fuse DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3302 of 5267

7.CHECK IF THE DTC P0871 ALSO SET

With the scan tool, check Transmission DTCs.

Is the DTC P0871 also present?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom.

No>>

Go To 8

8.CHECK IF THE DTC SET IN PARK, REVERSE OR NEUTRAL

With the scan tool, check the DTC EVENT DATA for P0988.

NOTE: Make sure to record all DTC EVENT DATA stored in the scan tool for future reference in this test

procedure.

Does the DTC EVENT DATA show the DTC set in Park, Neutral, or Reverse for P0988?

Ye s>>

Go To 13

No>>

Go To 9

9.CHECK IF THE DTC EVENT DATA READS CLOSED

With the scan tool, check the DTC EVENT DATA for P0988.

NOTE: Make sure to record all DTC EVENT DATA stored in the scan tool for future reference in this test

procedure.

Does the DTC EVENT DATA show the 4C Pressure Switch reading CLOSED?

Ye s>>

Go To 11

No>>

Go To 10

10.CHECK THE PRIMARY OIL FILTER SEAL

In the DTC EVENT DATA recorded earlier,compare the Line Pressure and the Desired Line Pressure.

Is the Line Pressure less than 40 psi, and significantly below the Desired Line Pressure?

Ye s>>

Repair as necessary to correct low line pressure. Check fluid level and adjustasnecessary.Iffluidlevel

is OK, check the Primary Oil Filter seal for a split, crack, or improperly installed. If the filter and seal are

OK, check the Main Regulator Valve in the Oil Pump. Refer to the Service Information for the above

procedures.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Go To 15

11 .CHECK THE PCM AND WIRING

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator, Miller tool #8333.

Ignition on, engine not running.

With the Transmission Simulator, turn the Pressure Switch selector switchtothe4Cposition.

Page 3318 of 5267

P1684-BATTERY WAS DISCONNECTED

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Whenever the ignition is in the Run/Start position.

Set Condition:

This DTC will set whenever Powertrain Control Module is disconnected fromFused B(+) or ground. It will also

be set using the scan tool to perform a Battery Disconnect and/or Quick Learn procedure.

Possible Causes

BATTERY WAS DISCONNECTED

SCAN TOOL BATTERY DISCONNECT PERFORMED

PCM WAS REPLACED OR DISCONNECTED

QUICK LEARN WAS PERFORMED

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The PCM uses a battery backed RAM (Random Access Memory) is used to maintainsome learned values. When

the battery B(+) is disconnected, the memory is lost. When the B(+) is restored, this memory loss is detected by the

Transmission Control System. The DTC is set and the learned values are initialized to known constants or previ-

ously learned values from EEPROM (Electronic Erasable Programmable ReadOnly Memory). This results in the

reinitialization of some parameters.

Diagnostic Test

1.POSSIBLE CAUSES

This DTC is an informational DTC only.

This DTC is set due to a momentary loss of power and/or the ground circuits tothe PCM.

Below are a list of possible causes associated with this DTC.

Battery was disconnected.

The BATTERY DISCONNECT feature on the scan tool was performed.

The QUICK LEARN feature on the scan tool was performed.

PCM was replaced or disconnected.

Were any of the above possible causes performed?

Ye s>>

This is the cause of the DTC. Erase the DTC and return vehicle to customer.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Go To 2

Page 3328 of 5267

3.CHECK THE PCM AND WIRING

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator, Miller tool #8333.

Ignition on, engine not running.

With the Transmission Simulator, turn the Pressure Switch selector switchtoL/R.

With the scan tool, monitor the L/R Pressure Switch state while pressing thePressureSwitchTestbuttononthe

Transmission Simulator.

Did the state of the L/R Pressure Switch change while pressing the PressureSwitch Test button?

Ye s>>

Go To 4

No>>

Go To 5

4.CHECK IF THE SOLENOID SWITCH VALVE STICKING

Turn the ignition off to the lock position.

Remove the Transmission Oil Pan per the Service Information.

Remove the Transmission Valve body per the Service Information.

Inspect the Solenoid Switch Valve and Plugs for sticking.

Is the Solenoid Switch Valve or Plugs sticking?

Ye s>>

Clean and inspect per the Service Information. Repair as necessary.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Replace the Transmission Solenoid/TRS Assembly per the Service Information.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

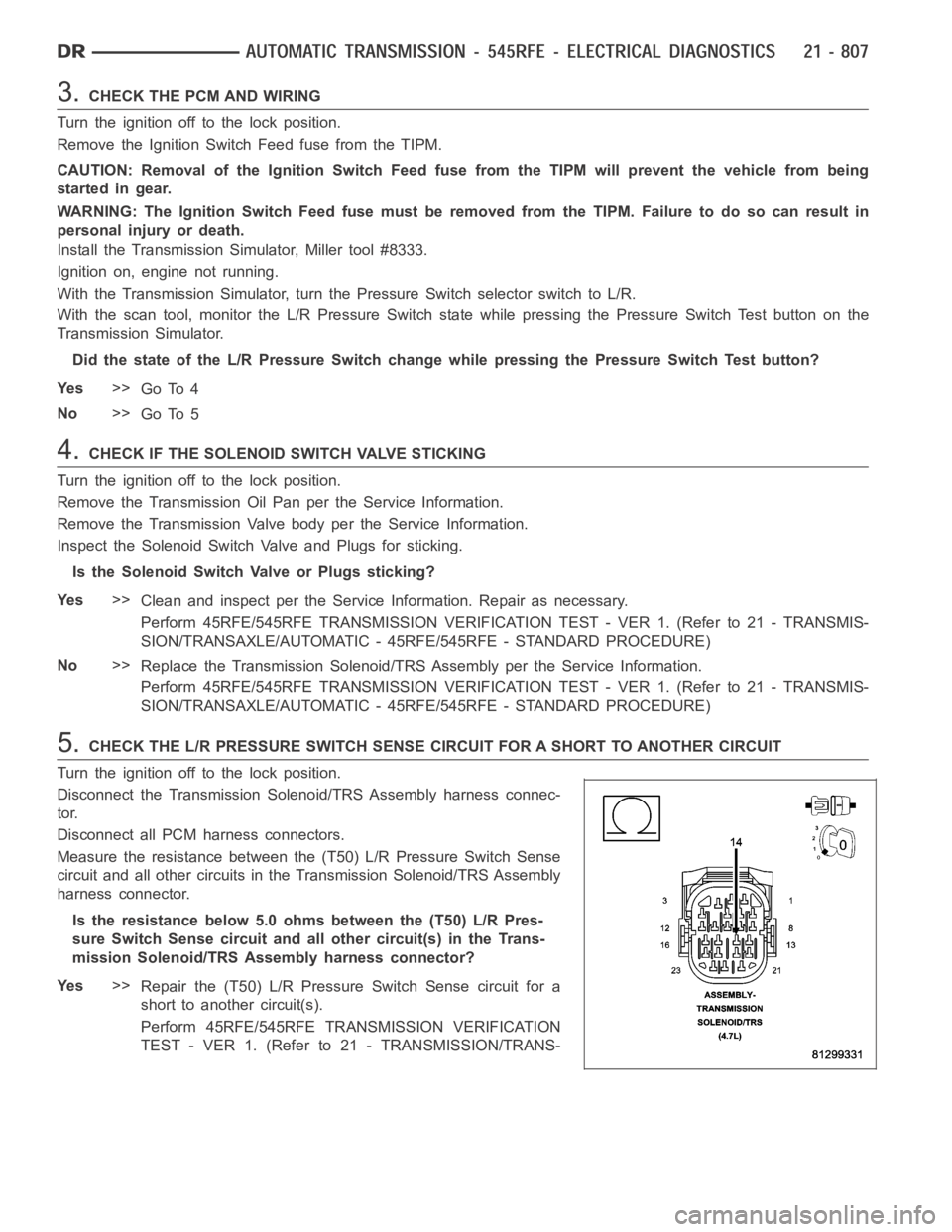

5.CHECK THE L/R PRESSURE SWITCH SENSE CIRCUIT FOR A SHORT TO ANOTHER CIRCUIT

Turn the ignition off to the lock position.

Disconnect the Transmission Solenoid/TRS Assembly harness connec-

tor.

Disconnect all PCM harness connectors.

Measure the resistance between the (T50) L/R Pressure Switch Sense

circuit and all other circuits in the Transmission Solenoid/TRS Assembly

harness connector.

Is the resistance below 5.0 ohms between the (T50) L/R Pres-

sure Switch Sense circuit and all other circuit(s) in the Trans-

mission Solenoid/TRS Assembly harness connector?

Ye s>>

Repair the (T50) L/R PressureSwitch Sense circuit for a

short to another circuit(s).

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

Page 3332 of 5267

3.CHECK THE PCM AND WIRING

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator, Miller tool #8333.

Ignition on, engine not running.

With the Transmission Simulator, turn the Pressure Switch selector switchtotheLRposition.

With the scan tool, monitor the LR Pressure Switch state while pressing thePressure Switch Test button on the

Transmission Simulator.

Did the state of the LR Pressure Switch change while pressing the Pressure Switch Test button?

Ye s>>

Go To 4

No>>

Go To 5

4.CHECK THE SOLENOID SWITCH VALVE

Remove the Valve Body per the Service Information.

Inspect the Solenoid Switch Valve and plugs for sticking in the bore and/orwear.

Were there any problems found?

Ye s>>

Clean and repair as necessary per the Service Information.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Go To 7

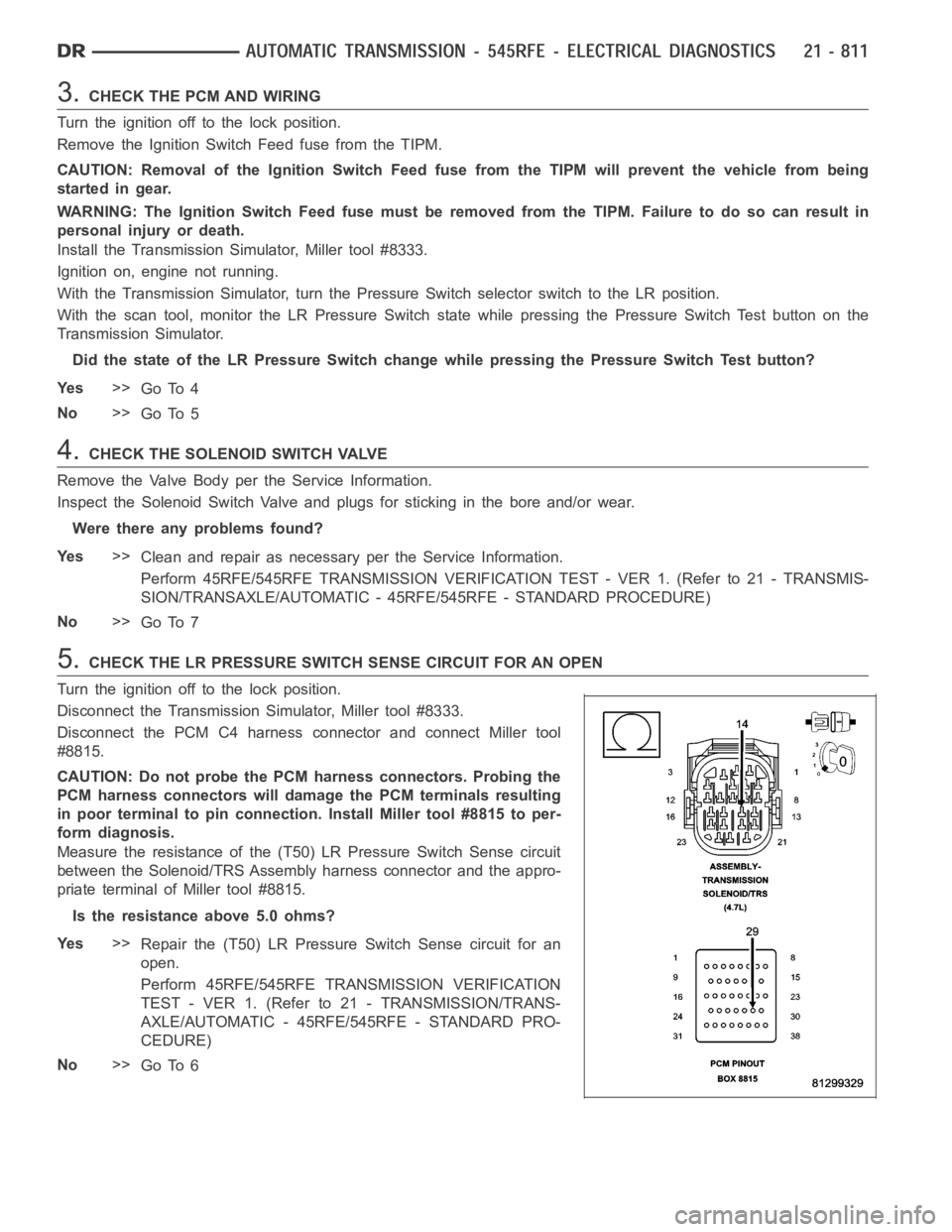

5.CHECK THE LR PRESSURE SWITCH SENSE CIRCUIT FOR AN OPEN

Turn the ignition off to the lock position.

Disconnect the Transmission Simulator, Miller tool #8333.

Disconnect the PCM C4 harness connector and connect Miller tool

#8815.

CAUTION: Do not probe the PCM harness connectors. Probing the

PCM harness connectors will damage the PCM terminals resulting

in poor terminal to pin connection. Install Miller tool #8815 to per-

form diagnosis.

Measure the resistance of the (T50) LR Pressure Switch Sense circuit

between the Solenoid/TRS Assembly harness connector and the appro-

priate terminal of Miller tool #8815.

Is the resistance above 5.0 ohms?

Ye s>>

Repair the (T50) LR Pressure Switch Sense circuit for an

open.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

No>>

Go To 6

Page 3336 of 5267

When Monitored:

The gear ratio is monitored continuously while the Transmission is in gear.

Set Condition:

After a controller reset in neutral and a ratio of input to output, of 1 to 2. ThisDTCcantakeuptofiveminutes

of problem identification before illuminating the MIL.

Possible Causes

(T13) SPEED SENSOR GROUND CIRCUIT OPEN

(T13) SPEED SENSOR GROUND CIRCUIT SHORT TO GROUND

(T13) SPEED SENSOR GROUND CIRCUIT SHORT TO VOLTAGE

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The transmission system uses two speed sensors, one to measure input RPM and one to measure output RPM.

These inputs are essential for proper transmission operation. Therefore, the integrity of this data is verified through

the following checks:

1) When in gear, if the gear ratio does not compare to a known gear ratio, the corresponding in-gear trouble code

is set (DTCs P0731–36).

2) An excessive change in input or output speeds indicating signal intermittent which may result in the DTCs P0715

and/or P0720 to set.

3) If the common speed sensor ground circuit is lost, both sensor inputs will read the signal from the input speed

sensor at idle in neutral. Since the input speed sensor reads 60 teeth from the input clutch hub and the output

speed sensor reads 30 teeth from the park gear, the result is an apparent speed ratio of 1:2 and may cause the

DTC P1794 to set when at a stop.

Diagnostic Test

1.CHECK TO SEE IF DTC P1794 IS CURRENT

Engine Running, Shift lever in park.

With the scan tool, read the Transmission Output and Input Speed Sensor states.

Is the Output Speed Sensor reading twice the Input Speed Sensor reading?

Ye s>>

Go To 2

No>>

Go To 6

2.PCM AND WIRING

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator, Miller tool 8333.

With the Transmission Simulator, set the Input/Output Speed selector switch to the

3000/1000position. Turn the

Input/Output Speed switch to

ON.

Ignition on, engine not running.

Page 3350 of 5267

When Monitored:

Initially at power-up, then every 10 seconds thereafter. The solenoid circuits will also be tested immediately

after a gear ratio or pressure switch error is detected.

Set Condition:

After three consecutive solenoid continuity test failures, or one failure if test is run in response to a gear ratio

or pressure switch error.Note: This DTC is strictly an electrical fault and does not apply to any internal

transmission failures.

Possible Causes

RELATED TCM POWER INPUT DTCS PRESENT

(T118) MS SOLENOID CONTROL CIRCUIT SHORT TO OTHER CIRCUITS

(T118) MS SOLENOID CONTROL CIRCUIT OPEN

(T118) MS SOLENOID CONTROL CIRCUIT SHORT TO GROUND

TRANSMISSION SOLENOID/TRS ASSEMBLY

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The Transmission Control System uses six electronically controlled solenoids that allow hydraulic fluid to be applied

to various friction elements (clutches), which enables the gear requested. The continuity of each solenoid circuit is

periodically tested. Each inactive solenoid is turned on for a few milliseconds, then off. Each active solenoid is

turned off for a few milliseconds, then on. This pulsing of voltage to the solenoid causes an inductive spike which

can be sensed by the Transmission Control System. If an inductive spike is not sensed by the Transmission Control

System during the continuity check, it is tested again. If the test fails three consecutive times, the appropriate Diag-

nostic Trouble Code (DTC) is set. If the solenoid test is run in response to agear ratio or pressure switch error, one

failure will result in setting the appropriate DTC.Note: This DTC is strictly an electrical fault and does not apply

to any internal transmission failures.

Diagnostic Test

1.RELATED TCM POWER INPUT DTCS PRESENT

With the scan tool, check for other transmission DTCs.

Are there any TCM Power Input DTCs present?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom.

No>>

Go To 2

2.TRANSMISSION SOLENOID/TRS ASSEMBLY

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install Transmission Simulator, Miller tool #8333.

Ignition on, engine not running.

With the scan tool, actuate the MS Solenoid.

Page 3489 of 5267

RELAY-TRANSMISSION CONTROL

DESCRIPTION

The relay is supplied fused B+ voltage, energized by the TCM, and is used to supply power to the solenoid pack

when the transmission is in normal operating mode.

OPERATION

When the relay is “off”, no power is supplied to the solenoid pack and the transmission is in “limp-in” mode. After a

controller reset, the TCM energizes the relay. Prior to this, the TCM verifies that the contacts are open by checking

for no voltage at the switched batteryterminals. After this is verified, the voltage at the solenoid pack pressure

switches is checked. After the relay is energized, the TCM monitors the terminals to verify that the voltage is greater

than 3 volts.

Page 3539 of 5267

Theory of Operation

The Torque Converter Clutch (TCC) solenoid is used to engage the TCC which improves fuel economy.

When Monitored:

Continuously with the ignition on.

Set Condition:

This DTC will set if the voltage detected by the PCM for the Torque ConverterClutch SolenoidControl circuit

is different than the expected voltage. Note: To clear this DTC it is necessarytodrivethevehicleatasus-

tained speed which would allow the TCC and/or Overdrive Clutch to operate.

Possible Causes

TRANSMISSION CONTROL OUTPUT DTCS PRESENT

(F941) FUSED IGNITION SWITCH OUTPUT CIRCUIT (RUN-START) OPEN

(T16) TRANSMISSION CONTROL OUTPUT CIRCUIT OPEN

(T16) TRANSMISSION CONTROL OUTPUT CIRCUIT SHORT TO GROUND

(T75) TCC SOLENOID CONTROL CIRCUIT SHORT TO GROUND

(T75) TCC SOLENOID CONTROL CIRCUIT SHORT TO OTHER CIRCUITS

TOTALLY INTEGRATED POWER MODULE (TIPM)

TORQUE CONVERTER CLUTCH SOLENOID

POWERTRAIN CONTROL MODULE

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 48RE - STANDARD PROCEDURE)

Diagnostic Test

1.CHECK IF THERE ANY TRANSMISSION CONTROL DTCS PRESENT

Ignition on, engine not running.

With the scan tool, read Engine DTCs.

Are there any TIPM TCM Power Control Circuit DTCs also present?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom(s). (Refer to 21 - TRANS-

MISSION/TRANSAXLE/AUTOMATIC - 48RE - DIAGNOSIS AND TESTING)

No>>

Go To 2

2.CHECK IF THE DTC IS CURRENT

With the scan tool, read Engine DTCs.

Record the Freeze Frame data for the reported DTC.

With the scan tool, erase DTCs.

Turn the ignition off to the lock position.

Using the Freeze Frame data recorded earlier, try to duplicate the conditions in which the DTC originally set.

NOTE: It may be necessary to road test the vehicle to duplicate the originalset conditions.

With the scan tool, read Engine DTCs.

Did the DTC reset?

Ye s>>

Go To 3

No>>

Go To 11

Page 3811 of 5267

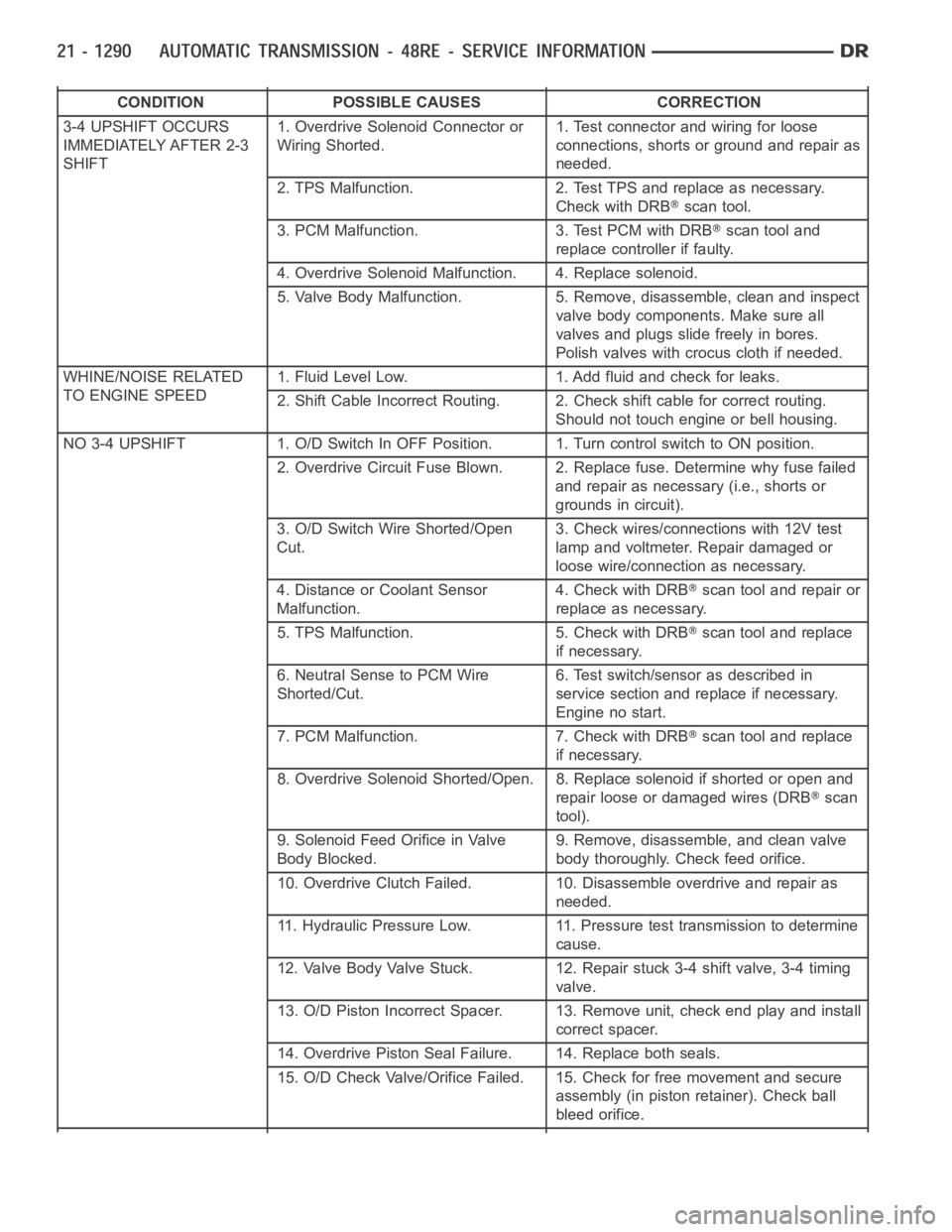

CONDITION POSSIBLE CAUSES CORRECTION

3-4 UPSHIFT OCCURS

IMMEDIATELY AFTER 2-3

SHIFT1. Overdrive Solenoid Connector or

Wiring Shorted.1. Test connector and wiring for loose

connections, shorts or ground and repair as

needed.

2. TPS Malfunction. 2. Test TPS and replace as necessary.

Check with DRB

scan tool.

3. PCM Malfunction. 3. Test PCM with DRB

scan tool and

replace controller if faulty.

4. Overdrive Solenoid Malfunction. 4. Replace solenoid.

5. Valve Body Malfunction. 5. Remove, disassemble, clean and inspect

valve body components. Make sure all

valves and plugs slide freely in bores.

Polish valves with crocus cloth if needed.

WHINE/NOISE RELATED

TO ENGINE SPEED1. Fluid Level Low. 1. Add fluid and check for leaks.

2. Shift Cable Incorrect Routing. 2. Check shift cable for correct routing.

Should not touch engine or bell housing.

NO3-4UPSHIFT 1.O/DSwitchInOFFPosition. 1.TurncontrolswitchtoONposition.

2. Overdrive Circuit Fuse Blown. 2. Replace fuse. Determine why fuse failed

and repair as necessary (i.e., shorts or

grounds in circuit).

3. O/D Switch Wire Shorted/Open

Cut.3. Check wires/connections with 12V test

lamp and voltmeter. Repair damaged or

loose wire/connection as necessary.

4. Distance or Coolant Sensor

Malfunction.4. Check with DRB

scan tool and repair or

replace as necessary.

5. TPS Malfunction. 5. Check with DRB

scan tool and replace

if necessary.

6. Neutral Sense to PCM Wire

Shorted/Cut.6. Test switch/sensor as described in

service section and replace if necessary.

Engine no start.

7. PCM Malfunction. 7. Check with DRB

scan tool and replace

if necessary.

8. Overdrive Solenoid Shorted/Open. 8. Replace solenoid if shorted or openand

repair loose or damaged wires (DRB

scan

tool).

9. Solenoid Feed Orifice in Valve

Body Blocked.9. Remove, disassemble, and clean valve

body thoroughly. Check feed orifice.

10. Overdrive Clutch Failed. 10. Disassemble overdrive and repair as

needed.

11. Hydraulic Pressure Low. 11. Pressure test transmission to determine

cause.

12. Valve Body Valve Stuck. 12. Repair stuck 3-4 shift valve, 3-4 timing

valve.

13. O/D Piston Incorrect Spacer. 13. Remove unit, check end play and install

correct spacer.

14. Overdrive Piston Seal Failure. 14. Replace both seals.

15. O/D Check Valve/Orifice Failed. 15. Check for free movement and secure

assembly (in piston retainer). Check ball

bleed orifice.

Page 3964 of 5267

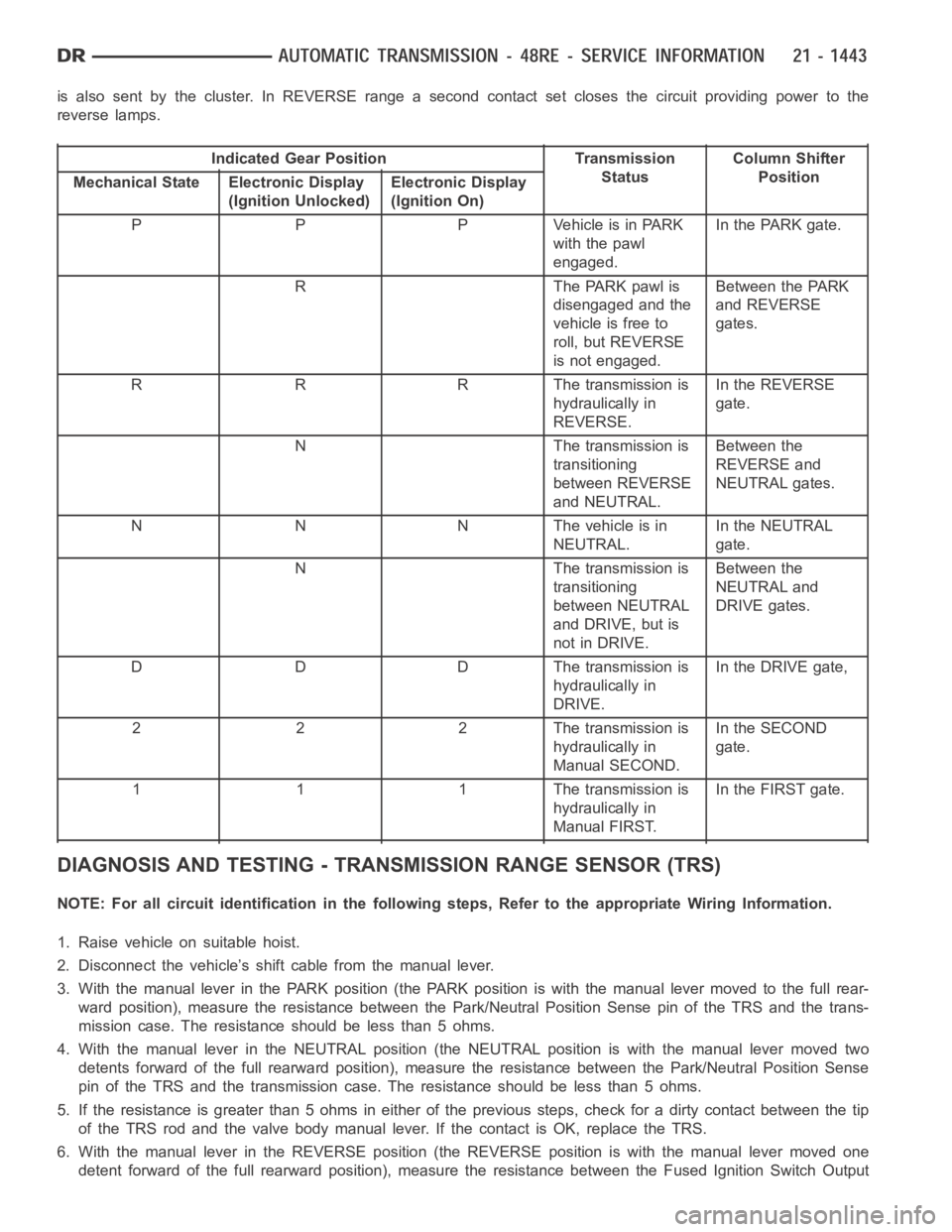

is also sent by the cluster. In REVERSE range a second contact set closes thecircuit providing power to the

reverse lamps.

Indicated Gear Position Transmission

StatusColumn Shifter

Position

Mechanical State Electronic Display

(Ignition Unlocked)Electronic Display

(Ignition On)

P P P Vehicle is in PARK

with the pawl

engaged.In the PARK gate.

R The PARK pawl is

disengaged and the

vehicle is free to

roll, but REVERSE

is not engaged.Between the PARK

and REVERSE

gates.

R R R The transmission is

hydraulically in

REVERSE.In the REVERSE

gate.

N The transmission is

transitioning

between REVERSE

and NEUTRAL.Between the

REVERSE and

NEUTRAL gates.

N N N The vehicle is in

NEUTRAL.In the NEUTRAL

gate.

N The transmission is

transitioning

between NEUTRAL

and DRIVE, but is

not in DRIVE.Between the

NEUTRAL and

DRIVE gates.

D D D The transmission is

hydraulically in

DRIVE.In the DRIVE gate,

2 2 2 The transmission is

hydraulically in

Manual SECOND.In the SECOND

gate.

1 1 1 The transmission is

hydraulically in

Manual FIRST.In the FIRST gate.

DIAGNOSIS AND TESTING - TRANSMISSION RANGE SENSOR (TRS)

NOTE: For all circuit identification in the following steps, Refer to the appropriate Wiring Information.

1. Raise vehicle on suitable hoist.

2. Disconnect the vehicle’s shift cable from the manual lever.

3. With the manual lever in the PARK position (the PARK position is with the manual lever moved to the full rear-

ward position), measure the resistance between the Park/Neutral PositionSensepinoftheTRSandthetrans-

mission case. The resistance should be less than 5 ohms.

4. With the manual lever in the NEUTRAL position (the NEUTRAL position is with the manual lever moved two

detents forward of the full rearward position), measure the resistance between the Park/Neutral Position Sense

pin of the TRS and the transmission case. The resistance should be less than5ohms.

5. If the resistance is greater than 5 ohms in either of the previous steps, check for a dirty contact between the tip

of the TRS rod and the valve body manual lever. If the contact is OK, replace the TRS.

6. With the manual lever in the REVERSE position (the REVERSE position is with the manual lever moved one

detent forward of the full rearward position), measure the resistance between the Fused Ignition Switch Output