check engine DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 517 of 5267

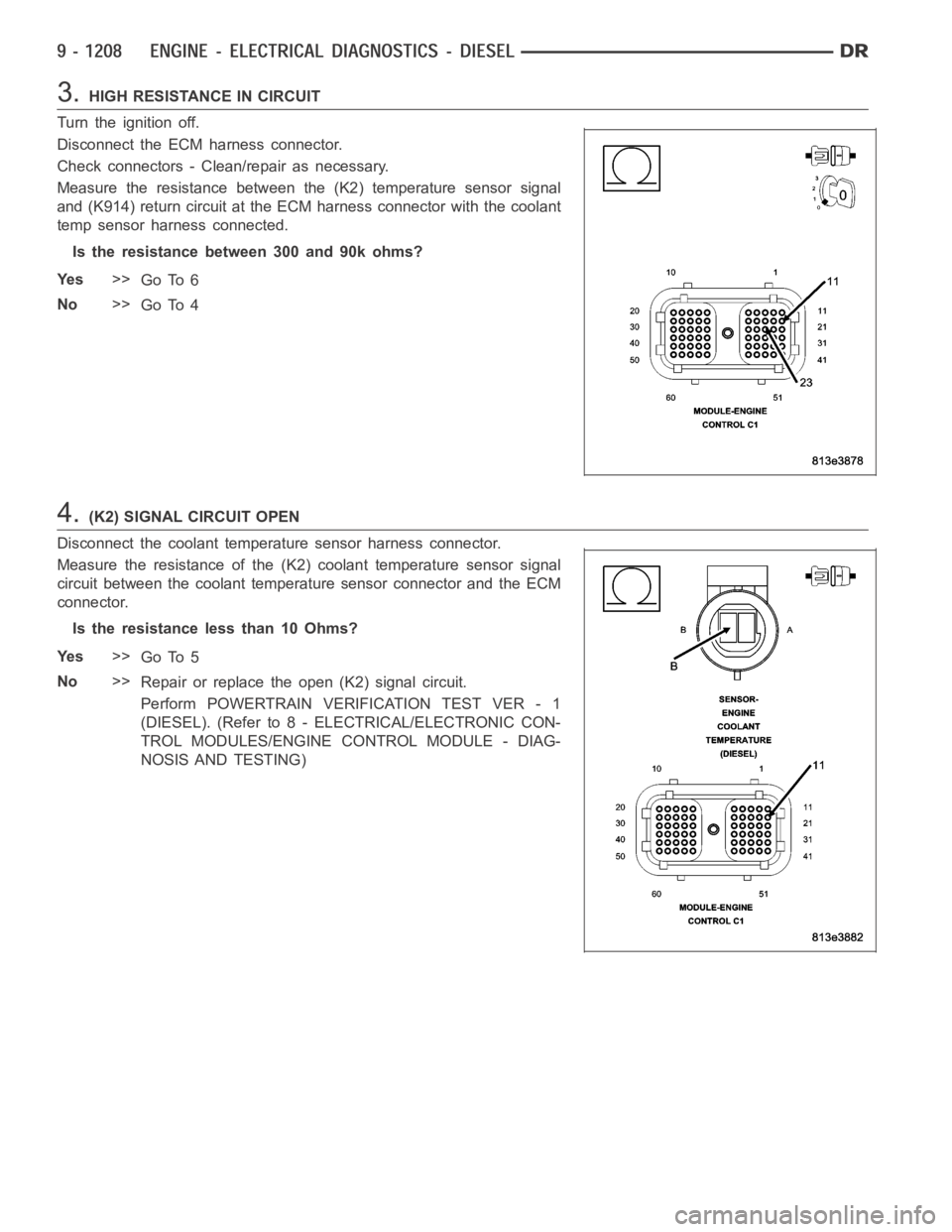

3.HIGH RESISTANCE IN CIRCUIT

Turn the ignition off.

Disconnect the ECM harness connector.

Check connectors - Clean/repair as necessary.

Measure the resistance between the (K2) temperature sensor signal

and (K914) return circuit at the ECM harness connector with the coolant

temp sensor harness connected.

Is the resistance between 300 and 90k ohms?

Ye s>>

Go To 6

No>>

Go To 4

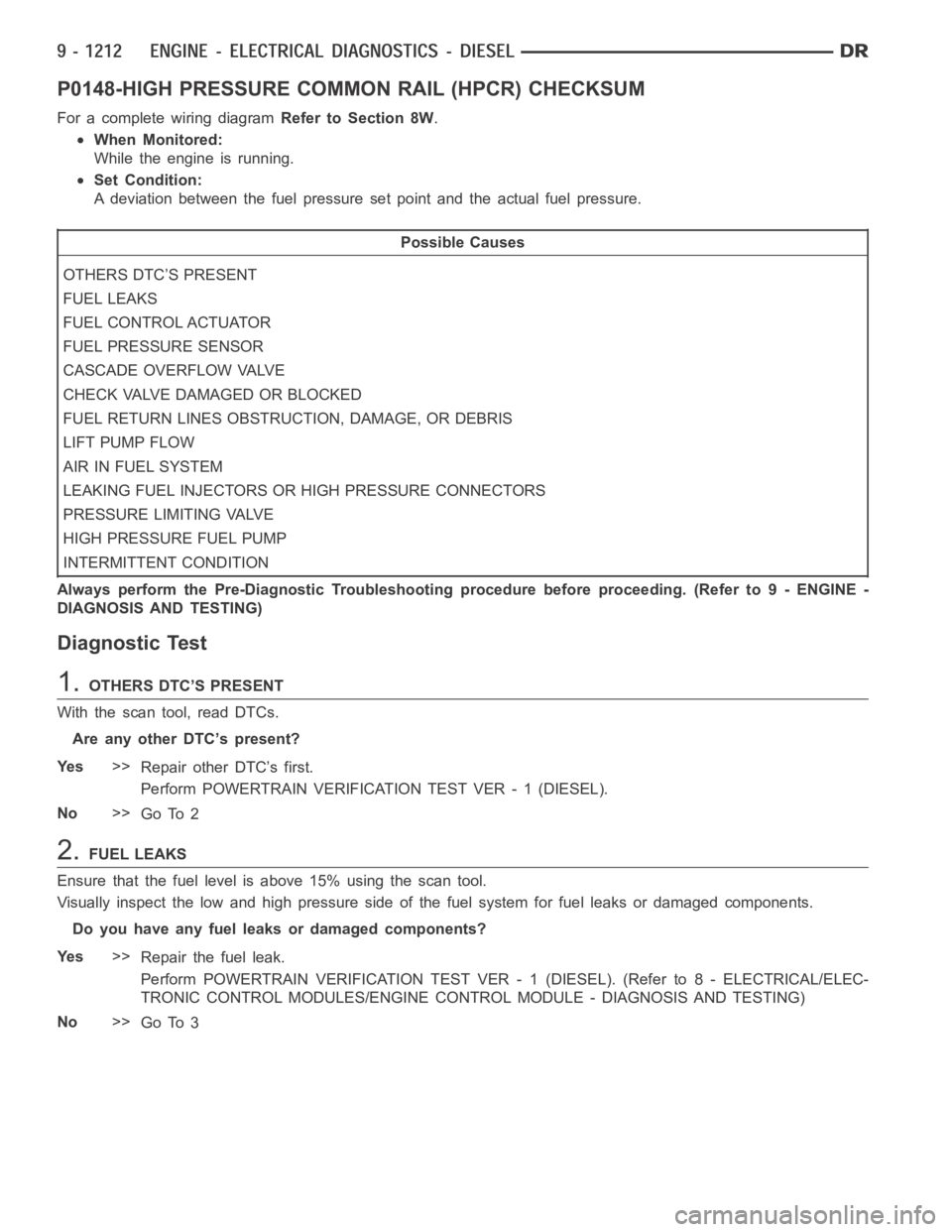

4.(K2) SIGNAL CIRCUIT OPEN

Disconnect the coolant temperature sensor harness connector.

Measure the resistance of the (K2) coolant temperature sensor signal

circuit between the coolant temperature sensor connector and the ECM

connector.

Is the resistance less than 10 Ohms?

Ye s>>

Go To 5

No>>

Repair or replace the open (K2) signal circuit.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

Page 521 of 5267

P0148-HIGH PRESSURE COMMON RAIL (HPCR) CHECKSUM

For a complete wiring diagramRefer to Section 8W.

When Monitored:

While the engine is running.

Set Condition:

A deviation between the fuel pressure set point and the actual fuel pressure.

Possible Causes

OTHERS DTC’S PRESENT

FUEL LEAKS

FUEL CONTROL ACTUATOR

FUEL PRESSURE SENSOR

CASCADE OVERFLOW VALVE

CHECK VALVE DAMAGED OR BLOCKED

FUEL RETURN LINES OBSTRUCTION, DAMAGE, OR DEBRIS

LIFT PUMP FLOW

AIRINFUELSYSTEM

LEAKING FUEL INJECTORS OR HIGH PRESSURE CONNECTORS

PRESSURE LIMITING VALVE

HIGH PRESSURE FUEL PUMP

INTERMITTENT CONDITION

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.OTHERS DTC’S PRESENT

With the scan tool, read DTCs.

Are any other DTC’s present?

Ye s>>

Repair other DTC’s first.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL).

No>>

Go To 2

2.FUEL LEAKS

Ensure that the fuel level is above 15% using the scan tool.

Visually inspect the low and high pressure side of the fuel system for fuel leaks or damaged components.

Do you have any fuel leaks or damaged components?

Ye s>>

Repair the fuel leak.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 3

Page 522 of 5267

3.FUEL CONTROL ACTUATOR

Check for a mechanically stuck Fuel Control Actuator (FCA). Using the scantool, actuate the fuel control actuator.

NOTE: The fuel control actuator will only click when cycled off..

Do you hear a click from the actuator when you cycle the actuator off with thescan tool?

Ye s>>

Go To 4

No>>

Replace the fuel Injector pump.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

4.FUEL PRESSURE SENSOR

Using the scan tool, monitor the fuel pressure reading from the fuel rail pressure sensor at idle and at 2000 RPM

Is the fuel rail pressure reading higher at 2000 RPM than at idle?

Ye s>>

Go To 5

No>>

Replace the fuel pressure sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

5.HIGH FUEL PRESSURE

Using the scan tool compare the fuel rail pressure set point with the actualfuel rail pressure.

Is the actual fuel rail pressure higher than the fuel rail pressure set point?

Ye s>>

Go To 6

No>>

Go To 9

6.CASCADE OVERFLOW VALVE

Perform the no trouble code test*fuel pump return flow test. (Refer to 9 - ENGINE - DIAGNOSIS AND TESTING)

Did the fuel injection pump pass the test?

Ye s>>

Go To 7

No>>

Replace the Fuel pump.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

7.CHECK VALVE DAMAGED OR BLOCKED

Check the fuel drain line check valve in the rear of the cylinder head for signs of damage, blockage, or debris.

Is the check valve damaged or blocked?

Ye s>>

Repair the cause of the damaged or blocked check valve or replace the valve.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 8

Page 523 of 5267

8.FUEL RETURN LINE OBSTRUCTION, DAMAGED OR DEBRIS

Check the fuel return lines for signs of obstruction, damage, or debris.

Are the fuel drain lines damaged or blocked?

Ye s>>

Repair cause of high fuel drain line restriction.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 9

9.LIFT PUMP FLOW

Perform the no trouble code*LIFT PUMP FLOW TEST. (Refer to 9 - ENGINE - DIAGNOSIS AND TESTING)

Did the Lift pump pass the test?

Ye s>>

Go To 10

No>>

Replace the Lift Pump.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

10.PRESSURE LIMITING VALVE

Perform the no trouble code test*PRESSURE LIMITING VALVE ON THE FUEL RAIL FOR INTERNAL LEAKS.

Did the pressure limiting valve pass the test procedure?

Ye s>>

Go To 11

No>>

Replace the Pressure Limiting Valve.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

11 .LEAKING FUEL INJECTORS OR HIGH PRESSURE CONNECTORS

Perform the no trouble test*INJECTOR RETURN FLOW TEST. (Refer to 9 - ENGINE - DIAGNOSIS AND TEST-

ING)

Are any Injectors leaking or high pressure connectors leaking?

Ye s>>

Replace or repair the leaking fuel injectors or high pressure connectors.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 12

12.HIGH PRESSURE FUEL PUMP

Perform the no trouble code test*HIGH PRESSURE FUEL PUMP PERFORMANCE TEST. (Refer to 9 - ENGINE

- DIAGNOSIS AND TESTING)

Did the fuel pump pass the high pressure fuel pump performance test?

Ye s>>

Refer to the INTERMITTENT CONDITION Symptom (Diagnostic Procedure). (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

No>>

Replace the High pressure fuel pump.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 529 of 5267

When Monitored:

With the ignition on and battery voltage greater than 10.4 volts.

Set Condition:

The circuit voltage to the ECM falls below a calibrated threshold for a certain period of time.

Possible Causes

OTHER DTC’S

FUEL PRESSURE SENSOR

(F855) 5-VOLT SUPPLY CIRCUIT SHORTED TO (F855) RETURN CIRCUIT

(K181) SIGNAL CIRCUIT SHORTED TO (F855) RETURN CIRCUIT

(K181) SIGNAL CIRCUIT OPEN

(F855) 5-VOLT SUPPLY CIRCUIT OPEN

(K181) SIGNAL CIRCUIT SHORTED TO GROUND

(F855) 5-VOLT SUPPLY CIRCUIT SHORTED TO GROUND

ECM

INTERMITTENT CONDITION

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.OTHER DTC’S

Ignition on, engine not running.

With the scan tool, read DTCs.

Do you have multiple DTC’s?

Ye s>>

Repair other DTC’s first.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 2

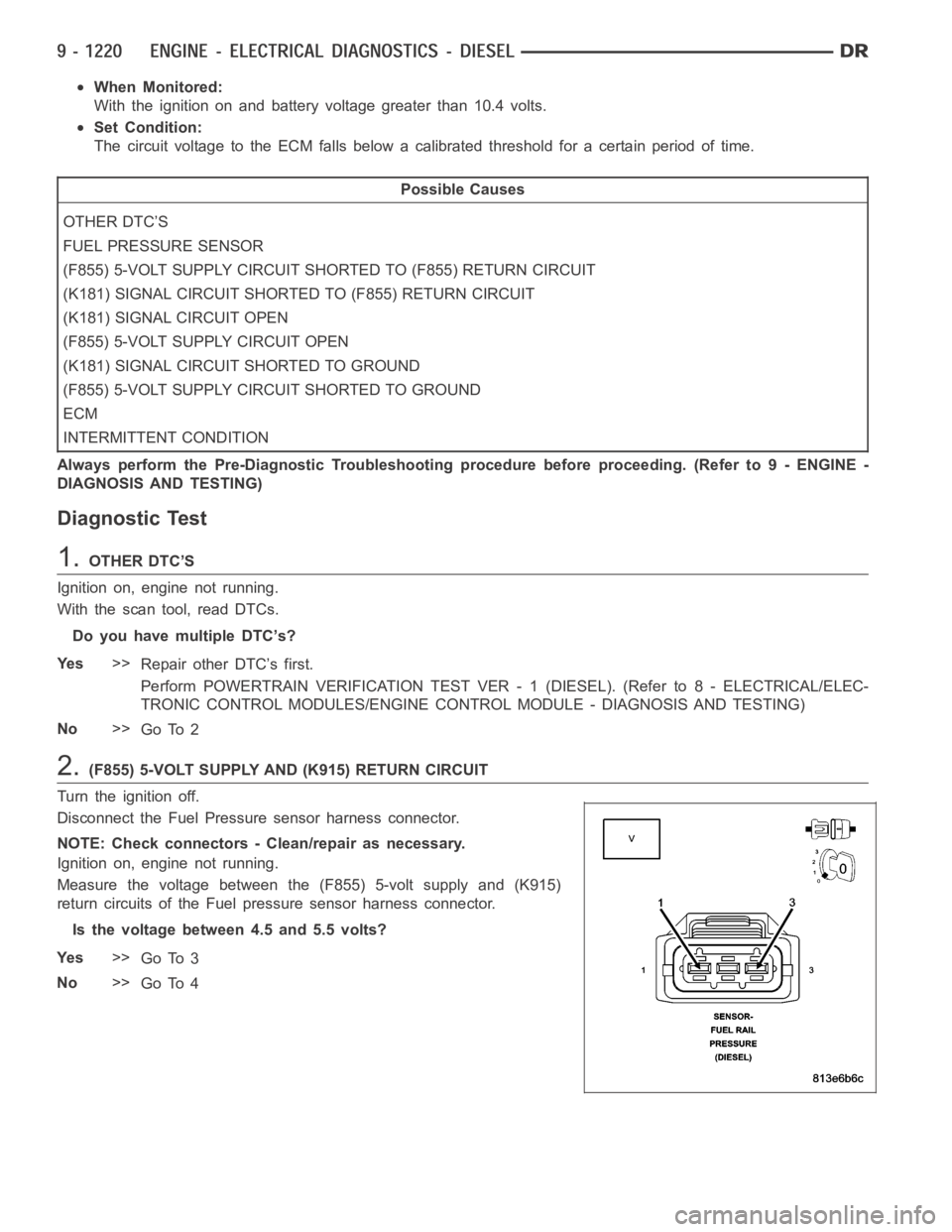

2.(F855) 5-VOLT SUPPLY AND (K915) RETURN CIRCUIT

Turn the ignition off.

Disconnect the Fuel Pressure sensor harness connector.

NOTE: Check connectors - Clean/repair as necessary.

Ignition on, engine not running.

Measure the voltage between the (F855) 5-volt supply and (K915)

return circuits of the Fuel pressure sensor harness connector.

Is the voltage between 4.5 and 5.5 volts?

Ye s>>

Go To 3

No>>

Go To 4

Page 530 of 5267

3.FUEL PRESSURE SENSOR

Reconnect the disconnected Fuel Pressure Sensor harness connector.

While monitoring scan tool, disconnect the Fuel Pressure sensor harness connector.

Does the DTC P0193 set?

Ye s>>

Replace the Fuel Pressure Sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 4

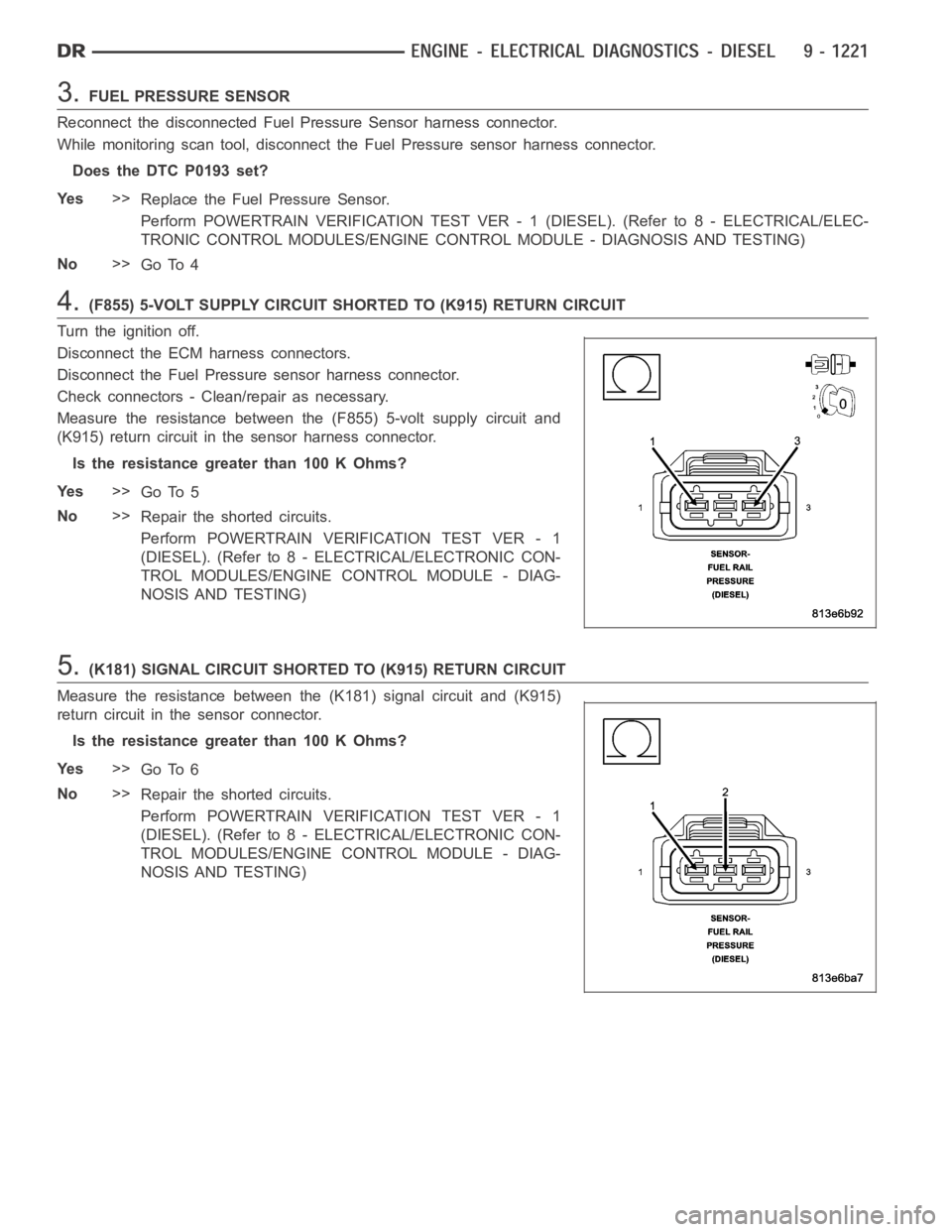

4.(F855) 5-VOLT SUPPLY CIRCUIT SHORTED TO (K915) RETURN CIRCUIT

Turn the ignition off.

Disconnect the ECM harness connectors.

Disconnect the Fuel Pressure sensor harness connector.

Check connectors - Clean/repair as necessary.

Measure the resistance between the (F855) 5-volt supply circuit and

(K915) return circuit in the sensor harness connector.

Is the resistance greater than 100 K Ohms?

Ye s>>

Go To 5

No>>

Repair the shorted circuits.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

5.(K181) SIGNAL CIRCUIT SHORTED TO (K915) RETURN CIRCUIT

Measure the resistance between the (K181) signal circuit and (K915)

return circuit in the sensor connector.

Is the resistance greater than 100 K Ohms?

Ye s>>

Go To 6

No>>

Repair the shorted circuits.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

Page 534 of 5267

When Monitored:

With the ignition on and battery voltage greater than 10.4 volts.

Set Condition:

The circuit voltage to the ECM is above a calibrated threshold for a certainperiod of time.

Possible Causes

OTHER DTC’S

FUEL PRESSURE SENSOR

(K181) SIGNAL CIRCUIT SHORTED TO VOLTAGE

(F855) 5-VOLT SUPPLY CIRCUIT SHORTED TO VOLTAGE

(K181) SIGNAL CIRCUIT SHORTED TO (F855) 5-VOLT SUPPLY CIRCUIT

(K915) RETURN CIRCUIT OPEN

ECM

INTERMITTENT CONDITION

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.OTHER DTC’S

Ignition on, engine not running.

With the scan tool, read DTCs.

Do you have multiple DTC’s?

Ye s>>

Refer to multiple fault troubleshooting tree.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 2

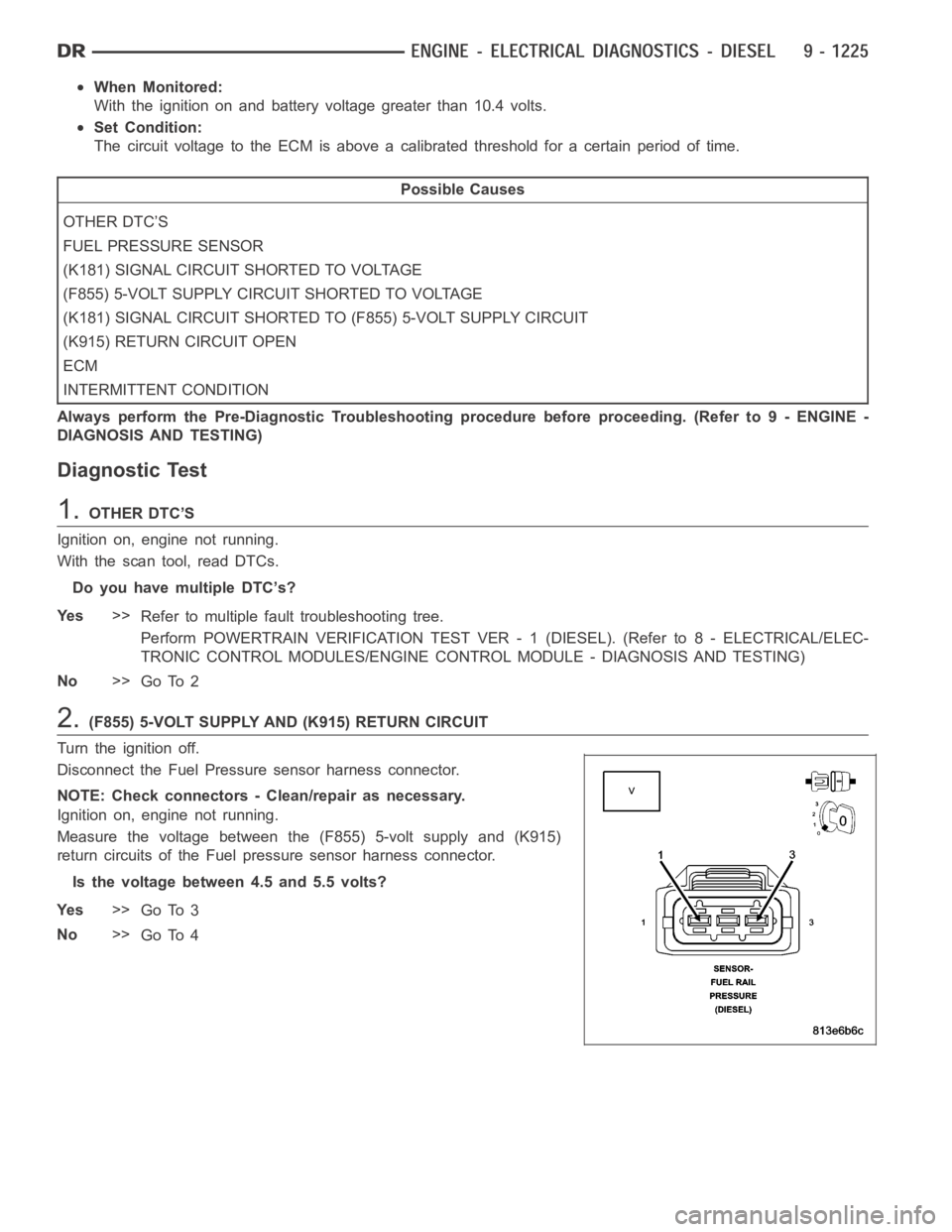

2.(F855) 5-VOLT SUPPLY AND (K915) RETURN CIRCUIT

Turn the ignition off.

Disconnect the Fuel Pressure sensor harness connector.

NOTE: Check connectors - Clean/repair as necessary.

Ignition on, engine not running.

Measure the voltage between the (F855) 5-volt supply and (K915)

return circuits of the Fuel pressure sensor harness connector.

Is the voltage between 4.5 and 5.5 volts?

Ye s>>

Go To 3

No>>

Go To 4

Page 535 of 5267

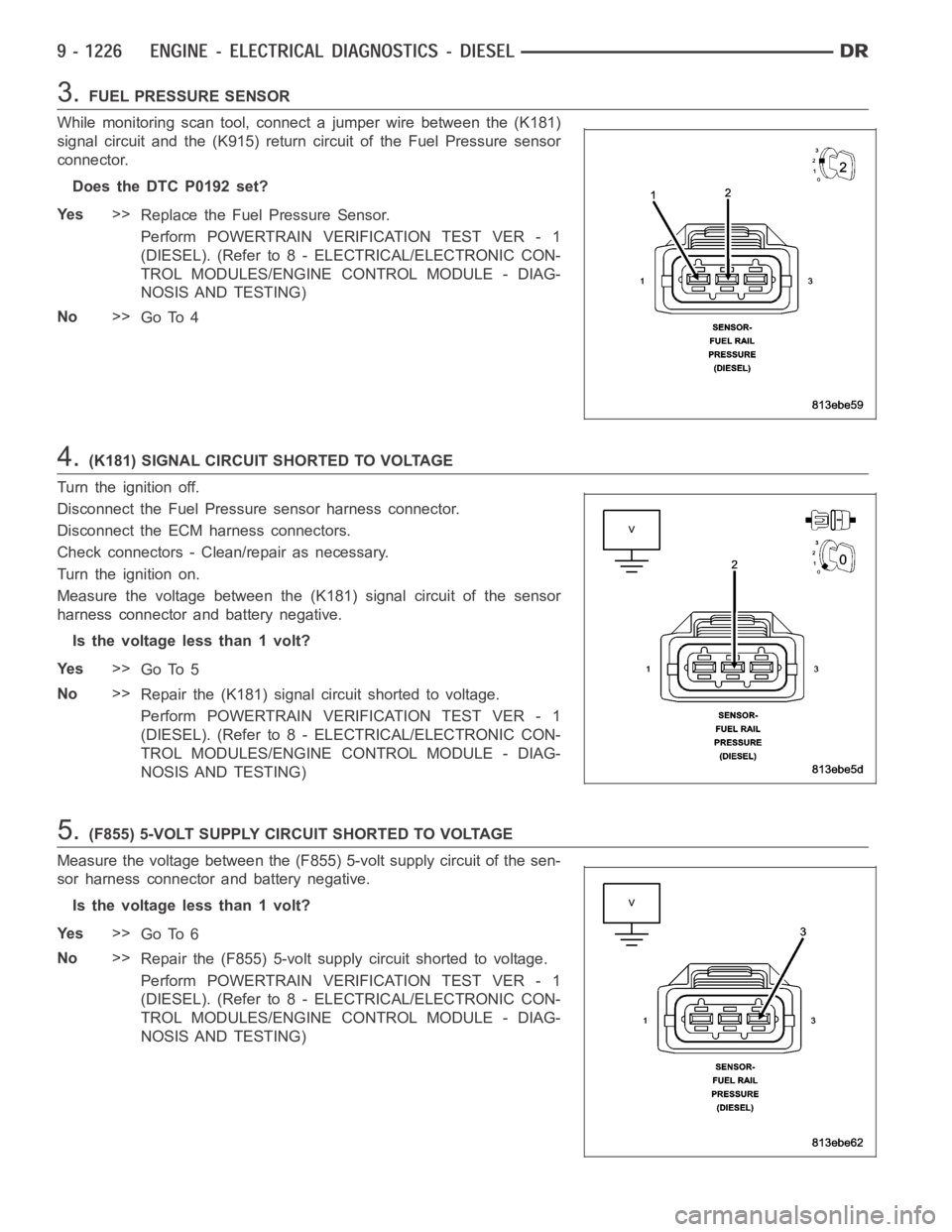

3.FUEL PRESSURE SENSOR

While monitoring scan tool, connect a jumper wire between the (K181)

signal circuit and the (K915) return circuit of the Fuel Pressure sensor

connector.

Does the DTC P0192 set?

Ye s>>

Replace the Fuel Pressure Sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

No>>

Go To 4

4.(K181) SIGNAL CIRCUIT SHORTED TO VOLTAGE

Turn the ignition off.

Disconnect the Fuel Pressure sensor harness connector.

Disconnect the ECM harness connectors.

Check connectors - Clean/repair as necessary.

Turn the ignition on.

Measure the voltage between the (K181) signal circuit of the sensor

harness connector and battery negative.

Is the voltage less than 1 volt?

Ye s>>

Go To 5

No>>

Repair the (K181) signal circuit shorted to voltage.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

5.(F855) 5-VOLT SUPPLY CIRCUIT SHORTED TO VOLTAGE

Measure the voltage between the (F855) 5-volt supply circuit of the sen-

sor harness connector and battery negative.

Is the voltage less than 1 volt?

Ye s>>

Go To 6

No>>

Repair the (F855) 5-volt supply circuit shorted to voltage.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

Page 539 of 5267

When Monitored:

While the engine is running.

Set Condition:

When the injector current falls below a calibrated threshold.

Possible Causes

PASS TROUGH CONNECTORS OPEN

FUEL INJECTOR

INJECTOR HARNESS OPEN

HIGH SIDE DRIVER HARNESS OPEN

LOW SIDE DRIVER HARNESS OPEN

ECM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.OTHER DTC’S

With the scan tool, read DTCs.

Are all 6 of the injector DTC’s (P0201 - P0206) present?

Ye s>>

Go To 2

No>>

Go To 3

2.PASS TROUGH CONNECTORS OPEN

Inspect wiring harness for signs of multiple open circuits between the ECMand the injector pass through connec-

tors. Inspect the wiring harness between the pass through connectors to theinjectors.

Are there open circuits in the wiring harness?

Ye s>>

Repair or replace the open connectors or wiring.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 3

3.FUEL INJECTOR

Turn the ignition off.

Disconnect the pigtail nuts from the suspect injector. Using an Ohmmeter,measure the resistance between the sole-

noid posts of the injector.

NOTE: Be sure to zero the ohm meter prior to checking the injector circuit.

Is the resistance less than 1 ohm and greater than 0 ohms?

Ye s>>

Go To 4

No>>

Replace the fuel injector.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 540 of 5267

4.INJECTOR HARNESS OPEN

Connect the pigtail nuts for the suspect injector.

Disconnect the injector harness connector for the suspect injector.

Measure the resistance of the injector harness circuit between the high

side driver circuit and the low side driver circuit for the suspect injector

at the injector harness connector.

NOTE: Be sure to zero the ohm meter prior to checking the injec-

tor circuit.

Is the resistance less than 1 ohm and greater than 0 ohms?

Ye s>>

Go To 5

No>>

Replace or repair the injector harness.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

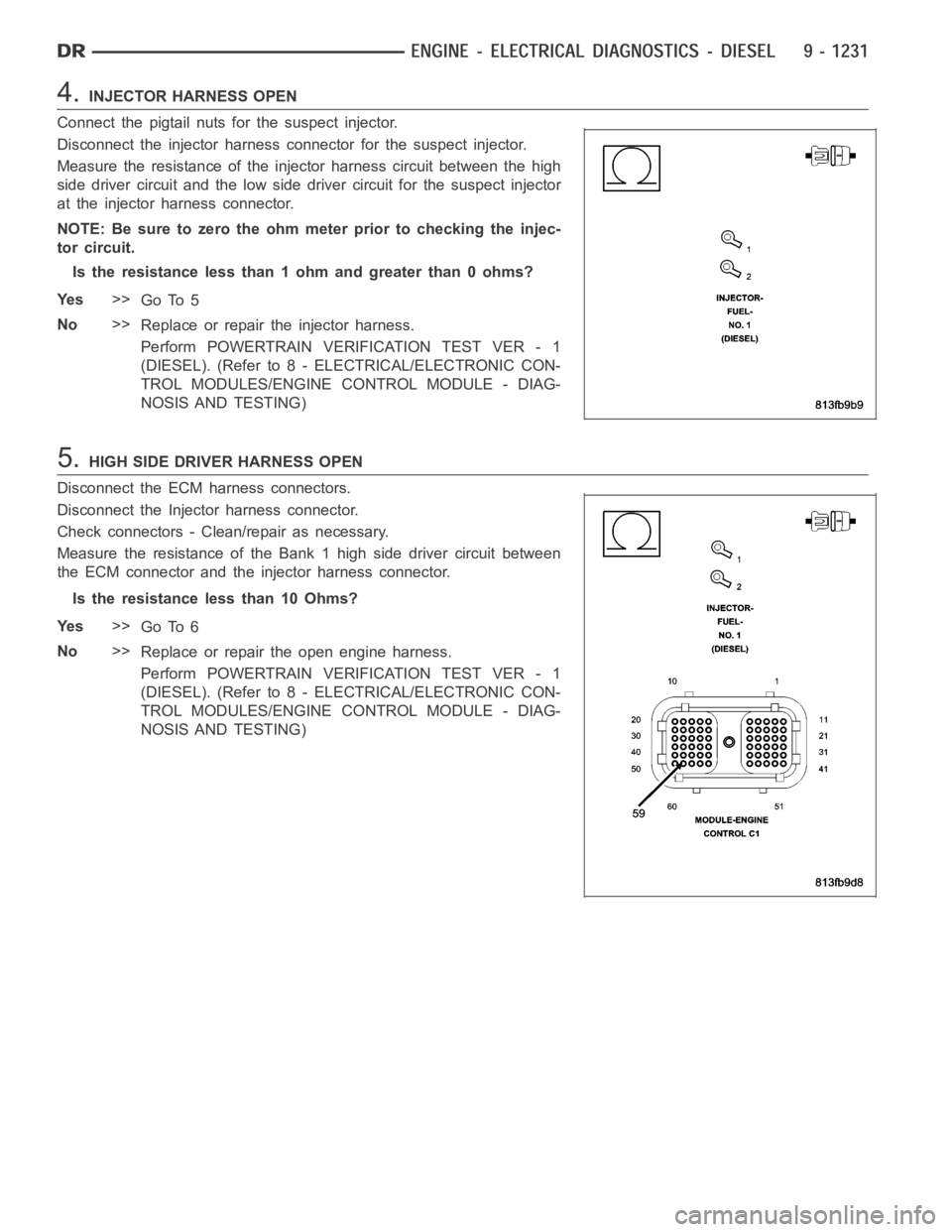

5.HIGH SIDE DRIVER HARNESS OPEN

Disconnect the ECM harness connectors.

Disconnect the Injector harness connector.

Check connectors - Clean/repair as necessary.

Measure the resistance of the Bank 1 high side driver circuit between

the ECM connector and the injector harness connector.

Is the resistance less than 10 Ohms?

Ye s>>

Go To 6

No>>

Replace or repair the open engine harness.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)