check engine DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 632 of 5267

When Monitored:

With the key on.

Set Condition:

Voltage detected at the CKP is above a calibrated value for a calibrated amount of time.

Possible Causes

(K853) 5-VOLT SUPPLY CIRCUIT SHORTED TO VOLTAGE

INTERMITTENT CONDITION

ECM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

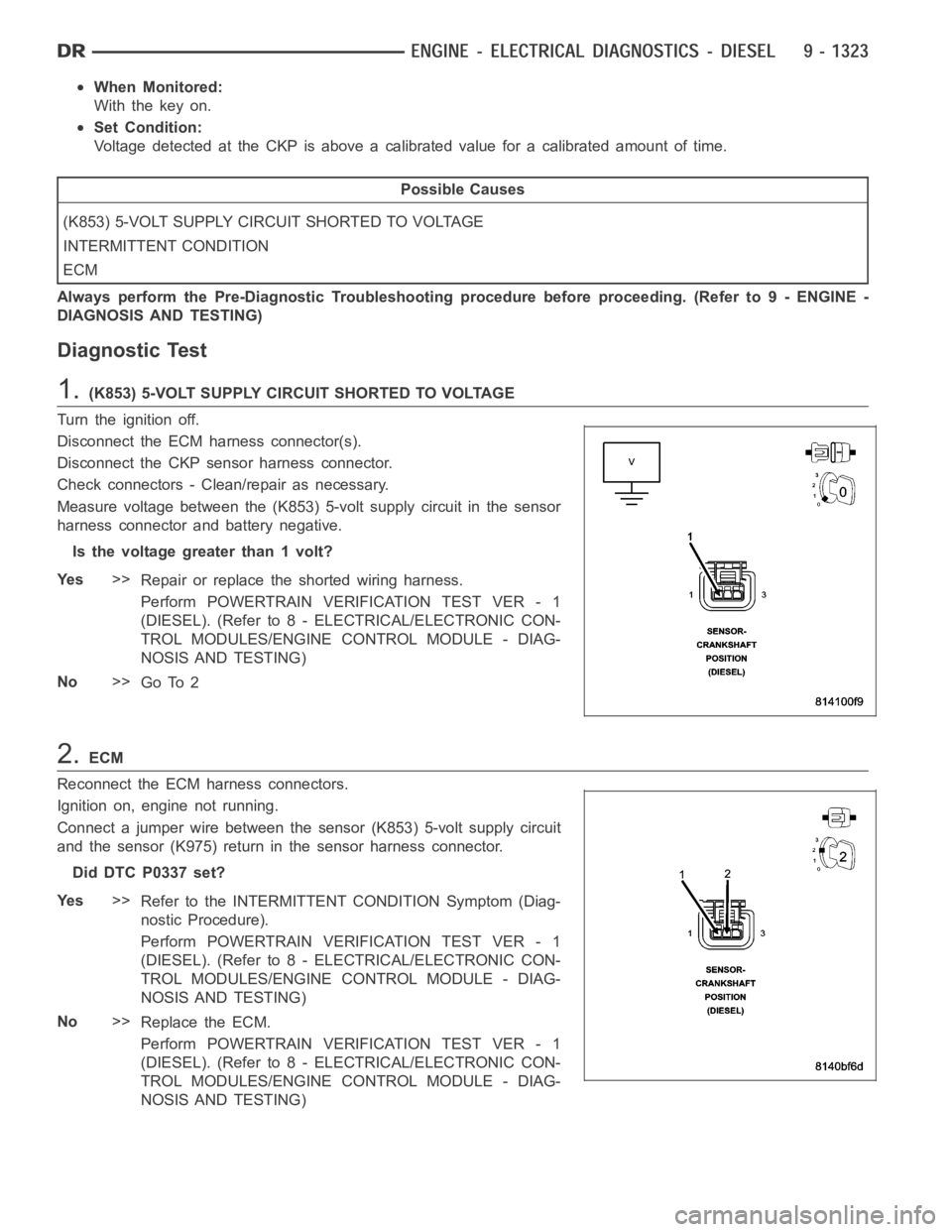

1.(K853) 5-VOLT SUPPLY CIRCUIT SHORTED TO VOLTAGE

Turn the ignition off.

Disconnect the ECM harness connector(s).

Disconnect the CKP sensor harness connector.

Check connectors - Clean/repair as necessary.

Measure voltage between the (K853) 5-volt supply circuit in the sensor

harness connector and battery negative.

Is the voltage greater than 1 volt?

Ye s>>

Repair or replace the shorted wiring harness.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

No>>

Go To 2

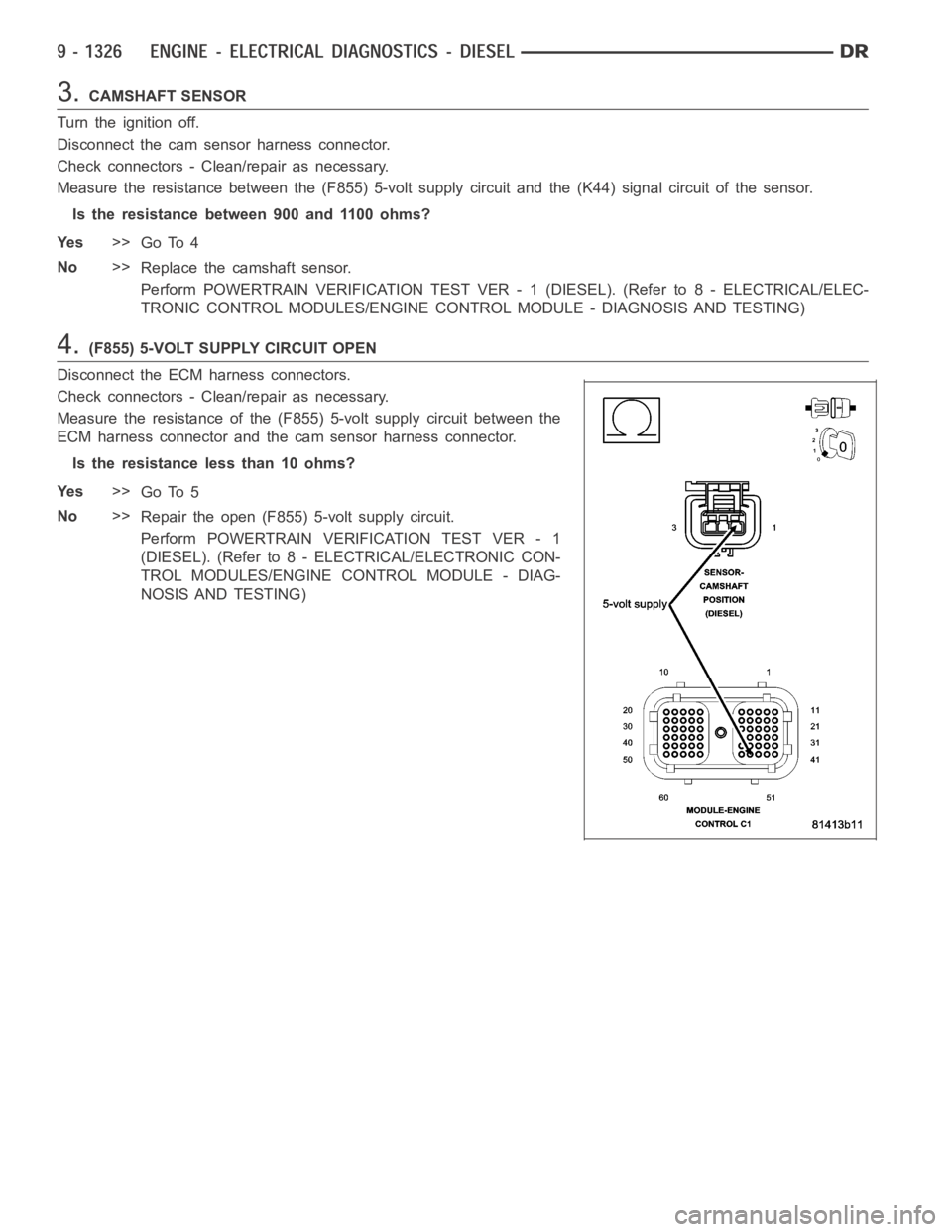

2.ECM

Reconnect the ECM harness connectors.

Ignition on, engine not running.

Connect a jumper wire between the sensor (K853) 5-volt supply circuit

and the sensor (K975) return in the sensor harness connector.

Did DTC P0337 set?

Ye s>>

Refer to the INTERMITTENT CONDITION Symptom (Diag-

nostic Procedure).

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

No>>

Replace the ECM.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

Page 635 of 5267

3.CAMSHAFT SENSOR

Turn the ignition off.

Disconnect the cam sensor harness connector.

Check connectors - Clean/repair as necessary.

Measure the resistance between the (F855) 5-volt supply circuit and the (K44) signal circuit of the sensor.

Is the resistance between 900 and 1100 ohms?

Ye s>>

Go To 4

No>>

Replace the camshaft sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

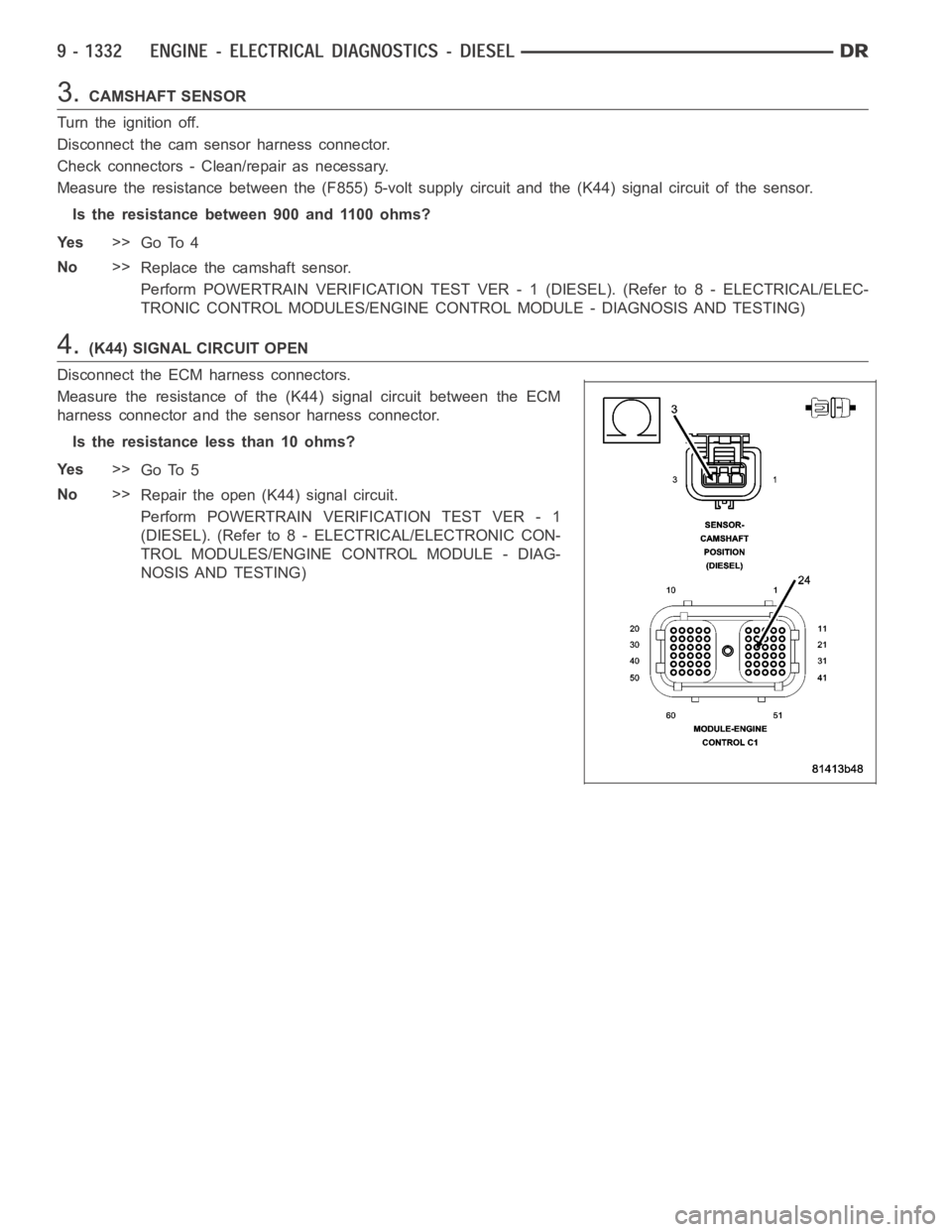

4.(F855) 5-VOLT SUPPLY CIRCUIT OPEN

Disconnect the ECM harness connectors.

Check connectors - Clean/repair as necessary.

Measure the resistance of the (F855) 5-volt supply circuit between the

ECM harness connector and the cam sensor harness connector.

Is the resistance less than 10 ohms?

Ye s>>

Go To 5

No>>

Repair the open (F855) 5-volt supply circuit.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

Page 641 of 5267

3.CAMSHAFT SENSOR

Turn the ignition off.

Disconnect the cam sensor harness connector.

Check connectors - Clean/repair as necessary.

Measure the resistance between the (F855) 5-volt supply circuit and the (K44) signal circuit of the sensor.

Is the resistance between 900 and 1100 ohms?

Ye s>>

Go To 4

No>>

Replace the camshaft sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

4.(K44) SIGNAL CIRCUIT OPEN

Disconnect the ECM harness connectors.

Measure the resistance of the (K44) signal circuit between the ECM

harness connector and the sensor harness connector.

Is the resistance less than 10 ohms?

Ye s>>

Go To 5

No>>

Repair the open (K44) signal circuit.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

Page 646 of 5267

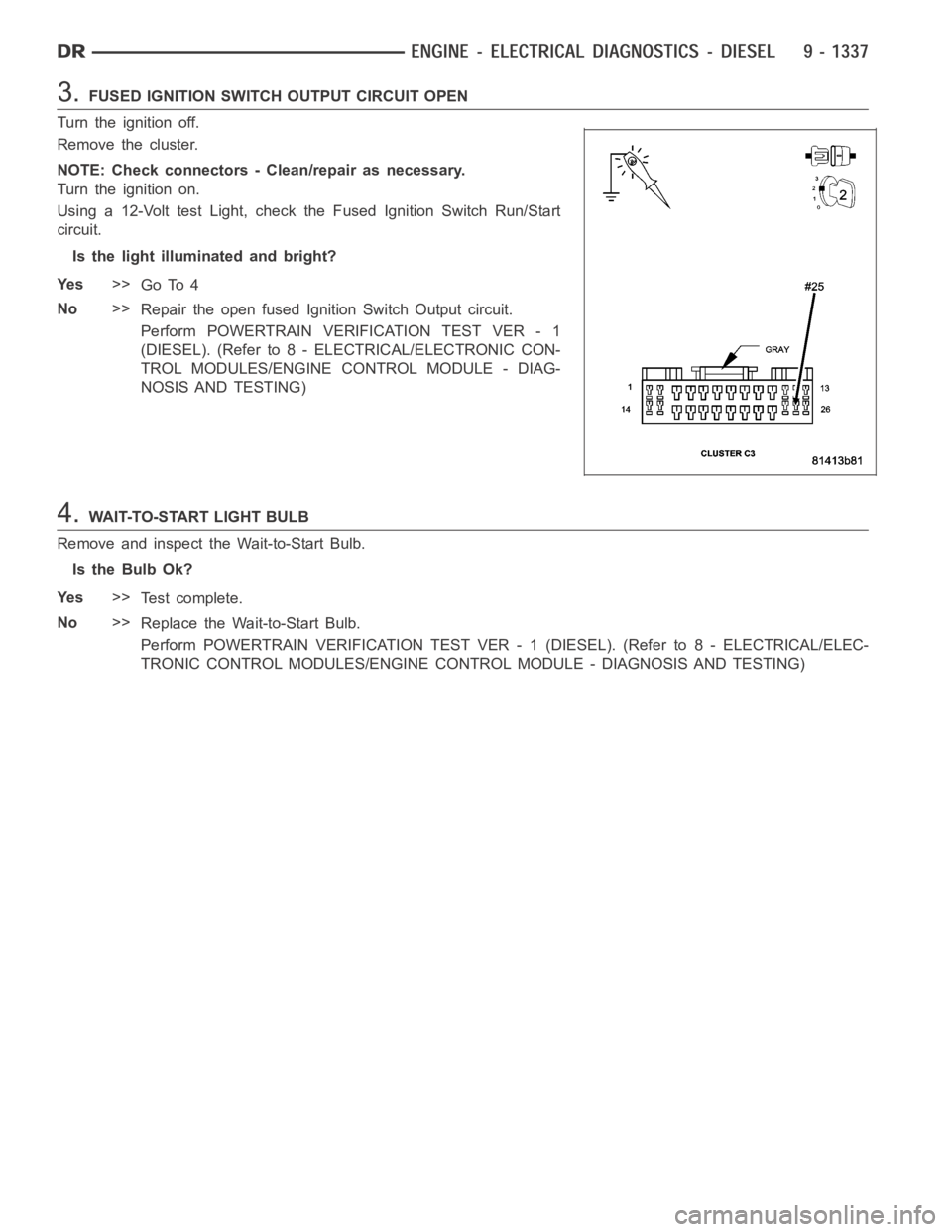

3.FUSED IGNITION SWITCH OUTPUT CIRCUIT OPEN

Turn the ignition off.

Remove the cluster.

NOTE: Check connectors - Clean/repair as necessary.

Turn the ignition on.

Using a 12-Volt test Light, check the Fused Ignition Switch Run/Start

circuit.

Is the light illuminated and bright?

Ye s>>

Go To 4

No>>

Repair the open fused Ignition Switch Output circuit.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

4.WAIT-TO-START LIGHT BULB

Remove and inspect the Wait-to-Start Bulb.

Is the Bulb Ok?

Ye s>>

Te s t c o m p l e t e .

No>>

Replace the Wait-to-Start Bulb.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 648 of 5267

When Monitored:

While the engine is running.

Set Condition:

Fuel level does not change by a calibrated amount over a calibrated amount oftime.

Possible Causes

EXTERNAL DAMAGE TO FUEL TANK

FUEL LEVEL SENSOR

INSIDE OF FUEL TANK OBSTRUCTED DAMAGED

INTERMITTENT CONDITION

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.EXTERNAL DAMAGE TO FUEL TANK

Visually inspect the fuel tank for external damage.

Is the fuel tank damaged from the outside?

Ye s>>

Fix or replace the fuel tank.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 2

2.FUEL LEVEL SENSOR

Disconnect the wiring harness from the fuel level sensor.

NOTE: Check connectors - Clean/repair as necessary.

Remove the fuel level sensor from the fuel tank.

Does the fuel level float move freely?

Ye s>>

Go To 3

No>>

Replace the fuel level sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

3.FUEL LEVEL SENSOR

Measure the resistance between the sensor (N4) signal circuit and (K900) return circuit while moving the sensor

float arm.

Does the resistance level change as you move the sensor arm?

Ye s>>

Go To 4

No>>

Replace the fuel level sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 651 of 5267

When Monitored:

Ignition on and battery voltage above 10.4 volts.

Set Condition:

The signal voltage from the sensor falls below a calibrated value for a calibrated amount of time.

Possible Causes

FUEL LEVEL SENSOR

(N4) SIGNAL CIRCUIT OPEN

(N4) SIGNAL CIRCUIT SHORTED TO VOLTAGE

INTERMITTENT CONDITION

ECM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.FUEL LEVEL SENSOR

Turn the ignition off.

Disconnect the Fuel Level Sensor harness connector.

NOTE: Check connectors - Clean/repair as necessary.

Measure the resistance of the sensor across the (N4) signal circuit and (K900) return circuit.

Is the resistance less than 10 ohms?

Ye s>>

Go To 2

No>>

Replace the fuel level sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 652 of 5267

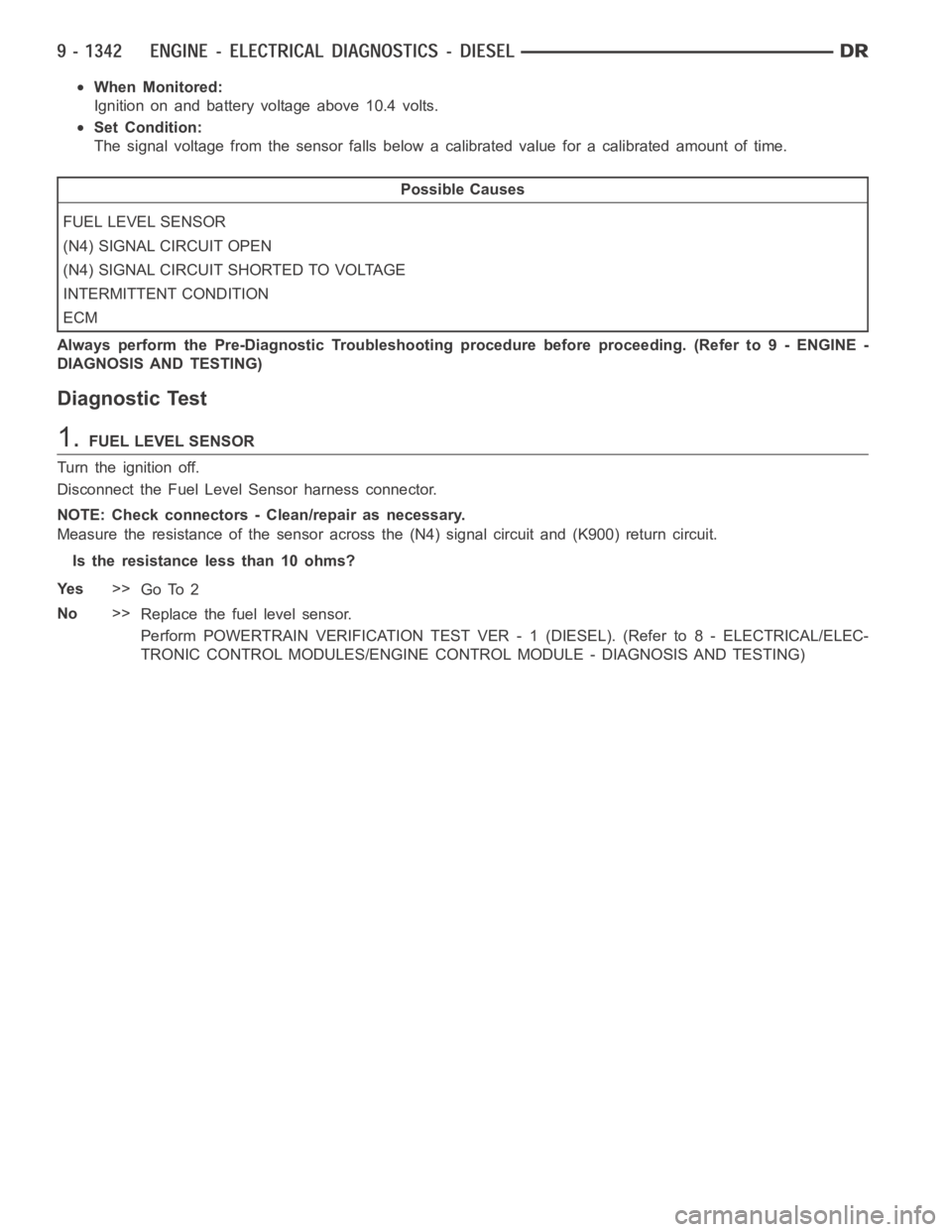

2.(G8) SIGNAL CIRCUIT OPEN

Disconnect the ECM harness connectors.

NOTE: Check connectors - Clean/repair as necessary.

Measure the resistance of the (N4) signal circuit between the ECM har-

ness connector and the sensor harness connector.

Is the resistance less than 10 ohms?

Ye s>>

Go To 3

No>>

Repair the open (N4) signal circuit.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

3.(G8) SIGNAL CIRCUIT SHORTED TO VOLTAGE

Measure the voltage between the (N4) signal circuit and battery nega-

tive.

Is the voltage greater than 1 volt?

Ye s>>

Repair the (N4) signal circuit shorted to voltage.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

No>>

Go To 4

Page 655 of 5267

When Monitored:

Ignition on and battery voltage above 10.4 volts.

Set Condition:

The signal voltage from the sensor goes above a calibrated value for a calibrated amount of time.

Possible Causes

FUEL LEVEL SENSOR

(N4) SIGNAL CIRCUIT SHORTED TO GROUND

INTERMITTENT CONDITION

ECM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.FUEL LEVEL SENSOR

Disconnect the ECM harness connectors.

Disconnect the Fuel level sensor harness connector.

NOTE: Check connectors - Clean/repair as necessary.

Measure the resistance of the Fuel level sensor across the (N4) signal circuit and (K900) return circuit.

Is the resistance less than 10 ohms?

Ye s>>

Go To 2

No>>

Replace the Fuel level sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

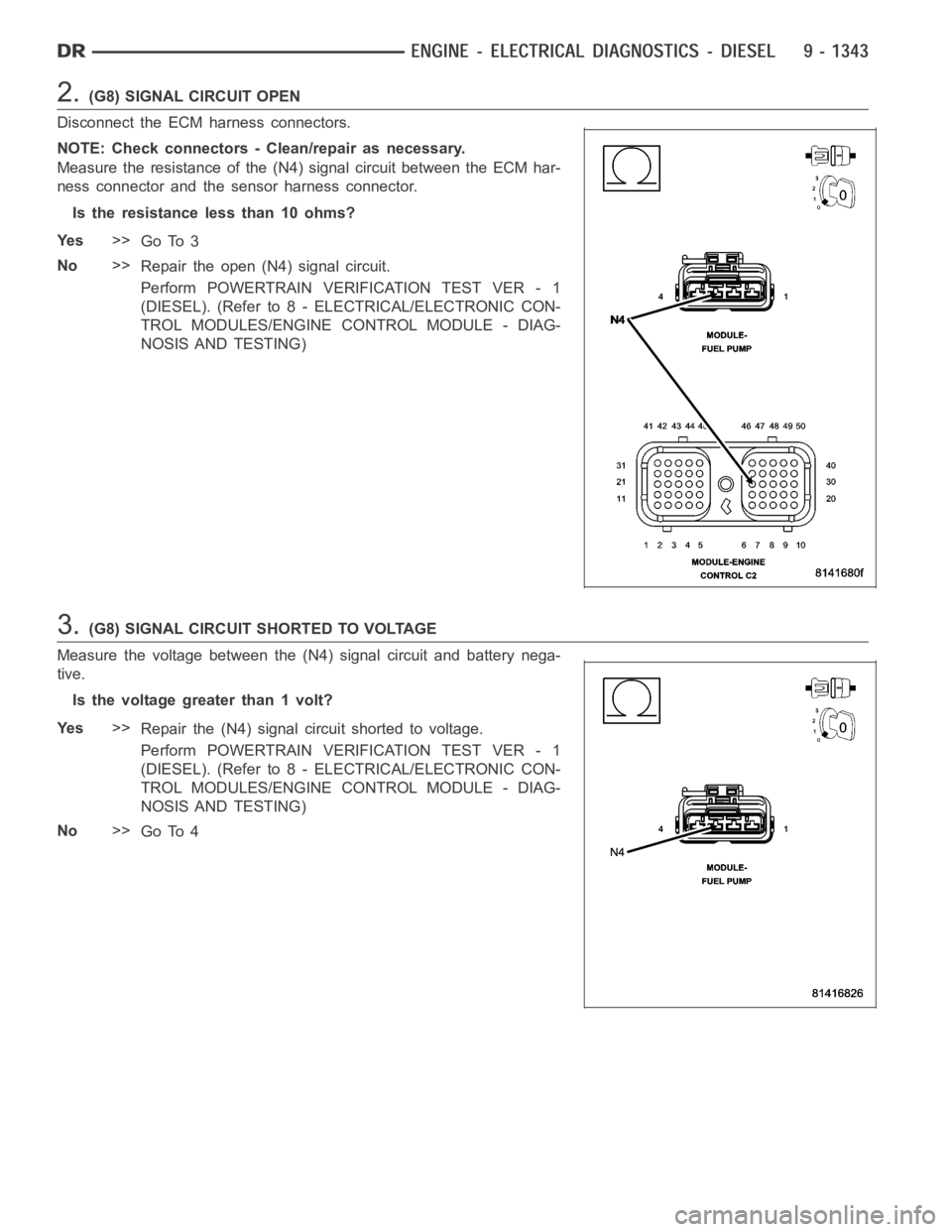

2.(N4) SIGNAL CIRCUIT SHORTED TO GROUND

Measure the resistance between the (N4) signal circuit in the sensor

harness connector and battery negative.

Is the resistance less than 10 Ohms?

Ye s>>

Repair the (N4) signal circuit shorted to ground.

Perform POWERTRAIN VERIFICATION TEST VER - 1

(DIESEL). (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/ENGINE CONTROL MODULE - DIAG-

NOSIS AND TESTING)

No>>

Go To 3

Page 657 of 5267

P0477-LOW VOLTAGE ON THE ENGINE BRAKE DRIVER

For a complete wiring diagramRefer to Section 8W.

When Monitored:

When the ignition is on.

Set Condition:

When the signal from the engine brake driver output does not match the signal from the engine brake driver

feedback.

Possible Causes

WIRING HARNESS

ENGINE BRAKE DRIVER RELAY

FUSED B+ OPEN

ENGINE BRAKE DRIVER SIGNAL CIRCUIT OPEN

INTERMITTENT CONDITION

ENGINE BRAKE DRIVER SIGNAL CIRCUIT SHORTED TO BATTERY NEGATIVE

ECM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.RELAY CLICKING

Turn the engine off (ignition on).

With the scan tool, actuate the exhaust brake relay.

Can you hear the Relay clicking?

Ye s>>

Go To 2

No>>

Go To 3

2.WIRING HARNESS

With the scan tool, actuate the exhaust brake relay.

While the relay is clicking, wiggle the wiring harness and connectors throughout the circuit.

Does this interrupt the clicking?

Ye s>>

Repair or replace the wiring harness.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

No>>

Go To 3

3.Engine Brake Driver Relay

Remove the Engine Brake Driver Relay.

Check connectors - Clean/repair as necessary.

Measure the resistance between terminals 86 and 85 of the engine brake relay.

Is the resistance less than 100 Ohms?

Ye s>>

Go To 4

No>>

Replace the Engine Brake Driver Relay.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

Page 658 of 5267

4.FUSED B+ OPEN

Ignition on, engine not running.

Measure the voltage of the Fused B+ Supply circuit at the Engine Brake Relay.

Is the voltage within 10% of battery voltage?

Ye s>>

Go To 5

No>>

Repair the open B+ circuit.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

5.ENGINE BRAKE DRIVER SIGNAL CIRCUIT OPEN

Turn the ignition off.

Disconnect the ECM harness connectors.

Check connectors - Clean/repair as necessary.

Measure the resistance of the Engine Brake Driver signal circuit between the Relay harness connector and the ECM

harness connector.

Is the resistance less than 10 Ohms?

Ye s>>

Go To 6

No>>

Repair the open Engine Brake driver circuit open from relay to ECM.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

6.ENGINE BRAKE DRIVER SIGNAL CIRCUIT SHORTED TO BATTERY NEGATIVE

Measure the resistance of the Engine Brake Driver signal circuit between the Relay connector and battery negative.

Is the resistance greater than 100k Ohms?

Ye s>>

Go To 7

No>>

Repair Engine brake driver shorted to Battery negative.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)

7.ECM

Reconnect the ECM harness connectors.

Using the scan tool, actuate the Engine Brake Driver Relay.

While monitoring with the scan tool, use a jumper wire to connect 12 volts tothe relay signal circuit with the relay

disconnected.

Did the DTC P0478?

Ye s>>

Refer to the INTERMITTENT CONDITION Symptom (Diagnostic Procedure). (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

No>>

Replace ECM.

Perform POWERTRAIN VERIFICATION TEST VER - 1 (DIESEL). (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/ENGINE CONTROL MODULE - DIAGNOSIS AND TESTING)