fuse DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 4046 of 5267

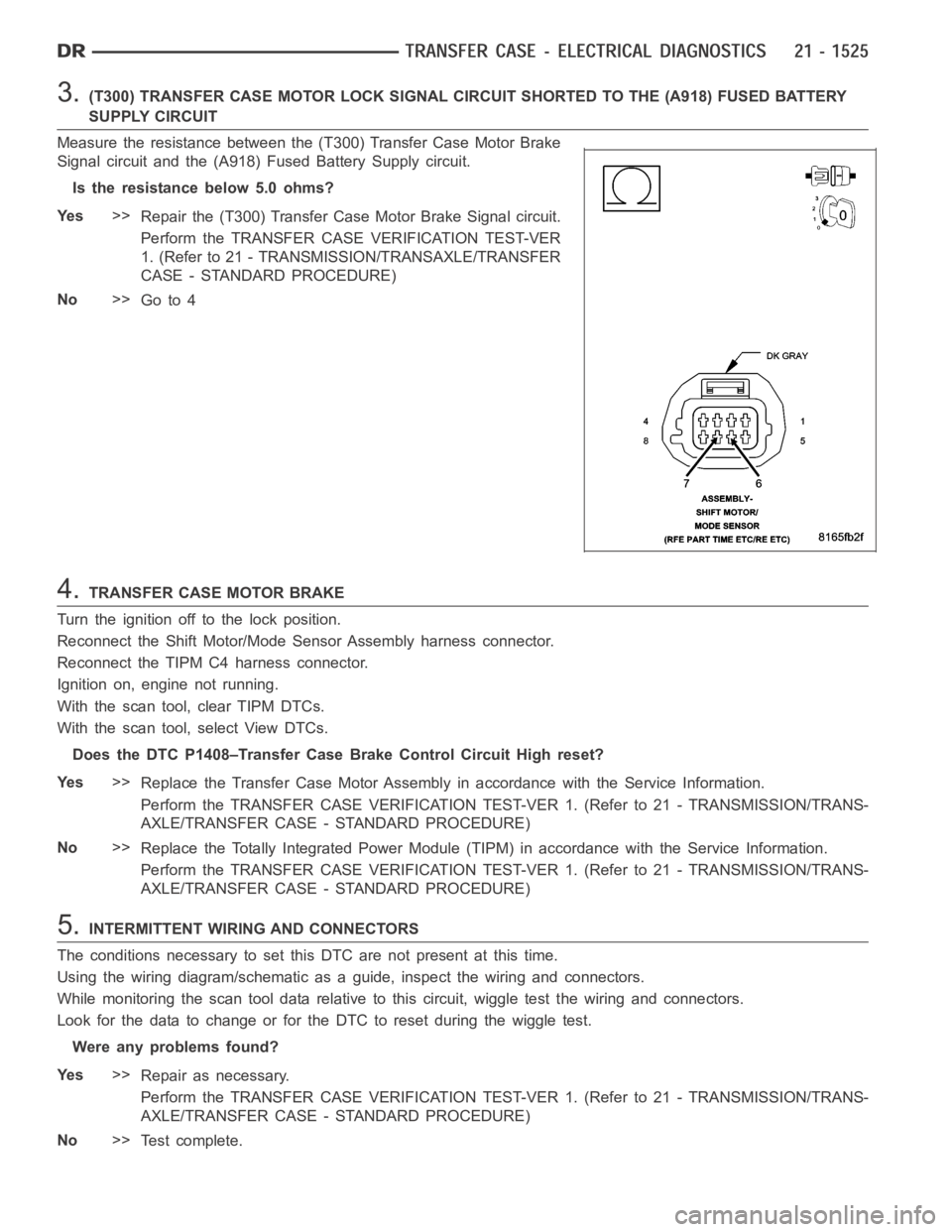

3.(T300) TRANSFER CASE MOTOR LOCK SIGNAL CIRCUIT SHORTED TO THE (A918) FUSEDBATTERY

SUPPLY CIRCUIT

Measure the resistance between the (T300) Transfer Case Motor Brake

Signal circuit and the (A918) Fused Battery Supply circuit.

Is the resistance below 5.0 ohms?

Ye s>>

Repair the (T300) Transfer Case Motor Brake Signal circuit.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

No>>

Go to 4

4.TRANSFER CASE MOTOR BRAKE

Turn the ignition off to the lock position.

Reconnect the Shift Motor/Mode Sensor Assembly harness connector.

Reconnect the TIPM C4 harness connector.

Ignition on, engine not running.

With the scan tool, clear TIPM DTCs.

With the scan tool, select View DTCs.

Does the DTC P1408–Transfer Case Brake Control Circuit High reset?

Ye s>>

Replace the Transfer Case Motor Assembly in accordance with the Service Information.

Perform the TRANSFER CASE VERIFICATION TEST-VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/TRANSFER CASE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module (TIPM) in accordance with theService Information.

Perform the TRANSFER CASE VERIFICATION TEST-VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/TRANSFER CASE - STANDARD PROCEDURE)

5.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set this DTC are not present at this time.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

While monitoring the scan tool data relative to this circuit, wiggle test the wiring and connectors.

Look for the data to change or for the DTC to reset during the wiggle test.

Were any problems found?

Ye s>>

Repair as necessary.

Perform the TRANSFER CASE VERIFICATION TEST-VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/TRANSFER CASE - STANDARD PROCEDURE)

No>>

Te s t c o m p l e t e .

Page 4070 of 5267

When Monitored:

The ignition on, with the T-Case Switch in 4W/LO position.

Set Condition:

The TIPM detects the Front Axle Lock Signal circuit is shorted low.

Possible Causes

(A880) FUSED B+ CIRCUIT OPEN

(G303) FRONT AXLE LOCK SIGNAL CIRCUIT OPEN

(G304) FRONT AXLE LOCK CONTROL CIRCUIT OPEN

FRONT AXLE DISCONNECT (FAD) MODULE

TOTALLY INTEGRATED POWER MODULE (TIPM)

Diagnostic Test

1.ACTIVE DTC

CAUTION: Before removing the TIPM harness connectors, clean the connector and locking cam area of dirt

and debris. Failure to do so can result in the connector being jammed or damage to the locking cams on

the harness connector or module. Do not force the assist arm when releasingor installing the harness con-

nector.

Ignition on, engine not running.

With the scan tool, read the TIPM DTCs.

Is the DTC currently active?

Ye s>>

Go To 2

No>>

Go To 6

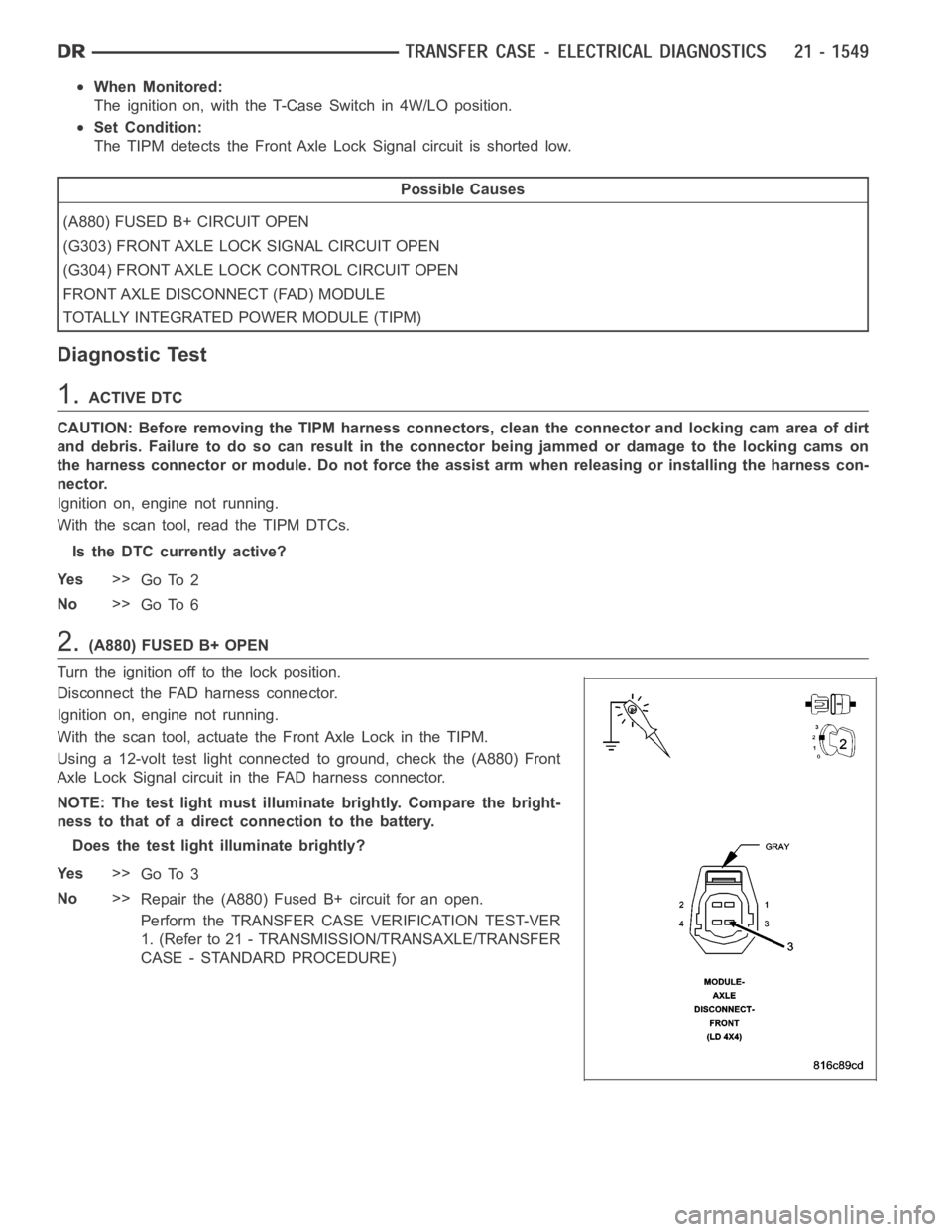

2.(A880) FUSED B+ OPEN

Turn the ignition off to the lock position.

Disconnect the FAD harness connector.

Ignition on, engine not running.

With the scan tool, actuate the Front Axle Lock in the TIPM.

Using a 12-volt test light connected to ground, check the (A880) Front

Axle Lock Signal circuit in the FAD harness connector.

NOTE: The test light must illuminate brightly. Compare the bright-

ness to that of a direct connection to the battery.

Does the test light illuminate brightly?

Ye s>>

Go To 3

No>>

Repair the (A880) Fused B+ circuit for an open.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

Page 4071 of 5267

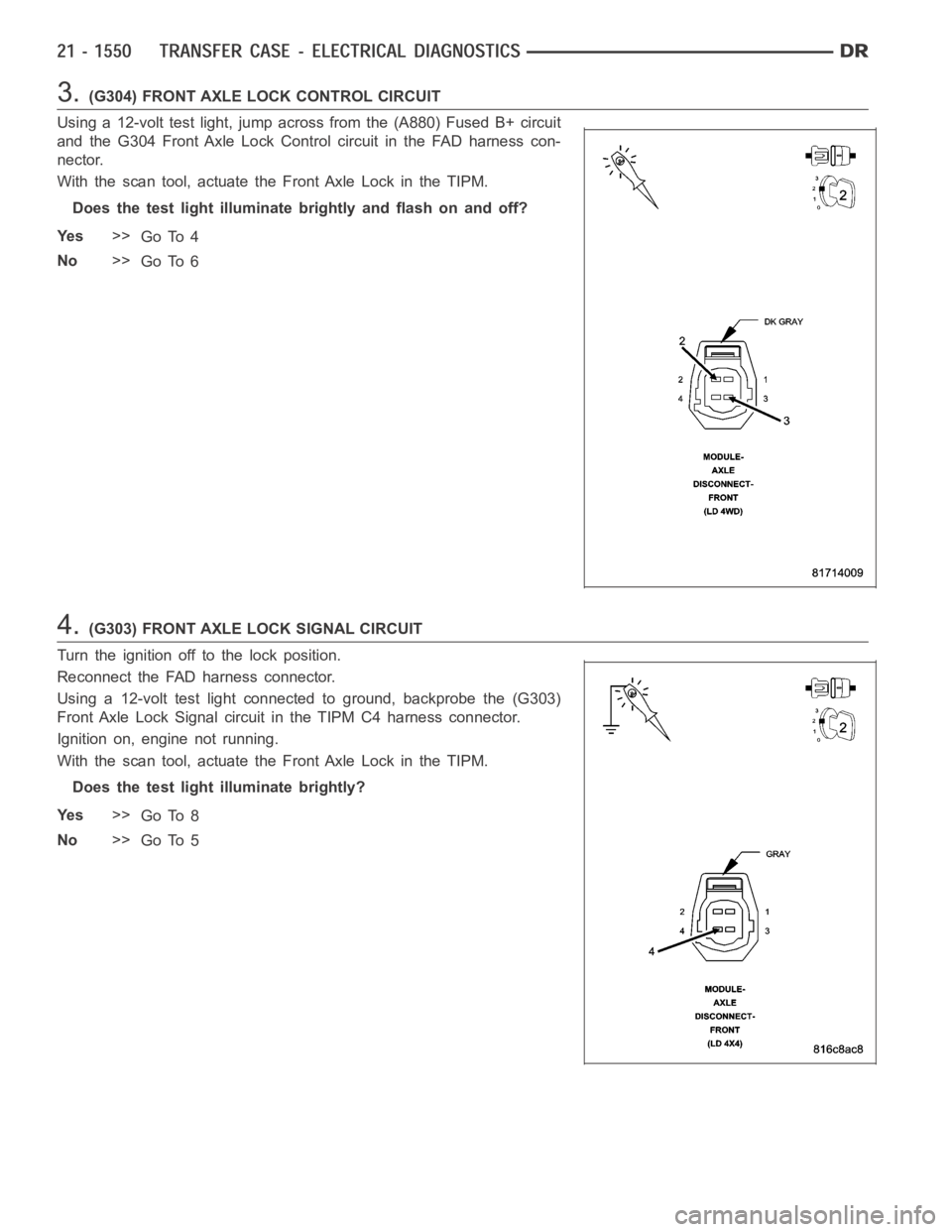

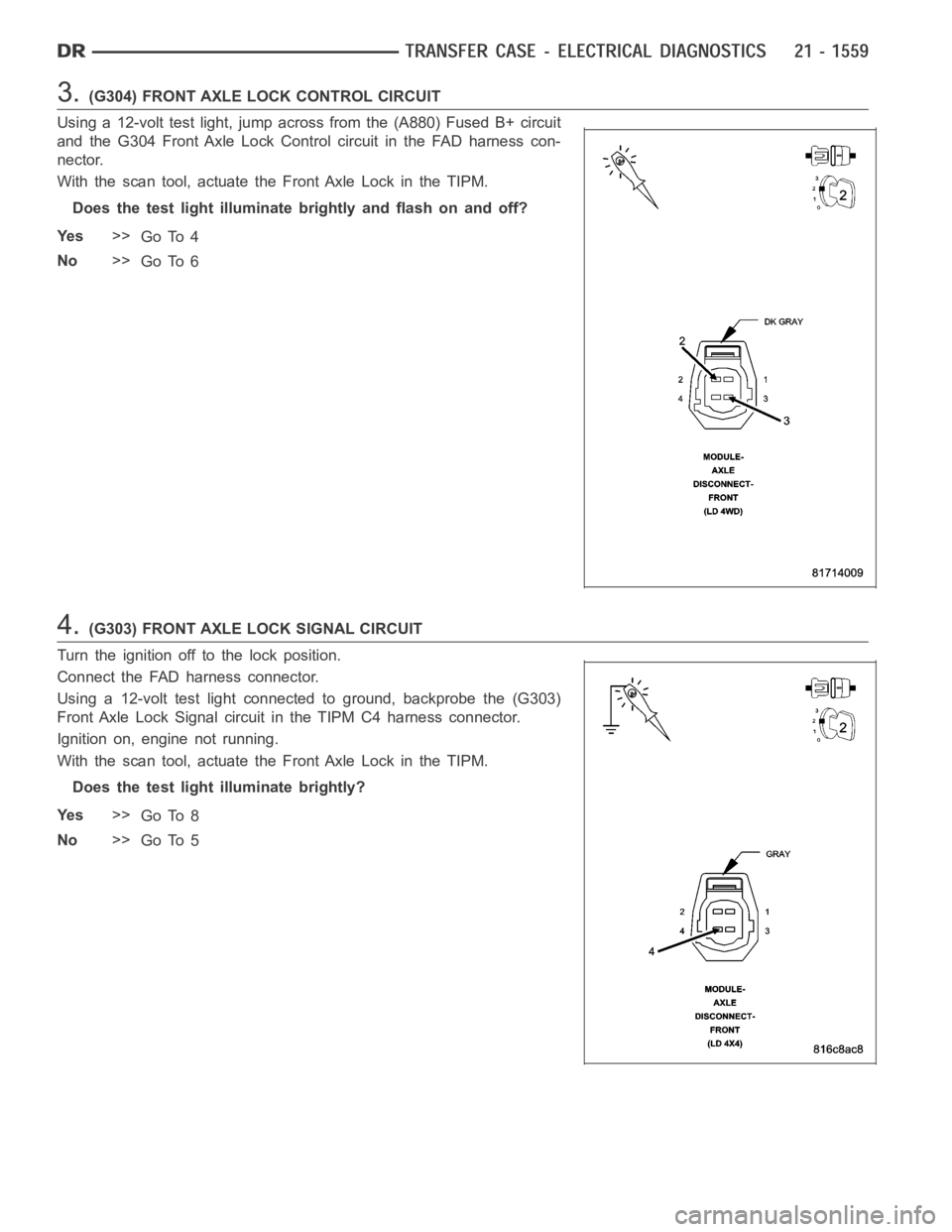

3.(G304) FRONT AXLE LOCK CONTROL CIRCUIT

Using a 12-volt test light, jump across from the (A880) Fused B+ circuit

and the G304 Front Axle Lock Control circuit in the FAD harness con-

nector.

With the scan tool, actuate the Front Axle Lock in the TIPM.

Does the test light illuminate brightly and flash on and off?

Ye s>>

Go To 4

No>>

Go To 6

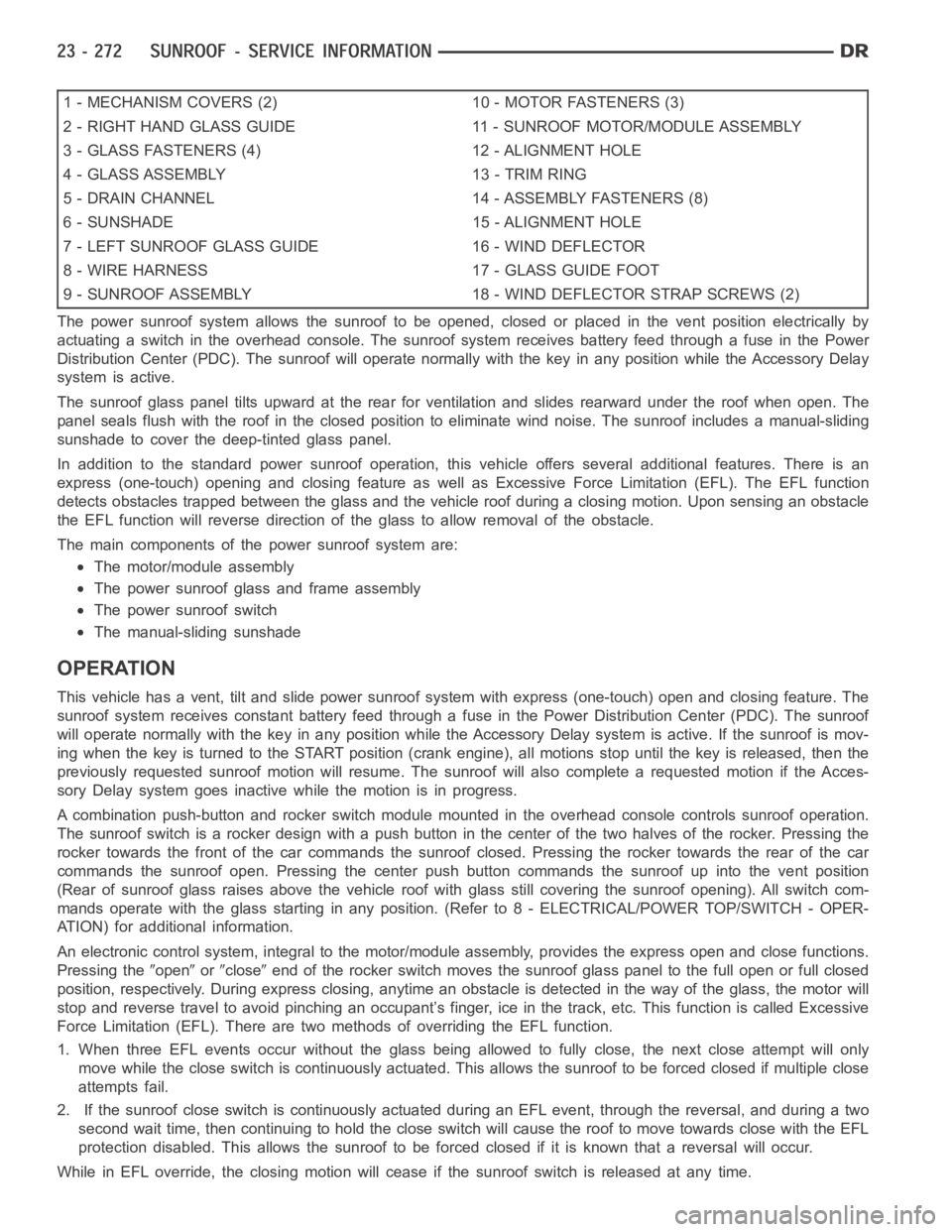

4.(G303) FRONT AXLE LOCK SIGNAL CIRCUIT

Turn the ignition off to the lock position.

Reconnect the FAD harness connector.

Using a 12-volt test light connected to ground, backprobe the (G303)

Front Axle Lock Signal circuit in the TIPM C4 harness connector.

Ignition on, engine not running.

With the scan tool, actuate the Front Axle Lock in the TIPM.

Does the test light illuminate brightly?

Ye s>>

Go To 8

No>>

Go To 5

Page 4079 of 5267

When Monitored:

The ignition on. T-Case Switch in 4W/LO position.

Set Condition:

The TIPM detects that the Front Axle Lock Signal circuit is shorted low.

Possible Causes

(A880) FUSED B+ CIRCUIT OPEN

(G303) FRONT AXLE LOCK SIGNAL CIRCUIT OPEN

(G304) FRONT AXLE LOCK CONTROL CIRCUIT OPEN

FRONT AXLE DISCONNECT (FAD) MODULE

TOTALLY INTEGRATED POWER MODULE (TIPM)

Diagnostic Test

1.ACTIVE DTC

CAUTION: Before removing the TIPM harness connectors, clean the connector and locking cam area of dirt

and debris. Failure to do so can result in the connector being jammed or damage to the locking cams on

the harness connector or module. Do not force the assist arm when releasingor installing the harness con-

nector.

Ignition on, engine not running.

With the scan tool, read the TIPM DTCs.

Is the status Active for this DTC?

Ye s>>

Go To 2

No>>

Go To 6

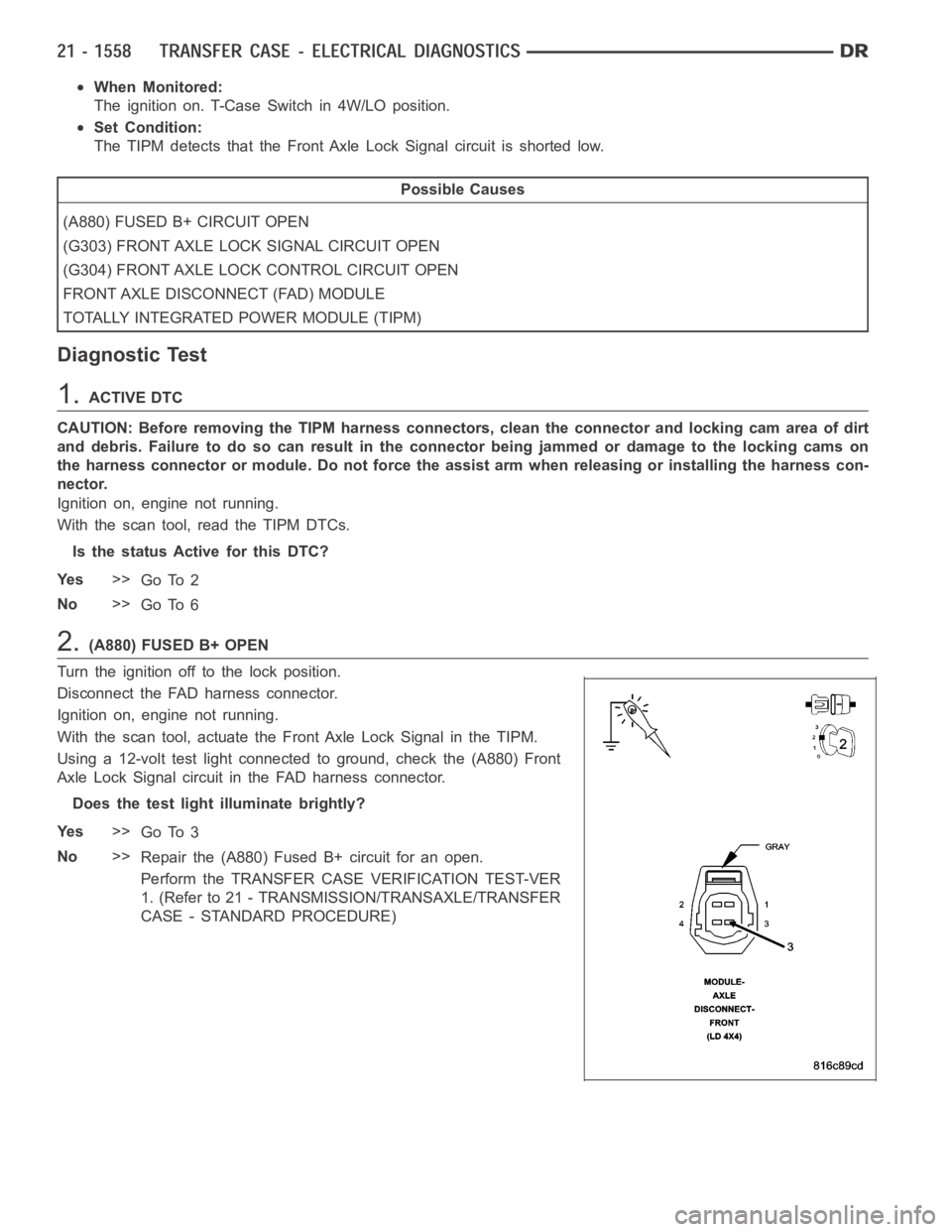

2.(A880) FUSED B+ OPEN

Turn the ignition off to the lock position.

Disconnect the FAD harness connector.

Ignition on, engine not running.

With the scan tool, actuate the Front Axle Lock Signal in the TIPM.

Using a 12-volt test light connected to ground, check the (A880) Front

Axle Lock Signal circuit in the FAD harness connector.

Does the test light illuminate brightly?

Ye s>>

Go To 3

No>>

Repair the (A880) Fused B+ circuit for an open.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

Page 4080 of 5267

3.(G304) FRONT AXLE LOCK CONTROL CIRCUIT

Using a 12-volt test light, jump across from the (A880) Fused B+ circuit

and the G304 Front Axle Lock Control circuit in the FAD harness con-

nector.

With the scan tool, actuate the Front Axle Lock in the TIPM.

Does the test light illuminate brightly and flash on and off?

Ye s>>

Go To 4

No>>

Go To 6

4.(G303) FRONT AXLE LOCK SIGNAL CIRCUIT

Turn the ignition off to the lock position.

Connect the FAD harness connector.

Using a 12-volt test light connected to ground, backprobe the (G303)

Front Axle Lock Signal circuit in the TIPM C4 harness connector.

Ignition on, engine not running.

With the scan tool, actuate the Front Axle Lock in the TIPM.

Does the test light illuminate brightly?

Ye s>>

Go To 8

No>>

Go To 5

Page 4609 of 5267

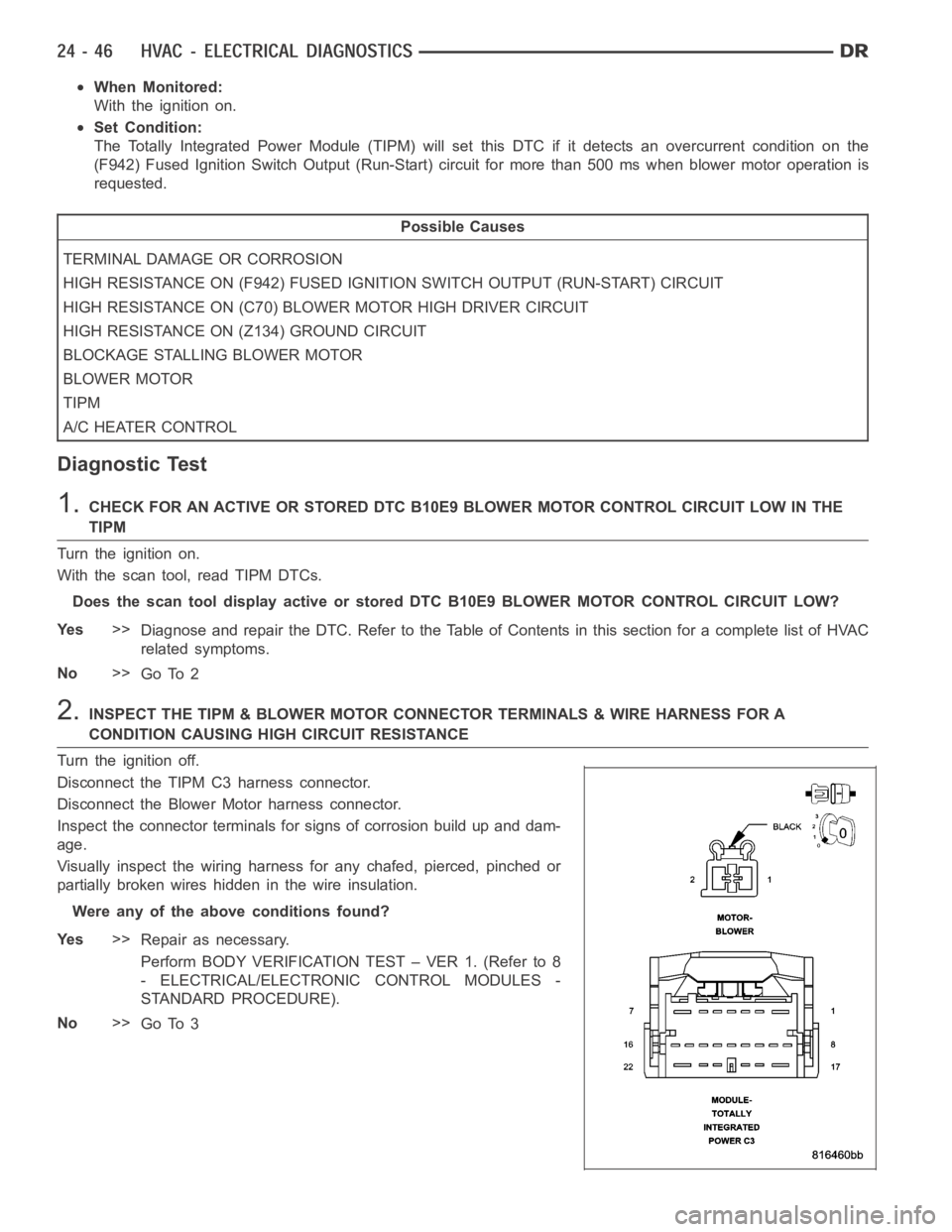

1 - MECHANISM COVERS (2) 10 - MOTOR FASTENERS (3)

2 - RIGHT HAND GLASS GUIDE 11 - SUNROOF MOTOR/MODULE ASSEMBLY

3 - GLASS FASTENERS (4) 12 - ALIGNMENT HOLE

4 - GLASS ASSEMBLY 13 - TRIM RING

5 - DRAIN CHANNEL 14 - ASSEMBLY FASTENERS (8)

6 - SUNSHADE 15 - ALIGNMENT HOLE

7 - LEFT SUNROOF GLASS GUIDE 16 - WIND DEFLECTOR

8 - WIRE HARNESS 17 - GLASS GUIDE FOOT

9 - SUNROOF ASSEMBLY 18 - WIND DEFLECTOR STRAP SCREWS (2)

The power sunroof system allows the sunroof to be opened, closed or placed in the vent position electrically by

actuating a switch in the overhead console. The sunroof system receives battery feed through a fuse in the Power

Distribution Center (PDC). The sunroof will operate normally with the keyin any position while the Accessory Delay

system is active.

The sunroof glass panel tilts upward at the rear for ventilation and slidesrearward under the roof when open. The

panel seals flush with the roof in the closed position to eliminate wind noise. The sunroof includes a manual-sliding

sunshade to cover the deep-tinted glass panel.

In addition to the standard power sunroof operation, this vehicle offers several additional features. There is an

express (one-touch) opening and closing feature as well as Excessive Force Limitation (EFL). The EFL function

detects obstacles trapped between the glass and the vehicle roof during a closing motion. Upon sensing an obstacle

the EFL function will reverse direction of the glass to allow removal of theobstacle.

The main components of thepower sunroof system are:

The motor/module assembly

The power sunroof glass and frame assembly

The power sunroof switch

The manual-sliding sunshade

OPERATION

This vehicle has a vent, tilt and slide power sunroof system with express (one-touch) open and closing feature. The

sunroof system receives constant battery feed through a fuse in the Power Distribution Center (PDC). The sunroof

will operate normally with the key in any position while the Accessory Delay system is active. If the sunroof is mov-

ing when the key is turned to the START position (crank engine), all motionsstop until the key is released, then the

previously requested sunroof motion will resume. The sunroof will also complete a requested motion if the Acces-

sory Delay system goes inactivewhile the motion is in progress.

A combination push-button and rocker switch module mounted in the overhead console controls sunroof operation.

The sunroof switch is a rocker design with a push button in the center of the two halves of the rocker. Pressing the

rocker towards the front of the car commands the sunroof closed. Pressing the rocker towards the rear of the car

commands the sunroof open. Pressing the center push button commands the sunroof up into the vent position

(Rear of sunroof glass raises above the vehicle roof with glass still covering the sunroof opening). All switch com-

mands operate with the glass startingin any position. (Refer to 8 - ELECTRICAL/POWER TOP/SWITCH - OPER-

ATION) for additional information.

An electronic control system, integralto the motor/module assembly, provides the express open and close functions.

Pressing the

openorcloseend of the rocker switch moves the sunroof glass panel to the full open or fullclosed

position, respectively. During express closing, anytime an obstacle is detected in the way of the glass, the motor will

stop and reverse travel to avoid pinching an occupant’s finger, ice in the track, etc. This function is called Excessive

Force Limitation (EFL). There are two methods of overriding the EFL function.

1. When three EFL events occur without the glass being allowed to fully close, the next close attempt will only

move while the close switch is continuously actuated. This allows the sunrooftobeforcedclosedifmultipleclose

attempts fail.

2. If the sunroof close switch is continuously actuated during an EFL event, through the reversal, and during a two

second wait time, then continuing to hold the close switch will cause the roof to move towards close with the EFL

protection disabled. This allows the sunroof to be forced closed if it is known that a reversal will occur.

While in EFL override, the closing motion will cease if the sunroof switch is released at any time.

Page 4887 of 5267

When Monitored:

With the ignition on.

Set Condition:

The Totally Integrated Power Module (TIPM) will set this DTC if it detects an overcurrent condition on the

(F942) Fused Ignition Switch Output (Run-Start) circuit for more than 500ms when blower motor operation is

requested.

Possible Causes

TERMINAL DAMAGE OR CORROSION

HIGH RESISTANCE ON (F942) FUSED IGNITION SWITCH OUTPUT (RUN-START) CIRCUIT

HIGH RESISTANCE ON (C70) BLOWER MOTOR HIGH DRIVER CIRCUIT

HIGH RESISTANCE ON (Z134) GROUND CIRCUIT

BLOCKAGE STALLING BLOWER MOTOR

BLOWER MOTOR

TIPM

A/C HEATER CONTROL

Diagnostic Test

1.CHECK FOR AN ACTIVE OR STORED DTC B10E9 BLOWER MOTOR CONTROL CIRCUIT LOW IN THE

TIPM

Turn the ignition on.

With the scan tool, read TIPM DTCs.

Does the scan tool display active or stored DTC B10E9 BLOWER MOTOR CONTROL CIRCUIT LOW?

Ye s>>

Diagnose and repair the DTC. Refer to the Table of Contents in this section for a complete list of HVAC

related symptoms.

No>>

Go To 2

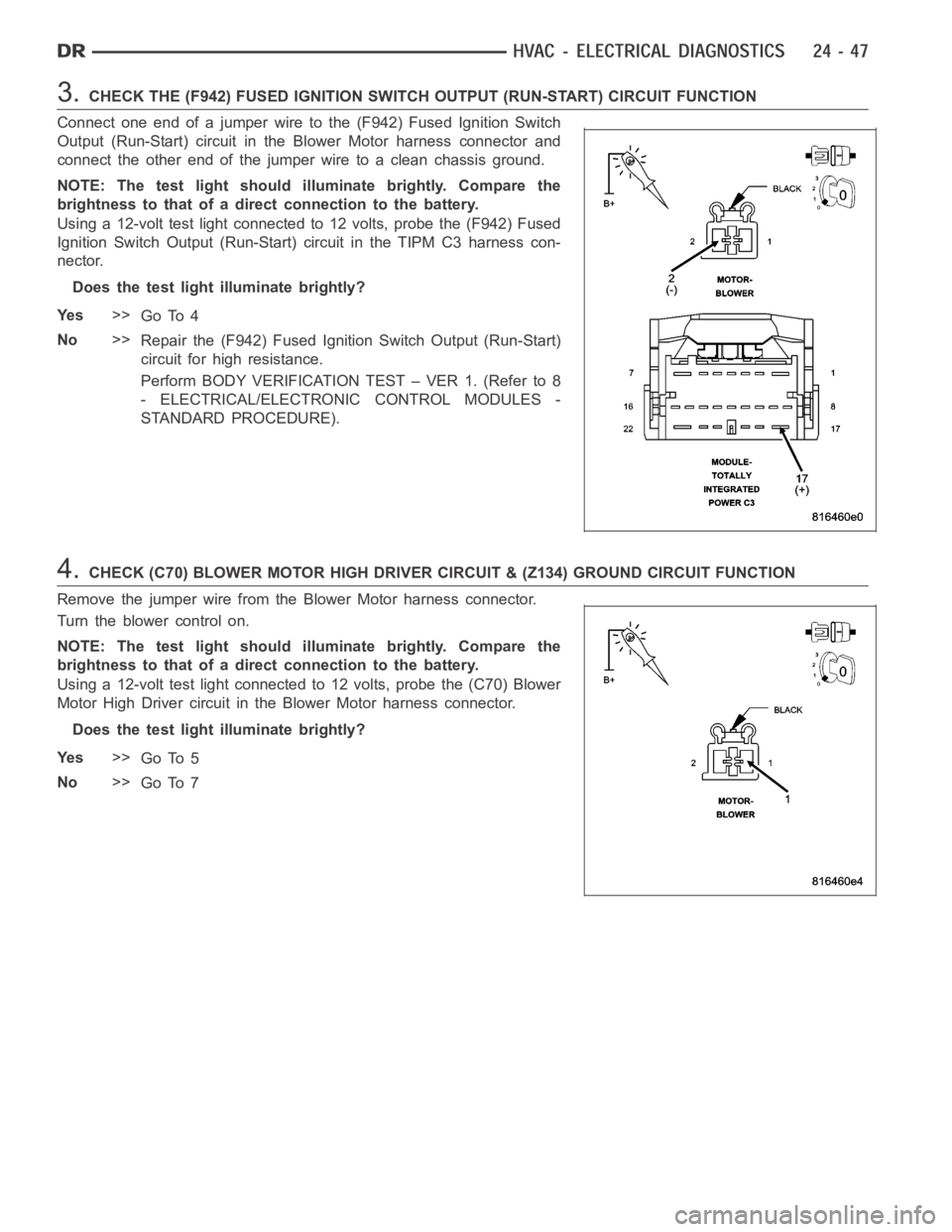

2.INSPECT THE TIPM & BLOWER MOTOR CONNECTOR TERMINALS & WIRE HARNESS FOR A

CONDITION CAUSING HIGH CIRCUIT RESISTANCE

Turn the ignition off.

Disconnect the TIPM C3 harness connector.

Disconnect the Blower Motor harness connector.

Inspect the connector terminals for signs of corrosion build up and dam-

age.

Visually inspect the wiring harness for any chafed, pierced, pinched or

partially broken wires hidden in the wire insulation.

Were any of the above conditions found?

Ye s>>

Repair as necessary.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE).

No>>

Go To 3

Page 4888 of 5267

3.CHECK THE (F942) FUSED IGNITION SWITCH OUTPUT (RUN-START) CIRCUIT FUNCTION

Connect one end of a jumper wire to the (F942) Fused Ignition Switch

Output (Run-Start) circuit in the Blower Motor harness connector and

connect the other end of the jumper wire to a clean chassis ground.

NOTE: The test light should illuminate brightly. Compare the

brightness to that of a direct connection to the battery.

Using a 12-volt test light connected to 12 volts, probe the (F942) Fused

Ignition Switch Output (Run-Start) circuit in the TIPM C3 harness con-

nector.

Does the test light illuminate brightly?

Ye s>>

Go To 4

No>>

Repair the (F942) Fused Ignition Switch Output (Run-Start)

circuit for high resistance.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE).

4.CHECK (C70) BLOWER MOTOR HIGH DRIVER CIRCUIT & (Z134) GROUND CIRCUIT FUNCTION

Remove the jumper wire from the Blower Motor harness connector.

Turn the blower control on.

NOTE: The test light should illuminate brightly. Compare the

brightness to that of a direct connection to the battery.

Using a 12-volt test light connected to 12 volts, probe the (C70) Blower

Motor High Driver circuit in the Blower Motor harness connector.

Does the test light illuminate brightly?

Ye s>>

Go To 5

No>>

Go To 7

Page 4889 of 5267

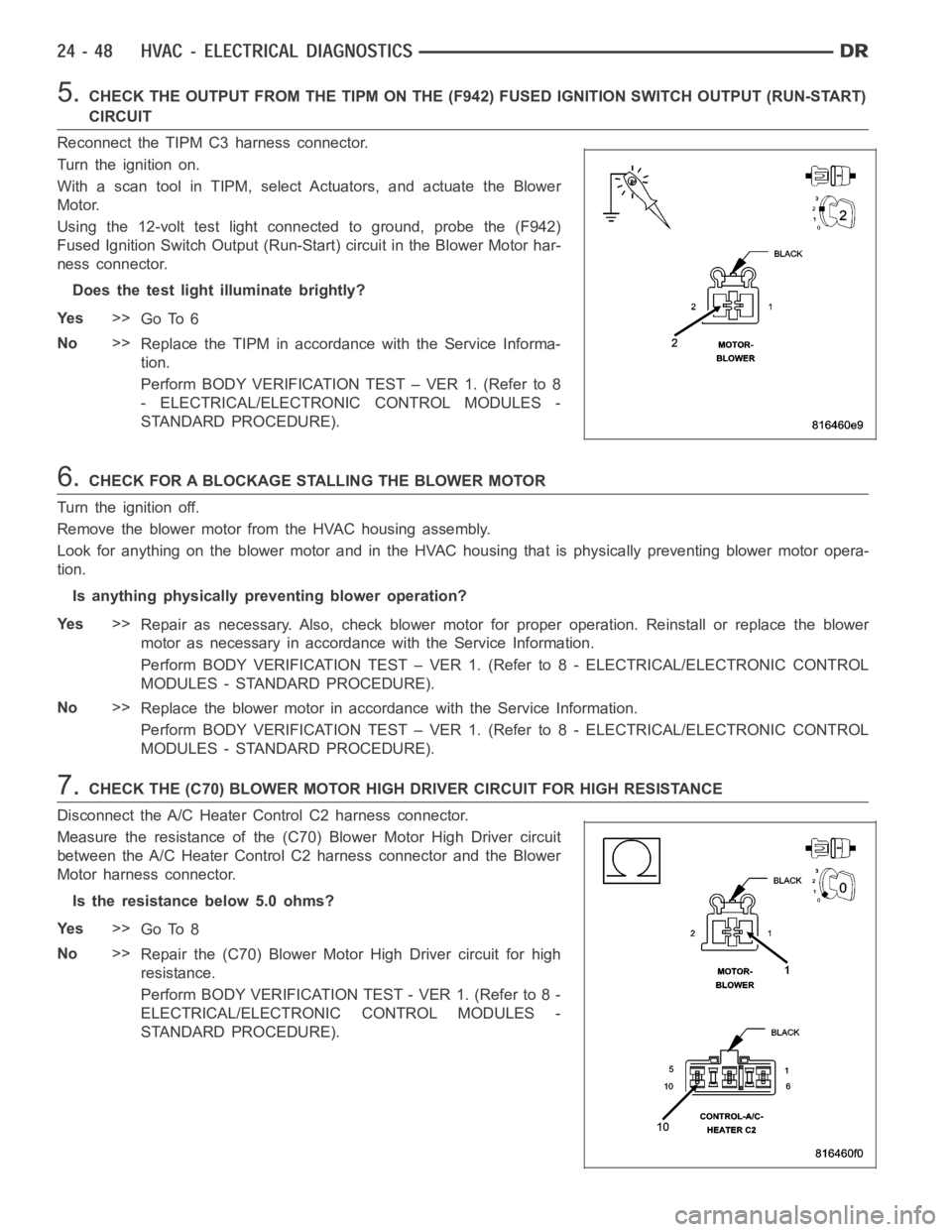

5.CHECK THE OUTPUT FROM THE TIPM ON THE (F942) FUSED IGNITION SWITCH OUTPUT (RUN-START)

CIRCUIT

Reconnect the TIPM C3 harness connector.

Turn the ignition on.

With a scan tool in TIPM, select Actuators, and actuate the Blower

Motor.

Using the 12-volt test light connected to ground, probe the (F942)

Fused Ignition Switch Output (Run-Start) circuit in the Blower Motor har-

ness connector.

Does the test light illuminate brightly?

Ye s>>

Go To 6

No>>

Replace the TIPM in accordance with the Service Informa-

tion.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE).

6.CHECK FOR A BLOCKAGE STALLING THE BLOWER MOTOR

Turn the ignition off.

Remove the blower motor from the HVAC housing assembly.

Look for anything on the blower motor and in the HVAC housing that is physically preventing blower motor opera-

tion.

Is anything physically preventing blower operation?

Ye s>>

Repair as necessary. Also, check blower motor for proper operation. Reinstall or replace the blower

motor as necessary in accordancewith the Service Information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

No>>

Replace the blower motor in accordance with the Service Information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

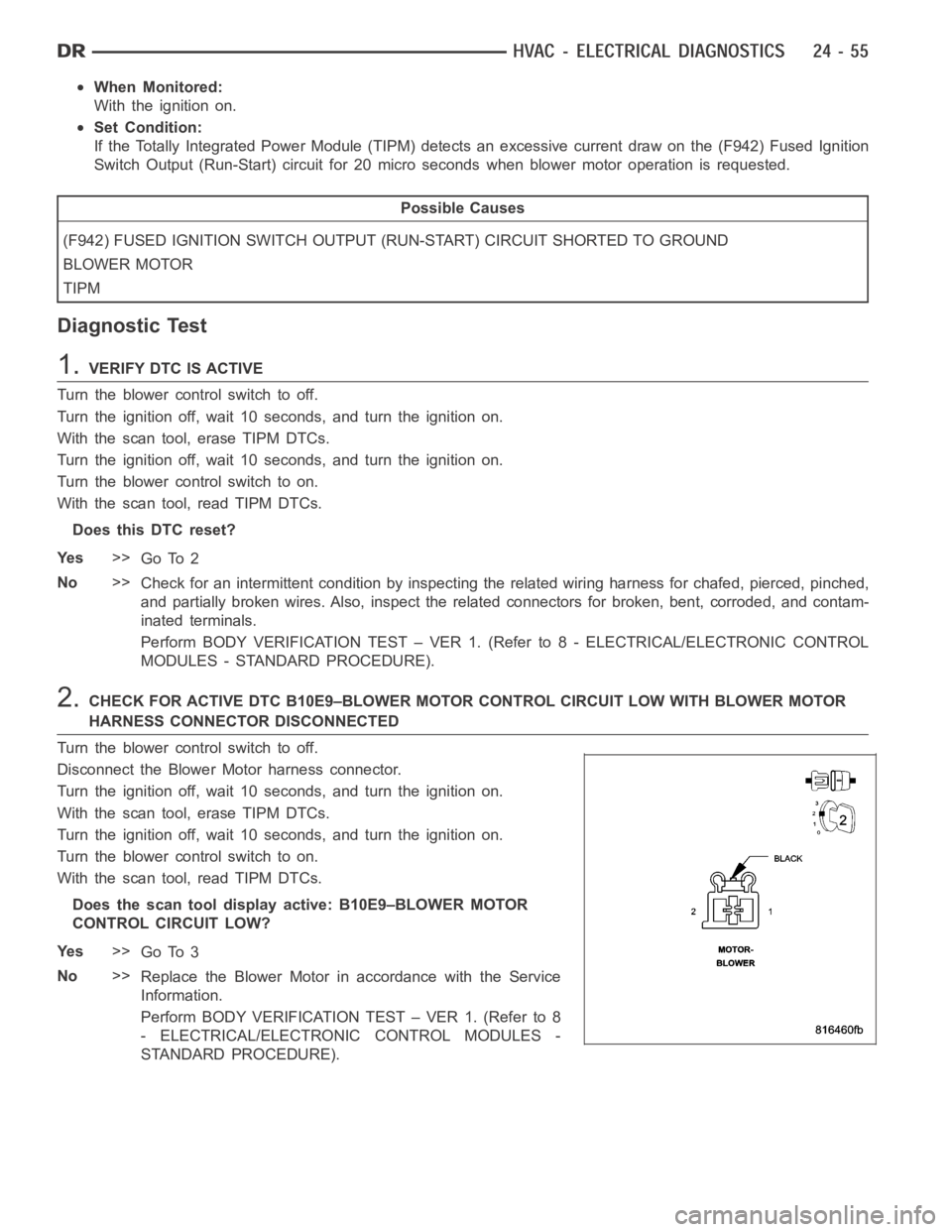

7.CHECK THE (C70) BLOWER MOTOR HIGH DRIVER CIRCUIT FOR HIGH RESISTANCE

Disconnect the A/C Heater Control C2 harness connector.

Measure the resistance of the (C70) Blower Motor High Driver circuit

between the A/C Heater Control C2 harness connector and the Blower

Motor harness connector.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 8

No>>

Repair the (C70) Blower Motor High Driver circuit for high

resistance.

Perform BODY VERIFICATION TEST - VER 1. (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE).

Page 4896 of 5267

When Monitored:

With the ignition on.

Set Condition:

If the Totally Integrated Power Module (TIPM) detects an excessive current draw on the (F942) Fused Ignition

Switch Output (Run-Start) circuit for 20 micro seconds when blower motor operation is requested.

Possible Causes

(F942) FUSED IGNITION SWITCH OUTPUT (RUN-START) CIRCUIT SHORTED TO GROUND

BLOWER MOTOR

TIPM

Diagnostic Test

1.VERIFY DTC IS ACTIVE

Turn the blower control switch to off.

Turn the ignition off, wait 10 seconds, and turn the ignition on.

With the scan tool, erase TIPM DTCs.

Turn the ignition off, wait 10 seconds, and turn the ignition on.

Turn the blower control switch to on.

With the scan tool, read TIPM DTCs.

Does this DTC reset?

Ye s>>

Go To 2

No>>

Check for an intermittent condition by inspecting the related wiring harness for chafed, pierced, pinched,

and partially broken wires. Also, inspect the related connectors for broken, bent, corroded, and contam-

inated terminals.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES - STANDARD PROCEDURE).

2.CHECK FOR ACTIVE DTC B10E9–BLOWER MOTOR CONTROL CIRCUIT LOW WITH BLOWER MOTOR

HARNESS CONNECTOR DISCONNECTED

Turn the blower control switch to off.

Disconnect the Blower Motor harness connector.

Turn the ignition off, wait 10 seconds, and turn the ignition on.

With the scan tool, erase TIPM DTCs.

Turn the ignition off, wait 10 seconds, and turn the ignition on.

Turn the blower control switch to on.

With the scan tool, read TIPM DTCs.

Does the scan tool display active: B10E9–BLOWER MOTOR

CONTROL CIRCUIT LOW?

Ye s>>

Go To 3

No>>

Replace the Blower Motor in accordance with the Service

Information.

Perform BODY VERIFICATION TEST – VER 1. (Refer to 8

- ELECTRICAL/ELECTRONIC CONTROL MODULES -

STANDARD PROCEDURE).