air condition DODGE RAM SRT-10 2006 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 74 of 5267

When Monitored:

With the ignition on. Battery voltage greater than 10.4 volts and the ASD sense switch is on.

Set Condition:

Actual Starter state is not equal to desired state. One Trip Fault. Three goodtripstoturnofftheMIL.

Possible Causes

(T40) STARTER RELAY OUTPUT CIRCUIT OPEN

(T750) STARTER RELAY OUTPUT CIRCUIT OPEN

STARTER RELAY

STARTER

TIPM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

Ignition on, engine not running.

With a scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.(T40) STARTER FEED CIRCUIT OPEN

Turn the ignition.

Disconnect the Starter Relay.

Disconnect the C9 TIPM harness connector.

Measure the resistance of the (T40) Starter Relay Output circuit between the C9 TIPM harness connector and the

Starter Relay harness connector.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 3

No>>

Repair the open in the (T40) Starter Relay Output circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

3.(T750) STARTER RELAY OUTPUT CIRCUIT OPEN

Disconnect the Starter Solenoid connector.

Measure the resistance of the (T750) Starter Relay Output circuit betweenthe Starter Solenoid harness connector

and the Starter Relay harness connector.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 4

No>>

Repair the open in the (T750) Starter Relay Output circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 77 of 5267

When Monitored:

With the ignition on. Battery voltage greater than 10.4 volts.

Set Condition:

The TIPM has detected on overcurrent condition in the Starter Control circuit. One Trip Fault. Three good trips

to turn off the MIL.

Possible Causes

(T40) STARTER RELAY OUTPUT CIRCUIT EXCESSIVE RESISTANCE

(T40) STARTER RELAY OUTPUT CIRCUIT SHORTED TO GROUND

(T750) STARTER RELAY OUTPUT CIRCUIT EXCESSIVE RESISTANCE

(T750) STARTER RELAY OUTPUT CIRCUIT SHORTED TO GROUND

STARTER RELAY

STARTER

TIPM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

Ignition on, engine not running.

With a scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.(T750) STARTER RELAY OUTPUT CIRCUIT SHORTED TO GROUND

Turn the ignition off.

Remove the Starter Relay.

Disconnect the Starter Solenoid harness connector.

Measure the resistance between ground and the (T750) Starter Relay Outputcircuit at the Starter Relay harness

connector.

Istheresistancebelow100ohms?

Ye s>>

Repair the short to ground in the (T750) Starter Relay Output circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 3

3.(T750) STARTER RELAY OUTPUT CIRCUIT EXCESSIVE RESISTANCE

Measure the resistance of the (T750) Starter Relay Output circuit from theStarter Relay terminal to the Starter

Solenoid harness connector.

Is the resistance above 5.0 ohms?

Ye s>>

Repair the excessive resistance in the (T750) Starter Relay Output circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 4

Page 91 of 5267

When Monitored:

With the ignition on. Battery voltage greater than 10.4 volts. TIPM requesting Fuel Pump operation.

Set Condition:

An overcurrent condition is detected in the fuel pump control output circuit. One Trip Fault. Three good trips to

turn off the MIL.

Possible Causes

TERMINAL DAMAGE OR CORROSION

FUEL PUMP MOTOR GROUND HIGH RESISTANCE

(A109) FUEL PUMP CONTROL OUTPUT CIRCUIT HIGH RESISTANCE

FUEL PUMP MOTOR

TIPM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.FUEL PUMP OPERATION

Ignition on, engine not running.

With a scan tool in the TIPM Actuators, actuate the Fuel Pump.

Is the Fuel Pump operating?

Ye s>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 2

2.VISUAL AND PHYSICAL CONNECTOR AND TERMINAL INSPECTION

Turn the ignition off.

Disconnect the C10 TIPM harness connector.

Disconnect the Fuel Pump Module harness connector.

Inspect the terminal and connector condition. Check for signs of corrosion build up or damage the would compro-

mise the terminal to controller pin connector.

NOTE: Make sure that all in-line connectors are inspected for corrosion and/or damage.

Visually inspect the wiring harness. Look for any chafed, pierced, pinched or partially broken wires hidden in the

wire insulation.

Were any of the above conditions found?

Ye s>>

Repair or replace as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 3

Page 94 of 5267

Theory of Operation

TheEGRvalvehasapositionsensorandthe EGR position rationality is designed to make sure that the valve

moves freely within its operating range. Closed valve position referencecheck verifies that the valve is within its

allowable upper and lower limits. The EGR position rationality test looksfor a sustained error relative to commanded

valve position.

When Monitored:

Engine running.

Set Condition:

The EGR flow or valve movement is not what is expected. A rationality error has been detected for the EGR

Open Position Performance. Two trip fault.

Possible Causes

EXCESSIVE RESISTANCE IN THE (F856) 5-VOLT SUPPLY CIRCUIT

(K35) EGR SOLENOID CONTROL CIRCUIT OPEN

(K34) EGR SENSOR SIGNAL CIRCUIT SHORTED TO GROUND

EGR SOLENOID ASSEMBLY

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

Ignition on, engine not running.

With a scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

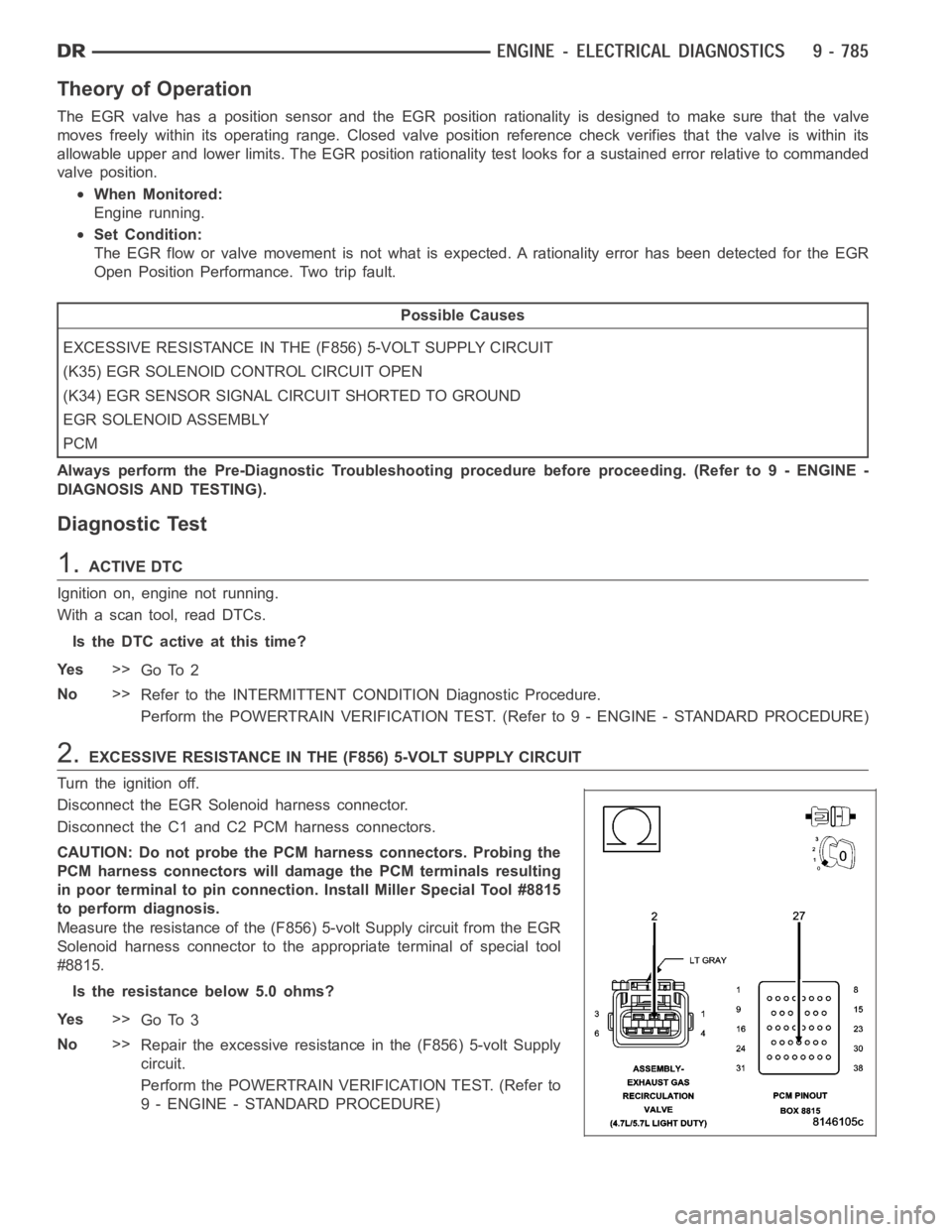

2.EXCESSIVE RESISTANCE IN THE (F856) 5-VOLT SUPPLY CIRCUIT

Turn the ignition off.

Disconnect the EGR Solenoid harness connector.

Disconnect the C1 and C2 PCM harness connectors.

CAUTION: Do not probe the PCM harness connectors. Probing the

PCM harness connectors will damage the PCM terminals resulting

in poor terminal to pin connection. Install Miller Special Tool #8815

to perform diagnosis.

Measure the resistance of the (F856) 5-volt Supply circuit from the EGR

Solenoid harness connector to the appropriate terminal of special tool

#8815.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 3

No>>

Repair the excessive resistance in the (F856) 5-volt Supply

circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

Page 98 of 5267

For a complete wiring diagramRefer to Section 8W.

Theory of Operation

When all criteria has been met, power is supplied to each MDS Solenoid when the engine is making a transition

from 8 cylinder mode to 4 cylinder mode. By actuating the solenoid, oil pressure is raised to the pair of lifters that

coincide with each particular solenoid. The oil pressure pushes in the locking pins that allows the lifter to collapse,

decoupling the valves and camshaft.

When Monitored:

Transition from 8 to 4 cylinder mode.

Set Condition:

The MDS fails to active and take place for cylinder 1. One trip fault.

Possible Causes

(K451) MDS SOLENOID NO.1 CONTROL SHORT TO GROUND

(K451) MDS SOLENOID NO.1 CONTROL OPEN

(Z42) GROUND CIRCUIT OPEN

INSUFFICIENT OIL PRESSURE ACTING ON THE LIFTER LOCKING PINS

OIL PASSAGES RESTRICTED

LIFTER

MDS SOLENOID NO.1

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

Ignition on, engine not running.

With a scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 103 of 5267

For a complete wiring diagramRefer to Section 8W.

Theory of Operation

When all criteria has been met, power is supplied to each MDS Solenoid when the engine is making a transition

from 8 cylinder mode to 4 cylinder mode. By actuating the solenoid, oil pressure is raised to the pair of lifters that

coincide with each particular solenoid. The oil pressure pushes in the locking pins that allows the lifter to collapse,

decoupling the valves and camshaft.

When Monitored:

Transition from 8 to 4 cylinder mode.

Set Condition:

The MDS fails to active and take place for cylinder 4. One trip fault.

Possible Causes

(K452) MDS SOLENOID NO.4 CONTROL SHORT TO GROUND

(K452) MDS SOLENOID NO.4 CONTROL OPEN

(Z42) GROUND CIRCUIT OPEN

INSUFFICIENT OIL PRESSURE ACTING ON THE LIFTER LOCKING PINS

OIL PASSAGES RESTRICTED

LIFTER

MDS SOLENOID NO.4

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

Ignition on, engine not running.

With a scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 108 of 5267

For a complete wiring diagramRefer to Section 8W.

Theory of Operation

When all criteria has been met, power is supplied to each MDS Solenoid when the engine is making a transition

from 8 cylinder mode to 4 cylinder mode. By actuating the solenoid, oil pressure is raised to the pair of lifters that

coincide with each particular solenoid. The oil pressure pushes in the locking pins that allows the lifter to collapse,

decoupling the valves and camshaft.

When Monitored:

Transition from 8 to 4 cylinder mode.

Set Condition:

The MDS fails to active and take place for cylinder 6. One trip fault.

Possible Causes

(K453) MDS SOLENOID NO.6 CONTROL SHORT TO GROUND

(K453) MDS SOLENOID NO.6 CONTROL OPEN

(Z42) GROUND CIRCUIT OPEN

INSUFFICIENT OIL PRESSURE ACTING ON THE LIFTER LOCKING PINS

OIL PASSAGES RESTRICTED

LIFTER

MDS SOLENOID NO.6

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

Ignition on, engine not running.

With a scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

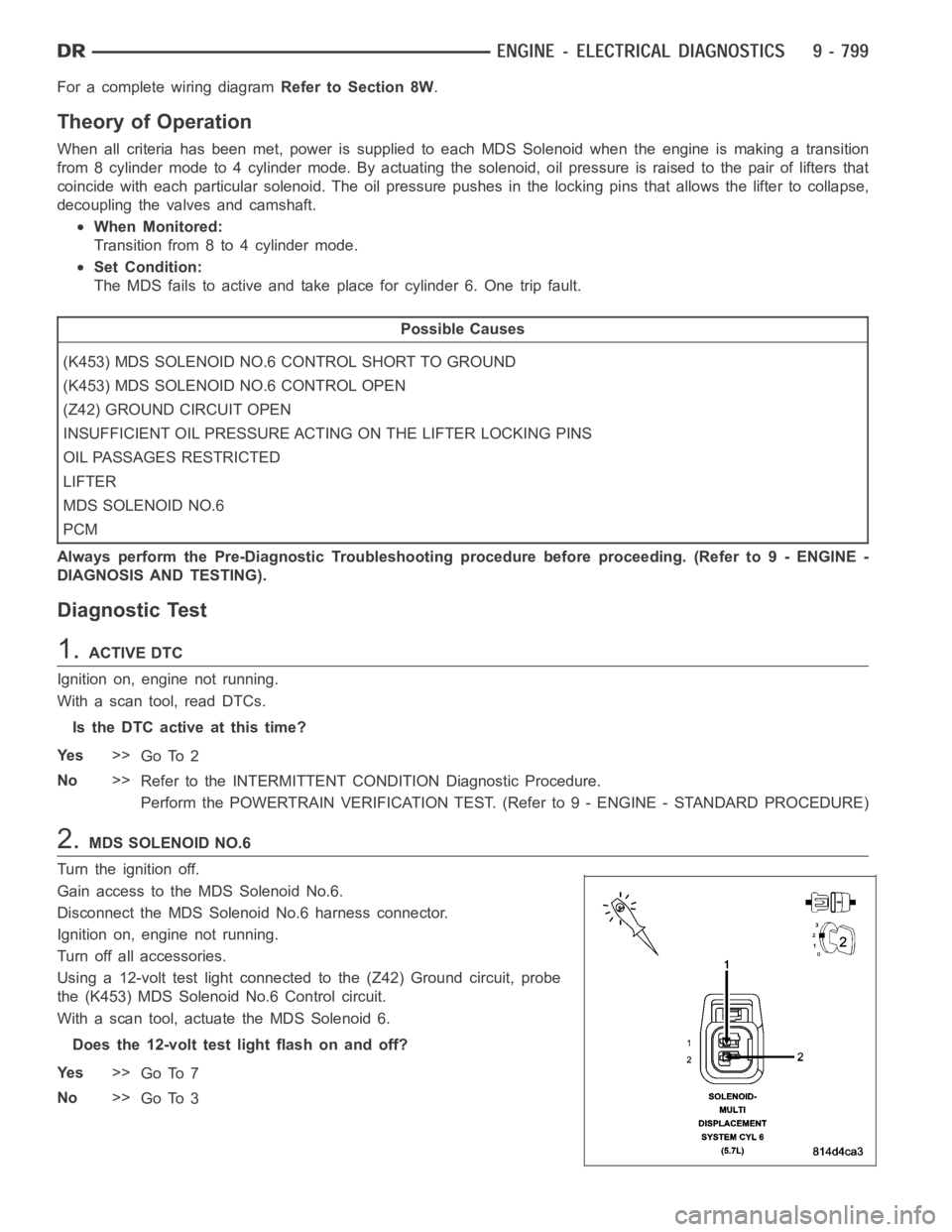

2.MDS SOLENOID NO.6

Turn the ignition off.

Gain access to the MDS Solenoid No.6.

Disconnect the MDS Solenoid No.6 harness connector.

Ignition on, engine not running.

Turn off all accessories.

Using a 12-volt test light connected to the (Z42) Ground circuit, probe

the (K453) MDS Solenoid No.6 Control circuit.

With a scan tool, actuate the MDS Solenoid 6.

Does the 12-volt test light flash on and off?

Ye s>>

Go To 7

No>>

Go To 3

Page 113 of 5267

For a complete wiring diagramRefer to Section 8W.

Theory of Operation

When all criteria has been met, power is supplied to each MDS Solenoid when the engine is making a transition

from 8 cylinder mode to 4 cylinder mode. By actuating the solenoid, oil pressure is raised to the pair of lifters that

coincide with each particular solenoid. The oil pressure pushes in the locking pins that allows the lifter to collapse,

decoupling the valves and camshaft.

When Monitored:

Transition from 8 to 4 cylinder mode.

Set Condition:

The MDS fails to active and take place for cylinder 7. One trip fault.

Possible Causes

(K454) MDS SOLENOID NO.7 CONTROL SHORT TO GROUND

(K454) MDS SOLENOID NO.7 CONTROL OPEN

(Z42) GROUND CIRCUIT OPEN

INSUFFICIENT OIL PRESSURE ACTING ON THE LIFTER LOCKING PINS

OIL PASSAGES RESTRICTED

LIFTER

MDS SOLENOID NO.7

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

Ignition on, engine not running.

With a scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

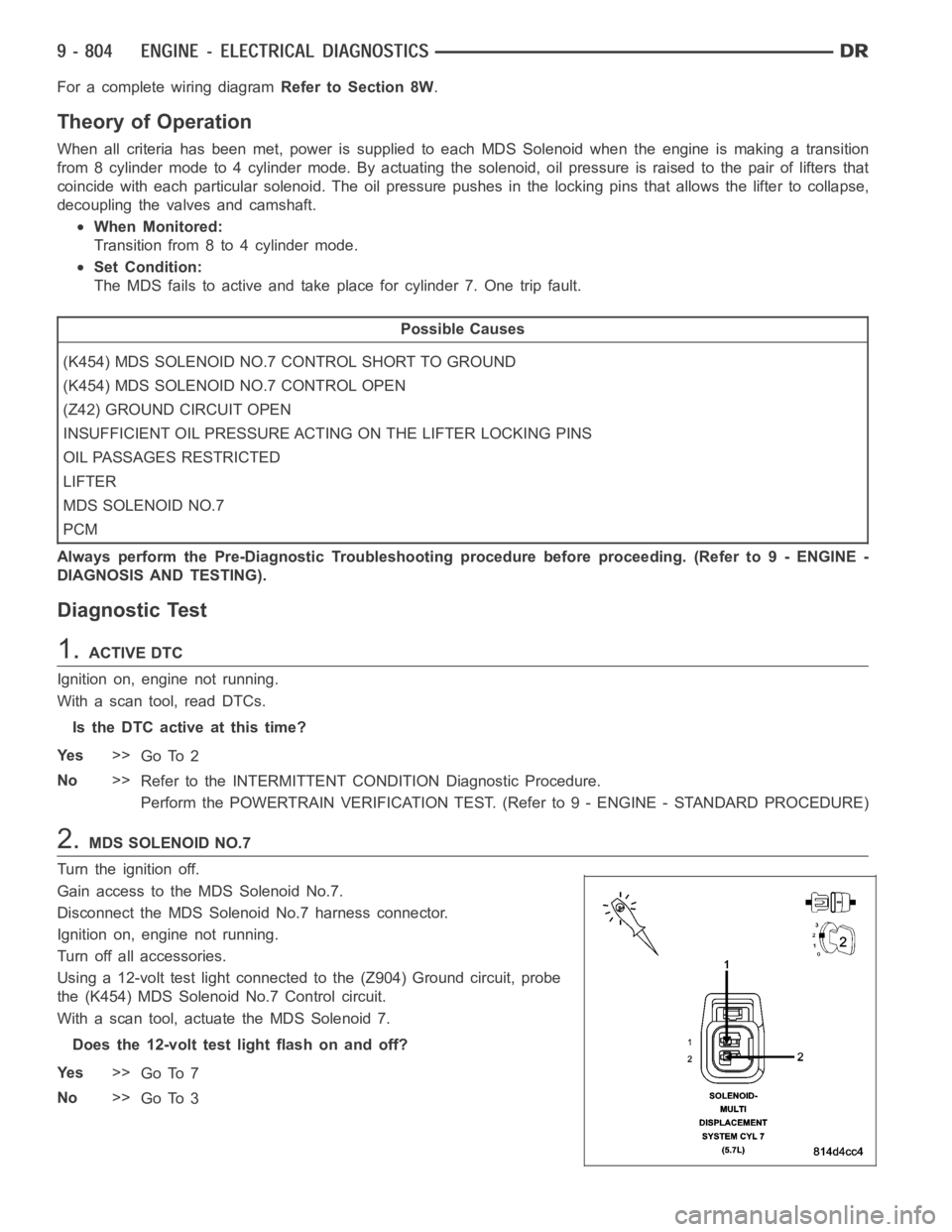

2.MDS SOLENOID NO.7

Turn the ignition off.

Gain access to the MDS Solenoid No.7.

Disconnect the MDS Solenoid No.7 harness connector.

Ignition on, engine not running.

Turn off all accessories.

Using a 12-volt test light connected to the (Z904) Ground circuit, probe

the (K454) MDS Solenoid No.7 Control circuit.

With a scan tool, actuate the MDS Solenoid 7.

Does the 12-volt test light flash on and off?

Ye s>>

Go To 7

No>>

Go To 3

Page 118 of 5267

When Monitored:

Ignition on and vehicle moving. Cruise is learned and customer is trying touse the Cruise.

Set Condition:

The PCM recognizes rear wheel speed is greater than front wheel speed. One trip fault.

Possible Causes

ACTIVE BUS OR COMMUNICATION DTCS

TIRE CIRCUMFERENCE

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

Ignition on, engine not running.

NOTE: Check for any Bus Communication DTCs. If no Bus Communication DTCs are set, check for active

DTCs stored in the Ant-Lock Brake Module. Any Bus Communication DTCs or VSSDTCs in the Ant-Lock

Brake Module must be properly diagnosed before continuing.

With a scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.VISUAL INSPECTION

NOTE: This code can set due to tire circumference differences and from the front or rear wheels being on

a slippery surface while the opposite tires are not.

This code may also set on a hard acceleration on loose gravel or during otheroff road driving conditions.

Check tire pressure of all the tires.

Checktirewearonallthetires.

Ask the customer what the road and driving conditions were like when the fault set.

Were any problems found?

Ye s>>

Repair as necessary. If the code set during a front OR rear wheel spin condition, no repair is necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 3

Page 121 of 5267

When Monitored:

Ignition on and vehicle moving. Brake pedal must not be applied.

Set Condition:

The PCM recognizes front axle speed is greater than rear axle speed. One tripfault.

Possible Causes

ACTIVE BUS OR COMMUNICATION DTCS

TIRE CIRCUMFERENCE

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

Ignition on, engine not running.

NOTE: Check for any Bus Communication DTCs. If no Bus Communication DTCs are set, check for active

DTCs stored in the Ant-Lock Brake Module. Any Bus Communication DTCs or VSSDTCs in the Ant-Lock

Brake Module must be properly diagnosed before continuing.

With a scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.VISUAL INSPECTION

NOTE: This code can set due to tire circumference differences and from the front or rear wheels being on

a slippery surface while the opposite tires are not.

This code may also set on a hard acceleration on loose gravel or during otheroff road driving conditions.

Check tire pressure of all the tires.

Checktirewearonallthetires.

Ask the customer what the road and driving conditions were like when the fault set.

Were any problems found?

Ye s>>

Repair as necessary. If the code set during a front OR rear wheel spin condition, no repair is necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 3