ABS DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 5161 of 5267

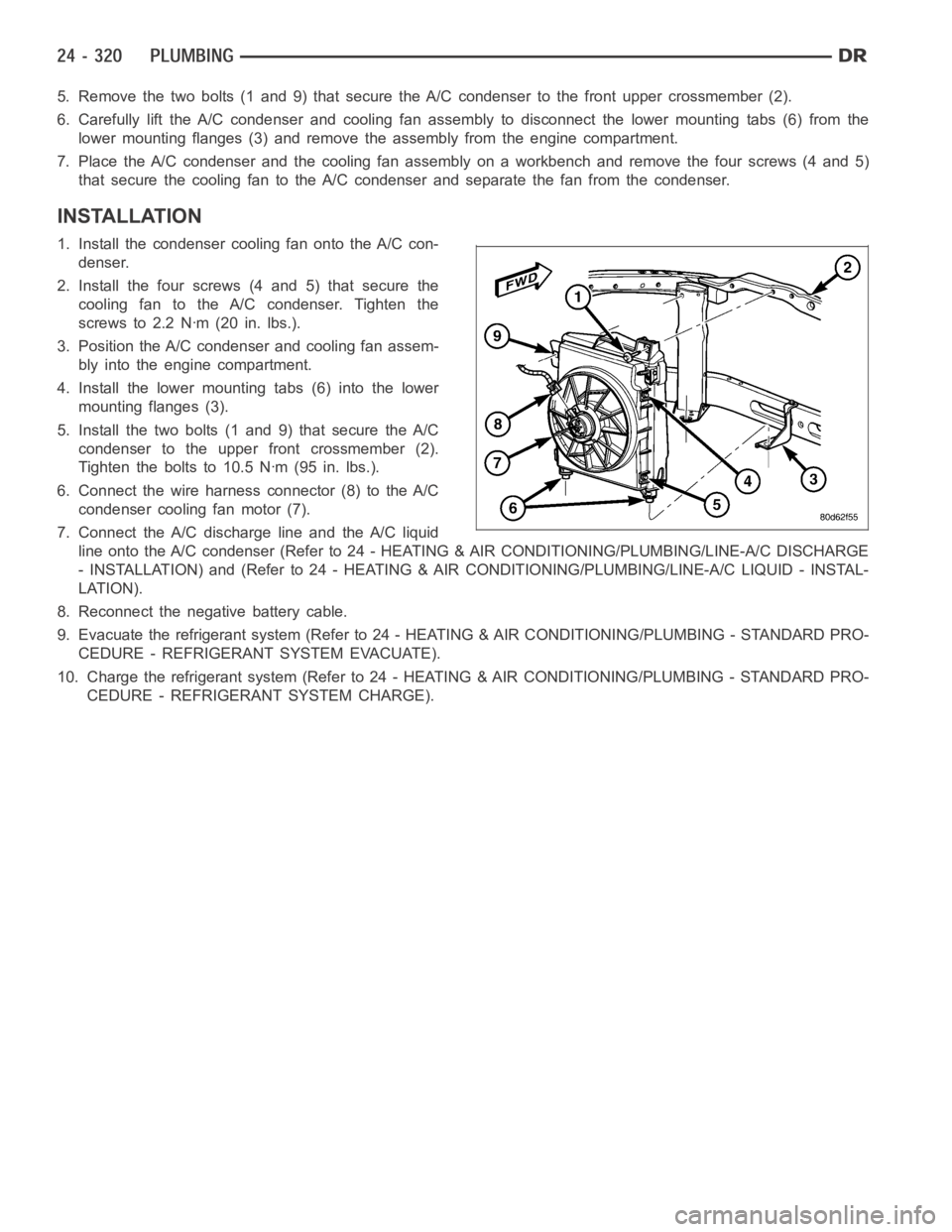

5. Remove the two bolts (1 and 9) that secure the A/C condenser to the front upper crossmember (2).

6. Carefully lift the A/C condenser and cooling fan assembly to disconnectthe lower mounting tabs (6) from the

lower mounting flanges (3) and remove the assembly from the engine compartment.

7. Place the A/C condenser and the cooling fan assembly on a workbench and remove the four screws (4 and 5)

that secure the cooling fan to the A/C condenser and separate the fan from the condenser.

INSTALLATION

1. Install the condenser cooling fan onto the A/C con-

denser.

2. Install the four screws (4 and 5) that secure the

cooling fan to the A/C condenser. Tighten the

screws to 2.2 Nꞏm (20 in. lbs.).

3. Position the A/C condenser and cooling fan assem-

bly into the engine compartment.

4. Install the lower mounting tabs (6) into the lower

mounting flanges (3).

5. Install the two bolts (1 and 9) that secure the A/C

condenser to the upper front crossmember (2).

Tighten the bolts to 10.5 Nꞏm (95 in. lbs.).

6. Connect the wire harness connector (8) to the A/C

condenser cooling fan motor (7).

7. Connect the A/C discharge line and the A/C liquid

line onto the A/C condenser (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING/LINE-A/C DISCHARGE

- INSTALLATION) and (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING/LINE-A/C LIQUID - INSTAL-

LATION).

8. Reconnect the negative battery cable.

9. Evacuate the refrigerant system (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE - REFRIGERANT SYSTEM EVACUATE).

10. Charge the refrigerant system (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE - REFRIGERANT SYSTEM CHARGE).

Page 5188 of 5267

OIL-A/C REFRIGERANT

DESCRIPTION

The refrigerant oil used in R-134a refrigerant systems is a synthetic-based, polyalkylene glycol (PAG), wax-free

lubricant. Mineral-based R-12 refrigerant oils are not compatible with PAG oils, and should never be introduced to

an R-134a refrigerant system.

There are different PAG oils available, and each contains a different additive package. Useonlyrefrigerant oil of the

same type as recommended to service the refrigerant system (always refer to the specification tagincluded with

the replacement A/C compressor or the A/C Underhood Specification Label located in the engine compartment).

The Denso 10S17 A/C compressor used in this vehicle when equipped with the 3.7L, 4.7L, 5.7L or 8.3L engine is

designed to use ND-8 PAG refrigerant oil. Use only this type of refrigerantoil when servicing the A/C compressor for

these engines.

The Visteon HS-18 A/C compressor used in this vehicle when equipped with 5.9L diesel engine is designed to use

VC-46 PAG refrigerant oil. Use only this type of refrigerant oil when servicing this A/C compressor.

OPERATION

After performing any refrigerant recovery or recycling operation, always replenish the refrigerant system with the

same amount of the recommended refrigerant oil as was removed. Too little refrigerant oil can cause A/C compres-

sor damage, and too much can reduce A/C system performance.

PAG refrigerant oil is more hygroscopic than mineral oil, and will absorb any moisture it comes into contact with,

even moisture in the air. The PAG oil container should always be kept tightly capped until it is ready to be used.

After use, recap the oil container immediately to prevent moisture contamination.

STANDARD PROCEDURE

REFRIGERANT OIL LEVEL

When an A/C system is assembled at the factory, all components except the A/C compressor are refrigerant oil free.

After the refrigerant system has been charged and operated, the refrigerant oil in the A/C compressor is dispersed

throughout the refrigerant system. The accumulator, A/C evaporator, A/Ccondenser and the A/C compressor will

each retain a significant amount of the needed refrigerant oil.

It is important to have the correct amount of refrigerant oil in the A/C system. This ensures proper lubrication of the

A/C compressor. Too little oil will result in damage to the A/C compressor,while too much oil will reduce the cooling

capacity of the A/C system and consequently result in higher discharge airtemperatures.

CAUTION: The refrigerant oil in the R-134a A/C system is unique depending on the A/C compressor used.

Use only PAG oils that are designed to work with R-134a refrigerant and the A/C compressor in the vehicle.

Always refer to the A/C Underhood Specification Label for the correct oil designation. The oil container

should be kept tightly capped until it is ready for use and then tightly capped after use to prevent contam-

ination from dirt and moisture. Refrigerant oil will quickly absorb any moisture it comes in contact with,

therefore, special effort must be used to keep all R-134a system components moisture-free. Moisture in the

refrigerant oil is very difficult toremove and will cause a reliability problem with the A/C compressor.

NOTE: Most reclaim/recycling equipment will measure the lubricant beingremoved during recovery. This

amount of lubricant should be added back into the system. Refer to the reclaim/recycling equipment man-

ufacturers instructions.

It will not be necessary to check the oil level in the A/C compressor or to addoil, unless there has been an oil loss.

An oil loss may occur due to a rupture or leak from a refrigerant line, a connector fitting, a component, or a com-

ponent seal. If a leak occurs, add 30 milliliters (1 fluid ounce) of refrigerant oil to the refrigerant system after the

repair has been made. Refrigerant oil loss will be evident at the leak pointby the presence of a wet, shiny surface

around the leak.

Refrigerant oil must be added when an accumulator, A/C evaporator or A/C condenser is replaced. See the Refrig-

erant Oil Capacities chart. When an A/C compressor is replaced, the refrigerant oil must be drained from the old

Page 5196 of 5267

CATALYST MONITOR

To comply with clean air regulations, vehicles are equipped with catalytic converters. These converters reduce the

emission of hydrocarbons, oxides of nitrogen and carbon monoxide.

Normal vehicle miles or engine misfire can cause a catalyst to decay. This can increase vehicle emissions and

deteriorate engine performance, driveability and fuel economy.

The catalyst monitor uses dual oxygen sensors (O2S’s) to monitor the efficiency of the converter. The dual O2S’s

sensor strategy is based on the fact that as a catalyst deteriorates, its oxygen storage capacity and its efficiency are

both reduced. By monitoring the oxygen storage capacity of a catalyst, itsefficiency can be indirectly calculated. The

upstream O2S is used to detect the amount of oxygen in the exhaust gas beforethe gas enters the catalytic con-

verter. The PCM calculates the A/F mixture from the output of the O2S. A low voltage indicates high oxygen content

(lean mixture). A high voltage indicates a low content of oxygen (rich mixture).

When the upstream O2S detects a lean condition, there is an abundance of oxygen in the exhaust gas. A function-

ing converter would store this oxygen so it can use it for the oxidation of HCand CO. As the converter absorbs the

oxygen, there will be a lack of oxygen downstream of the converter. The output of the downstream O2S will indicate

limited activity in this condition.

As the converter loses the ability to store oxygen, the condition can be detected from the behavior of the down-

stream O2S. When the efficiency drops, no chemical reaction takes place. This means the concentration of oxygen

will be the same downstream as upstream. The output voltage of the downstream O2S copies the voltage of the

upstream sensor. The only difference is a time lag (seen by the PCM) betweenthe switching of the O2S’s.

To monitor the system, the number of lean-to-rich switches of upstream anddownstream O2S’s is counted. The

ratio of downstream switches to upstream switches is used to determine whether the catalyst is operating properly.

An effective catalyst will have fewer downstream switches than it has upstream switches i.e., a ratio closer to zero.

For a totally ineffective catalyst, this ratio will be one-to-one, indicating that no oxidation occurs in the device.

The system must be monitored so that when catalyst efficiency deteriorates and exhaust emissions increase to over

the legal limit, the MIL will be illuminated.

TRIP DEFINITION

The term “Trip” has different meanings depending on what the circumstances are. If the MIL (Malfunction Indicator

Lamp) is OFF, a Trip is defined as when the Oxygen Sensor Monitor and the Catalyst Monitor have been completed

in the same drive cycle.

When any Emission DTC is set, the MIL on the dash is turned ON. When the MIL is ON, it takes 3 good trips to turn

the MIL OFF. In this case, it depends on what type of DTC is set to know what a “Trip” is.

For the Fuel Monitor or Mis-Fire Monitor (continuous monitor), the vehicle must be operated in the “Similar Condition

Window” for a specified amount of time to be considered a Good Trip.

If a Non-Continuous OBDII Monitor fails twice in a row and turns ON the MIL, re-running that monitor which previ-

ously failed, on the next start-up and passing the monitor, is considered tobeaGoodTrip.Thesewillincludethe

following:

Oxygen Sensor

Catalyst Monitor

Purge Flow Monitor

Leak Detection Pump Monitor (if equipped)

EGR Monitor (if equipped)

Oxygen Sensor Heater Monitor

If any other Emission DTC is set (not an OBDII Monitor), a Good Trip is considered to be when the Oxygen Sensor

Monitor and Catalyst Monitor have been completed; or 2 Minutes of engine run time if the Oxygen Sensor Monitor

or Catalyst Monitor have been stopped from running.

It can take up to 2 Failures in a row to turn on the MIL. After the MIL is ON, it takes3GoodTripstoturntheMIL

OFF. After the MIL is OFF, the PCM will self-erase the DTC after 40 Warm-up cycles. A Warm-up cycle is counted

when the ECT (Engine Coolant Temperature Sensor) has crossed 160°F (71.1C) and has risen by at least 40°F

(4.4°C) since the engine has been started.

Page 5200 of 5267

If the MIL is ON and a DTC was set by the Fuel Monitor or Misfire Monitor (both continuous monitors), the

vehicle must be operated in the Similar Condition Window for a specified amount of time.

If the MIL is ON and a DTC was set by a Task Manager commanded once-per-trip monitor (such as the Oxy-

gen Sensor Monitor, Catalyst Monitor, Purge Flow Monitor, Leak DetectionPump Monitor, EGR Monitor or

Oxygen Sensor Heater Monitor), a good trip is when the monitor is passed on the next start-up.

If the MIL is ON and any other emissions DTC was set (not an OBD II monitor), a good trip occurs when the

Oxygen Sensor Monitor and Catalyst Monitor have been completed, or two minutes of engine run time if the

Oxygen Sensor Monitor and Catalyst Monitor have been stopped from running.

Fuel System Good Trip

To count a good trip (three required) and turn off the MIL, the following conditions must occur:

Engine in closed loop

Operating in Similar Conditions Window

Short Term multiplied by Long Term less than threshold

Less than threshold for a predetermined time

If all of the previous criteria are met, the PCM will count a good trip (threerequired) and turn off the MIL.

Misfire Good Trip

If the following conditions are met the PCM will count one good trip (three required) in order to turn off the MIL:

Operating in Similar Condition Window

1000 engine revolutions with no misfire

Warm-Up Cycles

Once the MIL has been extinguished by the Good Trip Counter, the PCM automatically switches to a Warm-Up

CycleCounterthatcanbeviewedontheDRBIII.Warm-UpCyclesareusedtoerase DTCs and Freeze Frames.

Forty Warm-Up cycles must occur in order for the PCM to self-erase a DTC and Freeze Frame. A Warm-Up Cycle

is defined as follows:

Engine coolant temperature must start below and rise above 160° F (71.1°C).

Engine coolant temperature must rise by 40° F (4.4°C)

No further faults occur

Freeze Frame Data Storage

Once a failure occurs, the Task Manager records several engine operating conditions and stores it in a Freeze

Frame. The Freeze Frame is considered one frame of information taken by an on-board data recorder. When a fault

occurs, the PCM stores the input data from various sensors so that technicians can determine under what vehicle

operating conditions the failure occurred.

The data stored in Freeze Frame is usually recorded when a system fails the first time for two trip faults. Freeze

Frame data will only be overwritten by a different fault with a higher priority.

CAUTION: Erasing DTCs, either with the DRB III or by disconnecting the battery, also clears all Freeze

Frame data.

Similar Conditions Window

The Similar Conditions Window displays information about engine operation during a monitor. Absolute MAP (engine

load) and Engine RPM are stored in this window when a failure occurs. There are two different Similar conditions

Windows: Fuel System and Misfire.

FUEL SYSTEM

Fuel System Similar Conditions Window— An indicator that ’Absolute MAP When Fuel Sys Fail’ and ’RPM

When Fuel Sys Failed’ are all in the same range when the failure occurred. Indicated by switching from ’NO’

to ’YES’.

Absolute MAP When Fuel Sys Fail— The stored MAP reading at the time of failure. Informs the user at

what engine load the failure occurred.

Absolute MAP— A live reading of engine load to aid the user in accessing the Similar Conditions Window.

RPM When Fuel Sys Fail— The stored RPM reading at the time of failure. Informs the user at what engine

RPM the failure occurred.

Page 5201 of 5267

Engine RPM— A live reading of engine RPM to aid the user in accessing the Similar Conditions Window.

Adaptive Memory Factor— The PCM utilizes both Short Term Compensation and Long Term Adaptive to

calculate the Adaptive Memory Factor for total fuel correction.

Upstream O2S Volts— A live reading of the Oxygen Sensor to indicate its performance. For example, stuck

lean, stuck rich, etc.

SCW Time in Window (Similar Conditions Window Time in Window)—Atimer used by the PCM that

indicates that, after all Similar Conditions have been met, if there has been enough good engine running time

in the SCW without failure detected. This timer is used to increment a Good Trip.

Fuel System Good Trip Counter—ATripCounterusedtoturnOFFtheMILforFuelSystemDTCs.To

increment a Fuel System Good Trip, the engine must be in the Similar Conditions Window, Adaptive Memory

Factor must be less than calibrated threshold and the Adaptive Memory Factor must stay below that threshold

for a calibrated amount of time.

Test Done This Trip— Indicates that the monitor has already been run and completed during the current trip.

MISFIRE

Same Misfire Warm-Up State— Indicates if the misfire occurred when the engine was warmed up above

160° F (71.1°C).

In Similar Misfire Window— An indicator that ’Absolute MAP When Misfire Occurred’ and ’RPM When Mis-

fire Occurred’ are all in the same range when the failure occurred. Indicated by switching from ’NO’ to ’YES’.

Absolute MAP When Misfire Occurred— The stored MAP reading at the time of failure. Informs the user at

what engine load the failure occurred.

Absolute MAP— A live reading of engine load to aid the user in accessing the Similar Conditions Window.

RPM When Misfire Occurred— The stored RPM reading at the time of failure. Informs the user at what

engine RPM the failure occurred.

Engine RPM— A live reading of engine RPM to aid the user in accessing the Similar Conditions Window.

Adaptive Memory Factor— The PCM utilizes both Short Term Compensation and Long Term Adaptive to

calculate the Adaptive Memory Factor for total fuel correction.

200 Rev Counter— Counts 0–100 720 degree cycles.

SCW Cat 200 Rev Counter— Counts when in similar conditions.

SCW FTP 1000 Rev Counter— Counts 0–4 when in similar conditions.

Misfire Good Trip Counter— Counts up to three to turn OFF the MIL.

Misfire Data— Data collected during test.

Test Done This Trip— Indicates YES when the test is done.

NON-MONITORED CIRCUITS

The PCM does not monitor the following circuits, systems and conditions that could have malfunctions causing

driveability problems. The PCM might not store diagnostic trouble codes for these conditions. However, problems

with these systems may cause the PCM to store diagnostic trouble codes for other systems or components.EXAM-

PLE:a fuel pressure problem will not register a fault directly, but could causea rich/lean condition or misfire. This

could cause the PCM to store an oxygen sensor or misfire diagnostic troublecode

FUEL PRESSURE

The fuel pressure regulator controls fuel system pressure. The PCM cannotdetect a clogged fuel pump inlet filter,

clogged in-line fuel filter, or a pinched fuel supply or return line. However, these could result in a rich or lean con-

dition causing the PCM to store an oxygen sensor or fuel system diagnostic trouble code.

SECONDARY IGNITION CIRCUIT

The PCM cannot detect an inoperative ignition coil, fouled or worn spark plugs, ignition cross firing, or open spark

plug cables.

CYLINDER COMPRESSION

The PCM cannot detect uneven, low, or high engine cylinder compression.

Page 5212 of 5267

ORVR

DESCRIPTION

The ORVR (On-Board Refueling Vapor Recovery) system consists of a unique fuel tank, flow management valve,

fluid control valve, one-way check valve and vapor canister.

OPERATION

The ORVR (On-Board Refueling Vapor Recovery) system is used to remove excess fuel tank vapors. This is done

while the vehicle is being refueled.

Fuel flowing into the fuel filler tube (approx. 1” I.D.) creates an aspiration effect drawing air into the fuel fill tube.

During refueling, the fuel tank is vented to the EVAP canister to capture escaping vapors. With air flowing into the

filler tube, there are no fuel vapors escaping to the atmosphere. Once the refueling vapors are captured by the

EVAP canister, the vehicle’s computer controlled purge system draws vapor out of the canister for the engine to

burn. The vapor flow is metered by the purge solenoid so that there is no, or minimal impact on driveability or

tailpipe emissions.

As fuel starts to flow through the fuel fill tube, it opens the normally closed check valve and enters the fuel tank.

Vapor or air is expelled from the tank through the control valve and on to thevapor canister. Vapor is absorbed in

the EVAP canister until vapor flow in the lines stops. This stoppage occursfollowing fuel shut-off, or by having the

fuel level in the tank rise high enough to close the control valve. This control valve contains a float that rises to seal

the large diameter vent path to the EVAP canister. At this point in the refueling process, fuel tank pressure

increases, the check valve closes (preventing liquid fuel from spiting back at the operator), and fuel then rises up

the fuel filler tube to shut off the dispensing nozzle.

Page 5224 of 5267

During periods of moderate manifold vacuum, the

plunger is only pulled part way back from inlet. This

results in maximum vapor flow through the valve.

DIAGNOSIS AND TESTING

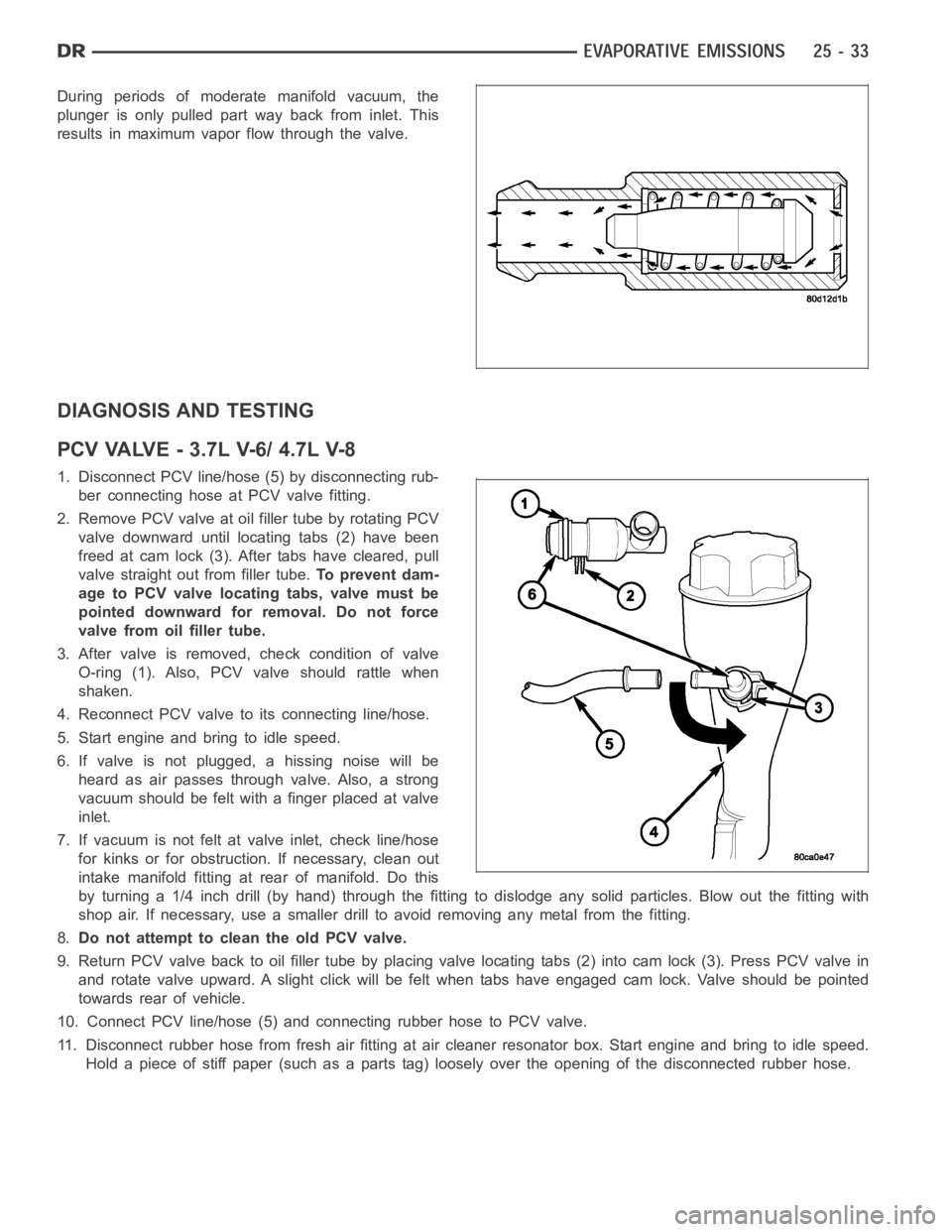

PCVVALVE-3.7LV-6/4.7LV-8

1. Disconnect PCV line/hose (5) by disconnecting rub-

ber connecting hose at PCV valve fitting.

2. Remove PCV valve at oil filler tube by rotating PCV

valve downward until locating tabs (2) have been

freed at cam lock (3). After tabs have cleared, pull

valve straight out from filler tube.To prevent dam-

age to PCV valve locating tabs, valve must be

pointed downward for removal. Do not force

valve from oil filler tube.

3. After valve is removed, check condition of valve

O-ring (1). Also, PCV valve should rattle when

shaken.

4. Reconnect PCV valve to its connecting line/hose.

5. Start engine and bring to idle speed.

6. If valve is not plugged, a hissing noise will be

heard as air passes through valve. Also, a strong

vacuum should be felt with a finger placed at valve

inlet.

7. If vacuum is not felt at valve inlet, check line/hose

for kinks or for obstruction. If necessary, clean out

intake manifold fitting at rear of manifold. Do this

byturninga1/4inchdrill(byhand)throughthefittingtodislodgeanysolid particles. Blow out the fitting with

shop air. If necessary, use a smaller drill to avoid removing any metal fromthe fitting.

8.Do not attempt to clean the old PCV valve.

9. Return PCV valve back to oil filler tube by placing valve locating tabs (2) into cam lock (3). Press PCV valve in

and rotate valve upward. A slight click will be felt when tabs have engaged cam lock. Valve should be pointed

towards rear of vehicle.

10. Connect PCV line/hose (5) and connecting rubber hose to PCV valve.

11. Disconnect rubber hose from fresh air fitting at air cleaner resonatorbox. Start engine and bring to idle speed.

Hold a piece of stiff paper (such as a parts tag) loosely over the opening of the disconnected rubber hose.

Page 5226 of 5267

REMOVAL

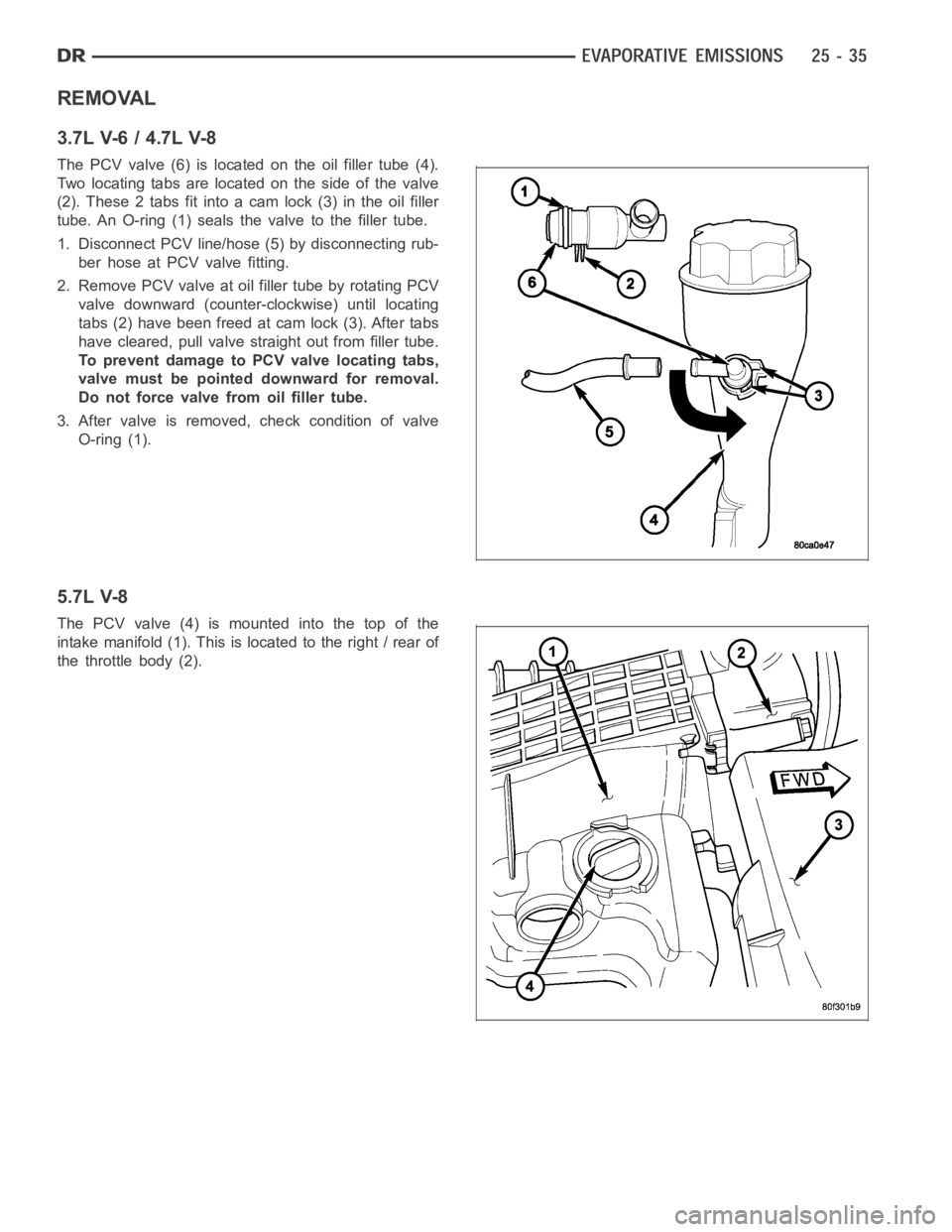

3.7L V-6 / 4.7L V-8

The PCV valve (6) is located on the oil filler tube (4).

Two locating tabs are located on the side of the valve

(2). These 2 tabs fit into a cam lock (3) in the oil filler

tube. An O-ring (1) seals the valve to the filler tube.

1. Disconnect PCV line/hose (5) by disconnecting rub-

ber hose at PCV valve fitting.

2. Remove PCV valve at oil filler tube by rotating PCV

valve downward (counter-clockwise) until locating

tabs (2) have been freed at cam lock (3). After tabs

have cleared, pull valve straight out from filler tube.

To prevent damage to PCV valve locating tabs,

valve must be pointed downward for removal.

Do not force valve from oil filler tube.

3. After valve is removed, check condition of valve

O-ring (1).

5.7L V-8

The PCV valve (4) is mounted into the top of the

intake manifold (1). This is located to the right / rear of

the throttle body (2).

Page 5227 of 5267

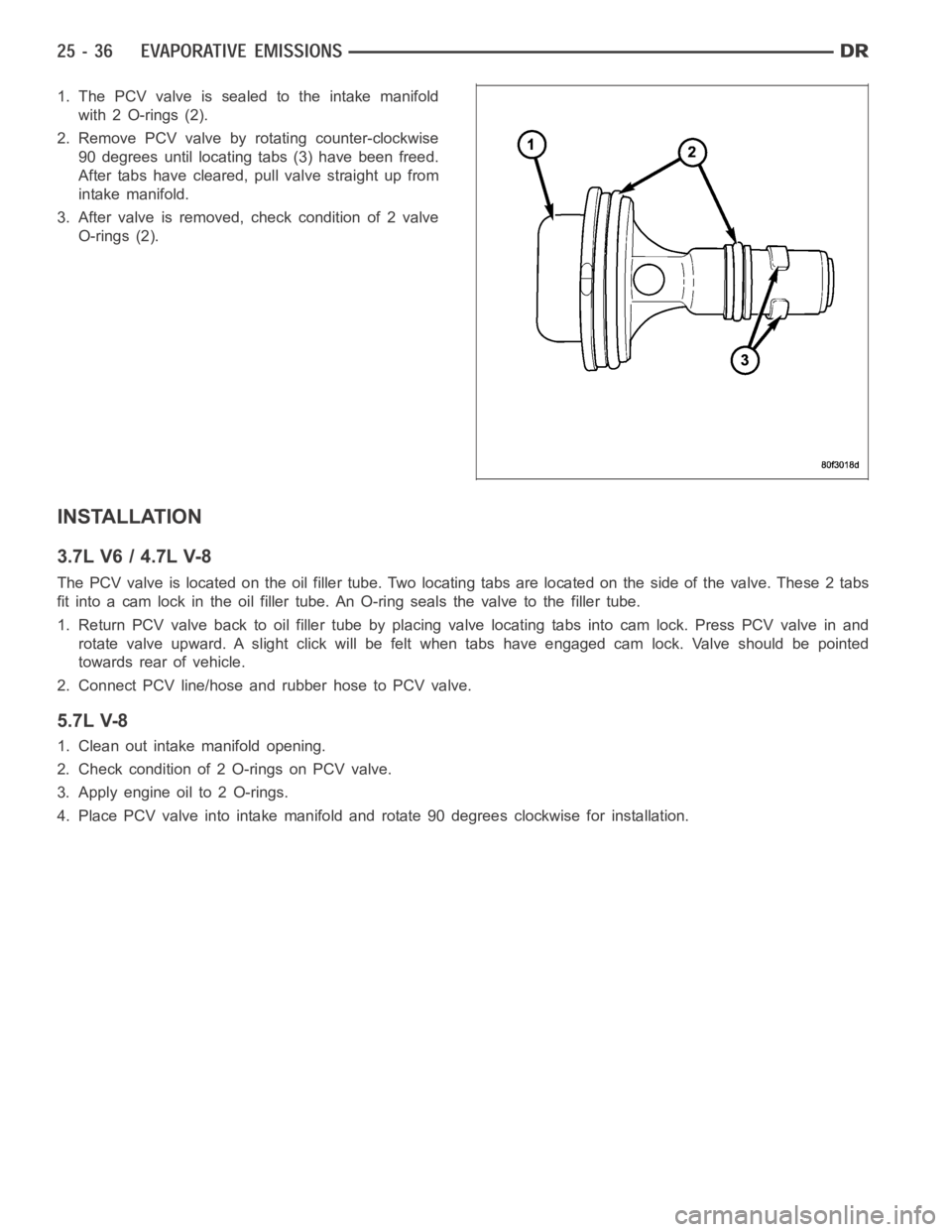

1. The PCV valve is sealed to the intake manifold

with 2 O-rings (2).

2. Remove PCV valve by rotating counter-clockwise

90 degrees until locating tabs (3) have been freed.

After tabs have cleared, pull valve straight up from

intake manifold.

3. After valve is removed, check condition of 2 valve

O-rings (2).

INSTALLATION

3.7L V6 / 4.7L V-8

The PCV valve is located on the oil filler tube. Two locating tabs are locatedonthesideofthevalve.These2tabs

fit into a cam lock in the oil filler tube.An O-ring seals the valve to the filler tube.

1. Return PCV valve back to oil filler tube by placing valve locating tabs into cam lock. Press PCV valve in and

rotate valve upward. A slight click will be felt when tabs have engaged cam lock. Valve should be pointed

towards rear of vehicle.

2. Connect PCV line/hose and rubber hose to PCV valve.

5.7L V-8

1. Clean out intake manifold opening.

2. Check condition of 2 O-rings on PCV valve.

3. Apply engine oil to 2 O-rings.

4. Place PCV valve into intake manifold and rotate 90 degrees clockwise forinstallation.

Page 5231 of 5267

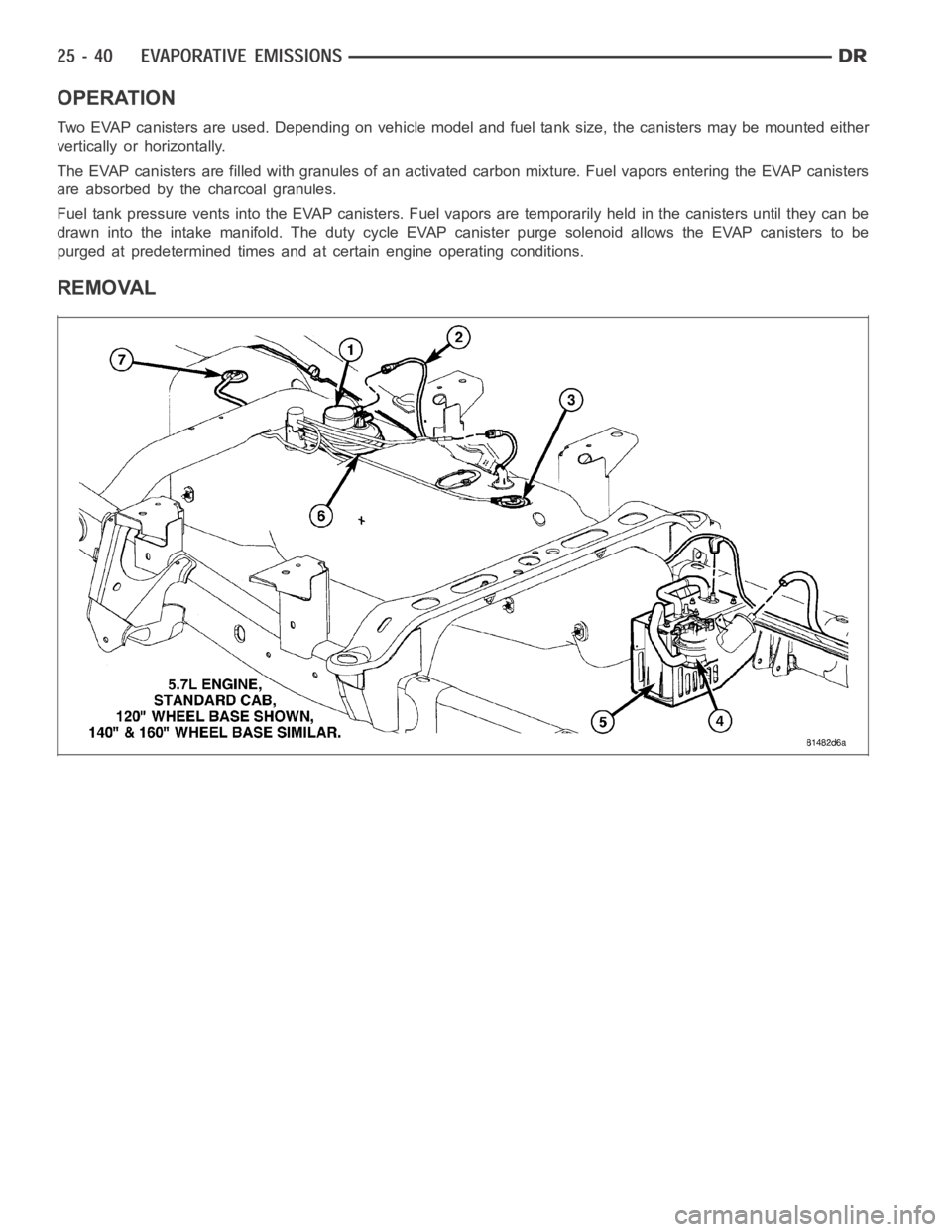

OPERATION

Two EVAP canisters are used. Depending on vehicle model and fuel tank size,the canisters may be mounted either

vertically or horizontally.

The EVAP canisters are filled with granules of an activated carbon mixture. Fuel vapors entering the EVAP canisters

are absorbed by the charcoal granules.

Fuel tank pressure vents into the EVAP canisters. Fuel vapors are temporarily held in the canisters until they can be

drawn into the intake manifold. The duty cycle EVAP canister purge solenoid allows the EVAP canisters to be

purged at predetermined times and at certain engine operating conditions.

REMOVAL