lock DODGE RAM SRT-10 2006 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 121 of 5267

When Monitored:

Ignition on and vehicle moving. Brake pedal must not be applied.

Set Condition:

The PCM recognizes front axle speed is greater than rear axle speed. One tripfault.

Possible Causes

ACTIVE BUS OR COMMUNICATION DTCS

TIRE CIRCUMFERENCE

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

Ignition on, engine not running.

NOTE: Check for any Bus Communication DTCs. If no Bus Communication DTCs are set, check for active

DTCs stored in the Ant-Lock Brake Module. Any Bus Communication DTCs or VSSDTCs in the Ant-Lock

Brake Module must be properly diagnosed before continuing.

With a scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.VISUAL INSPECTION

NOTE: This code can set due to tire circumference differences and from the front or rear wheels being on

a slippery surface while the opposite tires are not.

This code may also set on a hard acceleration on loose gravel or during otheroff road driving conditions.

Check tire pressure of all the tires.

Checktirewearonallthetires.

Ask the customer what the road and driving conditions were like when the fault set.

Were any problems found?

Ye s>>

Repair as necessary. If the code set during a front OR rear wheel spin condition, no repair is necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 3

Page 146 of 5267

P1603-PCM INTERNAL DUAL-PORT RAM COMMUNICATION FAILURE

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Ignition on and battery voltage greater than 10 volts.

Set Condition:

Internal PCM failure detected. One Trip Fault. Three good trips to turn offthe MIL.

Possible Causes

PCM FUSED IGNITION SWITCH CIRCUIT

PCM INTERNAL

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

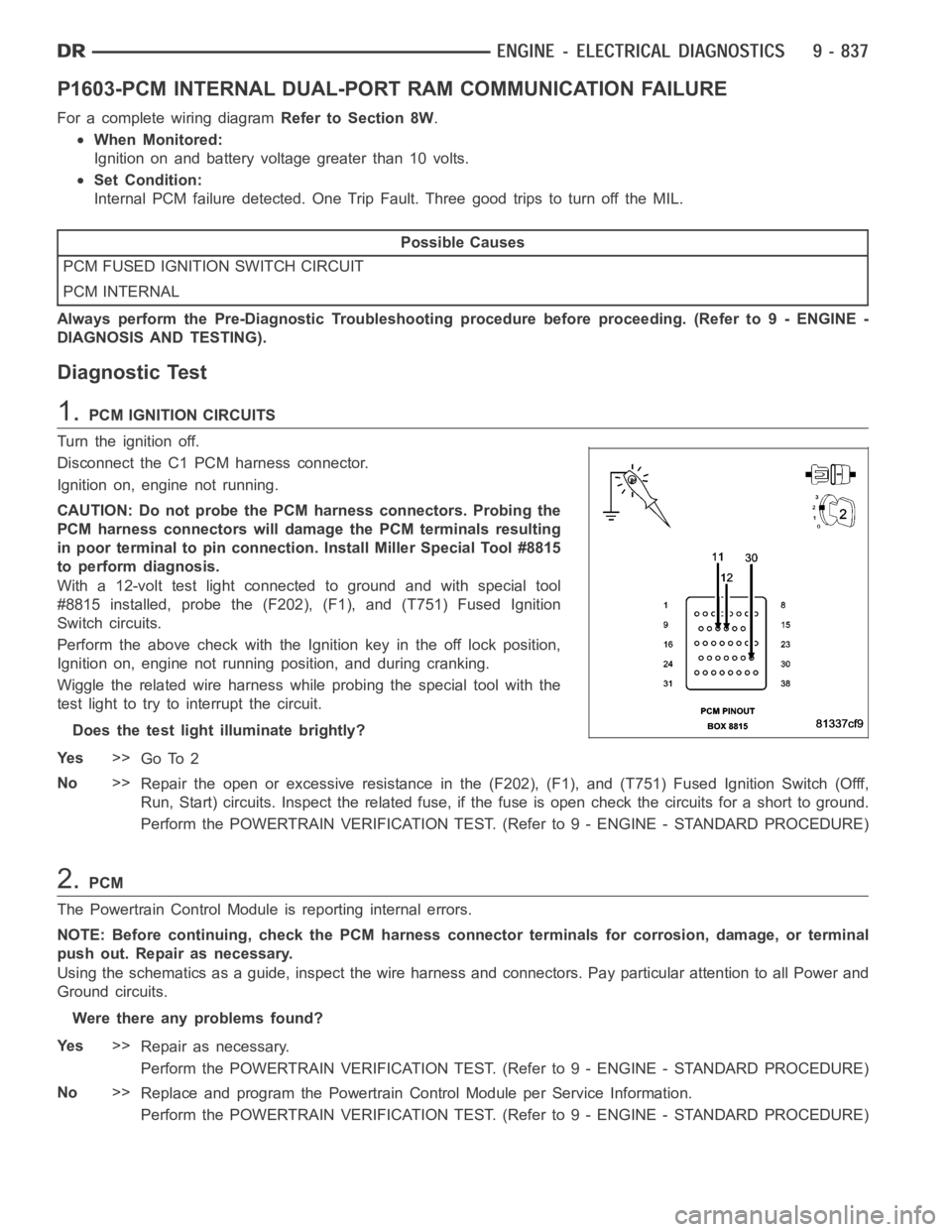

1.PCM IGNITION CIRCUITS

Turn the ignition off.

Disconnect the C1 PCM harness connector.

Ignition on, engine not running.

CAUTION: Do not probe the PCM harness connectors. Probing the

PCM harness connectors will damage the PCM terminals resulting

in poor terminal to pin connection. Install Miller Special Tool #8815

to perform diagnosis.

With a 12-volt test light connected to ground and with special tool

#8815 installed, probe the (F202), (F1), and (T751) Fused Ignition

Switch circuits.

Perform the above check with the Ignition key in the off lock position,

Ignition on, engine not running position, and during cranking.

Wiggle the related wire harness while probing the special tool with the

test light to try to interrupt the circuit.

Does the test light illuminate brightly?

Ye s>>

Go To 2

No>>

Repair the open or excessive resistance in the (F202), (F1), and (T751) Fused Ignition Switch (Offf,

Run, Start) circuits. Inspect the related fuse, if the fuse is open check the circuits for a short to ground.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.PCM

The Powertrain Control Module is reporting internal errors.

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 147 of 5267

P1604-PCM INTERNAL DUAL-PORT RAM READ/WRITE INTEGRITY FAILURE

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Ignition on and battery voltage greater than 10 volts.

Set Condition:

Internal PCM failure detected. One Trip Fault. Three good trips to turn offthe MIL.

Possible Causes

PCM FUSED IGNITION SWITCH CIRCUIT

PCM INTERNAL

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

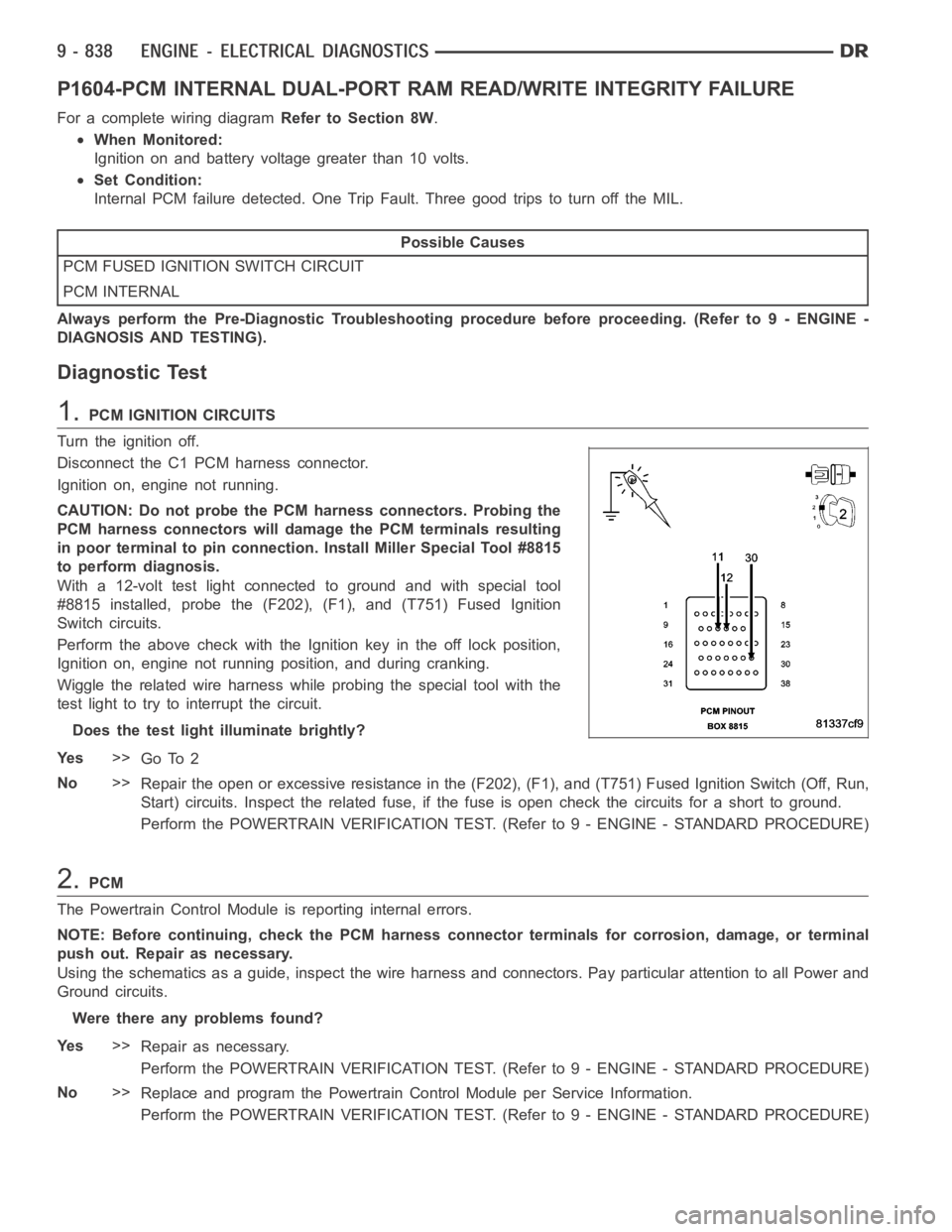

1.PCM IGNITION CIRCUITS

Turn the ignition off.

Disconnect the C1 PCM harness connector.

Ignition on, engine not running.

CAUTION: Do not probe the PCM harness connectors. Probing the

PCM harness connectors will damage the PCM terminals resulting

in poor terminal to pin connection. Install Miller Special Tool #8815

to perform diagnosis.

With a 12-volt test light connected to ground and with special tool

#8815 installed, probe the (F202), (F1), and (T751) Fused Ignition

Switch circuits.

Perform the above check with the Ignition key in the off lock position,

Ignition on, engine not running position, and during cranking.

Wiggle the related wire harness while probing the special tool with the

test light to try to interrupt the circuit.

Does the test light illuminate brightly?

Ye s>>

Go To 2

No>>

Repair the open or excessive resistance in the (F202), (F1), and (T751) Fused Ignition Switch (Off, Run,

Start) circuits. Inspect the related fuse, if the fuse is open check the circuits for a short to ground.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.PCM

The Powertrain Control Module is reporting internal errors.

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 148 of 5267

P1607-PCM INTERNAL SHUTDOWN TIMER SLOW RATIONALITY

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Ignition on and battery voltage greater than 10 volts.

Set Condition:

Internal PCM failure detected. One Trip Fault. Three good trips to turn offthe MIL.

Possible Causes

PCM FUSED IGNITION SWITCH CIRCUIT

PCM INTERNAL

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

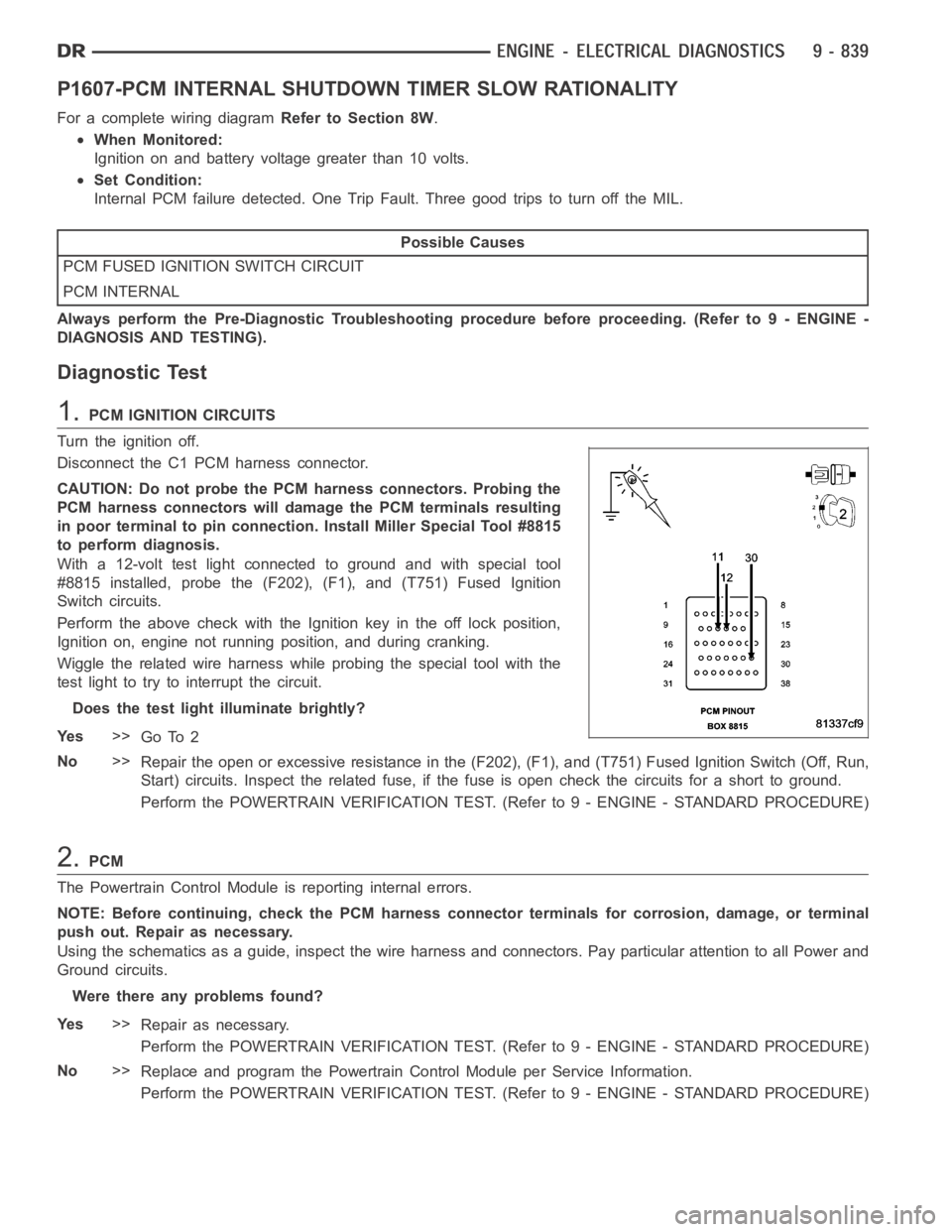

1.PCM IGNITION CIRCUITS

Turn the ignition off.

Disconnect the C1 PCM harness connector.

CAUTION: Do not probe the PCM harness connectors. Probing the

PCM harness connectors will damage the PCM terminals resulting

in poor terminal to pin connection. Install Miller Special Tool #8815

to perform diagnosis.

With a 12-volt test light connected to ground and with special tool

#8815 installed, probe the (F202), (F1), and (T751) Fused Ignition

Switch circuits.

Perform the above check with the Ignition key in the off lock position,

Ignition on, engine not running position, and during cranking.

Wiggle the related wire harness while probing the special tool with the

test light to try to interrupt the circuit.

Does the test light illuminate brightly?

Ye s>>

Go To 2

No>>

Repair the open or excessive resistance in the (F202), (F1), and (T751) Fused Ignition Switch (Off, Run,

Start) circuits. Inspect the related fuse, if the fuse is open check the circuits for a short to ground.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.PCM

The Powertrain Control Module is reporting internal errors.

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 162 of 5267

P1897-LEVEL 1 RPM BUS UNLOCK

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Engine running.

Set Condition:

When the PCM recognizes an internal failure to communicate with the FCM or the CMP and CKP Sensor

count periods are too short. One trip fault. ETC light is flashing.

Possible Causes

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.PCM

NOTE: Diagnose any CMP or CKP Sensor faults before continuing. Check for intermittent loose CMP or CKP

connections.

The Powertrain Control Module is reporting internal errors, view repair to continue.

Repair

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 163 of 5267

P2072-ELECTRONIC THROTTLE CONTROL SYSTEM - ICE BLOCKAGE

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Ignition on.

Set Condition:

The PCM recognizes the Throttle plate is stuck during extremely cold Ambient Temperature operation. The

throttle plate goes through a de-icing procedure. If the throttle blade still doesn’t move this fault sets. The MIL

will not illuminate. The vehicle willbe in Limp home condition, limiting rpm and vehicle speed.

Possible Causes

THROTTLE PLATE FROZEN

Diagnostic Test

1.THROTTLE BODY INSPECTION

Ignition on, engine not running.

With a scan tool, read DTCs and record the related Freeze Frame data.

NOTE: This DTC sets in extreme cold Ambient Temperatures with the throttleplatestuckbythetimethe

vehicle gets to the dealership the condition may be corrected.

NOTE: Diagnose any other DTCs that may also be set before continuing.

Turn the ignition off.

Remove the Air Cleaner Assembly from the Throttle Body.

Check for any signs of a foreign material (ice or dirt) on the Throttle Plateor in the bore causing the Throttle Plate

to stick.

Isthethrottlebladestillstuckbecauseitisfrozen?

Ye s>>

Allow the Throttle Body to thaw naturally in a room temperature climate.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .

Page 175 of 5267

When Monitored:

With the engine running in closed loop mode, the ambient/battery temperature above (-7°C) 20°F, altitude

below 8500 ft.

Set Condition:

If the PCM multiplies short term compensation by long term adaptive as wellas a purge fuel multiplier and the

result is below a certain value for 30 seconds over two trips, a freeze frameis stored, the MIL illuminates and

a trouble code is stored. Two Trip Fault. Three good trips to turn off the MIL.

Possible Causes

EXHAUST LEAK

ENGINE MECHANICAL

1/2O2SENSOR

(K141) O2 SENSOR 1/2 SIGNAL CIRCUIT

(K299) O2 1/2 HEATER CONTROL CIRCUIT

(K904) O2 RETURN DOWNSTREAM CIRCUIT

FUEL CONTAMINATION

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

NOTE: Check the vehicle repair history. If the 1/2 O2 has been replaced makesure that the O2 sensor was

properly installed and meets OEM specification.

NOTE: Check for contaminants that may have damaged the O2 Sensor: contaminated fuel, unapproved sil-

icone, oil and coolant.

Ignition on, engine not running.

With a scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.EXHAUST LEAK

Turn the ignition off.

WARNING: To avoid personal injury from the exhaust system being hot, allowthe exhaust to cool down to

a safe temperature before performing a physical inspection. Failure to follow these instructions can result in

personal injury or death.

Visually and Physically inspect the exhaust system for holes, cracks and blockage in the exhaust system.

Is the exhaust system is good condition?

Ye s>>

Go To 3

No>>

Repair or Replace as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 180 of 5267

When Monitored:

With the engine running in closed loop mode, the ambient/battery temperature above (-7°C) 20°F, altitude

below 8500 ft.

Set Condition:

If the PCM multiplies short term compensation by long term adaptive as wellas a purge fuel multiplier and the

result is below a certain value for 30 seconds over two trips, a freeze frameis stored, the MIL illuminates and

a trouble code is stored. Two Trip Fault. Three good trips to turn off the MIL.

Possible Causes

EXHAUST LEAK

ENGINE MECHANICAL

1/2O2SENSOR

(K141) O2 SENSOR 1/2 SIGNAL CIRCUIT

(K299) O2 HEATER 1/2 CONTROL CIRCUIT

(K904) O2 RETURN DOWNSTREAM CIRCUIT

FUEL CONTAMINATION

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

NOTE: Check the vehicle repair history. If the 1/2 O2 has been replaced makesure that the O2 sensor was

properly installed and meets OEM specification.

NOTE: Check for contaminants that may have damaged the O2 Sensor: contaminated fuel, unapproved sil-

icone, oil and coolant.

Ignition on, engine not running.

With a scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.EXHAUST LEAK

Turn the ignition off.

WARNING: To avoid personal injury from the exhaust system being hot, allowthe exhaust to cool down to

a safe temperature before performing a physical inspection. Failure to follow these instructions can result in

personal injury or death.

Visually and Physically inspect the exhaust system for holes, cracks and blockage in the exhaust system.

Is the exhaust system is good condition?

Ye s>>

Go To 3

No>>

Repair or Replace as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 186 of 5267

When Monitored:

With the engine running in closed loop mode, the ambient/battery temperature above (-7°C) 20°F, altitude

below 8500 ft and fuel level greater than 15%.

Set Condition:

If the PCM multiplies short term compensation by long term adaptive and a certain percentage is exceeded for

two trips, a freeze frame is stored, the MIL illuminates and a trouble code is stored. Two Trip Fault. Three good

trips to turn off the MIL.

Possible Causes

EXHAUST LEAK

ENGINE MECHANICAL

2/2O2SENSOR

(K243) O2 2/2 SIGNAL CIRCUIT

(K399) O2 HEATER 2/2 CONTROL CIRCUIT

(K904) O2 RETURN DOWNSTREAM CIRCUIT

FUEL CONTAMINATION

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

NOTE: Check the vehicle repair history. If the 2/2 O2 has been replaced makesure that the O2 sensor was

properly installed and meets OEM specification.

NOTE: Check for contaminants that may have damaged the O2 Sensor: contaminated fuel, unapproved sil-

icone, oil and coolant.

Ignition on, engine not running.

With a scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.EXHAUST LEAK

Turn the ignition off.

WARNING: To avoid personal injury from the exhaust system being hot, allowthe exhaust to cool down to

a safe temperature before performing a physical inspection. Failure to follow these instructions can result in

personal injury or death.

Visually and Physically inspect the exhaust system for holes, cracks and blockage in the exhaust system.

Is the exhaust system is good condition?

Ye s>>

Go To 3

No>>

Repair or Replace as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 191 of 5267

When Monitored:

With the engine running in closed loop mode, the ambient/battery temperature above (-7°C) 20°F, altitude

below 8500 ft.

Set Condition:

If the PCM multiplies short term compensation by long term adaptive as wellas a purge fuel multiplier and the

result is below a certain value for 30 seconds over two trips, a freeze frameis stored, the MIL illuminates and

a trouble code is stored. Two Trip Fault. Three good trips to turn off the MIL.

Possible Causes

EXHAUST LEAK

ENGINE MECHANICAL

2/2O2SENSOR

(K342) O2 SENSOR 2/2 SIGNAL CIRCUIT

(K399) O2 SENSOR 2/2 HEATER CONTROL CIRCUIT

(K904) O2 RETURN DOWNSTREAM CIRCUIT

FUEL CONTAMINATION

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ACTIVE DTC

NOTE: Check the vehicle repair history. If the 2/2 O2 has been replaced makesure that the O2 sensor was

properly installed and meets OEM specification.

NOTE: Check for contaminants that may have damaged the O2 Sensor: contaminated fuel, unapproved sil-

icone, oil and coolant.

Ignition on, engine not running.

With a scan tool, read DTCs.

Is the DTC active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.EXHAUST LEAK

Turn the ignition off.

WARNING: To avoid personal injury from the exhaust system being hot, allowthe exhaust to cool down to

a safe temperature before performing a physical inspection. Failure to follow these instructions can result in

personal injury or death.

Visually and Physically inspect the exhaust system for holes, cracks and blockage in the exhaust system.

Is the exhaust system is good condition?

Ye s>>

Go To 3

No>>

Repair or Replace as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)