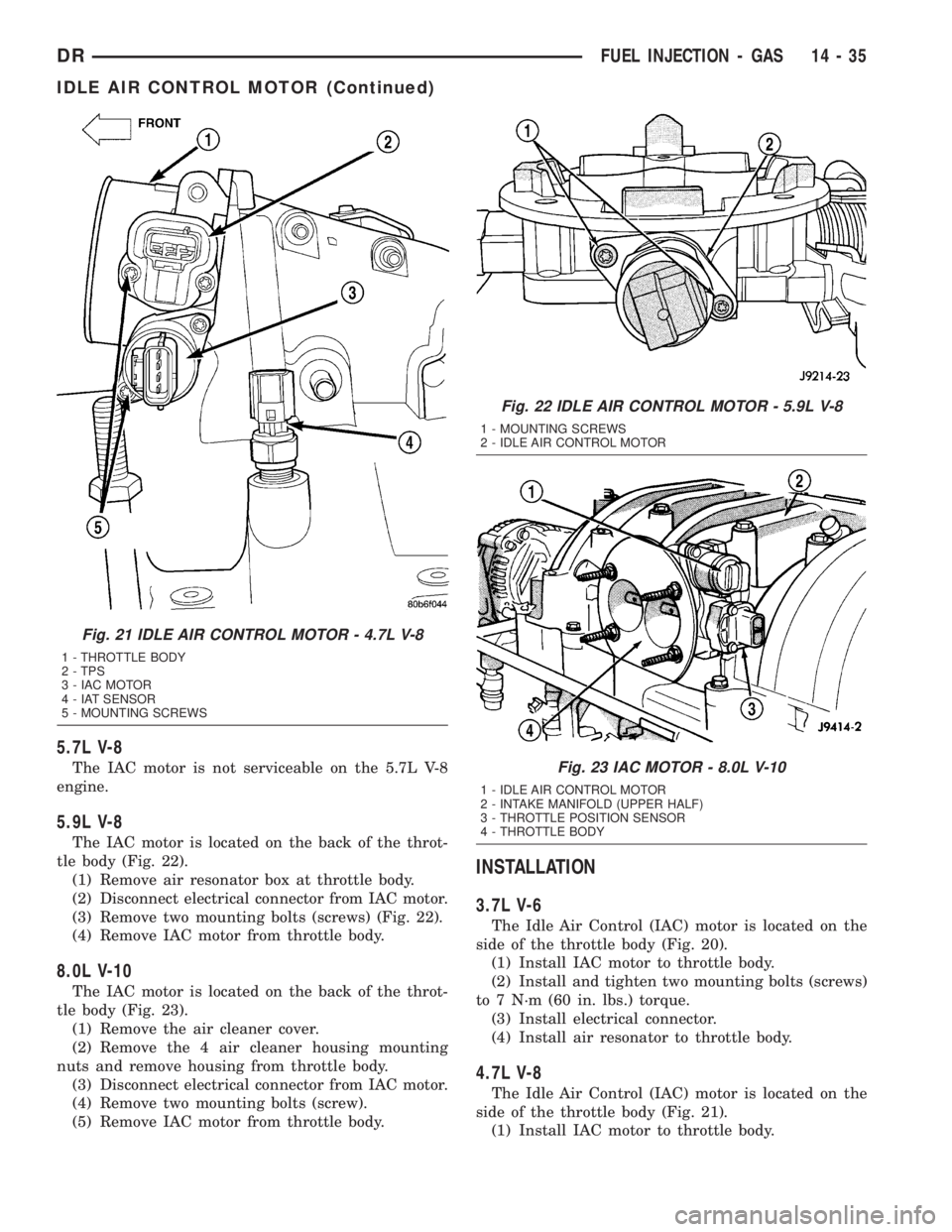

4.7L V-8

The Idle Air Control (IAC) motor is located on the

side of the throttle body (Fig. 21).

(1) Remove air resonator box at throttle body.

(2) Disconnect electrical connector from IAC motor.

(3) Remove two mounting bolts (screws).

(4) Remove IAC motor from throttle body.

Fig. 20 IDLE AIR CONTROL MOTOR - 3.7L V-6

1 - THROTTLE POSITION SENSOR (TPS)

2 - MOUNTING SCREWS

3 - IDLE AIR CONTROL MOTOR (IAC)

4 - MOUNTING SCREWS

14 - 34 FUEL INJECTION - GASDR

IDLE AIR CONTROL MOTOR (Continued)

Page 1732 of 2895

5.7L V-8

The IAC motor is not serviceable on the 5.7L V-8

engine.

5.9L V-8

The IAC motor is located on the back of the throt-

tle body (Fig. 22).

(1) Remove air resonator box at throttle body.

(2) Disconnect electrical connector from IAC motor.

(3) Remove two mounting bolts (screws) (Fig. 22).

(4) Remove IAC motor from throttle body.

8.0L V-10

The IAC motor is located on the back of the throt-

tle body (Fig. 23).

(1) Remove the air cleaner cover.

(2) Remove the 4 air cleaner housing mounting

nuts and remove housing from throttle body.

(3) Disconnect electrical connector from IAC motor.

(4) Remove two mounting bolts (screw).

(5) Remove IAC motor from throttle body.

INSTALLATION

3.7L V-6

The Idle Air Control (IAC) motor is located on the

side of the throttle body (Fig. 20).

(1) Install IAC motor to throttle body.

(2) Install and tighten two mounting bolts (screws)

to 7 N´m (60 in. lbs.) torque.

(3) Install electrical connector.

(4) Install air resonator to throttle body.

4.7L V-8

The Idle Air Control (IAC) motor is located on the

side of the throttle body (Fig. 21).

(1) Install IAC motor to throttle body.

Fig. 21 IDLE AIR CONTROL MOTOR - 4.7L V-8

1 - THROTTLE BODY

2 - TPS

3 - IAC MOTOR

4 - IAT SENSOR

5 - MOUNTING SCREWS

Fig. 22 IDLE AIR CONTROL MOTOR - 5.9L V-8

1 - MOUNTING SCREWS

2 - IDLE AIR CONTROL MOTOR

Fig. 23 IAC MOTOR - 8.0L V-10

1 - IDLE AIR CONTROL MOTOR

2 - INTAKE MANIFOLD (UPPER HALF)

3 - THROTTLE POSITION SENSOR

4 - THROTTLE BODY

DRFUEL INJECTION - GAS 14 - 35

IDLE AIR CONTROL MOTOR (Continued)