refrigerant type DODGE RAM SRT-10 2006 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 5136 of 5267

COMPRESSOR-A/C

DESCRIPTION

A/C COMPRESSOR

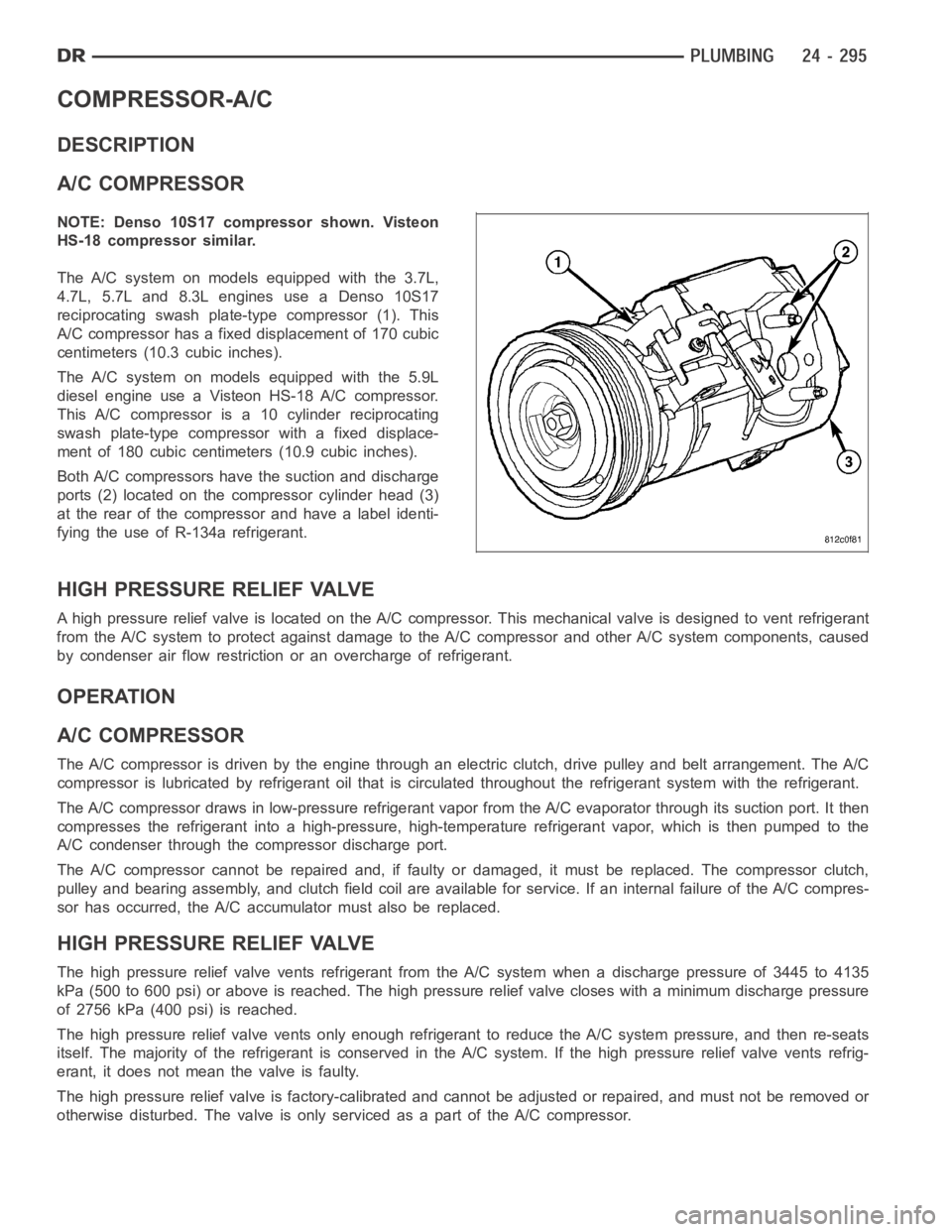

NOTE: Denso 10S17 compressor shown. Visteon

HS-18 compressor similar.

The A/C system on models equipped with the 3.7L,

4.7L, 5.7L and 8.3L engines use a Denso 10S17

reciprocating swash plate-type compressor (1). This

A/C compressor has a fixed displacement of 170 cubic

centimeters (10.3 cubic inches).

The A/C system on models equipped with the 5.9L

diesel engine use a Visteon HS-18 A/C compressor.

This A/C compressor is a 10 cylinder reciprocating

swash plate-type compressor with a fixed displace-

ment of 180 cubic centimeters (10.9 cubic inches).

Both A/C compressors have the suction and discharge

ports (2) located on the compressor cylinder head (3)

at the rear of the compressor and have a label identi-

fying the use of R-134a refrigerant.

HIGH PRESSURE RELIEF VALVE

A high pressure relief valve is located on the A/C compressor. This mechanical valve is designed to vent refrigerant

from the A/C system to protect against damage to the A/C compressor and other A/C system components, caused

by condenser air flow restriction or an overcharge of refrigerant.

OPERATION

A/C COMPRESSOR

The A/C compressor is driven by the engine through an electric clutch, drive pulley and belt arrangement. The A/C

compressor is lubricated by refrigerant oil that is circulated throughout the refrigerant system with the refrigerant.

The A/C compressor draws in low-pressure refrigerant vapor from the A/C evaporator through its suction port. It then

compresses the refrigerant into a high-pressure, high-temperature refrigerant vapor, which is then pumped to the

A/C condenser through the compressor discharge port.

The A/C compressor cannot be repaired and, if faulty or damaged, it must be replaced. The compressor clutch,

pulley and bearing assembly, and clutch field coil are available for service. If an internal failure of the A/C compres-

sor has occurred, the A/C accumulator must also be replaced.

HIGH PRESSURE RELIEF VALVE

The high pressure relief valve vents refrigerant from the A/C system when adischarge pressure of 3445 to 4135

kPa (500 to 600 psi) or above is reached. The high pressure relief valve closes with a minimum discharge pressure

of 2756 kPa (400 psi) is reached.

The high pressure relief valve vents only enough refrigerant to reduce theA/C system pressure, and then re-seats

itself. The majority of the refrigerant is conserved in the A/C system. If the high pressure relief valve vents refrig-

erant, it does not mean the valve is faulty.

The high pressure relief valve is factory-calibrated and cannot be adjusted or repaired, and must not be removed or

otherwise disturbed. The valve is only serviced as a part of the A/C compressor.

Page 5141 of 5267

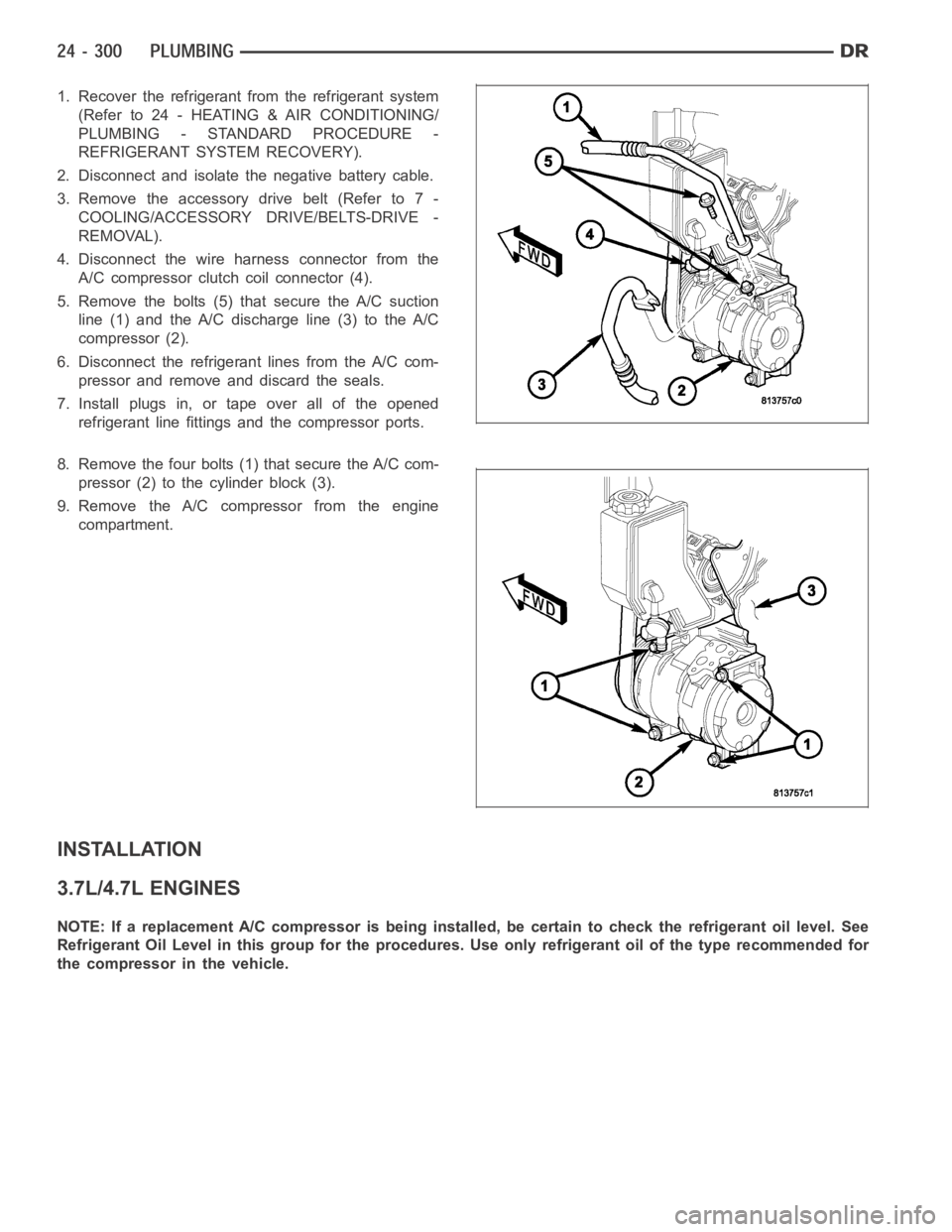

1. Recover the refrigerant from the refrigerant system

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - STANDARD PROCEDURE -

REFRIGERANT SYSTEM RECOVERY).

2. Disconnect and isolate the negative battery cable.

3. Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/BELTS-DRIVE -

REMOVAL).

4. Disconnect the wire harness connector from the

A/C compressor clutch coil connector (4).

5. Remove the bolts (5) that secure the A/C suction

line (1) and the A/C discharge line (3) to the A/C

compressor (2).

6. Disconnect the refrigerant lines from the A/C com-

pressor and remove and discard the seals.

7. Install plugs in, or tape over all of the opened

refrigerant line fittings and the compressor ports.

8. Remove the four bolts (1) that secure the A/C com-

pressor (2) to the cylinder block (3).

9. Remove the A/C compressor from the engine

compartment.

INSTALLATION

3.7L/4.7L ENGINES

NOTE: If a replacement A/C compressor is being installed, be certain to check the refrigerant oil level. See

Refrigerant Oil Level in this group for the procedures. Use only refrigerant oil of the type recommended for

the compressor in the vehicle.

Page 5142 of 5267

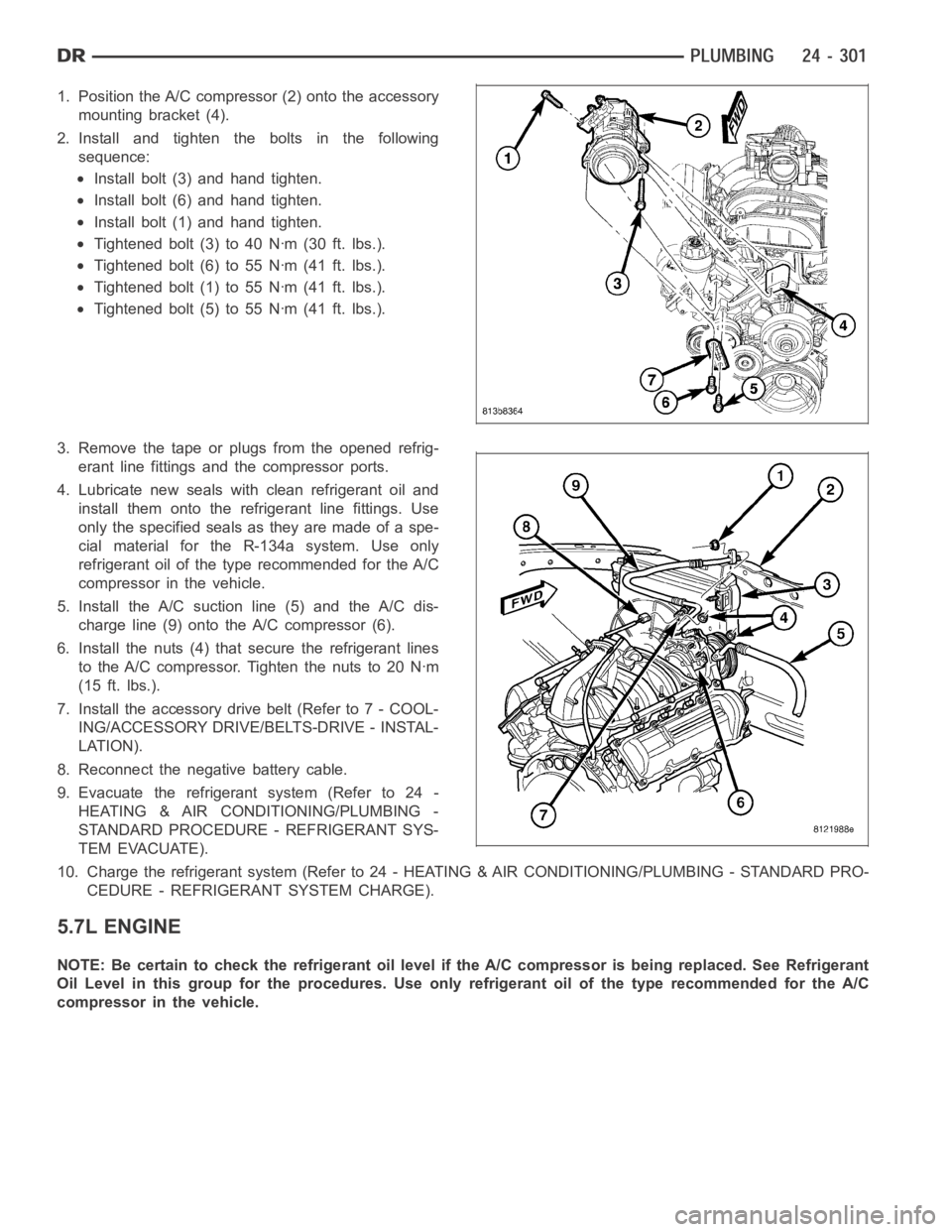

1. Position the A/C compressor (2) onto the accessory

mounting bracket (4).

2. Install and tighten the bolts in the following

sequence:

Install bolt (3) and hand tighten.

Install bolt (6) and hand tighten.

Install bolt (1) and hand tighten.

Tightened bolt (3) to 40 Nꞏm (30 ft. lbs.).

Tightened bolt (6) to 55 Nꞏm (41 ft. lbs.).

Tightened bolt (1) to 55 Nꞏm (41 ft. lbs.).

Tightened bolt (5) to 55 Nꞏm (41 ft. lbs.).

3. Remove the tape or plugs from the opened refrig-

erant line fittings and the compressor ports.

4. Lubricate new seals with clean refrigerant oil and

install them onto the refrigerant line fittings. Use

only the specified seals as they are made of a spe-

cial material for the R-134a system. Use only

refrigerant oil of the type recommended for the A/C

compressor in the vehicle.

5. Install the A/C suction line (5) and the A/C dis-

charge line (9) onto the A/C compressor (6).

6. Install the nuts (4) that secure the refrigerant lines

to the A/C compressor. Tighten the nuts to 20 Nꞏm

(15 ft. lbs.).

7. Install the accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/BELTS-DRIVE - INSTAL-

LATION).

8. Reconnect the negative battery cable.

9. Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE).

10. Charge the refrigerant system (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE - REFRIGERANT SYSTEM CHARGE).

5.7L ENGINE

NOTE: Be certain to check the refrigerant oil level if the A/C compressor isbeing replaced. See Refrigerant

Oil Level in this group for the procedures. Use only refrigerant oil of the type recommended for the A/C

compressor in the vehicle.

Page 5143 of 5267

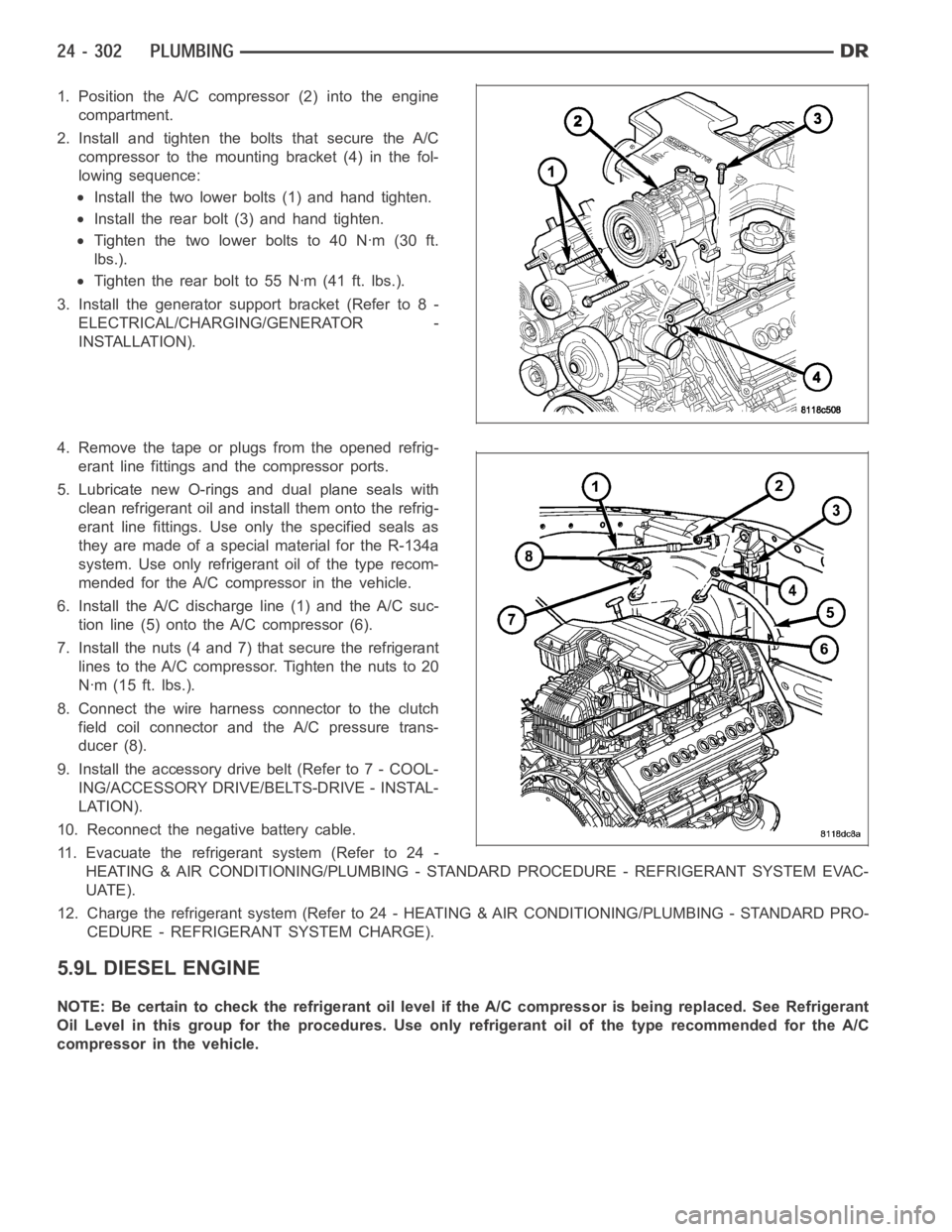

1. Position the A/C compressor (2) into the engine

compartment.

2. Install and tighten the bolts that secure the A/C

compressor to the mounting bracket (4) in the fol-

lowing sequence:

Install the two lower bolts (1) and hand tighten.

Install the rear bolt (3) and hand tighten.

Tightenthetwolowerboltsto40Nꞏm(30ft.

lbs.).

Tighten the rear bolt to 55 Nꞏm (41 ft. lbs.).

3. Install the generator support bracket (Refer to 8 -

ELECTRICAL/CHARGING/GENERATOR -

INSTALLATION).

4. Remove the tape or plugs from the opened refrig-

erant line fittings and the compressor ports.

5. Lubricate new O-rings and dual plane seals with

clean refrigerant oil and install them onto the refrig-

erant line fittings. Use only the specified seals as

they are made of a special material for the R-134a

system. Use only refrigerant oil of the type recom-

mended for the A/C compressor in the vehicle.

6. Install the A/C discharge line (1) and the A/C suc-

tion line (5) onto the A/C compressor (6).

7. Install the nuts (4 and 7) that secure the refrigerant

lines to the A/C compressor. Tighten the nuts to 20

Nꞏm (15 ft. lbs.).

8. Connect the wire harness connector to the clutch

field coil connector and the A/C pressure trans-

ducer (8).

9. Install the accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/BELTS-DRIVE - INSTAL-

LATION).

10. Reconnect the negative battery cable.

11. Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING - STANDARD PROCEDURE - REFRIGERANT SYSTEM EVAC-

UATE).

12. Charge the refrigerant system (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE - REFRIGERANT SYSTEM CHARGE).

5.9L DIESEL ENGINE

NOTE: Be certain to check the refrigerant oil level if the A/C compressor isbeing replaced. See Refrigerant

Oil Level in this group for the procedures. Use only refrigerant oil of the type recommended for the A/C

compressor in the vehicle.

Page 5144 of 5267

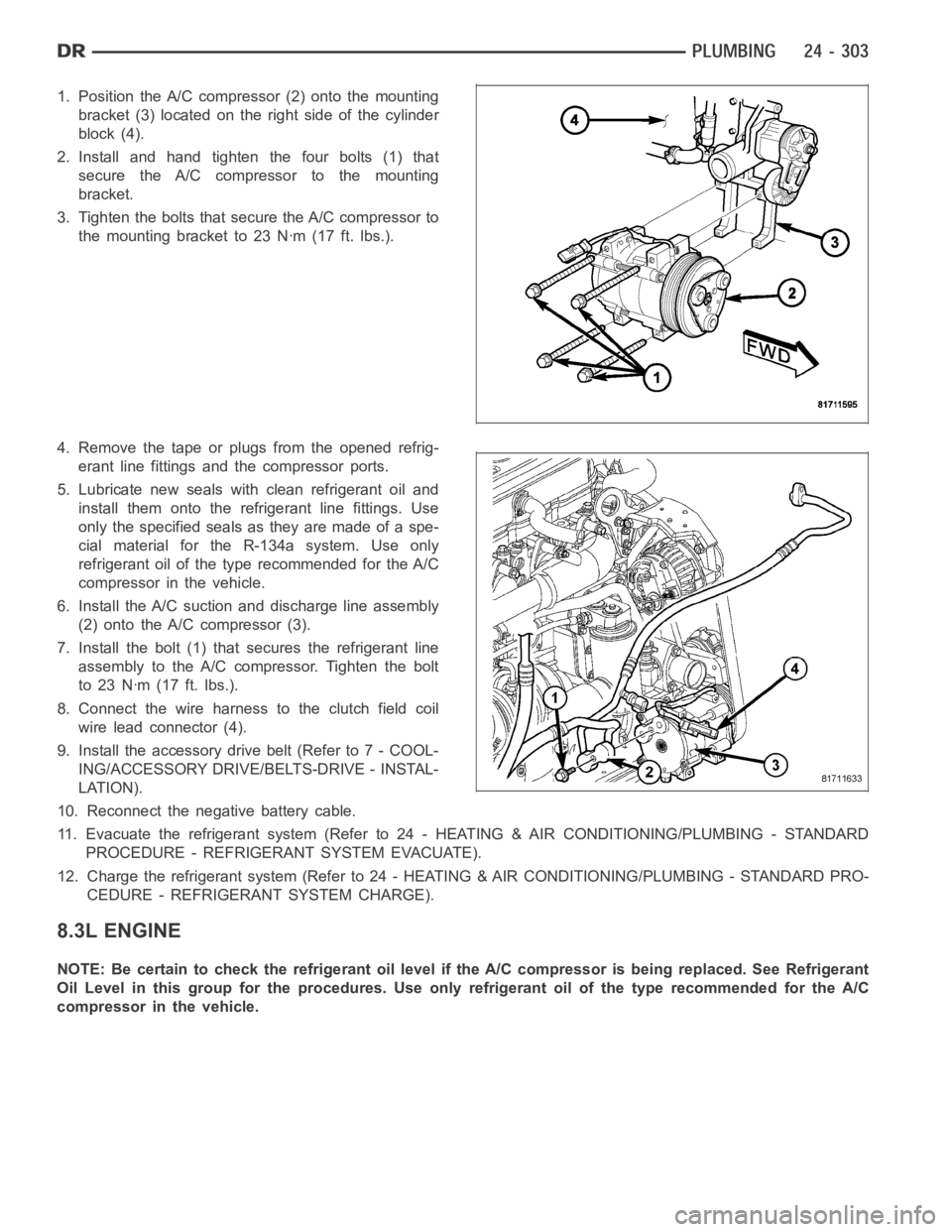

1. Position the A/C compressor (2) onto the mounting

bracket (3) located on the right side of the cylinder

block (4).

2. Install and hand tighten the four bolts (1) that

secure the A/C compressor to the mounting

bracket.

3. Tighten the bolts that secure the A/C compressor to

themountingbracketto23Nꞏm(17ft.lbs.).

4. Remove the tape or plugs from the opened refrig-

erant line fittings and the compressor ports.

5. Lubricate new seals with clean refrigerant oil and

install them onto the refrigerant line fittings. Use

only the specified seals as they are made of a spe-

cial material for the R-134a system. Use only

refrigerant oil of the type recommended for the A/C

compressor in the vehicle.

6. Install the A/C suction and discharge line assembly

(2) onto the A/C compressor (3).

7. Install the bolt (1) that secures the refrigerant line

assembly to the A/C compressor. Tighten the bolt

to 23 Nꞏm (17 ft. lbs.).

8. Connect the wire harness to the clutch field coil

wire lead connector (4).

9. Install the accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/BELTS-DRIVE - INSTAL-

LATION).

10. Reconnect the negative battery cable.

11. Evacuate the refrigerant system (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD

PROCEDURE - REFRIGERANT SYSTEM EVACUATE).

12. Charge the refrigerant system (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE - REFRIGERANT SYSTEM CHARGE).

8.3L ENGINE

NOTE: Be certain to check the refrigerant oil level if the A/C compressor isbeing replaced. See Refrigerant

Oil Level in this group for the procedures. Use only refrigerant oil of the type recommended for the A/C

compressor in the vehicle.

Page 5145 of 5267

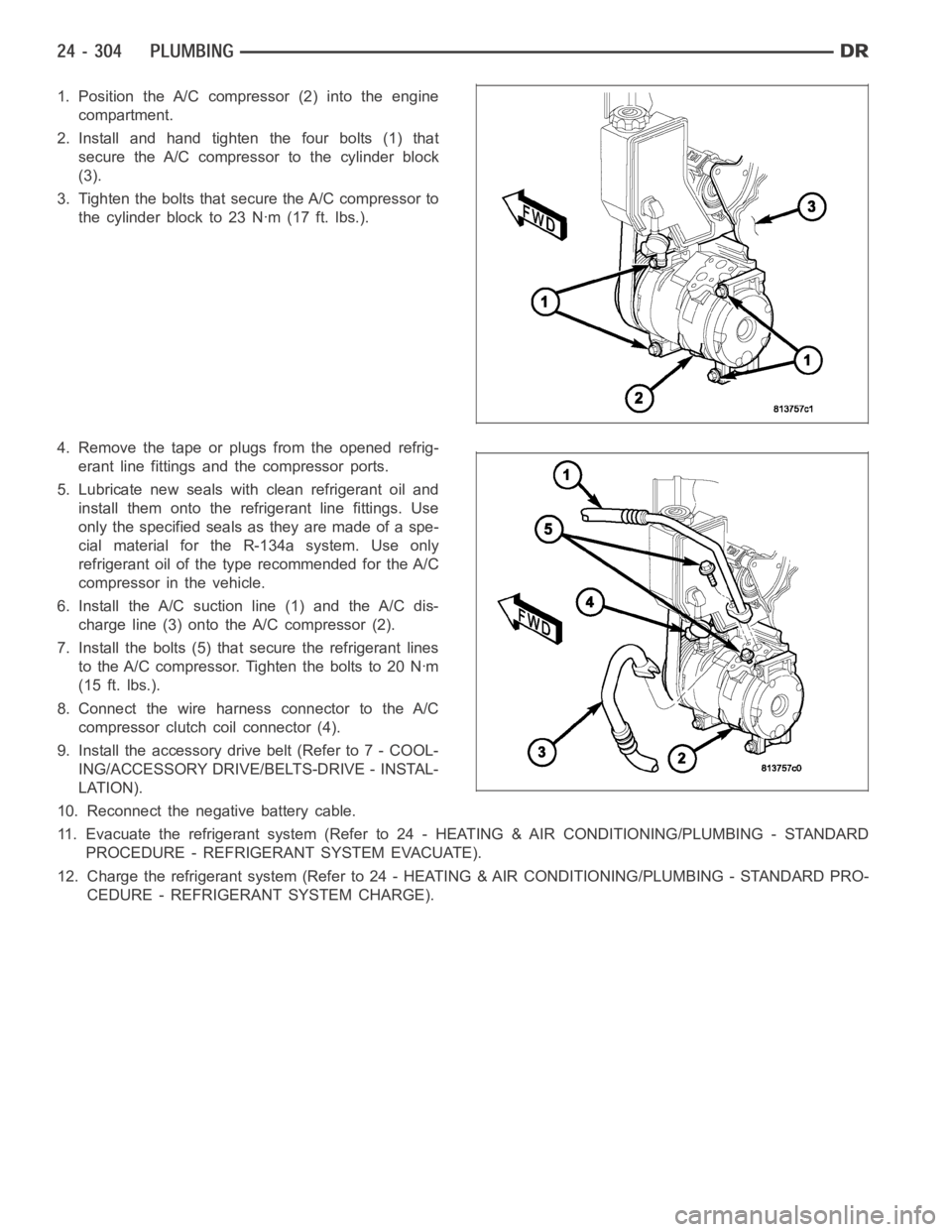

1. Position the A/C compressor (2) into the engine

compartment.

2. Install and hand tighten the four bolts (1) that

secure the A/C compressor to the cylinder block

(3).

3. Tighten the bolts that secure the A/C compressor to

the cylinder block to 23 Nꞏm (17 ft. lbs.).

4. Remove the tape or plugs from the opened refrig-

erant line fittings and the compressor ports.

5. Lubricate new seals with clean refrigerant oil and

install them onto the refrigerant line fittings. Use

only the specified seals as they are made of a spe-

cial material for the R-134a system. Use only

refrigerant oil of the type recommended for the A/C

compressor in the vehicle.

6. Install the A/C suction line (1) and the A/C dis-

charge line (3) onto the A/C compressor (2).

7. Install the bolts (5) that secure the refrigerant lines

to the A/C compressor. Tighten the bolts to 20 Nꞏm

(15 ft. lbs.).

8. Connect the wire harness connector to the A/C

compressor clutch coil connector (4).

9. Install the accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/BELTS-DRIVE - INSTAL-

LATION).

10. Reconnect the negative battery cable.

11. Evacuate the refrigerant system (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD

PROCEDURE - REFRIGERANT SYSTEM EVACUATE).

12. Charge the refrigerant system (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE - REFRIGERANT SYSTEM CHARGE).

Page 5148 of 5267

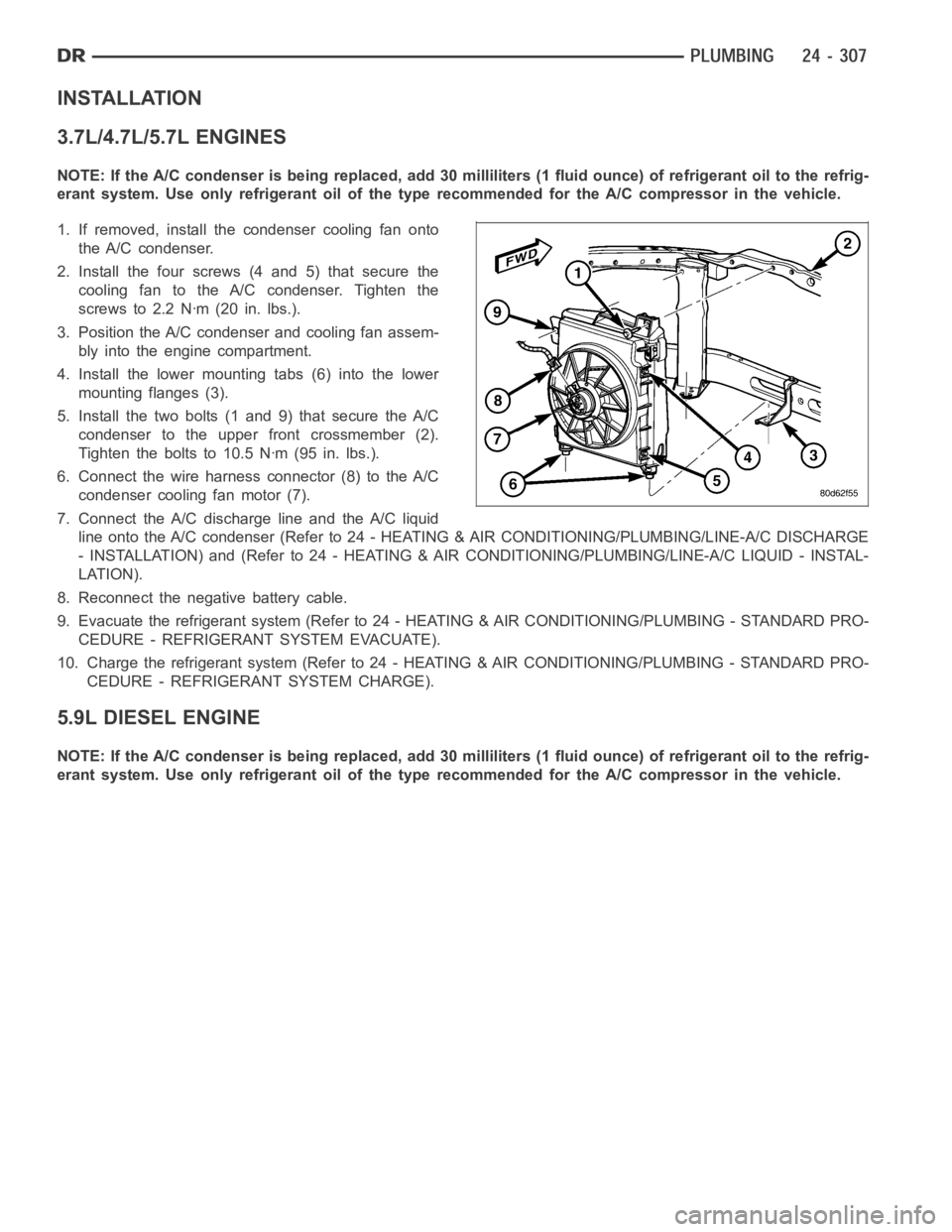

INSTALLATION

3.7L/4.7L/5.7L ENGINES

NOTE: If the A/C condenser is being replaced, add 30 milliliters (1 fluid ounce) of refrigerant oil to the refrig-

erant system. Use only refrigerant oil of the type recommended for the A/C compressor in the vehicle.

1. If removed, install the condenser cooling fan onto

the A/C condenser.

2. Install the four screws (4 and 5) that secure the

cooling fan to the A/C condenser. Tighten the

screws to 2.2 Nꞏm (20 in. lbs.).

3. Position the A/C condenser and cooling fan assem-

bly into the engine compartment.

4. Install the lower mounting tabs (6) into the lower

mounting flanges (3).

5. Install the two bolts (1 and 9) that secure the A/C

condenser to the upper front crossmember (2).

Tighten the bolts to 10.5 Nꞏm (95 in. lbs.).

6. Connect the wire harness connector (8) to the A/C

condenser cooling fan motor (7).

7. Connect the A/C discharge line and the A/C liquid

line onto the A/C condenser (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING/LINE-A/C DISCHARGE

- INSTALLATION) and (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING/LINE-A/C LIQUID - INSTAL-

LATION).

8. Reconnect the negative battery cable.

9. Evacuate the refrigerant system (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE - REFRIGERANT SYSTEM EVACUATE).

10. Charge the refrigerant system (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE - REFRIGERANT SYSTEM CHARGE).

5.9L DIESEL ENGINE

NOTE: If the A/C condenser is being replaced, add 30 milliliters (1 fluid ounce) of refrigerant oil to the refrig-

erant system. Use only refrigerant oil of the type recommended for the A/C compressor in the vehicle.

Page 5149 of 5267

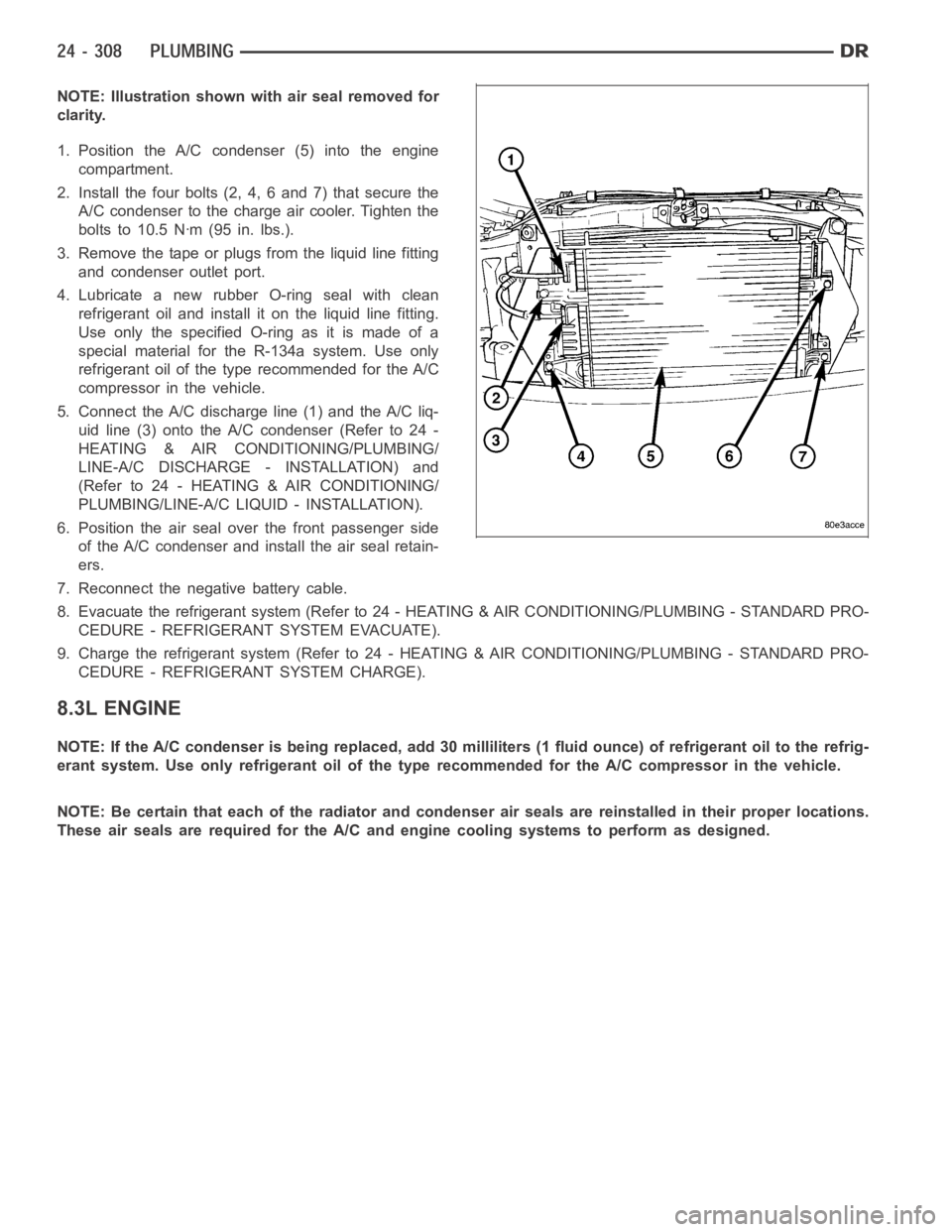

NOTE: Illustration shown with air seal removed for

clarity.

1. Position the A/C condenser (5) into the engine

compartment.

2. Install the four bolts (2, 4, 6 and 7) that secure the

A/C condenser to the charge air cooler. Tighten the

bolts to 10.5 Nꞏm (95 in. lbs.).

3. Remove the tape or plugs from the liquid line fitting

and condenser outlet port.

4. Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the liquid line fitting.

UseonlythespecifiedO-ringasitismadeofa

special material for the R-134a system. Use only

refrigerant oil of the type recommended for the A/C

compressor in the vehicle.

5. Connect the A/C discharge line (1) and the A/C liq-

uid line (3) onto the A/C condenser (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/

LINE-A/C DISCHARGE - INSTALLATION) and

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/LINE-A/C LIQUID - INSTALLATION).

6. Position the air seal over the front passenger side

of the A/C condenser and install the air seal retain-

ers.

7. Reconnect the negative battery cable.

8. Evacuate the refrigerant system (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE - REFRIGERANT SYSTEM EVACUATE).

9. Charge the refrigerant system (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE - REFRIGERANT SYSTEM CHARGE).

8.3L ENGINE

NOTE: If the A/C condenser is being replaced, add 30 milliliters (1 fluid ounce) of refrigerant oil to the refrig-

erant system. Use only refrigerant oil of the type recommended for the A/C compressor in the vehicle.

NOTE: Be certain that each of the radiator and condenser air seals are reinstalled in their proper locations.

These air seals are required for the A/C and engine cooling systems to perform as designed.

Page 5153 of 5267

CORE-VALVE-SERVICE PORT

DESCRIPTION

Two refrigerant system service ports are used to recover/recycle/evacuate/charge and test the A/C refrigerant sys-

tem. Unique sizes are used on the service ports for the R-134a refrigerant system to ensure the system is not

accidentally contaminated with R-12 refrigerant or service equipment used for R-12 refrigerant.

The high side service port is located on the A/C discharge line. The A/C pressure transducer is mounted on the high

side service port (Refer to 24 - HEATING & AIR CONDITIONING/CONTROLS/TRANSDUCER-A/C PRESSURE -

DESCRIPTION). The low side service port is located either on the top of the A/C accumulator or on the A/C suction

line near the accumulator, depending on engine application. Both the highside and low side A/C service port valve

cores are serviceable.

Each of the service ports has a threaded plastic protective cap installed over it from the factory. After servicing the

refrigerant system, always reinstall both of the service port caps.

REMOVAL

WARNING: Refer to the applicable warnings and cautions for this system before performing the following

operation (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - WARNINGS) and (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - CAUTIONS). Failure to follow the warnings and cautions could result

in possible personal injury or death.

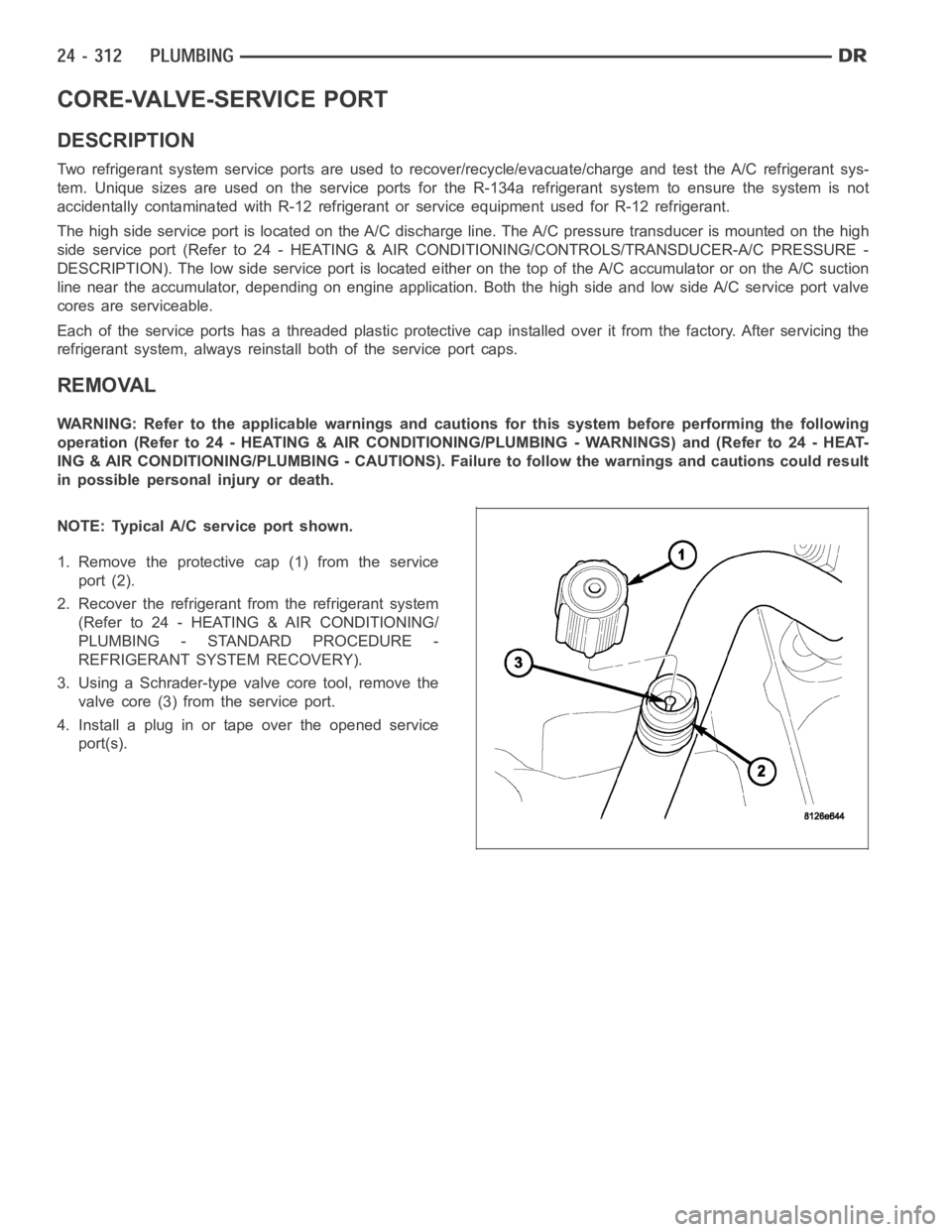

NOTE: Typical A/C service port shown.

1. Remove the protective cap (1) from the service

port (2).

2. Recover the refrigerant from the refrigerant system

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - STANDARD PROCEDURE -

REFRIGERANT SYSTEM RECOVERY).

3. Using a Schrader-type valve core tool, remove the

valve core (3) from the service port.

4. Install a plug in or tape over the opened service

port(s).

Page 5154 of 5267

INSTALLATION

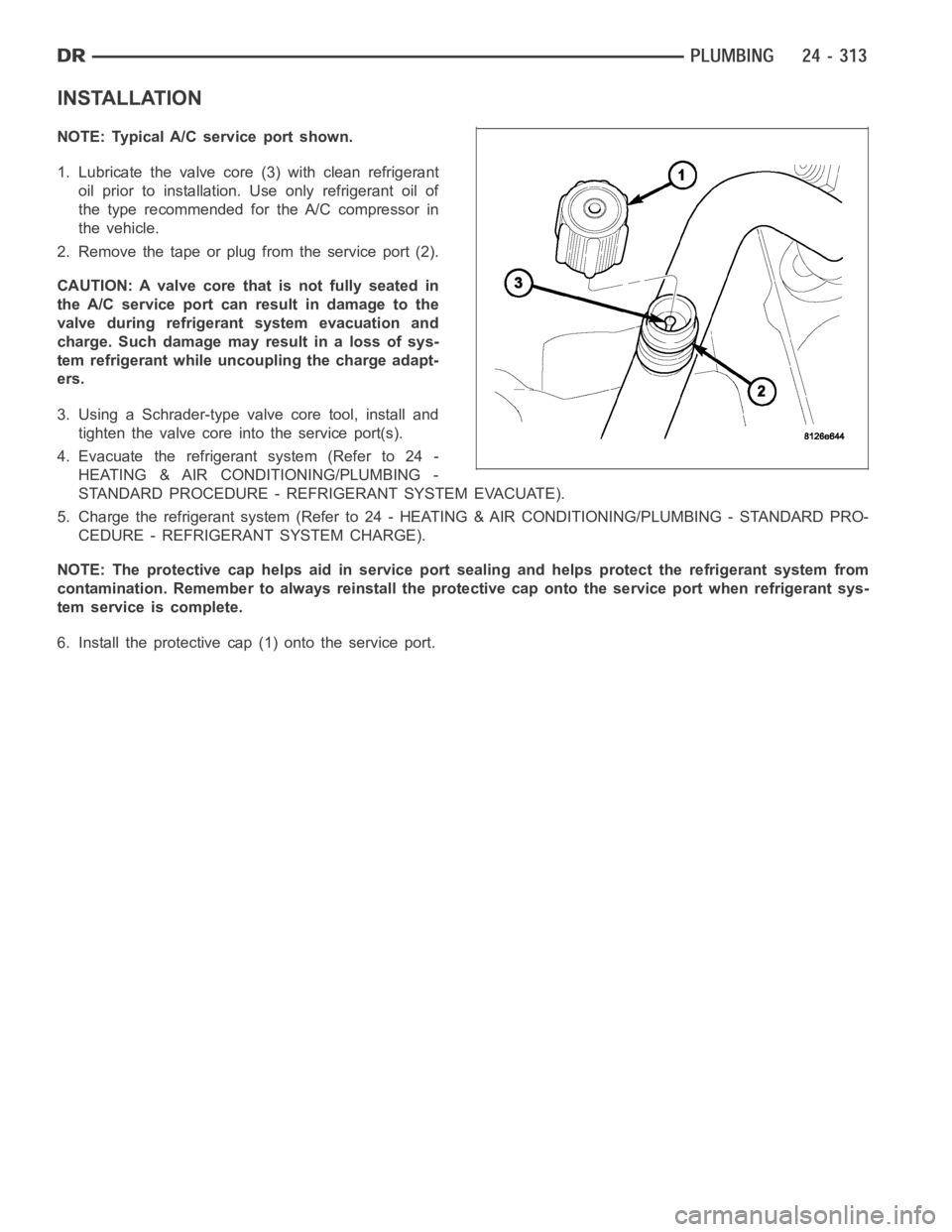

NOTE: Typical A/C service port shown.

1. Lubricate the valve core (3) with clean refrigerant

oil prior to installation. Use only refrigerant oil of

the type recommended for the A/C compressor in

the vehicle.

2. Remove the tape or plug from the service port (2).

CAUTION: A valve core that is not fully seated in

the A/C service port can result in damage to the

valve during refrigerant system evacuation and

charge. Such damage may result in a loss of sys-

tem refrigerant while uncoupling the charge adapt-

ers.

3. Using a Schrader-type valve core tool, install and

tighten the valve core into the service port(s).

4. Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYSTEM EVACUATE).

5. Charge the refrigerant system (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE - REFRIGERANT SYSTEM CHARGE).

NOTE: The protective cap helps aid in service port sealing and helps protect the refrigerant system from

contamination. Remember to always reinstall the protective cap onto the service port when refrigerant sys-

tem service is complete.

6. Install the protective cap (1) onto the service port.