light DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1588 of 5267

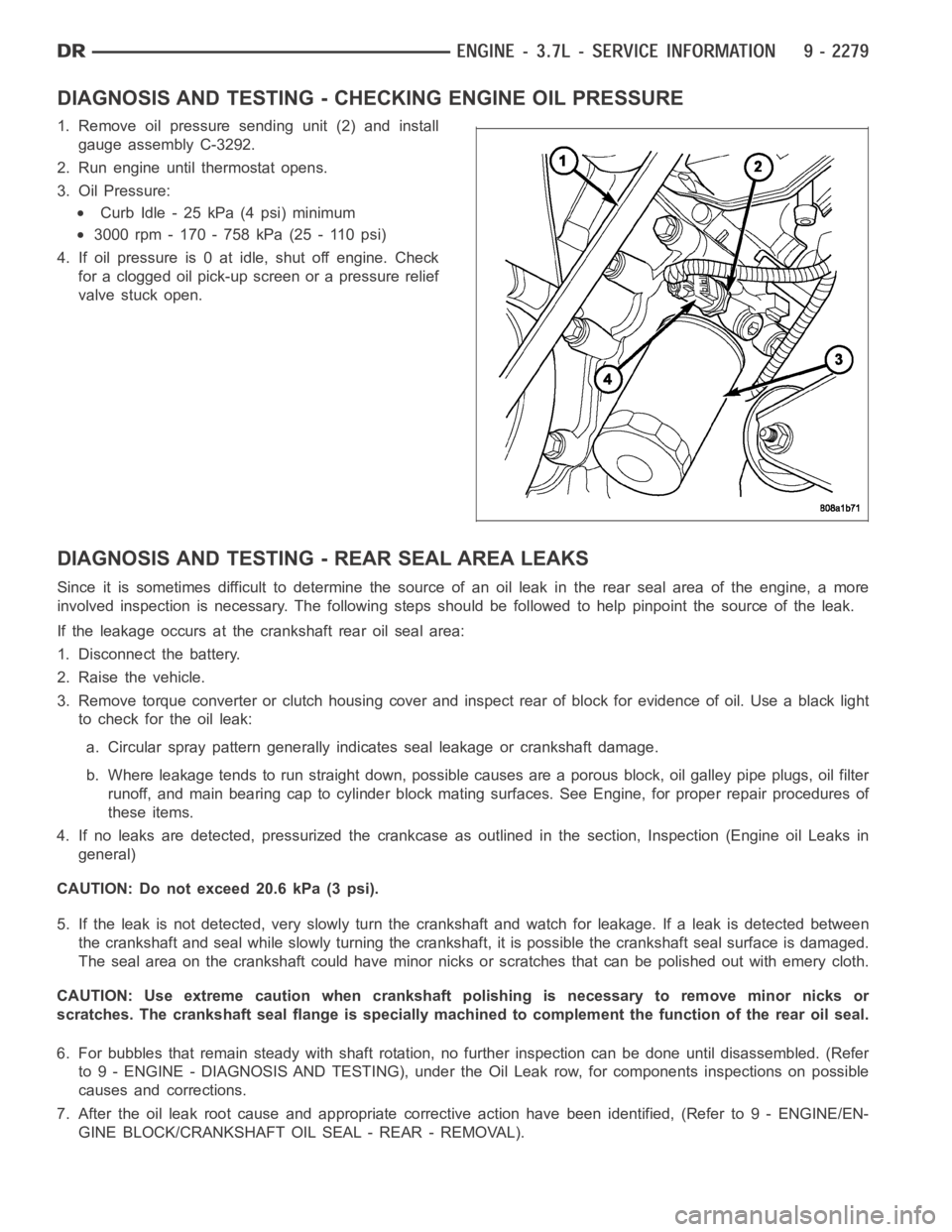

DIAGNOSIS AND TESTING - CHECKING ENGINE OIL PRESSURE

1. Remove oil pressure sending unit (2) and install

gauge assembly C-3292.

2. Run engine until thermostat opens.

3. Oil Pressure:

Curb Idle - 25 kPa (4 psi) minimum

3000 rpm - 170 - 758 kPa (25 - 110 psi)

4. If oil pressure is 0 at idle, shut off engine. Check

for a clogged oil pick-up screen or a pressure relief

valve stuck open.

DIAGNOSIS AND TESTING - REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the source of an oil leak in therear seal area of the engine, a more

involved inspection is necessary. The following steps should be followedto help pinpoint the source of the leak.

If the leakage occurs at the crankshaft rear oil seal area:

1. Disconnect the battery.

2. Raise the vehicle.

3. Remove torque converter or clutch housing cover and inspect rear of block for evidence of oil. Use a black light

to check for the oil leak:

a. Circular spray pattern generally indicates seal leakage or crankshaftdamage.

b. Where leakage tends to run straight down, possible causes are a porous block, oil galley pipe plugs, oil filter

runoff, and main bearing cap to cylinder block mating surfaces. See Engine, for proper repair procedures of

these items.

4. If no leaks are detected, pressurized the crankcase as outlined in the section, Inspection (Engine oil Leaks in

general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

5. If the leak is not detected, very slowly turn the crankshaft and watch forleakage. If a leak is detected between

the crankshaft and seal while slowly turning the crankshaft, it is possible the crankshaft seal surface is damaged.

The seal area on the crankshaft could have minor nicks or scratches that canbe polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft polishing is necessary to remove minor nicks or

scratches. The crankshaft seal flange is specially machined to complement the function of the rear oil seal.

6. For bubbles that remain steady with shaft rotation, no further inspection can be done until disassembled. (Refer

to 9 - ENGINE - DIAGNOSIS AND TESTING), under the Oil Leak row, for components inspections on possible

causes and corrections.

7. After the oil leak root cause and appropriate corrective action have been identified, (Refer to 9 - ENGINE/EN-

GINE BLOCK/CRANKSHAFT OIL SEAL - REAR - REMOVAL).

Page 1597 of 5267

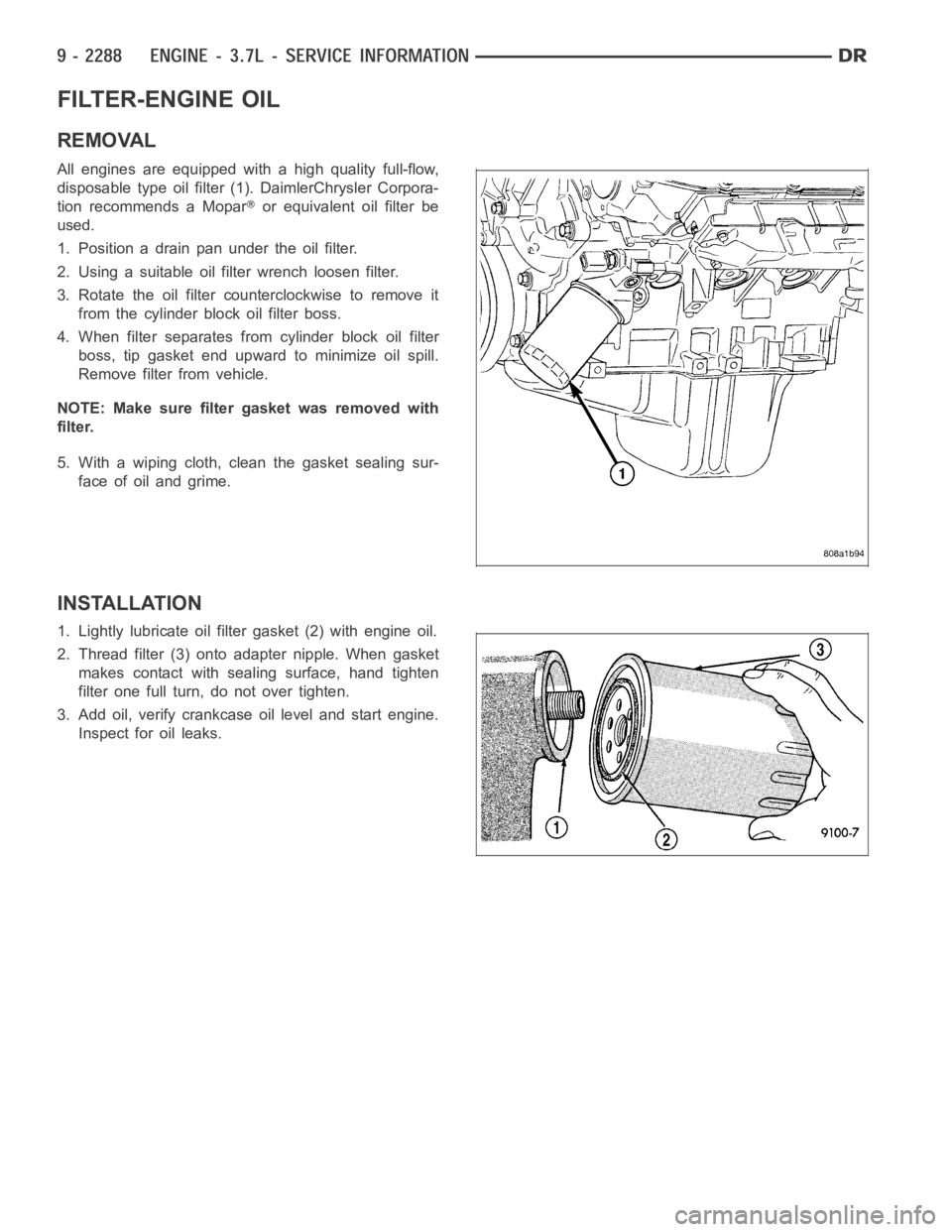

FILTER-ENGINE OIL

REMOVAL

All engines are equipped with a high quality full-flow,

disposable type oil filter (1). DaimlerChrysler Corpora-

tion recommends a Mopar

or equivalent oil filter be

used.

1. Position a drain pan under the oil filter.

2. Using a suitable oil filter wrench loosen filter.

3. Rotate the oil filter counterclockwise to remove it

from the cylinder block oil filter boss.

4. When filter separates from cylinder block oil filter

boss, tip gasket end upward to minimize oil spill.

Remove filter from vehicle.

NOTE: Make sure filter gasket was removed with

filter.

5. With a wiping cloth, clean the gasket sealing sur-

face of oil and grime.

INSTALLATION

1. Lightly lubricate oil filter gasket (2) with engine oil.

2. Thread filter (3) onto adapter nipple. When gasket

makes contact with sealing surface, hand tighten

filter one full turn, do not over tighten.

3. Add oil, verify crankcase oil level and start engine.

Inspect for oil leaks.

Page 1603 of 5267

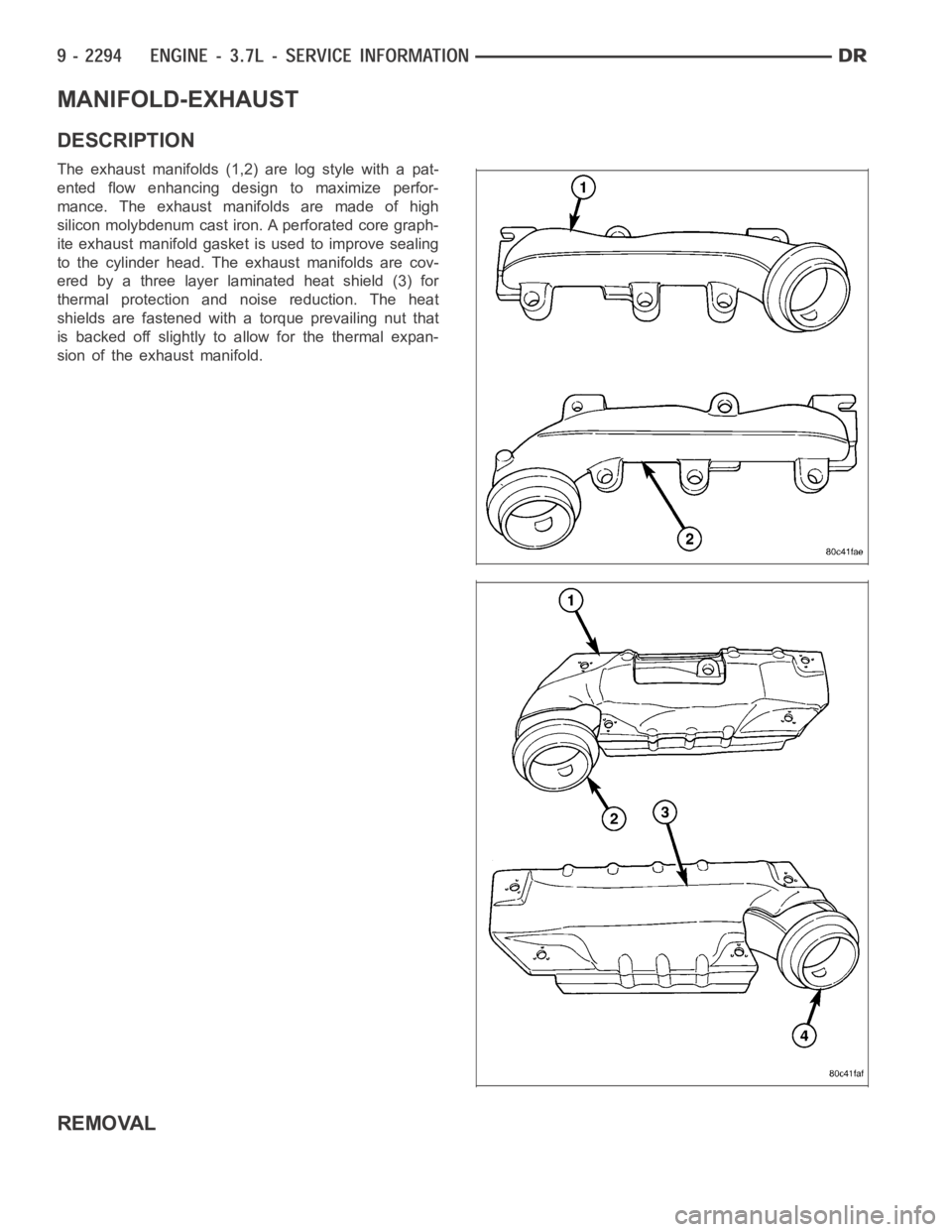

MANIFOLD-EXHAUST

DESCRIPTION

The exhaust manifolds (1,2) are log style with a pat-

ented flow enhancing design to maximize perfor-

mance. The exhaust manifolds are made of high

silicon molybdenum cast iron. A perforated core graph-

ite exhaust manifold gasket is used to improve sealing

to the cylinder head. The exhaust manifolds are cov-

ered by a three layer laminated heat shield (3) for

thermal protection and noise reduction. The heat

shields are fastened witha torque prevailing nut that

is backed off slightly to allow for the thermal expan-

sion of the exhaust manifold.

REMOVAL

Page 1606 of 5267

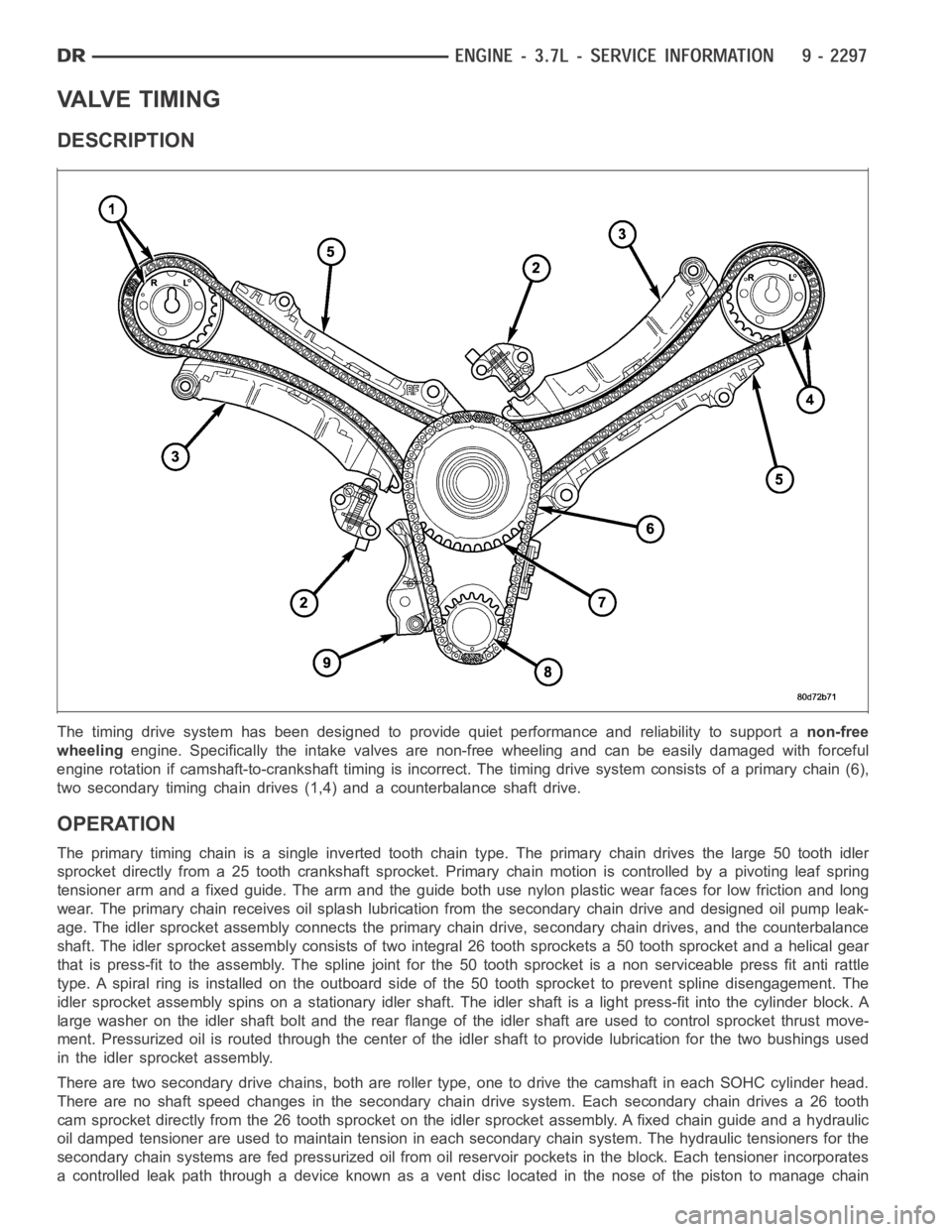

VALVE TIMING

DESCRIPTION

The timing drive system has been designed to provide quiet performance andreliability to support anon-free

wheelingengine. Specifically the intake valves are non-free wheeling and can be easily damaged with forceful

engine rotation if camshaft-to-crankshaft timing is incorrect. The timing drive system consists of a primary chain (6),

two secondary timing chain drives (1,4) and a counterbalance shaft drive.

OPERATION

The primary timing chain is a single inverted tooth chain type. The primarychaindrivesthelarge50toothidler

sprocket directly from a 25 tooth crankshaft sprocket. Primary chain motion is controlled by a pivoting leaf spring

tensioner arm and a fixed guide. The arm and the guide both use nylon plasticwear faces for low friction and long

wear. The primary chain receives oil splash lubrication from the secondary chain drive and designed oil pump leak-

age. The idler sprocket assembly connects the primary chain drive, secondary chain drives, and the counterbalance

shaft. The idler sprocket assembly consists of two integral 26 tooth sprockets a 50 tooth sprocket and a helical gear

that is press-fit to the assembly. Thespline joint for the 50 tooth sprocket is a non serviceable press fit anti rattle

type. A spiral ring is installed on the outboard side of the 50 tooth sprocket to prevent spline disengagement. The

idler sprocket assembly spins on a stationary idler shaft. The idler shaftis a light press-fit into the cylinder block. A

large washer on the idler shaft bolt and the rear flange of the idler shaft are used to control sprocket thrust move-

ment. Pressurized oil is routed through the center of the idler shaft to provide lubrication for the two bushings used

in the idler sprocket assembly.

There are two secondary drive chains, both are roller type, one to drive thecamshaft in each SOHC cylinder head.

There are no shaft speed changes in the secondary chain drive system. Each secondary chain drives a 26 tooth

cam sprocket directly from the 26 tooth sprocket on the idler sprocket assembly. A fixed chain guide and a hydraulic

oil damped tensioner are used to maintain tension in each secondary chain system. The hydraulic tensioners for the

secondary chain systems are fed pressurized oil from oil reservoir pockets in the block. Each tensioner incorporates

a controlled leak path through a device known as a vent disc located in the nose of the piston to manage chain

Page 1619 of 5267

INSTALLATION

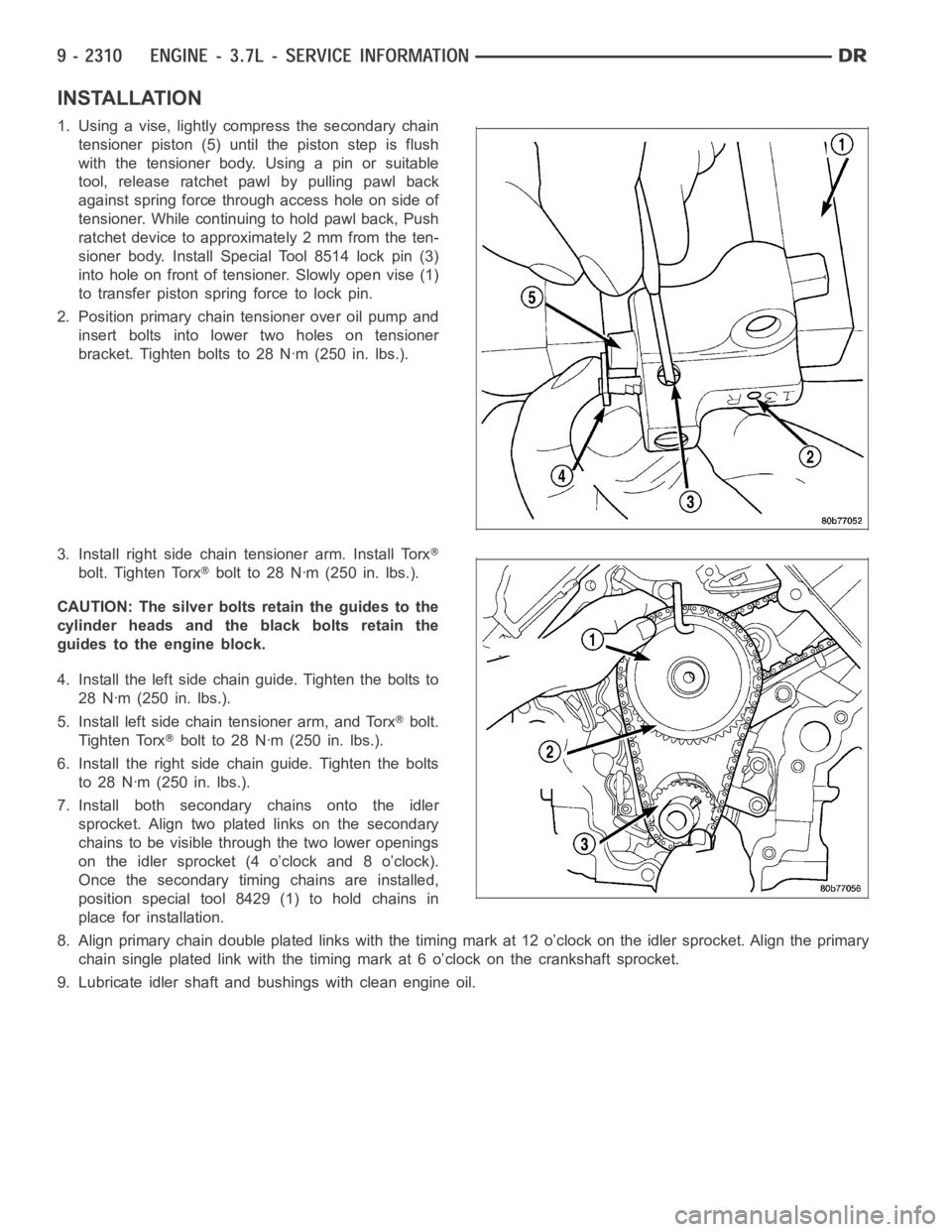

1. Using a vise, lightly compress the secondary chain

tensioner piston (5) until the piston step is flush

with the tensioner body. Using a pin or suitable

tool, release ratchet pawl by pulling pawl back

against spring force through access hole on side of

tensioner. While continuing to hold pawl back, Push

ratchet device to approximately 2 mm from the ten-

sioner body. Install Special Tool 8514 lock pin (3)

into hole on front of tensioner. Slowly open vise (1)

to transfer piston spring force to lock pin.

2. Position primary chain tensioner over oil pump and

insert bolts into lower two holes on tensioner

bracket. Tighten bolts to 28 Nꞏm (250 in. lbs.).

3. Install right side chain tensioner arm. Install Torx

bolt. Tighten Torxbolt to 28 Nꞏm (250 in. lbs.).

CAUTION: The silver bolts retain the guides to the

cylinder heads and the black bolts retain the

guides to the engine block.

4. Install the left side chain guide. Tighten the bolts to

28 Nꞏm (250 in. lbs.).

5. Install left side chain tensioner arm, and Torx

bolt.

Tighten Torx

bolt to 28 Nꞏm (250 in. lbs.).

6. Install the right side chain guide. Tighten the bolts

to 28 Nꞏm (250 in. lbs.).

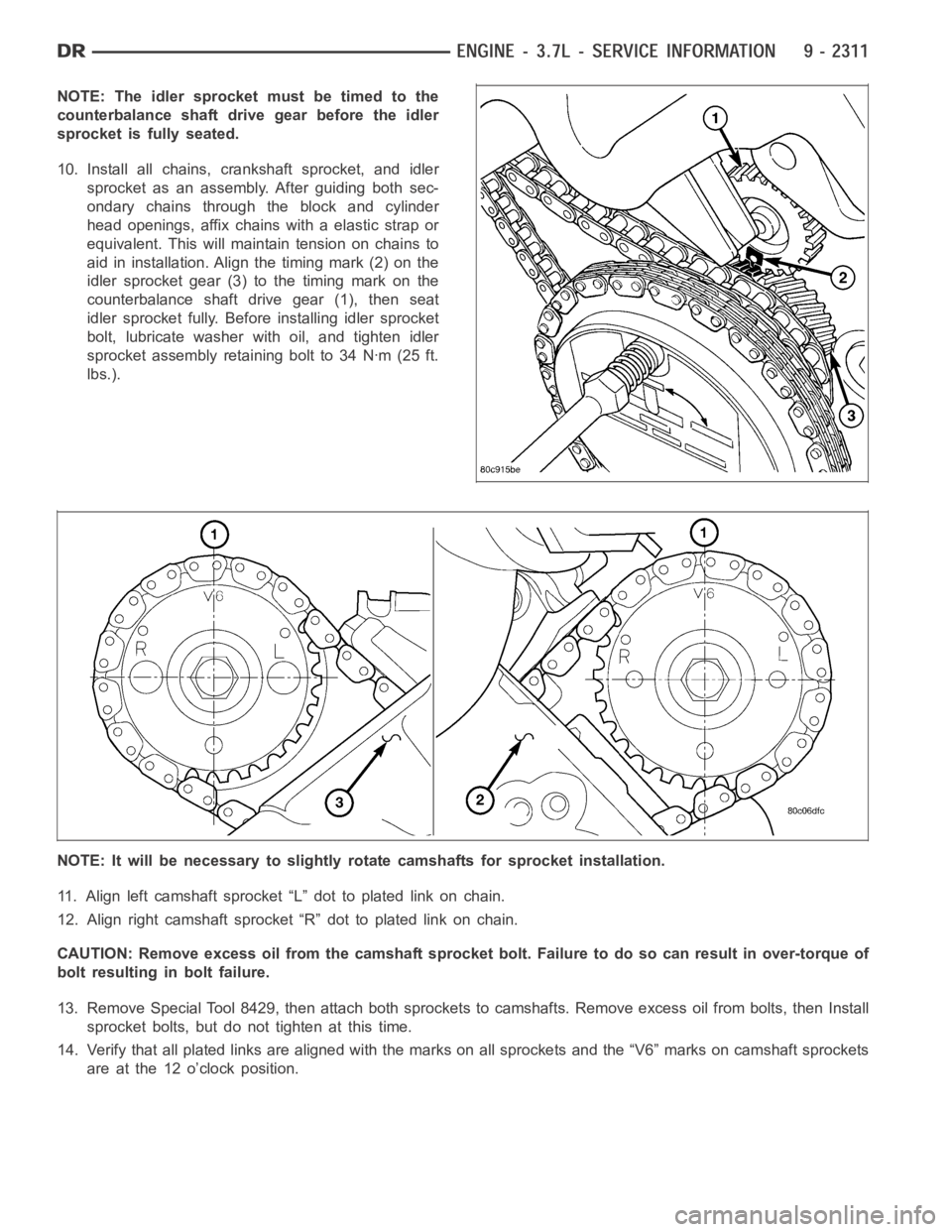

7. Install both secondary chains onto the idler

sprocket. Align two plated links on the secondary

chains to be visible through the two lower openings

on the idler sprocket (4 o’clock and 8 o’clock).

Once the secondary timing chains are installed,

position special tool 8429 (1) to hold chains in

place for installation.

8. Align primary chain double platedlinks with the timing mark at 12 o’clock on the idler sprocket. Align the primary

chain single plated link with the timing mark at 6 o’clock on the crankshaftsprocket.

9. Lubricate idler shaft and bushings with clean engine oil.

Page 1620 of 5267

NOTE: The idler sprocket must be timed to the

counterbalance shaft drive gear before the idler

sprocket is fully seated.

10. Install all chains, crankshaft sprocket, and idler

sprocket as an assembly. After guiding both sec-

ondary chains through the block and cylinder

head openings, affix chains with a elastic strap or

equivalent. This will maintain tension on chains to

aid in installation. Align the timing mark (2) on the

idler sprocket gear (3) to the timing mark on the

counterbalance shaft drive gear (1), then seat

idler sprocket fully. Before installing idler sprocket

bolt, lubricate washer with oil, and tighten idler

sprocketassemblyretainingboltto34Nꞏm(25ft.

lbs.).

NOTE: It will be necessary to slightly rotate camshafts for sprocket installation.

11. Align left camshaft sprocket “L” dot to plated link on chain.

12. Align right camshaft sprocket “R” dot to plated link on chain.

CAUTION: Remove excess oil from the camshaft sprocket bolt. Failure to do so can result in over-torque of

bolt resulting in bolt failure.

13. Remove Special Tool 8429, then attach both sprockets to camshafts. Remove excess oil from bolts, then Install

sprocket bolts, but do not tighten at this time.

14. Verify that all plated links are aligned with the marks on all sprocketsand the “V6” marks on camshaft sprockets

are at the 12 o’clock position.

Page 1625 of 5267

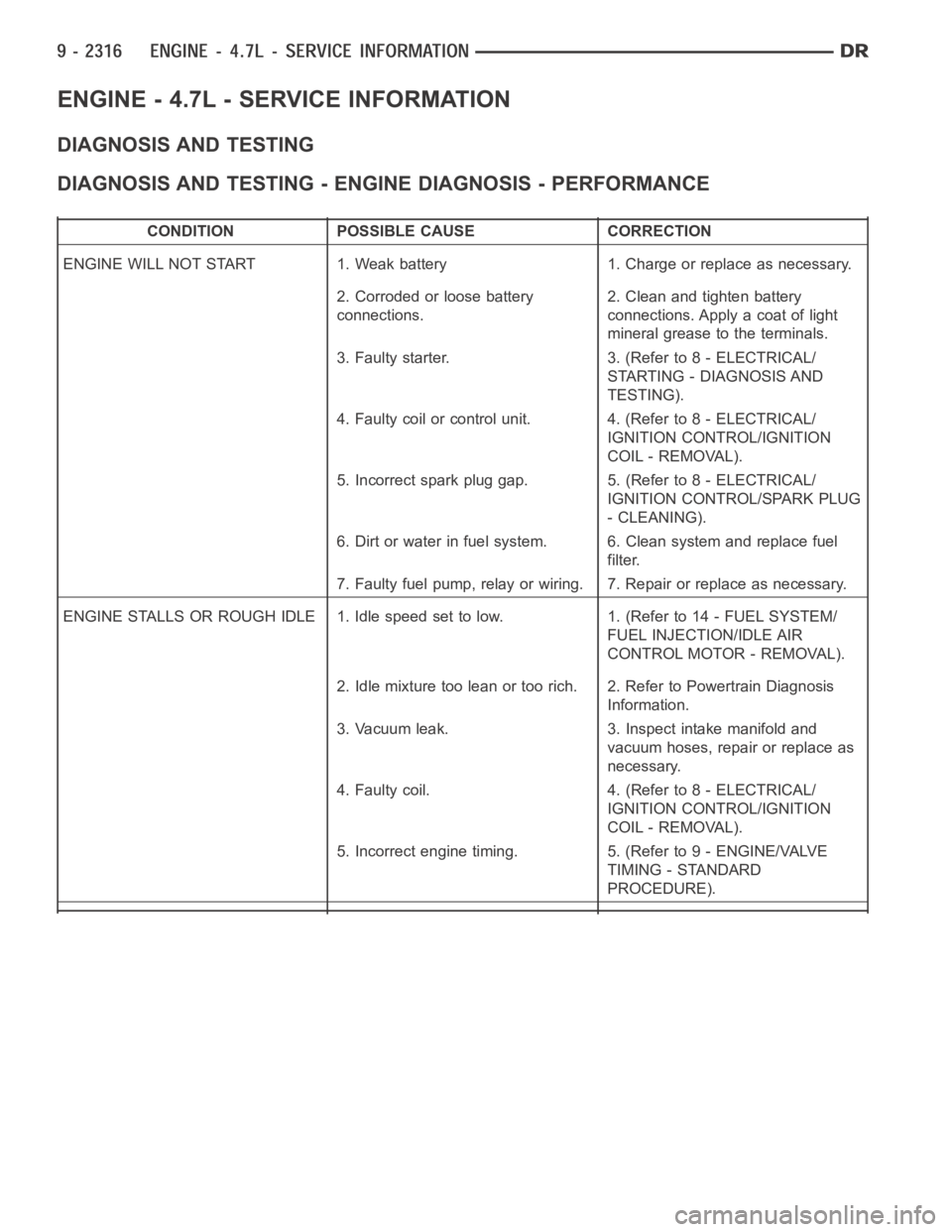

ENGINE - 4.7L - SERVICE INFORMATION

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE DIAGNOSIS - PERFORMANCE

CONDITION POSSIBLE CAUSE CORRECTION

ENGINE WILL NOT START 1. Weak battery 1. Charge or replace as necessary.

2. Corroded or loose battery

connections.2. Clean and tighten battery

connections. Apply a coat of light

mineral grease to the terminals.

3. Faulty starter. 3. (Refer to 8 - ELECTRICAL/

STARTING - DIAGNOSIS AND

TESTING).

4. Faulty coil or control unit. 4. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION

COIL - REMOVAL).

5. Incorrect spark plug gap. 5. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/SPARK PLUG

- CLEANING).

6. Dirt or water in fuel system. 6. Clean system and replace fuel

filter.

7. Faulty fuel pump, relay or wiring. 7. Repair or replace as necessary.

ENGINE STALLS OR ROUGH IDLE 1. Idle speed set to low. 1. (Refer to 14 - FUEL SYSTEM/

FUEL INJECTION/IDLE AIR

CONTROL MOTOR - REMOVAL).

2. Idle mixture too lean or too rich. 2. Refer to Powertrain Diagnosis

Information.

3. Vacuum leak. 3. Inspect intake manifold and

vacuum hoses, repair or replace as

necessary.

4. Faulty coil. 4. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION

COIL - REMOVAL).

5. Incorrect engine timing. 5. (Refer to 9 - ENGINE/VALVE

TIMING - STANDARD

PROCEDURE).

Page 1634 of 5267

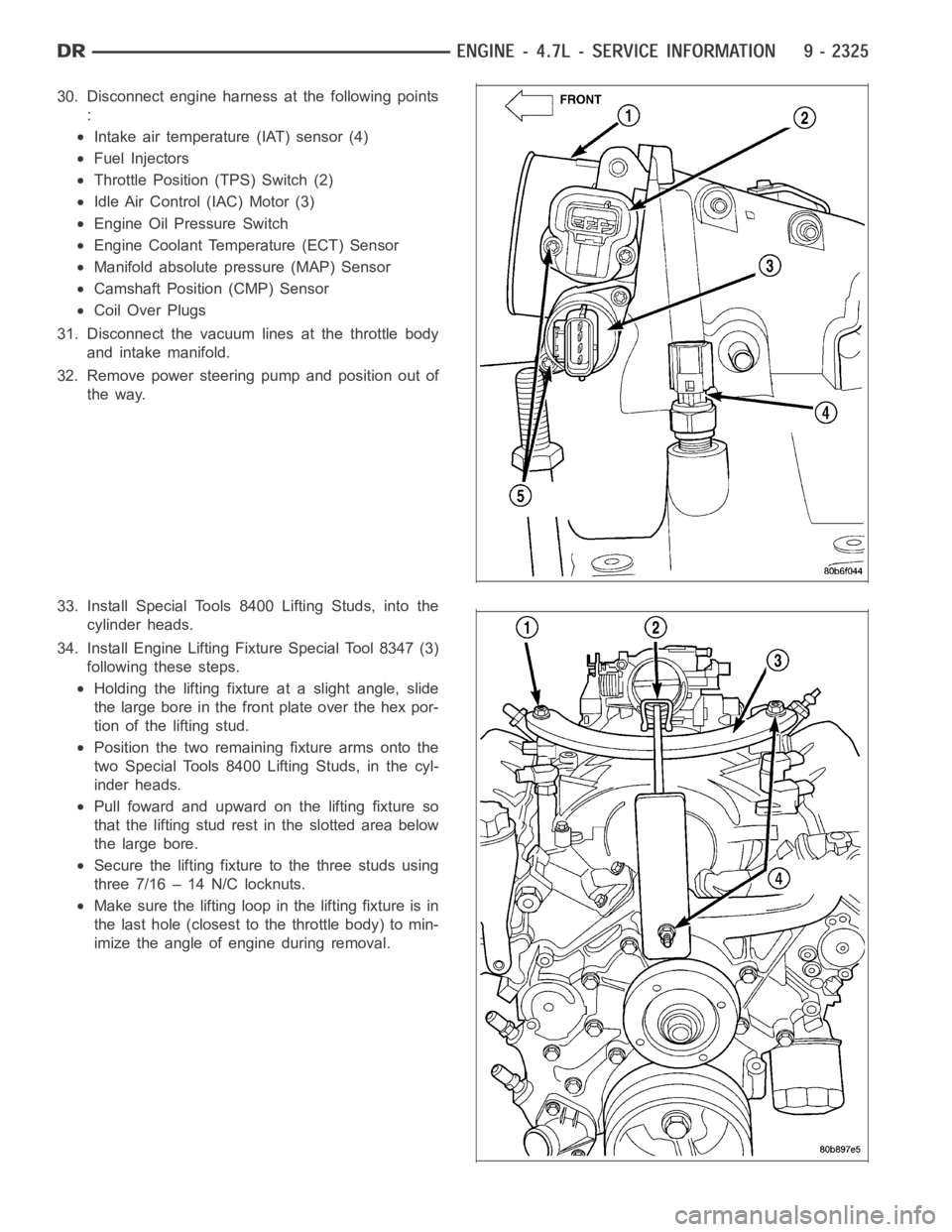

30. Disconnect engine harness at the following points

:

Intake air temperature (IAT) sensor (4)

Fuel Injectors

Throttle Position (TPS) Switch (2)

Idle Air Control (IAC) Motor (3)

Engine Oil Pressure Switch

Engine Coolant Temperature (ECT) Sensor

Manifold absolute pressure (MAP) Sensor

Camshaft Position (CMP) Sensor

Coil Over Plugs

31. Disconnect the vacuum lines at the throttle body

and intake manifold.

32. Remove power steering pump and position out of

the way.

33. Install Special Tools 8400 Lifting Studs, into the

cylinder heads.

34. Install Engine Lifting Fixture Special Tool 8347 (3)

following these steps.

Holding the lifting fixture at a slight angle, slide

the large bore in the front plate over the hex por-

tion of the lifting stud.

Position the two remaining fixture arms onto the

two Special Tools 8400 Lifting Studs, in the cyl-

inder heads.

Pull foward and upward on the lifting fixture so

that the lifting stud rest in the slotted area below

the large bore.

Secure the lifting fixture to the three studs using

three 7/16 – 14 N/C locknuts.

Make sure the lifting loop in the lifting fixture is in

the last hole (closest to the throttle body) to min-

imize the angle of engine during removal.

Page 1688 of 5267

ENGINE BLOCK

DESCRIPTION

The cylinder block is made of cast iron.The block is a closed deck design with the left bank forward. To provide

high rigidity and improved NVH an enhanced compacted graphite bedplate isbolted to the block. The block design

allows coolant flow between the cylinders bores, and an internal coolant bypass to a single poppet inlet thermostat

is included in the cast aluminum front cover.

STANDARD PROCEDURE - CYLINDER BORE HONING

Before honing, stuff plenty of clean shop towels under

the bores and over the crankshaft to keep abrasive

materials from entering the crankshaft area.

1. Used carefully, the Cylinder Bore Sizing Hone

C-823, equipped with 220 grit stones, is the best

tool for this job. In addition to deglazing, it will

reduce taper and out-of-round, as well as removing

light scuffing, scoring and scratches. Usually, a few

strokes will clean up a bore and maintain the

required limits.

CAUTION: DO NOT use rigid type hones to remove

cylinder wall glaze.

2. Deglazing of the cylinder walls may be done if the

cylinder bore is straight and round. Use a cylinder

surfacing hone, Honing Tool C-3501, equipped with

280 grit stones (C-3501-3810). about 20-60

strokes, depending on the bore condition, will be

sufficient to provide a satisfactory surface. Using

honing oil C-3501-3880, or a light honing oil, avail-

able from major oil distributors.

CAUTION: DO NOT use engine or transmission oil, mineral spirits, or kerosene.

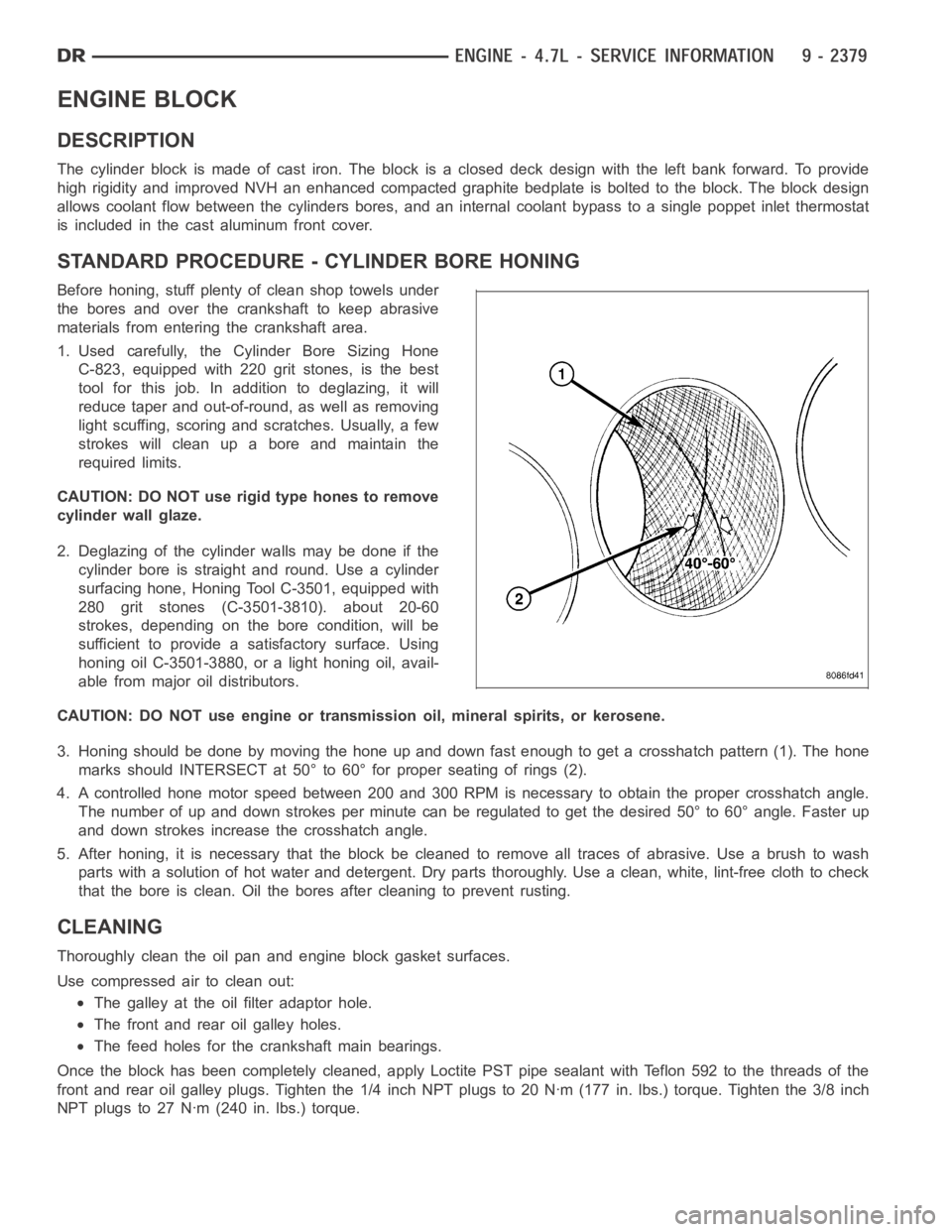

3. Honing should be done by moving the hone up and down fast enough to get a crosshatch pattern (1). The hone

marks should INTERSECT at 50° to 60° for proper seating of rings (2).

4. A controlled hone motor speed between 200 and 300 RPM is necessary to obtain the proper crosshatch angle.

The number of up and down strokes per minute can be regulated to get the desired 50° to 60° angle. Faster up

and down strokes increase the crosshatch angle.

5. After honing, it is necessary that the block be cleaned to remove all traces of abrasive. Use a brush to wash

parts with a solution of hot water and detergent. Dry parts thoroughly. Usea clean, white, lint-free cloth to check

that the bore is clean. Oil the bores after cleaning to prevent rusting.

CLEANING

Thoroughly clean the oil pan and engine block gasket surfaces.

Use compressed air to clean out:

The galley at the oil filter adaptor hole.

The front and rear oil galley holes.

The feed holes for the crankshaft main bearings.

Once the block has been completely cleaned, apply Loctite PST pipe sealantwith Teflon 592 to the threads of the

front and rear oil galley plugs. Tighten the 1/4 inch NPT plugs to 20 Nꞏm (177in. lbs.) torque. Tighten the 3/8 inch

NPT plugs to 27 Nꞏm (240 in. lbs.) torque.

Page 1689 of 5267

INSPECTION

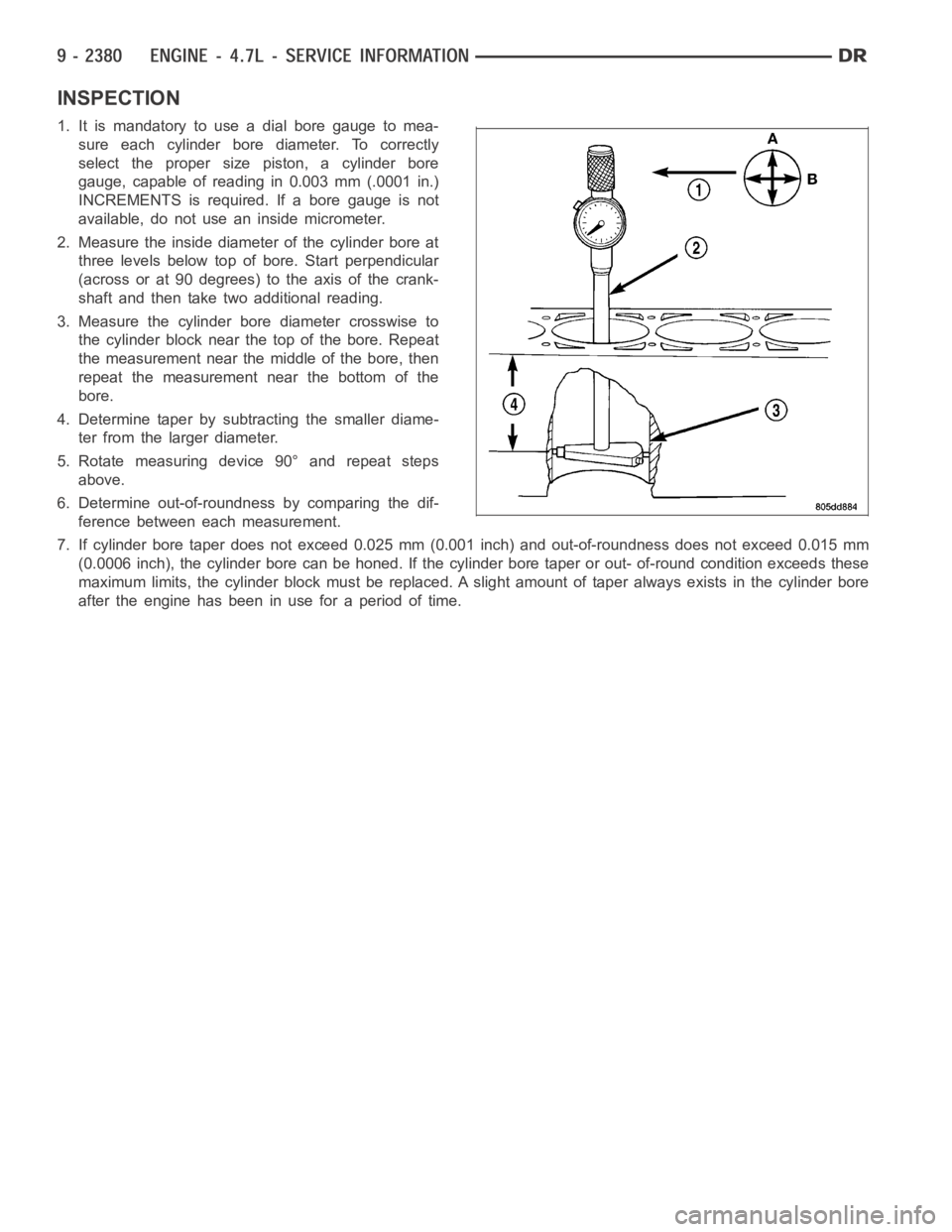

1. It is mandatory to use a dial bore gauge to mea-

sure each cylinder bore diameter. To correctly

select the proper size piston, a cylinder bore

gauge, capable of reading in 0.003 mm (.0001 in.)

INCREMENTS is required. If a bore gauge is not

available, do not use an inside micrometer.

2. Measure the inside diameter of the cylinder bore at

three levels below top of bore. Start perpendicular

(across or at 90 degrees) to the axis of the crank-

shaft and then take two additional reading.

3. Measure the cylinder bore diameter crosswise to

the cylinder block near the top of the bore. Repeat

the measurement near the middle of the bore, then

repeat the measurement near the bottom of the

bore.

4. Determine taper by subtracting the smaller diame-

ter from the larger diameter.

5. Rotate measuring device 90° and repeat steps

above.

6. Determine out-of-roundness by comparing the dif-

ference between each measurement.

7. If cylinder bore taper does not exceed 0.025 mm (0.001 inch) and out-of-roundness does not exceed 0.015 mm

(0.0006 inch), the cylinder bore can be honed. If the cylinder bore taper orout- of-round condition exceeds these

maximum limits, the cylinder block must be replaced. A slight amount of taper always exists in the cylinder bore

after the engine has been in use for a period of time.