lock DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1682 of 5267

6. lubricate the camshaft journal with clean engine oil

then Position the camshaft (with the sprocket dowel

on the left camshaft at 11 o’clock and the right

camshaft at 12 o’clock), then position the camshaft

bearing caps.

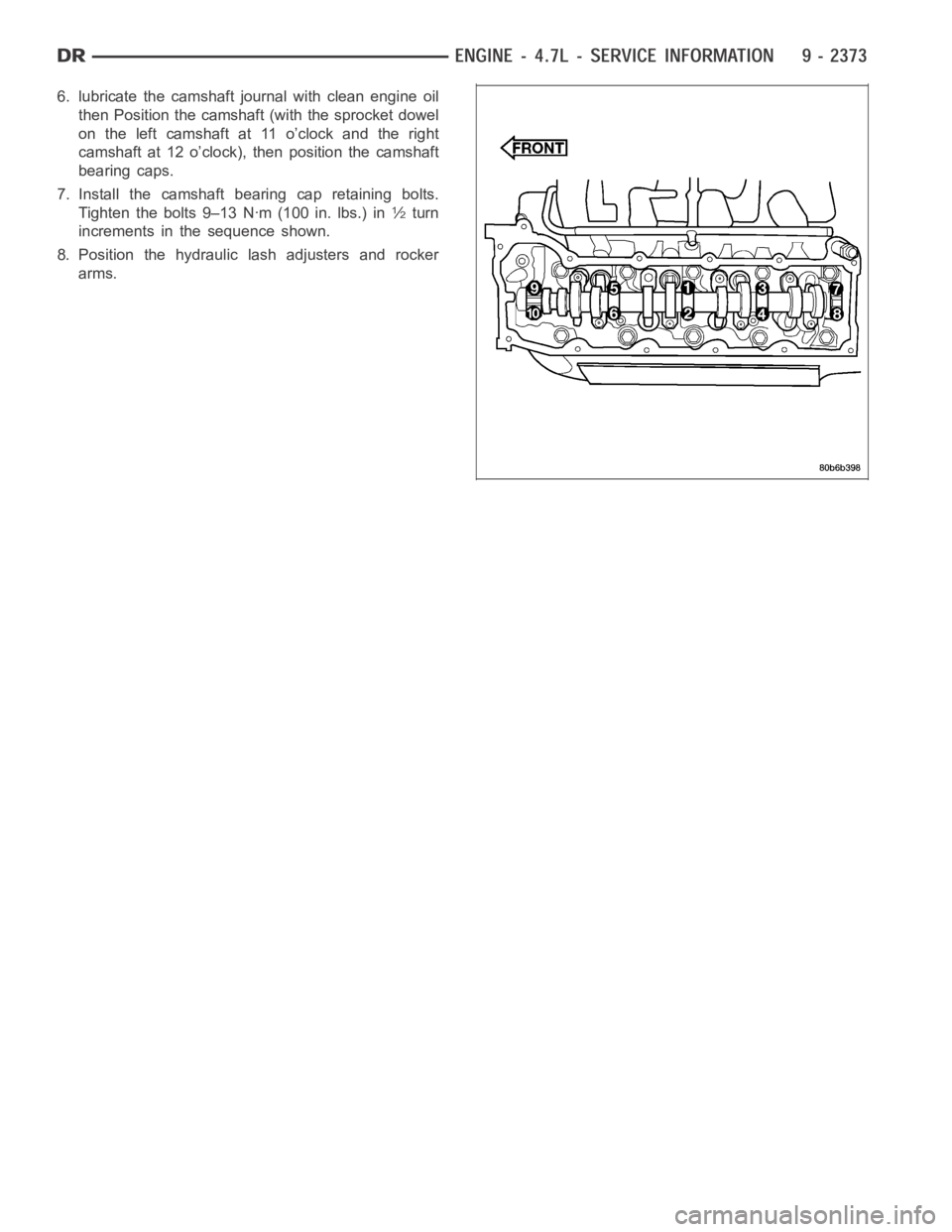

7. Install the camshaft bearing cap retaining bolts.

Tighten the bolts 9–13 Nꞏm (100 in. lbs.) in

1⁄2turn

increments in the sequence shown.

8. Position the hydraulic lash adjusters and rocker

arms.

Page 1685 of 5267

SPRINGS-VALVE

DESCRIPTION

The valve springs are made from high strength chrome silicon steel. The springs are common for intake and

exhaust applications. The valve spring seat is integral with the valve stem seal, which is a positive type seal to

control lubrication.

REMOVAL

1. Remove the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

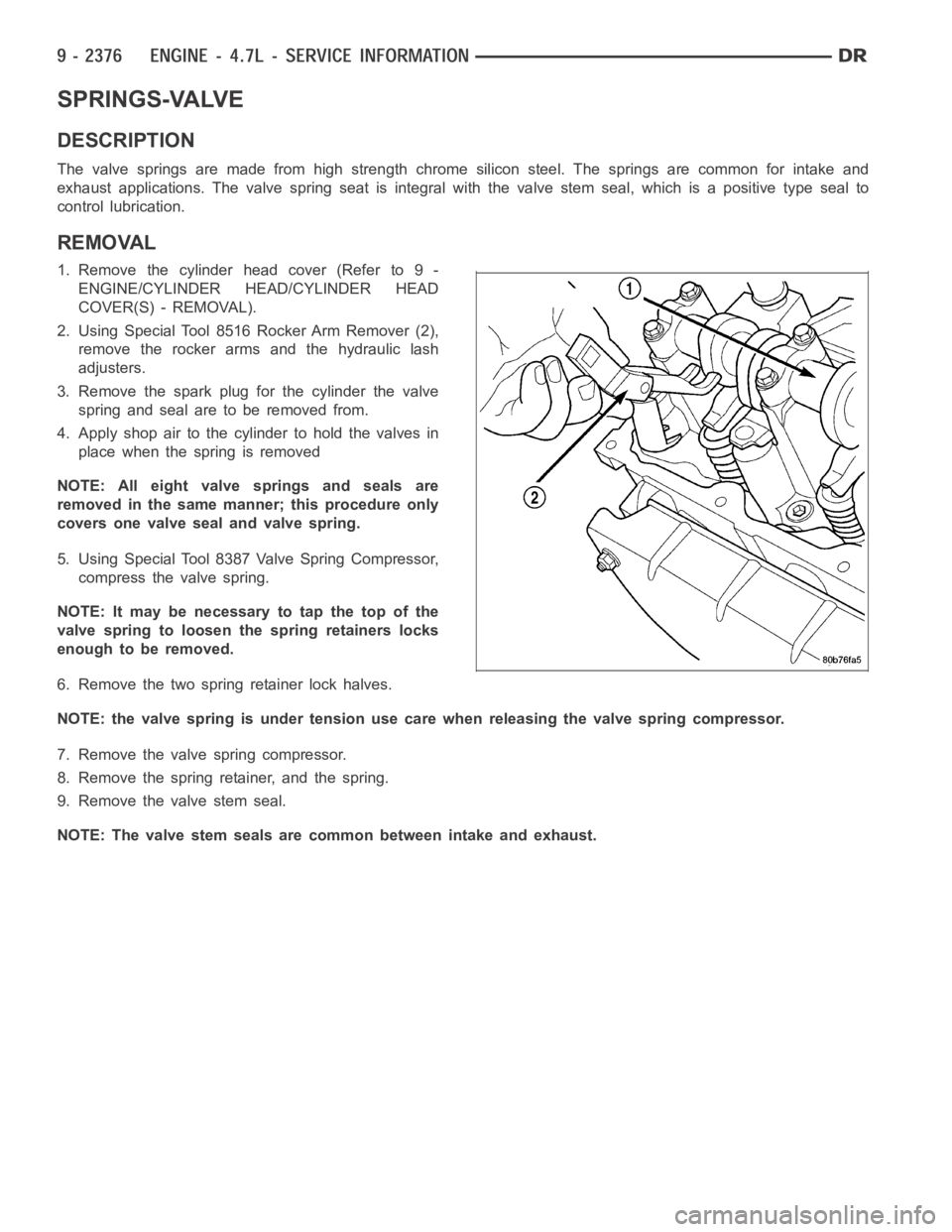

2. Using Special Tool 8516 Rocker Arm Remover (2),

remove the rocker arms and the hydraulic lash

adjusters.

3. Remove the spark plug for the cylinder the valve

spring and seal are to be removed from.

4. Apply shop air to the cylinder to hold the valves in

place when the spring is removed

NOTE: All eight valve springs and seals are

removed in the same manner; this procedure only

covers one valve seal and valve spring.

5. Using Special Tool 8387 Valve Spring Compressor,

compress the valve spring.

NOTE: It may be necessary to tap the top of the

valve spring to loosen the spring retainers locks

enough to be removed.

6. Remove the two spring retainer lock halves.

NOTE: the valve spring is under tension use care when releasing the valve spring compressor.

7. Remove the valve spring compressor.

8. Remove the spring retainer, and the spring.

9. Remove the valve stem seal.

NOTE: The valve stem seals are common between intake and exhaust.

Page 1688 of 5267

ENGINE BLOCK

DESCRIPTION

The cylinder block is made of cast iron.The block is a closed deck design with the left bank forward. To provide

high rigidity and improved NVH an enhanced compacted graphite bedplate isbolted to the block. The block design

allows coolant flow between the cylinders bores, and an internal coolant bypass to a single poppet inlet thermostat

is included in the cast aluminum front cover.

STANDARD PROCEDURE - CYLINDER BORE HONING

Before honing, stuff plenty of clean shop towels under

the bores and over the crankshaft to keep abrasive

materials from entering the crankshaft area.

1. Used carefully, the Cylinder Bore Sizing Hone

C-823, equipped with 220 grit stones, is the best

tool for this job. In addition to deglazing, it will

reduce taper and out-of-round, as well as removing

light scuffing, scoring and scratches. Usually, a few

strokes will clean up a bore and maintain the

required limits.

CAUTION: DO NOT use rigid type hones to remove

cylinder wall glaze.

2. Deglazing of the cylinder walls may be done if the

cylinder bore is straight and round. Use a cylinder

surfacing hone, Honing Tool C-3501, equipped with

280 grit stones (C-3501-3810). about 20-60

strokes, depending on the bore condition, will be

sufficient to provide a satisfactory surface. Using

honing oil C-3501-3880, or a light honing oil, avail-

able from major oil distributors.

CAUTION: DO NOT use engine or transmission oil, mineral spirits, or kerosene.

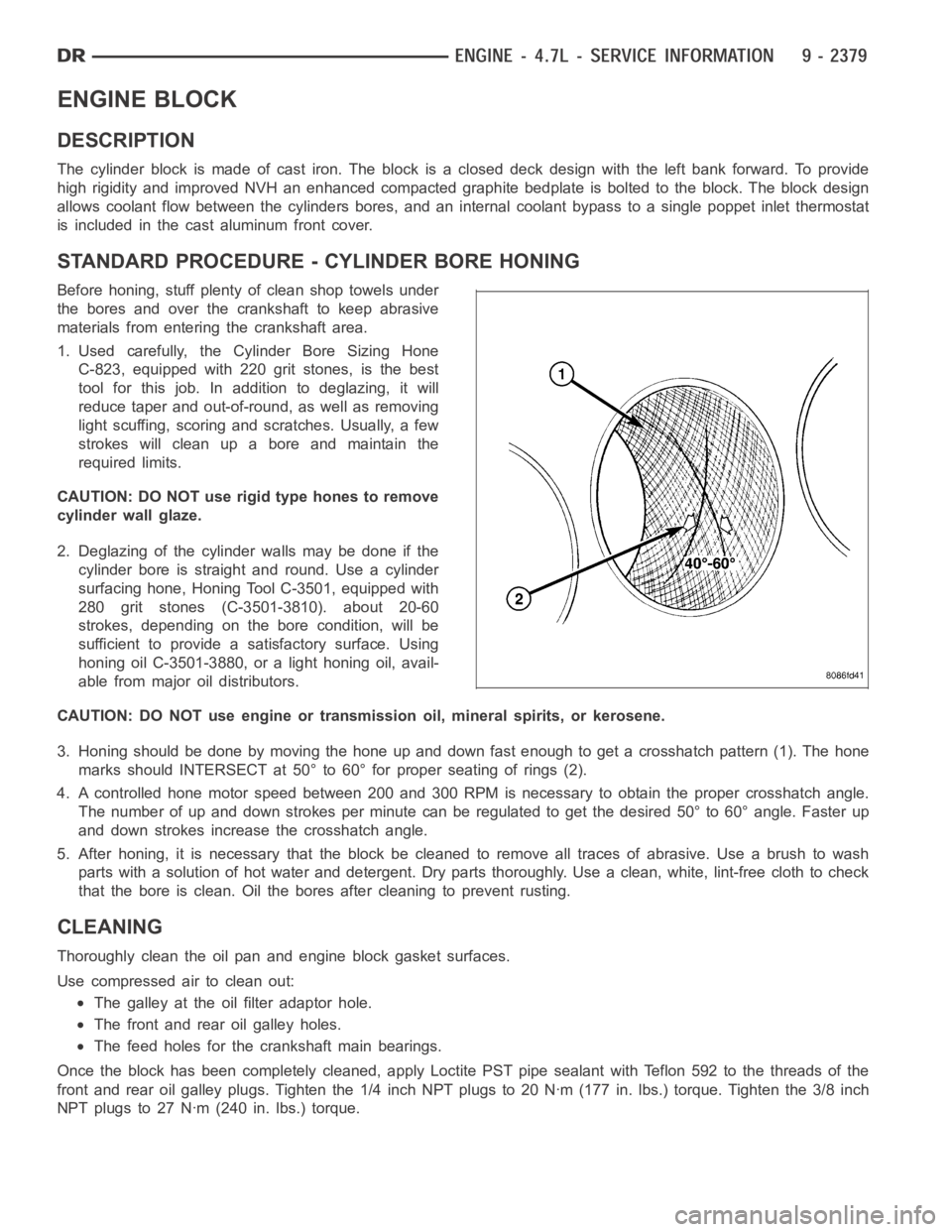

3. Honing should be done by moving the hone up and down fast enough to get a crosshatch pattern (1). The hone

marks should INTERSECT at 50° to 60° for proper seating of rings (2).

4. A controlled hone motor speed between 200 and 300 RPM is necessary to obtain the proper crosshatch angle.

The number of up and down strokes per minute can be regulated to get the desired 50° to 60° angle. Faster up

and down strokes increase the crosshatch angle.

5. After honing, it is necessary that the block be cleaned to remove all traces of abrasive. Use a brush to wash

parts with a solution of hot water and detergent. Dry parts thoroughly. Usea clean, white, lint-free cloth to check

that the bore is clean. Oil the bores after cleaning to prevent rusting.

CLEANING

Thoroughly clean the oil pan and engine block gasket surfaces.

Use compressed air to clean out:

The galley at the oil filter adaptor hole.

The front and rear oil galley holes.

The feed holes for the crankshaft main bearings.

Once the block has been completely cleaned, apply Loctite PST pipe sealantwith Teflon 592 to the threads of the

front and rear oil galley plugs. Tighten the 1/4 inch NPT plugs to 20 Nꞏm (177in. lbs.) torque. Tighten the 3/8 inch

NPT plugs to 27 Nꞏm (240 in. lbs.) torque.

Page 1689 of 5267

INSPECTION

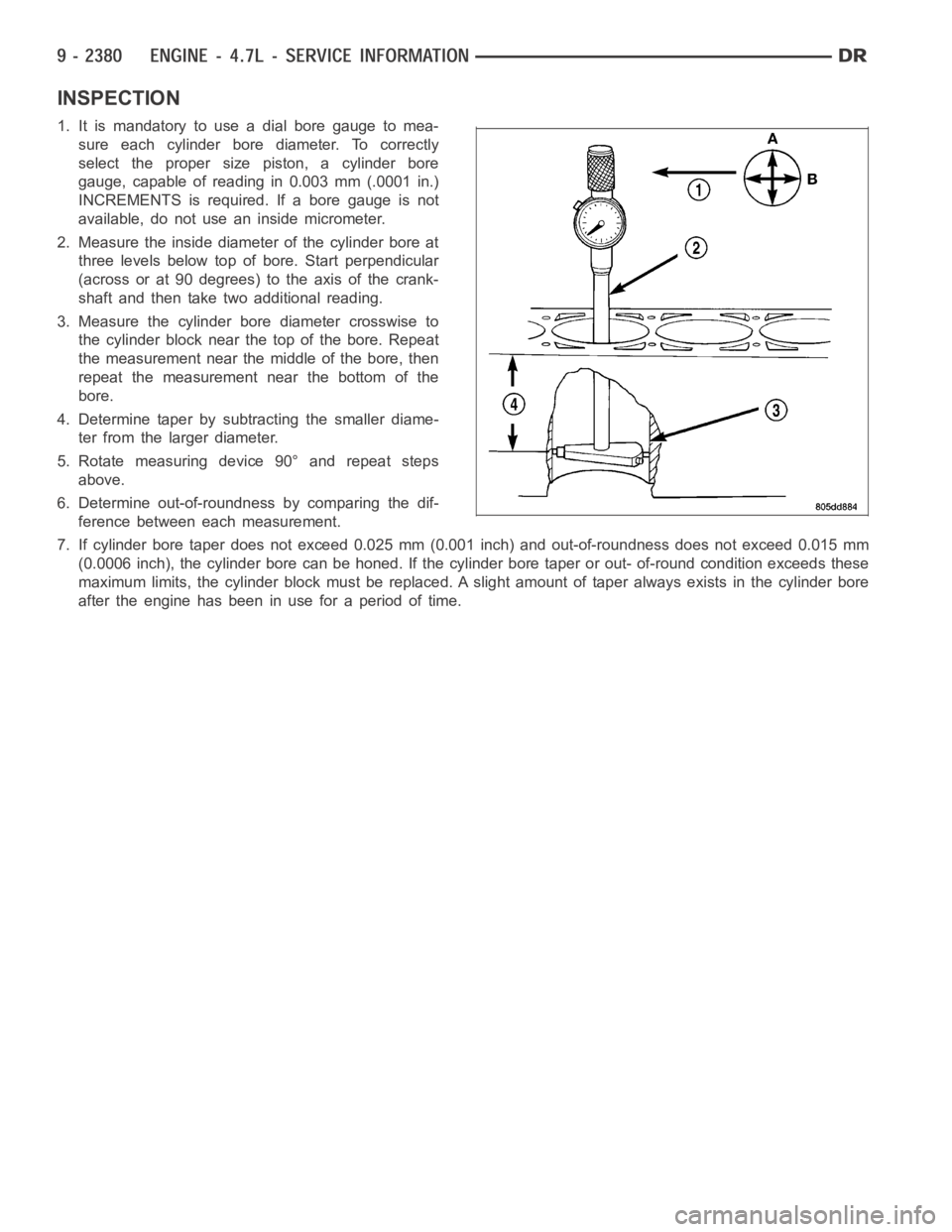

1. It is mandatory to use a dial bore gauge to mea-

sure each cylinder bore diameter. To correctly

select the proper size piston, a cylinder bore

gauge, capable of reading in 0.003 mm (.0001 in.)

INCREMENTS is required. If a bore gauge is not

available, do not use an inside micrometer.

2. Measure the inside diameter of the cylinder bore at

three levels below top of bore. Start perpendicular

(across or at 90 degrees) to the axis of the crank-

shaft and then take two additional reading.

3. Measure the cylinder bore diameter crosswise to

the cylinder block near the top of the bore. Repeat

the measurement near the middle of the bore, then

repeat the measurement near the bottom of the

bore.

4. Determine taper by subtracting the smaller diame-

ter from the larger diameter.

5. Rotate measuring device 90° and repeat steps

above.

6. Determine out-of-roundness by comparing the dif-

ference between each measurement.

7. If cylinder bore taper does not exceed 0.025 mm (0.001 inch) and out-of-roundness does not exceed 0.015 mm

(0.0006 inch), the cylinder bore can be honed. If the cylinder bore taper orout- of-round condition exceeds these

maximum limits, the cylinder block must be replaced. A slight amount of taper always exists in the cylinder bore

after the engine has been in use for a period of time.

Page 1694 of 5267

CRANKSHAFT

DESCRIPTION

The crankshaft is constructed of nodular cast iron. The crankshaft is a crosshaped four throw design with eight

counterweights for balancing purposes. The crankshaft is supported by five select fit main bearings with the number

three serving as the thrust washer location. The main journals of the crankshaft are cross drilled to improve rod

bearing lubrication. The number eight counterweight has provisions for crankshaft position sensor target wheel

mounting. The select fit main bearing markings are located on the rear sideof the target wheel. The crankshaft oil

seals are one piece design. The front oil seal is retained in the timing chain cover, and the rear seal is pressed in

to a bore formed by the cylinder block and the bedplate assembly.

REMOVAL

NOTE: To remove the crankshaft from the engine, the engine must be removed from the vehicle.

1. Remove the engine. (Refer to 9 - ENGINE - REMOVAL).

2. Remove the engine oil pump. (Refer to 9 - ENGINE/LUBRICATION/OIL PUMP - REMOVAL).

CAUTION: DO NOT pry on the oil pan gasket when removing the oil pan, The oil pan gasket is mounted to

the cylinder block in three locations and will remain attached to block when removing oil pan. Gasket can

not be removed with oil pan.

3. Remove oil pan. (Refer to 9 - ENGINE/LUBRICATION/OIL PAN - REMOVAL).

4. Remove the oil pump pickup tube and oil pan gasket /windage tray.

5. Remove the bedplate mounting bolts. Note the location of the three stud bolts for installation.

6. Remove the connecting rods from the crankshaft.

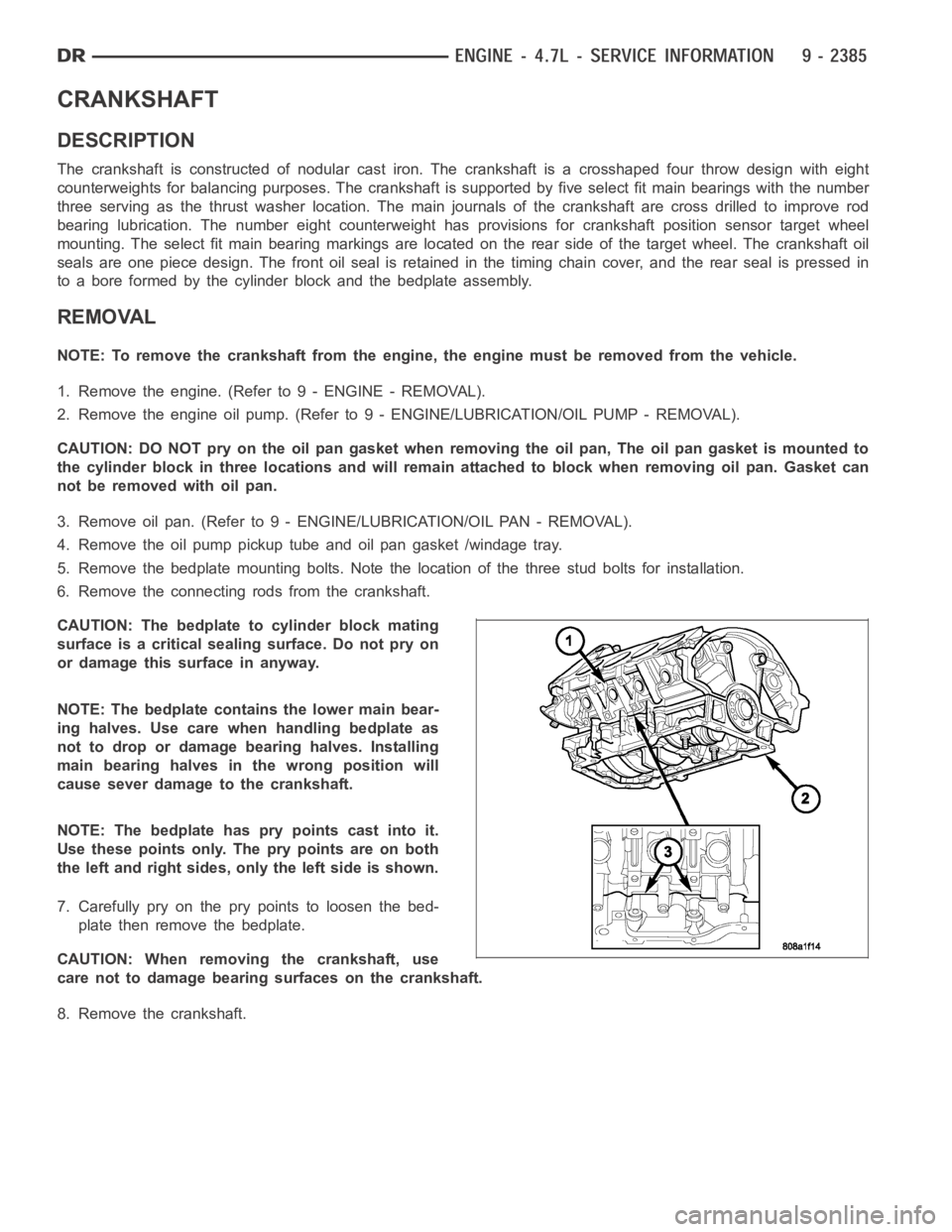

CAUTION: The bedplate to cylinder block mating

surface is a critical sealing surface. Do not pry on

or damage this surface in anyway.

NOTE: The bedplate contains the lower main bear-

ing halves. Use care when handling bedplate as

not to drop or damage bearing halves. Installing

main bearing halves in the wrong position will

cause sever damage to the crankshaft.

NOTE: The bedplate has pry points cast into it.

Use these points only. The pry points are on both

the left and right sides, only the left side is shown.

7. Carefully pry on the pry points to loosen the bed-

plate then remove the bedplate.

CAUTION: When removing the crankshaft, use

care not to damage bearing surfaces on the crankshaft.

8. Remove the crankshaft.

Page 1695 of 5267

INSPECTION

NOTE: Thoroughly inspect the connecting rod bearing bores and main bearing bores for scoring, blueing or

severe scratches. Further disassembly may be required.

If connecting rod bearing bores show damage, the cylinder heads must be removed to service the piston and rod

assemblies. If the bedplate or the cylinder block main bearing bores show damage the engine must be replaced.

1. If required, remove the main bearing halves from the cylinder block and bedplate.

2. Thoroughly clean the bedplate to cylinder block sealing surfaces and main bearing bores. Remove all oil and

sealant residue.

3. Inspect the bedplate main bearing bores for cracks, scoring or severe blueing. If either condition exists the

engine must be replaced.

4. Inspect the crankshaft thrust washers for scoring, scratches, wear or blueing. If either condition exist replace the

thrust washer.

5. Inspect the oil pan gasket/windage tray for splits, tears or cracks in the gasket sealing surfaces. Replace gasket

as necessary.

INSTALLATION

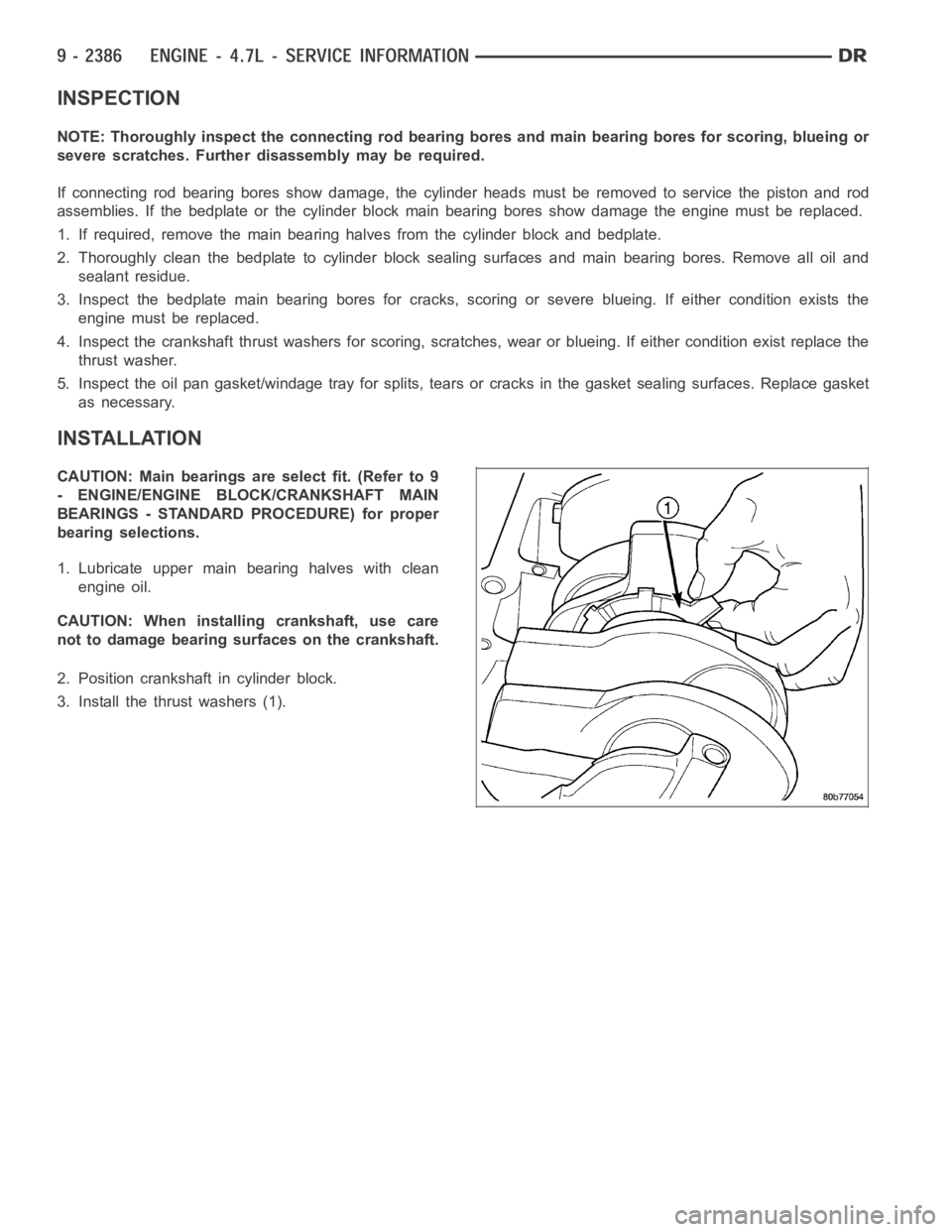

CAUTION: Main bearings are select fit. (Refer to 9

- ENGINE/ENGINE BLOCK/CRANKSHAFT MAIN

BEARINGS - STANDARD PROCEDURE) for proper

bearing selections.

1. Lubricate upper main bearing halves with clean

engine oil.

CAUTION: When installing crankshaft, use care

not to damage bearing surfaces on the crankshaft.

2. Position crankshaft in cylinder block.

3. Install the thrust washers (1).

Page 1696 of 5267

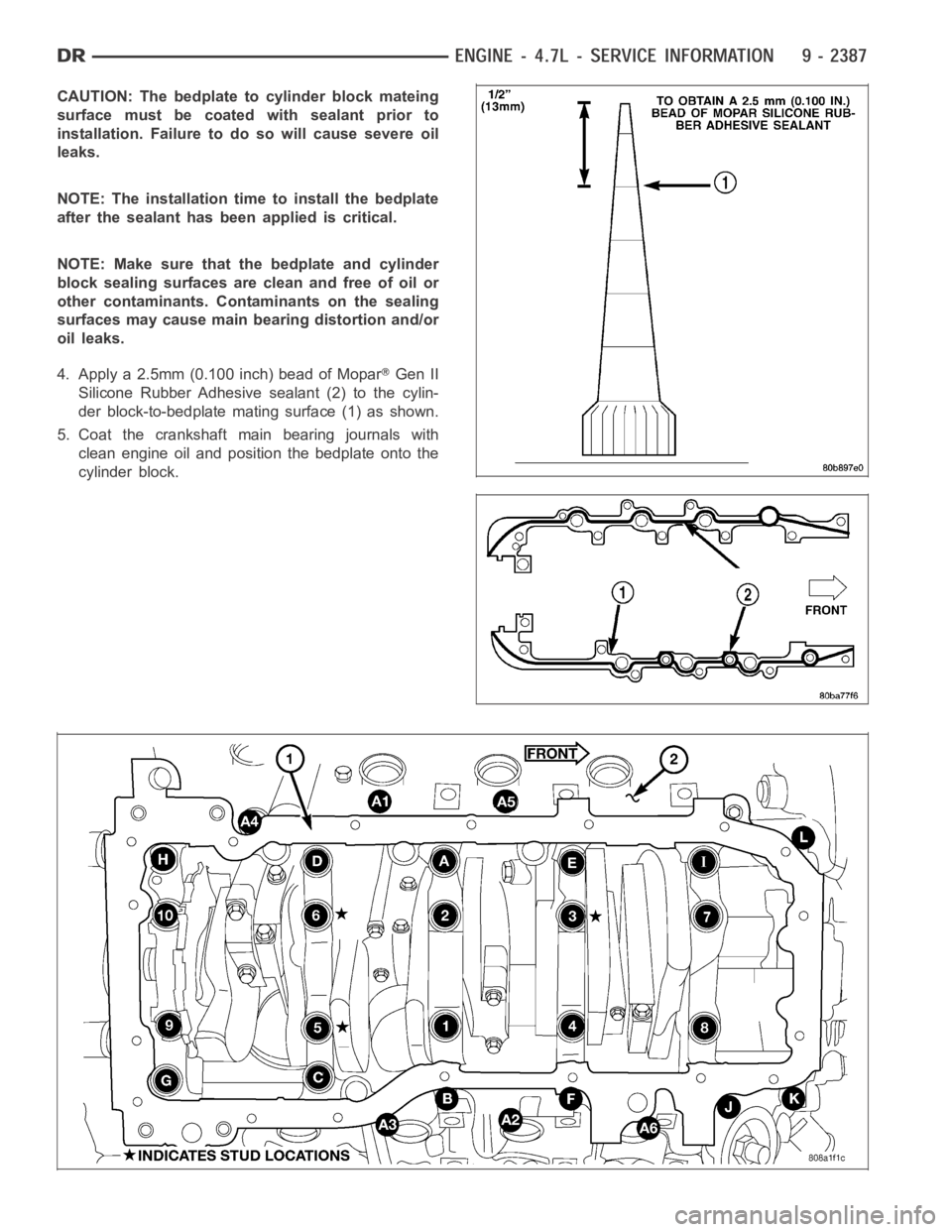

CAUTION: The bedplate to cylinder block mateing

surface must be coated with sealant prior to

installation. Failure to do so will cause severe oil

leaks.

NOTE: The installation time to install the bedplate

after the sealant has been applied is critical.

NOTE: Make sure that the bedplate and cylinder

block sealing surfaces are clean and free of oil or

other contaminants. Contaminants on the sealing

surfaces may cause main bearing distortion and/or

oil leaks.

4. Apply a 2.5mm (0.100 inch) bead of Mopar

Gen II

Silicone Rubber Adhesive sealant (2) to the cylin-

der block-to-bedplate mating surface (1) as shown.

5. Coat the crankshaft main bearing journals with

clean engine oil and position the bedplate onto the

cylinder block.

Page 1697 of 5267

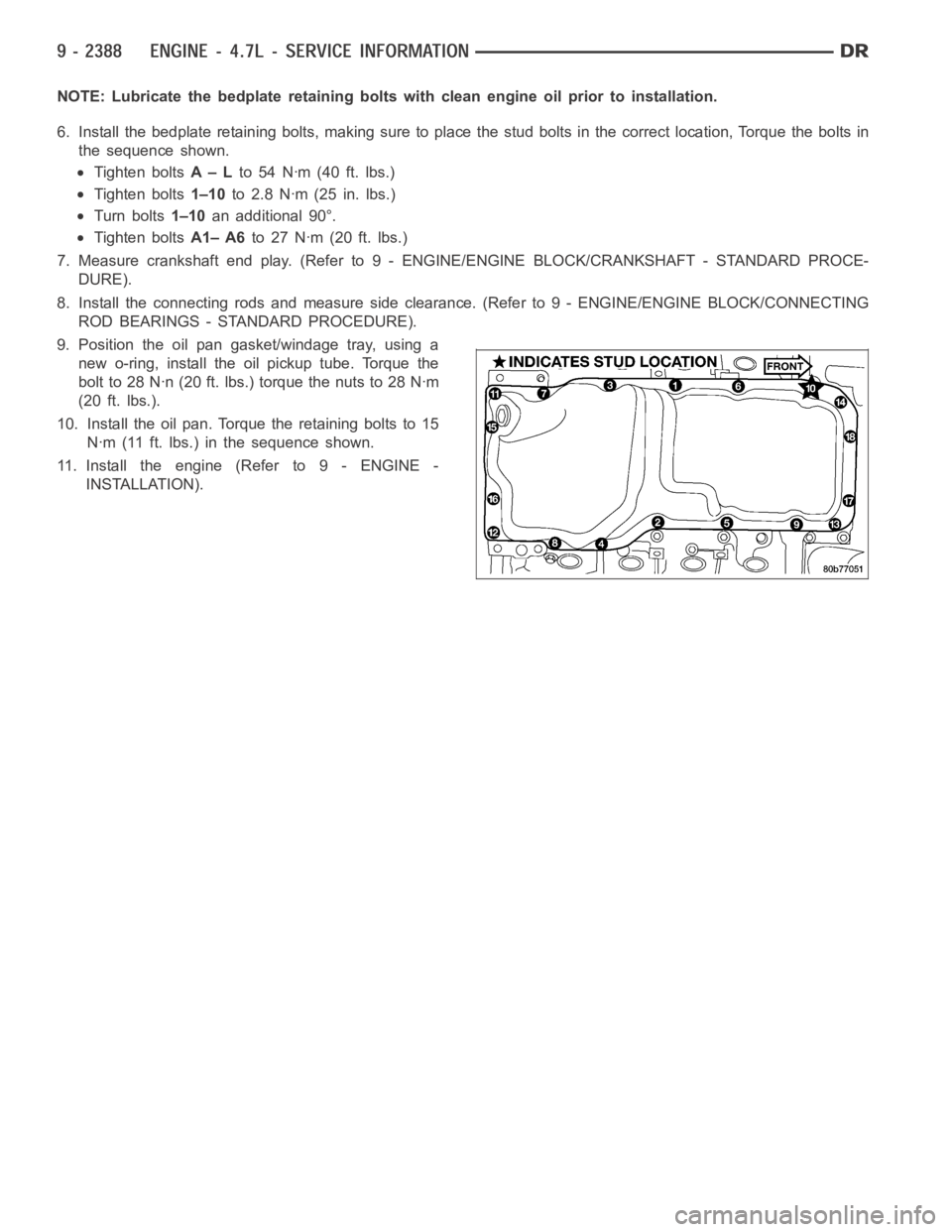

NOTE: Lubricate the bedplate retaining bolts with clean engine oil prior to installation.

6. Install the bedplate retaining bolts, making sure to place the stud bolts in the correct location, Torque the bolts in

the sequence shown.

Tighten boltsA–Lto 54 Nꞏm (40 ft. lbs.)

Tighten bolts1–10to 2.8 Nꞏm (25 in. lbs.)

Turn bolts1–10an additional 90°.

Tighten boltsA1– A6to 27 Nꞏm (20 ft. lbs.)

7. Measure crankshaft end play. (Refer to 9 - ENGINE/ENGINE BLOCK/CRANKSHAFT - STANDARD PROCE-

DURE).

8. Install the connecting rods and measure side clearance. (Refer to 9 - ENGINE/ENGINE BLOCK/CONNECTING

ROD BEARINGS - STANDARD PROCEDURE).

9. Position the oil pan gasket/windage tray, using a

new o-ring, install the oil pickup tube. Torque the

bolt to 28 Nꞏn (20 ft. lbs.) torque the nuts to 28 Nꞏm

(20 ft. lbs.).

10. Install the oil pan. Torque the retaining bolts to 15

Nꞏm (11 ft. lbs.) in the sequence shown.

11. Install the engine (Refer to 9 - ENGINE -

INSTALLATION).

Page 1698 of 5267

BEARINGS - CRANKSHAFT MAIN

STANDARD PROCEDURE - CRANKSHAFT MAIN BEARING - FITTING

MAIN BEARING JOURNAL DIAMETER (CRANKSHAFT REMOVED)

Crankshaft removed from the cylinder block.

Clean the oil off the main bearing journal.

Determine the maximum diameter of the journal with a micrometer. Measure at two locations 90° apart at each end

of the journal.

The maximum allowable taper is 0.008mm (0.0004 inch.) and maximum out of round is 0.005mm (0.002 inch). Com-

pare the measured diameter with the journal diameter specification (MainBearing Fitting Chart). Select inserts

required to obtain the specified bearing-to-journal clearance.

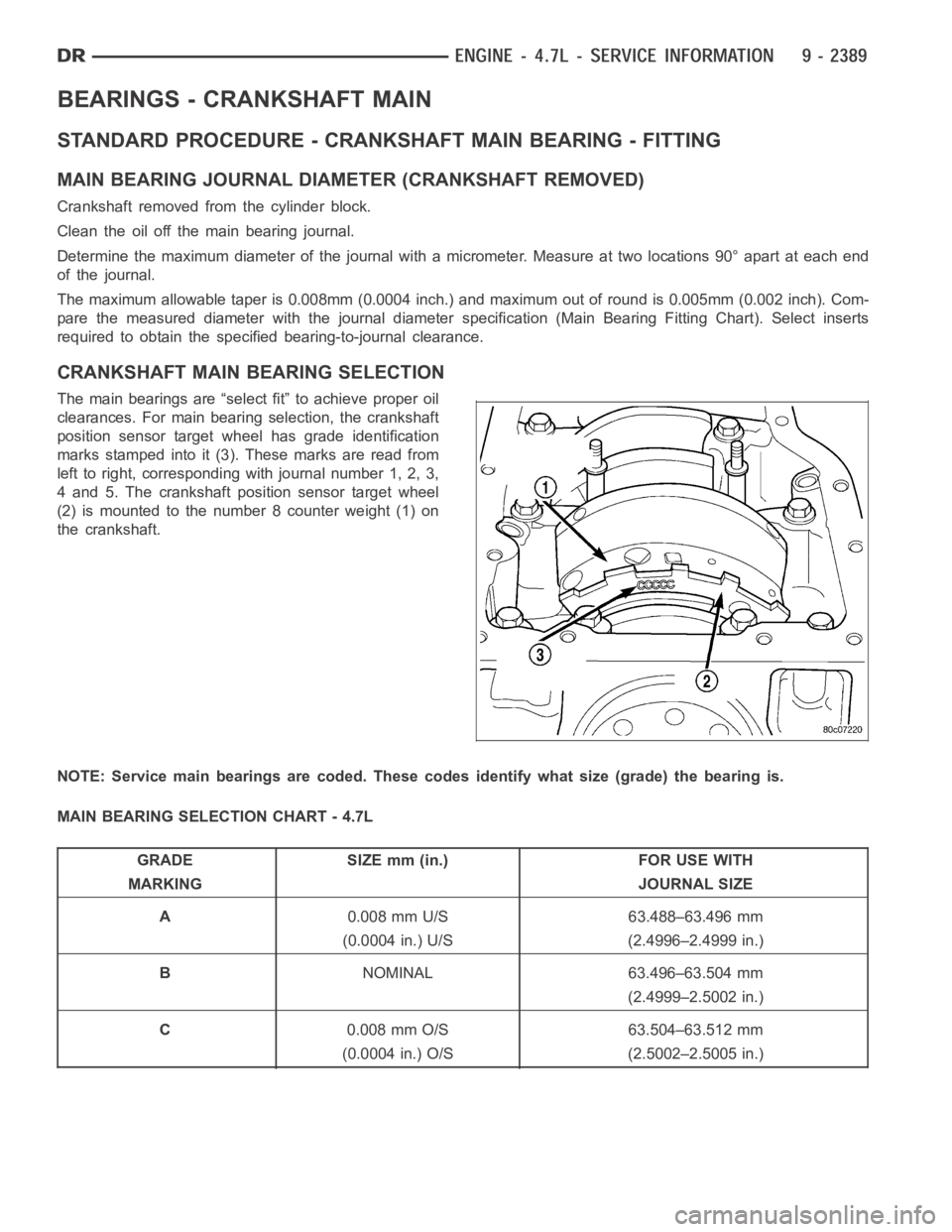

CRANKSHAFT MAIN BEARING SELECTION

The main bearings are “select fit” to achieve proper oil

clearances. For main bearing selection, the crankshaft

position sensor target wheel has grade identification

marks stamped into it (3). These marks are read from

left to right, corresponding with journal number 1, 2, 3,

4 and 5. The crankshaft position sensor target wheel

(2) is mounted to the number 8 counter weight (1) on

the crankshaft.

NOTE: Service main bearings are coded. These codes identify what size (grade) the bearing is.

MAIN BEARING SELECTION CHART - 4.7L

GRADE SIZE mm (in.) FOR USE WITH

MARKING JOURNAL SIZE

A0.008 mm U/S 63.488–63.496 mm

(0.0004 in.) U/S (2.4996–2.4999 in.)

BNOMINAL 63.496–63.504 mm

(2.4999–2.5002 in.)

C0.008 mm O/S 63.504–63.512 mm

(0.0004 in.) O/S (2.5002–2.5005 in.)

Page 1699 of 5267

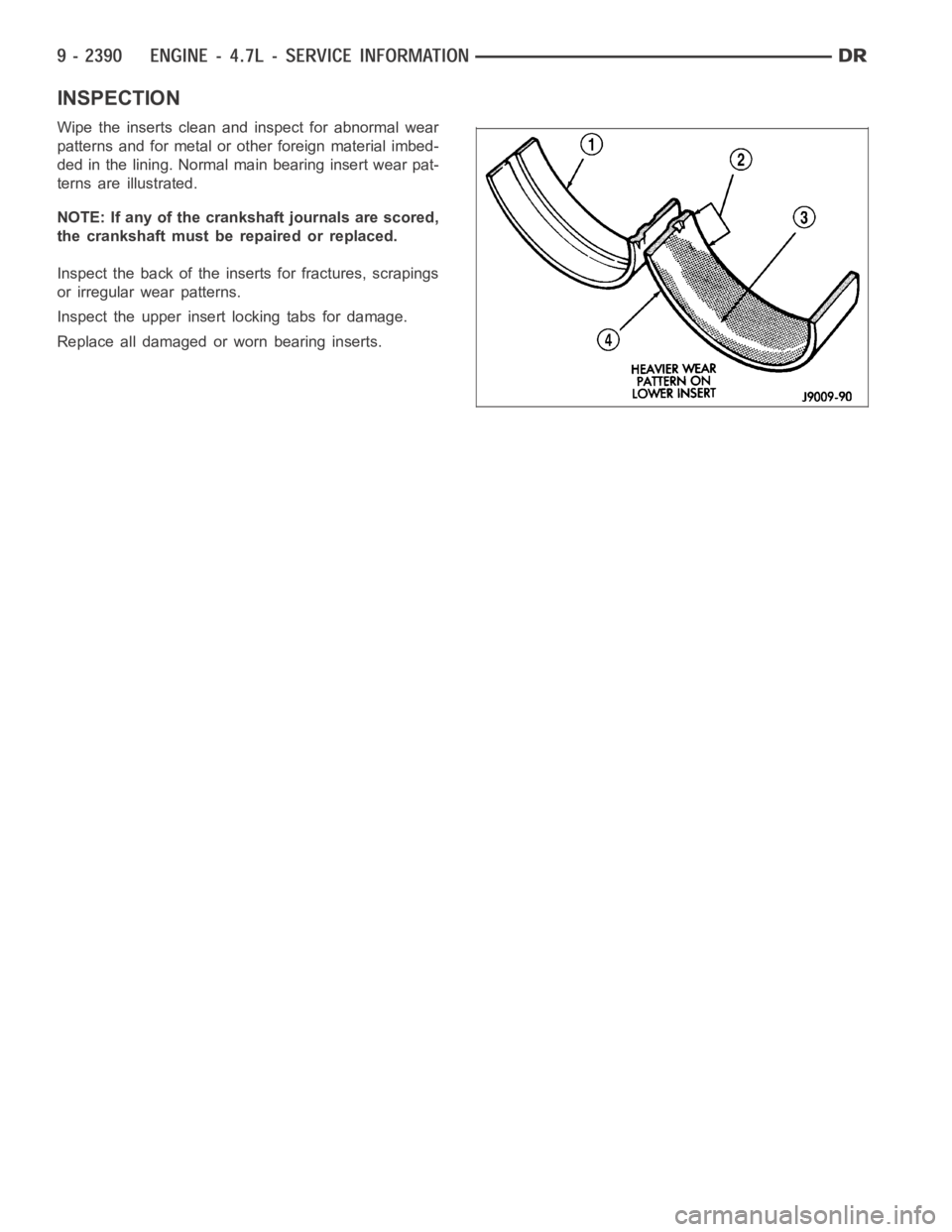

INSPECTION

Wipe the inserts clean and inspect for abnormal wear

patterns and for metal or other foreign material imbed-

ded in the lining. Normal main bearing insert wear pat-

terns are illustrated.

NOTE: If any of the crankshaft journals are scored,

the crankshaft must be repaired or replaced.

Inspect the back of the inserts for fractures, scrapings

or irregular wear patterns.

Inspect the upper insert locking tabs for damage.

Replace all damaged or worn bearing inserts.