engine DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2004 of 5267

FILTER - ENGINE OIL

REMOVAL

1. Clean the area around the oil filter head. Remove the filter from below using a cap-style filter wrench.

2. Clean the gasket surface of the filter head. The filter canister O-Ring seal can stick on the filter head. Make sure

it is removed.

INSTALLATION

1. Fill the oil filter element with clean oil before installation. Use the same type oil that will be used in the engine.

2. Apply a light film of lubricating oil to the sealing surface before installing the filter.

CAUTION: Mechanical over-tightening may distort the threads or damage the filter element seal.

3. Install the filter until it contacts the sealing surface of the oil filter adapter. Tighten filter an additional

1⁄2turn.

Page 2005 of 5267

PA N - E N G I N E O I L

REMOVAL

1. Disconnect the battery negative cables.

2. Install engine support fixture # 8534.

3. Raise vehicle on hoist.

4. Disconnect starter cables from starter motor.

5. Remove transmission and transfer case (if equipped).

6. Remove flywheel or flexplate.

7. Remove starter motor (Refer to 8 - ELECTRICAL/STARTING/STARTER MOTOR -REMOVAL) and transmission

adapter plate assembly.

WARNING: HOT OIL CAN CAUSE PERSONAL INJURY.

8. Drain the engine oil (Refer to 9 - ENGINE/LUBRICATION/OIL - STANDARD PROCEDURE).

9. Install the oil pan drain plug if sealing surface is not damaged and tighten to 50 Nꞏm (37 ft. lbs.) torque.

10. Remove oil pan bolts, break the pan to block seal, and lower pan slightlyandremoveoilsuctiontubefasteners.

11. Remove oil pan and suction tube.

CLEANING

Remove all gasket material from the oil pan and cylinder block sealing surfaces. Extra effort may be required

around T-joint areas. Clean oil pan and flush suction tube with a suitable solvent.

INSPECTION

Inspect the oil pan, suction tube, and tube braces for cracks and damage. Replace any defective component.

Inspect the oil drain plug and drain hole threads. Inspect the oil pan sealing surface for straightness. Repair any

minor imperfections with a ball-peen hammer. Do not attempt to repair an oil pan by welding.

INSTALLATION

1. Fill the T-joint between the pan rail/gear housing and pan rail/rear seal retainer with sealant. Use MoparSilicone

Rubber Adhesive Sealant or equivalent.

2. Place suction tube in oil pan and guide them into place. Slide oil pan gasket into postion.Using a new tube to

block gasket, install and tighten the suction tube bolts by hand. Startingwith the oil pump inlet bolts, tighten the

bolts to 24 Nꞏm (18 ft. lbs.) torque. Tighten the remaining tube brace boltsto 43 Nꞏm (32 ft. lbs.) torque.

3. Starting in the center and working outward, tighten the oil pan bolts to 28Nꞏm(21ft.lbs.)torque.

4. Install the flywheel housing assembly with the starter motor attached and tighten bolts to 77 Nꞏm (57 ft. lbs.)

torque.

5. Connect starter motor cables.

NOTE: A new clamping ring must be used on early or late builds, automatic or manual. Do not reuse clamp-

ing ring.

6. Install the flywheel to crankshaft adapter. Torque to 137 Nꞏm (101 ft. lbs.).

7. Install transmission and transfer case (if equipped).

8. Lower vehicle.

9. Remove the engine support fixture # 8534.

10. Install battery negative cables.

11. Fill the crankcase with new engine oil.

12. Start engine and check for leaks. Stop engine, check oil level, and adjust, if necessary.

Page 2006 of 5267

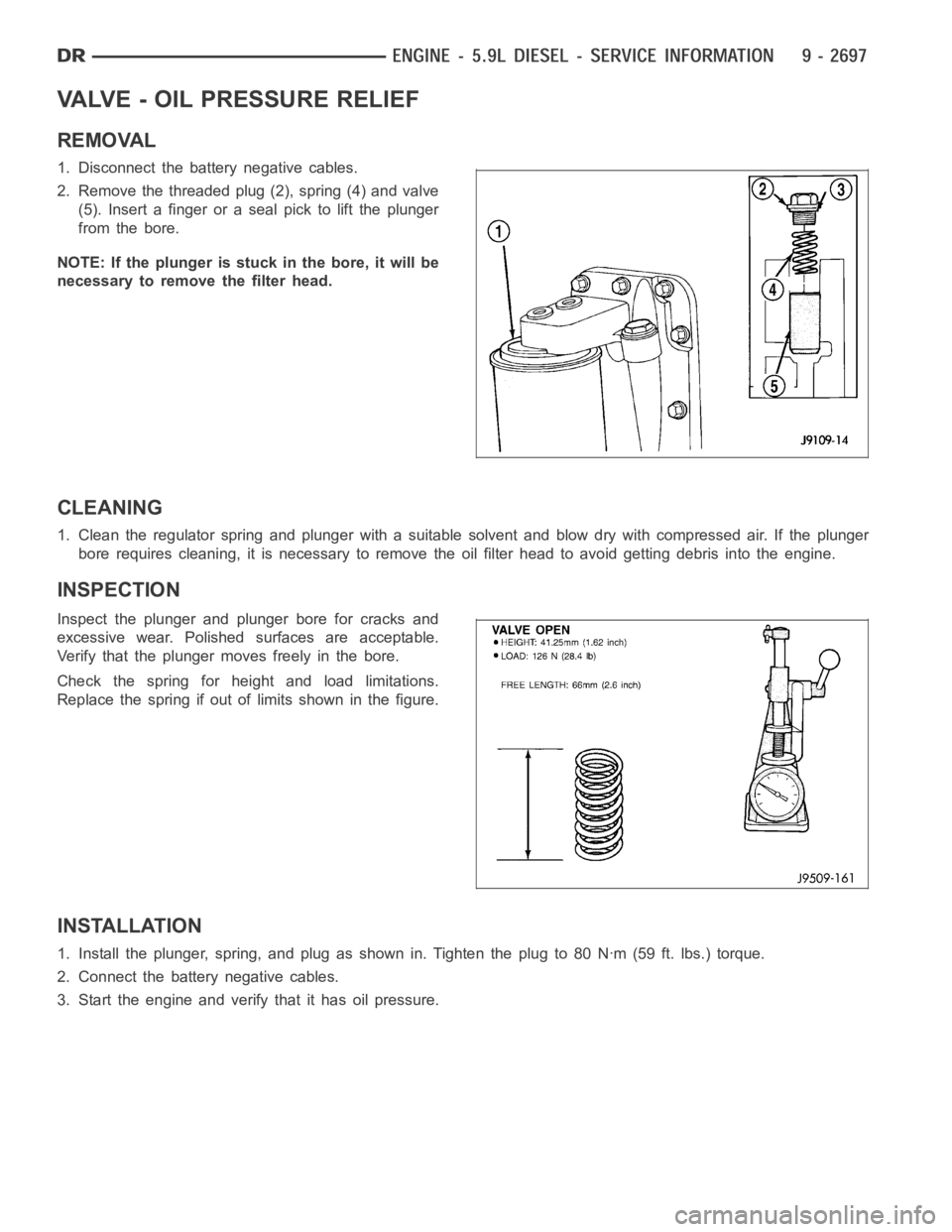

VALVE - OIL PRESSURE RELIEF

REMOVAL

1. Disconnect the battery negative cables.

2. Remove the threaded plug (2), spring (4) and valve

(5). Insert a finger or a seal pick to lift the plunger

from the bore.

NOTE: If the plunger is stuck in the bore, it will be

necessary to remove the filter head.

CLEANING

1. Clean the regulator spring and plunger with a suitable solvent and blow dry with compressed air. If the plunger

bore requires cleaning, it is necessaryto remove the oil filter head to avoid getting debris into the engine.

INSPECTION

Inspect the plunger and plunger bore for cracks and

excessive wear. Polished surfaces are acceptable.

Verify that the plunger moves freely in the bore.

Check the spring for height and load limitations.

Replace the spring if out of limits shown in the figure.

INSTALLATION

1. Install the plunger, spring, and plug as shown in. Tighten the plug to 80 Nꞏm (59 ft. lbs.) torque.

2. Connect the battery negative cables.

3. Start the engine and verify that it has oil pressure.

Page 2007 of 5267

SWITCH - OIL PRESSURE

REMOVAL

1. Disconnect the battery negative cables.

2. Disconnect the oil pressure switch connector.

3. Usingasuitablesocket,removetheoil pressure switch from the block (counter-clockwise).

INSTALLATION

1. If the switch is not being replaced, replace and lubricate the o-ring.

2. Install the oil pressure switch and tighten to 18 Nꞏm (159 in. lbs.) torque.

3. Connect oil pressure switch connector.

4. Connect the battery negative cables.

5. Start engine and check for oil leaks at the switch.

Page 2008 of 5267

PUMP - ENGINE OIL

REMOVAL

1. Disconnect the battery negative cables.

2. Remove fan/drive assembly (Refer to 7 - COOL-

ING/ENGINE/RADIATOR FAN - REMOVAL).

3. Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

4. Remove the fan support/hub assembly.

5. Remove crankshaft damper (Refer to 9 - ENGINE/

ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL) and speed indicator ring.

6. Remove power steering pump.

7. Remove accessory drive belt tensioner.

8. Remove the gear housing cover (Refer to 9 -

ENGINE/VALVE TIMING/GEAR HOUSING COVER

- REMOVAL).

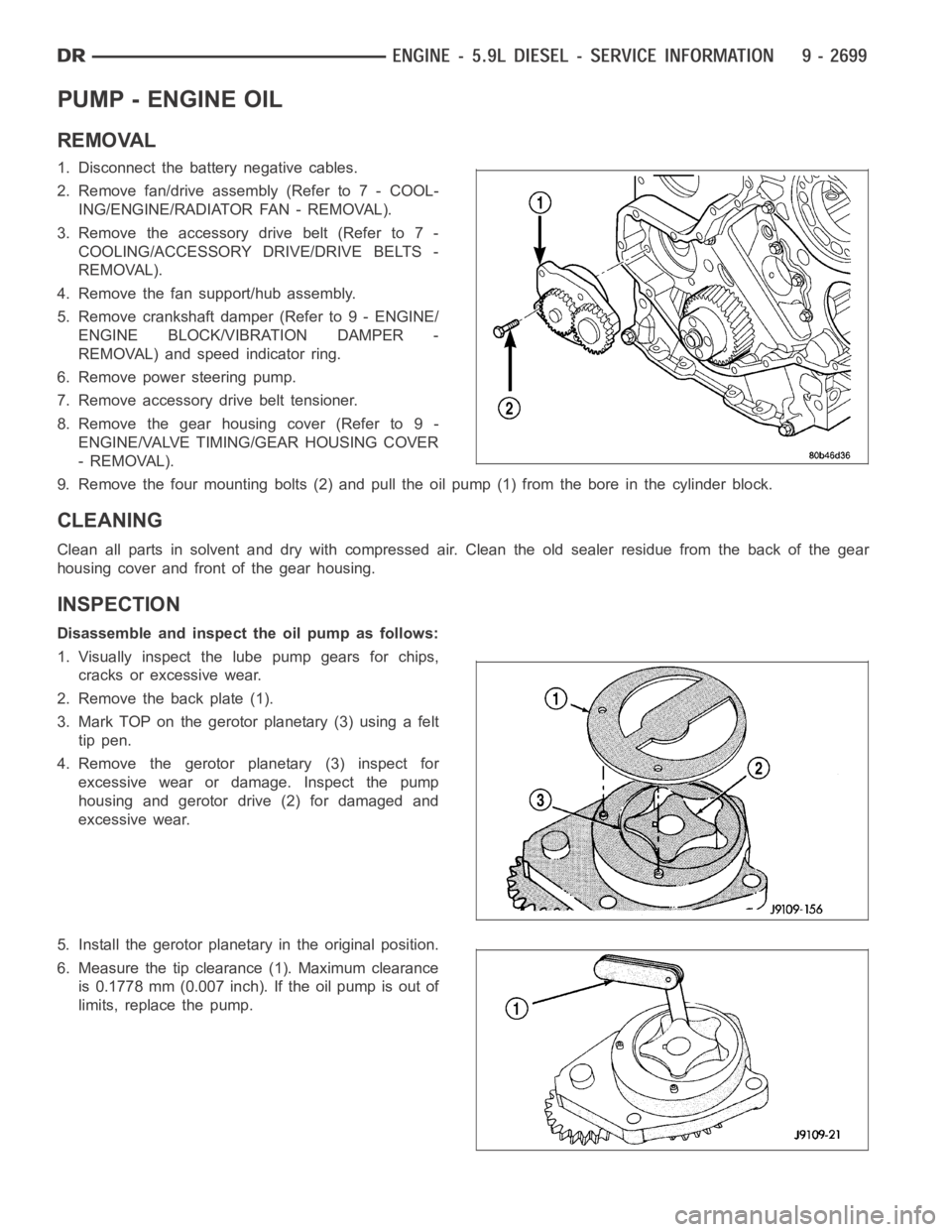

9. Remove the four mounting bolts (2) and pull the oil pump (1) from the bore in the cylinder block.

CLEANING

Clean all parts in solvent and dry with compressed air. Clean the old sealerresidue from the back of the gear

housing cover and front of the gear housing.

INSPECTION

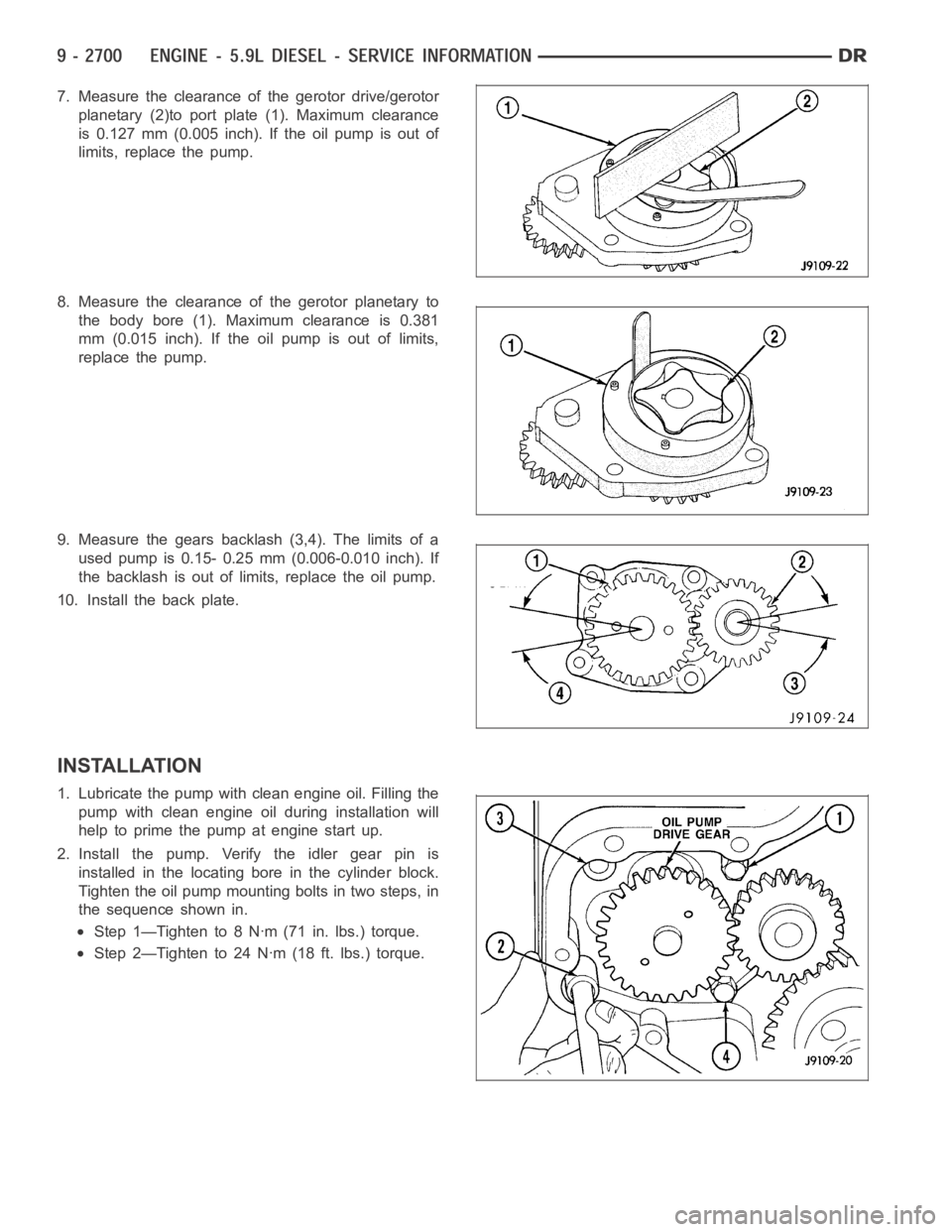

Disassemble and inspect the oil pump as follows:

1. Visually inspect the lube pump gears for chips,

cracks or excessive wear.

2. Remove the back plate (1).

3. Mark TOP on the gerotor planetary (3) using a felt

tip pen.

4. Remove the gerotor planetary (3) inspect for

excessive wear or damage. Inspect the pump

housing and gerotor drive (2) for damaged and

excessive wear.

5. Install the gerotor planetary in the original position.

6. Measure the tip clearance (1). Maximum clearance

is 0.1778 mm (0.007 inch). If the oil pump is out of

limits, replace the pump.

Page 2009 of 5267

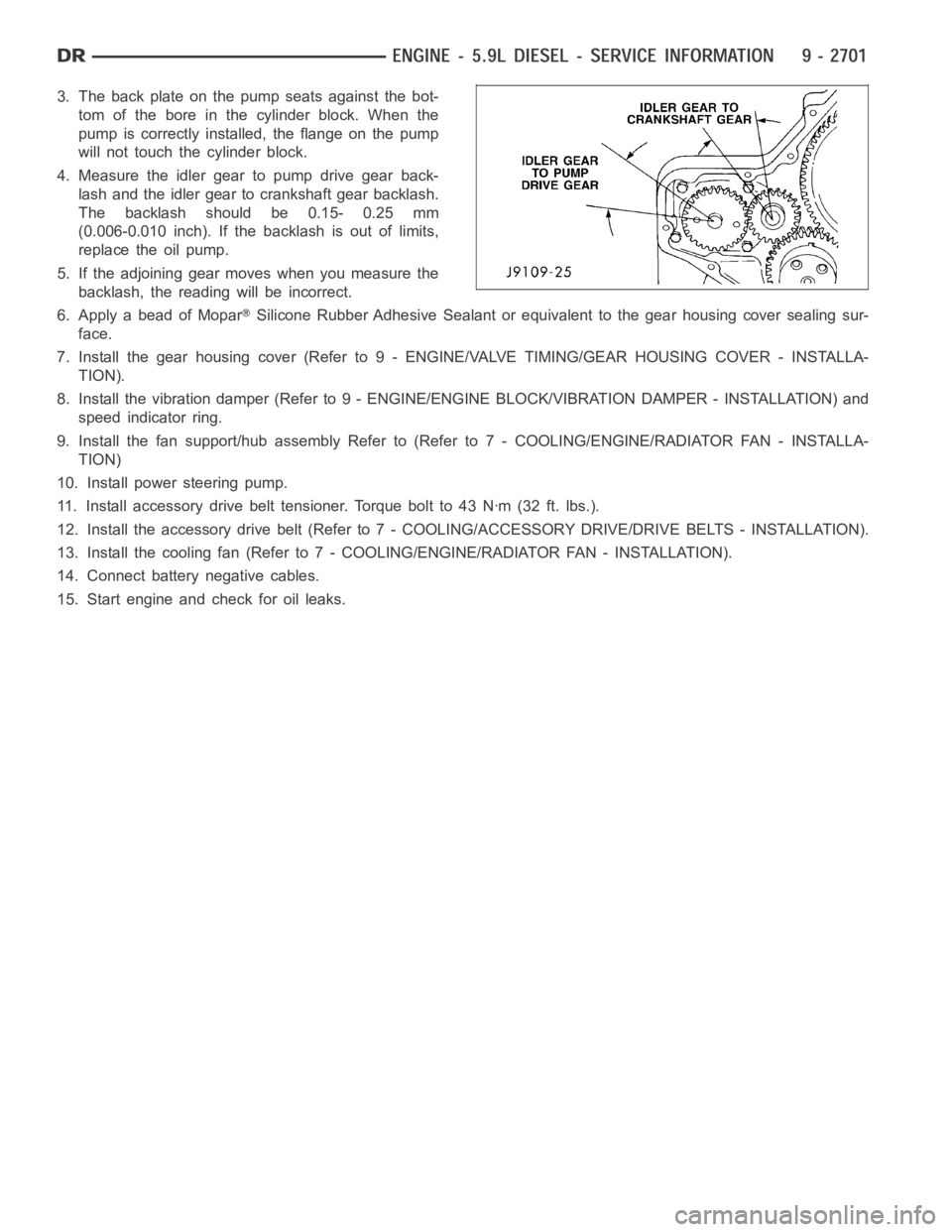

7. Measure the clearance of the gerotor drive/gerotor

planetary (2)to port plate (1). Maximum clearance

is 0.127 mm (0.005 inch). If the oil pump is out of

limits, replace the pump.

8. Measure the clearance of the gerotor planetary to

the body bore (1). Maximum clearance is 0.381

mm (0.015 inch). If the oil pump is out of limits,

replace the pump.

9. Measure the gears backlash (3,4). The limits of a

used pump is 0.15- 0.25 mm (0.006-0.010 inch). If

the backlash is out of limits, replace the oil pump.

10. Install the back plate.

INSTALLATION

1. Lubricate the pump withclean engine oil. Filling the

pump with clean engine oil during installation will

help to prime the pump at engine start up.

2. Install the pump. Verify the idler gear pin is

installed in the locating bore in the cylinder block.

Tighten the oil pump mounting bolts in two steps, in

the sequence shown in.

Step 1—Tighten to 8 Nꞏm (71 in. lbs.) torque.

Step 2—Tighten to 24 Nꞏm (18 ft. lbs.) torque.

Page 2010 of 5267

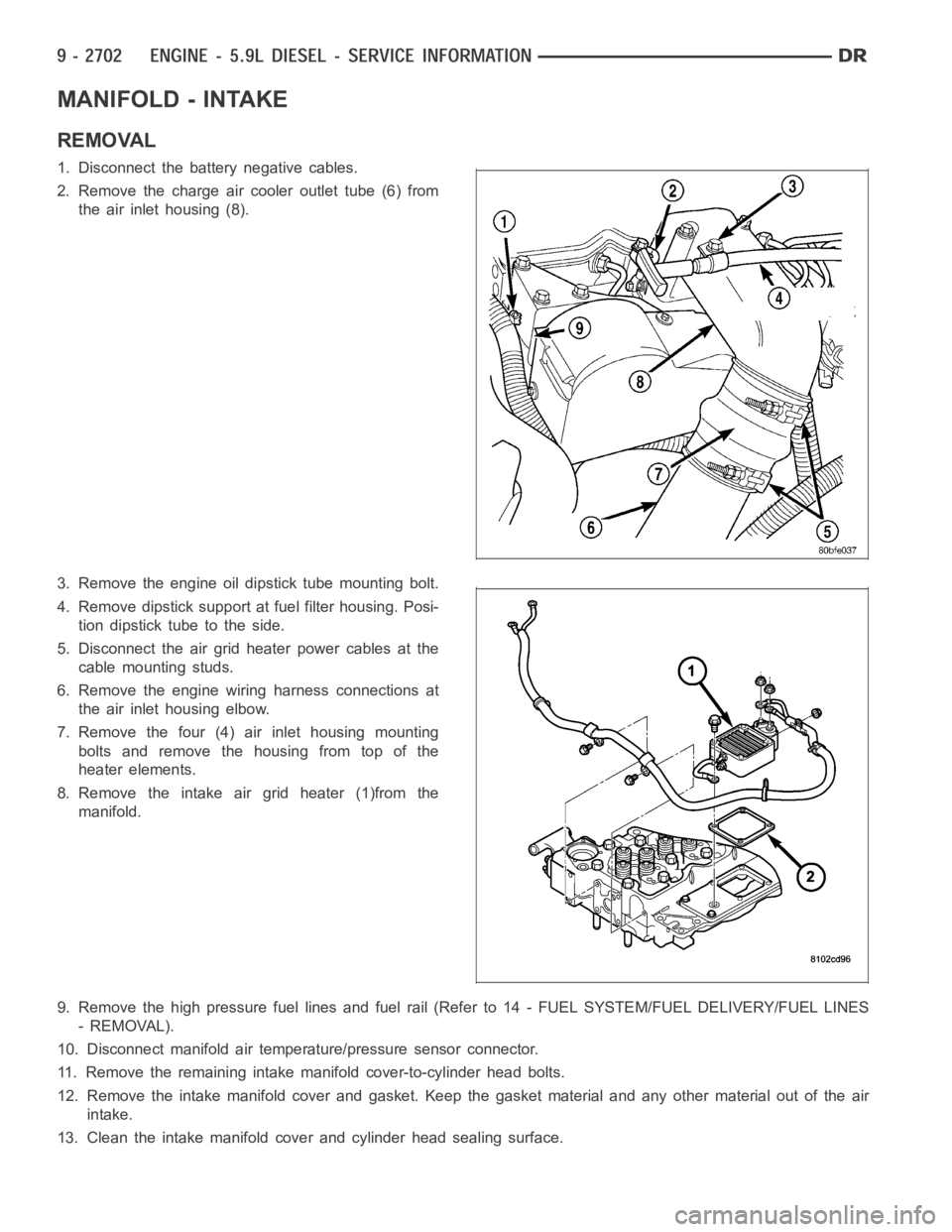

3. The back plate on the pump seats against the bot-

tom of the bore in the cylinder block. When the

pump is correctly installed, the flange on the pump

will not touch the cylinder block.

4. Measure the idler gear to pump drive gear back-

lash and the idler gear to crankshaft gear backlash.

The backlash should be 0.15- 0.25 mm

(0.006-0.010 inch). If the backlash is out of limits,

replace the oil pump.

5. If the adjoining gear moves when you measure the

backlash, the reading will be incorrect.

6. Apply a bead of Mopar

Silicone Rubber Adhesive Sealant or equivalent to the gear housing cover sealing sur-

face.

7. Install the gear housing cover (Refer to 9 - ENGINE/VALVE TIMING/GEAR HOUSING COVER - INSTALLA-

TION).

8. Install the vibration damper (Refer to 9 - ENGINE/ENGINE BLOCK/VIBRATION DAMPER - INSTALLATION) and

speed indicator ring.

9. Install the fan support/hub assemblyRefer to (Refer to 7 - COOLING/ENGINE/RADIATOR FAN - INSTALLA-

TION)

10. Install power steering pump.

11. Install accessory drive belt tensioner. Torque bolt to 43 Nꞏm (32 ft. lbs.).

12. Install the accessory drive belt (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - INSTALLATION).

13. Install the cooling fan (Refer to 7 - COOLING/ENGINE/RADIATOR FAN - INSTALLATION).

14. Connect battery negative cables.

15. Start engine and check for oil leaks.

Page 2011 of 5267

MANIFOLD - INTAKE

REMOVAL

1. Disconnect the battery negative cables.

2. Remove the charge air cooler outlet tube (6) from

the air inlet housing (8).

3. Remove the engine oil dipstick tube mounting bolt.

4. Remove dipstick support at fuel filter housing. Posi-

tion dipstick tube to the side.

5. Disconnect the air grid heater power cables at the

cable mounting studs.

6. Remove the engine wiring harness connections at

the air inlet housing elbow.

7. Remove the four (4) air inlet housing mounting

bolts and remove the housing from top of the

heater elements.

8. Remove the intake air grid heater (1)from the

manifold.

9. Remove the high pressure fuel lines and fuel rail (Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/FUEL LINES

- REMOVAL).

10. Disconnect manifold air temperature/pressure sensor connector.

11. Remove the remaining intake manifold cover-to-cylinder head bolts.

12. Remove the intake manifold cover and gasket. Keep the gasket material and any other material out of the air

intake.

13. Clean the intake manifold cover and cylinder head sealing surface.

Page 2012 of 5267

CLEANING

Clean manifold in solvent and blow dry with compressed air.

Clean cylinder block gasket surfaces using a suitable solvent.

The plenum pan rail must be clean and dry (free of all foreign material).

INSPECTION

Inspect manifold for cracks.

Inspect mating surfaces of manifold for flatness with a straightedge.

INSTALLATION

1. Using a new gasket, install the intake manifold cover.

2. Install the cover-to-cylinder head bolts that do not hold down the fuel rail.Tightentheboltsto24Nꞏm(18ft.lbs.)

torque.

3. Install the high pressure rail and fuel lines (Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/FUEL LINES -

INSTALLATION).

4. Using two (2) new gaskets, install the intake air grid heater and air inlet housing.

5. Connect the manifold air temperature/pressure sensor connector.

6. Install and tighten the air intake heater power supply nut to 14 Nꞏm (120 in. lbs.) torque.

7. Install oil dipstick tube support at fuel filter housing.

8. Install the engine oil dipstick tube and mounting bolt.

9. Position the charge air cooler outlet tube onto the air inlet housing. Tightentheclampsto11Nꞏm(100in.lbs.)

torque.

10. Attach the engine wire harness to the air inlet housing.

11. Prime the fuel system. Refer to the fuel priming procedure in Group 14, Fuel System.

12. Connect the battery negative cables.

Page 2014 of 5267

10. Connect the exhaust pipe to the turbocharger and tighten the bolts to 11Nꞏm (100 ft. lbs.) torque.

11. Connect the wastegate command valve connector.

12. Lower the vehicle.

13.Pre-lube the turbocharger.Pour 50 to 60 cc (2 to 3 oz.) clean engine oil in the oil supply line fitting on the

turbo. Rotate the turbocharger impeller by hand to distrubute the oil thoroughly.

14. Install and tighten the oil supply line fitting nut to 24 Nꞏm (18 ft. lbs.) torque.

15. Position the charge air cooler inlet pipe to the turbocharger. With theclamp in position, tighten the clamp nut to

11 Nꞏm (95 in. lbs.) torque.

16. Position the air inlet hose to the turbocharger. Tighten the clamp to 4 Nꞏm (35 in. lbs.) torque.

17. Connect the battery negative cables.

18. Start the engine to check for leaks.