wheel bolt torque DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1411 of 5267

3.CMP WIRE HARNESS INSPECTION

Visually inspect the related wire harness. Look for any chafed, pierced, pinched, or partially broken wires.

Visually inspect the related wire harness connectors. Look for broken, bent, pushed out, or corroded terminals.

Make sure the Crankshaft Position Sensor and the Camshaft Position Sensorare properly installed and the mount-

ing bolt(s) are torqued to specification.

Refer to any TSB that may apply.

Were any of the above conditions present?

Ye s>>

Repair as necessary

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 4

4.TONE WHEEL/PULSE RING INSPECTION

Turn the ignition off.

Remove the Camshaft Position Sensor.

Inspect the Tone Wheel/Pulse Ring for damage, foreign material, or excessive movement.

Were any problems found?

Ye s>>

Repair or replace the Tone Wheel/Pulse Ring as necessary.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 5

5.CAMSHAFT POSITION SENSOR

If there are no possible causes remaining, view repair.

Repair

Replace the Camshaft Position Sensor.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

6.CHECKING CKP SIGNAL WITH THE SCAN TOOL LAB

Turn the ignition off.

With the scan tool as a Dual Channel Lab Scope and the Miller special tool #6801, backprobe the (K24) CKP Signal

circuit in the CKP harness connector and PCM harness connector.

WARNING: When the engine is operating, do not stand in a direct line with thefan. Do not put your hand

near the pulleys, belts, or fan. Do not wear loose clothing.

Start the engine.

Observe the lab scope screen.

Are there any irregular or missing signals?

Ye s>>

Go To 7

No>>

Go To 10

Page 1412 of 5267

7.CKP WIRE HARNESS INSPECTION

Visually inspect the related wire harness. Look for any chafed, pierced, pinched, or partially broken wires.

Visually inspect the related wire harness connectors. Look for broken, bent, pushed out, or corroded terminals.

Ensure the Crankshaft Position Sensor and the Camshaft Position Sensor are properly installed and the mounting

bolt(s) are torqued to specification.

Refer to any TSB that may apply.

Were any of the above conditions present?

Ye s>>

Repair as necessary

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 8

8.TONE WHEEL/FLEX PLATE INSPECTION

Remove the Crankshaft Position Sensor.

Inspect the Tone Wheel/Flex Plate slots for damage, foreign material, or excessive movement.

Were any problems found?

Ye s>>

Repair or replace the Tone Wheel/Flex Plate as necessary.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 9

9.CRANKSHAFT POSITION SENSOR

If there are no possible causes remaining, view repair.

Repair

Replace the Crankshaft Position Sensor.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

10.CHECKING CKP SIGNAL WITH LAB SCOPE

NOTE: The conditions that set this DTC are not present at this time. The following test may help in identi-

fying the intermittent condition.

Turn the ignition off.

With the scan tool as a Dual Channel Lab Scope and the Miller special tool #6801, backprobe the (K24) CKP Signal

circuit in the PCM harness connector and CKP harness connector.

WARNING: When the engine is operating, do not stand in a direct line with thefan. Do not put your hand

near the pulleys, belts, or fan. Do not wear loose clothing.

Start the engine.

Carefully wiggle the related wire harness and gently tap on the CKP sensor.

Compare the Channel 1 reading to the Channel 2 reading on the lab scope screen.

Both of the readings should be the same.

Were any of the above conditions present?

Ye s>>

Repair the wiring or connector concern.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .

Page 1538 of 5267

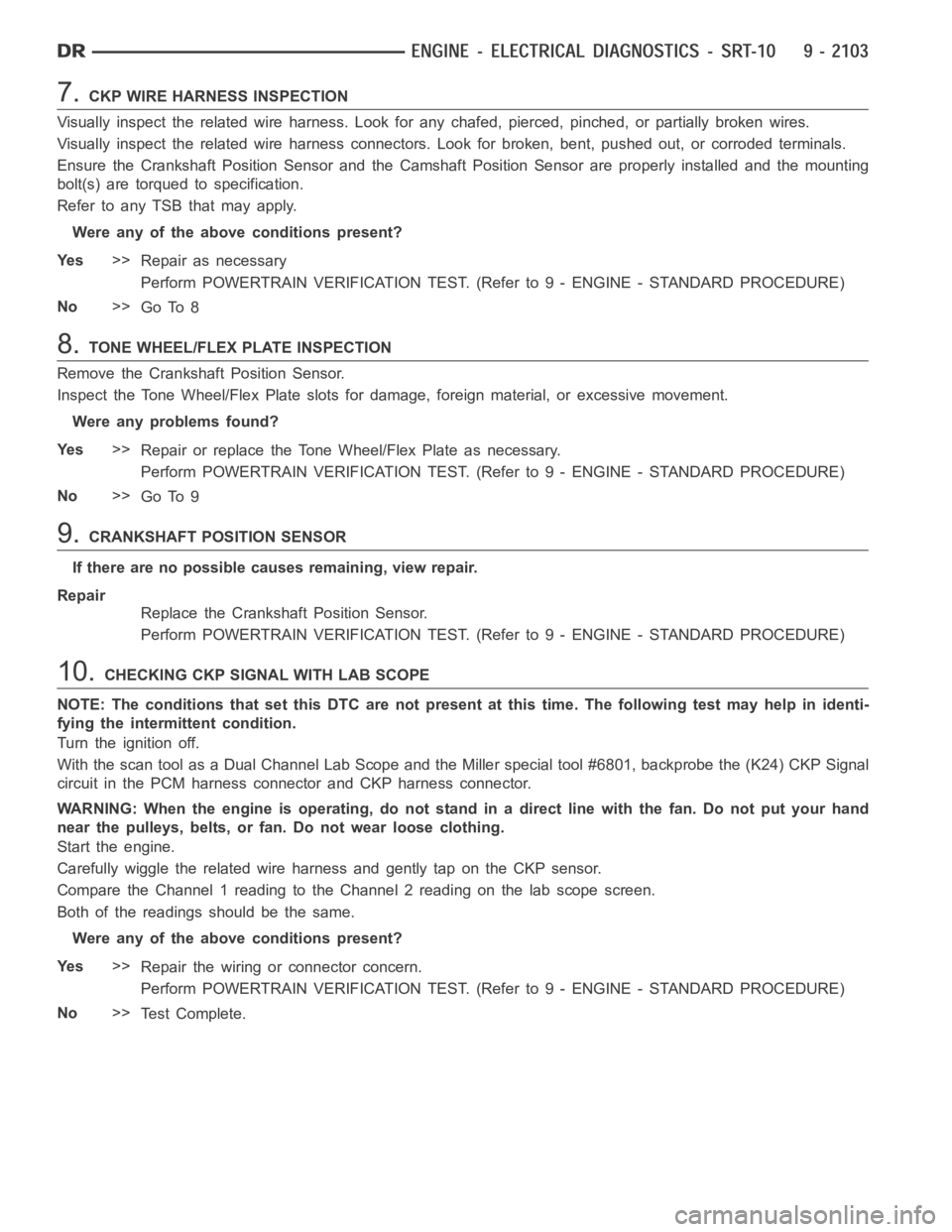

18. Remove the cylinder head access plug (1,2).

19. Remove the right side secondary chain guide

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT/CHAIN AND SPROCKETS - REMOVAL).

CAUTION: The nut on the right side camshaft

sprocket should not be removed for any reason,

as the sprocket and camshaft sensor target wheel

is serviced as an assembly. If the nut was

removed, torque nut to 5 Nꞏm (44 in. lbs.).

20. Remove the retaining bolt and the camshaft drive

gear.

CAUTION: Do not allow the engine to rotate.

severe damage to the valve train can occur.

CAUTION: Do not overlook the four smaller bolts at the front of the cylinderhead.Donotattempttoremove

the cylinder head without removing these four bolts.

CAUTION: Do not hold or pry on the camshaft target wheel for any reason. A damaged target wheel can

result in a vehicle no start condition.

NOTE: The cylinder head is attached to the cylin-

der block with twelve bolts.

21. Remove the cylinder head retaining bolts.

22. Remove the cylinder head and gasket. Discard

the gasket.

CAUTION: Do not lay the cylinder head on its gas-

ket sealing surface, do to the design of the cylin-

der head gasket any distortion to the cylinder

head sealing surface may prevent the gasket from

properly sealing resulting in leaks.

Page 1541 of 5267

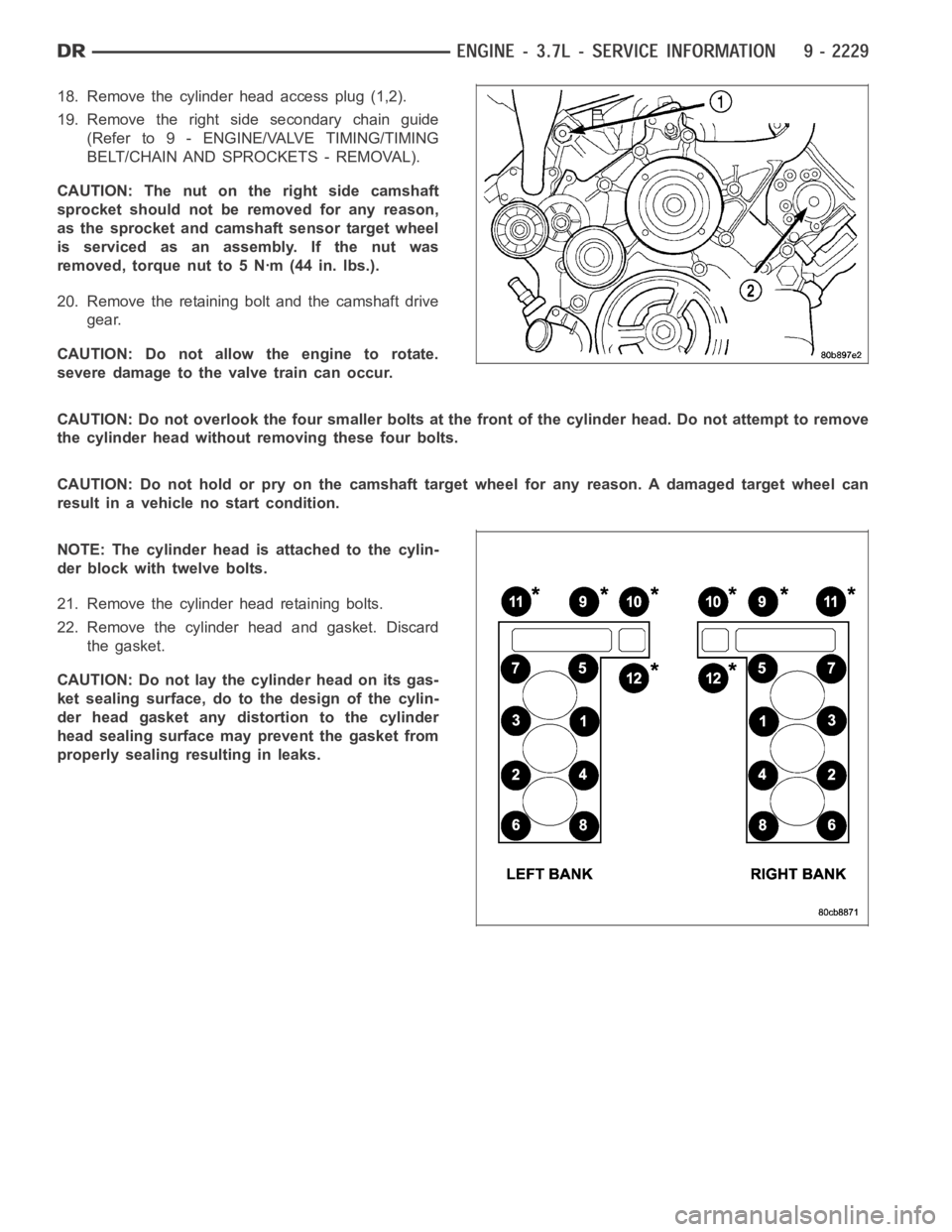

CAUTION: The nut on the right side camshaft sprocket should not be removed for any reason, as the

sprocket and camshaft sensor target wheel is serviced as an assembly. If the nut was removed, torque nut

to 5 NM ( 60 in. lbs.).

7. Position the secondary chain (2) onto the camshaft drive gear, making sure one marked chain link is on either

side of the V6 mark (1) on the gear then using Special Tool 8428 Camshaft Wrench, position the gear onto the

camshaft.

CAUTION: Remove excess oil from camshaft sprocket retaining bolt before reinstalling bolt. Failure to do so

may cause over-torquing of bolt resulting in bolt failure.

8. Install the camshaft drive gear retaining bolt.

9. Install the right side secondary chain guide (Refer to 9 - ENGINE/VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION).

10. Install the cylinder head access plug (1,2).

11. Re-set and install the right side secondary chain

tensioner (Refer to 9 - ENGINE/VALVE TIMING/

TIMING BELT/CHAIN AND SPROCKETS -

INSTALLATION).

Page 1764 of 5267

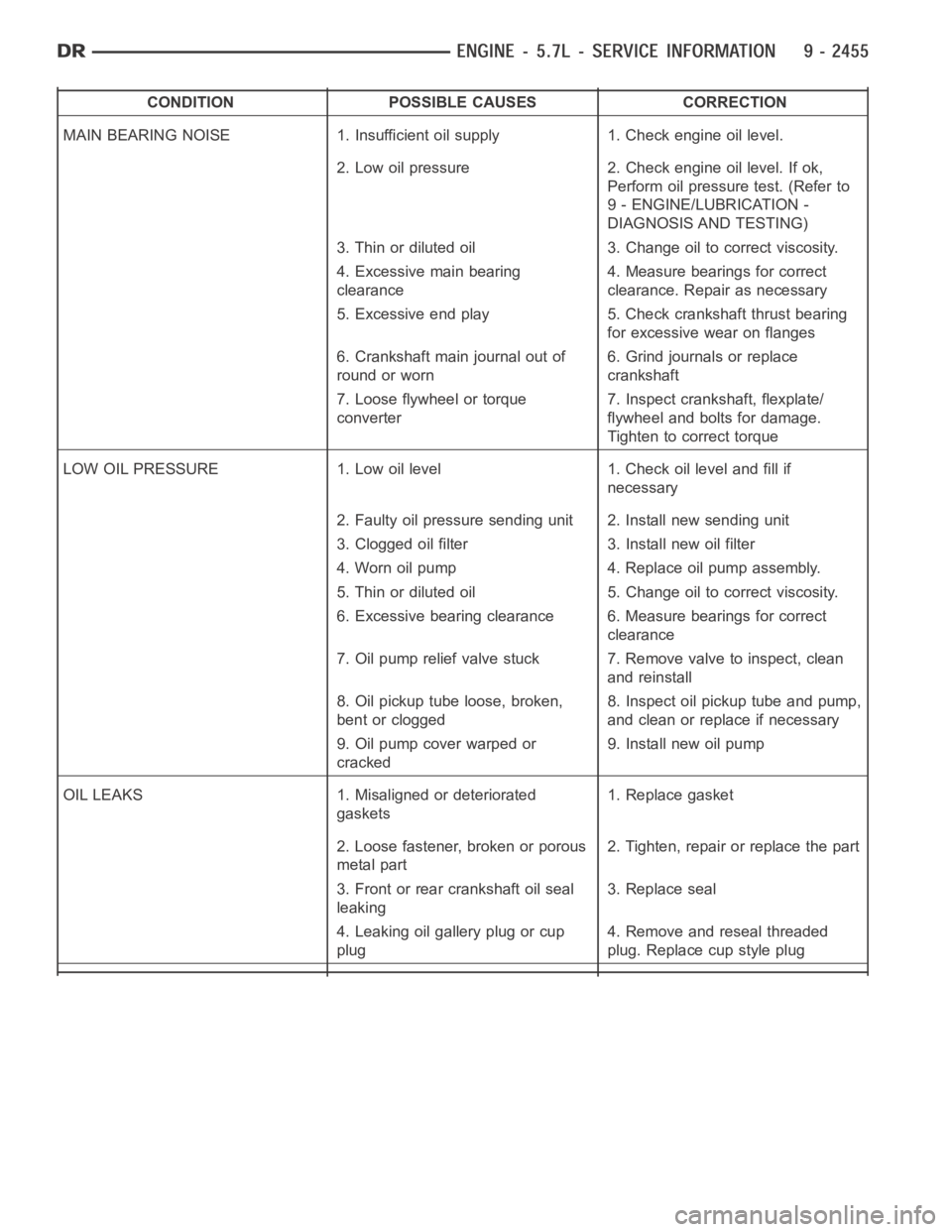

CONDITION POSSIBLE CAUSES CORRECTION

MAIN BEARING NOISE 1. Insufficient oil supply 1. Check engine oil level.

2. Low oil pressure 2. Check engine oil level. If ok,

Perform oil pressure test. (Refer to

9 - ENGINE/LUBRICATION -

DIAGNOSIS AND TESTING)

3. Thin or diluted oil 3. Change oil to correct viscosity.

4. Excessive main bearing

clearance4. Measure bearings for correct

clearance. Repair as necessary

5. Excessive end play 5. Check crankshaft thrust bearing

for excessive wear on flanges

6. Crankshaft main journal out of

round or worn6. Grind journals or replace

crankshaft

7. Loose flywheel or torque

converter7. Inspect crankshaft, flexplate/

flywheel and bolts for damage.

Tighten to correct torque

LOW OIL PRESSURE 1. Low oil level 1. Check oil level and fill if

necessary

2. Faulty oil pressure sending unit 2. Install new sending unit

3. Clogged oil filter 3. Install new oil filter

4. Worn oil pump 4. Replace oil pump assembly.

5. Thin or diluted oil 5. Change oil to correct viscosity.

6. Excessive bearing clearance 6. Measure bearings for correct

clearance

7. Oil pump relief valve stuck 7. Remove valve to inspect, clean

and reinstall

8. Oil pickup tube loose, broken,

bent or clogged8. Inspect oil pickup tube and pump,

and clean or replace if necessary

9. Oil pump cover warped or

cracked9. Install new oil pump

OIL LEAKS 1. Misaligned or deteriorated

gaskets1. Replace gasket

2. Loose fastener, broken or porous

metal part2. Tighten, repair or replace the part

3. Front or rear crankshaft oil seal

leaking3. Replace seal

4. Leaking oil gallery plug or cup

plug4. Remove and reseal threaded

plug. Replace cup style plug

Page 1781 of 5267

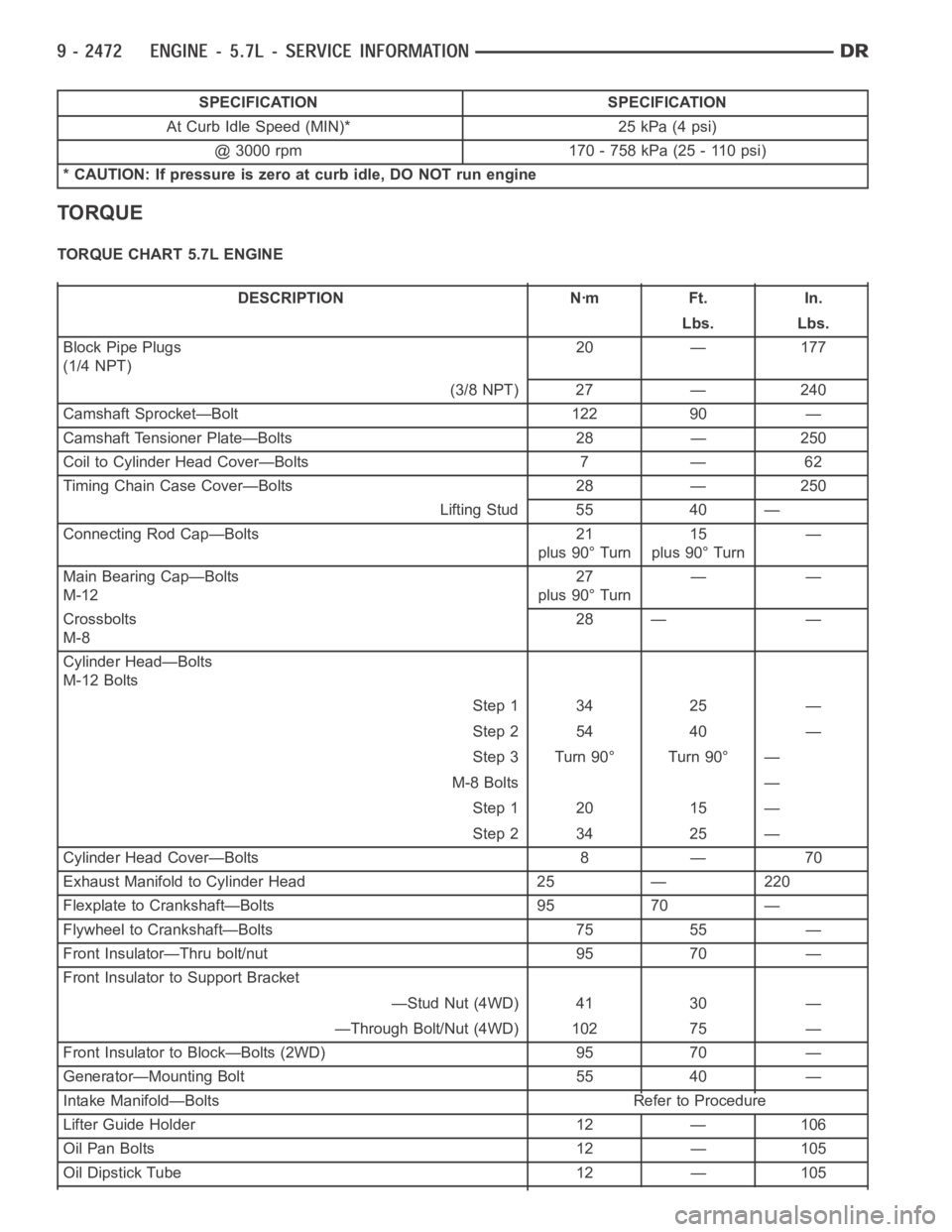

SPECIFICATION SPECIFICATION

At Curb Idle Speed (MIN)* 25 kPa (4 psi)

@ 3000 rpm 170 - 758 kPa (25 - 110 psi)

* CAUTION: If pressure is zero at curb idle, DO NOT run engine

TORQUE

TORQUE CHART 5.7L ENGINE

DESCRIPTION Nꞏm Ft. In.

Lbs. Lbs.

Block Pipe Plugs

(1/4 NPT)20 — 177

(3/8 NPT) 27 — 240

Camshaft Sprocket—Bolt 122 90 —

Camshaft Tensioner Plate—Bolts 28 — 250

Coil to Cylinder Head Cover—Bolts 7 — 62

Timing Chain Case Cover—Bolts 28 — 250

Lifting Stud 55 40 —

Connecting Rod Cap—Bolts 21

plus 90° Turn15

plus 90° Turn—

Main Bearing Cap—Bolts

M-1227

plus 90° Turn——

Crossbolts

M-828 — —

Cylinder Head—Bolts

M-12 Bolts

Step 1 34 25 —

Step 2 54 40 —

Step 3 Turn 90° Turn 90° —

M-8 Bolts —

Step 1 20 15 —

Step 2 34 25 —

Cylinder Head Cover—Bolts 8 — 70

Exhaust Manifold to Cylinder Head 25 — 220

Flexplate to Crankshaft—Bolts 95 70 —

Flywheel to Crankshaft—Bolts 75 55 —

Front Insulator—Thru bolt/nut 95 70 —

Front Insulator to Support Bracket

—Stud Nut (4WD) 41 30 —

—Through Bolt/Nut (4WD) 102 75 —

Front Insulator to Block—Bolts (2WD) 95 70 —

Generator—Mounting Bolt 55 40 —

Intake Manifold—Bolts Refer to Procedure

Lifter Guide Holder 12 — 106

Oil Pan Bolts 12 — 105

Oil Dipstick Tube 12 — 105

Page 1935 of 5267

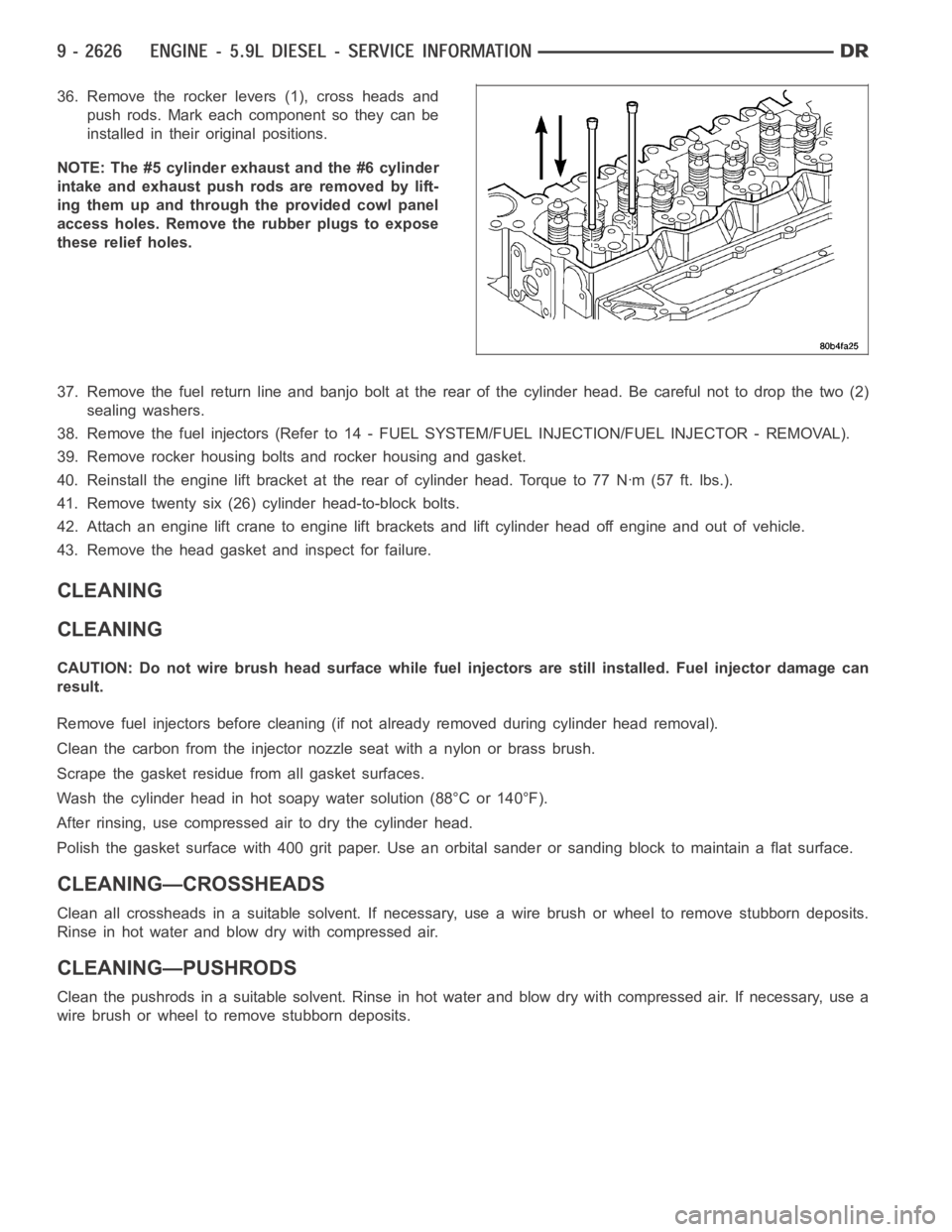

36. Remove the rocker levers (1), cross heads and

push rods. Mark each component so they can be

installed in their original positions.

NOTE: The #5 cylinder exhaust and the #6 cylinder

intake and exhaust push rods are removed by lift-

ing them up and through the provided cowl panel

access holes. Remove the rubber plugs to expose

these relief holes.

37. Remove the fuel return line and banjo bolt at the rear of the cylinder head. Be careful not to drop the two (2)

sealing washers.

38. Remove the fuel injectors (Refer to 14 - FUEL SYSTEM/FUEL INJECTION/FUEL INJECTOR - REMOVAL).

39. Remove rocker housing bolts and rocker housing and gasket.

40. Reinstall the engine lift bracket at the rear of cylinder head. Torque to77Nꞏm(57ft.lbs.).

41. Remove twenty six (26) cylinder head-to-block bolts.

42. Attach an engine lift crane to engine lift brackets and lift cylinder head off engine and out of vehicle.

43. Remove the head gasket and inspect for failure.

CLEANING

CLEANING

CAUTION: Do not wire brush head surface while fuel injectors are still installed. Fuel injector damage can

result.

Remove fuel injectors before cleaning (if not already removed during cylinder head removal).

Clean the carbon from the injector nozzle seat with a nylon or brass brush.

Scrape the gasket residuefrom all gasket surfaces.

Wash the cylinder head in hot soapy water solution (88°C or 140°F).

After rinsing, use compressed air to dry the cylinder head.

Polish the gasket surface with 400 grit paper. Use an orbital sander or sanding block to maintain a flat surface.

CLEANING—CROSSHEADS

Clean all crossheads in a suitable solvent. If necessary, use a wire brush or wheel to remove stubborn deposits.

Rinse in hot water and blow dry with compressed air.

CLEANING—PUSHRODS

Clean the pushrods in a suitable solvent. Rinse in hot water and blow dry with compressed air. If necessary, use a

wire brush or wheel to remove stubborn deposits.

Page 1979 of 5267

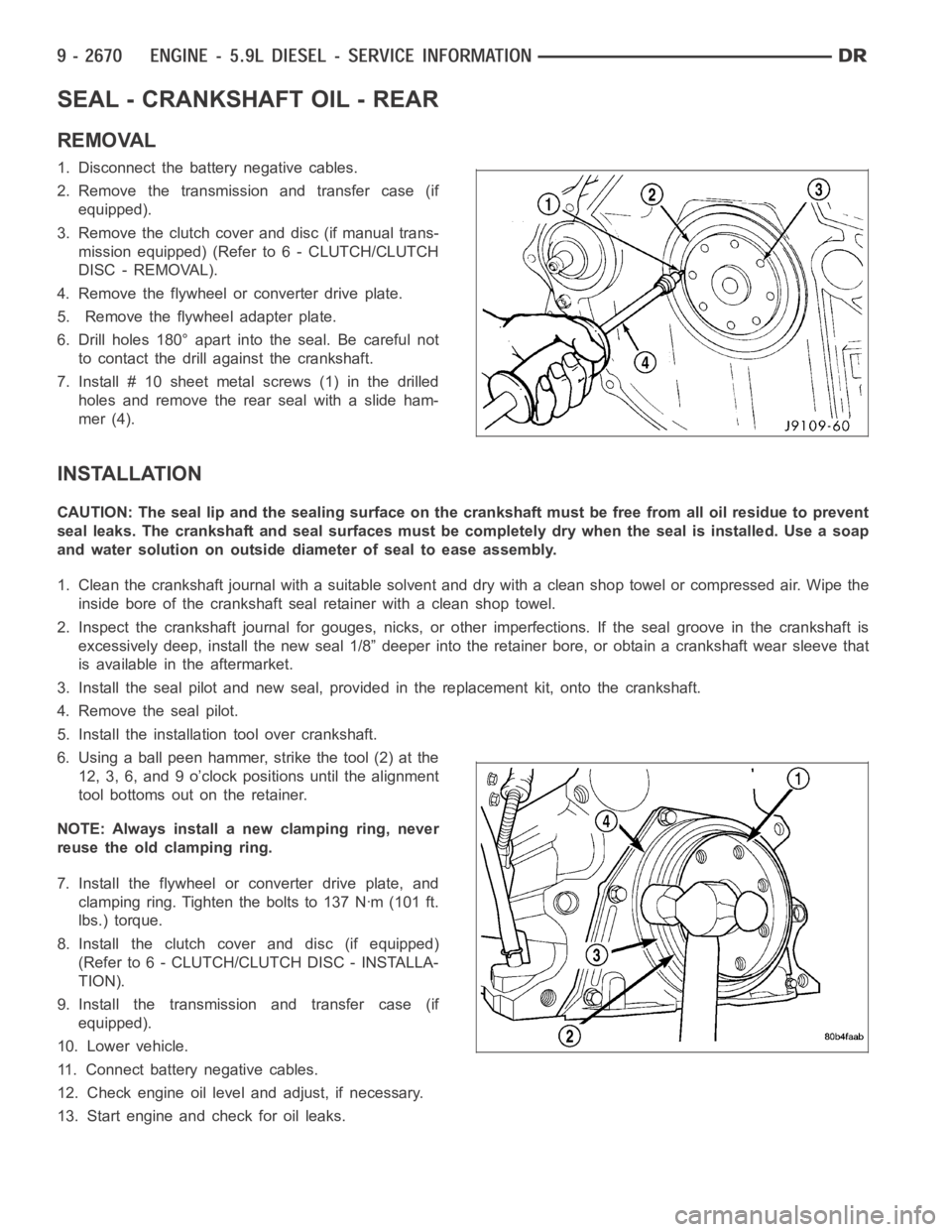

SEAL - CRANKSHAFT OIL - REAR

REMOVAL

1. Disconnect the battery negative cables.

2. Remove the transmission and transfer case (if

equipped).

3. Remove the clutch cover and disc (if manual trans-

mission equipped) (Refer to 6 - CLUTCH/CLUTCH

DISC - REMOVAL).

4. Remove the flywheel or converter drive plate.

5. Remove the flywheel adapter plate.

6. Drill holes 180° apart into the seal. Be careful not

to contact the drill against the crankshaft.

7. Install # 10 sheet metalscrews (1) in the drilled

holes and remove the rear seal with a slide ham-

mer (4).

INSTALLATION

CAUTION: The seal lip and the sealing surface on the crankshaft must be freefrom all oil residue to prevent

seal leaks. The crankshaft and seal surfaces must be completely dry when the seal is installed. Use a soap

and water solution on outside diameter of seal to ease assembly.

1. Clean the crankshaft journal with a suitable solvent and dry with a cleanshop towel or compressed air. Wipe the

inside bore of the crankshaft seal retainer with a clean shop towel.

2. Inspect the crankshaft journal forgouges, nicks, or other imperfections. If the seal groove in the crankshaft is

excessively deep, install the new seal 1/8” deeper into the retainer bore,or obtain a crankshaft wear sleeve that

is available in the aftermarket.

3. Install the seal pilot and new seal, provided in the replacement kit, onto the crankshaft.

4. Remove the seal pilot.

5. Install the installation tool over crankshaft.

6. Using a ball peen hammer, strike the tool (2) at the

12, 3, 6, and 9 o’clock positions until the alignment

tool bottoms out on the retainer.

NOTE: Always install a new clamping ring, never

reuse the old clamping ring.

7. Install the flywheel or converter drive plate, and

clamping ring. Tighten the bolts to 137 Nꞏm (101 ft.

lbs.) torque.

8. Install the clutch cover and disc (if equipped)

(Refer to 6 - CLUTCH/CLUTCH DISC - INSTALLA-

TION).

9. Install the transmission and transfer case (if

equipped).

10. Lower vehicle.

11. Connect battery negative cables.

12. Check engine oil level and adjust, if necessary.

13. Start engine and check for oil leaks.

Page 1980 of 5267

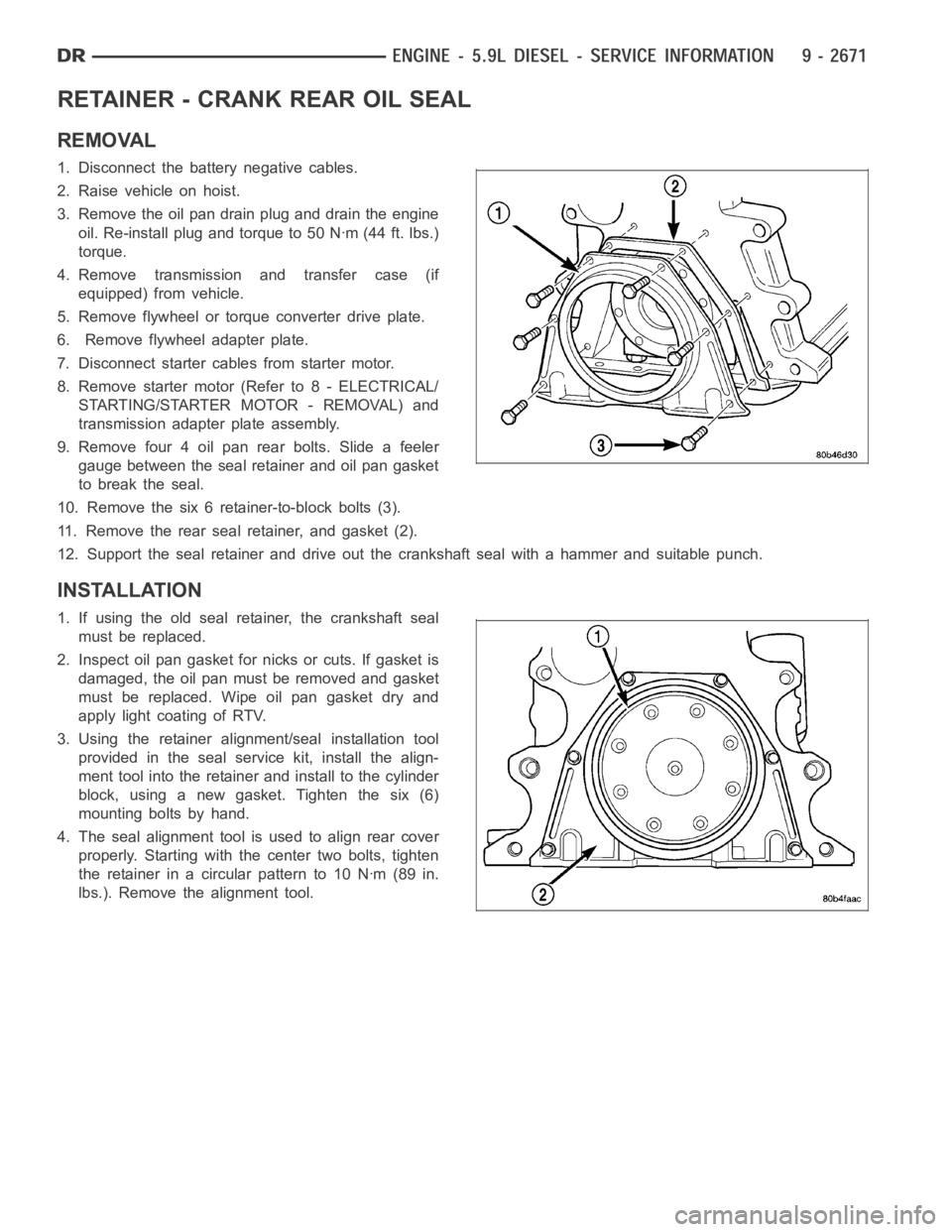

RETAINER - CRANK REAR OIL SEAL

REMOVAL

1. Disconnect the battery negative cables.

2. Raise vehicle on hoist.

3. Remove the oil pan drain plug and drain the engine

oil. Re-install plug and torque to 50 Nꞏm (44 ft. lbs.)

torque.

4. Remove transmission and transfer case (if

equipped) from vehicle.

5. Remove flywheel or torque converter drive plate.

6. Remove flywheel adapter plate.

7. Disconnect starter cables from starter motor.

8. Remove starter motor (Refer to 8 - ELECTRICAL/

STARTING/STARTER MOTOR - REMOVAL) and

transmission adapter plate assembly.

9. Remove four 4 oil pan rear bolts. Slide a feeler

gauge between the seal retainer and oil pan gasket

to break the seal.

10. Remove the six 6 retainer-to-block bolts (3).

11. Remove the rear seal retainer, and gasket (2).

12. Support the seal retainer and drive out the crankshaft seal with a hammer and suitable punch.

INSTALLATION

1. If using the old seal retainer, the crankshaft seal

must be replaced.

2. Inspect oil pan gasket for nicks or cuts. If gasket is

damaged, the oil pan must be removed and gasket

must be replaced. Wipe oil pan gasket dry and

apply light coating of RTV.

3. Using the retainer alignment/seal installation tool

provided in the seal service kit, install the align-

ment tool into the retainer and install to the cylinder

block, using a new gasket. Tighten the six (6)

mounting bolts by hand.

4. The seal alignment tool is used to align rear cover

properly. Starting with the center two bolts, tighten

the retainer in a circular pattern to 10 Nꞏm (89 in.

lbs.). Remove the alignment tool.

Page 1981 of 5267

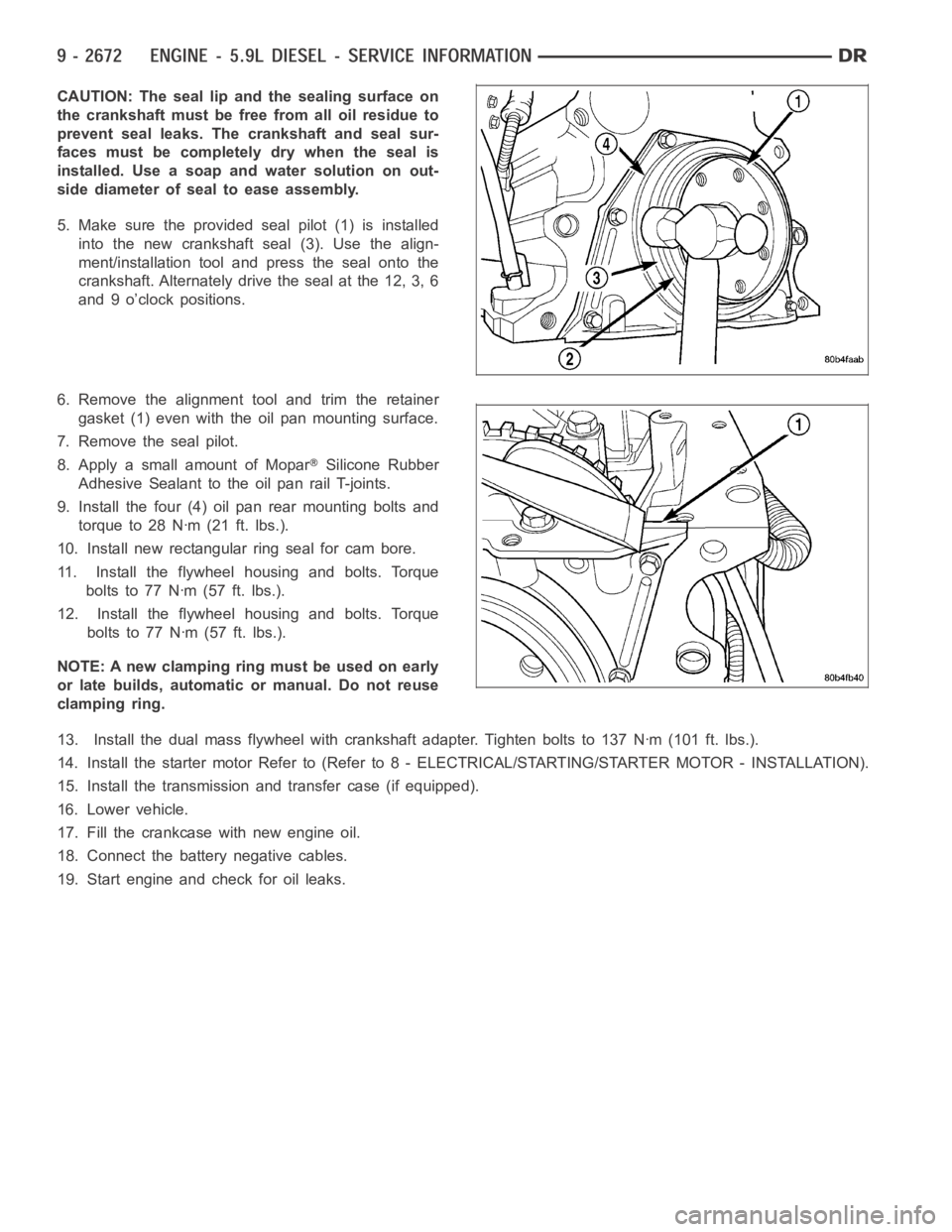

CAUTION: The seal lip and the sealing surface on

the crankshaft must be free from all oil residue to

prevent seal leaks. The crankshaft and seal sur-

faces must be completely dry when the seal is

installed. Use a soap and water solution on out-

side diameter of seal to ease assembly.

5. Make sure the provided seal pilot (1) is installed

into the new crankshaft seal (3). Use the align-

ment/installation tool and press the seal onto the

crankshaft. Alternately drive the seal at the 12, 3, 6

and 9 o’clock positions.

6. Remove the alignment tool and trim the retainer

gasket (1) even with the oil pan mounting surface.

7. Remove the seal pilot.

8. Apply a small amount of Mopar

Silicone Rubber

Adhesive Sealant to the oil pan rail T-joints.

9. Install the four (4) oil pan rear mounting bolts and

torque to 28 Nꞏm (21 ft. lbs.).

10. Install new rectangular ring seal for cam bore.

11. Install the flywheel housing and bolts. Torque

boltsto77Nꞏm(57ft.lbs.).

12. Install the flywheel housing and bolts. Torque

boltsto77Nꞏm(57ft.lbs.).

NOTE: A new clamping ring must be used on early

or late builds, automatic or manual. Do not reuse

clamping ring.

13. Install the dual mass flywheel with crankshaft adapter. Tighten boltsto 137 Nꞏm (101 ft. lbs.).

14. Install the starter motor Refer to (Refer to 8 - ELECTRICAL/STARTING/STA R T E R M O TO R - I N S TA L L AT I O N ) .

15. Install the transmission and transfer case (if equipped).

16. Lower vehicle.

17. Fill the crankcase with new engine oil.

18. Connect the battery negative cables.

19. Start engine and check for oil leaks.