engine DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3988 of 5267

and volume must be regulated to maintain the balance within the transmission. To do this, throttle pressure is routed

tothereactionareaontherightsideofthethrottlepressureplug(intheregulator valve).

The higher engine speed and line pressure would open the vent too far and reduce line pressure too much. Throttle

pressure, which increases with engine speed (throttle opening), is used to oppose the movement of the pressure

valve to help control the metering passage at the vent. The throttle pressure is combined with spring pressure to

reduce the force of the throttle pressure plug on the pressure valve. The larger spring at the right closes the reg-

ulator valve passage and maintains or increases line pressure. The increased line pressure works against the reac-

tion area of the line pressure plug and the reaction area left of land #3 simultaneously moves the regulator valve

train to the right and controls the metering passage.

The kickdown valve, along with the throttle valve, serve to delay upshiftsuntil the correct vehicle speed has been

reached. It also controls downshifts upon driver demand, or increased engine load. If these valves were not in

place, the shift points would be at the same speed for all throttle positions. The kickdown valve is actuated by a

cam connected to the throttle. This is accomplished through either a linkage or a cable. The cam forces the kick-

down valve toward the throttle valve compressing the spring between them and moving the throttle valve. As the

throttle valve land starts to uncover its port, line pressure is “metered”out into the circuits and viewed as throttle

pressure. This increased throttle pressure is metered out into the circuits it is applied to: the 1-2 and 2-3 shift

valves. When the throttle pressure is high enough, a 3-2 downshift will occur. If the vehicle speed is low enough, a

2-1 downshift will occur.

Page 4023 of 5267

When Monitored:

With the ignition on.

Set Condition:

Transfer Case Range Select Switch voltage less than 0.1568 volts for 5 seconds

Possible Causes

(K77) 5 VOLT SELECTOR SWITCH SUPPLY CIRCUIT OPEN

(K77) 5 VOLT SELECTOR SWITCH SUPPLY CIRCUIT SHORTED TO GROUND

(K977) MODE SELECT CIRCUIT OPEN

(K977) MODE SELECT CIRCUIT SHORT TO GROUND

TRANSFER CASE SELECTOR SWITCH

INSTRUMENT CLUSTER

Diagnostic Test

1.TRANSFER CASE SWITCH VOLTAGE LESS THAN 0.2 VOLTS

Ignition on, engine not running.

With the scan tool under Instrument Cluster, read the Transfer Case Switchvoltage.

Is the voltage less than 0.2 volts?

Ye s>>

Go To 2

No>>

Go To 8

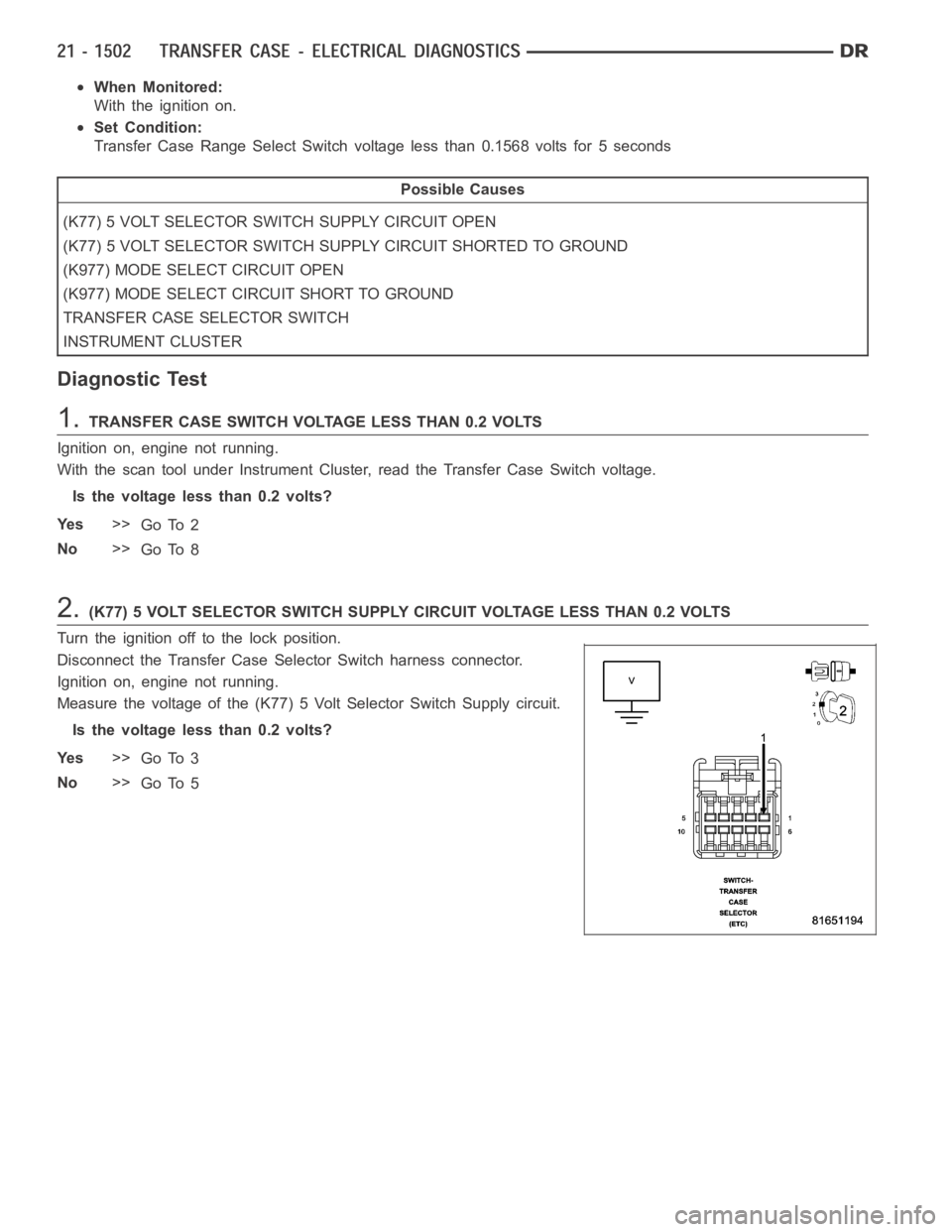

2.(K77) 5 VOLT SELECTOR SWITCH SUPPLY CIRCUIT VOLTAGE LESS THAN 0.2 VOLTS

Turn the ignition off to the lock position.

Disconnect the Transfer Case Selector Switch harness connector.

Ignition on, engine not running.

Measure the voltage of the (K77) 5 Volt Selector Switch Supply circuit.

Is the voltage less than 0.2 volts?

Ye s>>

Go To 3

No>>

Go To 5

Page 4025 of 5267

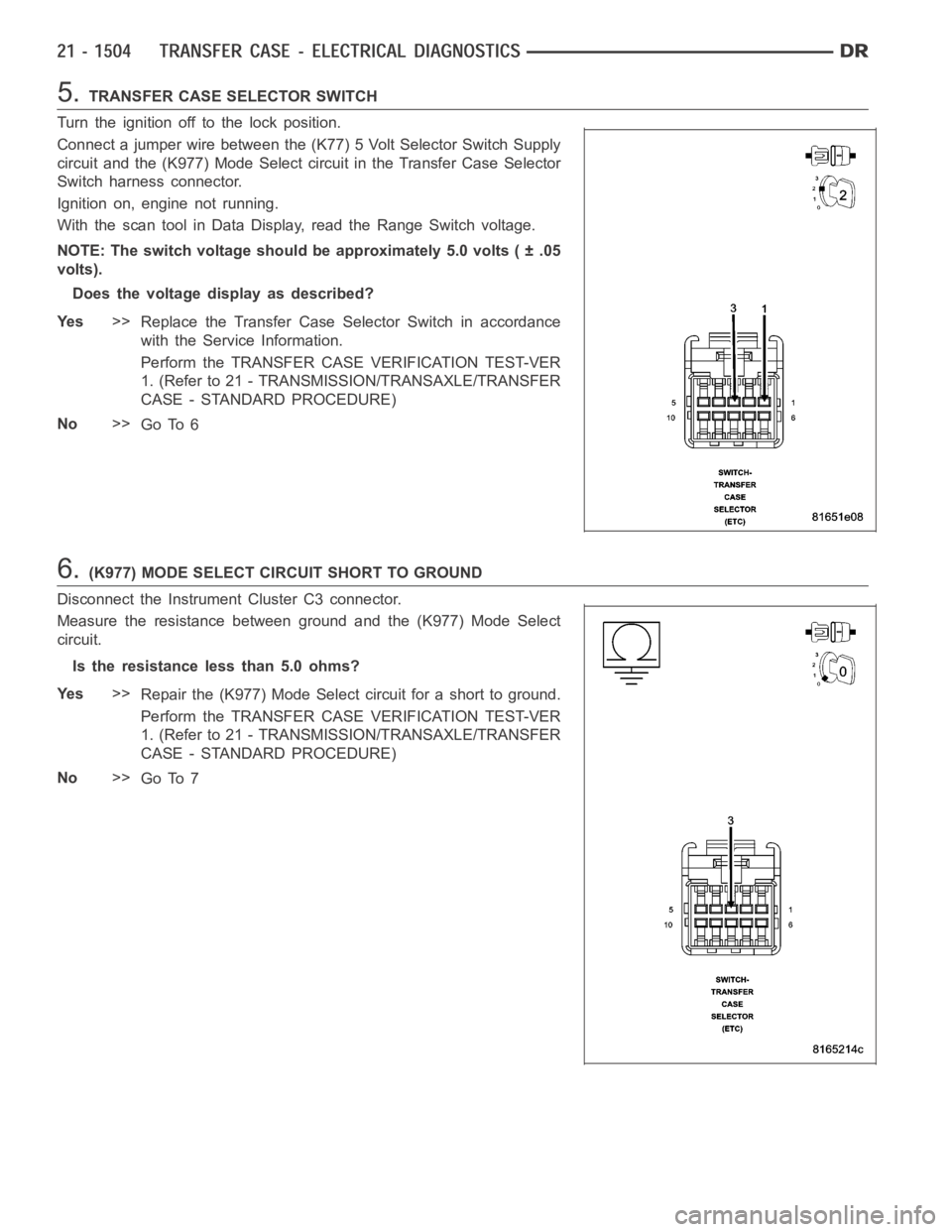

5.TRANSFER CASE SELECTOR SWITCH

Turn the ignition off to the lock position.

Connect a jumper wire between the (K77) 5 Volt Selector Switch Supply

circuit and the (K977) Mode Select circuit in the Transfer Case Selector

Switch harness connector.

Ignition on, engine not running.

With the scan tool in Data Display, read the Range Switch voltage.

NOTE: The switch voltage should be approximately 5.0 volts ( ± .05

volts).

Does the voltage display as described?

Ye s>>

Replace the Transfer Case Selector Switch in accordance

with the Service Information.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

No>>

Go To 6

6.(K977) MODE SELECT CIRCUIT SHORT TO GROUND

Disconnect the Instrument Cluster C3 connector.

Measure the resistance between ground and the (K977) Mode Select

circuit.

Is the resistance less than 5.0 ohms?

Ye s>>

Repair the (K977) Mode Select circuit for a short to ground.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

No>>

Go To 7

Page 4028 of 5267

When Monitored:

With the ignition on.

Set Condition:

Transfer Case Range Select Switch voltage greater than 4.86 volts for 5 seconds

Possible Causes

(K77) 5 VOLT SELECTOR SWITCH SUPPLY CIRCUIT SHORTED TO VOLTAGE

(K977) MODE SELECT CIRCUIT SHORTED TO VOLTAGE

(K977) MODE SELECT CIRCUIT OPEN

(Z905) TRANSFER CASE SELECTOR SWITCH GROUND CIRCUIT OPEN

TRANSFER CASE SELECTOR SWITCH

INSTRUMENT CLUSTER

Diagnostic Test

1.TCASE SWITCH VOLTAGE ABOVE 4.8 VOLTS

Ignition on, engine not running.

With the scan tool under Instrument Cluster, read the Transfer Case Switchvoltage.

Is the volage above 4.8 volts?

Ye s>>

Go To 2

No>>

Go to 8

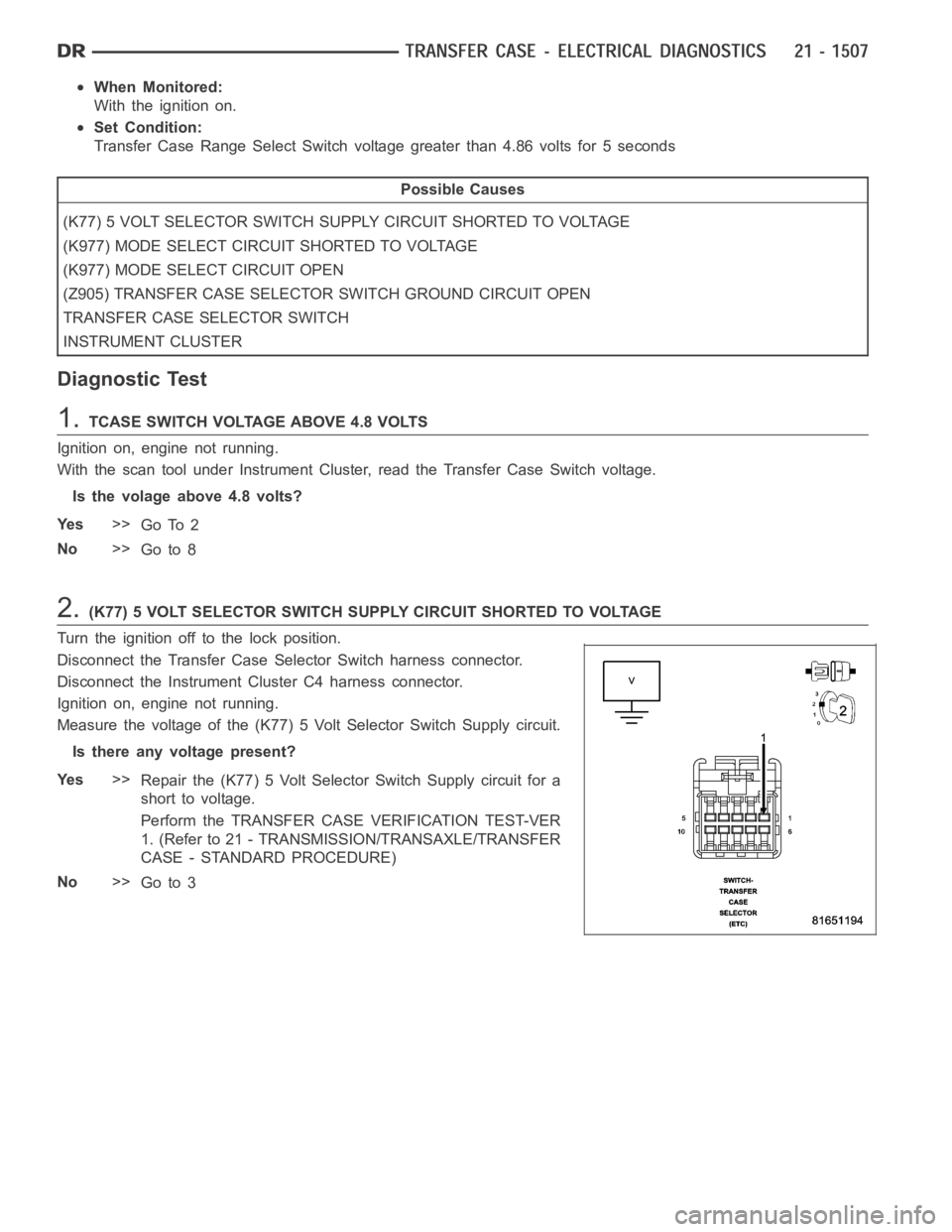

2.(K77) 5 VOLT SELECTOR SWITCH SUPPLY CIRCUIT SHORTED TO VOLTAGE

Turn the ignition off to the lock position.

Disconnect the Transfer Case Selector Switch harness connector.

Disconnect the Instrument Cluster C4 harness connector.

Ignition on, engine not running.

Measure the voltage of the (K77) 5 Volt Selector Switch Supply circuit.

Is there any voltage present?

Ye s>>

Repair the (K77) 5 Volt Selector Switch Supply circuit for a

short to voltage.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

No>>

Go to 3

Page 4029 of 5267

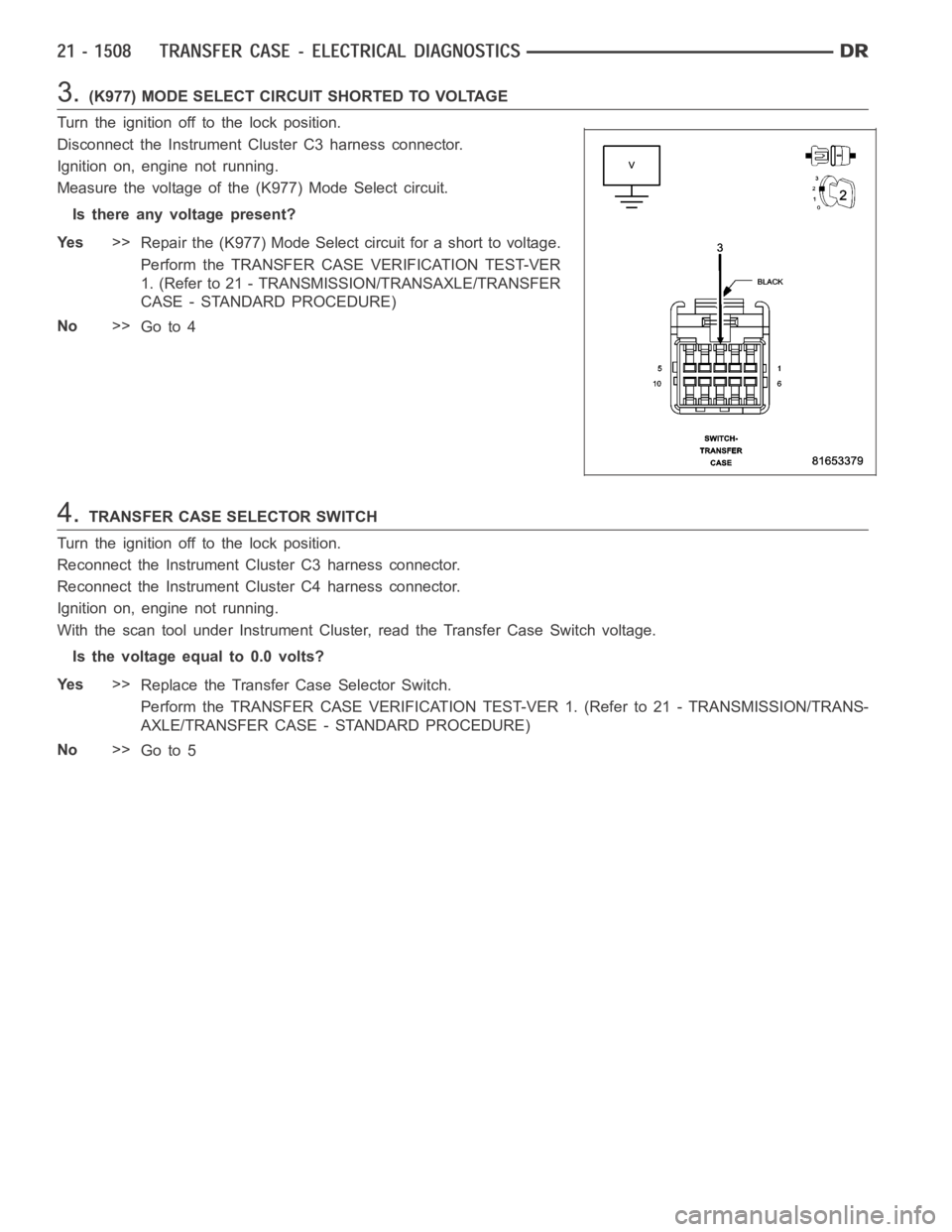

3.(K977) MODE SELECT CIRCUIT SHORTED TO VOLTAGE

Turn the ignition off to the lock position.

Disconnect the Instrument Cluster C3 harness connector.

Ignition on, engine not running.

Measure the voltage of the (K977) Mode Select circuit.

Is there any voltage present?

Ye s>>

Repair the (K977) Mode Select circuit for a short to voltage.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

No>>

Go to 4

4.TRANSFER CASE SELECTOR SWITCH

Turn the ignition off to the lock position.

Reconnect the Instrument Cluster C3 harness connector.

Reconnect the Instrument Cluster C4 harness connector.

Ignition on, engine not running.

With the scan tool under Instrument Cluster, read the Transfer Case Switchvoltage.

Is the voltage equal to 0.0 volts?

Ye s>>

Replace the Transfer Case Selector Switch.

Perform the TRANSFER CASE VERIFICATION TEST-VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/TRANSFER CASE - STANDARD PROCEDURE)

No>>

Go to 5

Page 4033 of 5267

When Monitored:

Ignition on. Battery voltage between 9.0 and 16.0 volts.

Set Condition:

The TIPM detects a short to ground on the Transfer Case Position Sensor Signal circuit for 2.0 seconds.

Possible Causes

(T103) 5 VOLT SUPPLY CIRCUIT OPEN

(T103) 5 VOLT SUPPLY CIRCUIT SHORTED TO GROUND

(D201) MODE SENSOR A CIRCUIT SHORTED TO GROUND

(D201) MODE SENSOR A CIRCUIT SHORTED TO (G180) SENSOR RETURN CIRCUIT

SHIFT MOTOR/MODE SENSOR ASSEMBLY

TOTALLY INTERGRATED POWER MODULE (TIPM)

Diagnostic Test

1.T-CASE POSITION SENSOR VOLTAGE BELOW 0.2 VOLTS

Ignition on, engine not running.

With the scan tool under TIPM, read the T-Case Position Sensor voltage.

Is the voltage below 0.2 volts?

Ye s>>

Go to 2

No>>

Go to 8

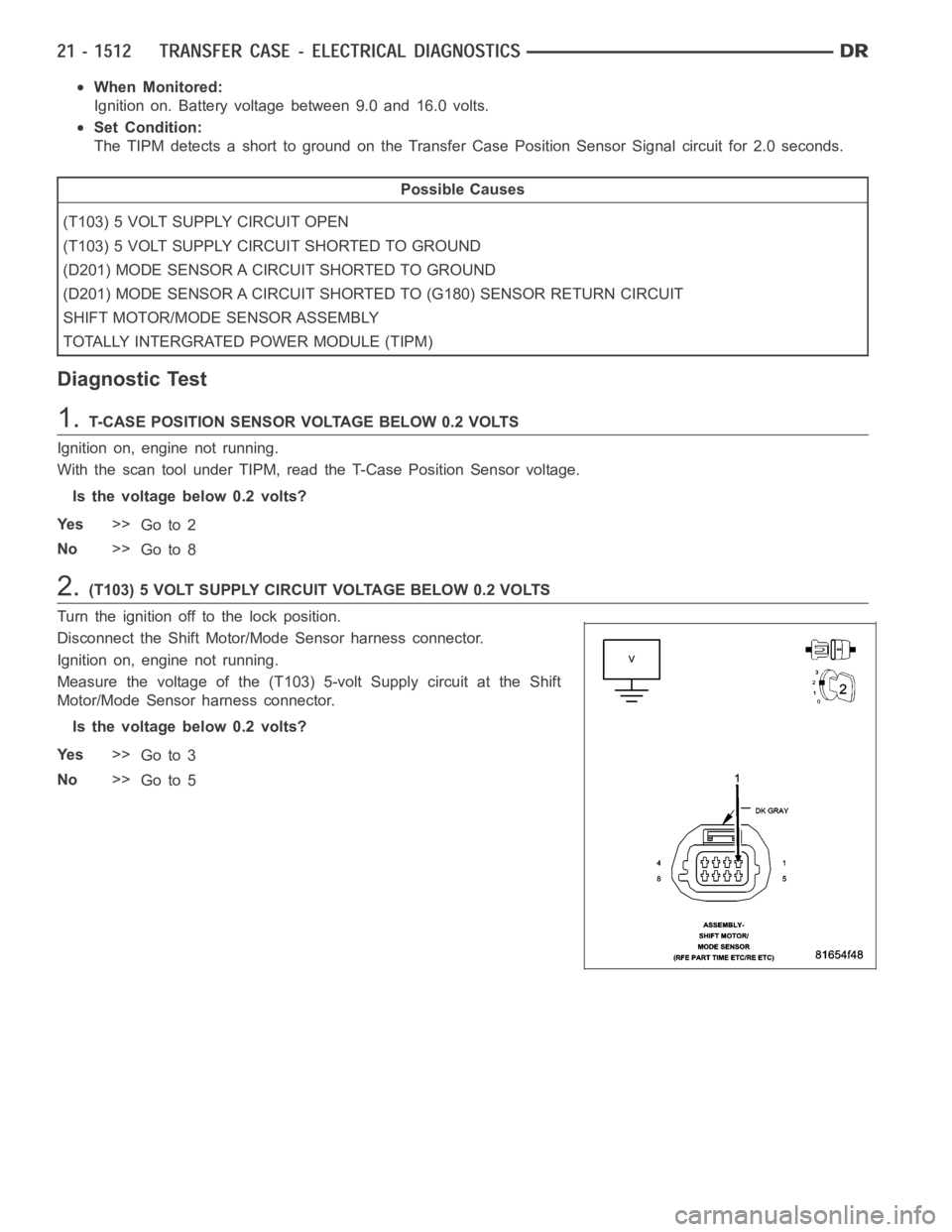

2.(T103) 5 VOLT SUPPLY CIRCUIT VOLTAGE BELOW 0.2 VOLTS

Turn the ignition off to the lock position.

Disconnect the Shift Motor/Mode Sensor harness connector.

Ignition on, engine not running.

Measure the voltage of the (T103) 5-volt Supply circuit at the Shift

Motor/Mode Sensor harness connector.

Is the voltage below 0.2 volts?

Ye s>>

Go to 3

No>>

Go to 5

Page 4037 of 5267

When Monitored:

With the ignition on. Battery voltage between 9.0 and 16.0 volts

Set Condition:

The TIPM detects 5.0 volts on the Transfer Case Range Position Sensor Signal circuit for 2.0 seconds when

voltage should not be present.

Possible Causes

(T103) 5 VOLT SUPPLY CIRCUIT SHORTED TO VOLTAGE

(D201) MODE SENSOR A CIRCUIT SHORTED TO VOLTAGE

(D201) MODE SENSOR A CIRCUIT OPEN

(G180) TIPM SENSOR RETURN CIRCUIT OPEN

SHIFT MOTOR/MODE SENSOR ASSEMBLY

TOTALLY INTEGRATED POWER MODULE (TIPM)

Diagnostic Test

1.T-CASE POSITION SENSOR VOLTAGE ABOVE 4.8 VOLTS

Ignition on, engine not running.

With the scan tool under TIPM, read the T-Case Position sensor voltage.

Is the voltage above 4.8 volts?

Ye s>>

Go To 2

No>>

Go to 7

2.(T103) 5 VOLT SUPPLY CIRCUIT SHORTED TO VOLTAGE

Turn the ignition off to the lock position.

Disconnect the Shift Motor/Mode sensor harness connector.

Ignition on, engine not running.

Measure the voltage of the (T103) 5 Volt Supply circuit.

Is the voltage above 5.5 volts?

Ye s>>

Repair the (T103) 5 Volt Supply circuit for a short to volt-

age.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

No>>

Go to 3

Page 4038 of 5267

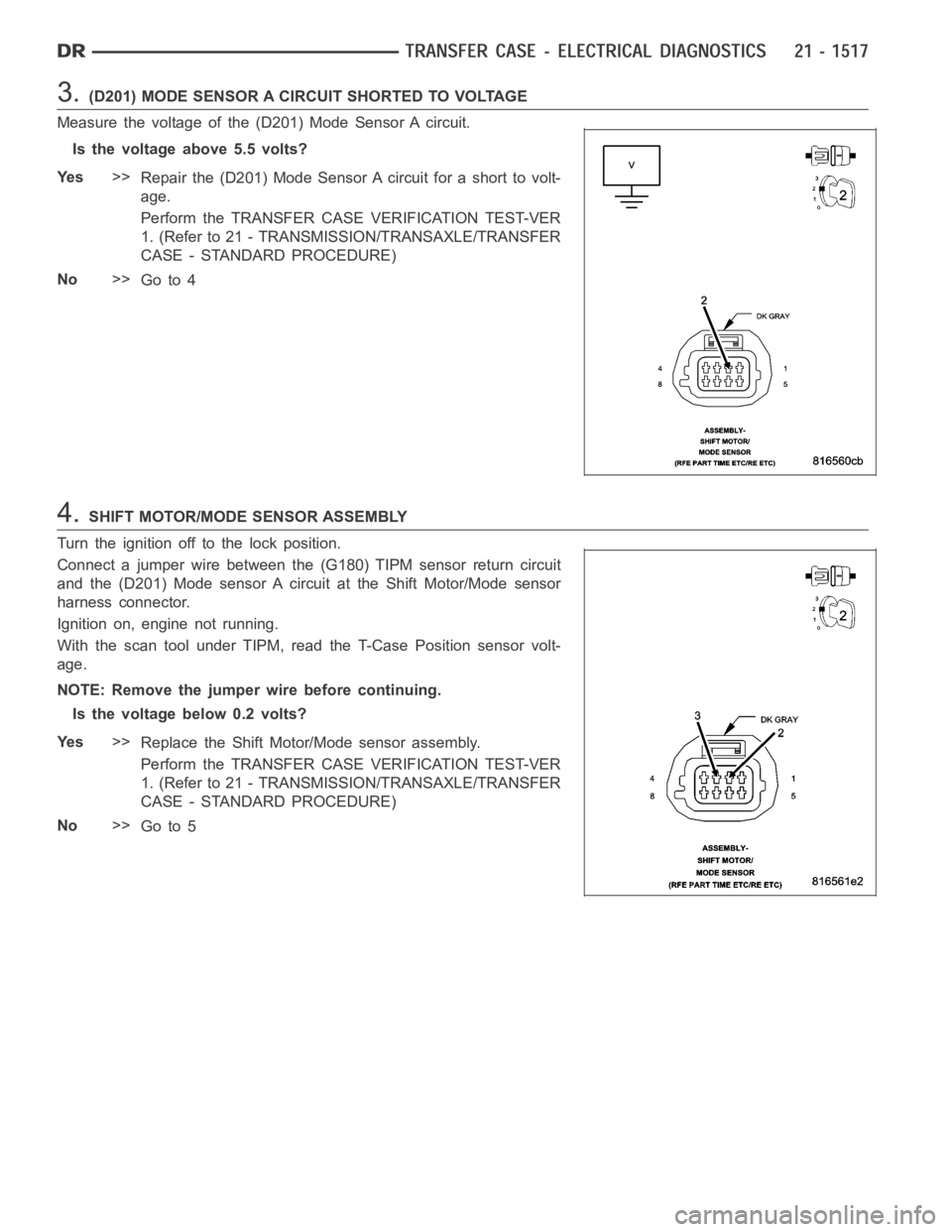

3.(D201) MODE SENSOR A CIRCUIT SHORTED TO VOLTAGE

Measure the voltage of the (D201) Mode Sensor A circuit.

Is the voltage above 5.5 volts?

Ye s>>

Repair the (D201) Mode Sensor A circuit for a short to volt-

age.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

No>>

Go to 4

4.SHIFT MOTOR/MODE SENSOR ASSEMBLY

Turn the ignition off to the lock position.

Connect a jumper wire between the (G180) TIPM sensor return circuit

and the (D201) Mode sensor A circuit at the Shift Motor/Mode sensor

harness connector.

Ignition on, engine not running.

With the scan tool under TIPM, read the T-Case Position sensor volt-

age.

NOTE: Remove the jumper wire before continuing.

Is the voltage below 0.2 volts?

Ye s>>

Replace the Shift Motor/Mode sensor assembly.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

No>>

Go to 5

Page 4042 of 5267

When Monitored:

With the ignition on and no system undervoltage or overvoltage condition present.

Set Condition:

The Totally Integrated Power Module (TIPM) detects that the Transfer CaseBrake circuit input is low when

output is off.

Possible Causes

(T300) T-CASE MOTOR BRAKE CIRCUIT OPEN

(T300) T-CASE MOTOR BRAKE CIRCUIT SHORTED TO GROUND

TRANSFER CASE MOTOR ASSEMBLY

TOTALLY INTEGRATED POWER MODULE (TIPM)

Diagnostic Test

1.DTC IS ACTIVE

Start the engine and allow it to idle.

Move the Transfer Case Selector Switch to each position several times.

With the scan tool, read the TIPM DTCs.

Is the status Active for this DTC?

Ye s>>

Go to 2

No>>

Go to 5

2.(T300) TRANSFER CASE MOTOR BRAKE SIGNAL CIRCUIT SHORTED TO GROUND

Turn the ignition off to the lock position.

Disconnect the Shift Motor/Mode Sensor Assembly harness connector.

Disconnect the TIPM C4 harness connector.

Measure the resistance between ground and the (T300) Transfer Case

Motor Brake Signal circuit.

Is the resistance below 5.0 ohms?

Ye s>>

Repair the (T300) Transfer Case Motor Brake Signal circuit

for a short to ground.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

No>>

Go to 3

Page 4043 of 5267

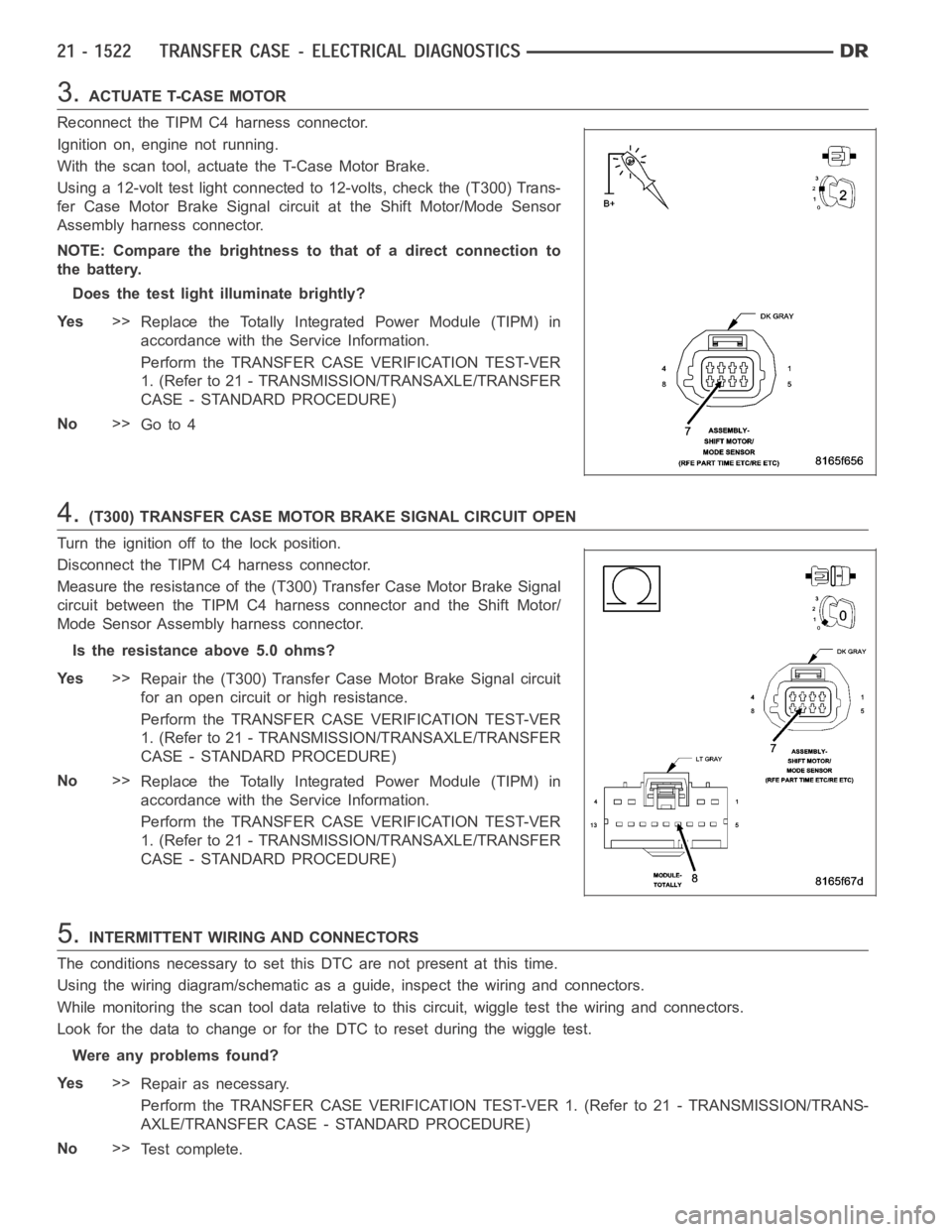

3.ACTUATE T-CASE MOTOR

Reconnect the TIPM C4 harness connector.

Ignition on, engine not running.

With the scan tool, actuate the T-Case Motor Brake.

Using a 12-volt test light connected to 12-volts, check the (T300) Trans-

fer Case Motor Brake Signal circuit at the Shift Motor/Mode Sensor

Assembly harness connector.

NOTE: Compare the brightness to that of a direct connection to

the battery.

Does the test light illuminate brightly?

Ye s>>

Replace the Totally Integrated Power Module (TIPM) in

accordance with the Service Information.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

No>>

Go to 4

4.(T300) TRANSFER CASE MOTOR BRAKE SIGNAL CIRCUIT OPEN

Turn the ignition off to the lock position.

Disconnect the TIPM C4 harness connector.

Measure the resistance of the (T300) Transfer Case Motor Brake Signal

circuit between the TIPM C4 harness connector and the Shift Motor/

Mode Sensor Assembly harness connector.

Is the resistance above 5.0 ohms?

Ye s>>

Repair the (T300) Transfer Case Motor Brake Signal circuit

for an open circuit or high resistance.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module (TIPM) in

accordance with the Service Information.

Perform the TRANSFER CASE VERIFICATION TEST-VER

1. (Refer to 21 - TRANSMISSION/TRANSAXLE/TRANSFER

CASE - STANDARD PROCEDURE)

5.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set this DTC are not present at this time.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

While monitoring the scan tool data relative to this circuit, wiggle test the wiring and connectors.

Look for the data to change or for the DTC to reset during the wiggle test.

Were any problems found?

Ye s>>

Repair as necessary.

Perform the TRANSFER CASE VERIFICATION TEST-VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/TRANSFER CASE - STANDARD PROCEDURE)

No>>

Te s t c o m p l e t e .