Speedometer DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 392 of 2895

OPERATION

OPERATION - PCM

The PCM operates the fuel system. The PCM is a

pre-programmed, triple microprocessor digital com-

puter. It regulates ignition timing, air-fuel ratio,

emission control devices, charging system, certain

transmission features, speed control, air conditioning

compressor clutch engagement and idle speed. The

PCM can adapt its programming to meet changing

operating conditions.

The PCM receives input signals from various

switches and sensors. Based on these inputs, the

PCM regulates various engine and vehicle operations

through different system components. These compo-

nents are referred to as Powertrain Control Module

(PCM) Outputs. The sensors and switches that pro-

vide inputs to the PCM are considered Powertrain

Control Module (PCM) Inputs.

The PCM adjusts ignition timing based upon

inputs it receives from sensors that react to: engine

rpm, manifold absolute pressure, engine coolant tem-

perature, throttle position, transmission gear selec-

tion (automatic transmission), vehicle speed, power

steering pump pressure, and the brake switch.

The PCM adjusts idle speed based on inputs it

receives from sensors that react to: throttle position,

vehicle speed, transmission gear selection, engine

coolant temperature and from inputs it receives from

the air conditioning clutch switch and brake switch.

Based on inputs that it receives, the PCM adjusts

ignition coil dwell. The PCM also adjusts the gener-

ator charge rate through control of the generator

field and provides speed control operation.

NOTE: PCM Inputs:

²ABS module (if equipped)

²A/C request (if equipped with factory A/C)

²A/C select (if equipped with factory A/C)

²A/C pressure transducer

²Auto shutdown (ASD) sense

²Battery temperature sensor

²Battery voltage

²Brake switch

²J1850 bus (+) circuits

²J1850 bus (-) circuits

²Camshaft position sensor signal

²Crankshaft position sensor

²Data link connection for DRB scan tool

²EATX module (if equipped)

²Engine coolant temperature sensor

²Fuel level (through J1850 circuitry)

²Generator (battery voltage) output

²Ignition circuit sense (ignition switch in on/off/

crank/run position)²Intake manifold air temperature sensor

²Knock sensors (2 on 3.7L engine)

²Leak detection pump (switch) sense (if equipped)

²Manifold absolute pressure (MAP) sensor

²Oil pressure

²Oxygen sensors

²Park/neutral switch (auto. trans. only)

²Power ground

²Power steering pressure switch (if equipped)

²Sensor return

²Signal ground

²Speed control multiplexed single wire input

²Throttle position sensor

²Transfer case switch (4WD range position)

²Vehicle speed signal

NOTE: PCM Outputs:

²A/C clutch relay

²Auto shutdown (ASD) relay

²J1850 bus (+/-) circuits for: speedometer, voltme-

ter, fuel gauge, oil pressure gauge/lamp, engine temp.

gauge and speed control warn. lamp

²Data link connection for DRB scan tool

²EGR valve control solenoid (if equipped)

²EVAP canister purge solenoid

²Five volt sensor supply (primary)

²Five volt sensor supply (secondary)

²Fuel injectors

²Fuel pump relay

²Generator field driver (-)

²Generator field driver (+)

²Idle air control (IAC) motor

²Ignition coil(s)

²Leak detection pump (if equipped)

²Malfunction indicator lamp (Check engine lamp).

Driven through J1850 circuits.

²Oxygen sensor heater relays

²Oxygen sensors (pulse width modulated)

²Radiator cooling fan relay (pulse width modu-

lated)

²Speed control vacuum solenoid

²Speed control vent solenoid

²Tachometer (if equipped). Driven through J1850

circuits.

²Transmission convertor clutch circuit. Driven

through J1850 circuits.

OPERATION - 5 VOLT SUPPLIES

Primary 5±volt supply:

²supplies the required 5 volt power source to the

Crankshaft Position (CKP) sensor.

²supplies the required 5 volt power source to the

Camshaft Position (CMP) sensor.

²supplies a reference voltage for the Manifold

Absolute Pressure (MAP) sensor.

DRELECTRONIC CONTROL MODULES 8E - 11

POWERTRAIN CONTROL MODULE (Continued)

Page 494 of 2895

INSTRUMENT CLUSTER

TABLE OF CONTENTS

page page

INSTRUMENT CLUSTER

DESCRIPTION..........................2

OPERATION............................6

DIAGNOSIS AND TESTING - INSTRUMENT

CLUSTER...........................10

REMOVAL.............................14

DISASSEMBLY.........................14

ASSEMBLY............................15

INSTALLATION.........................16

ABS INDICATOR

DESCRIPTION.........................17

OPERATION...........................17

AIRBAG INDICATOR

DESCRIPTION.........................18

OPERATION...........................18

BRAKE/PARK BRAKE INDICATOR

DESCRIPTION.........................18

OPERATION...........................19

DIAGNOSIS AND TESTING - BRAKE

INDICATOR..........................19

CARGO LAMP INDICATOR

DESCRIPTION.........................20

OPERATION...........................20

CHECK GAUGES INDICATOR

DESCRIPTION.........................21

OPERATION...........................21

CRUISE INDICATOR

DESCRIPTION.........................22

OPERATION...........................22

DOOR AJAR INDICATOR

DESCRIPTION.........................23

OPERATION...........................23

ENGINE TEMPERATURE GAUGE

DESCRIPTION.........................23

OPERATION...........................23

ETC INDICATOR

DESCRIPTION.........................24

OPERATION...........................25

FUEL GAUGE

DESCRIPTION.........................25

OPERATION...........................26

GEAR SELECTOR INDICATOR

DESCRIPTION.........................26

OPERATION...........................27

HIGH BEAM INDICATOR

DESCRIPTION.........................27

OPERATION...........................28LAMP OUT INDICATOR

DESCRIPTION.........................28

OPERATION...........................28

LOW FUEL INDICATOR

DESCRIPTION.........................29

OPERATION...........................29

MALFUNCTION INDICATOR LAMP (MIL)

DESCRIPTION.........................30

OPERATION...........................30

ODOMETER

DESCRIPTION.........................31

OPERATION...........................31

OIL PRESSURE GAUGE

DESCRIPTION.........................32

OPERATION...........................32

OVERDRIVE OFF INDICATOR

DESCRIPTION.........................33

OPERATION...........................33

SEATBELT INDICATOR

DESCRIPTION.........................34

OPERATION...........................34

SECURITY INDICATOR

DESCRIPTION.........................34

OPERATION...........................35

SERVICE 4WD INDICATOR

DESCRIPTION.........................35

OPERATION...........................36

SPEEDOMETER

DESCRIPTION.........................36

OPERATION...........................36

TACHOMETER

DESCRIPTION.........................37

OPERATION...........................37

TRANS TEMP INDICATOR

DESCRIPTION.........................38

OPERATION...........................38

TURN SIGNAL INDICATOR

DESCRIPTION.........................39

OPERATION...........................39

UPSHIFT INDICATOR

DESCRIPTION.........................40

OPERATION...........................40

VOLTAGE GAUGE

DESCRIPTION.........................40

OPERATION...........................41

WAIT-TO-START INDICATOR

DESCRIPTION.........................42

OPERATION...........................42

DRINSTRUMENT CLUSTER 8J - 1

Page 496 of 2895

molded plastic cluster housing serves as the carrier

for the cluster circuit board and circuitry, the cluster

connector receptacles, the RKE interface connector,

the gauges, a Light Emitting Diode (LED) for each

cluster indicator, two VFD units, an audible tone

generator, the cluster overlay, the gauge pointers, the

odometer/trip odometer switch and the switch button.

The cluster overlay is a laminated plastic unit. The

dark, visible, outer surface of the overlay is marked

with all of the gauge dial faces and graduations, but

this layer is also translucent. The darkness of this

outer layer prevents the cluster from appearing clut-

tered or busy by concealing the cluster indicators

that are not illuminated, while the translucence of

this layer allows those indicators and icons that are

illuminated to be readily visible. The underlying

layer of the overlay is opaque and allows light from

the LED for each of the various indicators and the

incandescent illumination lamps behind it to be visi-

ble through the outer layer of the overlay only

through predetermined stencil-like cutouts. A rectan-

gular opening in the overlay at the base of both the

speedometer and tachometer dial faces has a smoked

clear lens through which the illuminated VFD units

can be viewed.

Several versions of the EMIC module are offered

on this model. These versions accommodate all of the

variations of optional equipment and regulatory

requirements for the various markets in which the

vehicle will be offered. The microprocessor-based

EMIC utilizes integrated circuitry and information

carried on the Programmable Communications Inter-

face (PCI) data bus network along with several hard

wired analog and multiplexed inputs to monitor sen-

sors and switches throughout the vehicle. In response

to those inputs, the internal circuitry and program-

ming of the EMIC allow it to control and integrate

many electronic functions and features of the vehicle

through both hard wired outputs and the transmis-

sion of electronic message outputs to other electronic

modules in the vehicle over the PCI data bus. (Refer

to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/COMMUNICATION - DESCRIPTION -

PCI BUS).

Besides typical instrument cluster gauge and indi-

cator support, the electronic functions and features

that the EMIC supports or controls include the fol-

lowing:

²Audible Warnings- The EMIC electronic cir-

cuit board is equipped with an audible tone generator

and programming that allows it to provide various

audible alerts to the vehicle operator, including

chime tones and beep tones. An electromechanical

relay is also soldered onto the circuit board to pro-

duce audible clicks that emulate the sound of a con-

ventional turn signal or hazard warning flasher.(Refer to 8 - ELECTRICAL/CHIME/BUZZER -

DESCRIPTION).

²Brake Lamp Control- The EMIC provides

electronic brake lamp request messages to the Front

Control Module (FCM) located on the Integrated

Power Module (IPM) for brake lamp control, exclud-

ing control of the Center High Mounted Stop Lamp

(CHMSL), which remains controlled by a direct hard

wired output of the brake lamp switch.

²Brake Transmission Shift Interlock Control

- The EMIC monitors inputs from the brake lamp

switch, ignition switch, and the Transmission Range

Sensor (TRS), then controls a high-side driver output

to operate the Brake Transmission Shift Interlock

(BTSI) solenoid that locks and unlocks the automatic

transmission gearshift selector lever on the steering

column.

²Cargo Lamp Control- The EMIC provides

direct control of cargo lamp operation with a load

shedding (battery saver) feature which will automat-

ically turn off the cargo lamp if it remains on after a

timed interval.

²Central Locking- The EMIC provides support

for the central locking feature of the power lock sys-

tem. This feature will lock or unlock all doors based

upon the input from the door cylinder lock switch.

Door cylinder lock switches are used only on models

equipped with the optional Vehicle Theft Security

System (VTSS).

²Door Lock Inhibit- The EMIC inhibits locking

of the doors with the power lock switch when the key

is in the ignition switch and the driver side front

door is ajar. However, operation of the door locks is

not inhibited under the same conditions when the

Lock button of the optional RKE transmitter is

depressed.

²Enhanced Accident Response- The EMIC

monitors an input from the Airbag Control Module

(ACM) and, following an airbag deployment, will

immediately disable the power lock output, unlock all

doors by activating the power unlock output, then

enables the power lock output if the power lock

switch input remains inactive for two seconds. This

feature, like all other enhanced accident response

features, is dependent upon a functional vehicle elec-

trical system following the vehicle impact event.

²Exterior Lighting Control- The EMIC pro-

vides electronic head lamp and/or park lamp request

messages to the Front Control Module (FCM) located

on the Integrated Power Module (IPM) for the appro-

priate exterior lamp control of standard head and

park lamps, as well as optional front fog lamps. This

includes support for headlamp beam selection and

the optical horn feature, also known as flash-to-pass.

²Exterior Lighting Fail-safe- In the absence of

a headlamp switch input, the EMIC will turn on the

DRINSTRUMENT CLUSTER 8J - 3

INSTRUMENT CLUSTER (Continued)

Page 498 of 2895

the vehicle speed remains greater than about twenty-

four kilometers-per-hour (fifteen miles-per-hour).

²Vacuum Fluorescent Display Synchroniza-

tion- The EMIC transmits electronic panel lamp

dimming level messages which allows all other elec-

tronic modules on the PCI data bus with Vacuum

Fluorescent Display (VFD) units to coordinate their

illumination intensity with that of the EMIC VFD

units.

²Vehicle Theft Security System- The EMIC

monitors inputs from the door cylinder lock switch-

(es), the door ajar switches, the ignition switch, and

the Remote Keyless Entry (RKE) receiver module,

then provides electronic horn and lighting request

messages to the Front Control Module (FCM) located

on the Integrated Power Module (IPM) for the appro-

priate VTSS alarm output features.

²Wiper/Washer System Control- The EMIC

provides electronic wiper and/or washer request mes-

sages to the Front Control Module (FCM) located on

the Integrated Power Module (IPM) for the appropri-

ate wiper and washer system features. (Refer to 8 -

ELECTRICAL/WIPERS/WASHERS - DESCRIP-

TION).

The EMIC houses six analog gauges and has pro-

visions for up to twenty-three indicators (Fig. 3) or

(Fig. 4). The EMIC includes the following analog

gauges:

²Coolant Temperature Gauge

²Fuel Gauge

²Oil Pressure Gauge

²Speedometer

²Tachometer

²Voltage Gauge

Some of the EMIC indicators are automatically

configured when the EMIC is connected to the vehi-

cle electrical system for compatibility with certain

optional equipment or equipment required for regula-

tory purposes in certain markets. While each EMIC

may have provisions for indicators to support every

available option, the configurable indicators will not

be functional in a vehicle that does not have the

equipment that an indicator supports. The EMIC

includes provisions for the following indicators (Fig.

3) or (Fig. 4):

²Airbag Indicator (with Airbag System only)

²Antilock Brake System (ABS) Indicator

(with ABS or Rear Wheel Anti-Lock [RWAL]

brakes only)

²Brake Indicator

²Cargo Lamp Indicator

²Check Gauges Indicator

²Cruise Indicator (with Speed Control only)

²Door Ajar Indicator

²Electronic Throttle Control (ETC) Indicator

(with 5.7L Gasoline Engine only)²Gear Selector Indicator (with Automatic

Transmission only)

²High Beam Indicator

²Lamp Out Indicator

²Low Fuel Indicator

²Malfunction Indicator Lamp (MIL)

²Overdrive-Off Indicator (with Automatic

Transmission only)

²Seatbelt Indicator

²Security Indicator (with Sentry Key Immo-

bilizer & Vehicle Theft Security Systems only)

²Service Four-Wheel Drive Indicator (with

Four-Wheel Drive only)

²Transmission Overtemp Indicator (with

Automatic Transmission only)

²Turn Signal (Right and Left) Indicators

²Upshift Indicator (with Manual Transmis-

sion only)

²Washer Fluid Indicator

²Wait-To-Start Indicator (with Diesel Engine

only)

²Water-In-Fuel Indicator (with Diesel Engine

only)

Each indicator in the EMIC, except those located

within one of the VFD units, is illuminated by a ded-

icated LED that is soldered onto the EMIC electronic

circuit board. The LED units are not available for

service replacement and, if damaged or faulty, the

entire EMIC must be replaced. Cluster illumination

is accomplished by dimmable incandescent back

lighting, which illuminates the gauges for visibility

when the exterior lighting is turned on. Each of the

incandescent bulbs is secured by an integral bulb

holder to the electronic circuit board from the back of

the cluster housing.

Hard wired circuitry connects the EMIC to the

electrical system of the vehicle. These hard wired cir-

cuits are integral to several wire harnesses, which

are routed throughout the vehicle and retained by

many different methods. These circuits may be con-

nected to each other, to the vehicle electrical system

and to the EMIC through the use of a combination of

soldered splices, splice block connectors, and many

different types of wire harness terminal connectors

and insulators. Refer to the appropriate wiring infor-

mation. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

further details on wire harness routing and reten-

tion, as well as pin-out and location views for the

various wire harness connectors, splices and grounds.

The EMIC modules for this model are serviced only

as complete units. The EMIC module cannot be

adjusted or repaired. If a gauge, an LED indicator, a

VFD unit, the electronic circuit board, the circuit

board hardware, the cluster overlay, or the EMIC

housing are damaged or faulty, the entire EMIC mod-

DRINSTRUMENT CLUSTER 8J - 5

INSTRUMENT CLUSTER (Continued)

Page 499 of 2895

ule must be replaced. The cluster lens, hood and

mask unit and the individual incandescent lamp

bulbs with holders are available for individual ser-

vice replacement.

OPERATION

The ElectroMechanical Instrument Cluster (EMIC)

in this model also includes the hardware and soft-

ware necessary to serve as the electronic body control

module and is sometimes referred to as the Cab

Compartment Node or CCN. The following informa-

tion deals primarily with the instrument cluster

functions of this unit. Additional details of the elec-

tronic body control functions of this unit may be

found within the service information for the system

or component that the EMIC controls. For example:

Additional details of the audible warning functions of

the EMIC are found within the Chime/Buzzer service

information.The EMIC is designed to allow the vehicle operator

to monitor the conditions of many of the vehicle com-

ponents and operating systems. The gauges and indi-

cators in the EMIC provide valuable information

about the various standard and optional powertrains,

fuel and emissions systems, cooling systems, lighting

systems, safety systems and many other convenience

items. The EMIC is installed in the instrument panel

so that all of these monitors can be easily viewed by

the vehicle operator when driving, while still allow-

ing relative ease of access for service. The micropro-

cessor-based EMIC hardware and software uses

various inputs to control the gauges and indicators

visible on the face of the cluster. Some of these

inputs are hard wired, but most are in the form of

electronic messages that are transmitted by other

electronic modules over the Programmable Communi-

cations Interface (PCI) data bus network. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/COMMUNICATION - OPERATION).

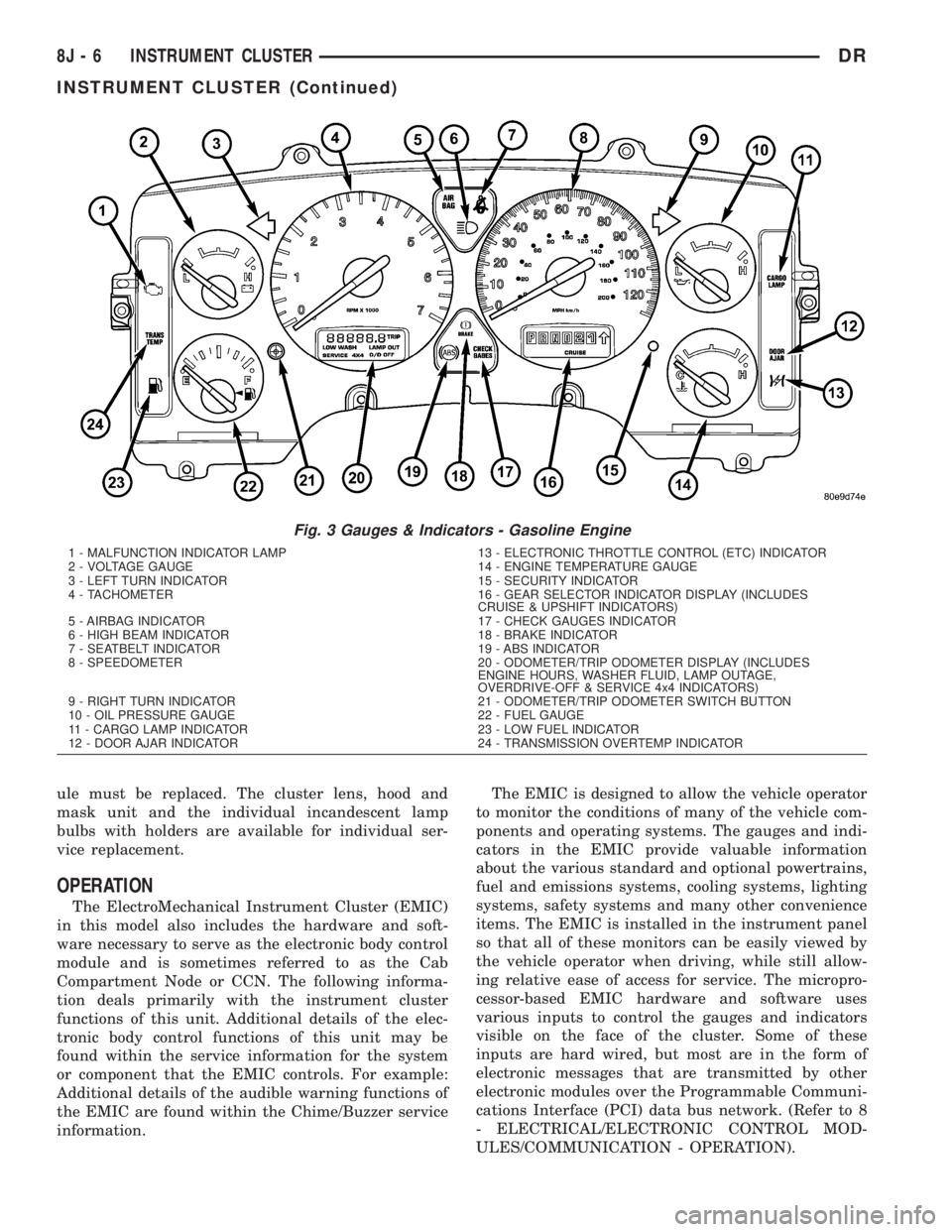

Fig. 3 Gauges & Indicators - Gasoline Engine

1 - MALFUNCTION INDICATOR LAMP 13 - ELECTRONIC THROTTLE CONTROL (ETC) INDICATOR

2 - VOLTAGE GAUGE 14 - ENGINE TEMPERATURE GAUGE

3 - LEFT TURN INDICATOR 15 - SECURITY INDICATOR

4 - TACHOMETER 16 - GEAR SELECTOR INDICATOR DISPLAY (INCLUDES

CRUISE & UPSHIFT INDICATORS)

5 - AIRBAG INDICATOR 17 - CHECK GAUGES INDICATOR

6 - HIGH BEAM INDICATOR 18 - BRAKE INDICATOR

7 - SEATBELT INDICATOR 19 - ABS INDICATOR

8 - SPEEDOMETER 20 - ODOMETER/TRIP ODOMETER DISPLAY (INCLUDES

ENGINE HOURS, WASHER FLUID, LAMP OUTAGE,

OVERDRIVE-OFF & SERVICE 4x4 INDICATORS)

9 - RIGHT TURN INDICATOR 21 - ODOMETER/TRIP ODOMETER SWITCH BUTTON

10 - OIL PRESSURE GAUGE 22 - FUEL GAUGE

11 - CARGO LAMP INDICATOR 23 - LOW FUEL INDICATOR

12 - DOOR AJAR INDICATOR 24 - TRANSMISSION OVERTEMP INDICATOR

8J - 6 INSTRUMENT CLUSTERDR

INSTRUMENT CLUSTER (Continued)

Page 500 of 2895

The EMIC microprocessor smooths the input data

using algorithms to provide gauge readings that are

accurate, stable and responsive to operating condi-

tions. These algorithms are designed to provide

gauge readings during normal operation that are con-

sistent with customer expectations. However, when

abnormal conditions exist such as high coolant tem-

perature, the algorithm can drive the gauge pointer

to an extreme position and the microprocessor can

sound a chime through the on-board audible tone

generator to provide distinct visual and audible indi-

cations of a problem to the vehicle operator. The

instrument cluster circuitry may also produce audi-

ble warnings for other electronic modules in the vehi-

cle based upon electronic tone request messages

received over the PCI data bus. Each audible warn-

ing is intended to provide the vehicle operator with

an audible alert to supplement a visual indication.The EMIC circuitry operates on battery current

received through a fused B(+) fuse in the Integrated

Power Module (IPM) on a non-switched fused B(+)

circuit, and on battery current received through a

fused ignition switch output (run-start) fuse in the

IPM on a fused ignition switch output (run-start) cir-

cuit. This arrangement allows the EMIC to provide

some features regardless of the ignition switch posi-

tion, while other features will operate only with the

ignition switch in the On or Start positions. The

EMIC circuitry is grounded through a ground circuit

and take out of the instrument panel wire harness

with an eyelet terminal connector that is secured by

a ground screw to a ground location near the center

of the instrument panel structural support.

The EMIC also has a self-diagnostic actuator test

capability, which will test each of the PCI bus mes-

sage-controlled functions of the cluster by lighting

the appropriate indicators, positioning the gauge nee-

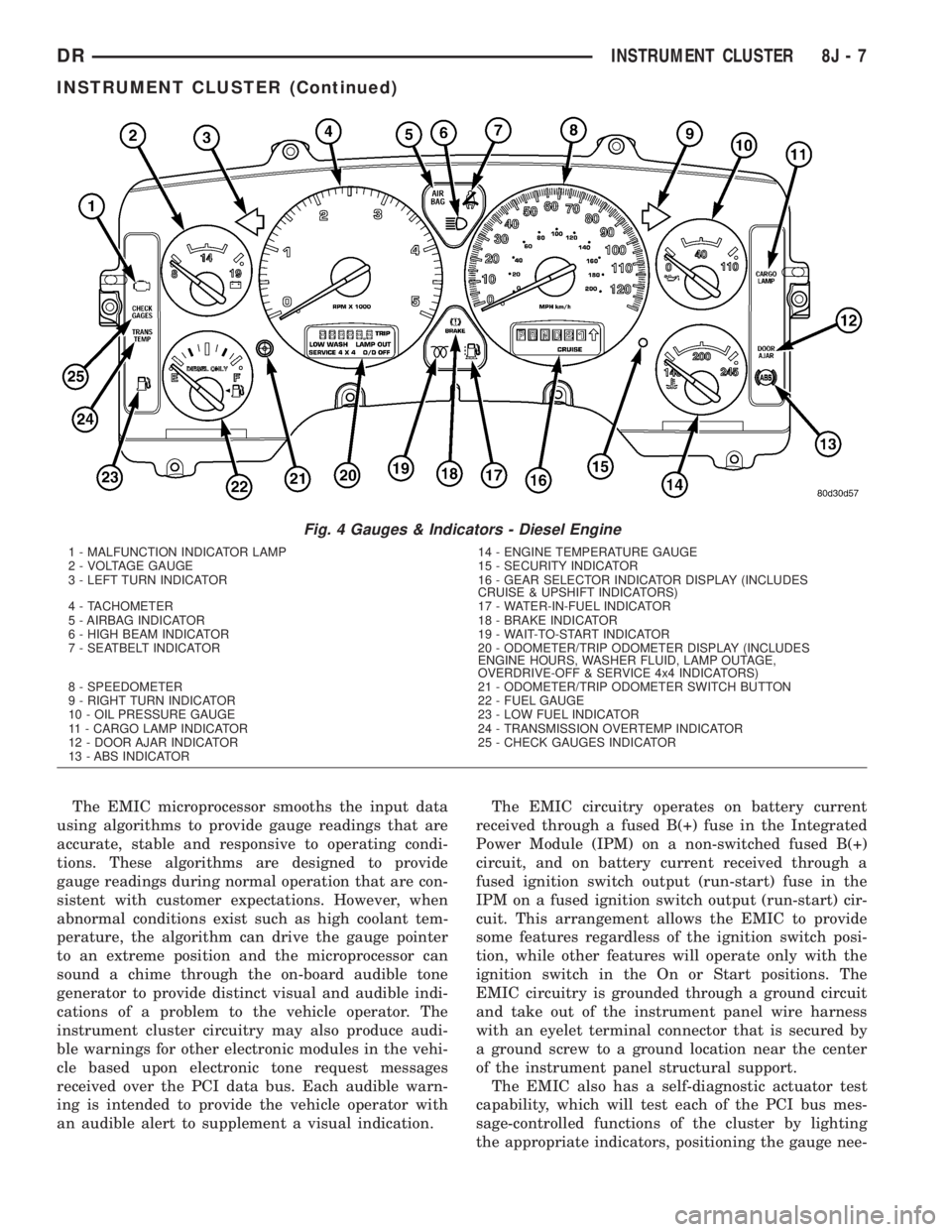

Fig. 4 Gauges & Indicators - Diesel Engine

1 - MALFUNCTION INDICATOR LAMP 14 - ENGINE TEMPERATURE GAUGE

2 - VOLTAGE GAUGE 15 - SECURITY INDICATOR

3 - LEFT TURN INDICATOR 16 - GEAR SELECTOR INDICATOR DISPLAY (INCLUDES

CRUISE & UPSHIFT INDICATORS)

4 - TACHOMETER 17 - WATER-IN-FUEL INDICATOR

5 - AIRBAG INDICATOR 18 - BRAKE INDICATOR

6 - HIGH BEAM INDICATOR 19 - WAIT-TO-START INDICATOR

7 - SEATBELT INDICATOR 20 - ODOMETER/TRIP ODOMETER DISPLAY (INCLUDES

ENGINE HOURS, WASHER FLUID, LAMP OUTAGE,

OVERDRIVE-OFF & SERVICE 4x4 INDICATORS)

8 - SPEEDOMETER 21 - ODOMETER/TRIP ODOMETER SWITCH BUTTON

9 - RIGHT TURN INDICATOR 22 - FUEL GAUGE

10 - OIL PRESSURE GAUGE 23 - LOW FUEL INDICATOR

11 - CARGO LAMP INDICATOR 24 - TRANSMISSION OVERTEMP INDICATOR

12 - DOOR AJAR INDICATOR 25 - CHECK GAUGES INDICATOR

13 - ABS INDICATOR

DRINSTRUMENT CLUSTER 8J - 7

INSTRUMENT CLUSTER (Continued)

Page 511 of 2895

ter that control the ABS indicator, a DRBIIItscan

tool is required. Refer to the appropriate diagnostic

information.

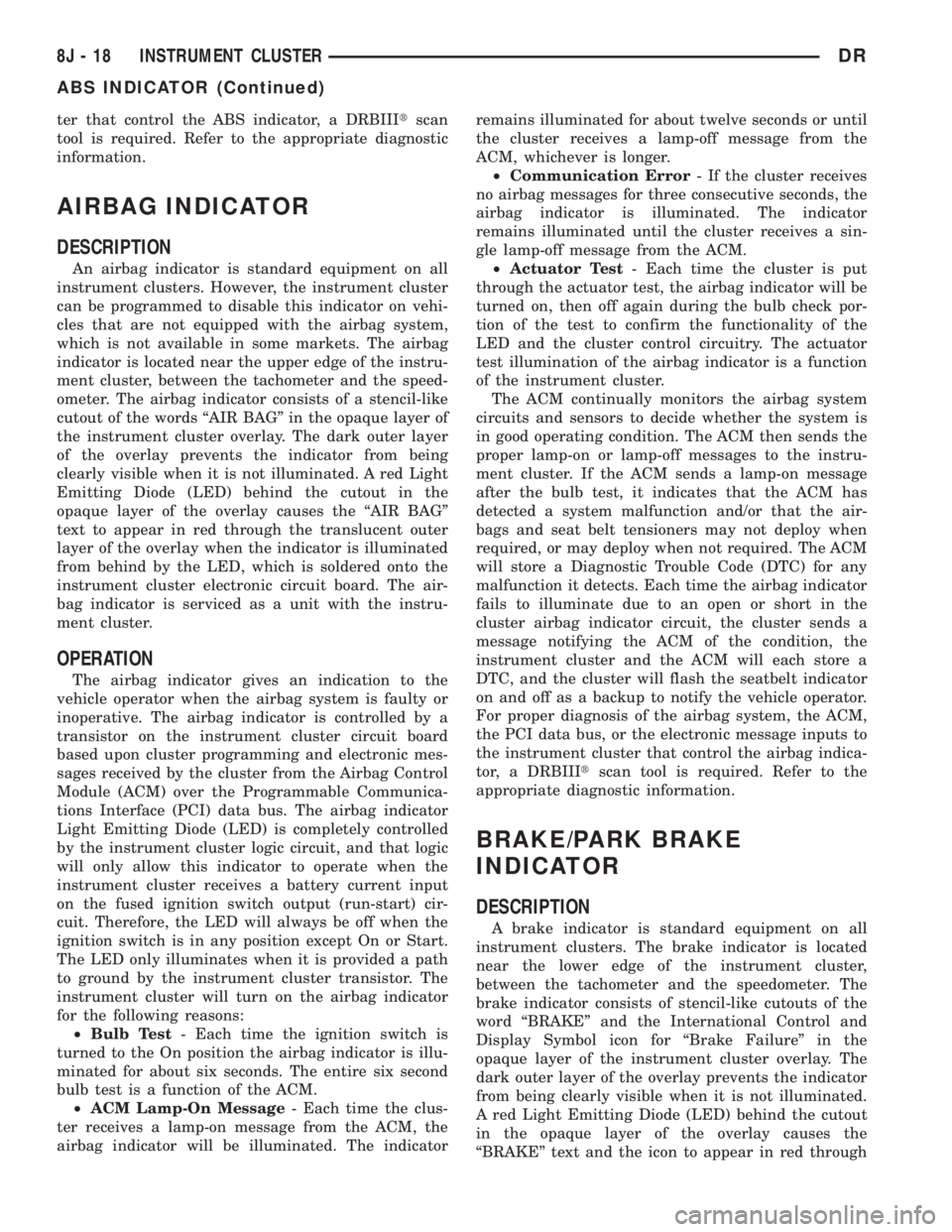

AIRBAG INDICATOR

DESCRIPTION

An airbag indicator is standard equipment on all

instrument clusters. However, the instrument cluster

can be programmed to disable this indicator on vehi-

cles that are not equipped with the airbag system,

which is not available in some markets. The airbag

indicator is located near the upper edge of the instru-

ment cluster, between the tachometer and the speed-

ometer. The airbag indicator consists of a stencil-like

cutout of the words ªAIR BAGº in the opaque layer of

the instrument cluster overlay. The dark outer layer

of the overlay prevents the indicator from being

clearly visible when it is not illuminated. A red Light

Emitting Diode (LED) behind the cutout in the

opaque layer of the overlay causes the ªAIR BAGº

text to appear in red through the translucent outer

layer of the overlay when the indicator is illuminated

from behind by the LED, which is soldered onto the

instrument cluster electronic circuit board. The air-

bag indicator is serviced as a unit with the instru-

ment cluster.

OPERATION

The airbag indicator gives an indication to the

vehicle operator when the airbag system is faulty or

inoperative. The airbag indicator is controlled by a

transistor on the instrument cluster circuit board

based upon cluster programming and electronic mes-

sages received by the cluster from the Airbag Control

Module (ACM) over the Programmable Communica-

tions Interface (PCI) data bus. The airbag indicator

Light Emitting Diode (LED) is completely controlled

by the instrument cluster logic circuit, and that logic

will only allow this indicator to operate when the

instrument cluster receives a battery current input

on the fused ignition switch output (run-start) cir-

cuit. Therefore, the LED will always be off when the

ignition switch is in any position except On or Start.

The LED only illuminates when it is provided a path

to ground by the instrument cluster transistor. The

instrument cluster will turn on the airbag indicator

for the following reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the airbag indicator is illu-

minated for about six seconds. The entire six second

bulb test is a function of the ACM.

²ACM Lamp-On Message- Each time the clus-

ter receives a lamp-on message from the ACM, the

airbag indicator will be illuminated. The indicatorremains illuminated for about twelve seconds or until

the cluster receives a lamp-off message from the

ACM, whichever is longer.

²Communication Error- If the cluster receives

no airbag messages for three consecutive seconds, the

airbag indicator is illuminated. The indicator

remains illuminated until the cluster receives a sin-

gle lamp-off message from the ACM.

²Actuator Test- Each time the cluster is put

through the actuator test, the airbag indicator will be

turned on, then off again during the bulb check por-

tion of the test to confirm the functionality of the

LED and the cluster control circuitry. The actuator

test illumination of the airbag indicator is a function

of the instrument cluster.

The ACM continually monitors the airbag system

circuits and sensors to decide whether the system is

in good operating condition. The ACM then sends the

proper lamp-on or lamp-off messages to the instru-

ment cluster. If the ACM sends a lamp-on message

after the bulb test, it indicates that the ACM has

detected a system malfunction and/or that the air-

bags and seat belt tensioners may not deploy when

required, or may deploy when not required. The ACM

will store a Diagnostic Trouble Code (DTC) for any

malfunction it detects. Each time the airbag indicator

fails to illuminate due to an open or short in the

cluster airbag indicator circuit, the cluster sends a

message notifying the ACM of the condition, the

instrument cluster and the ACM will each store a

DTC, and the cluster will flash the seatbelt indicator

on and off as a backup to notify the vehicle operator.

For proper diagnosis of the airbag system, the ACM,

the PCI data bus, or the electronic message inputs to

the instrument cluster that control the airbag indica-

tor, a DRBIIItscan tool is required. Refer to the

appropriate diagnostic information.

BRAKE/PARK BRAKE

INDICATOR

DESCRIPTION

A brake indicator is standard equipment on all

instrument clusters. The brake indicator is located

near the lower edge of the instrument cluster,

between the tachometer and the speedometer. The

brake indicator consists of stencil-like cutouts of the

word ªBRAKEº and the International Control and

Display Symbol icon for ªBrake Failureº in the

opaque layer of the instrument cluster overlay. The

dark outer layer of the overlay prevents the indicator

from being clearly visible when it is not illuminated.

A red Light Emitting Diode (LED) behind the cutout

in the opaque layer of the overlay causes the

ªBRAKEº text and the icon to appear in red through

8J - 18 INSTRUMENT CLUSTERDR

ABS INDICATOR (Continued)

Page 514 of 2895

input from the headlamp switch, or until the ignition

switch is turned to the Off position, whichever occurs

first.

²Actuator Test- Each time the cluster is put

through the actuator test, the cargo lamp indicator

will be turned on, then off again during the bulb

check portion of the test to confirm the functionality

of the LED and the cluster control circuitry.

The instrument cluster continually monitors the

headlamp dimmer switch circuit to determine the

proper interior lamps features and panel lamps illu-

mination levels to provide. The cluster then energizes

and de-energizes a low side driver circuit to control

the exterior cargo lamp. Each time the instrument

cluster energizes the cargo lamp driver and the igni-

tion switch is in the On or start positions, the cluster

also turns on the cargo lamp indicator. For further

diagnosis of the cargo lamp indicator or the instru-

ment cluster circuitry that controls the indicator,

(Refer to 8 - ELECTRICAL/INSTRUMENT CLUS-

TER - DIAGNOSIS AND TESTING). For proper

diagnosis of the cargo lamp or the headlamp switch

inputs to the instrument cluster that control the

cargo lamp indicator, a DRBIIItscan tool is required.

Refer to the appropriate diagnostic information.

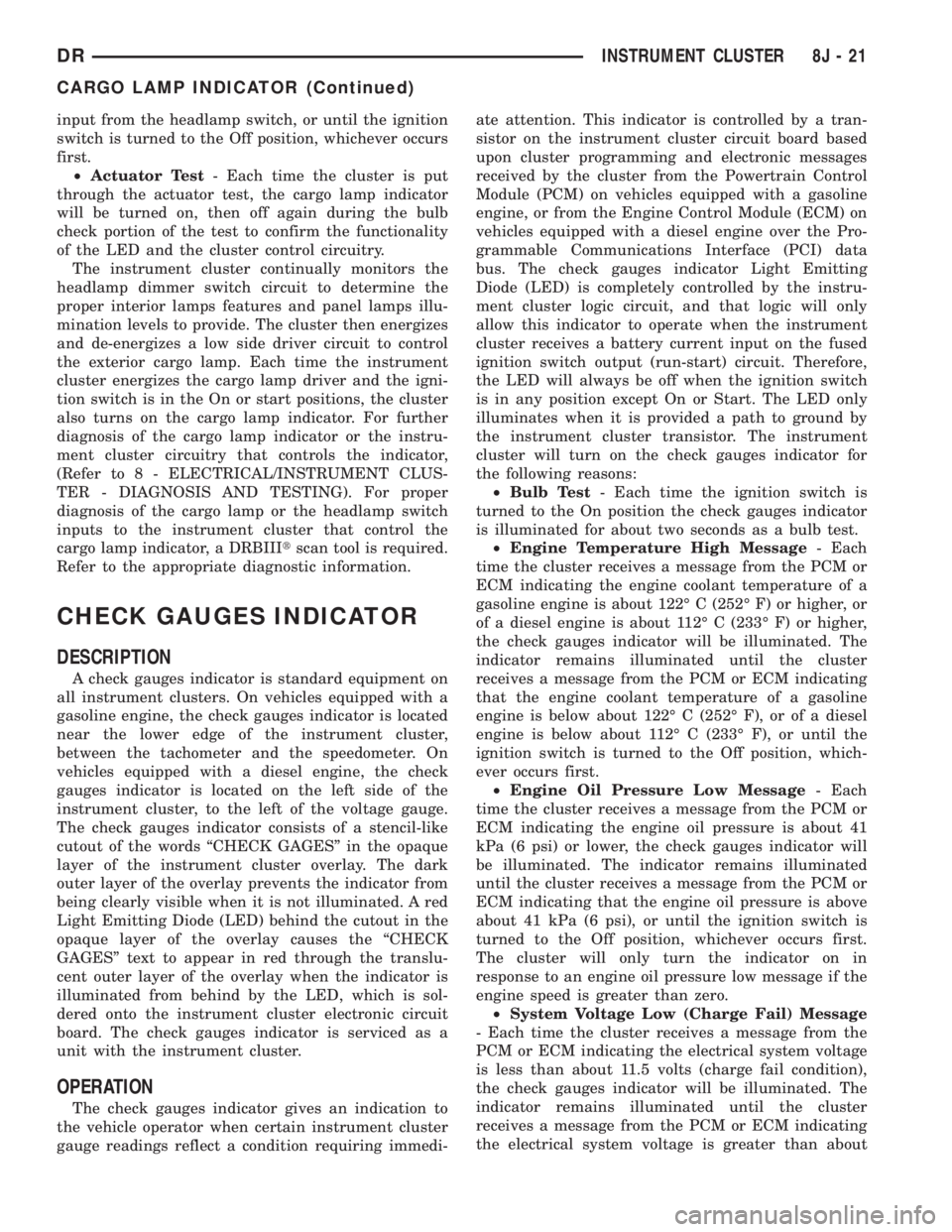

CHECK GAUGES INDICATOR

DESCRIPTION

A check gauges indicator is standard equipment on

all instrument clusters. On vehicles equipped with a

gasoline engine, the check gauges indicator is located

near the lower edge of the instrument cluster,

between the tachometer and the speedometer. On

vehicles equipped with a diesel engine, the check

gauges indicator is located on the left side of the

instrument cluster, to the left of the voltage gauge.

The check gauges indicator consists of a stencil-like

cutout of the words ªCHECK GAGESº in the opaque

layer of the instrument cluster overlay. The dark

outer layer of the overlay prevents the indicator from

being clearly visible when it is not illuminated. A red

Light Emitting Diode (LED) behind the cutout in the

opaque layer of the overlay causes the ªCHECK

GAGESº text to appear in red through the translu-

cent outer layer of the overlay when the indicator is

illuminated from behind by the LED, which is sol-

dered onto the instrument cluster electronic circuit

board. The check gauges indicator is serviced as a

unit with the instrument cluster.

OPERATION

The check gauges indicator gives an indication to

the vehicle operator when certain instrument cluster

gauge readings reflect a condition requiring immedi-ate attention. This indicator is controlled by a tran-

sistor on the instrument cluster circuit board based

upon cluster programming and electronic messages

received by the cluster from the Powertrain Control

Module (PCM) on vehicles equipped with a gasoline

engine, or from the Engine Control Module (ECM) on

vehicles equipped with a diesel engine over the Pro-

grammable Communications Interface (PCI) data

bus. The check gauges indicator Light Emitting

Diode (LED) is completely controlled by the instru-

ment cluster logic circuit, and that logic will only

allow this indicator to operate when the instrument

cluster receives a battery current input on the fused

ignition switch output (run-start) circuit. Therefore,

the LED will always be off when the ignition switch

is in any position except On or Start. The LED only

illuminates when it is provided a path to ground by

the instrument cluster transistor. The instrument

cluster will turn on the check gauges indicator for

the following reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the check gauges indicator

is illuminated for about two seconds as a bulb test.

²Engine Temperature High Message- Each

time the cluster receives a message from the PCM or

ECM indicating the engine coolant temperature of a

gasoline engine is about 122É C (252É F) or higher, or

of a diesel engine is about 112É C (233É F) or higher,

the check gauges indicator will be illuminated. The

indicator remains illuminated until the cluster

receives a message from the PCM or ECM indicating

that the engine coolant temperature of a gasoline

engine is below about 122É C (252É F), or of a diesel

engine is below about 112É C (233É F), or until the

ignition switch is turned to the Off position, which-

ever occurs first.

²Engine Oil Pressure Low Message- Each

time the cluster receives a message from the PCM or

ECM indicating the engine oil pressure is about 41

kPa (6 psi) or lower, the check gauges indicator will

be illuminated. The indicator remains illuminated

until the cluster receives a message from the PCM or

ECM indicating that the engine oil pressure is above

about 41 kPa (6 psi), or until the ignition switch is

turned to the Off position, whichever occurs first.

The cluster will only turn the indicator on in

response to an engine oil pressure low message if the

engine speed is greater than zero.

²System Voltage Low (Charge Fail) Message

- Each time the cluster receives a message from the

PCM or ECM indicating the electrical system voltage

is less than about 11.5 volts (charge fail condition),

the check gauges indicator will be illuminated. The

indicator remains illuminated until the cluster

receives a message from the PCM or ECM indicating

the electrical system voltage is greater than about

DRINSTRUMENT CLUSTER 8J - 21

CARGO LAMP INDICATOR (Continued)

Page 515 of 2895

12.0 volts (but less than 16.0 volts), or until the igni-

tion switch is turned to the Off position, whichever

occurs first.

²System Voltage High Message- Each time

the cluster receives a message from the PCM or ECM

indicating the electrical system voltage is greater

than about 16.0 volts, the check gauges indicator will

be illuminated. The indicator remains illuminated

until the cluster receives a message from the PCM or

ECM indicating the electrical system voltage is less

than about 15.5 volts (but greater than 11.5 volts), or

until the ignition switch is turned to the Off position,

whichever occurs first.

²Actuator Test- Each time the cluster is put

through the actuator test, the check gauges indicator

will be turned on, then off again during the bulb

check portion of the test to confirm the functionality

of the LED and the cluster control circuitry.

On vehicles with a gasoline engine, the PCM con-

tinually monitors the engine temperature, oil pres-

sure, and electrical system voltage, then sends the

proper messages to the instrument cluster. On vehi-

cles with a diesel engine, the ECM continually mon-

itors the engine temperature, oil pressure, and

electrical system voltage, then sends the proper mes-

sages to the instrument cluster. For further diagnosis

of the check gauges indicator or the instrument clus-

ter circuitry that controls the LED, (Refer to 8 -

ELECTRICAL/INSTRUMENT CLUSTER - DIAGNO-

SIS AND TESTING). For proper diagnosis of the

PCM, the ECM, the PCI data bus, or the electronic

message inputs to the instrument cluster that control

the check gauges indicator, a DRBIIItscan tool is

required. Refer to the appropriate diagnostic infor-

mation.

CRUISE INDICATOR

DESCRIPTION

A cruise indicator is standard equipment on all

instrument clusters. However, on vehicles not

equipped with the optional speed control system, this

indicator is electronically disabled. The cruise indica-

tor consists of the word ªCRUISEº, which appears in

the lower portion of the gear selector indicator Vacu-

um-Fluorescent Display (VFD) unit. The VFD is sol-

dered onto the cluster electronic circuit board and is

visible through a window with a smoked clear lens

located on the lower edge of the speedometer gauge

dial face of the cluster overlay. The dark lens over

the VFD prevents the indicator from being clearly

visible when it is not illuminated. The word

ªCRUISEº appears in a blue-green color and at the

same lighting level as the gear selector indicator

information when it is illuminated by the instrumentcluster electronic circuit board. The cruise indicator

is serviced as a unit with the VFD in the instrument

cluster.

OPERATION

The cruise indicator gives an indication to the vehi-

cle operator when the speed control system is turned

On, regardless of whether the speed control is

engaged. This indicator is controlled by the instru-

ment cluster circuit board based upon cluster pro-

gramming and electronic messages received by the

cluster from the Powertrain Control Module (PCM)

over the Programmable Communications Interface

(PCI) data bus. The cruise indicator is completely

controlled by the instrument cluster logic circuit, and

that logic will only allow this indicator to operate

when the instrument cluster receives a battery cur-

rent input on the fused ignition switch output (run-

start) circuit. Therefore, the indicator will always be

off when the ignition switch is in any position except

On or Start. The indicator only illuminates when it is

switched to ground by the instrument cluster cir-

cuitry. The instrument cluster will turn on the cruise

indicator for the following reasons:

²Cruise Lamp-On Message- Each time the

cluster receives a cruise lamp-on message from the

PCM indicating the speed control system has been

turned On, the cruise indicator is illuminated. The

indicator remains illuminated until the cluster

receives a cruise lamp-off message from the PCM or

until the ignition switch is turned to the Off position,

whichever occurs first.

²Actuator Test- Each time the cluster is put

through the actuator test, the cruise indicator will be

turned on, then off again during the VFD portion of

the test to confirm the functionality of the VFD and

the cluster control circuitry.

The PCM continually monitors the speed control

switches to determine the proper outputs to the

speed control servo. The PCM then sends the proper

cruise indicator lamp-on and lamp-off messages to

the instrument cluster. For further diagnosis of the

cruise indicator or the instrument cluster circuitry

that controls the indicator, (Refer to 8 - ELECTRI-

CAL/INSTRUMENT CLUSTER - DIAGNOSIS AND

TESTING). For proper diagnosis of the speed control

system, the PCM, the PCI data bus, or the electronic

message inputs to the instrument cluster that control

the cruise indicator, a DRBIIItscan tool is required.

Refer to the appropriate diagnostic information.

8J - 22 INSTRUMENT CLUSTERDR

CHECK GAUGES INDICATOR (Continued)

Page 519 of 2895

OPERATION

The fuel gauge gives an indication to the vehicle

operator of the level of fuel in the fuel tank. This

gauge is controlled by the instrument cluster circuit

board based upon cluster programming and elec-

tronic messages received by the cluster from the

Powertrain Control Module (PCM) on vehicles

equipped with a gasoline engine, or from the Engine

Control Module (ECM) on vehicles equipped with a

diesel engine over the Programmable Communica-

tions Interface (PCI) data bus. The fuel gauge is an

air core magnetic unit that receives battery current

on the instrument cluster electronic circuit board

through the fused ignition switch output (run-start)

circuit whenever the ignition switch is in the On or

Start positions. The cluster is programmed to move

the gauge needle back to the low end of the scale

after the ignition switch is turned to the Off position.

The instrument cluster circuitry controls the gauge

needle position and provides the following features:

²Percent Tank Full Message- Each time the

cluster receives a message from the PCM or ECM

indicating the percent tank full, the cluster program-

ming applies an algorithm to calculate the proper

gauge needle position, then moves the gauge needle

to the proper relative position on the gauge scale.

The algorithm is used to dampen gauge needle move-

ment against the negative effect that fuel sloshing

within the fuel tank can have on accurate inputs

from the fuel tank sending unit to the PCM or ECM.

²Less Than Twenty Percent Tank Full Mes-

sage- Each time the cluster receives messages from

the PCM or ECM indicating the percent tank full is

about twenty percent or less for ten consecutive sec-

onds and the vehicle speed is zero, or for sixty con-

secutive seconds and the vehicle speed is greater

than zero, the gauge needle is moved to the one-

eighth graduation or below on the gauge scale, the

low fuel indicator is illuminated, and a single chime

tone is sounded. The low fuel indicator remains illu-

minated until the cluster receives messages from the

PCM or ECM indicating that the percent tank full is

greater than about twenty percent for ten consecu-

tive seconds and the vehicle speed is zero, or for sixty

consecutive seconds and the vehicle speed is greater

than zero, or until the ignition switch is turned to

the Off position, whichever occurs first. The chime

tone feature will only repeat during the same igni-

tion cycle if the low fuel indicator is cycled off and

then on again by the appropriate percent tank full

messages from the PCM or ECM.

²Less Than Empty Percent Tank Full Mes-

sage- Each time the cluster receives a message from

the PCM or ECM indicating the percent tank full is

less than empty, the gauge needle is moved to the far

left end of the gauge scale and the low fuel indicatoris illuminated immediately. This message would indi-

cate that the fuel tank sender input to the PCM or

ECM is a short circuit.

²More Than Full Percent Tank Full Message

- Each time the cluster receives a message from the

PCM or ECM indicating the percent tank full is more

than full, the gauge needle is moved to the far left

end of the gauge scale and the low fuel indicator is

illuminated immediately. This message would indi-

cate that the fuel tank sender input to the PCM or

ECM is an open circuit.

²Communication Error- If the cluster fails to

receive a percent tank full message, it will hold the

gauge needle at the last indication about five seconds

or until the ignition switch is turned to the Off posi-

tion, whichever occurs first. After five seconds, the

cluster will move the gauge needle to the low end of

the gauge scale.

²Actuator Test- Each time the cluster is put

through the actuator test, the fuel gauge needle will

be swept to several calibration points on the gauge

scale in a prescribed sequence in order to confirm the

functionality of the gauge and the cluster control cir-

cuitry.

On vehicles with a gasoline engine, the PCM con-

tinually monitors the fuel tank sending unit to deter-

mine the level of the fuel in the fuel tank. On

vehicles with a diesel engine, the ECM continually

monitors the fuel tank sending unit to determine the

level of the fuel in the fuel tank. The PCM or ECM

then sends the proper fuel level messages to the

instrument cluster. For further diagnosis of the fuel

gauge or the instrument cluster circuitry that con-

trols the gauge, (Refer to 8 - ELECTRICAL/INSTRU-

MENT CLUSTER - DIAGNOSIS AND TESTING).

For proper diagnosis of the fuel tank sending unit,

the PCM, the ECM, the PCI data bus, or the elec-

tronic message inputs to the instrument cluster that

control the fuel gauge, a DRBIIItscan tool is

required. Refer to the appropriate diagnostic infor-

mation.

GEAR SELECTOR INDICATOR

DESCRIPTION

An electronic automatic transmission gear selector

indicator is standard factory-installed equipment on

this model. The gear selector indicator information is

displayed in a Vacuum-Fluorescent Display (VFD)

unit. The VFD is soldered onto the cluster electronic

circuit board and is visible through a window with a

smoked clear lens located on the lower edge of the

speedometer gauge dial face of the cluster overlay.

The dark lens over the VFD prevents the indicator

from being clearly visible when it is not illuminated.

8J - 26 INSTRUMENT CLUSTERDR

FUEL GAUGE (Continued)