lock DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1621 of 5267

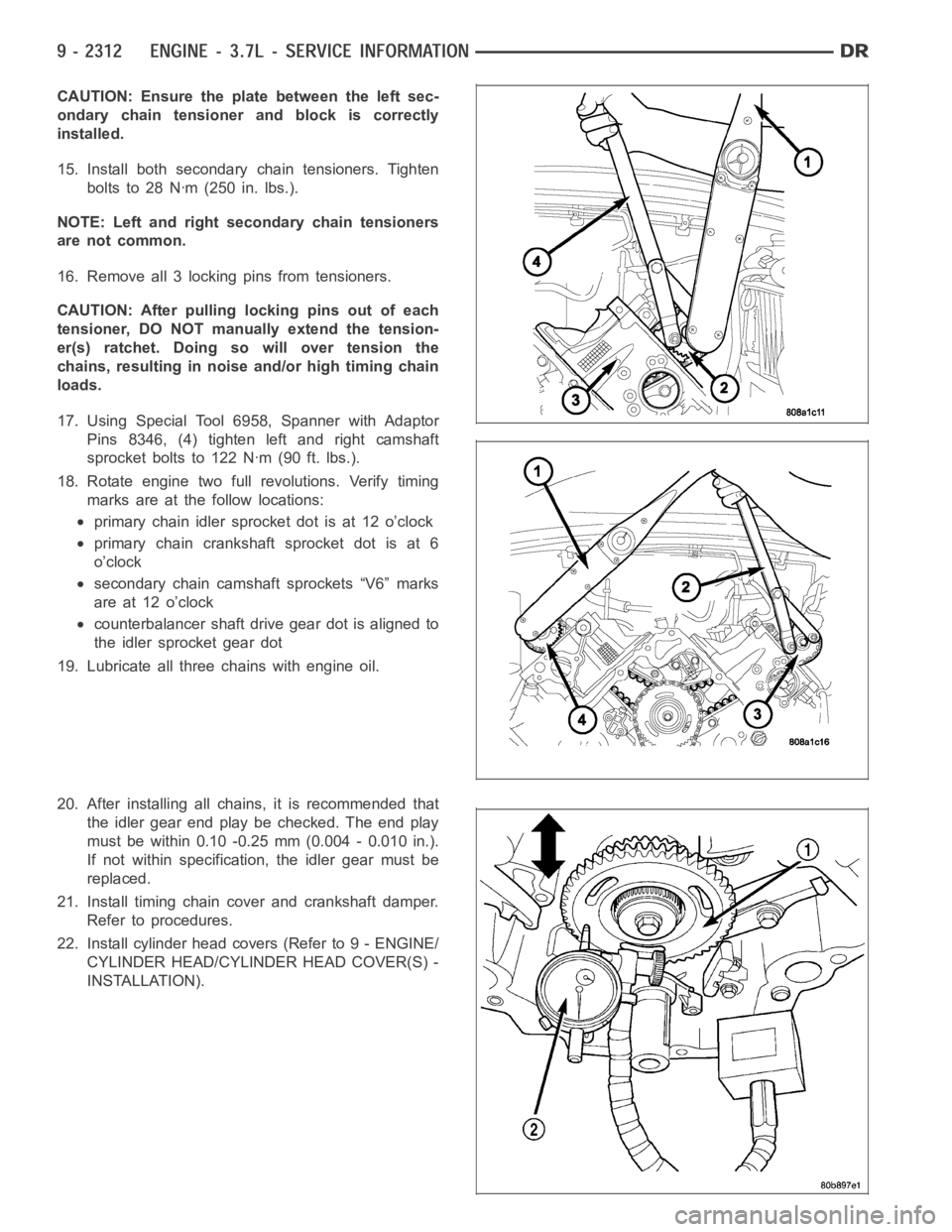

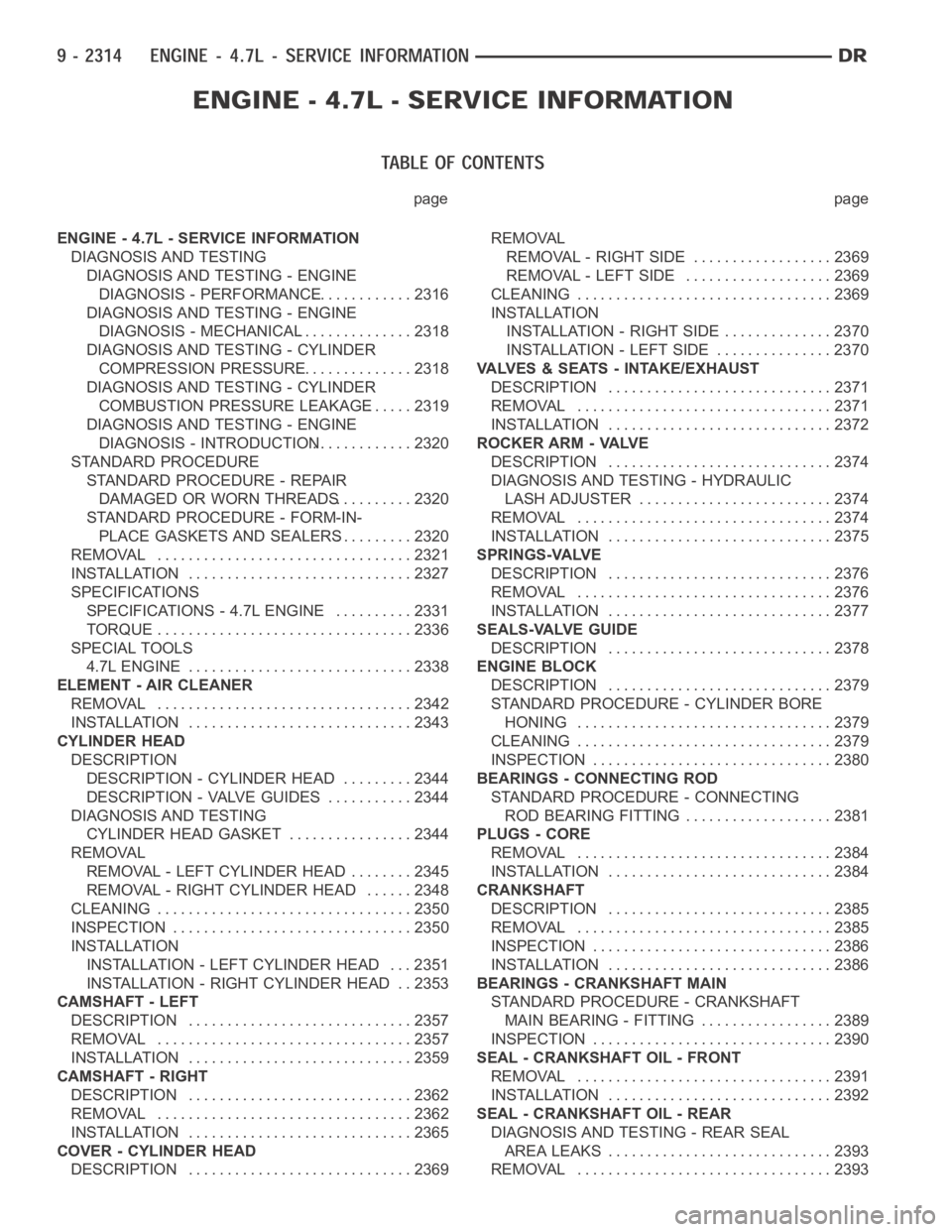

CAUTION: Ensure the plate between the left sec-

ondary chain tensioner and block is correctly

installed.

15. Install both secondary chain tensioners. Tighten

boltsto28Nꞏm(250in.lbs.).

NOTE: Left and right secondary chain tensioners

are not common.

16. Remove all 3 locking pins from tensioners.

CAUTION: After pulling locking pins out of each

tensioner, DO NOT manually extend the tension-

er(s) ratchet. Doing so will over tension the

chains, resulting in noise and/or high timing chain

loads.

17. Using Special Tool 6958, Spanner with Adaptor

Pins 8346, (4) tighten left and right camshaft

sprocket bolts to 122 Nꞏm (90 ft. lbs.).

18. Rotate engine two full revolutions. Verify timing

marks are at the follow locations:

primary chain idler sprocket dot is at 12 o’clock

primary chain crankshaft sprocket dot is at 6

o’clock

secondary chain camshaft sprockets “V6” marks

are at 12 o’clock

counterbalancer shaft drive gear dot is aligned to

the idler sprocket gear dot

19. Lubricate all three chains with engine oil.

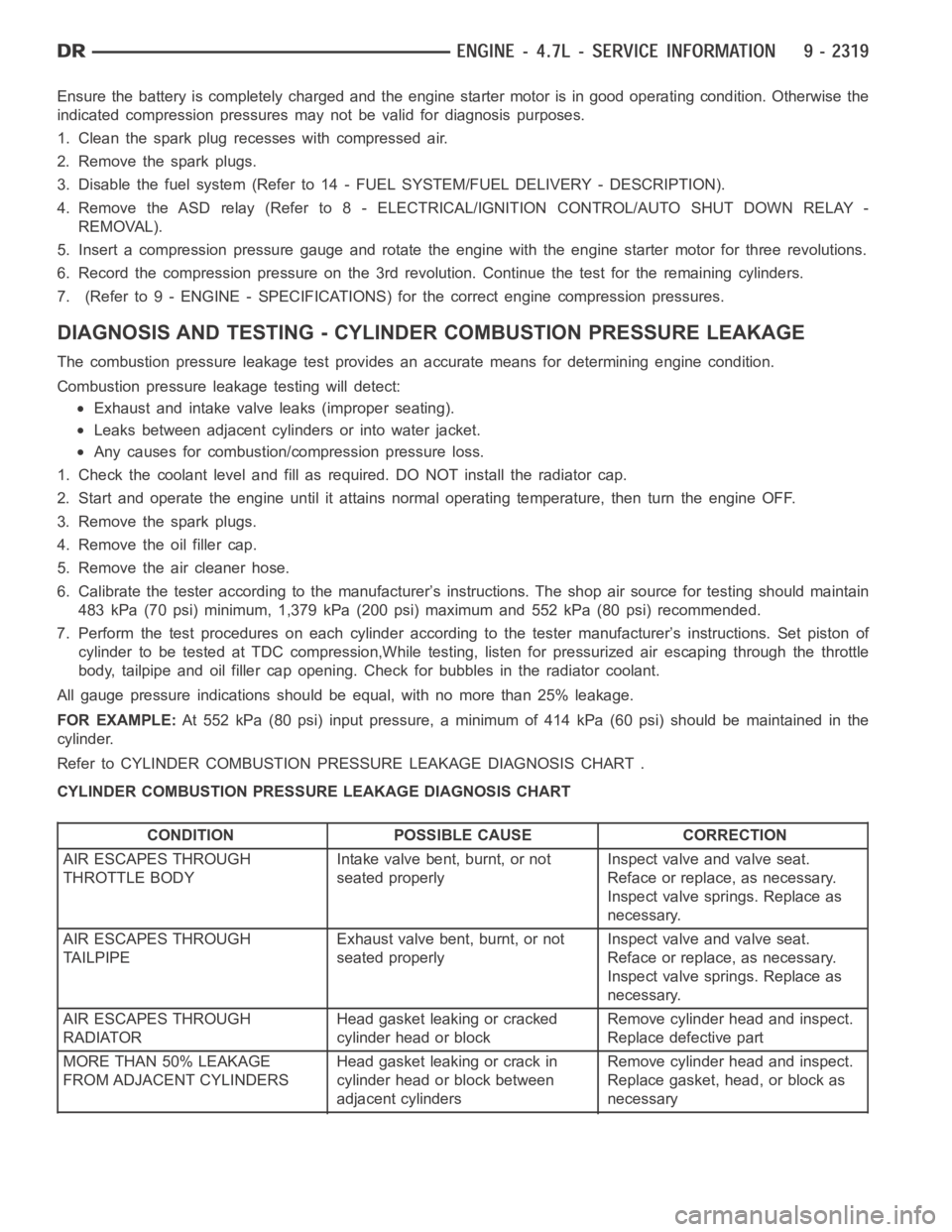

20. After installing all chains, it is recommended that

the idler gear end play be checked. The end play

must be within 0.10 -0.25 mm (0.004 - 0.010 in.).

If not within specification, the idler gear must be

replaced.

21. Install timing chain cover and crankshaft damper.

Refer to procedures.

22. Install cylinder head covers (Refer to 9 - ENGINE/

CYLINDER HEAD/CYLINDER HEAD COVER(S) -

INSTALLATION).

Page 1623 of 5267

page page

ENGINE - 4.7L - SERVICE INFORMATION

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - PERFORMANCE............. 2316

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - MECHANICAL............... 2318

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION PRESSURE............... 2318

DIAGNOSIS AND TESTING - CYLINDER

COMBUSTION PRESSURE LEAKAGE...... 2319

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - INTRODUCTION............. 2320

STANDARD PROCEDURE

STANDARD PROCEDURE - REPAIR

DAMAGED OR WORN THREADS.......... 2320

STANDARD PROCEDURE - FORM-IN-

PLACE GASKETS AND SEALERS.......... 2320

REMOVAL ................................. 2321

INSTALLATION ............................. 2327

SPECIFICATIONS

SPECIFICATIONS - 4.7L ENGINE .......... 2331

TORQUE ................................. 2336

SPECIAL TOOLS

4.7L ENGINE ............................. 2338

ELEMENT - AIR CLEANER

REMOVAL ................................. 2342

INSTALLATION ............................. 2343

CYLINDER HEAD

DESCRIPTION

DESCRIPTION - CYLINDER HEAD ......... 2344

DESCRIPTION - VALVE GUIDES ........... 2344

DIAGNOSIS AND TESTING

CYLINDER HEAD GASKET................ 2344

REMOVAL

REMOVAL - LEFT CYLINDER HEAD ........ 2345

REMOVAL - RIGHT CYLINDER HEAD ...... 2348

CLEANING ................................. 2350

INSPECTION ............................... 2350

INSTALLATION

INSTALLATION - LEFT CYLINDER HEAD . . . 2351

INSTALLATION - RIGHT CYLINDER HEAD . . 2353

CAMSHAFT - LEFT

DESCRIPTION ............................. 2357

REMOVAL ................................. 2357

INSTALLATION ............................. 2359

CAMSHAFT - RIGHT

DESCRIPTION ............................. 2362

REMOVAL ................................. 2362

INSTALLATION ............................. 2365

COVER - CYLINDER HEAD

DESCRIPTION ............................. 2369REMOVAL

REMOVAL - RIGHT SIDE .................. 2369

REMOVAL - LEFT SIDE ................... 2369

CLEANING ................................. 2369

INSTALLATION

INSTALLATION - RIGHT SIDE .............. 2370

INSTALLATION - LEFT SIDE ............... 2370

VALVES & SEATS - INTAKE/EXHAUST

DESCRIPTION ............................. 2371

REMOVAL ................................. 2371

INSTALLATION ............................. 2372

ROCKER ARM - VALVE

DESCRIPTION ............................. 2374

DIAGNOSIS AND TESTING - HYDRAULIC

LASH ADJUSTER ......................... 2374

REMOVAL ................................. 2374

INSTALLATION ............................. 2375

SPRINGS-VALVE

DESCRIPTION ............................. 2376

REMOVAL ................................. 2376

INSTALLATION ............................. 2377

SEALS-VALVE GUIDE

DESCRIPTION ............................. 2378

ENGINE BLOCK

DESCRIPTION ............................. 2379

STANDARD PROCEDURE - CYLINDER BORE

HONING ................................. 2379

CLEANING ................................. 2379

INSPECTION............................... 2380

BEARINGS - CONNECTING ROD

STANDARD PROCEDURE - CONNECTING

ROD BEARING FITTING ................... 2381

PLUGS - CORE

REMOVAL ................................. 2384

INSTALLATION ............................. 2384

CRANKSHAFT

DESCRIPTION ............................. 2385

REMOVAL ................................. 2385

INSPECTION............................... 2386

INSTALLATION ............................. 2386

BEARINGS - CRANKSHAFT MAIN

STANDARD PROCEDURE - CRANKSHAFT

MAIN BEARING - FITTING ................. 2389

INSPECTION............................... 2390

SEAL - CRANKSHAFT OIL - FRONT

REMOVAL ................................. 2391

INSTALLATION ............................. 2392

SEAL - CRANKSHAFT OIL - REAR

DIAGNOSIS AND TESTING - REAR SEAL

AREA LEAKS . ............................ 2393

REMOVAL ................................. 2393

Page 1628 of 5267

Ensurethebatteryiscompletelychargedandtheenginestartermotorisingood operating condition. Otherwise the

indicated compression pressures may not be valid for diagnosis purposes.

1. Clean the spark plug recesses with compressed air.

2. Remove the spark plugs.

3. Disable the fuel system (Refer to 14 - FUEL SYSTEM/FUEL DELIVERY - DESCRIPTION).

4. Remove the ASD relay (Refer to 8 - ELECTRICAL/IGNITION CONTROL/AUTO SHUTDOWNRELAY-

REMOVAL).

5. Insert a compression pressure gauge and rotate the engine with the engine starter motor for three revolutions.

6. Record the compression pressure on the 3rd revolution. Continue the test for the remaining cylinders.

7. (Refer to 9 - ENGINE - SPECIFICATIONS) for the correct engine compression pressures.

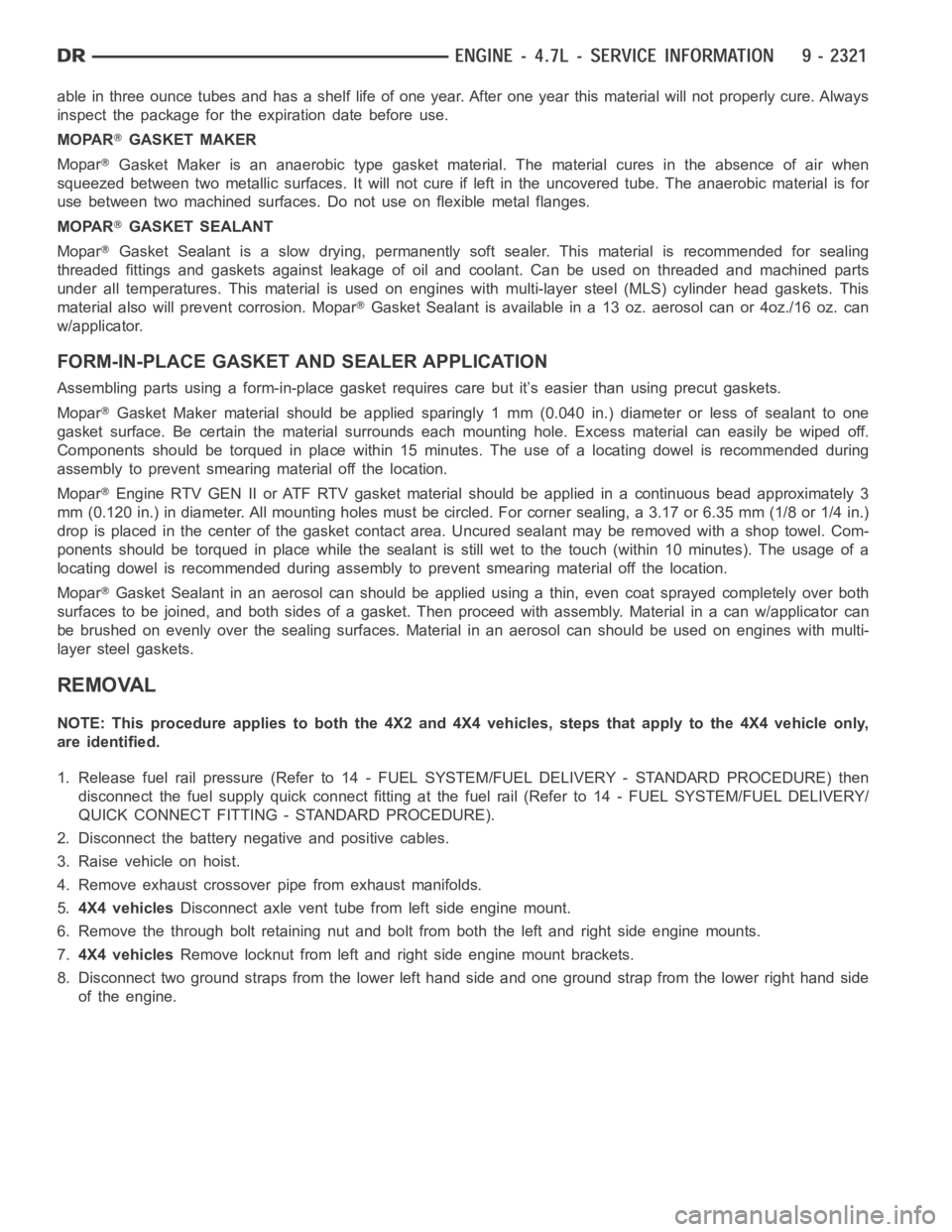

DIAGNOSIS AND TESTING - CYLINDERCOMBUSTION PRESSURE LEAKAGE

The combustion pressure leakage test provides an accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

Exhaust and intake valve leaks (improper seating).

Leaks between adjacent cylinders or into water jacket.

Any causes for combustion/compression pressure loss.

1. Check the coolant level and fill as required. DO NOT install the radiatorcap.

2. Start and operate the engine until it attains normal operating temperature, then turn the engine OFF.

3. Remove the spark plugs.

4. Remove the oil filler cap.

5. Remove the air cleaner hose.

6. Calibrate the tester according to the manufacturer’s instructions. The shop air source for testing should maintain

483 kPa (70 psi) minimum, 1,379 kPa (200 psi) maximum and 552 kPa (80 psi) recommended.

7. Perform the test procedures on each cylinder according to the tester manufacturer’s instructions. Set piston of

cylinder to be tested at TDC compression,While testing, listen for pressurized air escaping through the throttle

body, tailpipe and oil filler cap opening. Check for bubbles in the radiator coolant.

All gauge pressure indications should be equal, with no more than 25% leakage.

FOR EXAMPLE:At 552 kPa (80 psi) input pressure, a minimum of 414 kPa (60 psi) should be maintained in the

cylinder.

Refer to CYLINDER COMBUSTION PRESSURE LEAKAGE DIAGNOSIS CHART .

CYLINDER COMBUSTION PRESSURE LEAKAGE DIAGNOSIS CHART

CONDITION POSSIBLE CAUSE CORRECTION

AIR ESCAPES THROUGH

THROTTLE BODYIntake valve bent, burnt, or not

seated properlyInspect valve and valve seat.

Reface or replace, as necessary.

Inspect valve springs. Replace as

necessary.

AIR ESCAPES THROUGH

TAILPIPEExhaust valve bent, burnt, or not

seated properlyInspect valve and valve seat.

Reface or replace, as necessary.

Inspect valve springs. Replace as

necessary.

AIR ESCAPES THROUGH

RADIATORHead gasket leaking or cracked

cylinder head or blockRemove cylinder head and inspect.

Replace defective part

MORE THAN 50% LEAKAGE

FROM ADJACENT CYLINDERSHead gasket leaking or crack in

cylinder head or block between

adjacent cylindersRemove cylinder head and inspect.

Replace gasket, head, or block as

necessary

Page 1630 of 5267

able in three ounce tubes and has a shelf life of one year. After one year thismaterial will not properly cure. Always

inspect the package for the expiration date before use.

MOPAR

GASKET MAKER

Mopar

Gasket Maker is an anaerobic type gasket material. The material cures in the absence of air when

squeezed between two metallic surfaces. It will not cure if left in the uncovered tube. The anaerobic material is for

use between two machined surfaces. Do not use on flexible metal flanges.

MOPAR

GASKET SEALANT

Mopar

Gasket Sealant is a slow drying, permanently soft sealer. This material isrecommended for sealing

threaded fittings and gaskets against leakage of oil and coolant. Can be used on threaded and machined parts

under all temperatures. This material is used on engines with multi-layersteel (MLS) cylinder head gaskets. This

material also will prevent corrosion. Mopar

Gasket Sealant is available in a 13 oz. aerosol can or 4oz./16 oz. can

w/applicator.

FORM-IN-PLACE GASKET AND SEALER APPLICATION

Assembling parts using a form-in-place gasket requires care but it’s easier than using precut gaskets.

Mopar

Gasket Maker material should be applied sparingly 1 mm (0.040 in.) diameter or less of sealant to one

gasket surface. Be certain the material surrounds each mounting hole. Excess material can easily be wiped off.

Components should be torqued in place within 15 minutes. The use of a locating dowel is recommended during

assembly to prevent smearing material off the location.

Mopar

Engine RTV GEN II or ATF RTV gasket material should be applied in a continuous bead approximately 3

mm (0.120 in.) in diameter. All mounting holes must be circled. For corner sealing, a 3.17 or 6.35 mm (1/8 or 1/4 in.)

drop is placed in the center of the gasket contact area. Uncured sealant maybe removed with a shop towel. Com-

ponents should be torqued in place while the sealant is still wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to prevent smearing material off the location.

Mopar

Gasket Sealant in an aerosol can should be applied using a thin, even coat sprayed completely over both

surfaces to be joined, and both sides of a gasket. Then proceed with assembly. Material in a can w/applicator can

be brushed on evenly over the sealing surfaces. Material in an aerosol can shouldbeusedonengineswithmulti-

layer steel gaskets.

REMOVAL

NOTE:Thisprocedureappliestoboththe4X2and4X4vehicles,stepsthatapply to the 4X4 vehicle only,

are identified.

1. Release fuel rail pressure (Refer to 14 - FUEL SYSTEM/FUEL DELIVERY - STANDARD PROCEDURE) then

disconnect the fuel supply quick connect fitting at the fuel rail (Refer to14 - FUEL SYSTEM/FUEL DELIVERY/

QUICK CONNECT FITTING - STANDARD PROCEDURE).

2. Disconnect the battery negative and positive cables.

3. Raise vehicle on hoist.

4. Remove exhaust crossover pipe from exhaust manifolds.

5.4X4 vehiclesDisconnect axle vent tube from left side engine mount.

6. Remove the through bolt retaining nut and bolt from both the left and right side engine mounts.

7.4X4 vehiclesRemove locknut from left and right side engine mount brackets.

8. Disconnect two ground straps from the lower left hand side and one groundstrap from the lower right hand side

of the engine.

Page 1631 of 5267

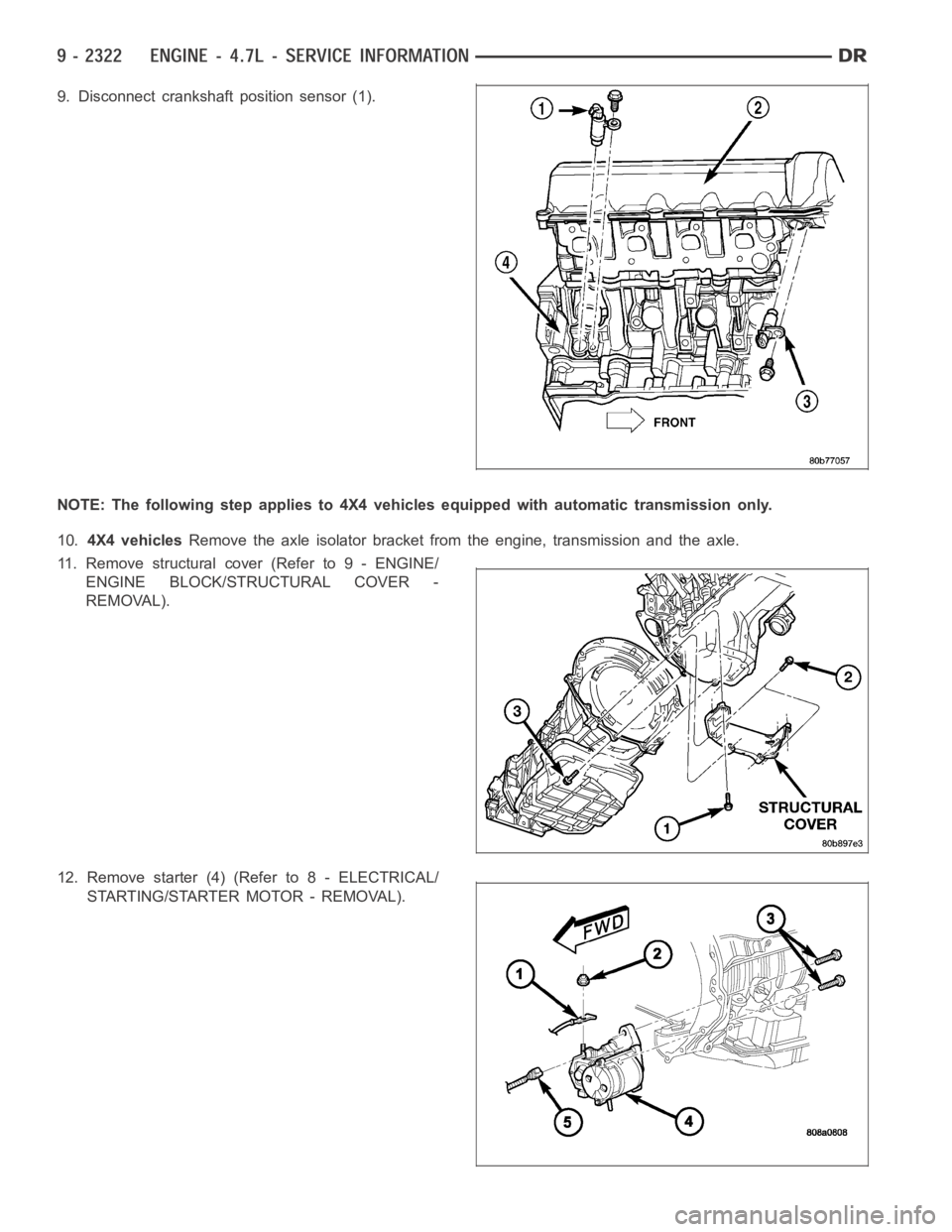

9. Disconnect crankshaft position sensor (1).

NOTE: The following step applies to 4X4vehicles equipped with automatic transmission only.

10.4X4 vehiclesRemove the axle isolator bracket from the engine, transmission and the axle.

11. Remove structural cover (Refer to 9 - ENGINE/

ENGINE BLOCK/STRUCTURAL COVER -

REMOVAL).

12. Remove starter (4) (Refer to 8 - ELECTRICAL/

STARTING/STARTER MOTOR - REMOVAL).

Page 1632 of 5267

13. Drain cooling system (Refer to 7 - COOLING - STANDARD PROCEDURE).

14. Remove torque converter bolts (Automatic Transmission Only).

15. Remove transmission to engine mounting bolts.

16. Disconnect the engine block heater power cable from the block heater, if equipped.

17. Lower vehicle.

18. Remove throttle body resonator assembly and air inlet hose.

19. Disconnect throttle and speed control cables.

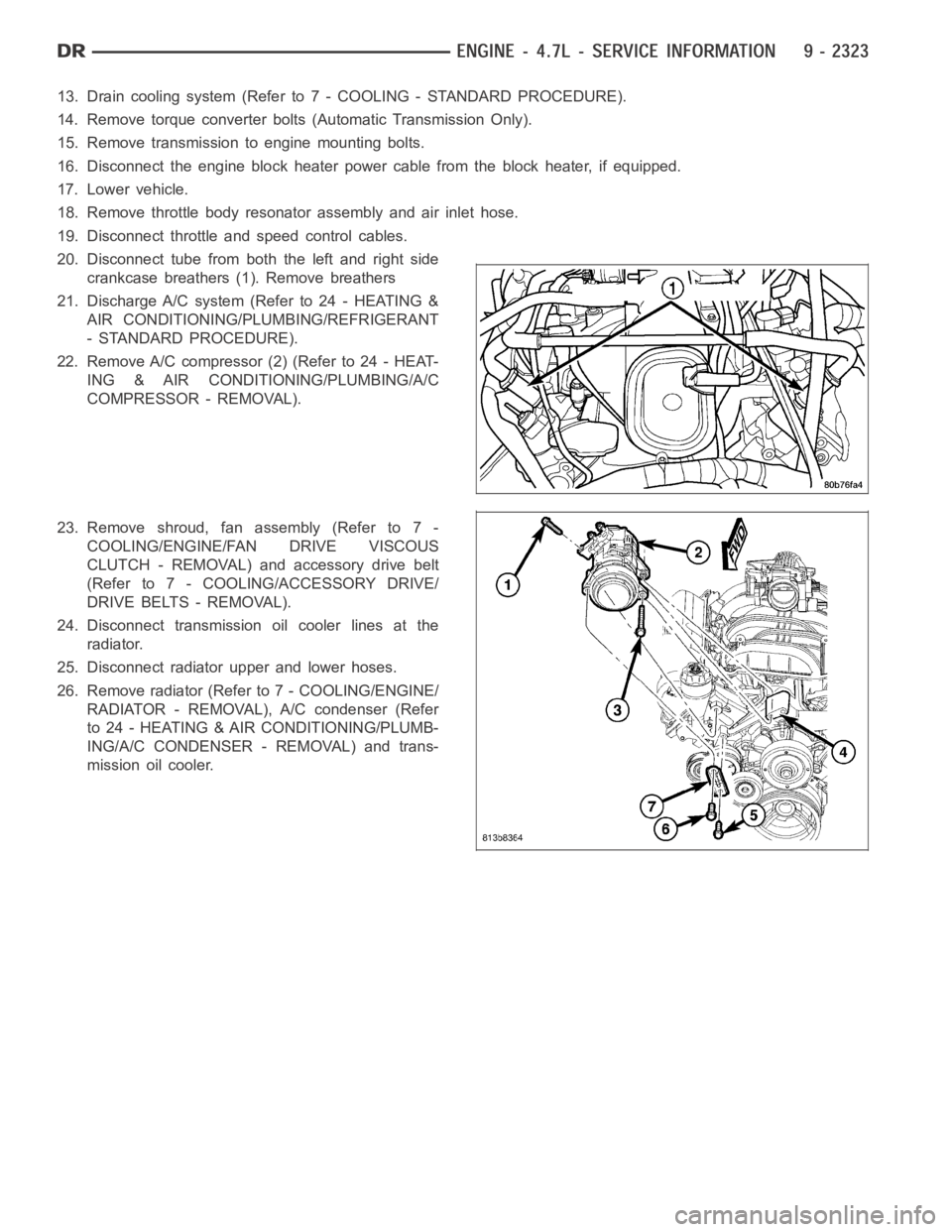

20. Disconnect tube from both the left and right side

crankcase breathers (1). Remove breathers

21. Discharge A/C system (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING/REFRIGERANT

- STANDARD PROCEDURE).

22. Remove A/C compressor (2) (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/A/C

COMPRESSOR - REMOVAL).

23. Remove shroud, fan assembly (Refer to 7 -

COOLING/ENGINE/FAN DRIVE VISCOUS

CLUTCH - REMOVAL) and accessory drive belt

(Refer to 7 - COOLING/ACCESSORY DRIVE/

DRIVE BELTS - REMOVAL).

24. Disconnect transmission oil cooler lines at the

radiator.

25. Disconnect radiator upper and lower hoses.

26. Remove radiator (Refer to 7 - COOLING/ENGINE/

RADIATOR - REMOVAL), A/C condenser (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMB-

ING/A/C CONDENSER - REMOVAL) and trans-

mission oil cooler.

Page 1634 of 5267

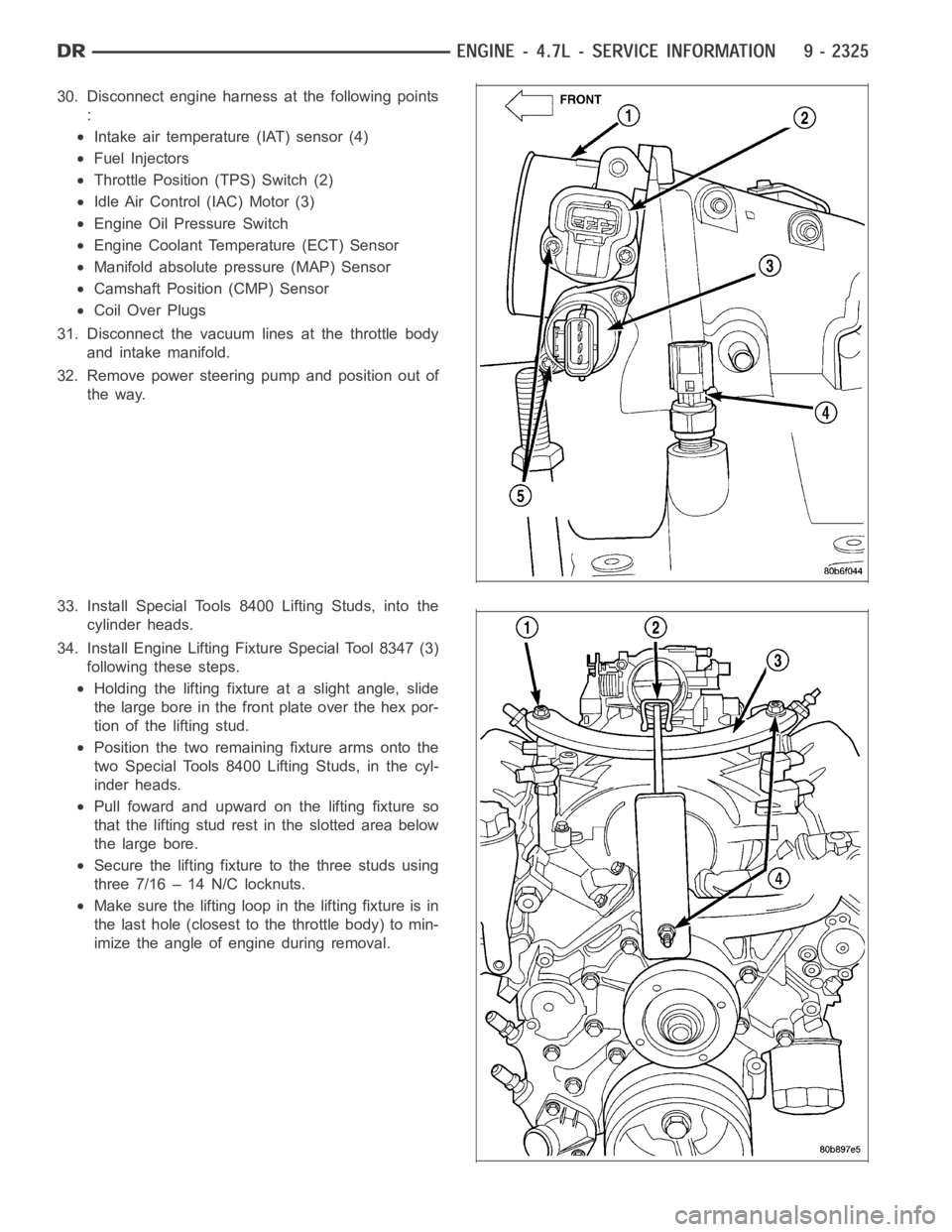

30. Disconnect engine harness at the following points

:

Intake air temperature (IAT) sensor (4)

Fuel Injectors

Throttle Position (TPS) Switch (2)

Idle Air Control (IAC) Motor (3)

Engine Oil Pressure Switch

Engine Coolant Temperature (ECT) Sensor

Manifold absolute pressure (MAP) Sensor

Camshaft Position (CMP) Sensor

Coil Over Plugs

31. Disconnect the vacuum lines at the throttle body

and intake manifold.

32. Remove power steering pump and position out of

the way.

33. Install Special Tools 8400 Lifting Studs, into the

cylinder heads.

34. Install Engine Lifting Fixture Special Tool 8347 (3)

following these steps.

Holding the lifting fixture at a slight angle, slide

the large bore in the front plate over the hex por-

tion of the lifting stud.

Position the two remaining fixture arms onto the

two Special Tools 8400 Lifting Studs, in the cyl-

inder heads.

Pull foward and upward on the lifting fixture so

that the lifting stud rest in the slotted area below

the large bore.

Secure the lifting fixture to the three studs using

three 7/16 – 14 N/C locknuts.

Make sure the lifting loop in the lifting fixture is in

the last hole (closest to the throttle body) to min-

imize the angle of engine during removal.

Page 1636 of 5267

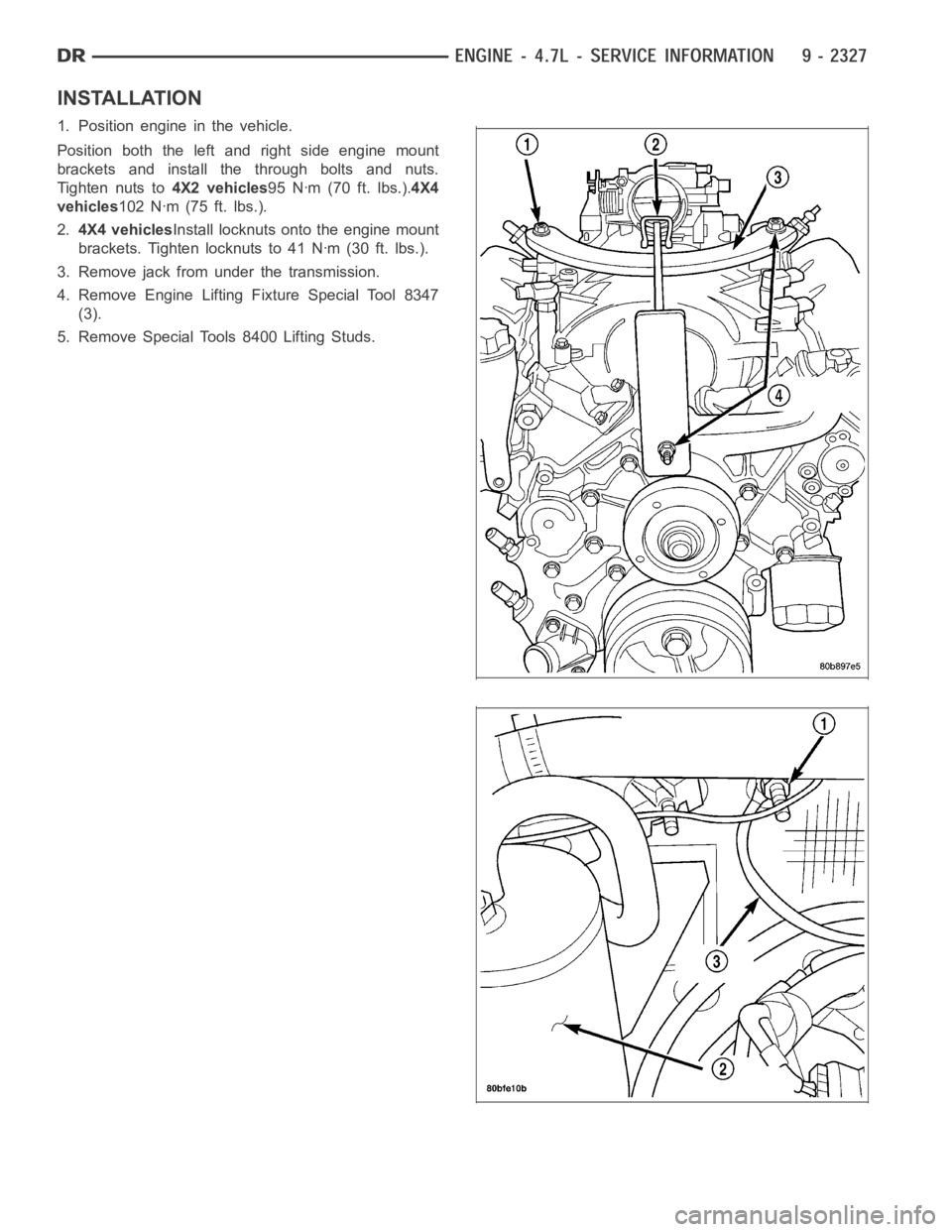

INSTALLATION

1. Position engine in the vehicle.

Position both the left and right side engine mount

brackets and install the through bolts and nuts.

Tighten nuts to4X2 vehicles95 Nꞏm (70 ft. lbs.).4X4

vehicles102Nꞏm(75ft.lbs.).

2.4X4 vehiclesInstall locknuts onto the engine mount

brackets. Tighten locknuts to 41 Nꞏm (30 ft. lbs.).

3. Remove jack from under the transmission.

4. Remove Engine Lifting Fixture Special Tool 8347

(3).

5. Remove Special Tools 8400 Lifting Studs.

Page 1639 of 5267

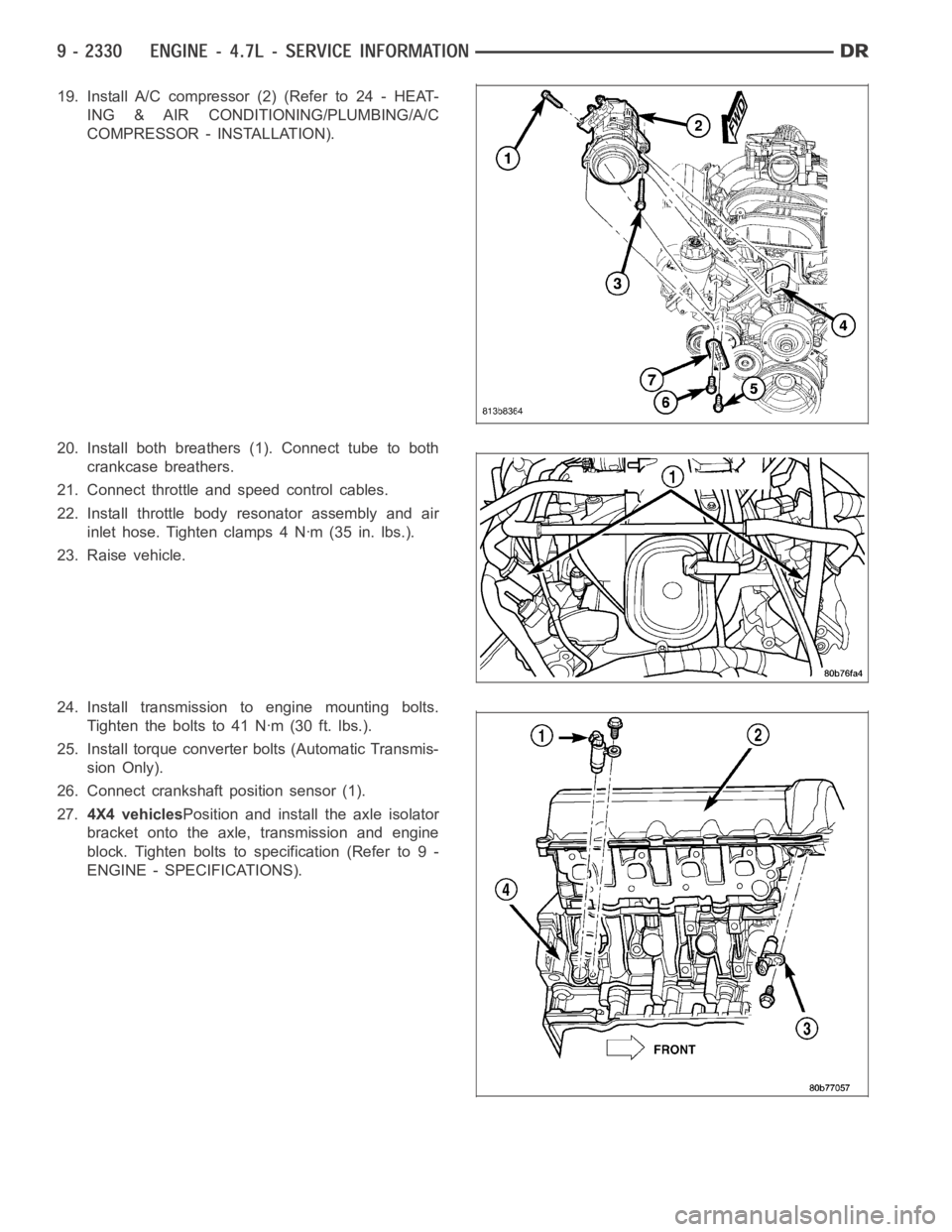

19. Install A/C compressor (2) (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/A/C

COMPRESSOR - INSTALLATION).

20. Install both breathers (1). Connect tube to both

crankcase breathers.

21. Connect throttle and speed control cables.

22. Install throttle body resonator assembly and air

inlet hose. Tighten clamps 4 Nꞏm (35 in. lbs.).

23. Raise vehicle.

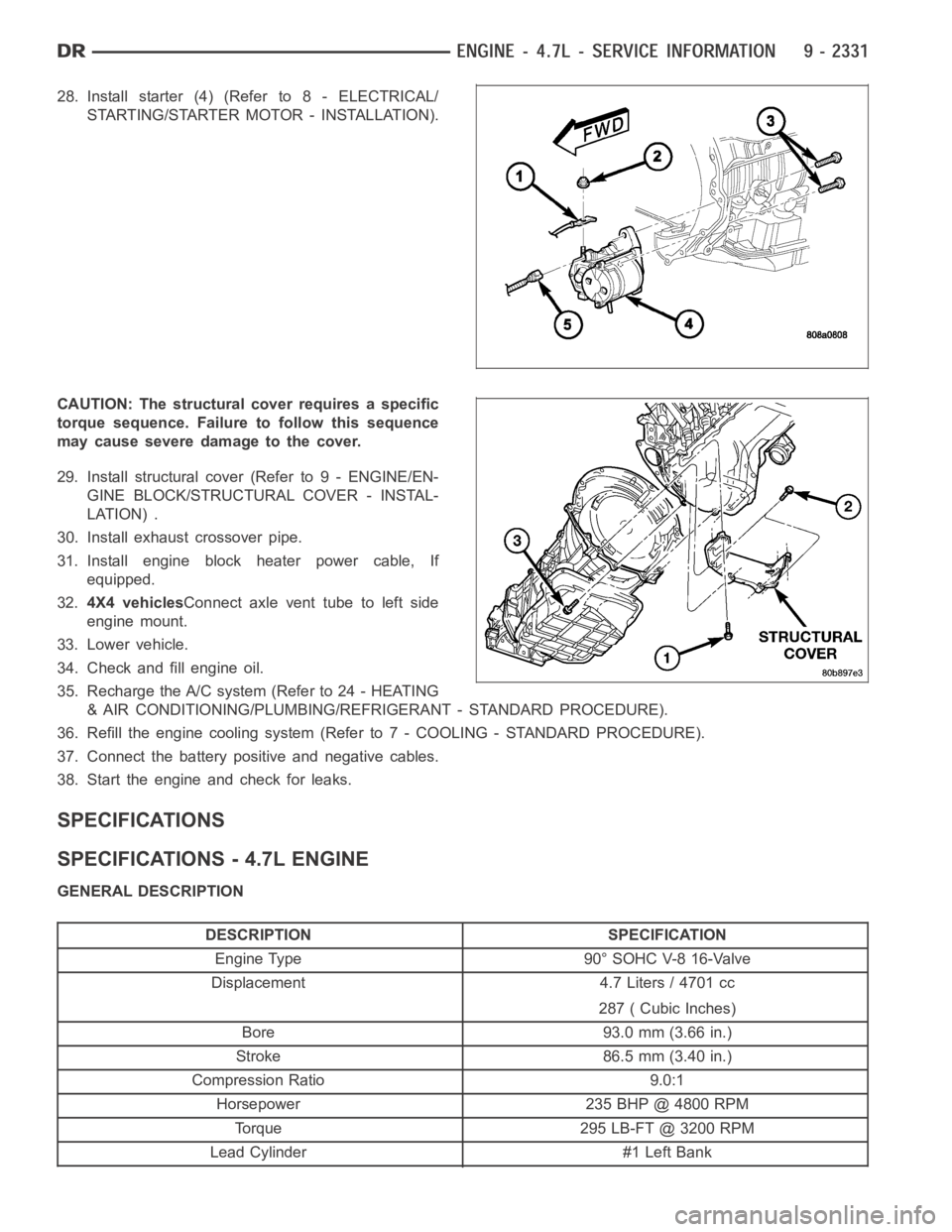

24. Install transmission to engine mounting bolts.

Tighten the bolts to 41 Nꞏm (30 ft. lbs.).

25. Install torque converter bolts (Automatic Transmis-

sion Only).

26. Connect crankshaft position sensor (1).

27.4X4 vehiclesPosition and install the axle isolator

bracket onto the axle, transmission and engine

block. Tighten bolts to specification (Refer to 9 -

ENGINE - SPECIFICATIONS).

Page 1640 of 5267

28. Install starter (4) (Refer to 8 - ELECTRICAL/

STARTING/STARTER MOTOR - INSTALLATION).

CAUTION: The structural cover requires a specific

torque sequence. Failure to follow this sequence

may cause severe damage to the cover.

29. Install structural cover (Refer to 9 - ENGINE/EN-

GINE BLOCK/STRUCTURAL COVER - INSTAL-

LATION) .

30. Install exhaust crossover pipe.

31. Install engine block heater power cable, If

equipped.

32.4X4 vehiclesConnect axle vent tube to left side

engine mount.

33. Lower vehicle.

34. Check and fill engine oil.

35. Recharge the A/C system (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING/REFRIGERANT - STANDARD PROCEDURE).

36. Refill the engine cooling system (Refer to 7 - COOLING - STANDARD PROCEDURE).

37. Connect the battery positive and negative cables.

38. Start the engine and check for leaks.

SPECIFICATIONS

SPECIFICATIONS - 4.7L ENGINE

GENERAL DESCRIPTION

DESCRIPTION SPECIFICATION

Engine Type 90° SOHC V-8 16-Valve

Displacement 4.7 Liters / 4701 cc

287 ( Cubic Inches)

Bore 93.0 mm (3.66 in.)

Stroke 86.5 mm (3.40 in.)

Compression Ratio 9.0:1

Horsepower 235 BHP @ 4800 RPM

Torque 295 LB-FT @ 3200 RPM

Lead Cylinder #1 Left Bank