engine DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3948 of 5267

CABLE-THROTTLE VALVE

DESCRIPTION

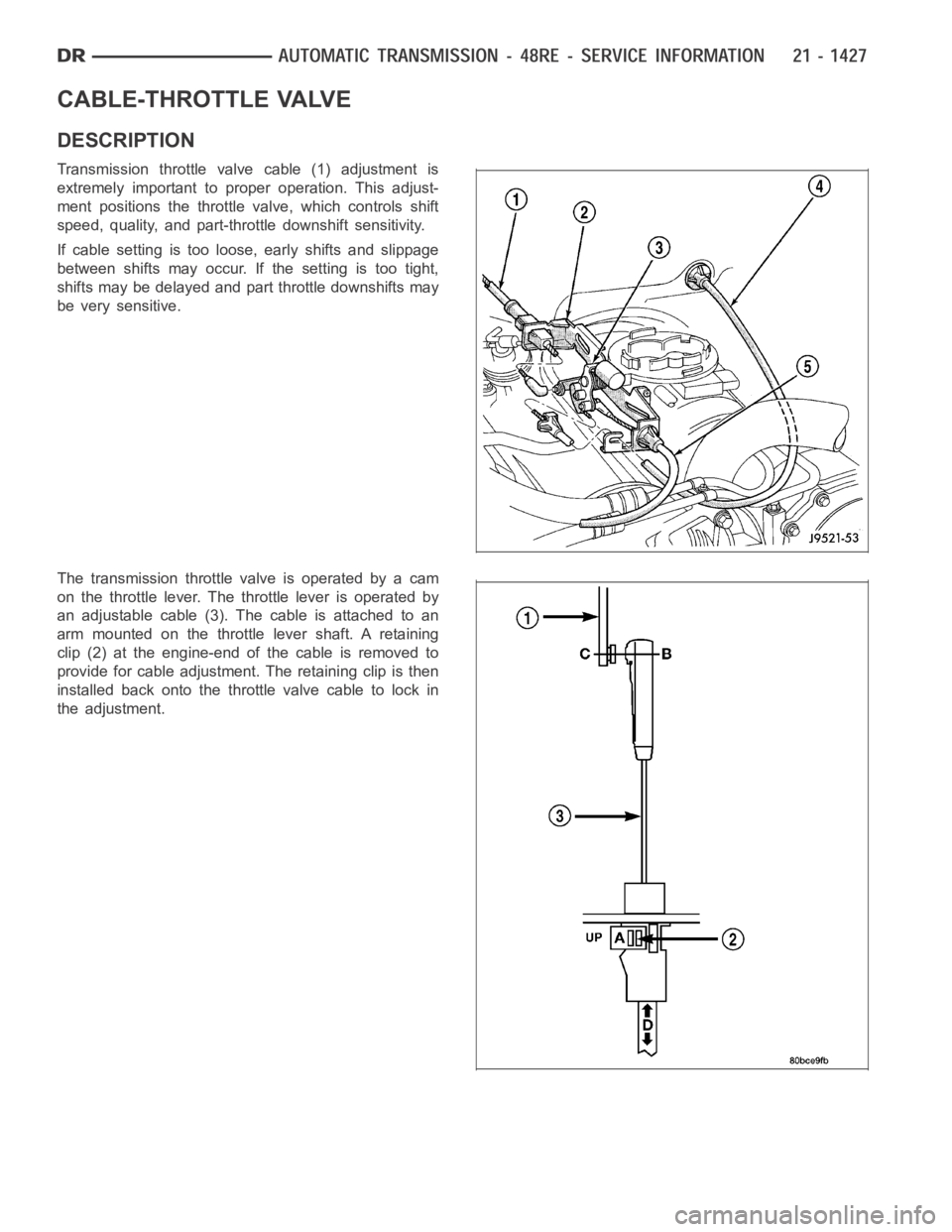

Transmission throttle valve cable (1) adjustment is

extremely important to proper operation. This adjust-

ment positions the throttle valve, which controls shift

speed, quality, and part-throttle downshift sensitivity.

If cable setting is too loose, early shifts and slippage

between shifts may occur. If the setting is too tight,

shifts may be delayed and part throttle downshifts may

be very sensitive.

The transmission throttlevalveisoperatedbyacam

on the throttle lever. The throttle lever is operated by

an adjustable cable (3). The cable is attached to an

arm mounted on the throttle lever shaft. A retaining

clip (2) at the engine-end of the cable is removed to

provide for cable adjustment. The retaining clip is then

installedbackontothethrottlevalvecabletolockin

the adjustment.

Page 3952 of 5267

CONVERTER-TORQUE

DESCRIPTION

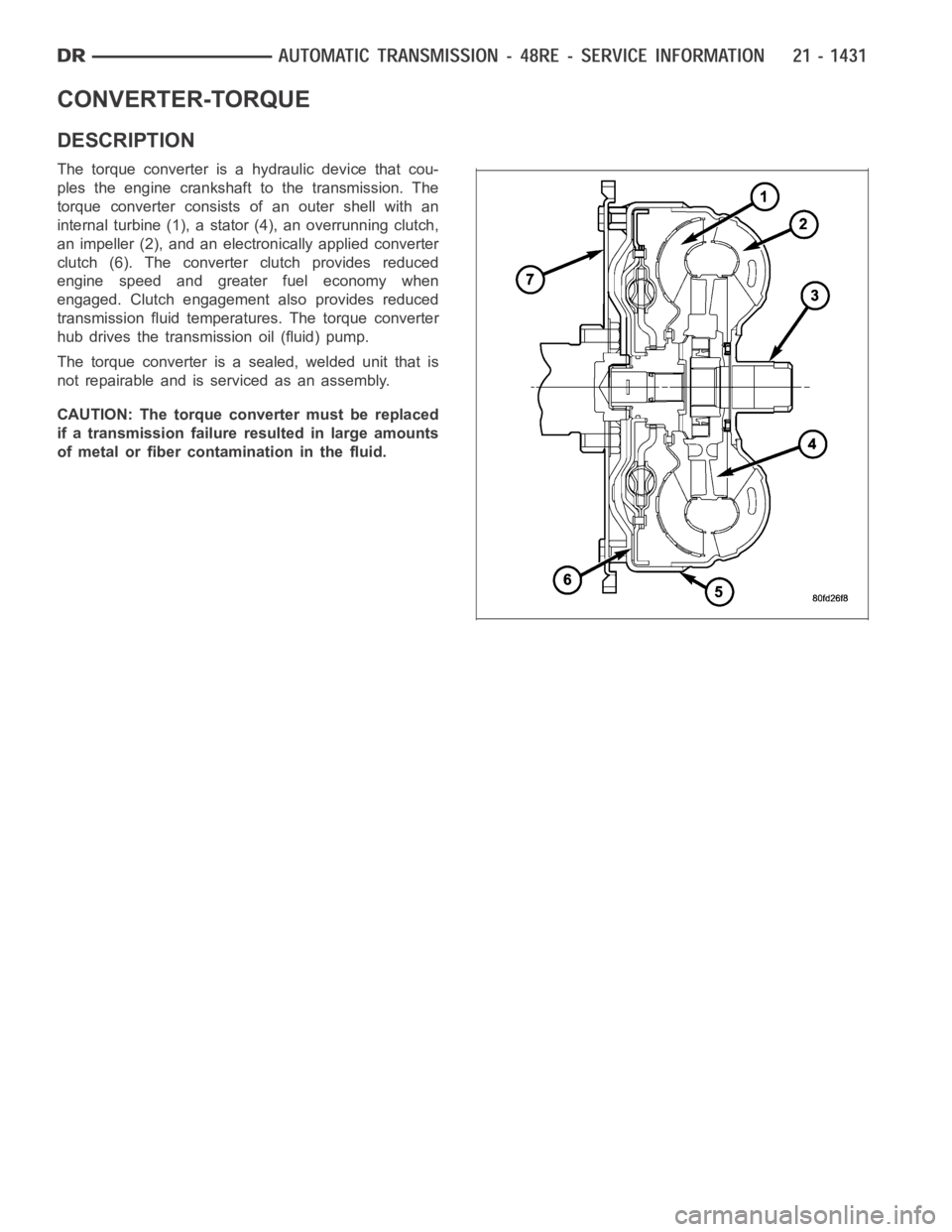

The torque converter is a hydraulic device that cou-

ples the engine crankshaft to the transmission. The

torque converter consists of an outer shell with an

internal turbine (1), a stator (4), an overrunning clutch,

an impeller (2), and an electronically applied converter

clutch (6). The converterclutch provides reduced

engine speed and greater fuel economy when

engaged. Clutch engagement also provides reduced

transmission fluid temperatures. The torque converter

hub drives the transmission oil (fluid) pump.

The torque converter is a sealed, welded unit that is

not repairable and is serviced as an assembly.

CAUTION: The torque converter must be replaced

if a transmission failure resulted in large amounts

of metal or fiber contamination in the fluid.

Page 3953 of 5267

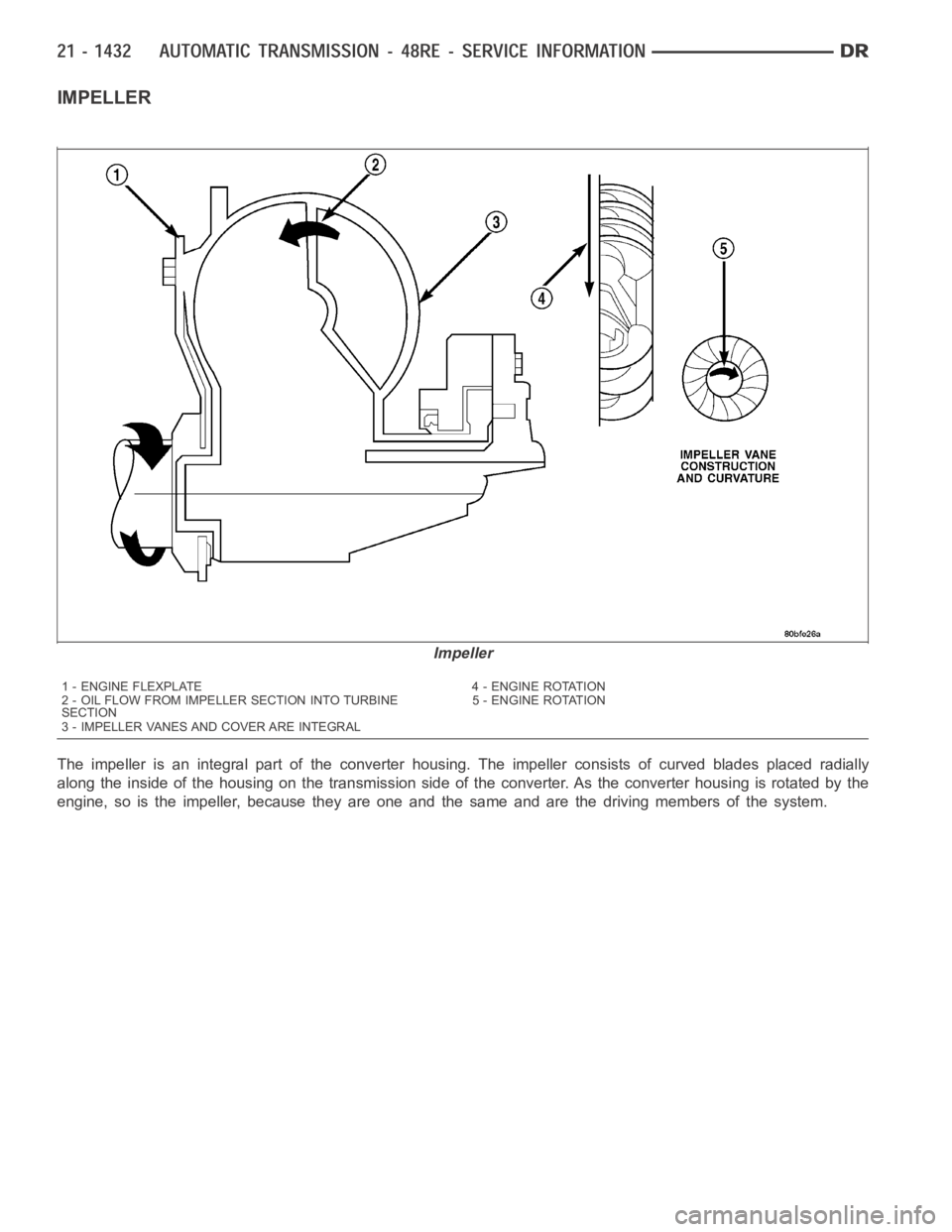

IMPELLER

The impeller is an integral part of the converter housing. The impeller consists of curved blades placed radially

along the inside of the housing on the transmission side of the converter. As the converter housing is rotated by the

engine, so is the impeller, because they are one and the same and are the driving members of the system.

Impeller

1 - ENGINE FLEXPLATE 4 - ENGINE ROTATION

2 - OIL FLOW FROM IMPELLER SECTION INTO TURBINE

SECTION5 - ENGINE ROTATION

3 - IMPELLER VANES AND COVER ARE INTEGRAL

Page 3954 of 5267

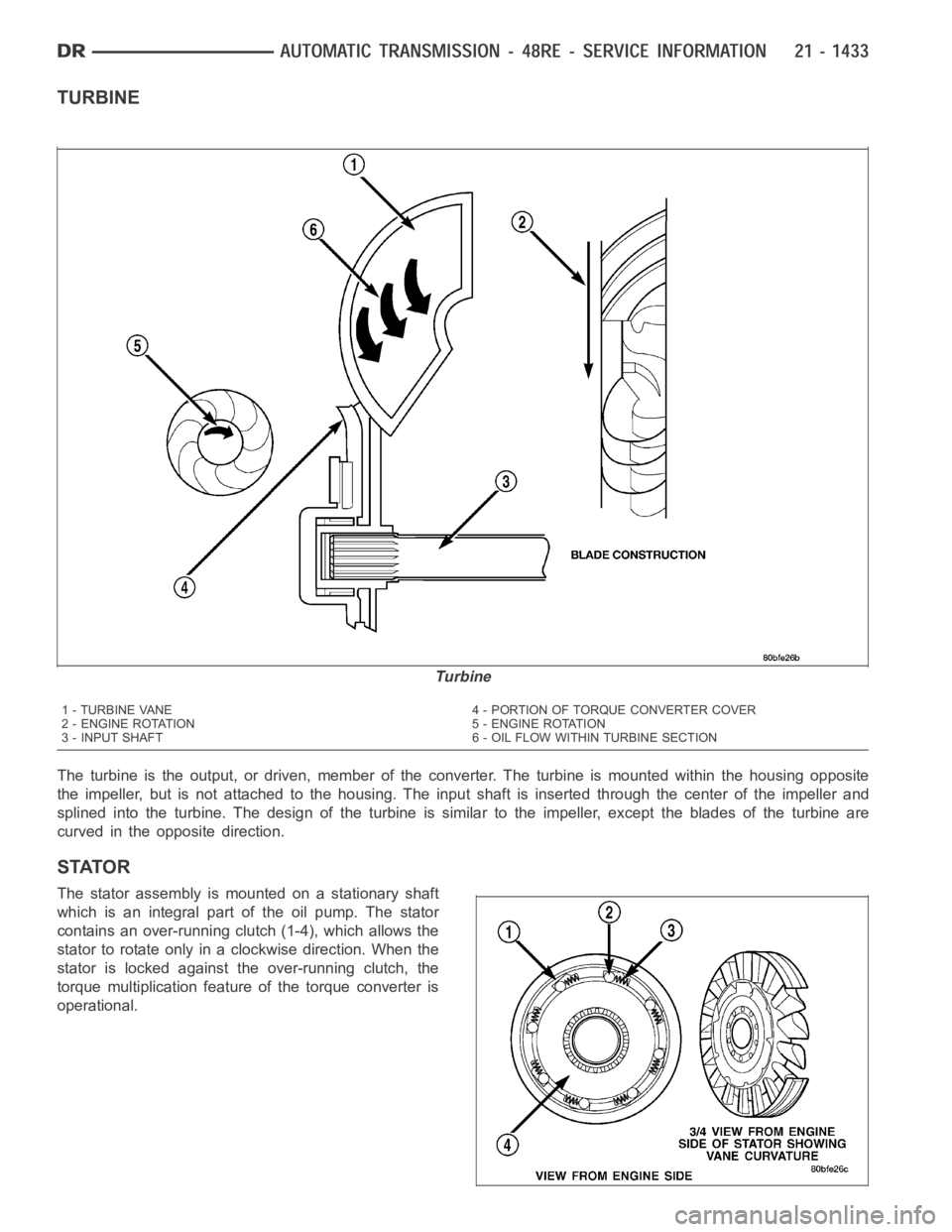

TURBINE

The turbine is the output, or driven, member of the converter. The turbine is mounted within the housing opposite

the impeller, but is not attached to the housing. The input shaft is inserted through the center of the impeller and

splined into the turbine. The design of the turbine is similar to the impeller, except the blades of the turbine are

curved in the opposite direction.

STATOR

The stator assembly is mounted on a stationary shaft

which is an integral part of the oil pump. The stator

contains an over-running clutch (1-4), which allows the

stator to rotate only in a clockwise direction. When the

stator is locked against theover-runningclutch,the

torque multiplication feature of the torque converter is

operational.

Turbine

1 - TURBINE VANE 4 - PORTION OF TORQUE CONVERTER COVER

2 - ENGINE ROTATION 5 - ENGINE ROTATION

3 - INPUT SHAFT 6 - OIL FLOW WITHIN TURBINE SECTION

Page 3956 of 5267

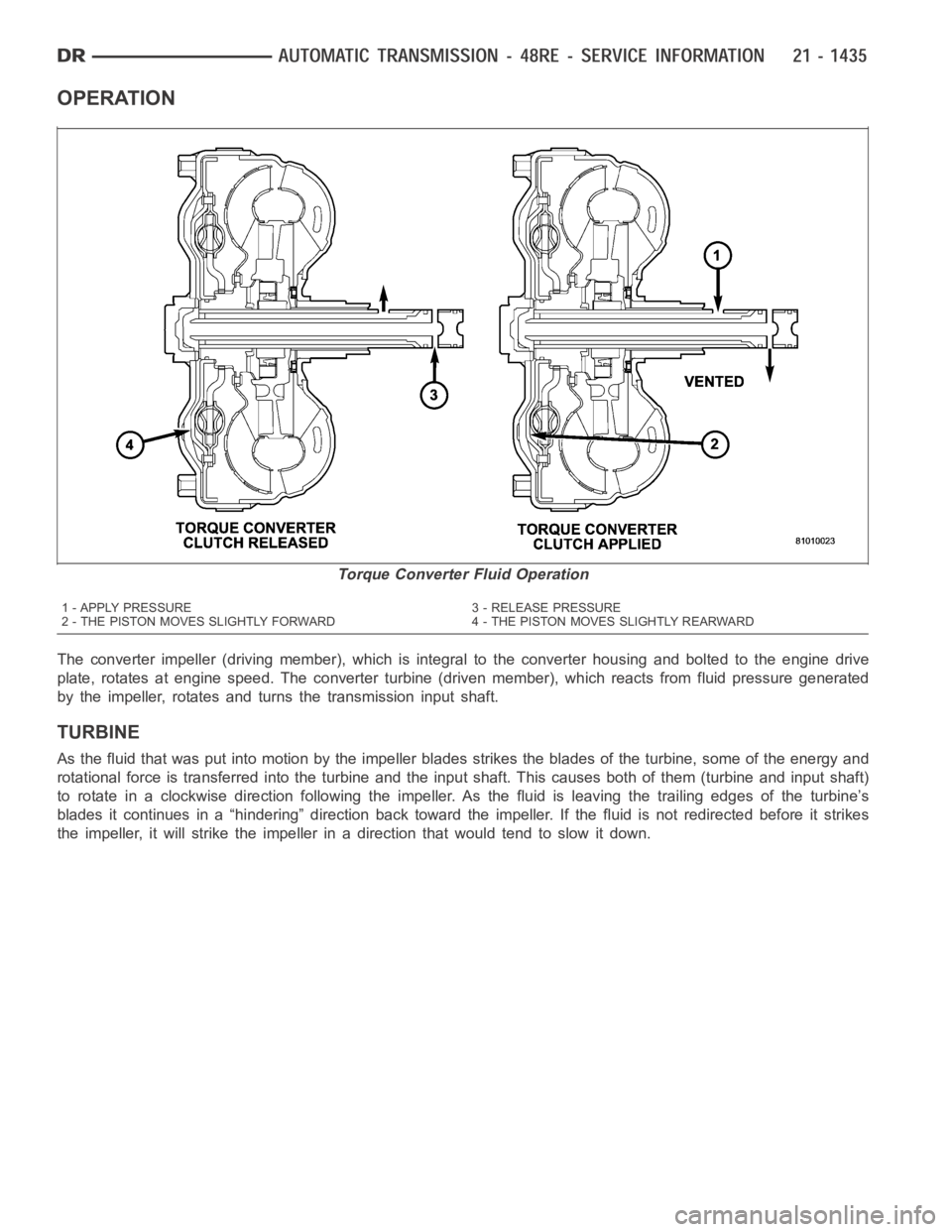

OPERATION

The converter impeller (driving member), which is integral to the converter housing and bolted to the engine drive

plate, rotates at engine speed. The converter turbine (driven member), which reacts from fluid pressure generated

by the impeller, rotates and turns the transmission input shaft.

TURBINE

As the fluid that was put into motion bythe impeller blades strikes the blades of the turbine, some of the energy and

rotational force is transferred into the turbine and the input shaft. Thiscauses both of them (turbine and input shaft)

to rotate in a clockwise direction following the impeller. As the fluid is leaving the trailing edges of the turbine’s

blades it continues in a “hindering” direction back toward the impeller. If the fluid is not redirected before it strikes

the impeller, it will strike the impeller in a direction that would tend to slow it down.

Torque Converter Fluid Operation

1 - APPLY PRESSURE 3 - RELEASE PRESSURE

2 - THE PISTON MOVES SLIGHTLY FORWARD 4 - THE PISTON MOVES SLIGHTLY REARWARD

Page 3957 of 5267

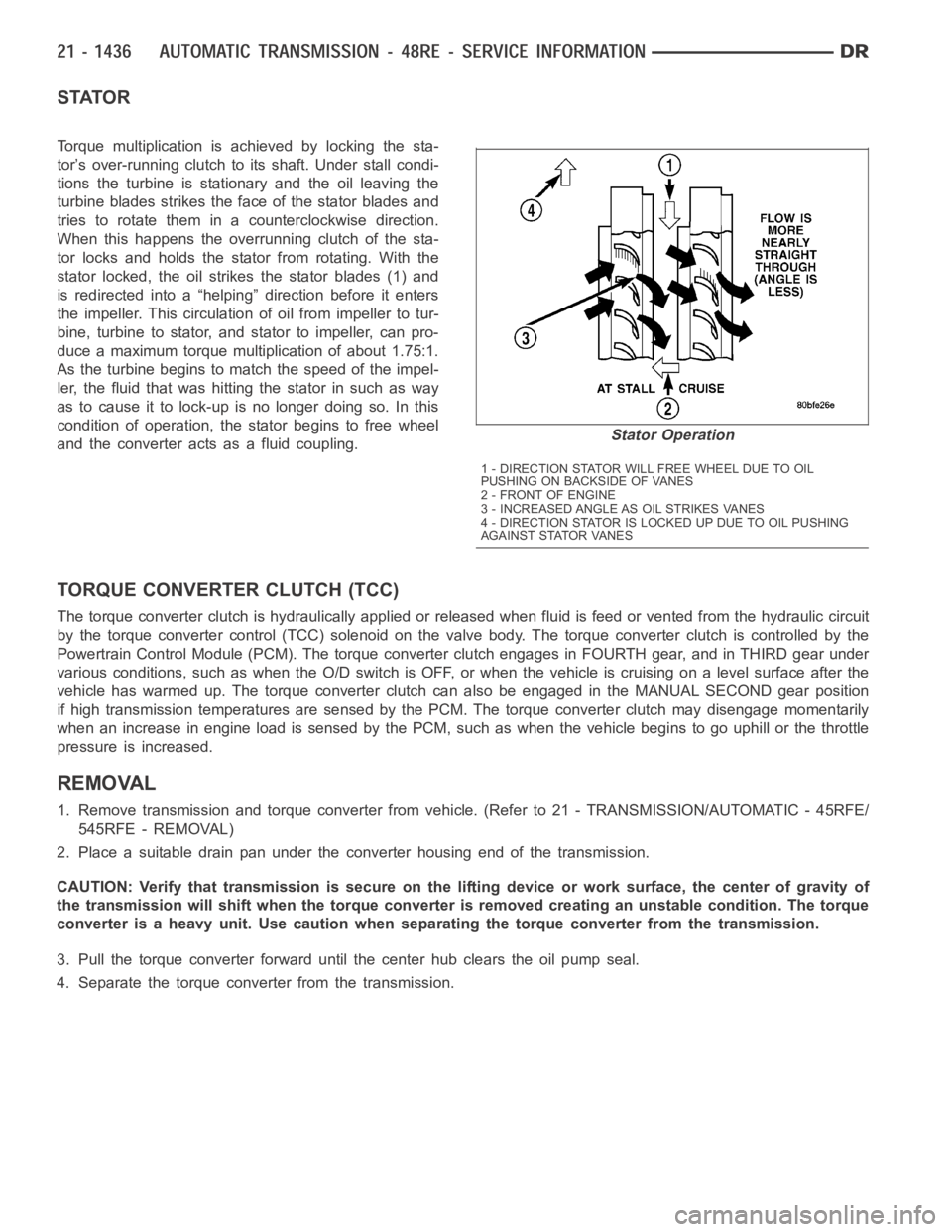

STATOR

Torque multiplication is achieved by locking the sta-

tor’s over-running clutch to its shaft. Under stall condi-

tions the turbine is stationary and the oil leaving the

turbine blades strikes the face of the stator blades and

tries to rotate them in a counterclockwise direction.

When this happens the overrunning clutch of the sta-

tor locks and holds the stator from rotating. With the

stator locked, the oil strikes the stator blades (1) and

is redirected into a “helping” direction before it enters

the impeller. This circulation of oil from impeller to tur-

bine, turbine to stator, and stator to impeller, can pro-

duce a maximum torque multiplication of about 1.75:1.

As the turbine begins to match the speed of the impel-

ler, the fluid that was hitting the stator in such as way

as to cause it to lock-up is no longer doing so. In this

condition of operation, the stator begins to free wheel

and the converter acts as a fluid coupling.

TORQUE CONVERTER CLUTCH (TCC)

The torque converter clutch is hydraulically applied or released when fluid is feed or vented from the hydraulic circuit

by the torque converter control (TCC) solenoid on the valve body. The torque converter clutch is controlled by the

Powertrain Control Module (PCM). The torque converter clutch engages in FOURTH gear, and in THIRD gear under

various conditions, such as when the O/D switch is OFF, or when the vehicle is cruising on a level surface after the

vehicle has warmed up. The torque converter clutch can also be engaged in the MANUAL SECOND gear position

if high transmission temperatures are sensed by the PCM. The torque converter clutch may disengage momentarily

when an increase in engine load is sensed by the PCM, such as when the vehiclebegins to go uphill or the throttle

pressure is increased.

REMOVAL

1. Remove transmission and torque converter from vehicle. (Refer to 21 - TRANSMISSION/AUTOMATIC - 45RFE/

545RFE - REMOVAL)

2. Place a suitable drain pan under the converter housing end of the transmission.

CAUTION: Verify that transmission is secure on the lifting device or work surface, the center of gravity of

the transmission will shift when the torque converter is removed creatingan unstable condition. The torque

converter is a heavy unit. Use caution when separating the torque converter from the transmission.

3. Pull the torque converter forward until the center hub clears the oil pumpseal.

4. Separate the torque converter from the transmission.

Stator Operation

1 - DIRECTION STATOR WILL FREE WHEEL DUE TO OIL

PUSHING ON BACKSIDE OF VANES

2-FRONTOFENGINE

3 - INCREASED ANGLE AS OIL STRIKES VANES

4 - DIRECTION STATOR IS LOCKED UP DUE TO OIL PUSHING

AGAINST STATOR VANES

Page 3959 of 5267

VALVE-TORQUE CONVERTER DRAINBACK

DESCRIPTION

GAS ENGINES

The drainback valve is located in the transmission cooler outlet (pressure) line.

DIESEL ENGINE

The converter drainback check valve is located in the in the TOC pressure - supply line, between the engine

mounted TOC and the air to oil TOC.

OPERATION

GAS ENGINES

The valve prevents fluid from draining from the converter into the cooler and lines when the vehicle is shut down for

lengthy periods. Production valves have a hose nipple at one end, while theopposite end is threaded for a flare

fitting. All valves have an arrow (or similar mark) to indicate direction of flow through the valve.

DIESEL ENGINE

The valve prevents fluid from draining from the converter into the cooler and lines when the vehicle is shut down for

lengthy periods. Production valves have pipe thread on one end, while the opposite end is threaded for a flare

fitting, and are threaded into the oil cooler mounted on the side of the engine. All valves have an arrow (or similar

mark) to indicate direction of flow through the valve.

STANDARD PROCEDURE

GAS ENGINES

The converter drainback check valve is located in the cooler outlet (pressure) line near the radiator tank. The valve

prevents fluid drainback when the vehicle is parked for lengthy periods. The valve check ball is spring loaded and

has an opening pressure of approximately 2 psi.

The valve is serviced as an assembly; it is not repairable. Do not clean the valve if restricted, or contaminated by

sludge, or debris. If the valve fails, or if a transmission malfunction occurs that generates significant amounts of

sludge and/or clutch particles and metal shavings, the valve must be replaced.

If the valve is restricted, installed backwards, or in the wrong line, it will cause an transmission overheating condition

and possible transmission failure.

CAUTION: The drainback valve is a one-way flow device. It must be properly orientedintermsofflowdirec-

tion for the cooler to function properly. The valve must be installed in thepressure line. Otherwise flow will

be blocked and would cause an transmission overheating condition and eventual transmission failure.

DIESEL ENGINE

The converter drainback check valve is located in the in the TOC pressure - supply line, between the engine

mounted transmission oil cooler and the air to oil transmission oil cooler. The valve prevents fluid drainback when

the vehicle is parked for lengthy periods. The valve check ball is spring loaded and has an opening pressure of

approximately 2 psi.

The valve is serviced as an assembly; it is not repairable. Do not clean the valve if restricted, or contaminated by

sludge, or debris. If the valve fails, or if a transmission malfunction occurs that generates significant amounts of

sludge and/or clutch particles and metal shavings, the valve must be replaced.

If the valve is restricted, installed backwards, or in the wrong line, it will cause an transmission overheating condition

and possible transmission failure.

Page 3963 of 5267

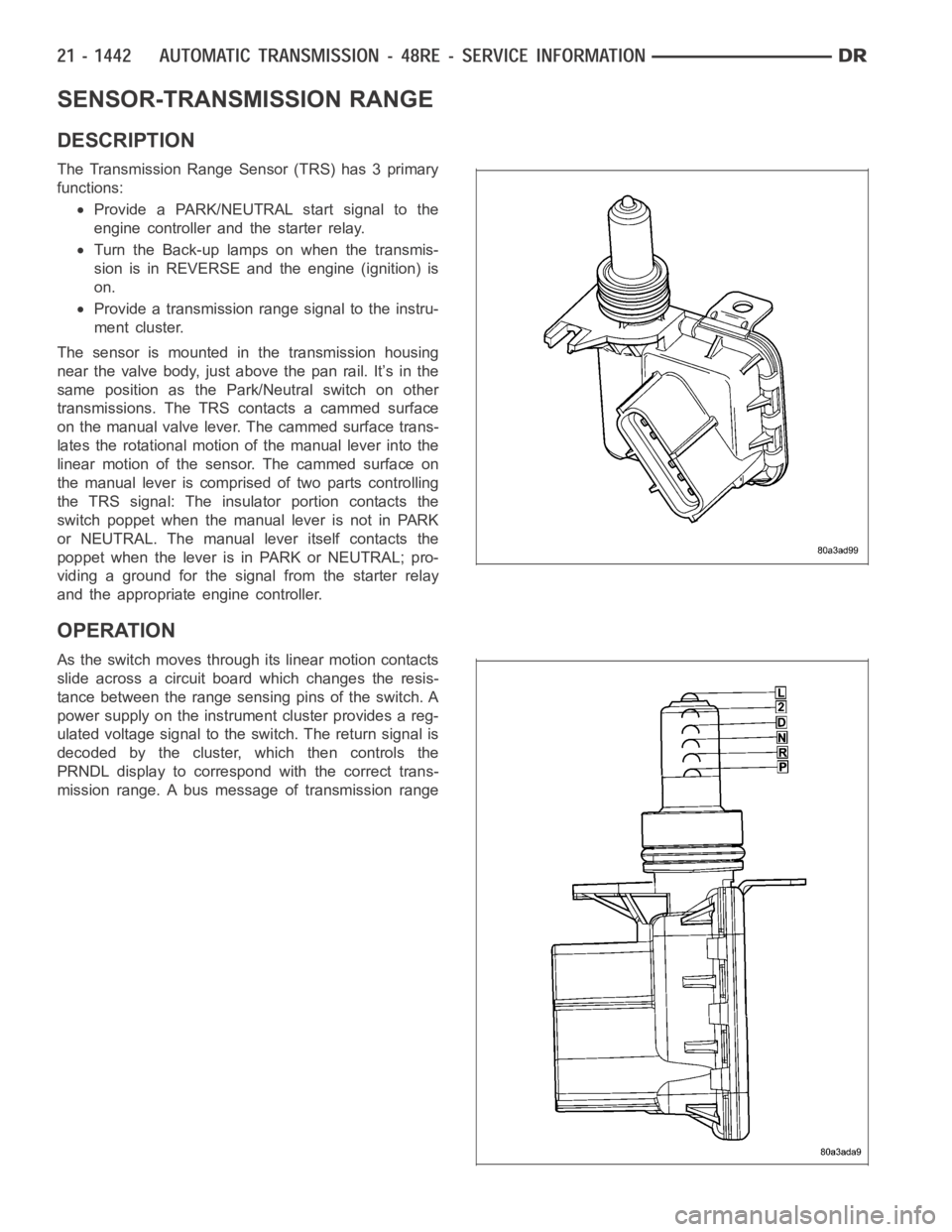

SENSOR-TRANSMISSION RANGE

DESCRIPTION

The Transmission Range Sensor (TRS) has 3 primary

functions:

Provide a PARK/NEUTRAL start signal to the

engine controller and the starter relay.

Turn the Back-up lamps on when the transmis-

sion is in REVERSE and the engine (ignition) is

on.

Provide a transmission range signal to the instru-

ment cluster.

The sensor is mounted in the transmission housing

near the valve body, just above the pan rail. It’s in the

same position as the Park/Neutral switch on other

transmissions. The TRS contacts a cammed surface

on the manual valve lever. The cammed surface trans-

lates the rotational motion of the manual lever into the

linear motion of the sensor. The cammed surface on

the manual lever is comprised of two parts controlling

the TRS signal: The insulator portion contacts the

switch poppet when the manual lever is not in PARK

or NEUTRAL. The manual lever itself contacts the

poppet when the lever is in PARK or NEUTRAL; pro-

viding a ground for the signal from the starter relay

and the appropriate engine controller.

OPERATION

As the switch moves through its linear motion contacts

slide across a circuit board which changes the resis-

tance between the range sensing pins of the switch. A

power supply on the instrument cluster provides a reg-

ulated voltage signal to the switch. The return signal is

decoded by the cluster, which then controls the

PRNDL display to correspond with the correct trans-

mission range. A bus message of transmission range

Page 3974 of 5267

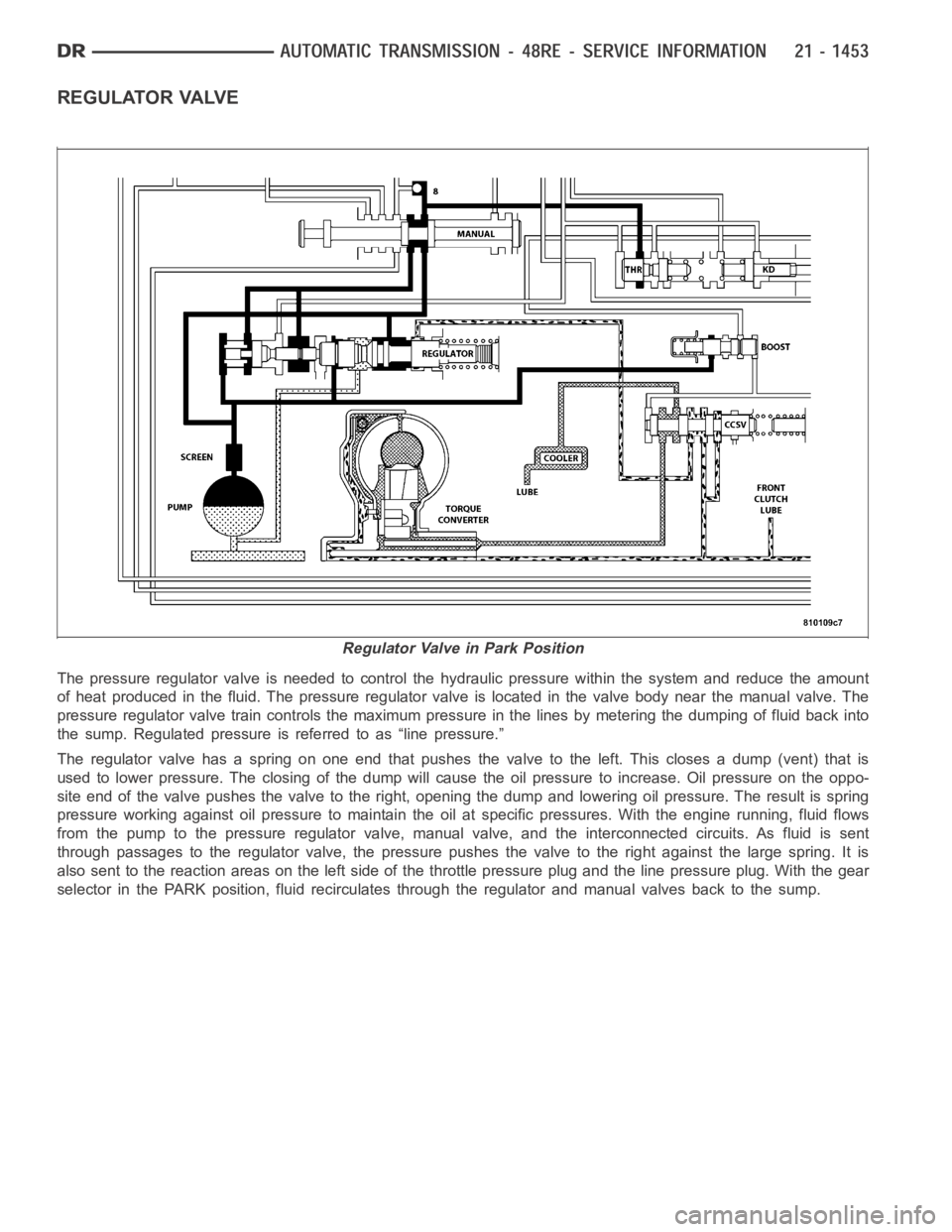

REGULATOR VALVE

The pressure regulator valve is needed to control the hydraulic pressure within the system and reduce the amount

of heat produced in the fluid. The pressure regulator valve is located in the valve body near the manual valve. The

pressure regulator valve train controls the maximum pressure in the linesby metering the dumping of fluid back into

the sump. Regulated pressure is referred to as “line pressure.”

The regulator valve has a spring on one end that pushes the valve to the left.This closes a dump (vent) that is

used to lower pressure. The closing of the dump will cause the oil pressure to increase. Oil pressure on the oppo-

site end of the valve pushes the valve to the right, opening the dump and lowering oil pressure. The result is spring

pressure working against oil pressureto maintain the oil at specific pressures. With the engine running, fluid flows

from the pump to the pressure regulator valve, manual valve, and the interconnected circuits. As fluid is sent

through passages to the regulator valve, the pressure pushes the valve to the right against the large spring. It is

also sent to the reaction areas on the left side of the throttle pressure plug and the line pressure plug. With the gear

selector in the PARK position, fluid recirculates through the regulator and manual valves back to the sump.

Regulator Valve in Park Position

Page 3987 of 5267

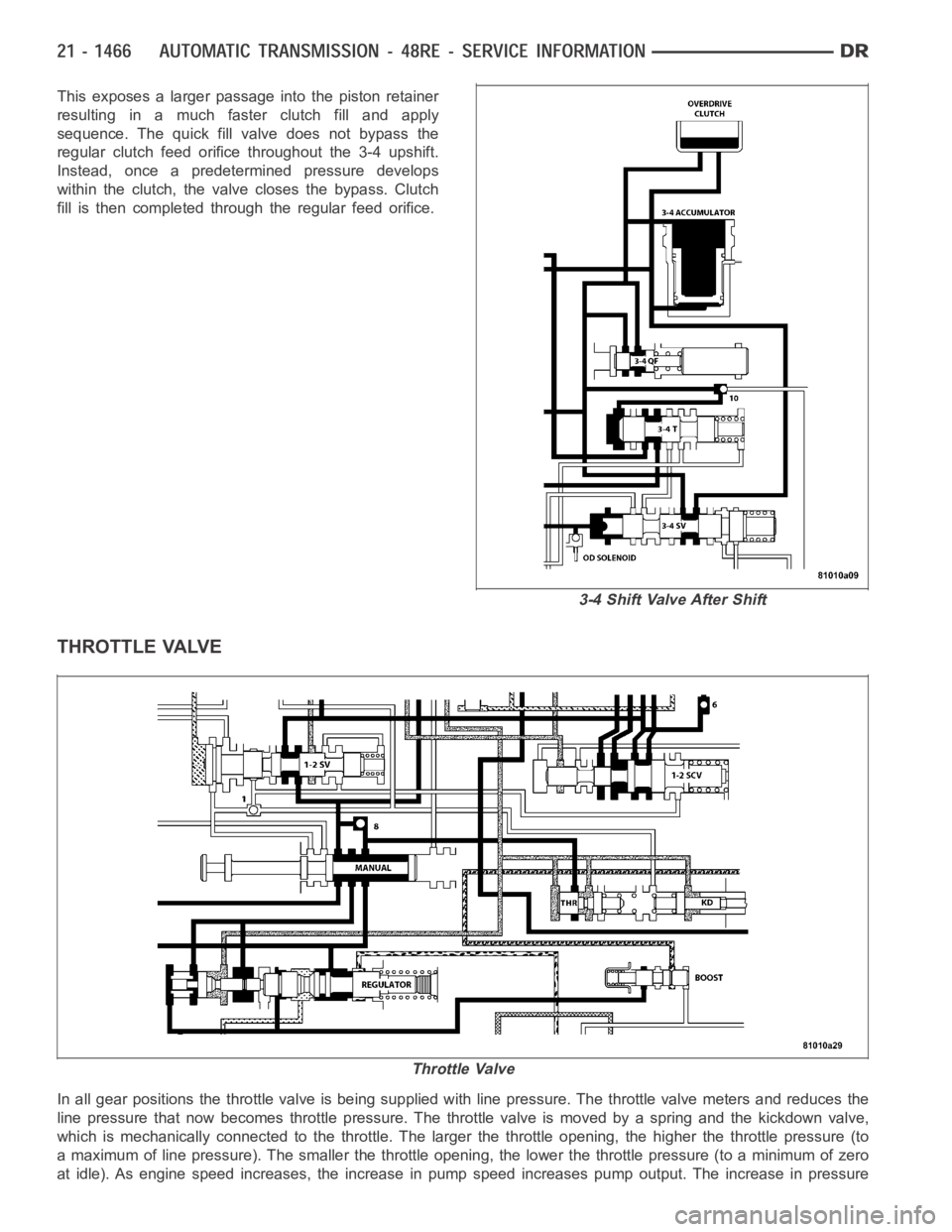

This exposes a larger passage into the piston retainer

resulting in a much faster clutch fill and apply

sequence. The quick fill valve does not bypass the

regular clutch feed orifice throughout the 3-4 upshift.

Instead, once a predetermined pressure develops

within the clutch, the valve closes the bypass. Clutch

fill is then completed through the regular feed orifice.

THROTTLE VALVE

In all gear positions the throttle valve is being supplied with line pressure. The throttle valve meters and reduces the

line pressure that now becomes throttle pressure. The throttle valve is moved by a spring and the kickdown valve,

which is mechanically connected to the throttle. The larger the throttle opening, the higher the throttle pressure (to

a maximum of line pressure). The smaller the throttle opening, the lower thethrottlepressure(toaminimumofzero

at idle). As engine speed increases, the increase in pump speed increases pump output. The increase in pressure

3-4 Shift Valve After Shift

Throttle Valve