light DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1408 of 5267

4.ASD RELAY

Install a substitute relay for the ASD Relay.

Attempt to startthe vehicle.

Did the engine start?

Ye s>>

Replace the ASD Relay.

Perform POWERTRAIN VERIFICATION TEST VER - 2.

No>>

Go To 5

5.(A14) FUSED B+ CIRCUITS

Turn the ignition off.

Remove the ASD Relay from the PDC.

Using a 12-volt test light, probe the (A14) Fused B+ circuits at the ASD Relay connector in the PDC.

Does the test light illuminate brightly?

Ye s>>

Go To 6

No>>

Repair the open or short to ground in the (A14) Fused B+ circuits. Inspect the related fuse and repair

as necessary.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

6.(K342) ASD RELAY OUTPUT CIRCUIT OPEN

Disconnect the PCM harness connectors.

Measure the resistance of the (K342) ASD Relay Output circuit from the ASD Relay cavity in the PDC to the PCM

harness connector.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 7

No>>

Repair the open in the (K342)ASD Relay Output circuit.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

7.PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

If there are no possible causes remaining, view repair.

Repair

Replace and program the Powertrain Control Module per Service Information.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 1432 of 5267

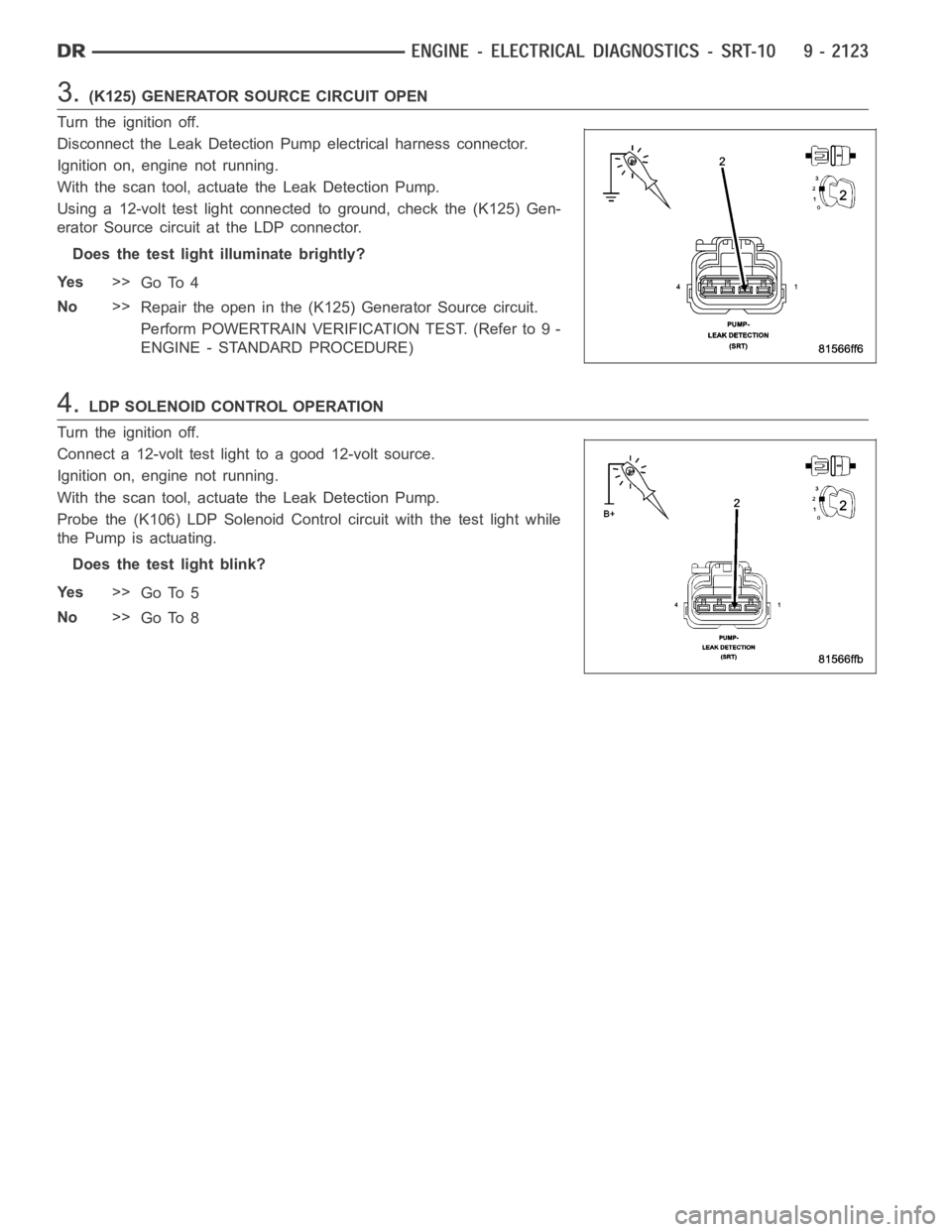

3.(K125) GENERATOR SOURCE CIRCUIT OPEN

Turn the ignition off.

Disconnect the Leak Detection Pump electrical harness connector.

Ignition on, engine not running.

With the scan tool, actuate the Leak Detection Pump.

Using a 12-volt test light connected to ground, check the (K125) Gen-

erator Source circuit at the LDP connector.

Does the test light illuminate brightly?

Ye s>>

Go To 4

No>>

Repair the open in the (K125) Generator Source circuit.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 -

ENGINE - STANDARD PROCEDURE)

4.LDP SOLENOID CONTROL OPERATION

Turn the ignition off.

Connect a 12-volt test light to a good 12-volt source.

Ignition on, engine not running.

With the scan tool, actuate the Leak Detection Pump.

Probe the (K106) LDP Solenoid Control circuit with the test light while

the Pump is actuating.

Does the test light blink?

Ye s>>

Go To 5

No>>

Go To 8

Page 1436 of 5267

When Monitored:

Ignition on and engine running.

Set Condition:

An open or shorted condition in the Hydraulic Fan Solenoid control circuitis detected by the Powertrain Control

Module.

Possible Causes

RADIATOR FAN INOP

(K342) FUSED ASD RELAY OUTPUT CIRCUIT

(C240) COOLING FAN CONTROL CIRCUIT OPEN

(C240) COOLING FAN CONTROL CIRCUIT SHORTED TO GROUND

HYDRAULIC FAN

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

1.RADIATOR FAN INOP

Ignition on, engine not running.

With the scan tool, perform the Hydraulic Fan Solenoid Test found under Engine Test and Systems Test.

Does the Radiator Fan operate properly?

Ye s>>

Refer to the INTERMITTENT CONDITIONSymptom (Diagnostic Procedure).

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 2

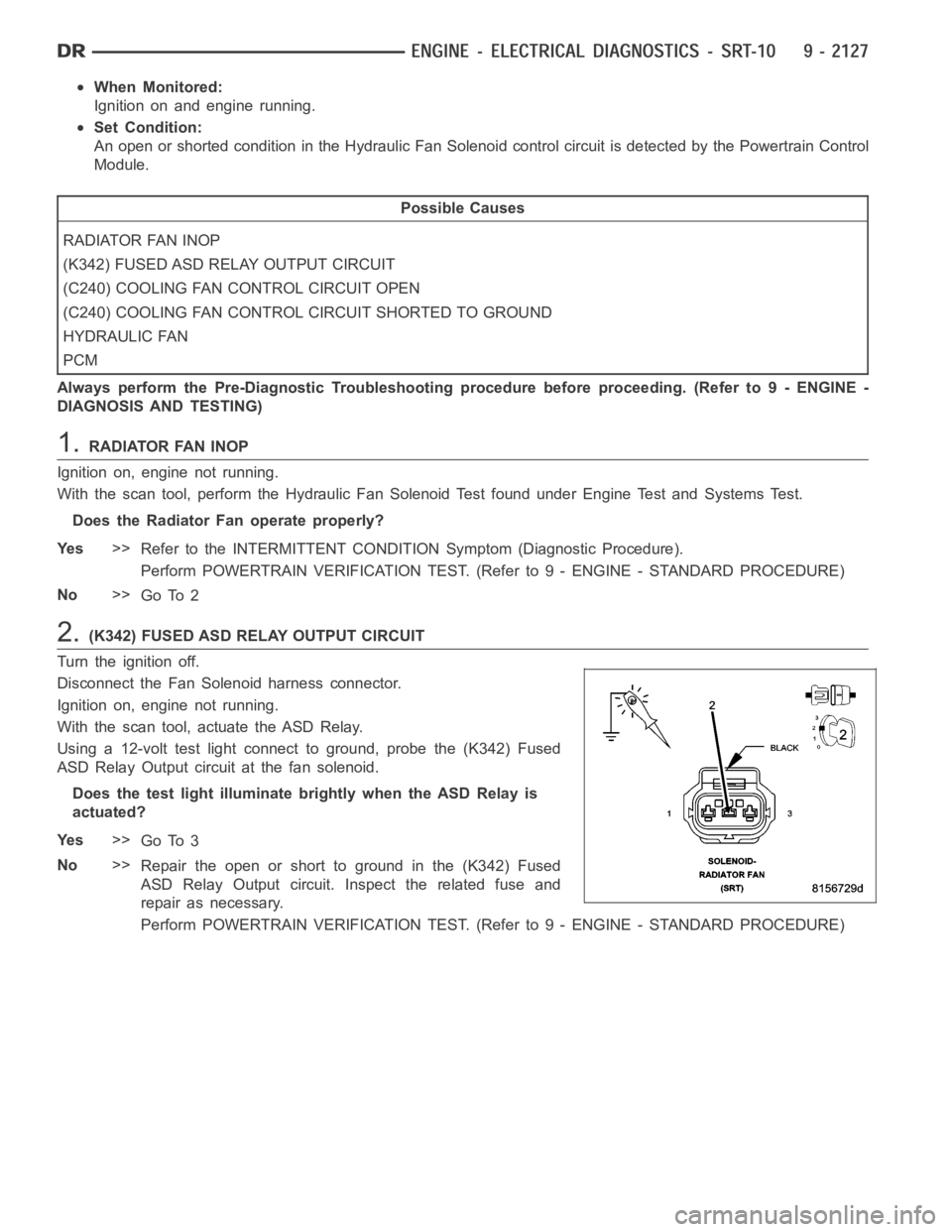

2.(K342) FUSED ASD RELAY OUTPUT CIRCUIT

Turn the ignition off.

Disconnect the Fan Solenoid harness connector.

Ignition on, engine not running.

With the scan tool, actuate the ASD Relay.

Using a 12-volt test light connect to ground, probe the (K342) Fused

ASD Relay Output circuit at the fan solenoid.

Does the test light illuminate brightly when the ASD Relay is

actuated?

Ye s>>

Go To 3

No>>

Repair the open or short to ground in the (K342) Fused

ASD Relay Output circuit. Inspect the related fuse and

repair as necessary.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 1440 of 5267

When Monitored:

With the ignition key on and the engine speed greater than 0 RPM.

Set Condition:

When the PCM regulates the generator field and there are no detected field problems, but the voltage output

does not decrease.

Possible Causes

(K20) GENERATOR FIELD CONTROL CIRCUIT SHORTED TO GROUND

GENERATOR FIELD COIL SHORTED TO GROUND

BATTERY TEMPERATURE SENSOR

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.CHARGING SYSTEM OPERATION

NOTE: Battery must be fully charged and be capable of passing a load test.

NOTE: Generator Belt tension and condition must be checked before continuing.

Ignition on, engine not running.

With the scan tool, read DTCs and the related Freeze Frame data then clear theDTCs.

With scan tool, actuate the Generator Field Driver.

With a 12-volt test light connected to ground, backprobe the (K20) Gen Field Control circuit in the back of Generator

Field harness connector.

Does the test light illuminate brightly and flash?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

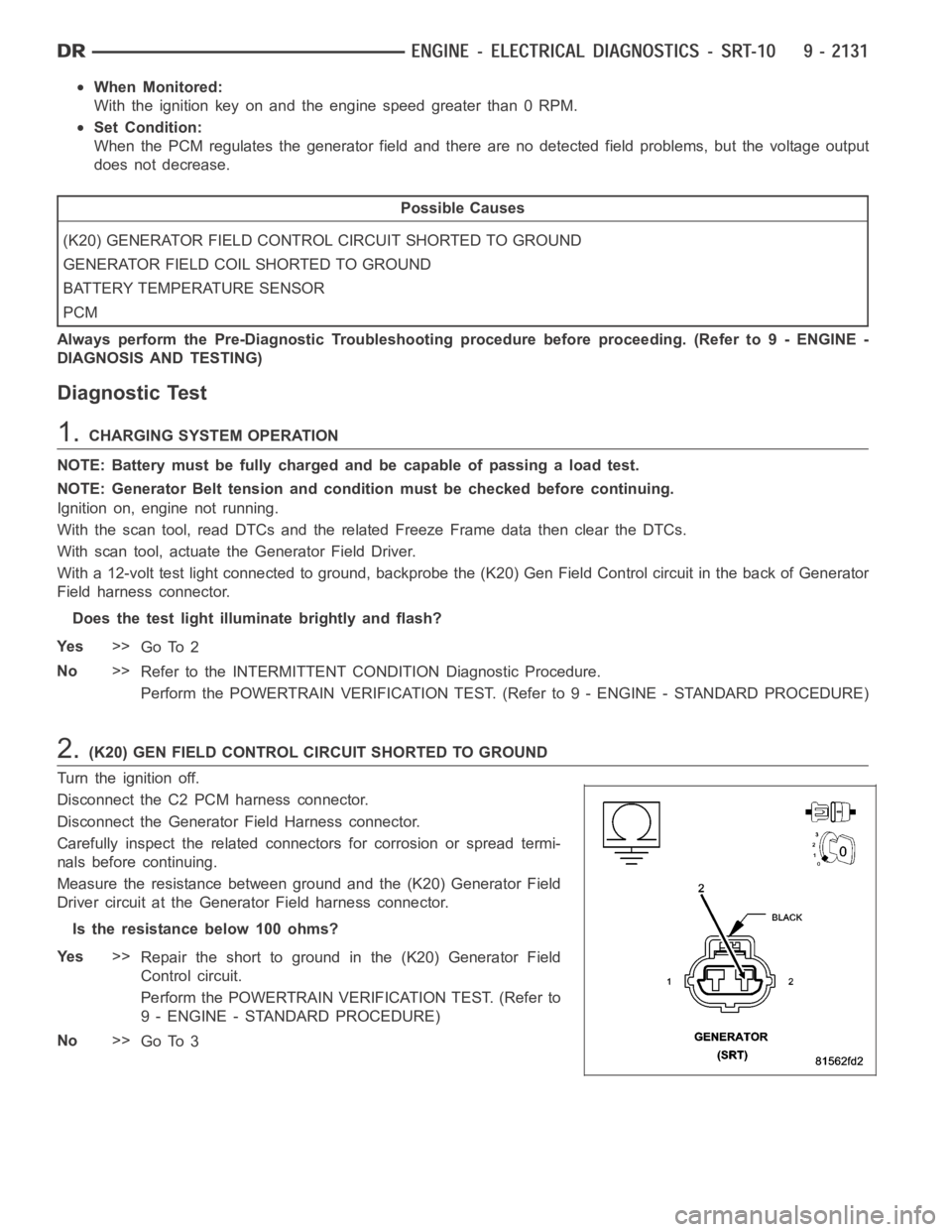

2.(K20) GEN FIELD CONTROL CIRCUIT SHORTED TO GROUND

Turn the ignition off.

Disconnect the C2 PCM harness connector.

Disconnect the Generator Field Harness connector.

Carefully inspect the related connectors for corrosion or spread termi-

nals before continuing.

Measure the resistance between ground and the (K20) Generator Field

Driver circuit at the Generator Field harness connector.

Istheresistancebelow100ohms?

Ye s>>

Repair the short to ground in the (K20) Generator Field

Control circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 3

Page 1463 of 5267

Possible Causes

(A103) FUSED B+ CIRCUIT

(Z429) BRAKE LAMP SWITCH GROUND CIRCUIT OPEN

BRAKE LAMP SWITCH

(B29) BRAKE SWITCH NO.1 SIGNAL CIRCUIT OPEN

(B29) BRAKE SWITCH NO.1 SIGNAL CIRCUIT SHORT TO GROUND

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.SCAN TOOL DOES NOT SHOW BRAKE SW PRESSED OR RELEASED

Ignition on, engine not running.

With the scan tool in Inputs/Outputs, read the Brake Switch state.

While observing the scan tool display, press and release the brake pedal several times.

Does the scan tool display Brake Switch PRESSED and RELEASED?

Ye s>>

The Brake Lamp Switch is operating properly at this time.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 2

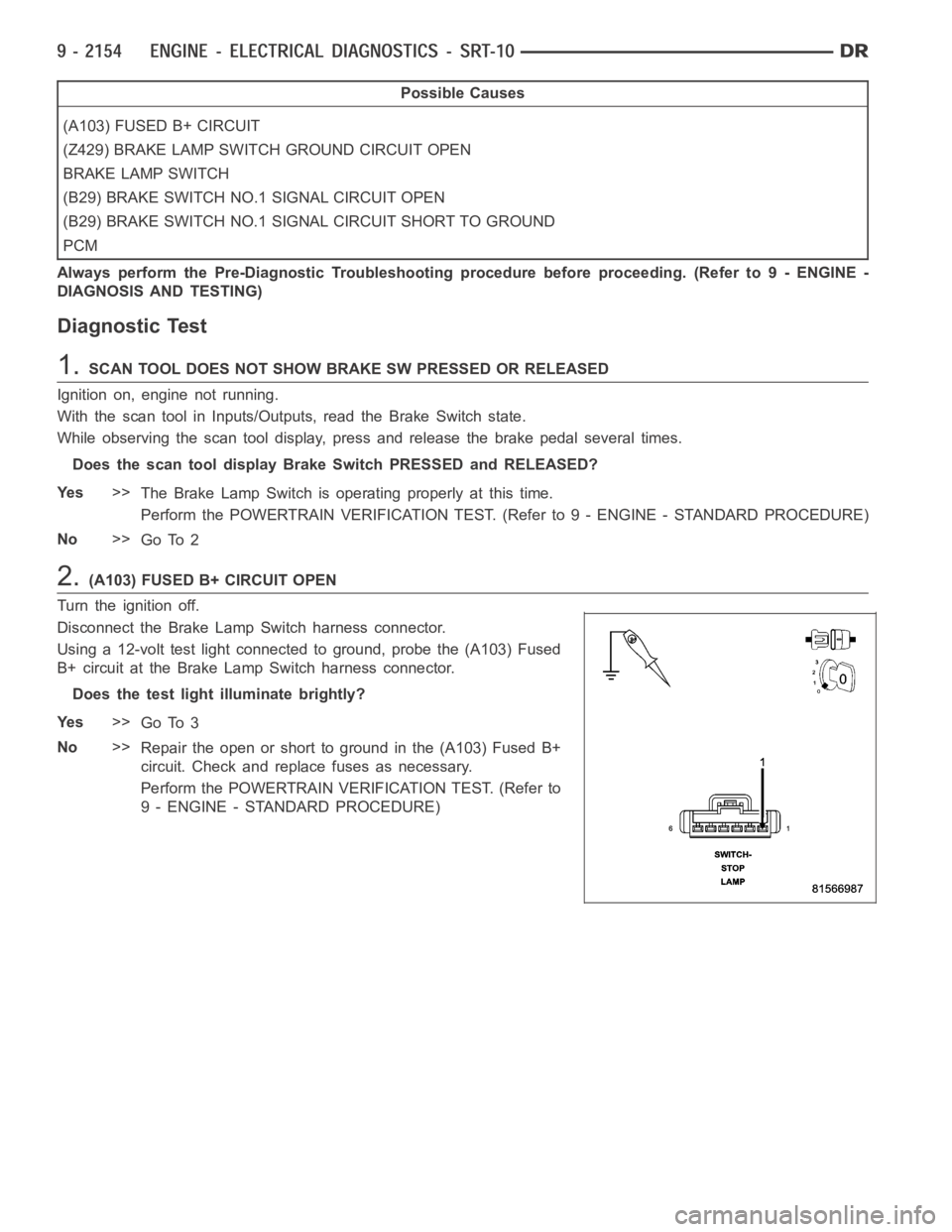

2.(A103) FUSED B+ CIRCUIT OPEN

Turn the ignition off.

Disconnect the Brake Lamp Switch harness connector.

Using a 12-volt test light connected to ground, probe the (A103) Fused

B+ circuit at the Brake Lamp Switch harness connector.

Does the test light illuminate brightly?

Ye s>>

Go To 3

No>>

Repair the open or short to ground in the (A103) Fused B+

circuit. Check and replace fuses as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

Page 1464 of 5267

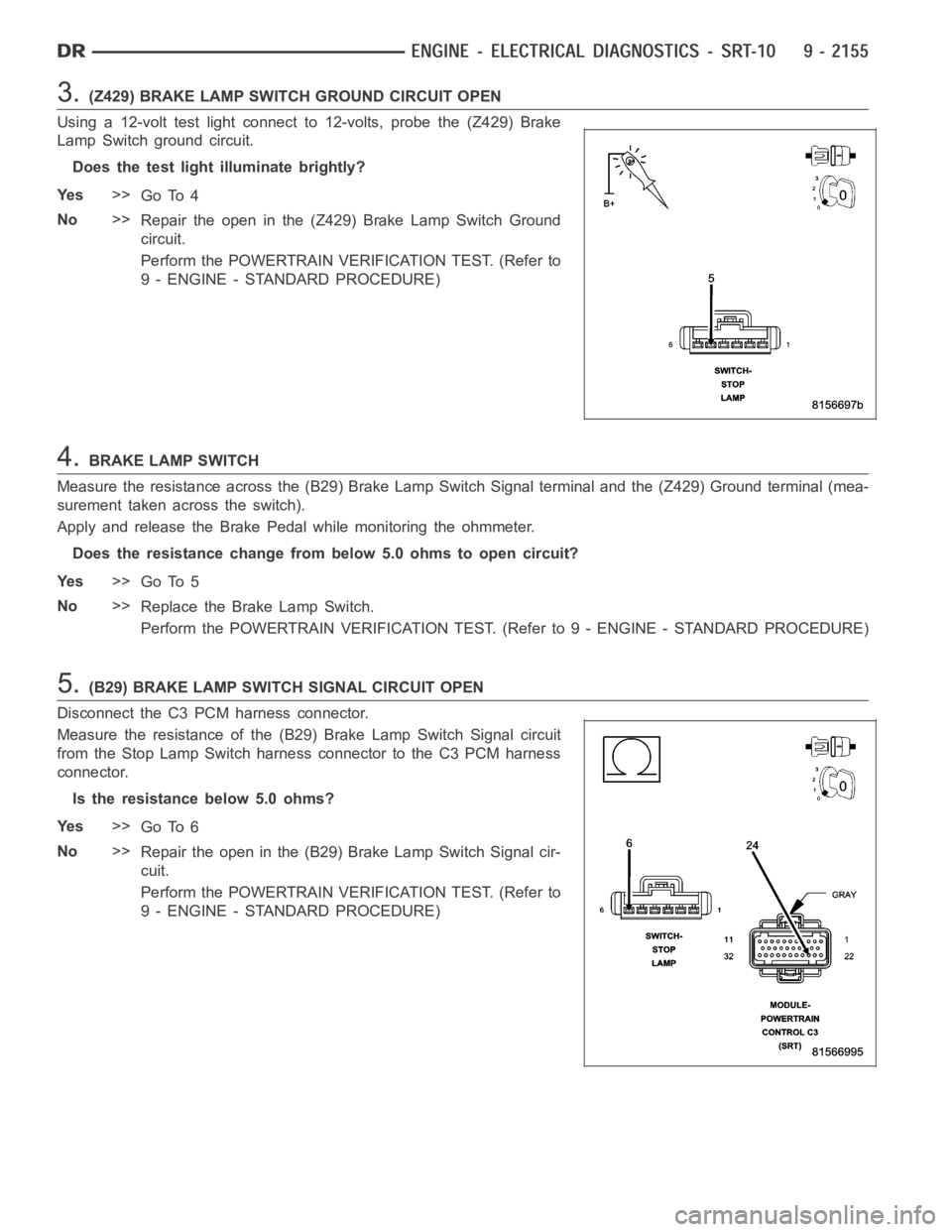

3.(Z429) BRAKE LAMP SWITCH GROUND CIRCUIT OPEN

Using a 12-volt test light connect to 12-volts, probe the (Z429) Brake

Lamp Switch ground circuit.

Does the test light illuminate brightly?

Ye s>>

Go To 4

No>>

Repair the open in the (Z429) Brake Lamp Switch Ground

circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

4.BRAKE LAMP SWITCH

Measure the resistance across the (B29) Brake Lamp Switch Signal terminaland the (Z429) Ground terminal (mea-

surement taken across the switch).

Apply and release the Brake Pedal while monitoring the ohmmeter.

Does the resistance change frombelow 5.0 ohms to open circuit?

Ye s>>

Go To 5

No>>

Replace the Brake Lamp Switch.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

5.(B29) BRAKE LAMP SWITCH SIGNAL CIRCUIT OPEN

Disconnect the C3 PCM harness connector.

Measure the resistance of the (B29) Brake Lamp Switch Signal circuit

from the Stop Lamp Switch harness connector to the C3 PCM harness

connector.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 6

No>>

Repair the open in the (B29) Brake Lamp Switch Signal cir-

cuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

Page 1465 of 5267

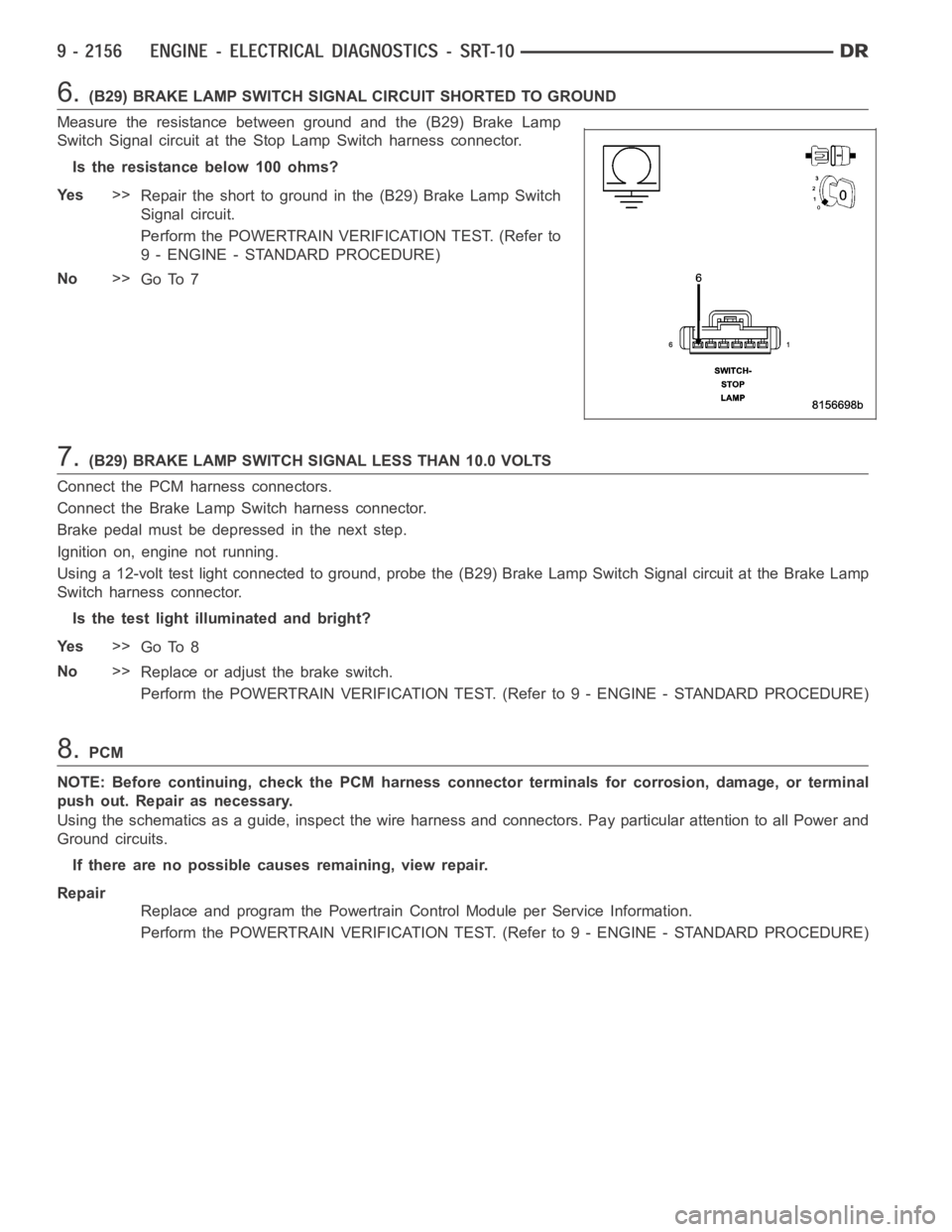

6.(B29) BRAKE LAMP SWITCH SIGNAL CIRCUIT SHORTED TO GROUND

Measure the resistance between ground and the (B29) Brake Lamp

Switch Signal circuit at the Stop Lamp Switch harness connector.

Istheresistancebelow100ohms?

Ye s>>

Repair the short to ground in the (B29) Brake Lamp Switch

Signal circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 7

7.(B29) BRAKE LAMP SWITCH SIGNAL LESS THAN 10.0 VOLTS

Connect the PCM harness connectors.

Connect the Brake Lamp Switch harness connector.

Brake pedal must be depressed in the next step.

Ignition on, engine not running.

Using a 12-volt test light connected to ground, probe the (B29) Brake Lamp Switch Signal circuit at the Brake Lamp

Switch harness connector.

Is the test light illuminated and bright?

Ye s>>

Go To 8

No>>

Replace or adjust the brake switch.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

8.PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

If there are no possible causes remaining, view repair.

Repair

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 1470 of 5267

4.REFRIGERATION SYSTEM NOT PROPERLY CHARGED

Turn the ignition off.

Verify that the Refrigerant System is properly charged per Service Procedure.

Is the Refrigerant System properly charged?

Ye s>>

Go To 5

No>>

Properly charge the Refrigerant System per Service Information.

Perform BODY VERIFICATION TEST - VER 1.

5.HIGH PRESSURE CUT-OFF SWITCH

Turn the ignition off.

Verify the High Pressure Cut-Off Switch operation per Service Information.

Is the High Pressure Cut-Off Switch OK?

Ye s>>

Go To 6

No>>

Replace the High Pressure Cut-Off Switch.

Perform BODY VERIFICATION TEST - VER 1.

6.LOW PRESSURE SWITCH

Turn the ignition off.

Verify the Low Pressure Switch operation per Service Information.

Is the Low Pressure Switch OK?

Ye s>>

Go To 7

No>>

Replace the Low Pressure Switch.

Perform BODY VERIFICATION TEST - VER 1.

7.A/C CLUTCH COIL

Ignition on, engine not running.

Disconnect the A/C Compressor Clutch harness connector.

Connect a test light between the ground circuit and the A/C Clutch Relay Output circuit.

With the scan tool, actuate the A/C Clutch Relay.

Does the test light illuminate brightly on and off with the relay actuation?

Ye s>>

Replace the A/C Clutch Coil.

Perform BODY VERIFICATION TEST - VER 1.

No>>

Go To 8

8.A/C COMPRESSOR CLUTCH GROUND CIRCUIT OPEN

Turn the ignition off.

Disconnect the A/C Clutch harness connector.

NOTE: Check connectors - Clean/repair as necessary.

Measure the resistance between ground and the A/C Compressor Clutch ground circuit in the A/C Clutch harness

connector.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 9

No>>

Repair the open in the A/C Compressor Clutch ground circuit.

Perform BODY VERIFICATION TEST - VER 1.

Page 1475 of 5267

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

8.GENERATOR BELT CONDITION

Turn the ignition off.

NOTE: Battery condition must be verified prior to this test.

Inspect the Generator Belt tension and condition.

Is the Generator Belt OK?

Ye s>>

Go To 9

No>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

9.ACTIVE DTC SET

Start the engine.

Turn on all accessories.

Raise engine speed to 2000 RPM for 30 seconds then return to idle.

With the scan tool, read DTCs.

Are there any

Charging SystemTrouble Codes?

Ye s>>

Refer to DTC list for the related Charging DTCs.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 10

10.WIRE HARNESS INSPECTION

Ignition on, engine not running.

With the scan tool, actuate the Generator Field Driver.

Using a 12-volt test light, backprobe the Generator Field Driver Terminalat the back of the Generator.

NOTE: The test light should blink On and Off every 1.4 seconds.

While monitoring the 12-volt test light, wiggle the Field Terminals back to the PCM and ASD Relay.

Was there any interruption in the normal cycle of the test light?

Ye s>>

Repair the wire or connector where the wiggling interrupted the voltage cycle.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .

Page 1479 of 5267

Possible Causes

(A919) PCM FUSED B+ CIRCUIT

(F202) PCM FUSED IGNITION SWITCH OUTPUT CIRCUIT

(Z130) AND (Z131) PCM GROUND CIRCUITS

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

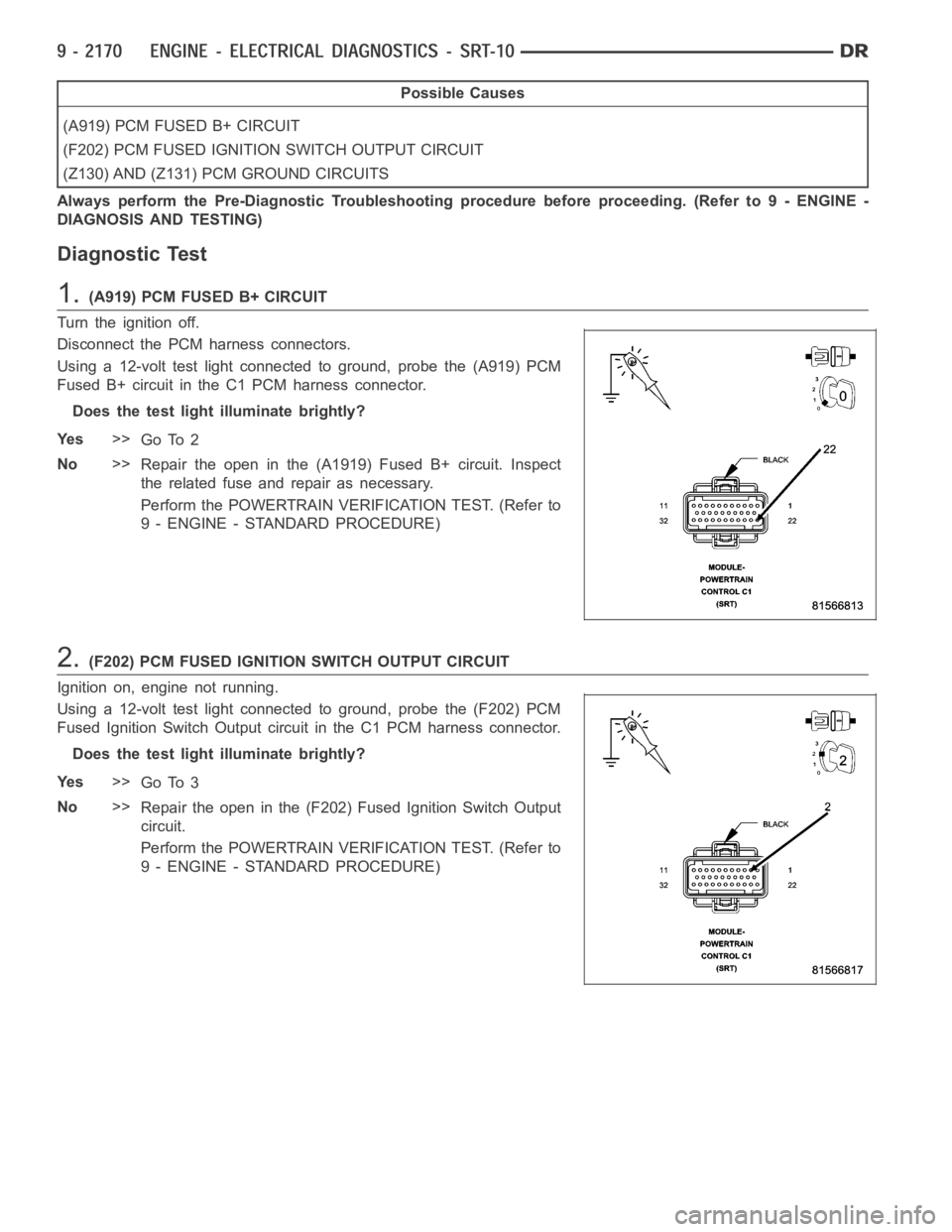

1.(A919) PCM FUSED B+ CIRCUIT

Turn the ignition off.

Disconnect the PCM harness connectors.

Using a 12-volt test light connected to ground, probe the (A919) PCM

Fused B+ circuit in the C1 PCM harness connector.

Does the test light illuminate brightly?

Ye s>>

Go To 2

No>>

Repair the open in the (A1919) Fused B+ circuit. Inspect

the related fuse and repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

2.(F202) PCM FUSED IGNITION SWITCH OUTPUT CIRCUIT

Ignition on, engine not running.

Using a 12-volt test light connected to ground, probe the (F202) PCM

Fused Ignition Switch Output circuit in the C1 PCM harness connector.

Does the test light illuminate brightly?

Ye s>>

Go To 3

No>>

Repair the open in the (F202) Fused Ignition Switch Output

circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)