check engine DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 599 of 5267

3.DAMAGED FUEL LINE

Visually inspect the injector supply line for damage.

Do you have any kinked or bent fuel lines?

Ye s>>

Repair or replace the damaged fuel line.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 4

4.VA LV E T R A I N

Visually inspect the valve train and check the valve lash on the suspect cylinder.

Is the valve train functional and the lash within the specifications listed in the service manual?

Ye s>>

Go To 5

No>>

Adjust the lash or fix or repair any damaged component(s).

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

5.OBSTRUCTED FUEL INJECTOR SUPPLY

Remove the fuel injector supply line for the suspect cylinder.

Inspect both ends of the fuel injector supply line for damage.

Using shop air pressure, blow out the fuel injector supply line to verify that they are not obstructed.

Are the fuel lines free of debris or damage?

Ye s>>

Go To 6

No>>

Replace the damaged or obstructed fuel injector supply line.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

6.DAMAGED OR OBSTRUCTED HIGH PRESSURE CONNECTOR

Remove the high pressure connector for the suspect cylinder.

Inspect both ends of the high pressure connector for signs of damage.

Using shop air pressure, blow out the high pressure connector to verify that it is not obstructed.

Are the high pressure connectors free of debris or damage?

Ye s>>

Go To 7

No>>

Replace the damaged or obstructed high pressure connector.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

7.FUEL INJECTOR

Remove the suspect fuel injector.

Are the fuel injectors damaged?

Ye s>>

Replace the external damaged fuel injector & high pressure connector.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 8

Page 602 of 5267

3.DAMAGED FUEL LINE

Visually inspect the injector supply line for damage.

Do you have any kinked or bent fuel line?

Ye s>>

Repair or replace the damaged fuel line.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 4

4.VA LV E T R A I N

Visually inspect the valve train and check the valve lash on the suspect cylinder.

Is the valve train functional and the lash within the specifications listed in the service manual?

Ye s>>

Go To 5

No>>

Adjust the lash or fix or repair any damaged component(s).

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

5.OBSTRUCTED FUEL INJECTOR SUPPLY

Remove the fuel injector supply line for the suspect cylinder.

Inspect both ends of the fuel injector supply line for damage.

Using shop air pressure, blow out the fuel injector supply line to verify that they are not obstructed.

Are the fuel lines free of debris or damage?

Ye s>>

Go To 6

No>>

Replace the damaged or obstructed fuel injector supply line.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

6.DAMAGED OR OBSTRUCTED HIGH PRESSURE CONNECTOR

Remove the high pressure connector for the suspect cylinder.

Inspect both ends of the high pressure connector for signs of damage.

Using shop air pressure, blow out the high pressure connector to verify that it is not obstructed.

Are the high pressure connectors free of debris or damage?

Ye s>>

Go To 7

No>>

Replace the damaged or obstructed high pressure connector.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

7.FUEL INJECTOR

Remove the suspect fuel injector.

Is the fuel injector damaged?

Ye s>>

Replace the external damaged fuel injector & high pressure connector.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 8

Page 605 of 5267

3.DAMAGED FUEL LINE

Visually inspect the injector supply line for damage.

Do you have any kinked or bent fuel line?

Ye s>>

Repair or replace the damaged fuel line.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 4

4.VA LV E T R A I N

Visually inspect the valve train and check the valve lash on the suspect cylinder.

Is the valve train functional and the lash within the specifications listed in the service manual?

Ye s>>

Go To 5

No>>

Adjust the lash or fix or repair any damaged component(s).

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

5.OBSTRUCTED FUEL INJECTOR SUPPLY

Remove the fuel injector supply line for the suspect cylinder.

Inspect both ends of the fuel injector supply lines for damage.

Using shop air pressure, blow out the fuel injector supply lines to verify that they are not obstructed.

Are the fuel lines free of debris or damage?

Ye s>>

Go To 6

No>>

Replace the damaged or obstructed fuel injector supply line.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

6.DAMAGED OR OBSTRUCTED HIGH PRESSURE CONNECTOR

Remove the high pressure connector for the suspect cylinder.

Inspect both ends of the high pressure connector for signs of damage.

Using shop air pressure, blow out the high pressure connector to verify that it is not obstructed.

Are the high pressure connectors free of debris or damage?

Ye s>>

Go To 7

No>>

Replace the damaged or obstructed high pressure connector.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

7.FUEL INJECTOR

Remove the suspect fuel injector.

Are the fuel injectors damaged?

Ye s>>

Replace the external damaged fuel injector & high pressure connector.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 8

Page 608 of 5267

3.DAMAGED FUEL LINE

Visually inspect the injector supply line for damage.

Do you have any kinked or bent fuel line?

Ye s>>

Repair or replace the damaged fuel line.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 4

4.VA LV E T R A I N

Visually inspect the valve train and check the valve lash on the suspect cylinder.

Is the valve train functional and the lash within the specifications listed in the service manual?

Ye s>>

Go To 5

No>>

Adjust the lash or fix or repair any damaged component(s).

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

5.OBSTRUCTED FUEL INJECTOR SUPPLY

Remove the fuel injector supply line for the suspect cylinder.

Inspect both ends of the fuel injector supply line for damage.

Using shop air pressure, blow out the fuel injector supply lines to verify that they are not obstructed.

Are the fuel lines free of debris or damage?

Ye s>>

Go To 6

No>>

Replace the damaged or obstructed fuel injector supply line.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

6.DAMAGED OR OBSTRUCTED HIGH PRESSURE CONNECTOR

Remove the high pressure connector for the suspect cylinder.

Inspect both ends of the high pressure connector for signs of damage.

Using shop air pressure, blow out the high pressure connectors to verify that it is not obstructed.

Are the high pressure connectors free of debris or damage?

Ye s>>

Go To 7

No>>

Replace the damaged or obstructed high pressure connector.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

7.FUEL INJECTOR

Remove the suspect fuel injector.

Are the fuel injectors damaged?

Ye s>>

Replace the external damaged fuel injector & high pressure connector.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 8

Page 611 of 5267

3.DAMAGED FUEL LINE

Visually inspect the injector supply line for damage.

Do you have any kinked or bent fuel line?

Ye s>>

Repair or replace the damaged fuel line.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 4

4.VA LV E T R A I N

Visually inspect the valve train and check the valve lash on the suspect cylinder.

Is the valve train functional and the lash within the specifications listed in the service manual?

Ye s>>

Go To 5

No>>

Adjust the lash or fix or repair any damaged component(s).

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

5.OBSTRUCTED FUEL INJECTOR SUPPLY

Remove the fuel injector supply lines for the suspect cylinder.

Inspect both ends of the fuel injector supply lines for damage.

Using shop air pressure, blow out the fuel injector supply lines to verify that they are not obstructed.

Are the fuel lines free of debris or damage?

Ye s>>

Go To 6

No>>

Replace the damaged or obstructed fuel injector supply lines.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

6.DAMAGED OR OBSTRUCTED HIGH PRESSURE CONNECTOR

Remove the high pressure connectors for the suspect cylinder.

Inspect both ends of the high pressure connector for signs of damage.

Using shop air pressure, blow out the high pressure connector to verify that they are not obstructed.

Are the high pressure connector free of debris or damage?

Ye s>>

Go To 7

No>>

Replace the damaged or obstructed high pressure connector.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

7.FUEL INJECTOR

Remove the suspect fuel injector.

Are the fuel injectors damaged?

Ye s>>

Replace the external damaged fuel injector & high pressure connector.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 8

Page 614 of 5267

3.DAMAGED FUEL LINE

Visually inspect the injector supply line for damage.

Do you have any kinked or bent fuel line?

Ye s>>

Repair or replace the damaged fuel line.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 4

4.VA LV E T R A I N

Visually inspect the valve train and check the valve lash on the suspect cylinder.

Is the valve train functional and the lash within the specifications listed in the service manual?

Ye s>>

Go To 5

No>>

Adjust the lash or fix or repair any damaged component(s).

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

5.OBSTRUCTED FUEL INJECTOR SUPPLY

Remove the fuel injector supply line for the suspect cylinder.

Inspect both ends of the fuel injector supply lines for damage.

Using shop air pressure, blow out the fuel injector supply line to verify that it is not obstructed.

Are the fuel lines free of debris or damage?

Ye s>>

Go To 6

No>>

Replace the damaged or obstructed fuel injector supply line.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

6.DAMAGED OR OBSTRUCTED HIGH PRESSURE CONNECTOR

Remove the high pressure connector for the suspect cylinder.

Inspect both ends of the high pressure connectors for signs of damage.

Using shop air pressure, blow out the high pressure connector to verify that they are not obstructed.

Are the high pressure connectors free of debris or damage?

Ye s>>

Go To 7

No>>

Replace the damaged or obstructed high pressure connector.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

7.FUEL INJECTOR

Remove the suspect fuel injector.

Are the fuel injectors damaged?

Ye s>>

Replace the external damaged fuel injector & high pressure connector.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 8

Page 618 of 5267

3.VISUAL DAMAGE

Visually inspect the sensor, engine belt, sensor connector, and the ECM connector.

Is there any damage?

Ye s>>

Repair or replace the sensor, engine belt, harness, or the ECM.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 4

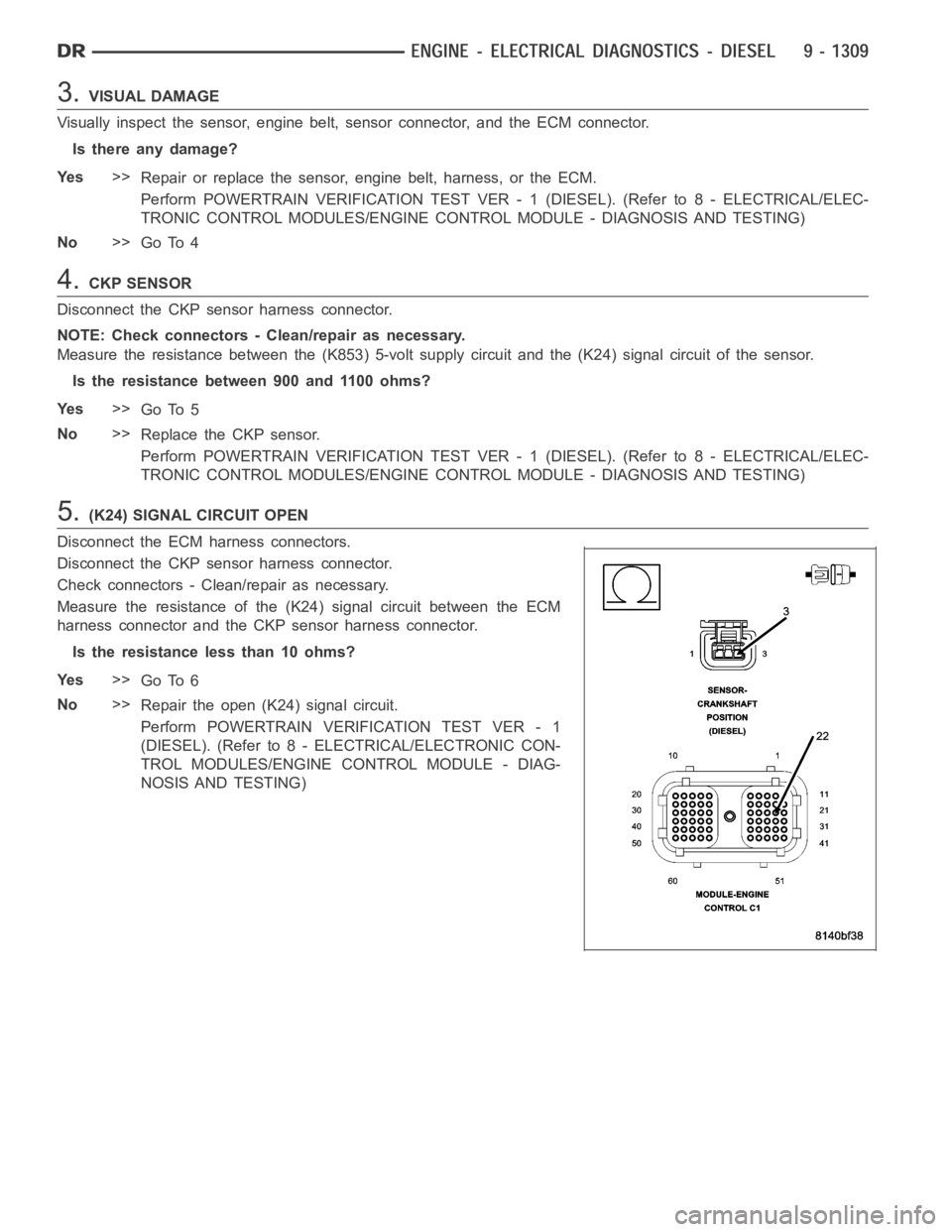

4.CKP SENSOR

Disconnect the CKP sensor harness connector.

NOTE: Check connectors - Clean/repair as necessary.

Measure the resistance between the (K853) 5-volt supply circuit and the (K24) signal circuit of the sensor.

Is the resistance between 900 and 1100 ohms?

Ye s>>

Go To 5

No>>

Replace the CKP sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

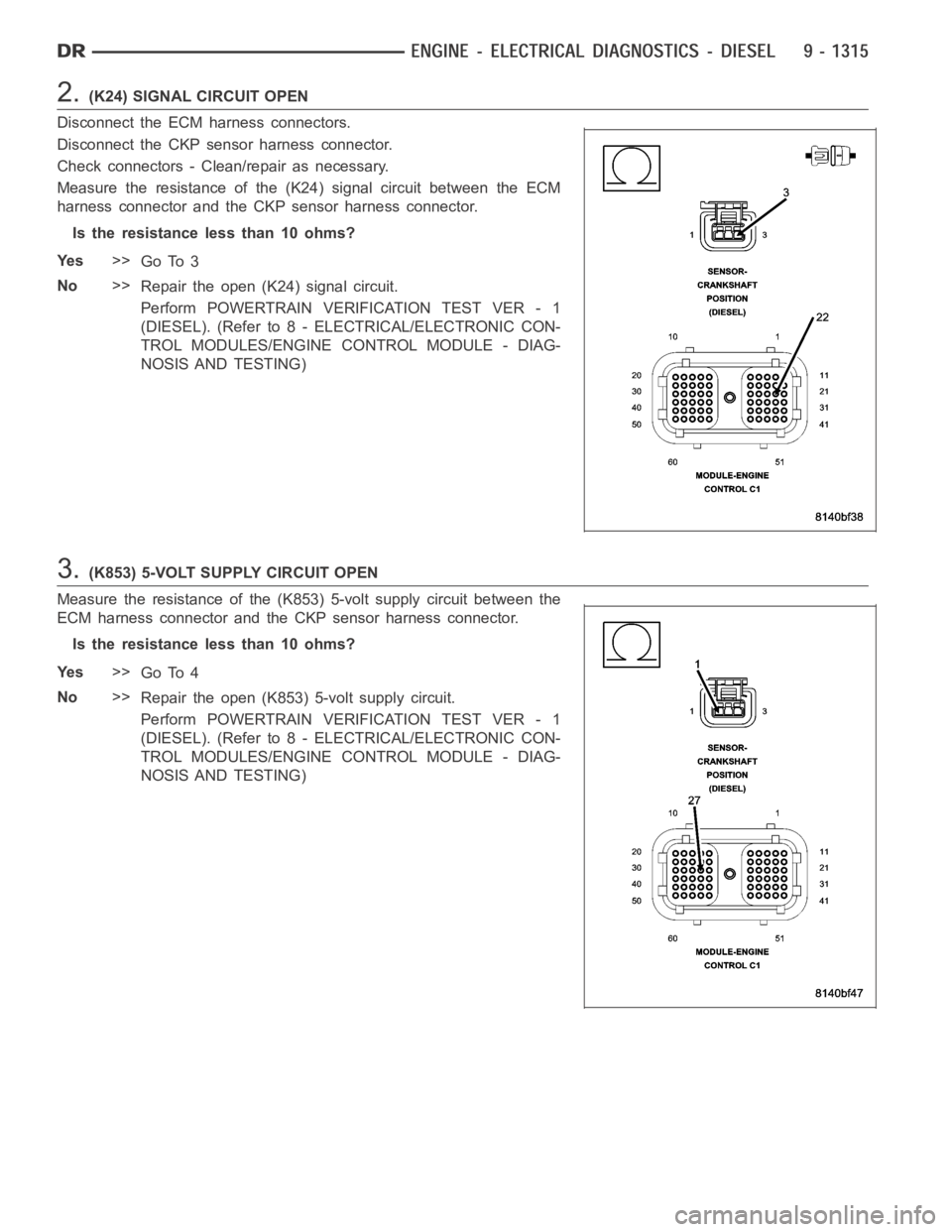

5.(K24) SIGNAL CIRCUIT OPEN

Disconnect the ECM harness connectors.

Disconnect the CKP sensor harness connector.

Check connectors - Clean/repair as necessary.

Measure the resistance of the (K24) signal circuit between the ECM

harness connector and the CKP sensor harness connector.

Is the resistance less than 10 ohms?

Ye s>>

Go To 6

No>>

Repair the open (K24) signal circuit.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

Page 623 of 5267

When Monitored:

With the key on.

Set Condition:

The voltage detected at the Crankshaft position sensor is below a calibrated value.

Possible Causes

CKP SENSOR

(K24) SIGNAL CIRCUIT OPEN

(K853) 5-VOLT SUPPLY CIRCUIT OPEN

(K975) RETURN CIRCUIT OPEN

(K24) SIGNAL CIRCUIT SHORTED TO (K975) RETURN CIRCUIT

(K853) 5-VOLT SUPPLY CIRCUIT SHORTED TO (K975) RETURN CIRCUIT

(K24) SIGNAL CIRCUIT SHORTED TO(K853) 5-VOLT SUPPLY CIRCUIT

(K24) SIGNAL CIRCUIT SHORTED TO GROUND

(K853) 5-VOLT SUPPLY CIRCUIT SHORTED TO BATTERY NEGATIVE

INTERMITTENT CONDITION

ECM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.CKP SENSOR

Disconnect the CKP sensor harness connector.

NOTE: Check connectors - Clean/repair as necessary.

Measure the resistance between the (K853) 5-volt supply circuit and the (K24) signal circuit of the sensor.

Is the resistance between 900 and 1100 ohms?

Ye s>>

Go To 2

No>>

Replace the CKP sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 624 of 5267

2.(K24) SIGNAL CIRCUIT OPEN

Disconnect the ECM harness connectors.

Disconnect the CKP sensor harness connector.

Check connectors - Clean/repair as necessary.

Measure the resistance of the (K24) signal circuit between the ECM

harness connector and the CKP sensor harness connector.

Is the resistance less than 10 ohms?

Ye s>>

Go To 3

No>>

Repair the open (K24) signal circuit.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

3.(K853) 5-VOLT SUPPLY CIRCUIT OPEN

Measure the resistance of the (K853) 5-volt supply circuit between the

ECM harness connector and the CKP sensor harness connector.

Is the resistance less than 10 ohms?

Ye s>>

Go To 4

No>>

Repair the open (K853) 5-volt supply circuit.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

Page 629 of 5267

When Monitored:

With the key on.

Set Condition:

Voltage detected at the CKP is below acalibrated value for a calibrated amountoftime.

Possible Causes

CKP SENSOR

(K853) 5-VOLT SUPPLY CIRCUIT SHORTED TO (K975) RETURN CIRCUIT

(K853) 5-VOLT SUPPLY CIRCUIT SHORTED BATTERY NEGATIVE

INTERMITTENT CONDITION

ECM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

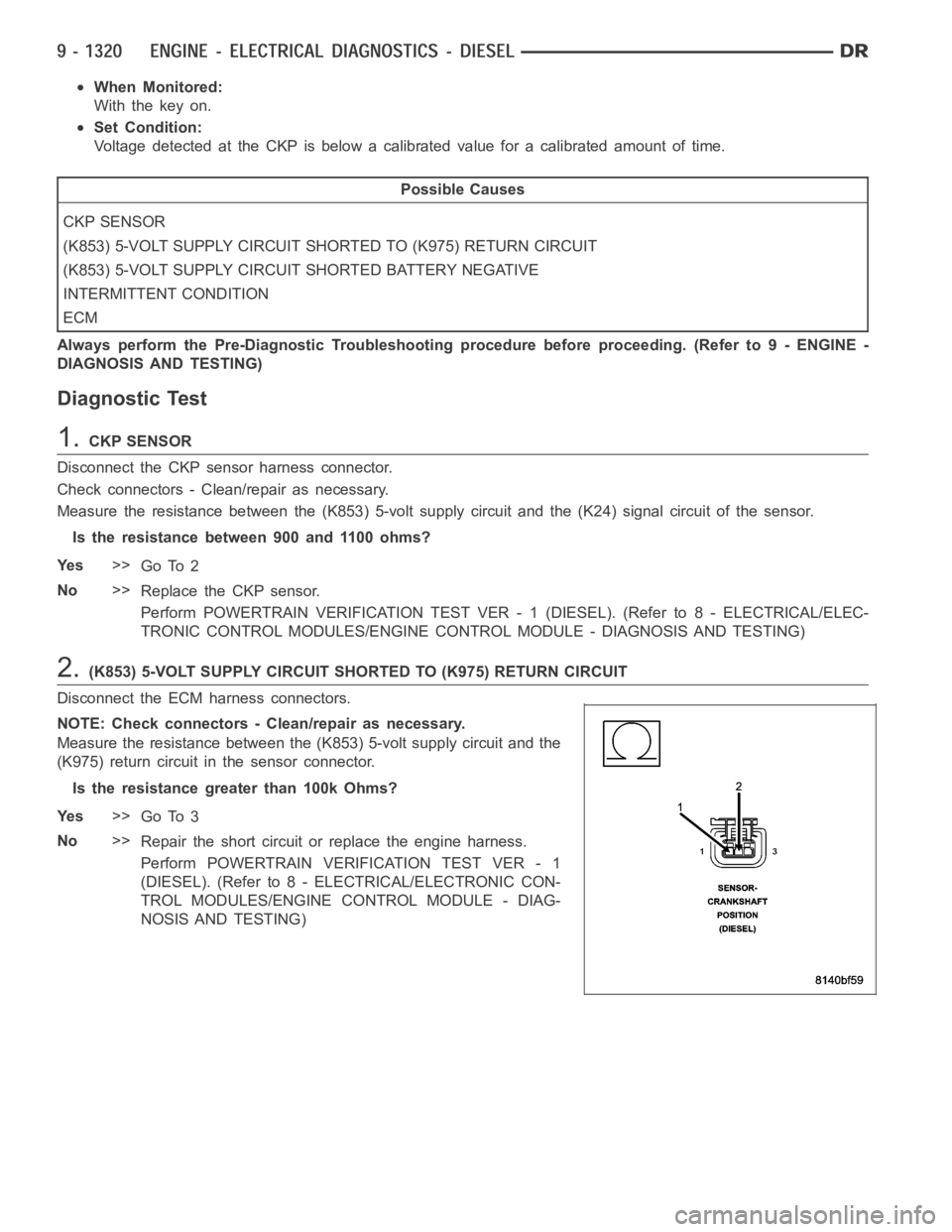

1.CKP SENSOR

Disconnect the CKP sensor harness connector.

Check connectors - Clean/repair as necessary.

Measure the resistance between the (K853) 5-volt supply circuit and the (K24) signal circuit of the sensor.

Is the resistance between 900 and 1100 ohms?

Ye s>>

Go To 2

No>>

Replace the CKP sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

2.(K853) 5-VOLT SUPPLY CIRCUIT SHORTED TO (K975) RETURN CIRCUIT

Disconnect the ECM harness connectors.

NOTE: Check connectors - Clean/repair as necessary.

Measure the resistance between the (K853) 5-volt supply circuit and the

(K975) return circuit in the sensor connector.

Is the resistance greater than 100k Ohms?

Ye s>>

Go To 3

No>>

Repair the short circuit or replace the engine harness.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)