coolant DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1940 of 5267

NOTE: Do not reuse the clamp for the exhaust pipe to turbocharger elbow connection.

48. Install the exhaust pipe to turbocharger elbow using a new clamp. Torque bolts to 11 Nꞏm (100 in. lbs.).

49. Lower vehicle.

50. Fill engine coolant (Refer to 7 - COOLING - STANDARD PROCEDURE).

51. Start engine and check for leaks.

Page 1952 of 5267

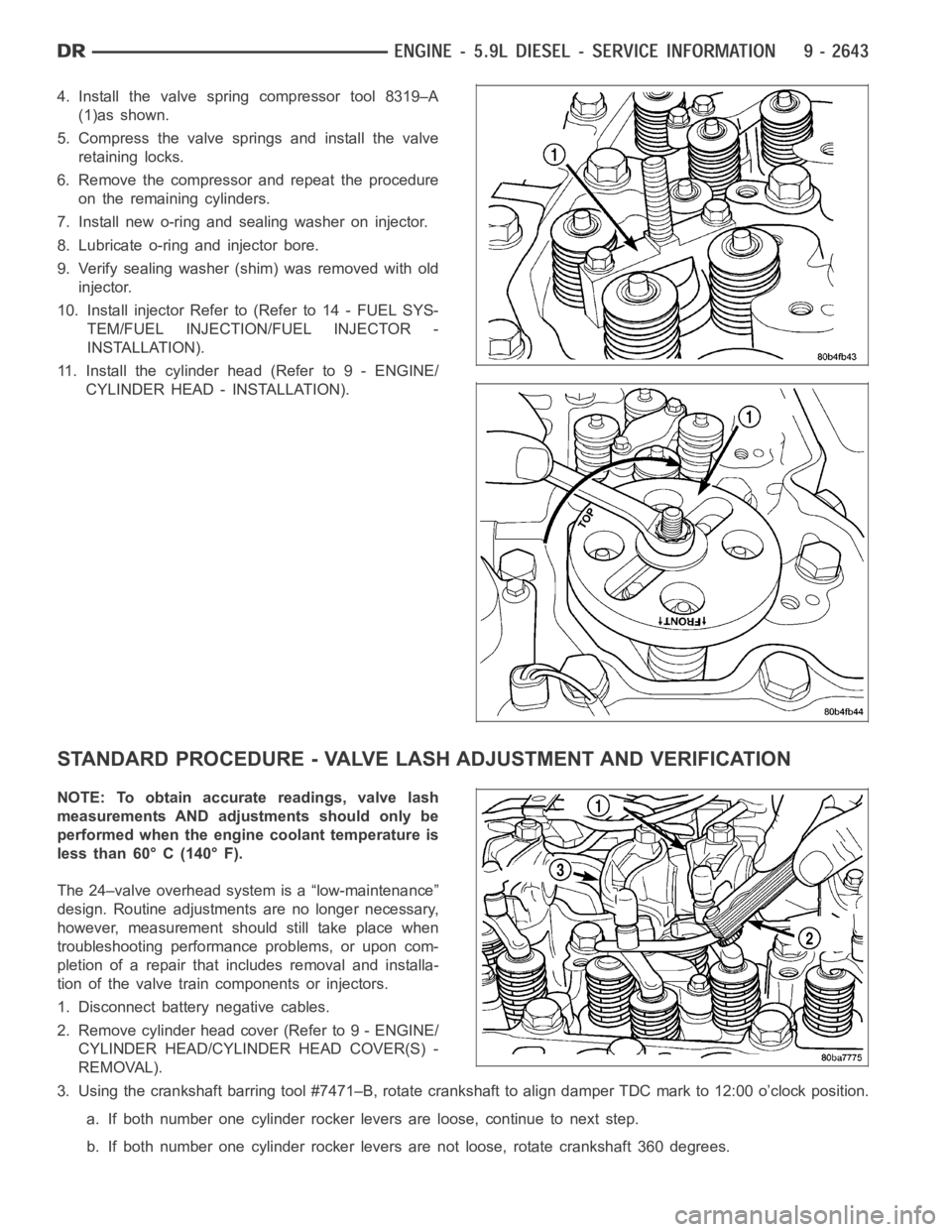

4. Install the valve spring compressor tool 8319–A

(1)as shown.

5. Compress the valve springs and install the valve

retaining locks.

6. Remove the compressor and repeat the procedure

on the remaining cylinders.

7. Install new o-ring and sealing washer on injector.

8. Lubricate o-ring and injector bore.

9. Verify sealing washer (shim) was removed with old

injector.

10. Install injector Refer to (Refer to 14 - FUEL SYS-

TEM/FUEL INJECTION/FUEL INJECTOR -

INSTALLATION).

11. Install the cylinder head (Refer to 9 - ENGINE/

CYLINDER HEAD - INSTALLATION).

STANDARD PROCEDURE - VALVE LASH ADJUSTMENT AND VERIFICATION

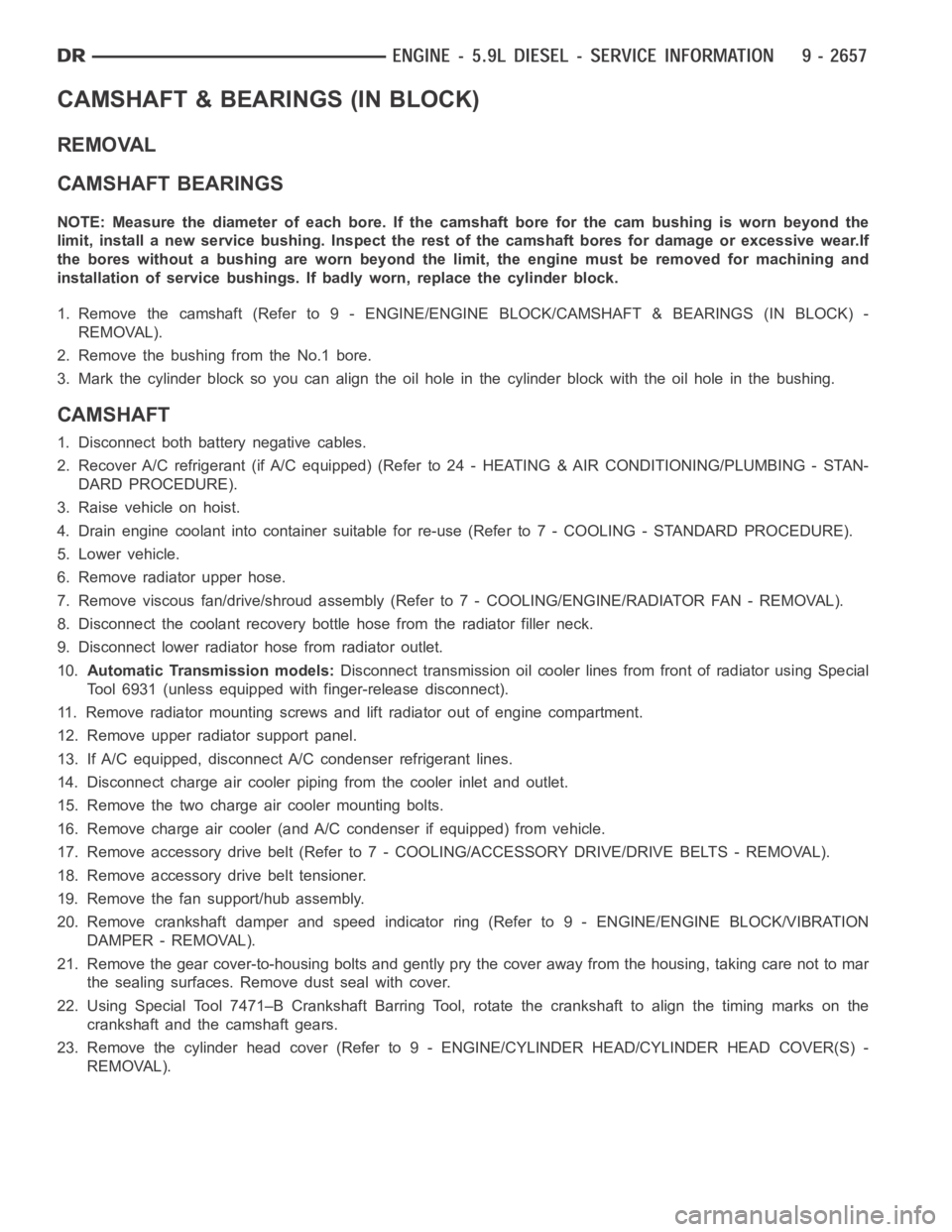

NOTE: To obtain accurate readings, valve lash

measurements AND adjustments should only be

performed when the engine coolant temperature is

less than 60° C (140° F).

The 24–valve overhead system is a “low-maintenance”

design. Routine adjustments are no longer necessary,

however, measurement should still take place when

troubleshooting performance problems, or upon com-

pletion of a repair that includes removal and installa-

tion of the valve train components or injectors.

1. Disconnect battery negative cables.

2. Remove cylinder head cover (Refer to 9 - ENGINE/

CYLINDER HEAD/CYLINDER HEAD COVER(S) -

REMOVAL).

3. Using the crankshaft barring tool #7471–B, rotate crankshaft to align damper TDC mark to 12:00 o’clock position.

a. If both number one cylinder rocker levers are loose, continue to next step.

b. If both number one cylinder rocker levers are not loose, rotate crankshaft 360 degrees.

Page 1966 of 5267

CAMSHAFT & BEARINGS (IN BLOCK)

REMOVAL

CAMSHAFT BEARINGS

NOTE: Measure the diameter of each bore. If the camshaft bore for the cam bushing is worn beyond the

limit, install a new service bushing. Inspect the rest of the camshaft bores for damage or excessive wear.If

the bores without a bushing are worn beyond the limit, the engine must be removed for machining and

installation of service bushings. If badly worn, replace the cylinder block.

1. Remove the camshaft (Refer to 9 - ENGINE/ENGINE BLOCK/CAMSHAFT & BEARINGS (IN BLOCK) -

REMOVAL).

2. Remove the bushing from the No.1 bore.

3. Mark the cylinder block so you can align the oil hole in the cylinder blockwith the oil hole in the bushing.

CAMSHAFT

1. Disconnect both battery negative cables.

2. Recover A/C refrigerant (if A/C equipped) (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STAN-

DARD PROCEDURE).

3. Raise vehicle on hoist.

4. Drain engine coolant into container suitable for re-use (Refer to 7 - COOLING - STANDARD PROCEDURE).

5. Lower vehicle.

6. Remove radiator upper hose.

7. Remove viscous fan/drive/shroud assembly (Refer to 7 - COOLING/ENGINE/RADIATOR FAN - REMOVAL).

8. Disconnect the coolant recovery bottle hose from the radiator filler neck.

9. Disconnect lower radiator hose from radiator outlet.

10.Automatic Transmission models:Disconnect transmission oil cooler lines from front of radiator using Special

Tool 6931 (unless equipped with finger-release disconnect).

11. Remove radiator mounting screws and lift radiator out of engine compartment.

12. Remove upper radiator support panel.

13. If A/C equipped, disconnect A/C condenser refrigerant lines.

14. Disconnect charge air cooler piping from the cooler inlet and outlet.

15. Remove the two charge air cooler mounting bolts.

16. Remove charge air cooler (and A/C condenser if equipped) from vehicle.

17. Remove accessory drive belt (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - REMOVAL).

18. Remove accessory drive belt tensioner.

19. Remove the fan support/hub assembly.

20. Remove crankshaft damper and speed indicator ring (Refer to 9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - REMOVAL).

21. Remove the gear cover-to-housing bolts and gently pry the cover away from the housing, taking care not to mar

the sealing surfaces. Remove dust seal with cover.

22. Using Special Tool 7471–B Crankshaft Barring Tool, rotate the crankshaft to align the timing marks on the

crankshaft and the camshaft gears.

23. Remove the cylinder head cover (Refer to 9 - ENGINE/CYLINDER HEAD/CYLINDER HEAD COVER(S) -

REMOVAL).

Page 1971 of 5267

12. Install gear housing cover (Refer to 9 - ENGINE/VALVE TIMING/GEAR HOUSING COVER - INSTALLATION).

Install front crankshaft dust seal.

13. Install the crankshaft damper with the speed indicator ring (Refer to 9- ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - INSTALLATION).

14. Install the fan support/hub assembly Refer to (Refer to 7 - COOLING/ENGINE/RADIATOR FAN - INSTALLA-

TION).

15. Install the power steering pump.

16. Install accessory drive belt tensioner. Torque bolt to 43 Nꞏm (32 ft. lbs.).

17. Install the accessory drive belt (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - INSTALLATION).

18. Install the charge air cooler (with a/c condenser and auxiliary transmission oil cooler, if equipped) and tighten

the mounting bolts to 2 Nꞏm (17 in. lbs.) torque.

19. Connect charge air cooler inlet and outlet pipes. Tighten clamps to 11 Nꞏm (95 in. lbs.) torque.

20. Install the radiator upper support panel.

21. Close radiator petcock and lower the radiator into the engine compartment. Tighten the mounting bolts to 11

Nꞏm (95 in. lbs.) torque.

22. Raise vehicle on hoist.

23. Connect radiator lower hose and install clamp.

24. Connect transmission auxiliary oil cooler lines (if equipped).

25. Lower vehicle.

26. Install the fandrive/shroud assembly. (Refer to 7 - COOLING/ENGINE/RADIATOR FAN - INSTALLATION)

27. Install the coolant recovery and windshield washer fluid reservoirs to the fan shroud.

28. Connect the coolant recovery hose to the radiator filler neck.

29. Add engine coolant (Refer to 7 - COOLING - STANDARD PROCEDURE).

30. Charge A/C system with refrigerant (if A/C equipped) (Refer to 24 - HEATING & AIR CONDITIONING/PLUMB-

ING - STANDARD PROCEDURE).

31. Connect the battery negative cables.

32. Start engine and check for engine oil and coolant leaks.

Page 1976 of 5267

SEAL - CRANKSHAFT OIL - FRONT

REMOVAL

1. Disconnect both battery negative cables.

2. Raise vehicle on hoist.

3. Partially drain engine coolant into container suitable for re-use (Refer to 7 - COOLING - STANDARD PROCE-

DURE).

4. Lower vehicle.

5. Remove radiator upper hose.

6. Disconnect coolant recovery bottle hose from radiator filler neck.

7. Disconnect windshield washer pump supply hose and electrical connections and lift washer bottle off of fan

shroud.

8. Remove viscous fan/drive assembly. (Refer to 7 - COOLING/ENGINE/RADIATOR FAN - REMOVAL).

9. Remove cooling fan shroud and fan assembly from the vehicle.

10. Remove the accessory drive belt (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - REMOVAL).

11. Remove the cooling fan support/hub from the front of the engine.

12. Raisethevehicleonhoist.

13. Remove the crankshaft damper and speed indicator ring.

14. Remove power steering pump.

15. Remove accessory drive belt tensioner.

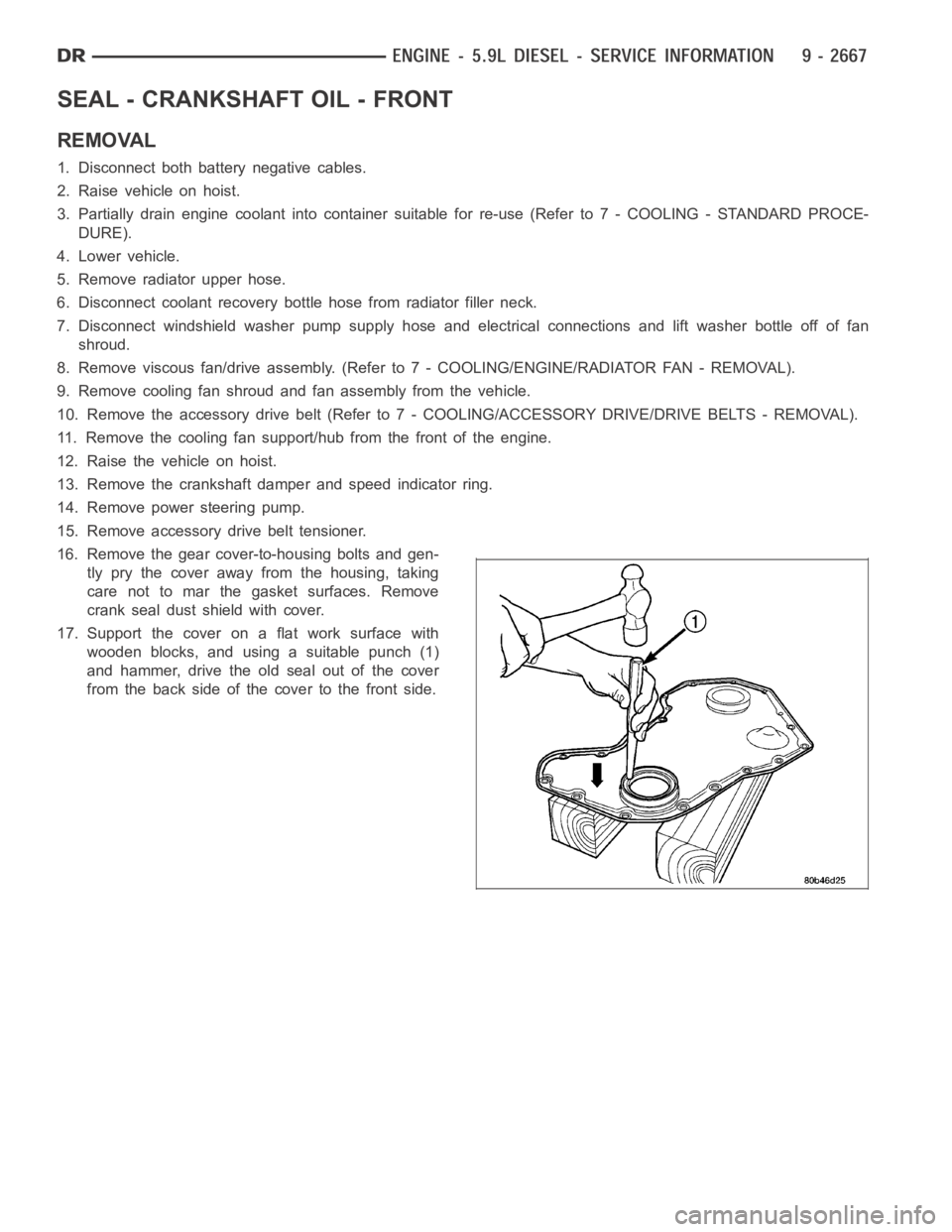

16. Remove the gear cover-to-housing bolts and gen-

tly pry the cover away from the housing, taking

care not to mar the gasket surfaces. Remove

crank seal dust shield with cover.

17. Support the cover on a flat work surface with

wooden blocks, and using a suitable punch (1)

and hammer, drive the old seal out of the cover

from the back side of the cover to the front side.

Page 1997 of 5267

LUBRICATION

DESCRIPTION

A gear driven gerotor type oil pump is mounted behind the front gear cover inthe lower right portion on the engine.

OPERATION

A gerotor style oil pump draws oil from the crankcase through the suction tube and delivers it through the block

where it enters the oil cooler cover and pressure regulator valve. When oilpressure exceeds 517 kPa (75 PSI), the

valve opens exposing the dump port, which routes excess oil back to the oil pump.

At the same time, oil is directed to a cast in passage in the oil cooler cover,leading to the oil cooler element. As the

oil travels through the element plates, it is cooled by engine coolant traveling past the outside of the plates. It is

then routed to the oil filter head and through a full flow oil filter. If a plugged filter is encountered, the filter by-pass

valve opens, allowing unfiltered oil to lubricate the engine. This condition can be avoided by frequent oil and filter

changes, per the maintenance schedules found in the owners manual. The by-pass valve is calibrated to open when

it sees a pressure drop of more than 345 kPa (50 psi) across the oil filter.

The oil filter head then divides the oil between the engine and the turbocharger. The turbocharger receives filtered,

cooled and pressurized oil through a supply line from the filter head. The oil lubricates the turbocharger and returns

to the pan by way of a drain tube connecting the bottom of the turbocharger toa tube in the cylinder block.

Page 2002 of 5267

OIL

STANDARD PROCEDURE

STANDARD PROCEDURE - ENGINE OIL LEVEL

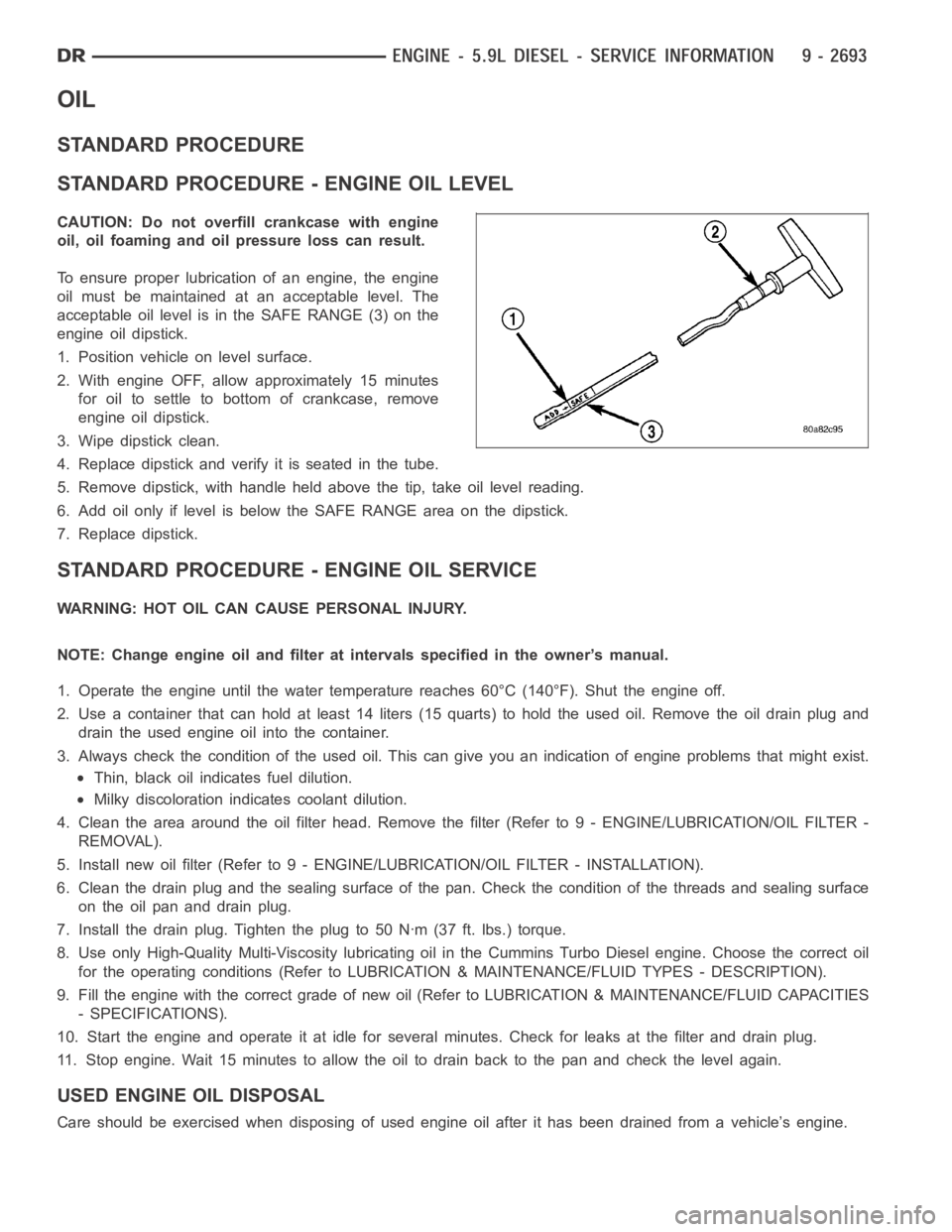

CAUTION: Do not overfill crankcase with engine

oil, oil foaming and oil pressure loss can result.

To ensure proper lubrication of an engine, the engine

oil must be maintained at an acceptable level. The

acceptable oil level is in the SAFE RANGE (3) on the

engine oil dipstick.

1. Position vehicle on level surface.

2. With engine OFF, allow approximately 15 minutes

for oil to settle to bottom of crankcase, remove

engine oil dipstick.

3. Wipe dipstick clean.

4. Replace dipstick and verify it is seated in the tube.

5. Remove dipstick, with handle held above the tip, take oil level reading.

6. Add oil only if level is below the SAFE RANGE area on the dipstick.

7. Replace dipstick.

STANDARD PROCEDURE - ENGINE OIL SERVICE

WARNING: HOT OIL CAN CAUSE PERSONAL INJURY.

NOTE: Change engine oil and filter at intervals specified in the owner’s manual.

1. Operate the engine until the water temperature reaches 60°C (140°F). Shut the engine off.

2. Use a container that can hold at least 14 liters (15 quarts) to hold the used oil. Remove the oil drain plug and

drain the used engine oil into the container.

3. Always check the condition of the used oil. This can give you an indication of engine problems that might exist.

Thin, black oil indicates fuel dilution.

Milky discoloration indicates coolant dilution.

4. Clean the area around the oil filter head. Remove the filter (Refer to 9 - ENGINE/LUBRICATION/OIL FILTER -

REMOVAL).

5. Install new oil filter (Refer to 9 - ENGINE/LUBRICATION/OIL FILTER - INSTA L L AT I O N ) .

6. Clean the drain plug and the sealing surface of the pan. Check the condition of the threads and sealing surface

on the oil pan and drain plug.

7. Install the drain plug. Tighten the plug to 50 Nꞏm (37 ft. lbs.) torque.

8. Use only High-Quality Multi-Viscosity lubricating oil in the Cummins Turbo Diesel engine. Choose the correct oil

for the operating conditions (Refer to LUBRICATION & MAINTENANCE/FLUID TYPES - DESCRIPTION).

9. Fill the engine with the correct grade of new oil (Refer to LUBRICATION & MAINTENANCE/FLUID CAPACITIES

- SPECIFICATIONS).

10. Start the engine and operate it at idle for several minutes. Check for leaks at the filter and drain plug.

11. Stop engine. Wait 15 minutes to allow the oil to drain back to the pan and check the level again.

USED ENGINE OIL DISPOSAL

Care should be exercised when disposing of used engine oil after it has beendrained from a vehicle’s engine.

Page 2016 of 5267

CASE - FRONT

REMOVAL

1. Disconnect the battery negative cables.

2. Raise vehicle on hoist.

3. Partially drain engine coolant into container suitable for re-use (Refer to 7 - COOLING - STANDARD PROCE-

DURE).

4. Lower vehicle.

5. Remove radiator upper hose.

6. Disconnect coolant recovery bottle hose from radiator filler neck.

7. Remove viscous fan/drive/shroud assembly (Refer to 7 - COOLING/ENGINE/RADIATOR FAN - REMOVAL).

8. Remove the accessory drive belt (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - REMOVAL).

9. Remove the cooling fan support/hub from the front of the engine.

10. Raisethevehicleonhoist.

11. Remove the crankshaft damper (Refer to 9 - ENGINE/ENGINE BLOCK/VIBRATION DAMPER - REMOVAL) and

speed indicator ring.

12. Remove the lower fan shroud bracket.

13. Remove the upper fan shroud bracket that is mounted to the gear housing.

14. Lower the vehicle.

15. Remove the power steering pump.

16. Remove the accessory drive belt tensioner.

17. Remove the gear cover-to-housing bolts and gently pry the cover away from the housing, taking care not to mar

the gasket surfaces.

18. Remove the fuel injection pump (Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/FUEL INJECTION PUMP -

REMOVAL).

19. Disconnect the camshaft position sensor connector.

20. Disconnect and remove engine speed sensor.

21. Remove the camshaft (Refer to 9 - ENGINE/ENGINE BLOCK/CAMSHAFT & BEARINGS (IN BLOCK) -

REMOVAL).

22. Remove the six front oil pan fasteners.

23. Remove the gear housing fasteners.

NOTE: Use care when removing the gear housing, to avoid damage to the oil pangasket, as the gasket will

be reused if it is not damaged.

24. Slide a feeler gauge between the gear housing and oil pan gasket, to break the gasket seal.

25. Remove the gear housing and gasket.

26. Clean the gasket material from the cylinder block and gear housing.

Page 2018 of 5267

13. Remove the seal pilot. Install front seal dust shield.

14. Raise the vehicle.

15. Install the crankshaft damper and speed indicator ring (Refer to 9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - INSTALLATION). Torque bolts to 40 Nm (30 ft. lbs.), plus an additional 60°.

16. Install the lower fan shroud bracket. Torque bolts to 24 Nꞏm (18 ft. lbs.) torque.

17. Install the upper fan shroud brackets. Hand tighten only.

18. Lower vehicle.

19. Install the fan support/hub assembly and tighten bolts to 32 Nꞏm (24 ft.lbs.) torque.

20. Install the power steering pump.

21. Install the accessory drive belt tensioner. Torque bolt to 43 Nꞏm (32 ft. lbs.) torque.

22. Install the accessory drive belt (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - INSTALLATION).

23. Install the upper cooling fan/drive/shroud assembly (Refer to 7 - COOLING/ENGINE/RADIATOR FAN - INSTAL-

LATION).

24. Torque the upper fan shroud brackets to 24 Nꞏm (18 ft. lbs.) torque.

25. Connect the coolant recovery bottle hose to the radiator filler neck.

26. Install the radiator upper hose and clamps.

27. Add engine oil.

28. Add coolant (Refer to 7 - COOLING - STANDARD PROCEDURE).

29. Connect the battery cables.

30. Start engine and inspect for leaks.

Page 2019 of 5267

COVER - TIMING

REMOVAL

1. Disconnect both battery negative cables.

2. Raise vehicle on hoist.

3. Partially drain engine coolant into container suitable for re-use (Refer to 7 - COOLING - STANDARD PROCE-

DURE).

4. Lower vehicle.

5. Remove radiator upper hose.

6. Remove viscous fan/drive/shroud assembly (Refer to 7 - COOLING/ENGINE/RADIATOR FAN - REMOVAL).

7. Remove the accessory drive belt (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - REMOVAL).

8. Remove the cooling fan support/hub from the front of the engine.

9. Raise the vehicle on hoist.

10. Remove power steering pump.

11. Remove accessory drive belt tensioner.

12. Remove the crankshaft damper and speed indicator ring (Refer to 9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - REMOVAL).

13. Lower the vehicle.

14. Remove the gear cover-to-housing bolts and gently pry the cover away from the housing, taking care not to mar

the gasket surfaces.

INSTALLATION

1. Install a new front crankshaft oil seal.

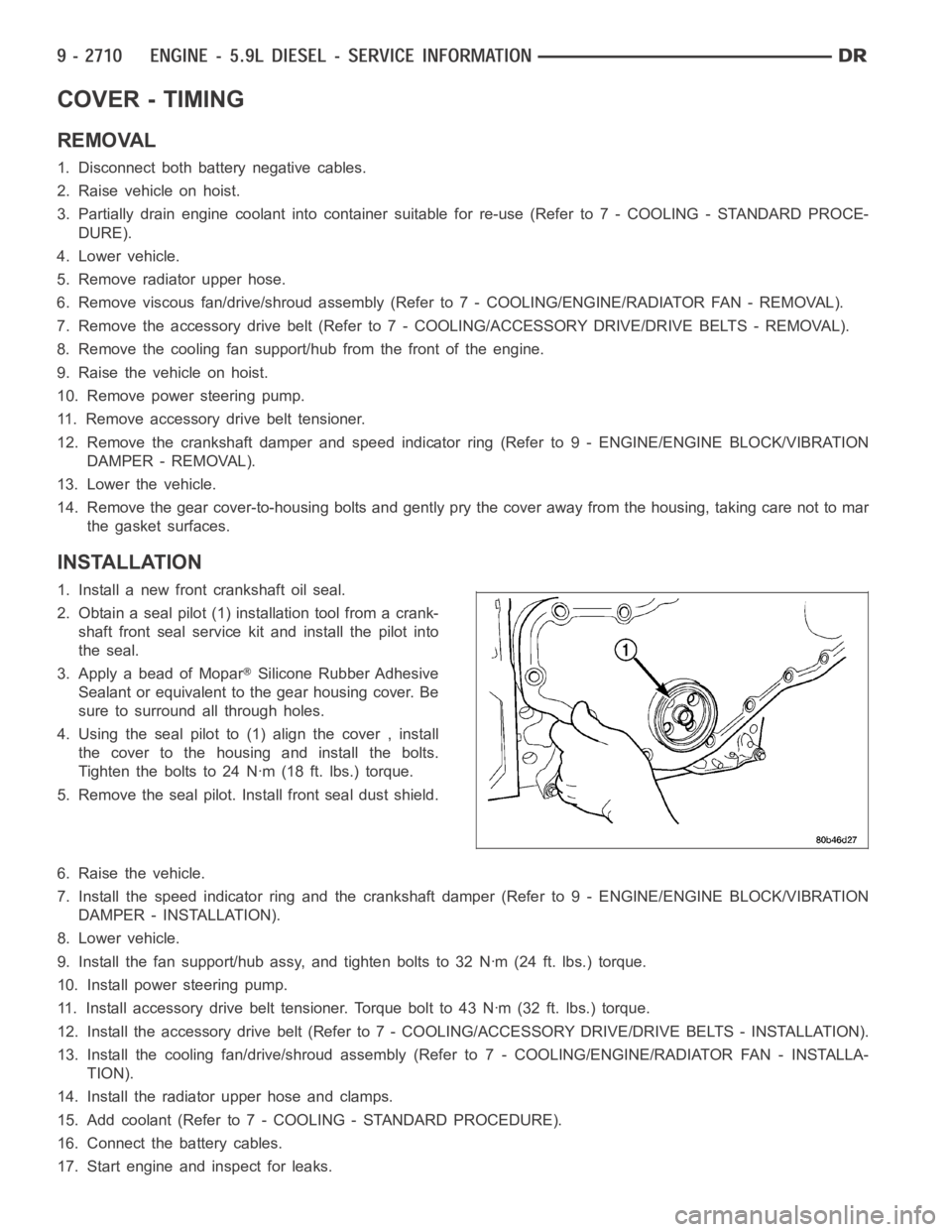

2. Obtain a seal pilot (1) installation tool from a crank-

shaft front seal service kit and install the pilot into

the seal.

3. Apply a bead of Mopar

Silicone Rubber Adhesive

Sealant or equivalent to the gear housing cover. Be

sure to surround all through holes.

4. Using the seal pilot to (1) align the cover , install

the cover to the housing and install the bolts.

Tighten the bolts to 24 Nꞏm (18 ft. lbs.) torque.

5. Remove the seal pilot. Install front seal dust shield.

6. Raise the vehicle.

7. Install the speed indicator ring and the crankshaft damper (Refer to 9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - INSTALLATION).

8. Lower vehicle.

9. Install the fan support/hub assy, and tighten bolts to 32 Nꞏm (24 ft. lbs.) torque.

10. Install power steering pump.

11. Install accessory drive belt tensioner. Torque bolt to 43 Nꞏm (32 ft. lbs.) torque.

12. Install the accessory drive belt (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - INSTALLATION).

13. Install the cooling fan/drive/shroud assembly (Refer to 7 - COOLING/ENGINE/RADIATOR FAN - INSTALLA-

TION).

14. Install the radiator upper hose and clamps.

15. Add coolant (Refer to 7 - COOLING - STANDARD PROCEDURE).

16. Connect the battery cables.

17. Start engine and inspect for leaks.