DODGE RAM SRT-10 2006 Service Repair Manual

Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2491 of 5267

INSTALLATION

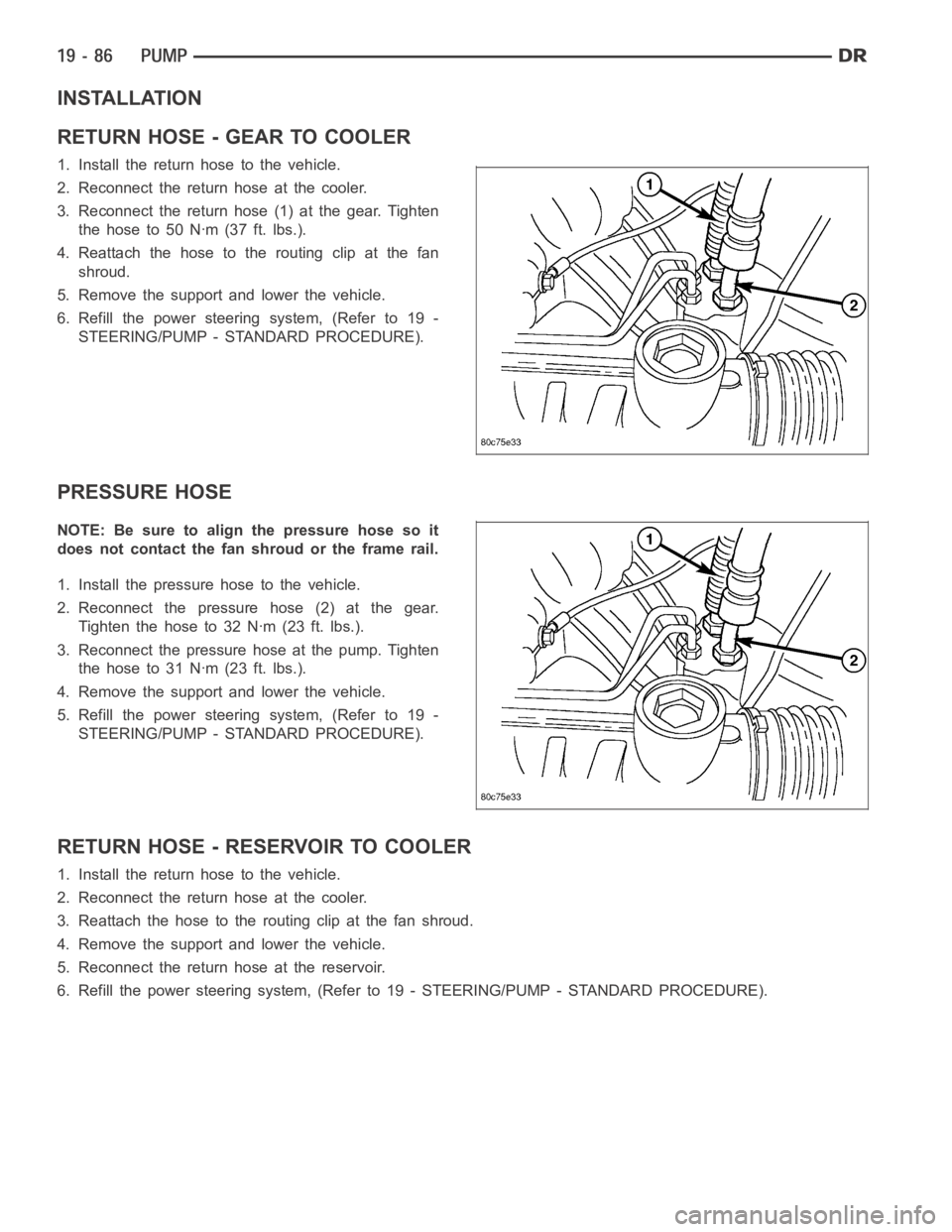

RETURN HOSE - GEAR TO COOLER

1. Install the return hose to the vehicle.

2. Reconnect the return hose at the cooler.

3. Reconnect the return hose (1) at the gear. Tighten

thehoseto50Nꞏm(37ft.lbs.).

4.Reattachthehosetotheroutingclipatthefan

shroud.

5. Remove the support and lower the vehicle.

6. Refill the power steering system, (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

PRESSURE HOSE

NOTE: Be sure to align the pressure hose so it

does not contact the fan shroud or the frame rail.

1. Install the pressure hose to the vehicle.

2. Reconnect the pressure hose (2) at the gear.

Tightenthehoseto32Nꞏm(23ft.lbs.).

3. Reconnect the pressure hose at the pump. Tighten

thehoseto31Nꞏm(23ft.lbs.).

4. Remove the support and lower the vehicle.

5. Refill the power steering system, (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

RETURN HOSE - RESERVOIR TO COOLER

1. Install the return hose to the vehicle.

2. Reconnect the return hose at the cooler.

3. Reattach the hose to the routing clip at the fan shroud.

4. Remove the support and lower the vehicle.

5. Reconnect the return hose at the reservoir.

6. Refill the power steering system, (Refer to 19 - STEERING/PUMP - STANDARD PROCEDURE).

Page 2492 of 5267

HOSES - LINK/COIL

REMOVAL

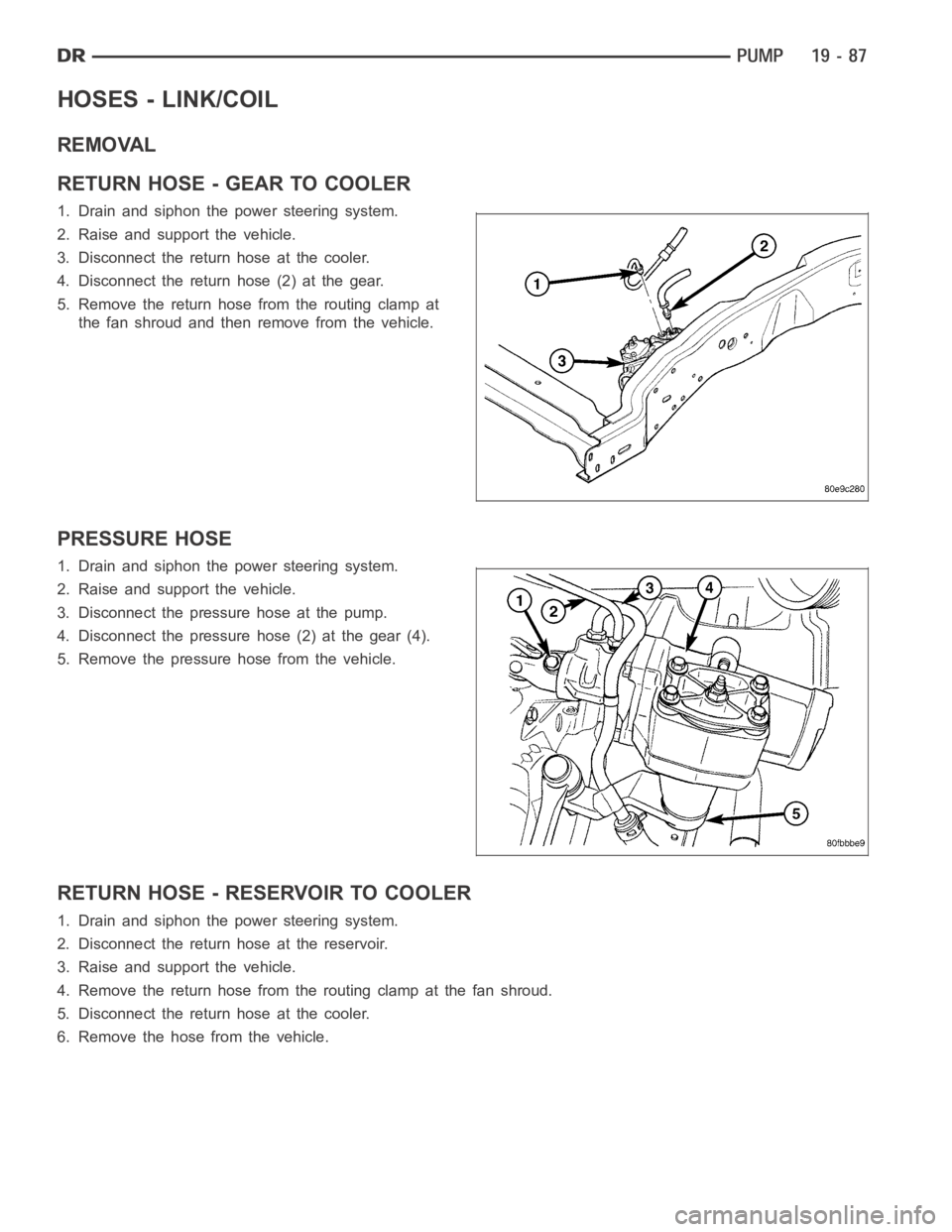

RETURN HOSE - GEAR TO COOLER

1. Drain and siphon the power steering system.

2. Raise and support the vehicle.

3. Disconnect the return hose at the cooler.

4. Disconnect the return hose (2) at the gear.

5. Remove the return hose from the routing clamp at

the fan shroud and then remove from the vehicle.

PRESSURE HOSE

1. Drain and siphon the power steering system.

2. Raise and support the vehicle.

3. Disconnect the pressure hose at the pump.

4. Disconnect the pressure hose (2) at the gear (4).

5. Remove the pressure hose from the vehicle.

RETURN HOSE - RESERVOIR TO COOLER

1. Drain and siphon the power steering system.

2. Disconnect the return hose at the reservoir.

3. Raise and support the vehicle.

4. Remove the return hose from the routing clamp at the fan shroud.

5. Disconnect the return hose at the cooler.

6. Remove the hose from the vehicle.

Page 2493 of 5267

INSTALLATION

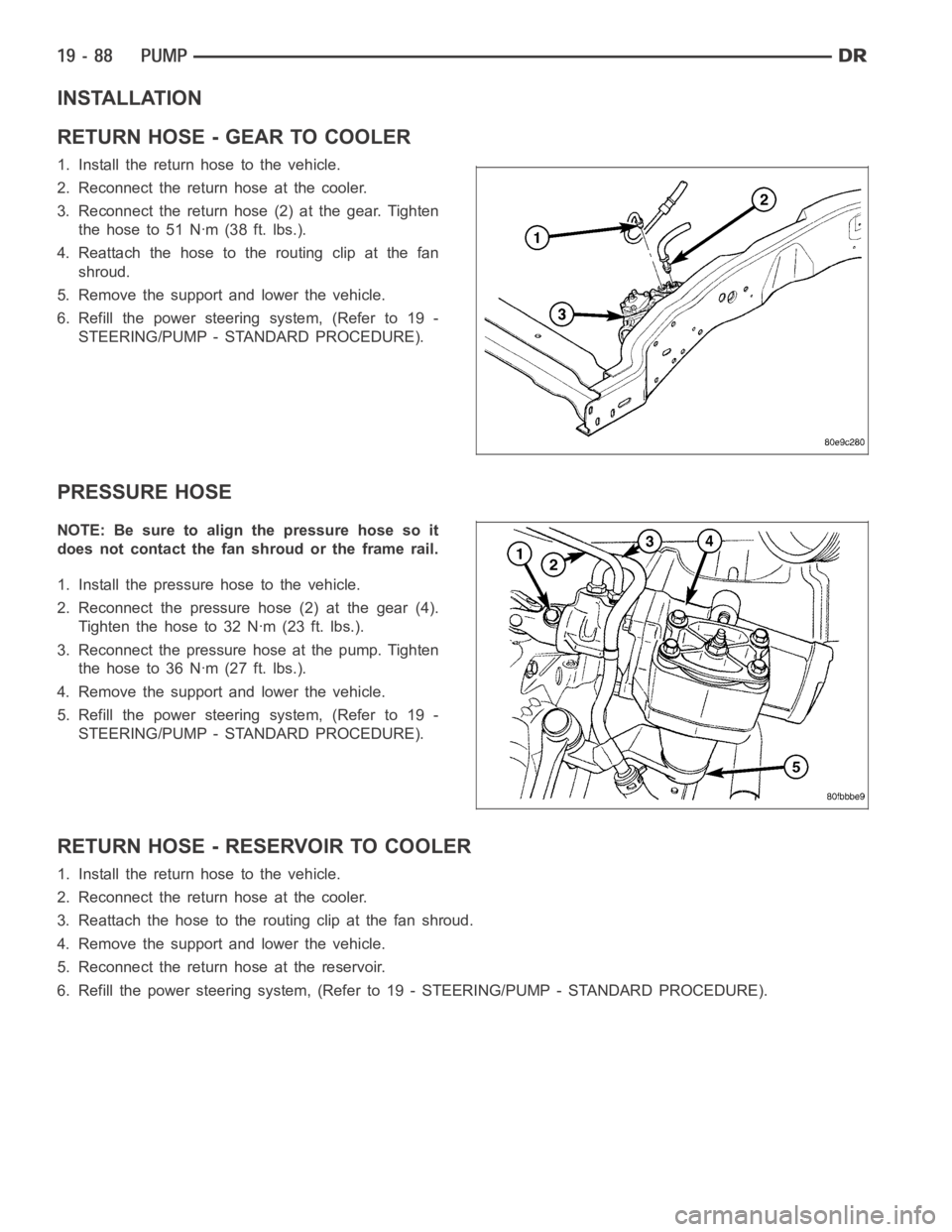

RETURN HOSE - GEAR TO COOLER

1. Install the return hose to the vehicle.

2. Reconnect the return hose at the cooler.

3. Reconnect the return hose (2) at the gear. Tighten

thehoseto51Nꞏm(38ft.lbs.).

4.Reattachthehosetotheroutingclipatthefan

shroud.

5. Remove the support and lower the vehicle.

6. Refill the power steering system, (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

PRESSURE HOSE

NOTE: Be sure to align the pressure hose so it

does not contact the fan shroud or the frame rail.

1. Install the pressure hose to the vehicle.

2. Reconnect the pressure hose (2) at the gear (4).

Tightenthehoseto32Nꞏm(23ft.lbs.).

3. Reconnect the pressure hose at the pump. Tighten

thehoseto36Nꞏm(27ft.lbs.).

4. Remove the support and lower the vehicle.

5. Refill the power steering system, (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

RETURN HOSE - RESERVOIR TO COOLER

1. Install the return hose to the vehicle.

2. Reconnect the return hose at the cooler.

3. Reattach the hose to the routing clip at the fan shroud.

4. Remove the support and lower the vehicle.

5. Reconnect the return hose at the reservoir.

6. Refill the power steering system, (Refer to 19 - STEERING/PUMP - STANDARD PROCEDURE).

Page 2494 of 5267

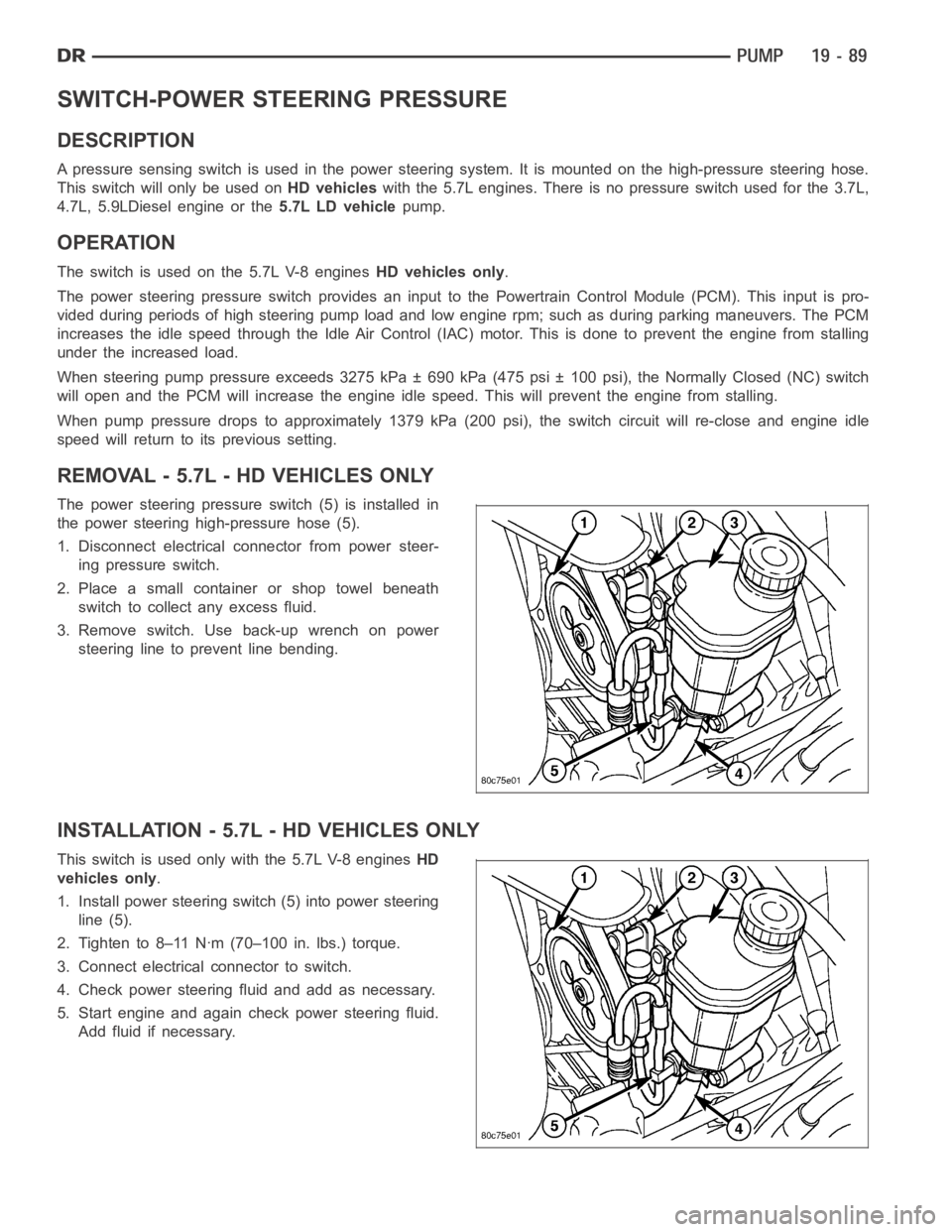

SWITCH-POWER STEERING PRESSURE

DESCRIPTION

A pressure sensing switch is used in the power steering system. It is mounted on the high-pressure steering hose.

This switch will only be used onHD vehicleswith the 5.7L engines. There is no pressure switch used for the 3.7L,

4.7L, 5.9LDiesel engine or the5.7L LD vehiclepump.

OPERATION

The switch is used on the 5.7L V-8 enginesHD vehicles only.

The power steering pressure switch provides an input to the Powertrain Control Module (PCM). This input is pro-

vided during periods of high steering pump load and low engine rpm; such as during parking maneuvers. The PCM

increases the idle speed through the Idle Air Control (IAC) motor. This is done to prevent the engine from stalling

under the increased load.

When steering pump pressure exceeds 3275 kPa ± 690 kPa (475 psi ± 100 psi), the Normally Closed (NC) switch

will open and the PCM will increase the engine idle speed. This will preventthe engine from stalling.

When pump pressure drops to approximately 1379 kPa (200 psi), the switch circuit will re-close and engine idle

speed will return to its previous setting.

REMOVAL - 5.7L - HD VEHICLES ONLY

The power steering pressureswitch (5) is installed in

the power steering high-pressure hose (5).

1. Disconnect electrical connector from power steer-

ing pressure switch.

2. Place a small container or shop towel beneath

switch to collect any excess fluid.

3. Remove switch. Use back-up wrench on power

steering line to prevent line bending.

INSTALLATION - 5.7L - HD VEHICLES ONLY

This switch is used only with the 5.7L V-8 enginesHD

vehicles only.

1. Install power steering switch (5) into power steering

line (5).

2. Tighten to 8–11 Nꞏm (70–100 in. lbs.) torque.

3. Connect electrical connector to switch.

4. Check power steering fluid and add as necessary.

5. Start engine and again check power steering fluid.

Add fluid if necessary.

Page 2495 of 5267

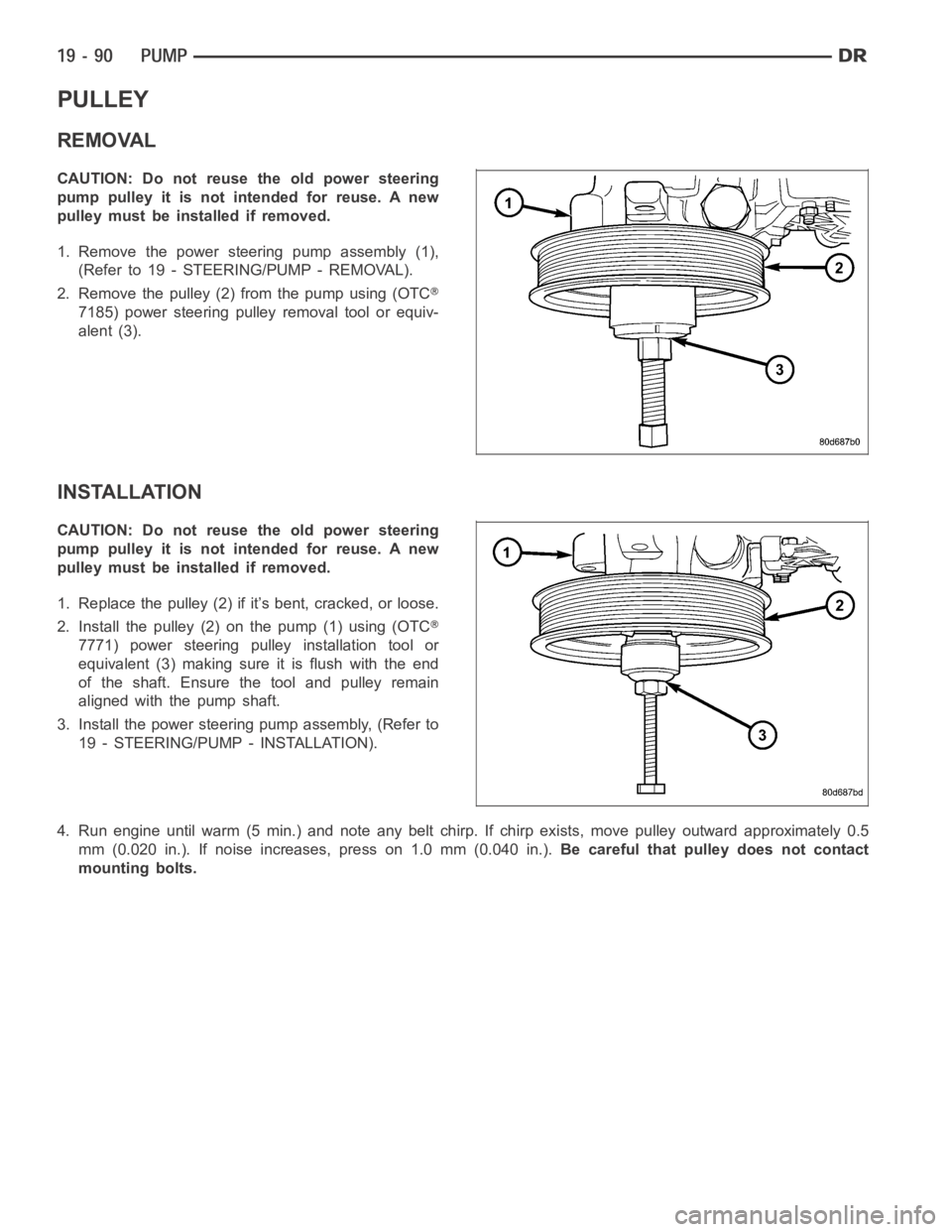

PULLEY

REMOVAL

CAUTION: Do not reuse the old power steering

pump pulley it is not intended for reuse. A new

pulley must be installed if removed.

1. Remove the power steering pump assembly (1),

(Refer to 19 - STEERING/PUMP - REMOVAL).

2. Remove the pulley (2) from the pump using (OTC

7185) power steering pulley removal tool or equiv-

alent (3).

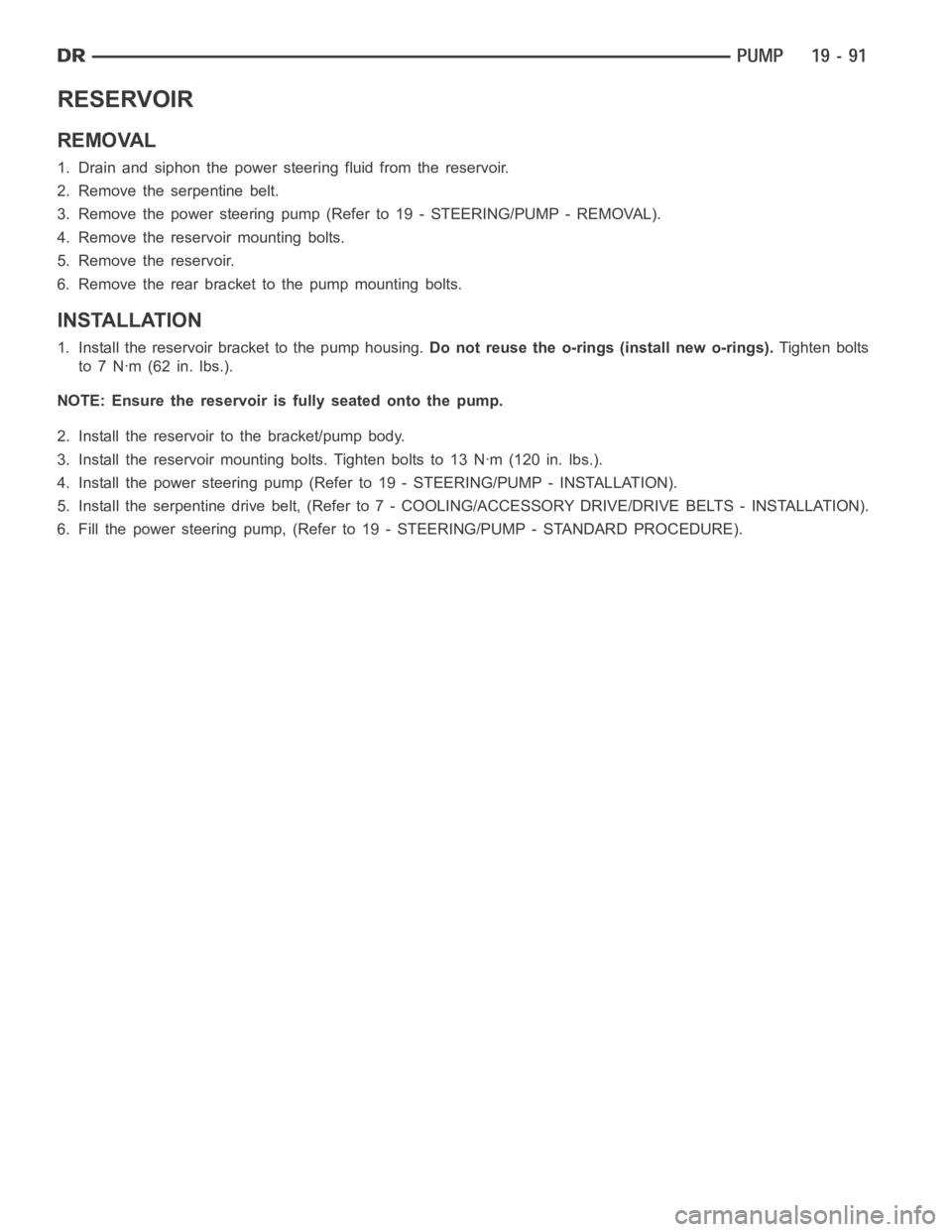

INSTALLATION

CAUTION: Do not reuse the old power steering

pump pulley it is not intended for reuse. A new

pulley must be installed if removed.

1. Replace the pulley (2) if it’s bent, cracked, or loose.

2. Install the pulley (2) on the pump (1) using (OTC

7771) power steering pulley installation tool or

equivalent (3) making sure it is flush with the end

of the shaft. Ensure the tool and pulley remain

aligned with the pump shaft.

3. Install the power steering pump assembly, (Refer to

19 - STEERING/PUMP - INSTALLATION).

4. Run engine until warm (5 min.) and note any belt chirp. If chirp exists, move pulley outward approximately 0.5

mm (0.020 in.). If noise increases, press on 1.0 mm (0.040 in.).Be careful that pulley does not contact

mounting bolts.

Page 2496 of 5267

RESERVOIR

REMOVAL

1. Drain and siphon the power steering fluid from the reservoir.

2. Remove the serpentine belt.

3. Remove the power steering pump (Refer to 19 - STEERING/PUMP - REMOVAL).

4. Remove the reservoir mounting bolts.

5. Remove the reservoir.

6. Remove the rear bracket to the pump mounting bolts.

INSTALLATION

1. Install the reservoir bracket to the pump housing.Do not reuse the o-rings (install new o-rings).Tighten bolts

to7Nꞏm(62in.lbs.).

NOTE: Ensure the reservoir is fully seated onto the pump.

2. Install the reservoir to the bracket/pump body.

3. Install the reservoir mounting bolts. Tighten bolts to 13 Nꞏm (120 in. lbs.).

4. Install the power steering pump (Refer to 19 - STEERING/PUMP - INSTALLATION).

5. Install the serpentine drive belt, (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - INSTALLATION).

6. Fill the power steering pump, (Refer to 19 - STEERING/PUMP - STANDARD PROCEDURE).

Page 2497 of 5267

page page

PUMP - SRT10

DIAGNOSIS AND TESTING - HYDRAULIC

FLOW AND PRESSURE ..................... 93

STANDARD PROCEDURE

INITIAL OPERATION ........................ 95

STANDARD PROCEDURE - FLUID COOLER

LINE QUICK CONNECT FITTING

DISASSEMBLY/ASSEMBLY. ................. 96

REMOVAL .................................... 97

INSTALLATION ............................... 99

SPECIFICATIONS

TORQUE .................................. 100

SPECIAL TOOLS

POWER STEERING ........................ 101

HOSES

REMOVAL

PRESSURE HOSE - PUMP TO FAN ......... 102

PRESSURE HOSE - FAN TO GEAR ......... 102

RETURN HOSE - FAN TO PUMP ............ 103

RETURN HOSE - GEAR TO COOLER ....... 103RETURN HOSE - COOLER TO PUMP ....... 105

INSTALLATION

PRESSURE HOSE - PUMP TO FAN ......... 105

PRESSURE HOSE - FAN TO GEAR ......... 106

RETURN HOSE - FAN TO PUMP ............ 107

RETURN HOSE - GEAR TO COOLER ....... 108

RETURN HOSE - COOLER TO PUMP ....... 108

RESERVOIR

REMOVAL ................................... 109

INSTALLATION .............................. 109

PULLEY

REMOVAL ................................... 110

INSTALLATION .............................. 110

FLUID COOLER TUBE

REMOVAL ................................... 111

INSTALLATION .............................. 112

FLUID COOLER

REMOVAL ................................... 113

INSTALLATION .............................. 115

Page 2498 of 5267

PUMP - SRT10

DIAGNOSIS AND TESTING - HYDRAULIC FLOW AND PRESSURE

The following procedures are used to test the operation of the power steering and hydraulic fan systems on this

vehicle. These tests will provide the gallons per minute (GPM) or flow rateof the power steering pump along with

the maximum relief pressure at given points in the system. Perform the first test anytime a power steering system

problem is present and the second as necessary once the first test is completed. These tests will determine if the

power steering pump, hydraulic fan, or power steering gear is not functioning properly. They will also determine if

the flow coming out of the hydraulic fan motor is sufficient for the power steering gear. The following pressure and

flow tests are performed using the Power Steering Analyzer kit 6815 (with appropriate hoses) and Adapter kit 9091.

(Refer to 19 - STEERING - SPECIAL TOOLS)

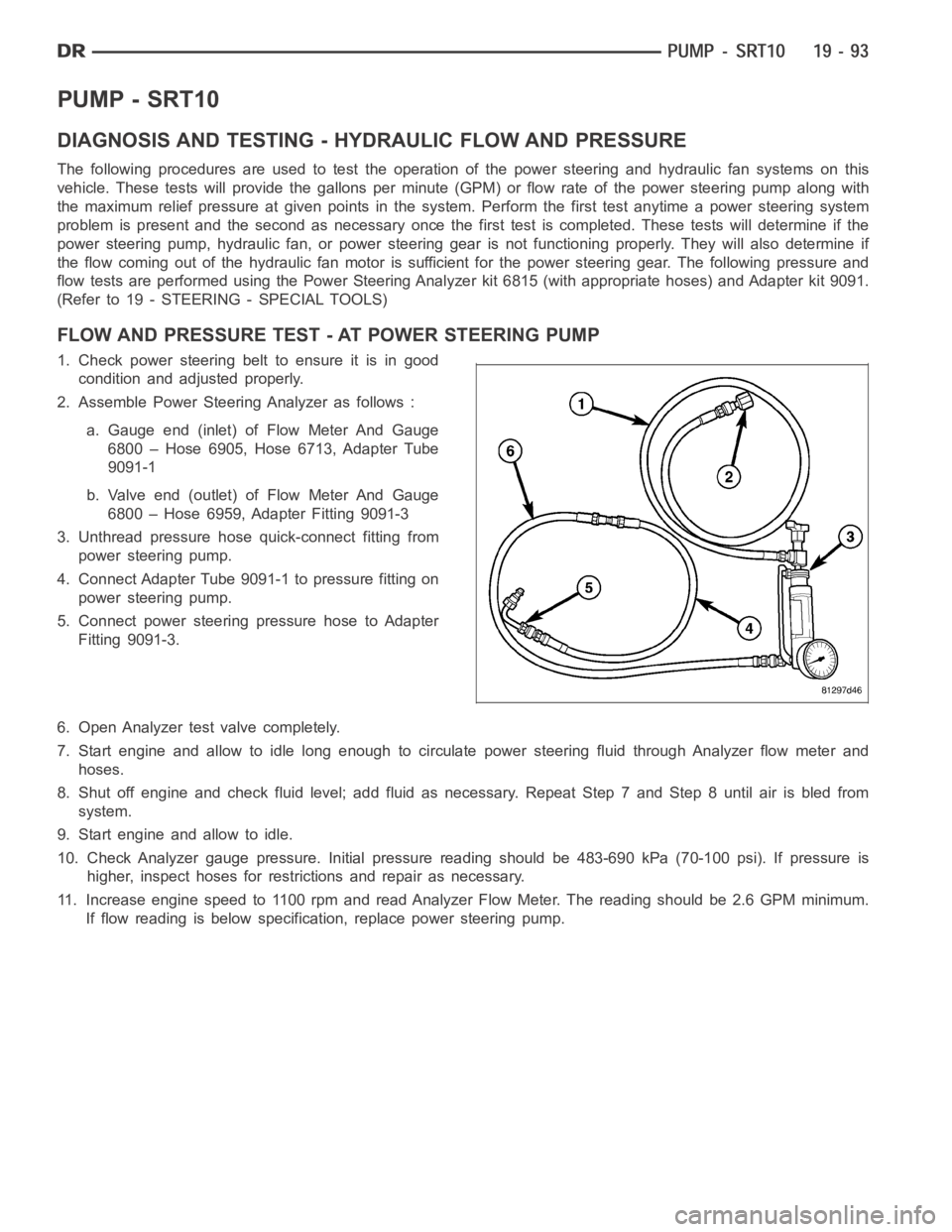

FLOW AND PRESSURE TEST - AT POWER STEERING PUMP

1. Check power steering belt to ensure it is in good

condition and adjusted properly.

2. Assemble Power Steering Analyzer as follows :

a. Gauge end (inlet) of Flow Meter And Gauge

6800 – Hose 6905, Hose 6713, Adapter Tube

9091-1

b. Valve end (outlet) of Flow Meter And Gauge

6800 – Hose 6959, Adapter Fitting 9091-3

3. Unthread pressure hose quick-connect fitting from

power steering pump.

4. Connect Adapter Tube 9091-1 to pressure fitting on

power steering pump.

5. Connect power steering pressure hose to Adapter

Fitting 9091-3.

6. Open Analyzer test valve completely.

7. Start engine and allow to idle long enough to circulate power steering fluid through Analyzer flow meter and

hoses.

8. Shut off engine and check fluid level; add fluid as necessary. Repeat Step7andStep8untilairisbledfrom

system.

9. Start engine and allow to idle.

10. Check Analyzer gauge pressure. Initial pressure reading should be 483-690 kPa (70-100 psi). If pressure is

higher, inspect hoses for restrictions and repair as necessary.

11. Increase engine speed to 1100 rpm and read Analyzer Flow Meter. The reading should be 2.6 GPM minimum.

If flow reading is below specification, replace power steering pump.

Page 2499 of 5267

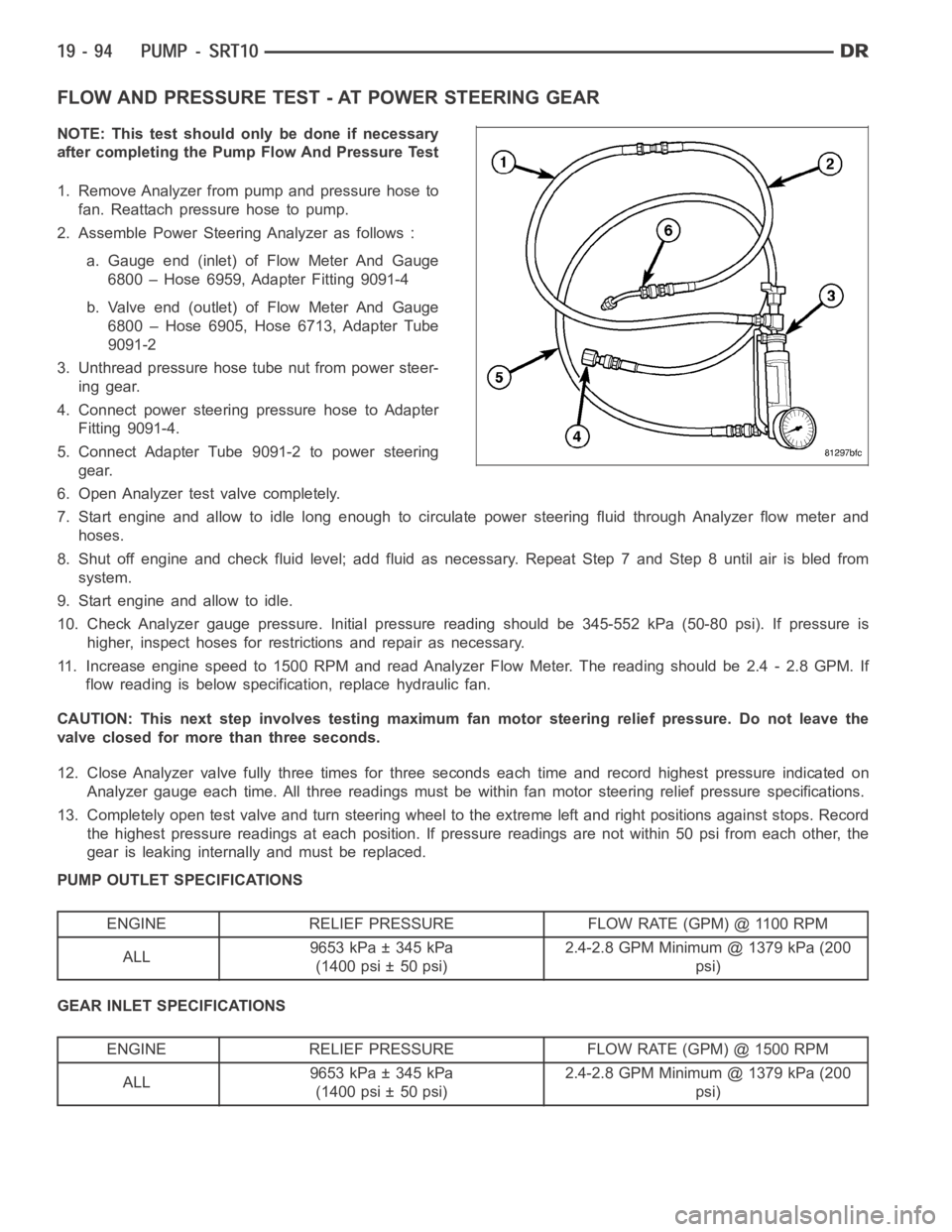

FLOW AND PRESSURE TEST - AT POWER STEERING GEAR

NOTE: This test should only be done if necessary

after completing the Pump Flow And Pressure Test

1. Remove Analyzer from pump and pressure hose to

fan. Reattach pressure hose to pump.

2. Assemble Power Steering Analyzer as follows :

a. Gauge end (inlet) of Flow Meter And Gauge

6800 – Hose 6959, Adapter Fitting 9091-4

b. Valve end (outlet) of Flow Meter And Gauge

6800 – Hose 6905, Hose 6713, Adapter Tube

9091-2

3. Unthread pressure hose tube nut from power steer-

ing gear.

4. Connect power steering pressure hose to Adapter

Fitting 9091-4.

5. Connect Adapter Tube 9091-2 to power steering

gear.

6. Open Analyzer test valve completely.

7. Start engine and allow to idle long enough to circulate power steering fluid through Analyzer flow meter and

hoses.

8. Shut off engine and check fluid level; add fluid as necessary. Repeat Step7andStep8untilairisbledfrom

system.

9. Start engine and allow to idle.

10. Check Analyzer gauge pressure. Initial pressure reading should be 345-552 kPa (50-80 psi). If pressure is

higher, inspect hoses for restrictions and repair as necessary.

11. Increase engine speed to 1500 RPM and read Analyzer Flow Meter. The reading should be 2.4 - 2.8 GPM. If

flow reading is below specification, replace hydraulic fan.

CAUTION: This next step involves testing maximum fan motor steering relief pressure. Do not leave the

valve closed for more than three seconds.

12. Close Analyzer valve fully three times for three seconds each time and record highest pressure indicated on

Analyzer gauge each time. All three readings must be within fan motor steering relief pressure specifications.

13. Completely open test valve and turn steering wheel to the extreme left and right positions against stops. Record

the highest pressure readings at each position. If pressure readings are not within 50 psi from each other, the

gear is leaking internally and must be replaced.

PUMP OUTLET SPECIFICATIONS

ENGINE RELIEF PRESSURE FLOW RATE (GPM) @ 1100 RPM

ALL9653 kPa ± 345 kPa

(1400 psi ± 50 psi)2.4-2.8 GPM Minimum @ 1379 kPa (200

psi)

GEAR INLET SPECIFICATIONS

ENGINE RELIEF PRESSURE FLOW RATE (GPM) @ 1500 RPM

ALL9653 kPa ± 345 kPa

(1400 psi ± 50 psi)2.4-2.8 GPM Minimum @ 1379 kPa (200

psi)

Page 2500 of 5267

STANDARD PROCEDURE

INITIAL OPERATION

WARNING: The fluid level should be checked with engine off to prevent injury from moving components.

NOTE: Remove as much of the old fluid out of the system as possible with a suction tool or by removing

a hose, when a component has failed. Then refill it with fresh fluid until itis clean. This may have to be

done more than once.

CAUTION: MOPAR

ATF+4 is to be used in the power steering system. No other power steering or auto-

matic transmission fluid is to be used in the system. Damage may result to the power steering pump and

system if any other fluid is used, and do not overfill.

Wipe filler cap clean, then check the fluid level. The dipstick should indicateCOLDwhen the fluid is at normal

ambient temperature.

1. Fill the pump fluid reservoir to the proper level and let the fluid settlefor at least two minutes.

2. Start the engine and let run for a few seconds then turn engine off.

3. Add fluid if necessary. Repeat the above procedure until the fluid levelremains constant after running the engine.

4. Raise the front wheels off the ground.

5. Slowly turn the steering wheel right and left, lightly contacting the wheel stops at least 20 times.

6. Check the fluid level add if necessary.

7. Lower the vehicle, start the engine, and use the DRB III to activate the hydraulic fan on full fan operation.

8. Turn the steering wheel slowly from lock to lock.

9. Stop the engine, check the fluid level and refill as required and repeat the process

CAUTION: Do not run a vehicle with foamy fluid for an extended period. This may cause pump damage.

10. If the fluid is extremely foamy or milky looking, allow the vehicle to stand a few minutes and repeat the pro-

cedure.

11. While the vehicle is in park, use the DRB III to activate the hydraulic fan to full fan operation and briefly rev the

engine up to 3000 rpm to fully engage the hydraulic fan.

12. Check the fluid level add if necessary.