ABS DODGE RAM SRT-10 2006 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 905 of 5267

U1412-IMPLAUSIBLE VEHICLE SPEED SIGNAL RECEIVED

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Ignition on.

Set Condition:

The ECM gets an implausible signal over the CAN C circuit from the ABS Module. The circuit is continuously

monitored. One Trip fault.

Possible Causes

CAN C BUS CIRCUIT SHORTED

CAN C BUS CIRCUIT OPEN

ABS MODULE

ECM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Theory of Operation

The ABS Module sends vehicle speed information over the CAN C Bus circuit tothe ECM.

Diagnostic Test

1.ACTIVE DTC

Ignition on, engine not running.

With a scan tool, read DTCs.

Is the U1412-IMPLAUSIBLE VEHICLE SPEED SIGNAL RECEIVED active at this time?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.U0001-NO COMMUNICATION ON THE CAN C BUS CIRCUIT IS ACTIVE

Continue reading DTCs.

Is the U0001-NO COMMUNICATION ON THE CAN C BUS CIRCUIT ACTIVE at this time?

Ye s>>

Refer to the Diagnostic Procedure for the U0001-NO COMMUNICATION ON THE CANCBUSCIR-

CUIT.

No>>

Go To 3

3.ABS MODULE IS ACTIVE ON THE CAN C BUS

With the scan tool, select ECU View.

Verify that the ABS Module active on the bus.

Is the ABS Module active on the bus?

Ye s>>

Go To 4

No>>

(Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL MODULES - DIAGNOSIS AND TESTING) for No

Response diagnostic procedures.

Perform BODY VERIFICATION TEST – VER 1.

Page 906 of 5267

4.ACTIVE DTCS IN THE FCM

With the scan tool, select ECU View and select FCM (TIPM).

With the scan tool, read active DTCs.

Is the U0001-NO COMMUNICATION ON THE CAN C BUS CIRCUIT ACTIVE in the FCM at this time?

Ye s>>

Replace the ABS Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 1296 of 5267

When Monitored:

Engine Temperature greater than 104 Deg F, MAP vacuum approximately 15

to 16inches of mercury and

Engine RPM between 1400 and 3000 rpm.

Set Condition:

No Vehicle Speed Signal for more than 15 seconds on two consecutive trips.

Possible Causes

(B22) VEHICLE SPEED SIGNAL CIRCUIT SHORTED TO VOLTAGE

(B22) VEHICLE SPEED SIGNAL CIRCUIT OPEN BETWEEN CAB AND PCM

(B22) VEHICLE SPEED SIGNAL CIRCUIT SHORTED TO GROUND

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

1.GOOD TRIP EQUAL TO ZERO

Ignition on, engine not running.

NOTE: With the scan tool check for any related DTCs that may be present in theABS/RWAL Module or TCM,

diagnose any ABS/RWAL Module DTC’s before continuing.

With the scan tool, read DTCs and record the related Freeze Frame data.

Is the Good Trip Counter displayed and equal to zero?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDTION Diagnostic Procedure.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

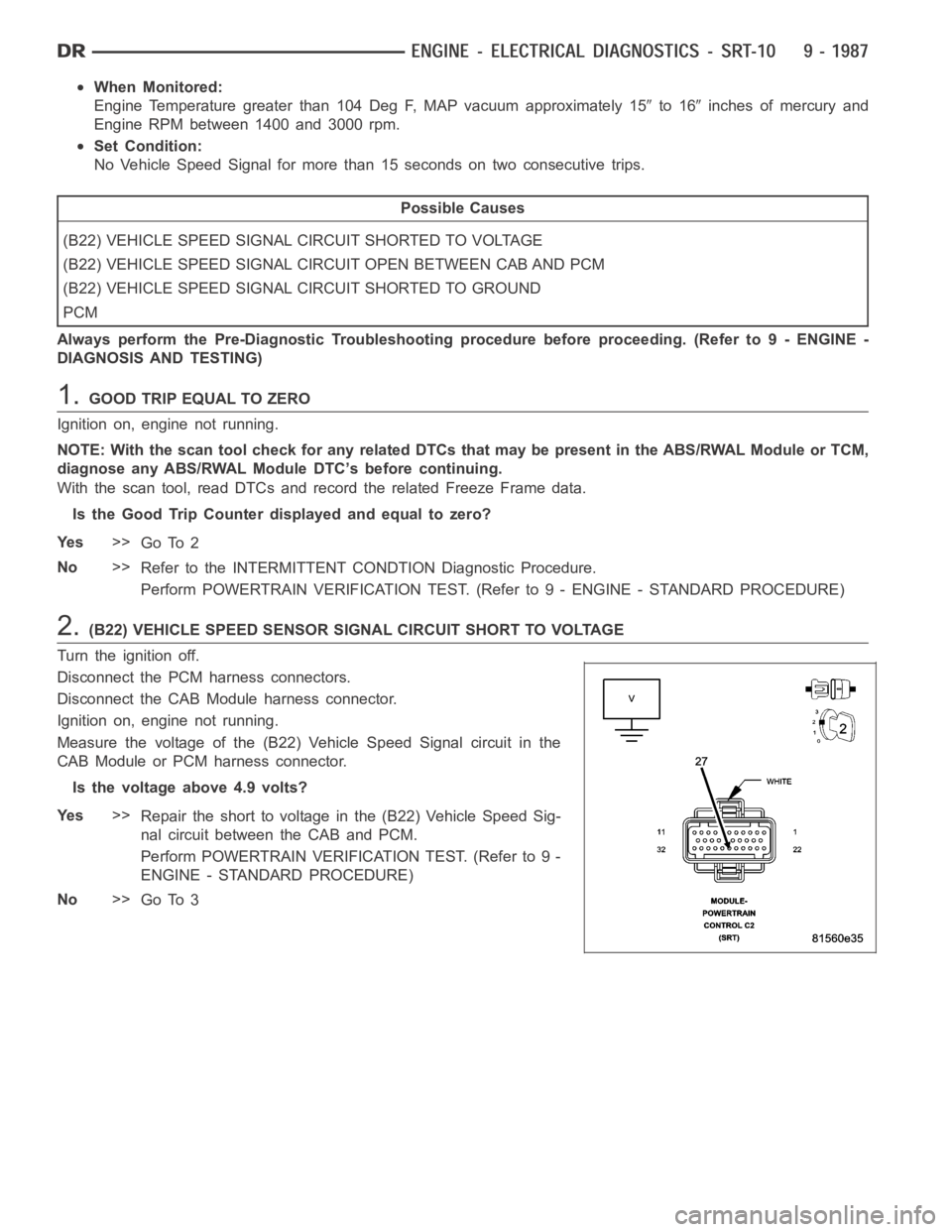

2.(B22) VEHICLE SPEED SENSOR SIGNAL CIRCUIT SHORT TO VOLTAGE

Turn the ignition off.

Disconnect the PCM harness connectors.

Disconnect the CAB Module harness connector.

Ignition on, engine not running.

Measure the voltage of the (B22) Vehicle Speed Signal circuit in the

CAB Module or PCM harness connector.

Is the voltage above 4.9 volts?

Ye s>>

Repair the short to voltage in the (B22) Vehicle Speed Sig-

nal circuit between the CAB and PCM.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 -

ENGINE - STANDARD PROCEDURE)

No>>

Go To 3

Page 1483 of 5267

POWERTRAIN VERIFICATION TEST

For a complete wiring diagramRefer to Section 8W.

Diagnostic Test

1.SELECTING THE PROPER VERIFICATION TEST

The following verification test are for different repairs. Select the appropriate Verification test for the

repair that has been completed.

Speed Control repair

Go To 2

Charging System repair

Go To 3

NVLD System repair

Go To 4

All other repairs

Go To 5

2.POWERTRAIN VERIFICATION TEST 1

NOTE: 1. If this vehicle is equipped with an Electronic Throttle Control system, and the APP Sensors, PCM,

or Throttle Body Assembly have been replaced, use the scan tool to perform the ETC RELEARN function.

NOTE: 2. After completing the Powertrain Verification Test the Transmission Verification Test must be per-

formed.

NOTE: 3. If the PCM has been replaced and the correct VIN and mileage have notbeen programmed, a DTC

will set in the ABS Module, Airbag Module and the SKIM/SKREEM.

NOTE: 4. If the vehicle is equipped with a Sentry Key Remote Entry, Secret Key data must be updated. Refer

to the Service Information for the PCM, SKIM/SKREEM and the Transponder (ignition key) for programming

information. Using the scan tool, program the Secret Key information intothe PCM using the PCM replaced

function under the WCM menu.

5. Inspect the vehicle to make sure that all engine components are properlyinstalled and connected.

6. Connect the scan tool to the data link connector and erase all codes.

7. Turn the speed control ON (if equipped, cruise light will be on).

8. Depress and release the SET Switch when the vehicle speed is greater than35 MPH. The speed control should

engage and hold the selected speed.

9. Press and hold the RESUME/ACCEL Switch. The vehicle speed should increase by at least 2 MPH.

10. Press and hold the COAST switch. The vehicle speed should decrease.

11. Using caution, press and release the brake pedal. The speed control should disengage.

12. Bring the vehicle speed back up to 35 MPH.

13. Press the RESUME/ACCEL switch. The speed control should resume the previously set speed.

14. Hold down the SET switch. The vehicle should decelerate.

15. Make sure vehicle speed is greater than 35 mph and release the SET Switch. The vehicle should adjust and set

a new vehicle speed.

16. Press and release the CANCEL switch. The speed control should disengage.

17. Bring the vehicle speed back up above 35 mph and engage speed control.

18. Turn the Speed Control Off. (Cruise light will be off). The speed control should disengage.

NOTE: OVERSHOOT/UNDERSHOOT FOLLOWING SPEED CONTROL SET.

19. If the vehicle operator repeatedly presses and releases the SET buttonwith their foot off of the accelerator

(referred to as

lift foot set), the vehicle may accelerate and exceed the desired set speed by up to 5 mph (8km/h).

20. It may also decelerate to less than the desired set speed, before finally achieving the desired set speed.

21. The Speed Control System has an adaptive strategy that compensates forvehicle-to-vehicle variations in speed

control cable lengths.

22. When the speed control is set with the vehicles operators foot off of theaccelerator pedal, the speed control

thinks there is excessive speed control cable slack and adapts accordingly.

Page 1484 of 5267

23. If thelift foot setsare continually used, a speed control overshoot/undershoot condition will develop.

24. To

unlearnthe overshoot/undershoot condition, the vehicle operator has to press and release the set button

while maintaining the desired set speedusing the accelerator pedal (not decelerating or accelerating).

25. Then turn the cruise control switch to the OFF position (or press the CANCEL button if equipped) after waiting

10 seconds.

26. This procedure must be performed approximately 10-15 times to completely unlearn the overshoot/undershoot

condition.

Did the Speed Control pass the above test?

Ye s>>

Repair is complete.

No>>

Check for any related Technical Service Bulletins and/or refer to the appropriate Diagnostic Procedure.

3.POWERTRAIN VERIFICATION TEST 2

1. If this vehicle is equipped with an Electronic Throttle Control system,and the APP Sensors, PCM, or Throttle

Body Assembly has been replaced use a scan tool to perform the ETC RELEARN function.

NOTE: 2. After completing the Powertrain Verification Test the Transmission Verification Test must be per-

formed.

NOTE: 3. If the PCM has been replaced and the correct VIN and mileage have notbeen programmed, a DTC

will set in the ABS Module, Airbag Module and the SKIM/SKREEM.

NOTE: 4. If the vehicle is equipped with a Sentry Key Remote Entry, Secret Key data must be updated. Refer

to the Service Information for the PCM, SKIM/SKREEM and the Transponder (ignition key) for programming

information. Using the scan tool, program the Secret Key information intothe PCM using the PCM replaced

function under the WCM menu.

5. Inspect the vehicle to make sure that all components related to the repair are properly installed and connected.

6. With the scan tool, clear DTCs.

7. Perform generator output test. Refer to the appropriate service information as necessary.

8. Start the engine and set engine speed to 2000 RPM for at least thirty seconds.

9. Cycle the ignition key off and on.

10. With the scan tool, read the DTCs.

Are any DTCs or symptoms remaining?

Ye s>>

Check for any Technical Service Bulletins and/or refer to the appropriateDiagnostic Procedure.

No>>

Repair is complete.

4.POWERTRAIN VERIFICATION TEST 3

1. Install the Miller Tool #8404 Evaporative Emission Leak Detector (EELD) according to the instructions in the pre-

vious DTC table.

2. Set the smoke/air control switch to AIR.

3. Insert the tester’s AIR supply tip (clear hose) into the appropriate calibration orifice on the tester’s control panel

(based on DTC leak size).

4. Press the remote smoke/air start button.

5. Position the red flag on the air flow meter so it is aligned with the indicator ball.

6. When the calibration is complete, release the remote button. The EELD flow meter is now calibrated in liters per

minute to the size of leak indicated by the DTC set in the PCM.

7. Install the service port adapter #8404-14 on the vehicle’s service port.

8. Connect the Air supply hose from the EELD to the vehicle.

9. Press the remote button to activate AIR flow.

NOTE: 10. Larger volume fuel tanks, lower fuel levels or if the vehicle is equipped with a Flow Management

Valve may indicate high flow and will require 4 to 5 minutes to fill.

11. Compare the flow meter indicator ball reading to the red flag.

12. ABOVE the red flag indicates a leak present.

13. BELOW the red flag indicates a sealed system.

Page 1485 of 5267

NOTE: If this vehicle is equipped with an Electronic Throttle Control system, and the APP Sensors, PCM, or

Throttle Body Assembly have been replaced, use the scan tool to perform theETC RELEARN function.

14. If the indicator ball shows a leak present, perform the smoke test indicated in the previous test and identify the

leak and repair. Perform this verification test when the repair is complete.

Didtheindicatorballindicatethealeakispresent?

Ye s>>

Repeat the DTC test to identify the leak and repair.

No>>

Repair is complete.

5.POWERTRAIN VERIFICATION TEST 4

NOTE: 1. After completing the Powertrain Verification Test the Transmission Verification Test must be per-

formed.

NOTE: 2. If the PCM has been replaced and the correct VIN and mileage have notbeen programmed, a DTC

will set in the ABS Module, Airbag Module and the SKIM/SKREEM.

NOTE: 3. If the vehicle is equipped with a Sentry Key Remote Entry, Secret Key data must be updated. Refer

to the Service Information for the PCM, SKIM/SKREEM and the Transponder (ignition key) for programming

information. Using the scan tool, program the Secret Key information intothe PCM using the PCM replaced

function under the WCM menu.

NOTE: 4. If this vehicle is equipped with an Electronic Throttle Control system, and the APP Sensors, PCM,

or Throttle Body Assembly have been replaced, use the scan tool to perform the ETC RELEARN function.

NOTE: 5. When replacing an O2 Sensor, the PCM RAM memory must be cleared, either by disconnecting the

PCM C1 connector or momentarily disconnecting the Battery negative terminal.

6. The NGC learns the characteristics of each O2 heater element and these old values should be cleared when

installing a new O2 sensor. The customermay experience driveability issues if this is not performed.

7. Inspect the vehicle to make sure that all engine components are properlyinstalled and connected. Reassemble

and reconnect components as necessary.

8. Connect the scan tool to the data link connector.

9. Make sure the fuel tank has at least a quarter tank of fuel. Turn off all accessories.

10. If the Catalyst was replaced, with the scan tool go to the MiscellaneousMenu Option

Catalyst Replacedand

press enter.

11. If a Comprehensive Component DTC was repaired, perform steps 12 - 14. Ifa Major OBDII Monitor DTC was

repaired skip those steps and continue verification.

12. After the ignition has been off for at least 10 seconds, restart the vehicle and run 2 minutes.

13. With the scan tool, monitor the appropriate pre-test enabling conditions until all conditions have been met. Once

the conditions have been met, switch screen to the appropriate OBDII monitor, (Audible beeps when the monitor is

running).

14. If the repaired OBDII trouble code has reset or was seen in the monitor while on the road test, the repair is not

complete. Check for any related technical service bulletins or flash updates and return to Engine Electrical Diag-

nostic List.

15. If the conditions cannot be duplicated, erase all DTCs with the Scan tool.

16. If another DTC has set, return to the Engine Electrical Diagnostic Listand follow the path specified for that DTC.

Did the OBDII Monitor run successfully and has the Good Trip Counter changed to one or more?

Ye s>>

Repair is complete.

No>>

Check for any related Technical Service Bulletins and/or refer to the appropriate Diagnostic Procedure.

Page 1496 of 5267

MoparGasket Maker is an anaerobic type gasket material. The material cures in the absence of air when

squeezed between two metallic surfaces. It will not cure if left in the uncovered tube. The anaerobic material is for

use between two machined surfaces. Do not use on flexible metal flanges.

MOPAR

GASKET SEALANT

Mopar

Gasket Sealant is a slow drying, permanently soft sealer. This material isrecommended for sealing

threaded fittings and gaskets against leakage of oil and coolant. Can be used on threaded and machined parts

under all temperatures. This material is used on engines with multi-layersteel (MLS) cylinder head gaskets. This

material also will prevent corrosion. Mopar

Gasket Sealant is available in a 13 oz. aerosol can or 4oz./16 oz. can

w/applicator.

FORM-IN-PLACE GASKET AND SEALER APPLICATION

Assembling parts using a form-in-place gasket requires care but it’s easier than using precut gaskets.

Mopar

Gasket Maker material should be applied sparingly 1 mm (0.040 in.) diameter or less of sealant to one

gasket surface. Be certain the material surrounds each mounting hole. Excess material can easily be wiped off.

Components should be torqued in place within 15 minutes. The use of a locating dowel is recommended during

assembly to prevent smearing material off the location.

Mopar

Engine RTV GEN II or ATF RTV gasket material should be applied in a continuous bead approximately 3

mm (0.120 in.) in diameter. All mounting holes must be circled. For corner sealing, a 3.17 or 6.35 mm (1/8 or 1/4 in.)

drop is placed in the center of the gasket contact area. Uncured sealant maybe removed with a shop towel. Com-

ponents should be torqued in place while the sealant is still wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to prevent smearing material off the location.

Mopar

Gasket Sealant in an aerosol can should be applied using a thin, even coat sprayed completely over both

surfaces to be joined, and both sides of a gasket. Then proceed with assembly. Material in a can w/applicator can

be brushed on evenly over the sealing surfaces. Material in an aerosol can shouldbeusedonengineswithmulti-

layer steel gaskets.

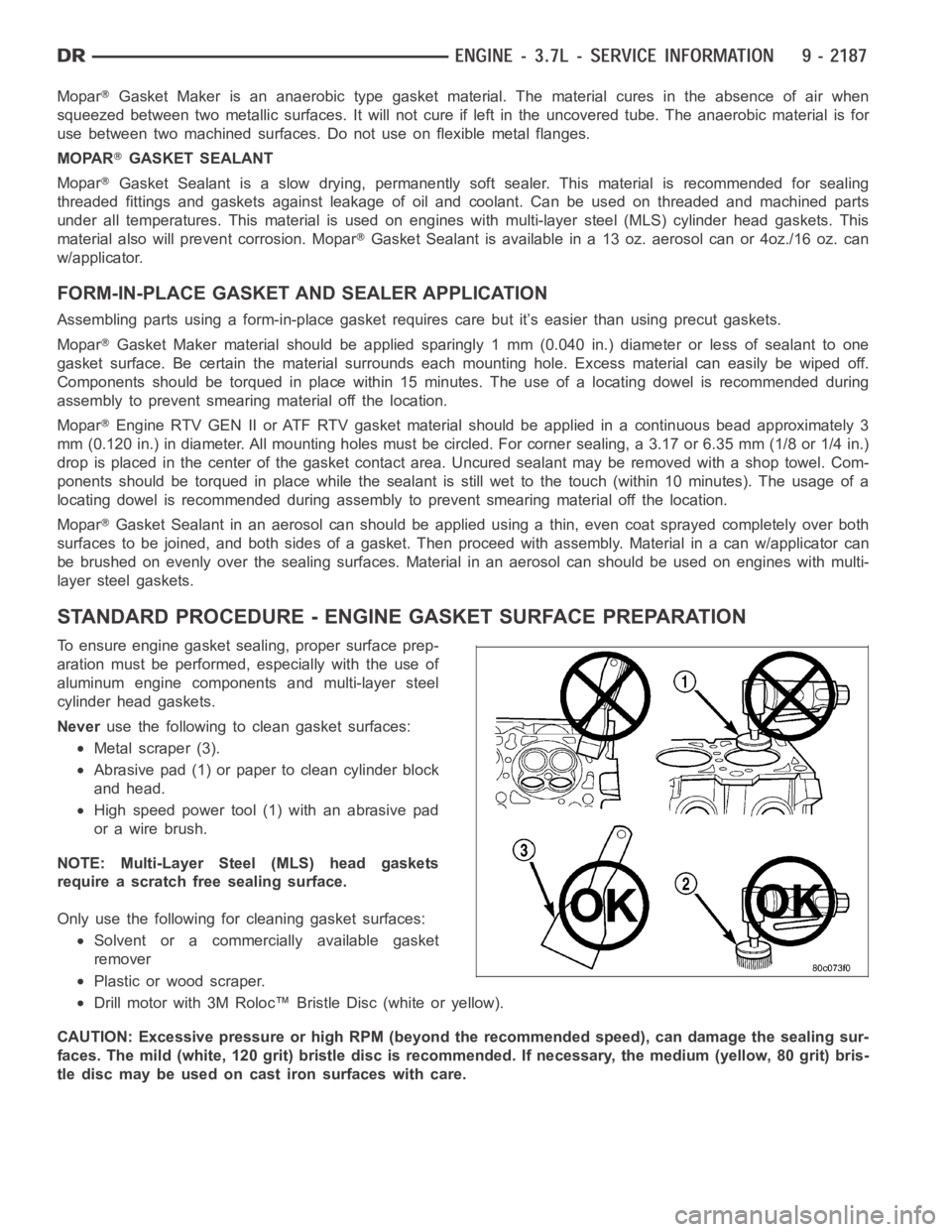

STANDARD PROCEDURE - ENGINE GASKET SURFACE PREPARATION

To ensure engine gasket sealing, proper surface prep-

aration must be performed, especially with the use of

aluminum engine components and multi-layer steel

cylinder head gaskets.

Neveruse the following to clean gasket surfaces:

Metal scraper (3).

Abrasive pad (1) or paper to clean cylinder block

and head.

High speed power tool (1) with an abrasive pad

orawirebrush.

NOTE: Multi-Layer Steel (MLS) head gaskets

require a scratch free sealing surface.

Only use the following for cleaning gasket surfaces:

Solvent or a commercially available gasket

remover

Plastic or wood scraper.

Drill motor with 3M Roloc™ Bristle Disc (white or yellow).

CAUTION: Excessive pressure or high RPM (beyond the recommended speed), can damage the sealing sur-

faces. The mild (white, 120 grit) bristle disc is recommended. If necessary, the medium (yellow, 80 grit) bris-

tle disc may be used on cast iron surfaces with care.

Page 1498 of 5267

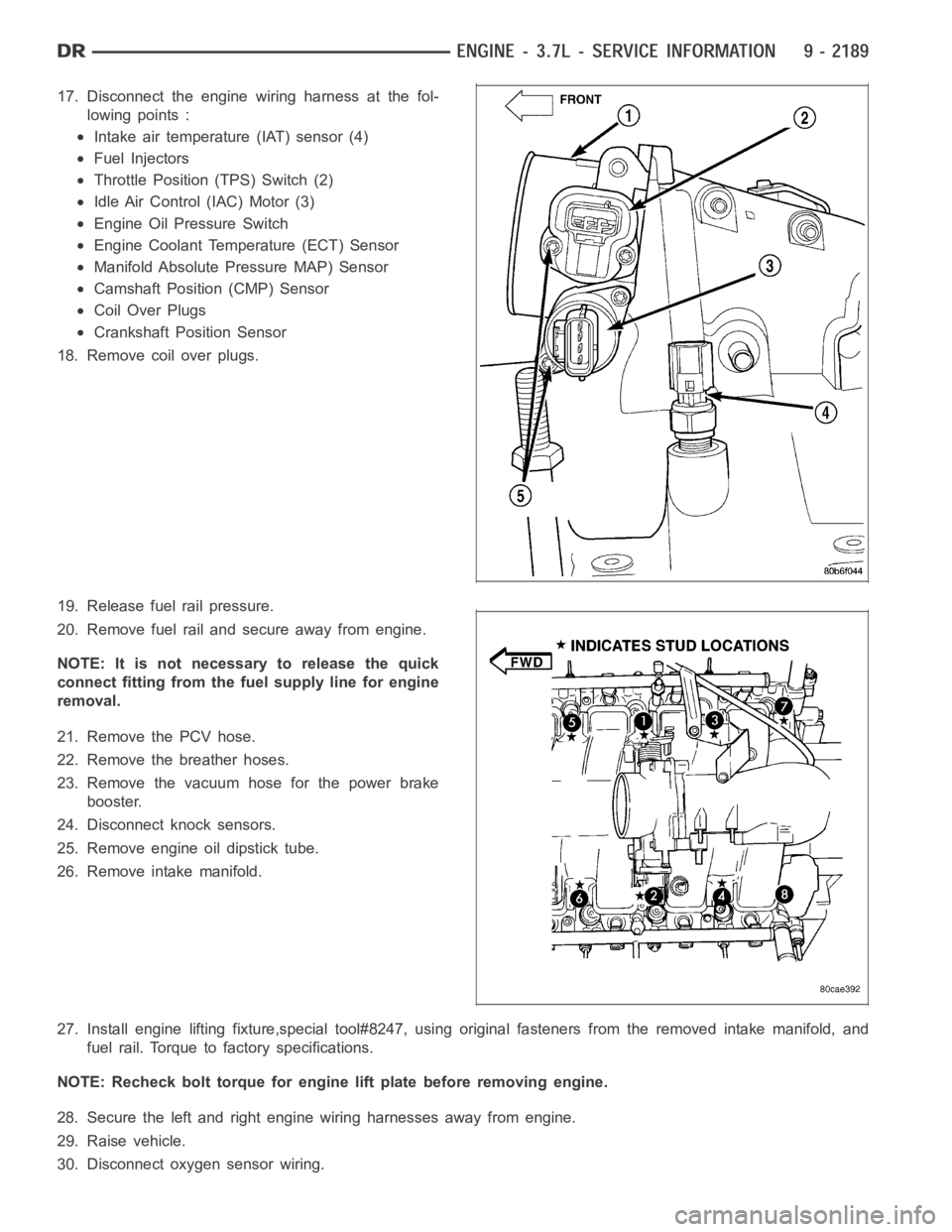

17. Disconnect the engine wiring harness at the fol-

lowing points :

Intake air temperature (IAT) sensor (4)

Fuel Injectors

Throttle Position (TPS) Switch (2)

Idle Air Control (IAC) Motor (3)

Engine Oil Pressure Switch

Engine Coolant Temperature (ECT) Sensor

Manifold Absolute Pressure MAP) Sensor

Camshaft Position (CMP) Sensor

Coil Over Plugs

Crankshaft Position Sensor

18. Remove coil over plugs.

19. Release fuel rail pressure.

20. Remove fuel rail and secure away from engine.

NOTE: It is not necessary to release the quick

connect fitting from the fuel supply line for engine

removal.

21. Remove the PCV hose.

22. Remove the breather hoses.

23. Remove the vacuum hose for the power brake

booster.

24. Disconnect knock sensors.

25. Remove engine oil dipstick tube.

26. Remove intake manifold.

27. Install engine lifting fixture,special tool#8247, using original fasteners from the removed intake manifold, and

fuel rail. Torque to factory specifications.

NOTE: Recheck bolt torque for engine lift plate before removing engine.

28. Secure the left and right engine wiring harnesses away from engine.

29. Raise vehicle.

30. Disconnect oxygen sensor wiring.

Page 1503 of 5267

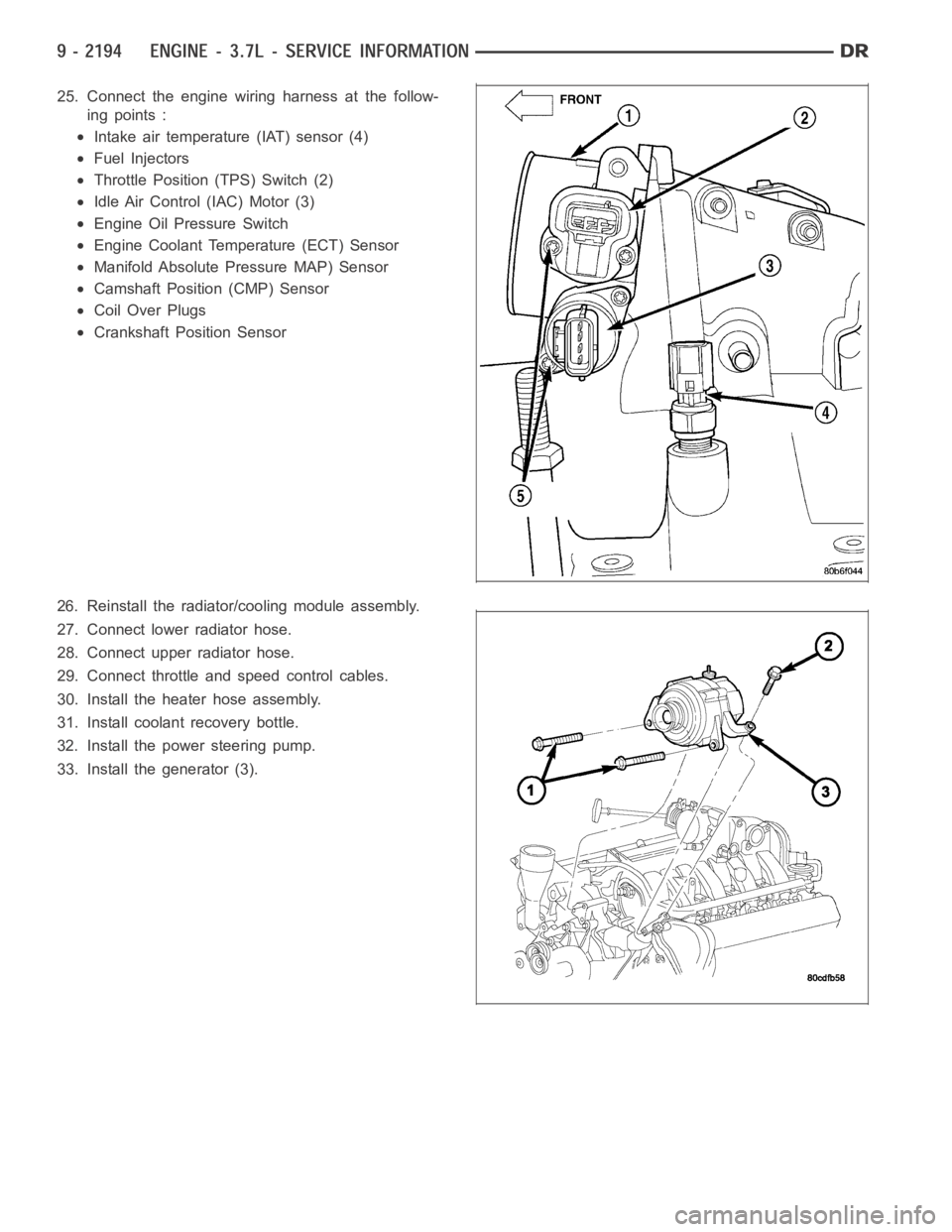

25. Connect the engine wiring harness at the follow-

ing points :

Intake air temperature (IAT) sensor (4)

Fuel Injectors

Throttle Position (TPS) Switch (2)

Idle Air Control (IAC) Motor (3)

Engine Oil Pressure Switch

Engine Coolant Temperature (ECT) Sensor

Manifold Absolute Pressure MAP) Sensor

Camshaft Position (CMP) Sensor

Coil Over Plugs

Crankshaft Position Sensor

26. Reinstall the radiator/cooling module assembly.

27. Connect lower radiator hose.

28. Connect upper radiator hose.

29. Connect throttle and speed control cables.

30. Install the heater hose assembly.

31. Install coolant recovery bottle.

32. Install the power steering pump.

33. Install the generator (3).

Page 1515 of 5267

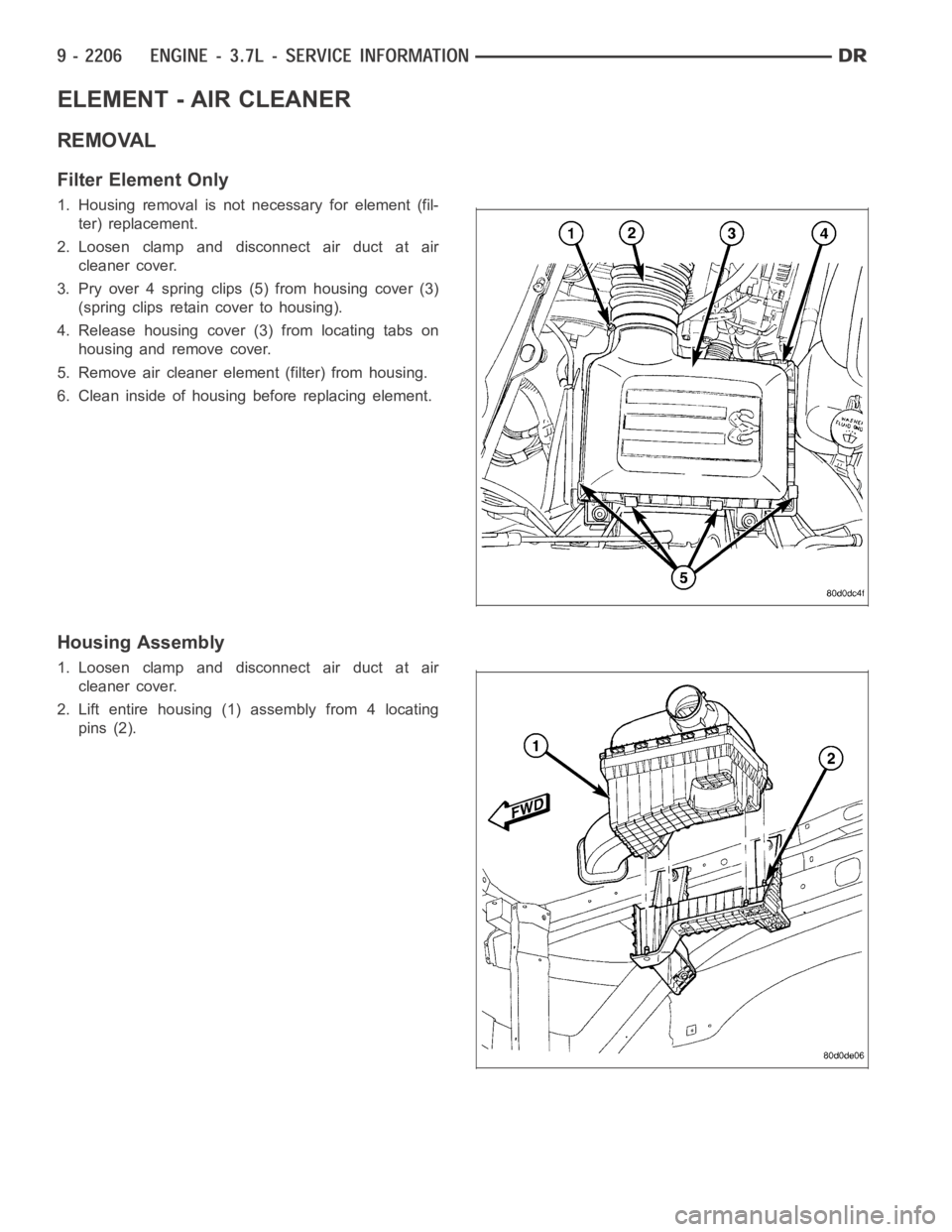

ELEMENT - AIR CLEANER

REMOVAL

Filter Element Only

1. Housing removal is not necessary for element (fil-

ter) replacement.

2. Loosen clamp and disconnect air duct at air

cleaner cover.

3. Pry over 4 spring clips (5) from housing cover (3)

(spring clips retain cover to housing).

4. Release housing cover (3) from locating tabs on

housing and remove cover.

5. Remove air cleaner element (filter) from housing.

6. Clean inside of housing before replacing element.

Housing Assembly

1. Loosen clamp and disconnect air duct at air

cleaner cover.

2. Lift entire housing (1) assembly from 4 locating

pins (2).