ABS DODGE RAM SRT-10 2006 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1932 of 5267

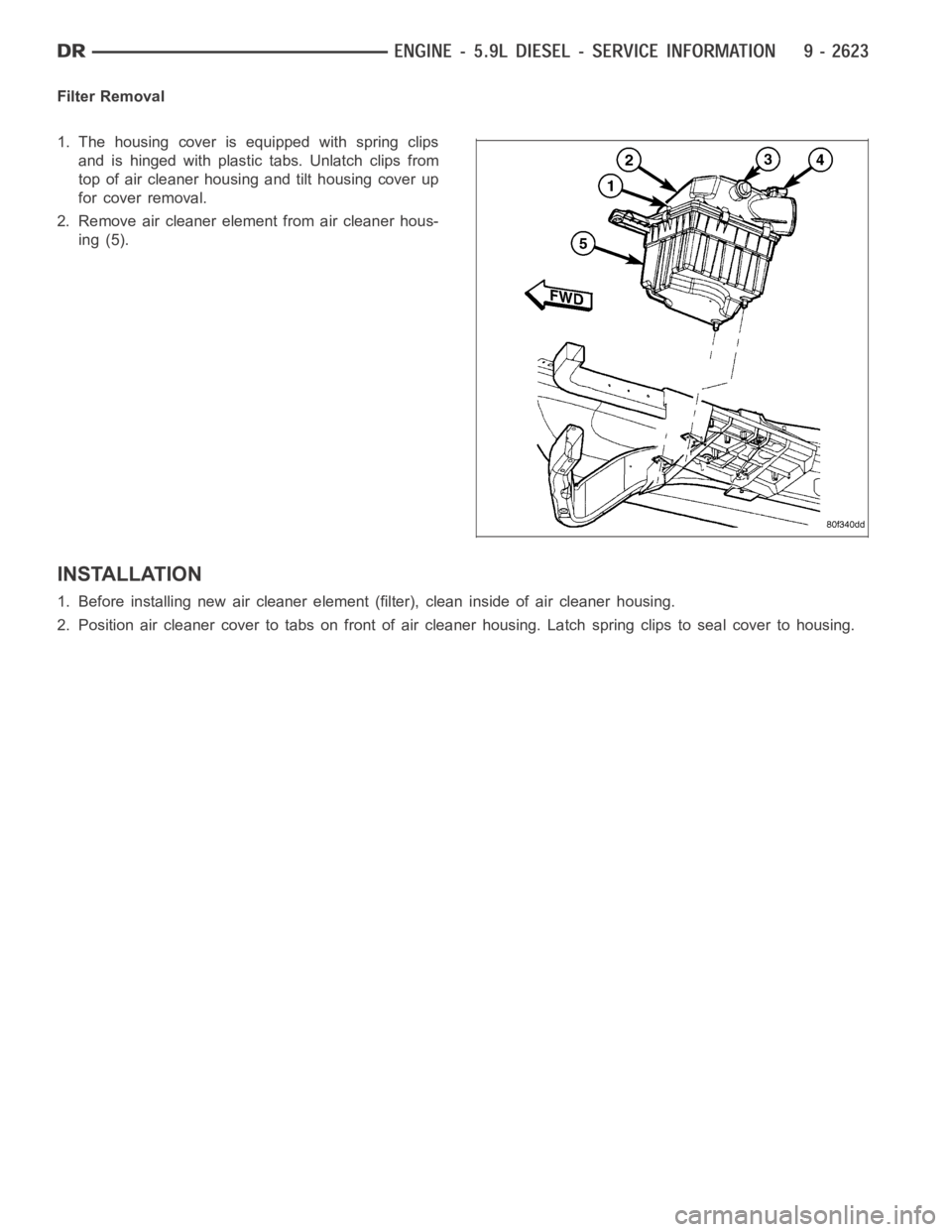

Filter Removal

1. The housing cover is equipped with spring clips

and is hinged with plastic tabs. Unlatch clips from

top of air cleaner housing and tilt housing cover up

for cover removal.

2. Remove air cleaner element from air cleaner hous-

ing (5).

INSTALLATION

1. Before installing new air cleaner element (filter), clean inside of aircleaner housing.

2. Position air cleaner cover to tabs on front of air cleaner housing. Latchspring clips to seal cover to housing.

Page 2031 of 5267

STANDARD PROCEDURE

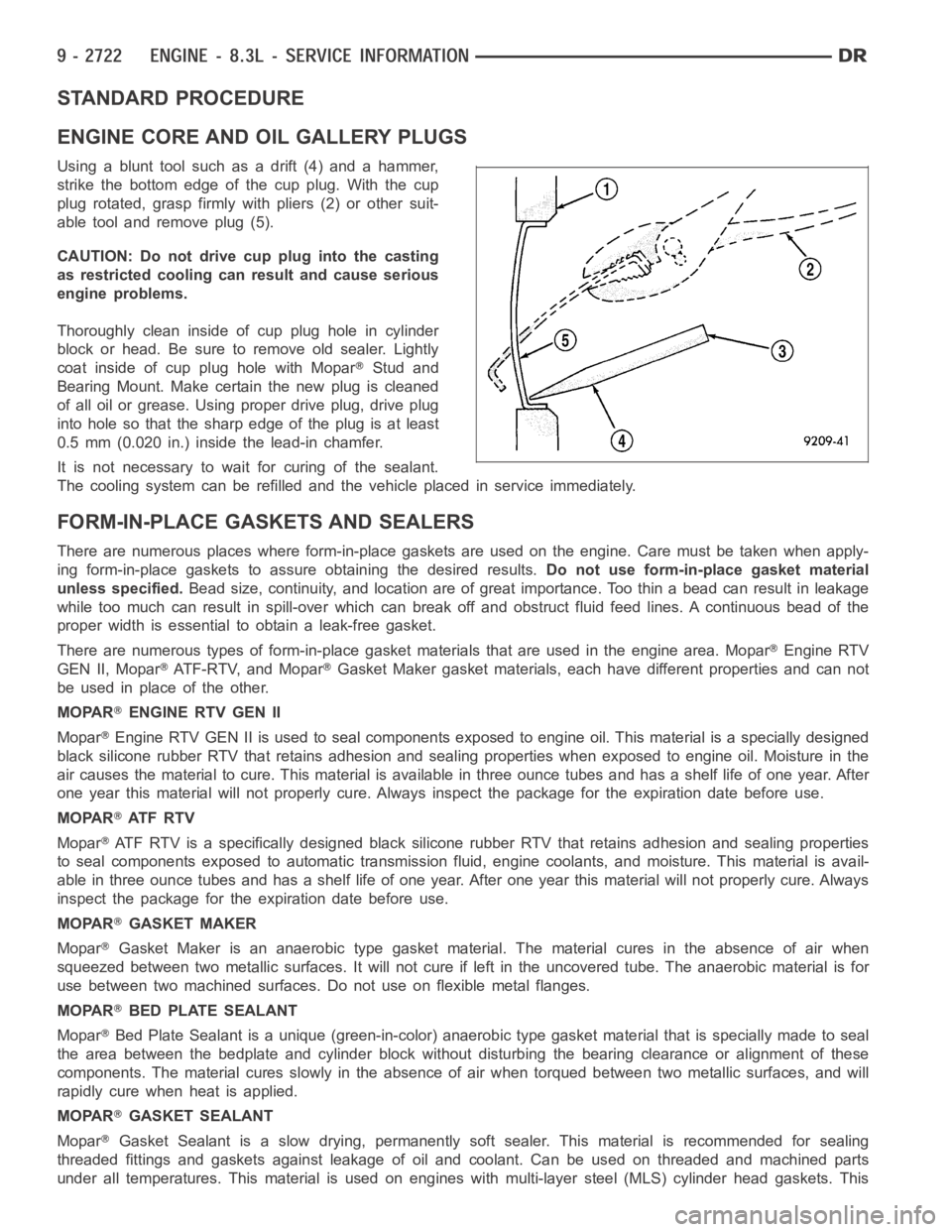

ENGINE CORE AND OIL GALLERY PLUGS

Using a blunt tool such as a drift (4) and a hammer,

strike the bottom edge of the cup plug. With the cup

plug rotated, grasp firmly with pliers (2) or other suit-

able tool and remove plug (5).

CAUTION: Do not drive cup plug into the casting

as restricted cooling can result and cause serious

engine problems.

Thoroughly clean inside of cup plug hole in cylinder

block or head. Be sure to remove old sealer. Lightly

coat inside of cup plug hole with Mopar

Stud and

Bearing Mount. Make certain the new plug is cleaned

of all oil or grease. Using proper drive plug, drive plug

into hole so that the sharp edge of the plug is at least

0.5 mm (0.020 in.) inside the lead-in chamfer.

It is not necessary to wait for curing of the sealant.

The cooling system can be refilled and the vehicle placed in service immediately.

FORM-IN-PLACE GASKETS AND SEALERS

There are numerous places where form-in-place gaskets are used on the engine. Care must be taken when apply-

ing form-in-place gaskets to assure obtaining the desired results.Do not use form-in-place gasket material

unless specified.Bead size, continuity, and location are of great importance. Too thin a bead can result in leakage

while too much can result in spill-overwhich can break off and obstruct fluid feed lines. A continuous bead of the

proper width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket materials that are used in the engine area. Mopar

Engine RTV

GEN II, Mopar

ATF-RTV, and MoparGasket Maker gasket materials, each have different properties and can not

be used in place of the other.

MOPAR

ENGINE RTV GEN II

Mopar

Engine RTV GEN II is used to seal components exposed to engine oil. This material is a specially designed

black silicone rubber RTV that retains adhesion and sealing properties when exposed to engine oil. Moisture in the

air causes the material to cure. This material is available in three ounce tubes and has a shelf life of one year. After

one year this material will not properly cure. Always inspect the package for the expiration date before use.

MOPAR

AT F R T V

Mopar

ATF RTV is a specifically designed black silicone rubber RTV that retains adhesion and sealing properties

to seal components exposed to automatic transmission fluid, engine coolants, and moisture. This material is avail-

able in three ounce tubes and has a shelf life of one year. After one year thismaterial will not properly cure. Always

inspect the package for the expiration date before use.

MOPAR

GASKET MAKER

Mopar

Gasket Maker is an anaerobic type gasket material. The material cures in the absence of air when

squeezed between two metallic surfaces. It will not cure if left in the uncovered tube. The anaerobic material is for

use between two machined surfaces. Do not use on flexible metal flanges.

MOPAR

BED PLATE SEALANT

Mopar

Bed Plate Sealant is a unique (green-in-color) anaerobic type gasket material that is specially made to seal

the area between the bedplate and cylinder block without disturbing the bearing clearance or alignment of these

components. The material cures slowly in the absence of air when torqued between two metallic surfaces, and will

rapidly cure when heat is applied.

MOPAR

GASKET SEALANT

Mopar

Gasket Sealant is a slow drying, permanently soft sealer. This material isrecommended for sealing

threaded fittings and gaskets against leakage of oil and coolant. Can be used on threaded and machined parts

under all temperatures. This material is used on engines with multi-layersteel (MLS) cylinder head gaskets. This

Page 2052 of 5267

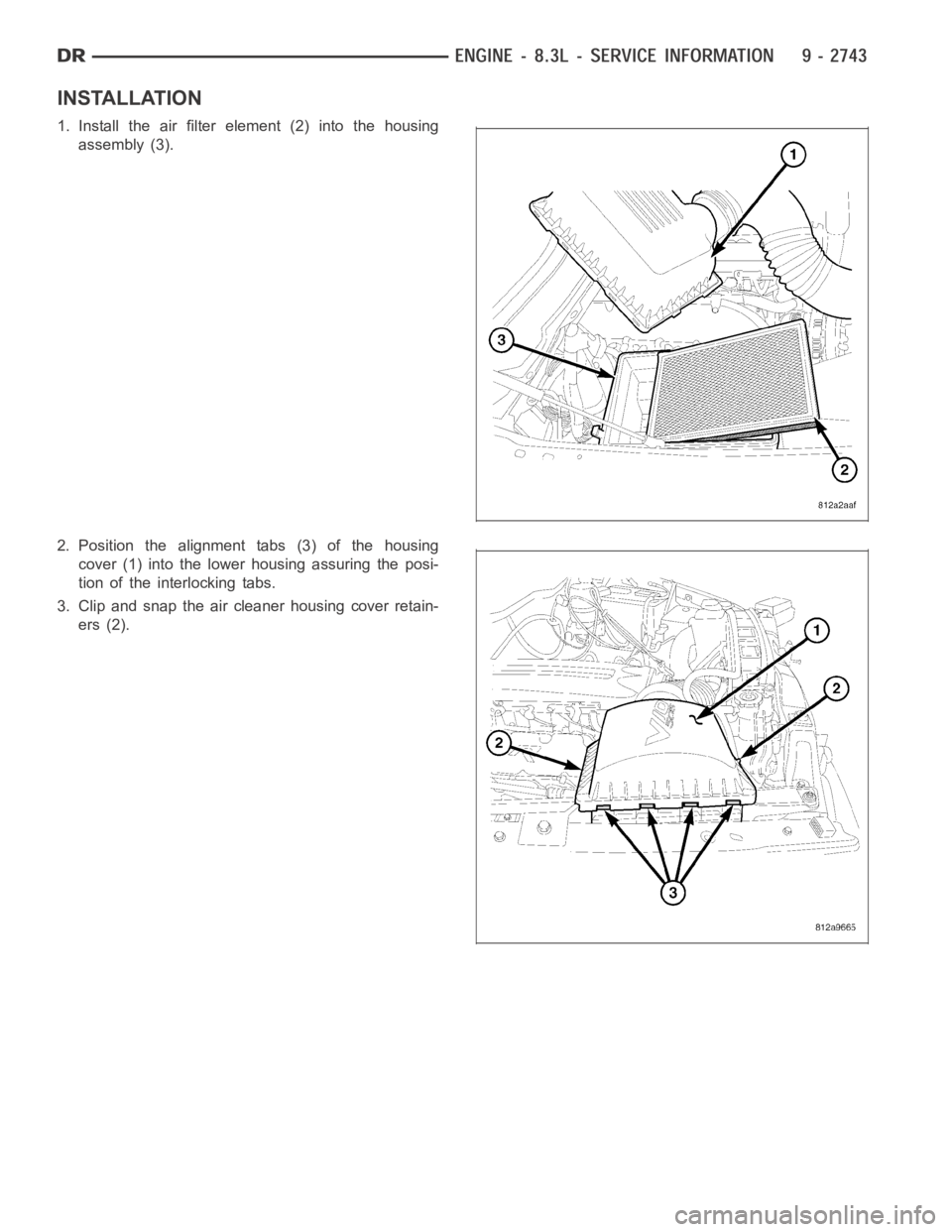

INSTALLATION

1. Install the air filter element (2) into the housing

assembly (3).

2. Position the alignment tabs (3) of the housing

cover (1) into the lower housing assuring the posi-

tion of the interlocking tabs.

3. Clip and snap the air cleaner housing cover retain-

ers (2).

Page 2202 of 5267

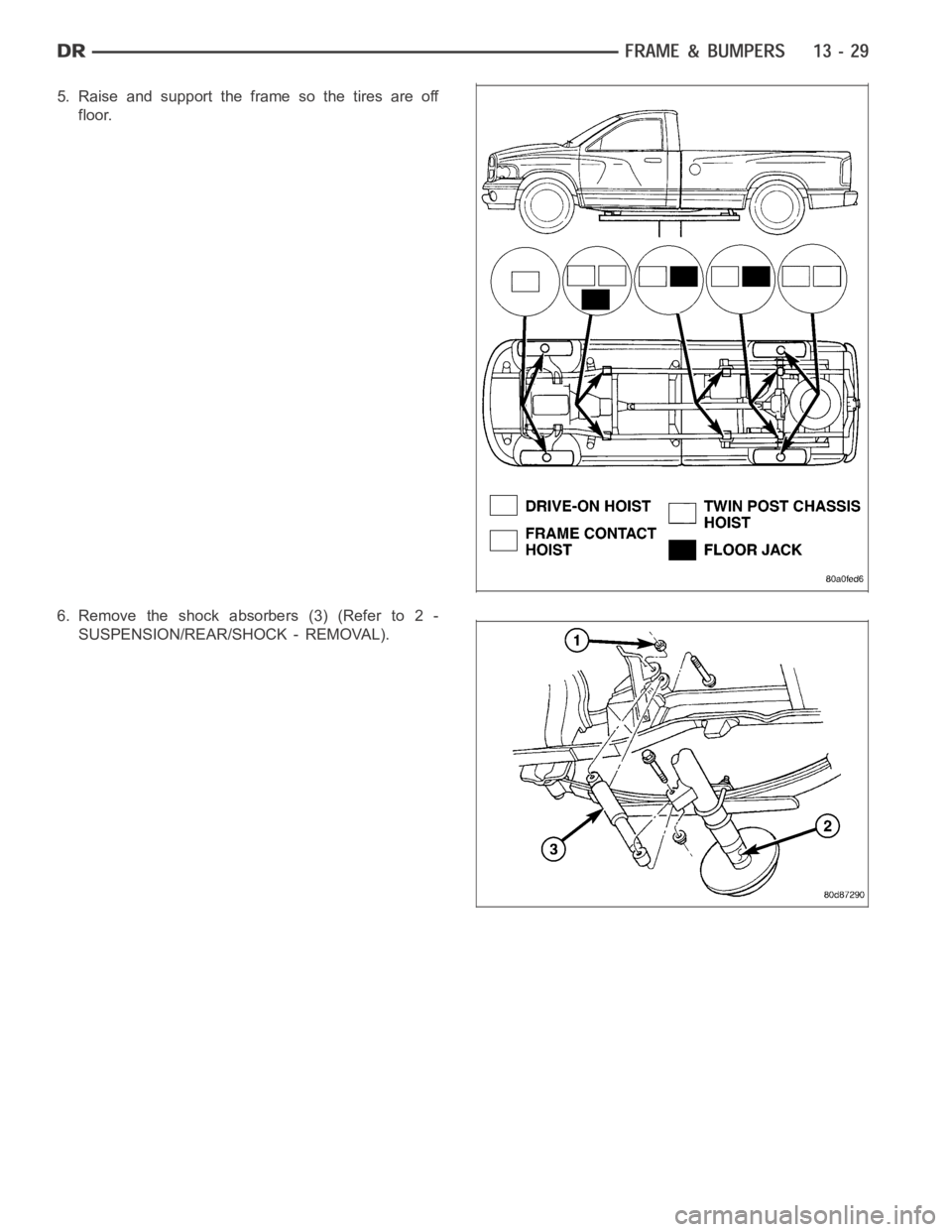

5. Raise and support the frame so the tires are off

floor.

6. Remove the shock absorbers (3) (Refer to 2 -

SUSPENSION/REAR/SHOCK - REMOVAL).

Page 2205 of 5267

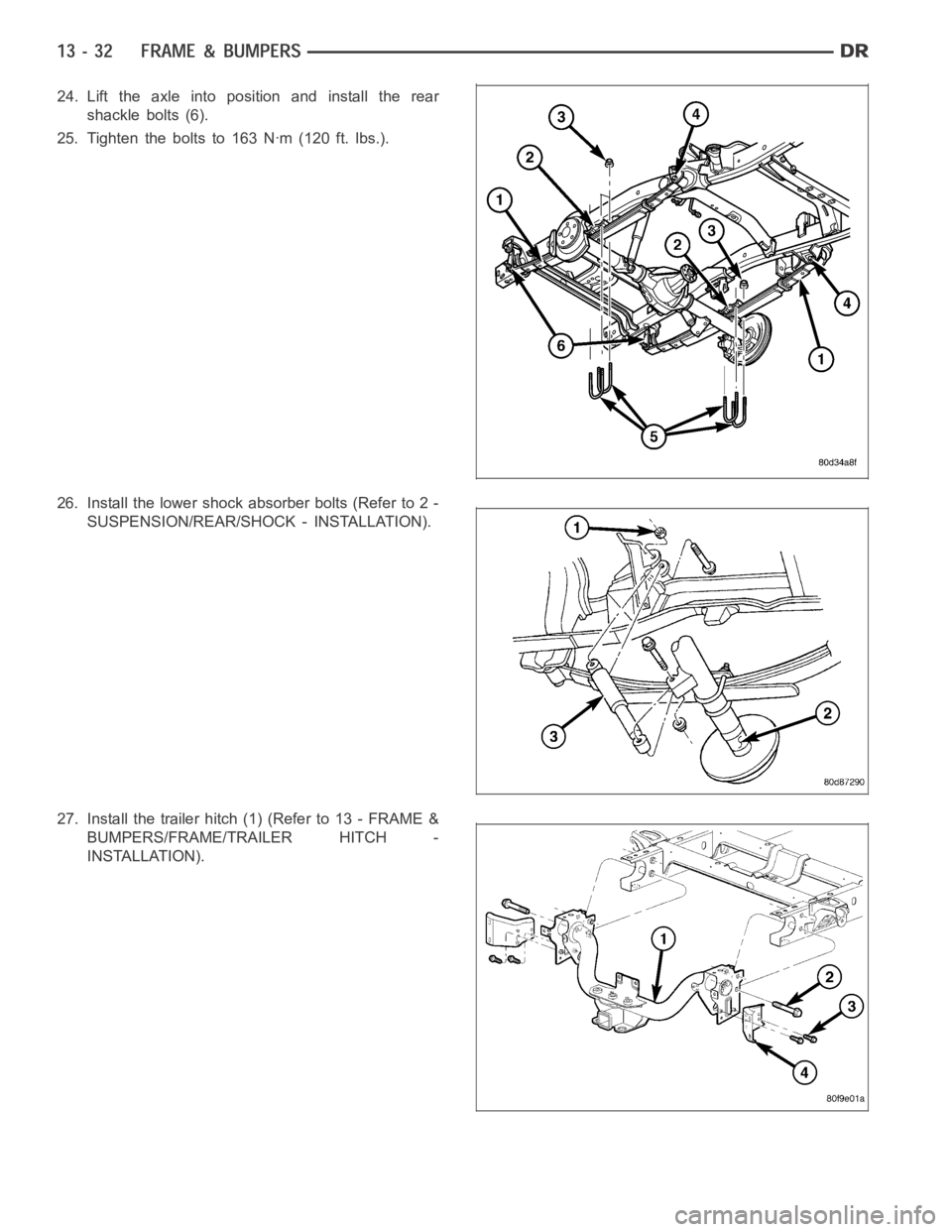

24. Lift the axle into position and install the rear

shackle bolts (6).

25. Tighten the bolts to 163 Nꞏm (120 ft. lbs.).

26. Install the lower shock absorber bolts (Refer to 2 -

SUSPENSION/REAR/SHOCK - INSTALLATION).

27. Install the trailer hitch (1) (Refer to 13 - FRAME &

BUMPERS/FRAME/TRAILER HITCH -

INSTALLATION).

Page 2224 of 5267

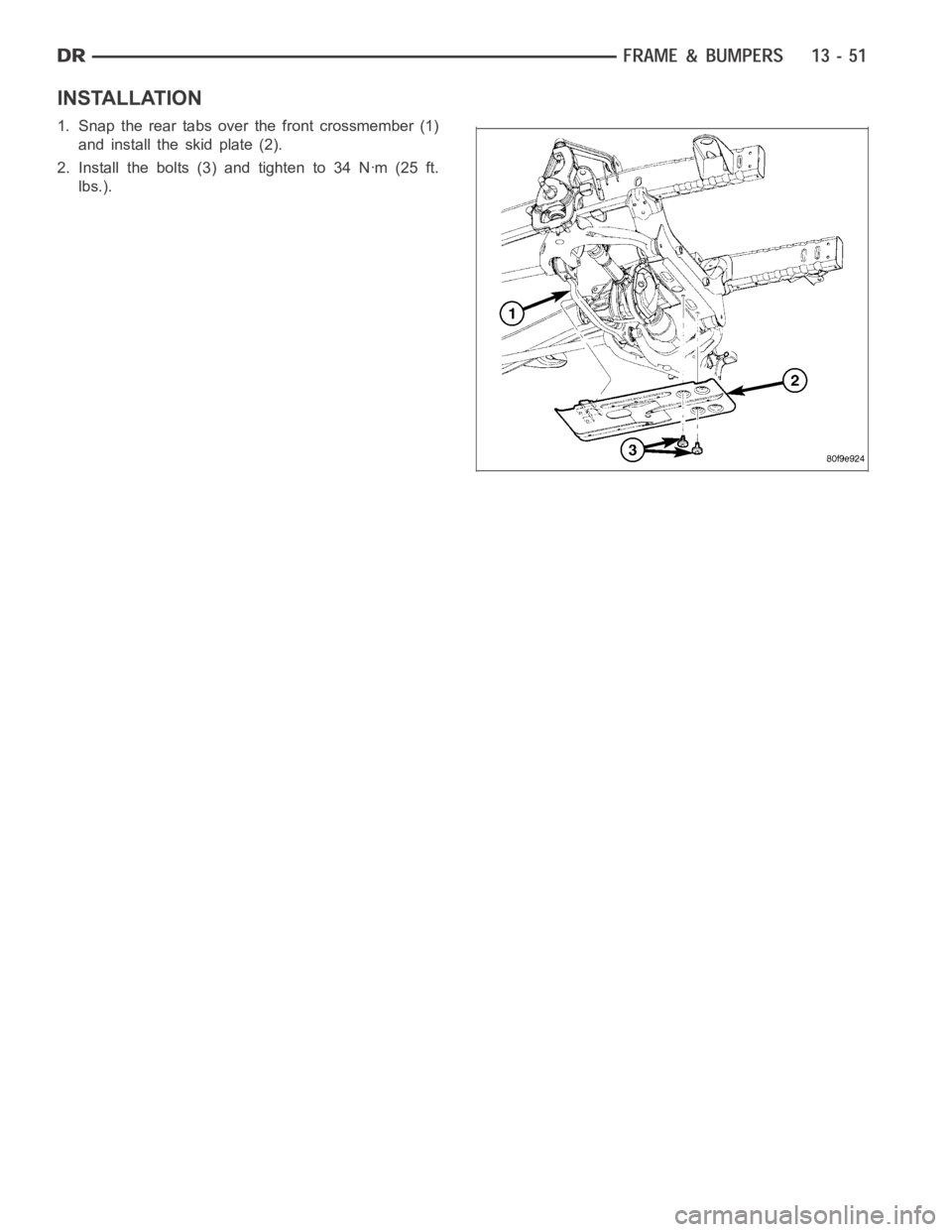

INSTALLATION

1. Snap the rear tabs over the front crossmember (1)

and install the skid plate (2).

2. Install the bolts (3) and tighten to 34 Nꞏm (25 ft.

lbs.).

Page 2252 of 5267

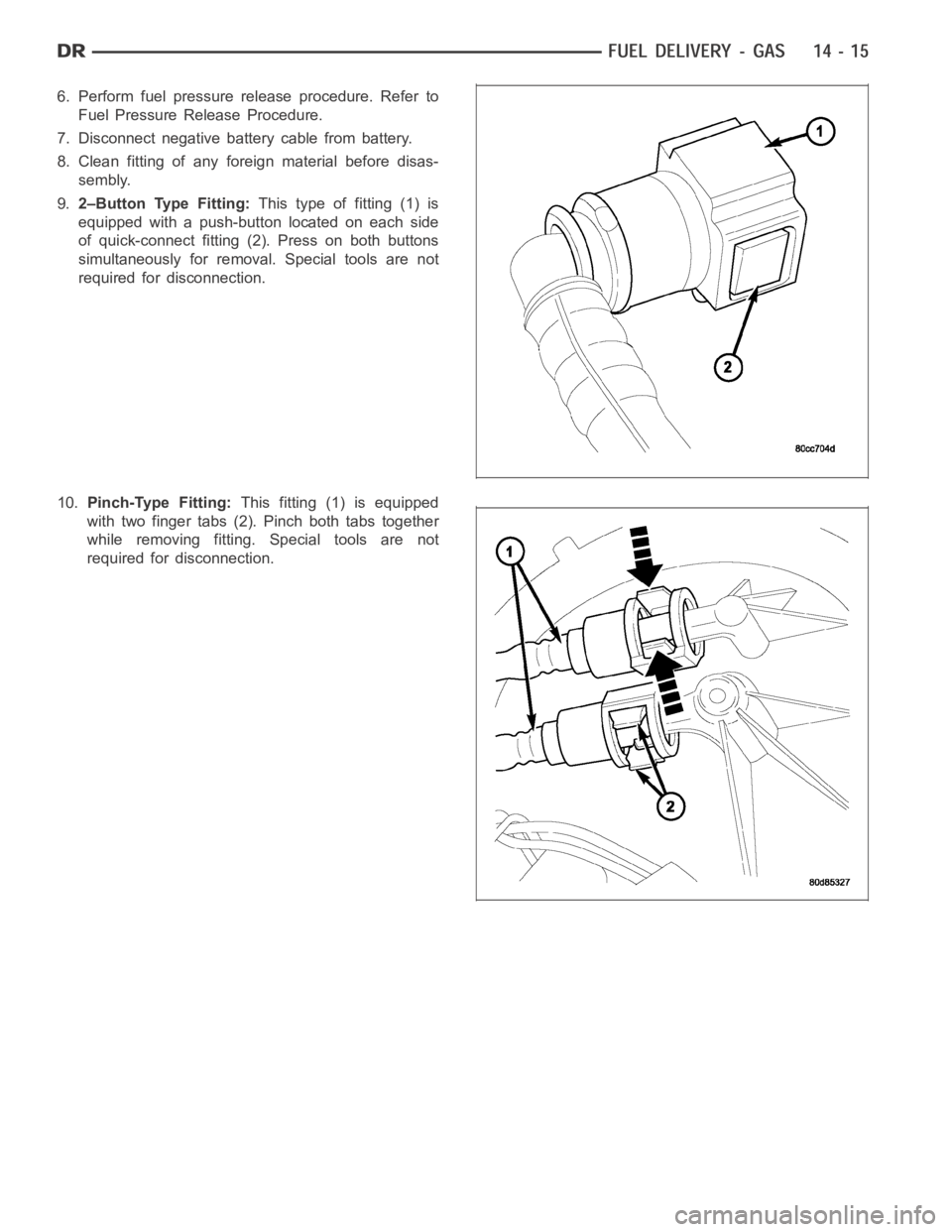

6. Perform fuel pressure release procedure. Refer to

Fuel Pressure Release Procedure.

7. Disconnect negative battery cable from battery.

8. Clean fitting of any foreign material before disas-

sembly.

9.2–Button Type Fitting:This type of fitting (1) is

equipped with a push-button located on each side

of quick-connect fitting (2). Press on both buttons

simultaneously for removal. Special tools are not

required for disconnection.

10.Pinch-Type Fitting:This fitting (1) is equipped

with two finger tabs (2). Pinch both tabs together

while removing fitting. Special tools are not

required for disconnection.

Page 2253 of 5267

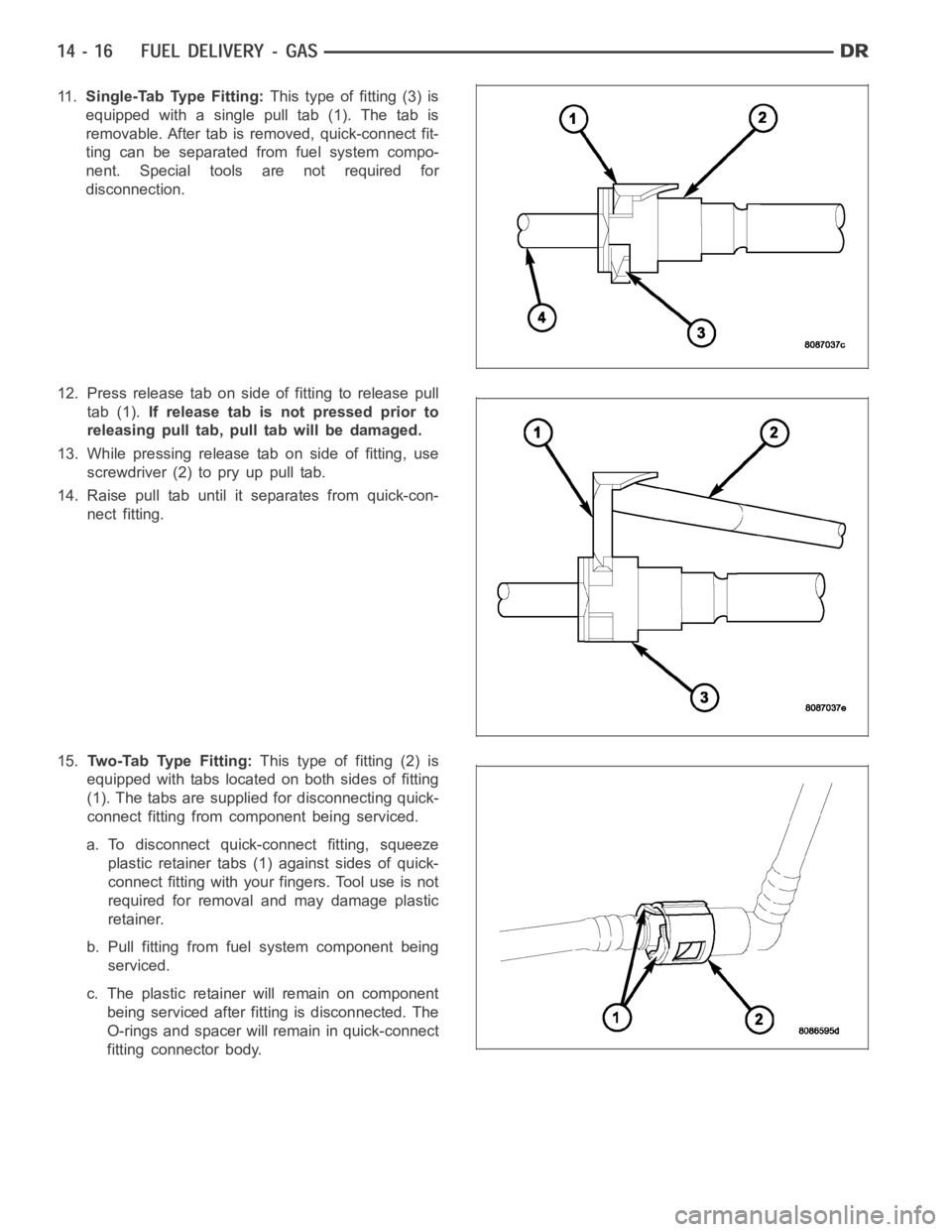

11 .Single-Tab Type Fitting:This type of fitting (3) is

equipped with a single pull tab (1). The tab is

removable. After tab is removed, quick-connect fit-

ting can be separated from fuel system compo-

nent. Special tools are not required for

disconnection.

12. Press release tab on side of fitting to release pull

tab (1).If release tab is not pressed prior to

releasing pull tab, pull tab will be damaged.

13. While pressing release tab on side of fitting, use

screwdriver (2) to pry up pull tab.

14. Raise pull tab until it separates from quick-con-

nect fitting.

15.Tw o - Ta b Ty p e F i t t i n g :This type of fitting (2) is

equipped with tabs located on both sides of fitting

(1). The tabs are supplied for disconnecting quick-

connect fitting from component being serviced.

a. To disconnect quick-connect fitting, squeeze

plastic retainer tabs (1) against sides of quick-

connect fitting with your fingers. Tool use is not

required for removal and may damage plastic

retainer.

b. Pull fitting from fuel system component being

serviced.

c. The plastic retainer will remain on component

being serviced after fitting is disconnected. The

O-rings and spacer will remain in quick-connect

fitting connector body.

Page 2280 of 5267

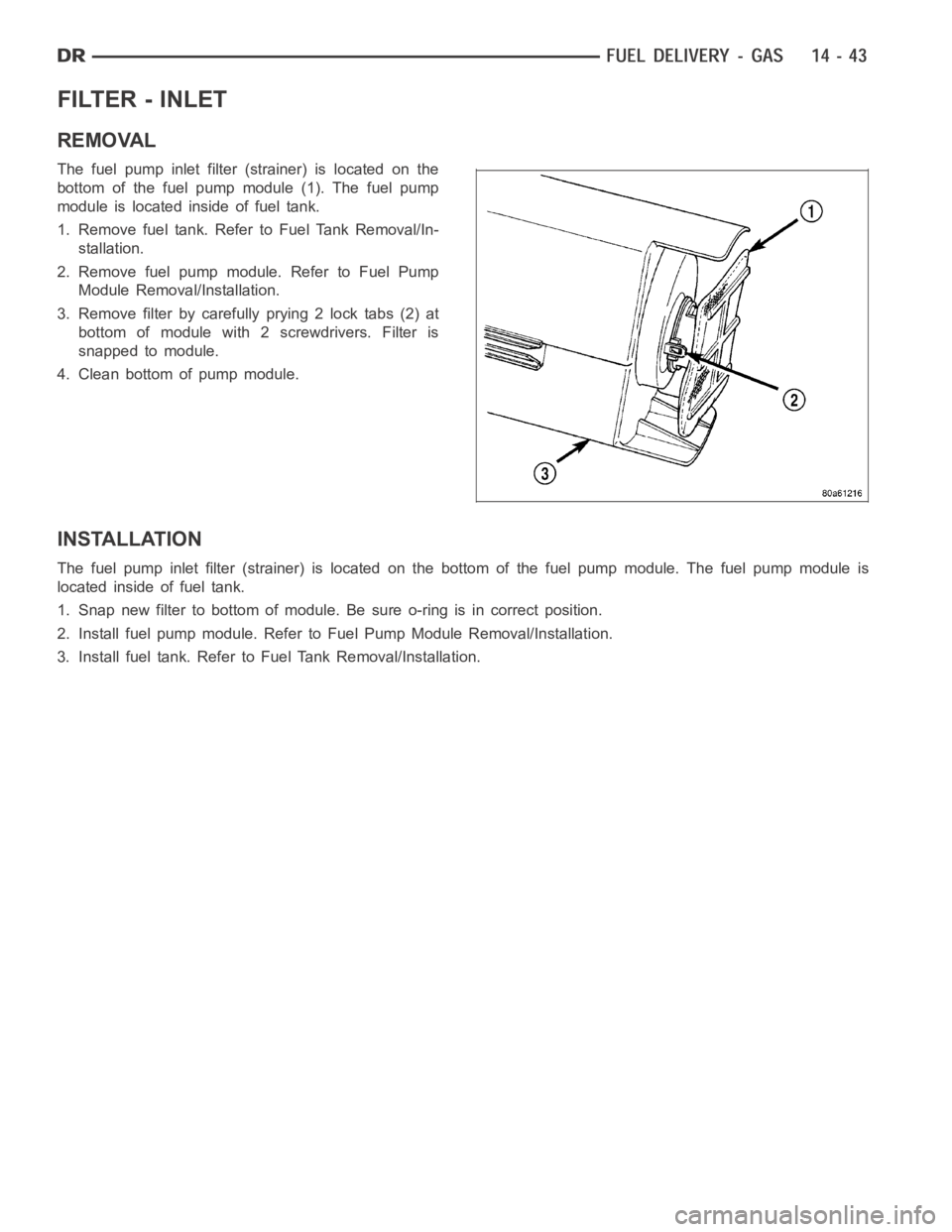

FILTER - INLET

REMOVAL

The fuel pump inlet filter (strainer) is located on the

bottom of the fuel pump module (1). The fuel pump

module is located inside of fuel tank.

1. Remove fuel tank. Refer to Fuel Tank Removal/In-

stallation.

2. Remove fuel pump module. Refer to Fuel Pump

Module Removal/Installation.

3. Remove filter by carefully prying 2 lock tabs (2) at

bottom of module with 2 screwdrivers. Filter is

snapped to module.

4. Clean bottom of pump module.

INSTALLATION

The fuel pump inlet filter (strainer) is located on the bottom of the fuel pump module. The fuel pump module is

located inside of fuel tank.

1. Snap new filter to bottom of module. Be sure o-ring is in correct position.

2. Install fuel pump module. Refer to Fuel Pump Module Removal/Installation.

3. Install fuel tank. Refer to Fuel Tank Removal/Installation.

Page 2313 of 5267

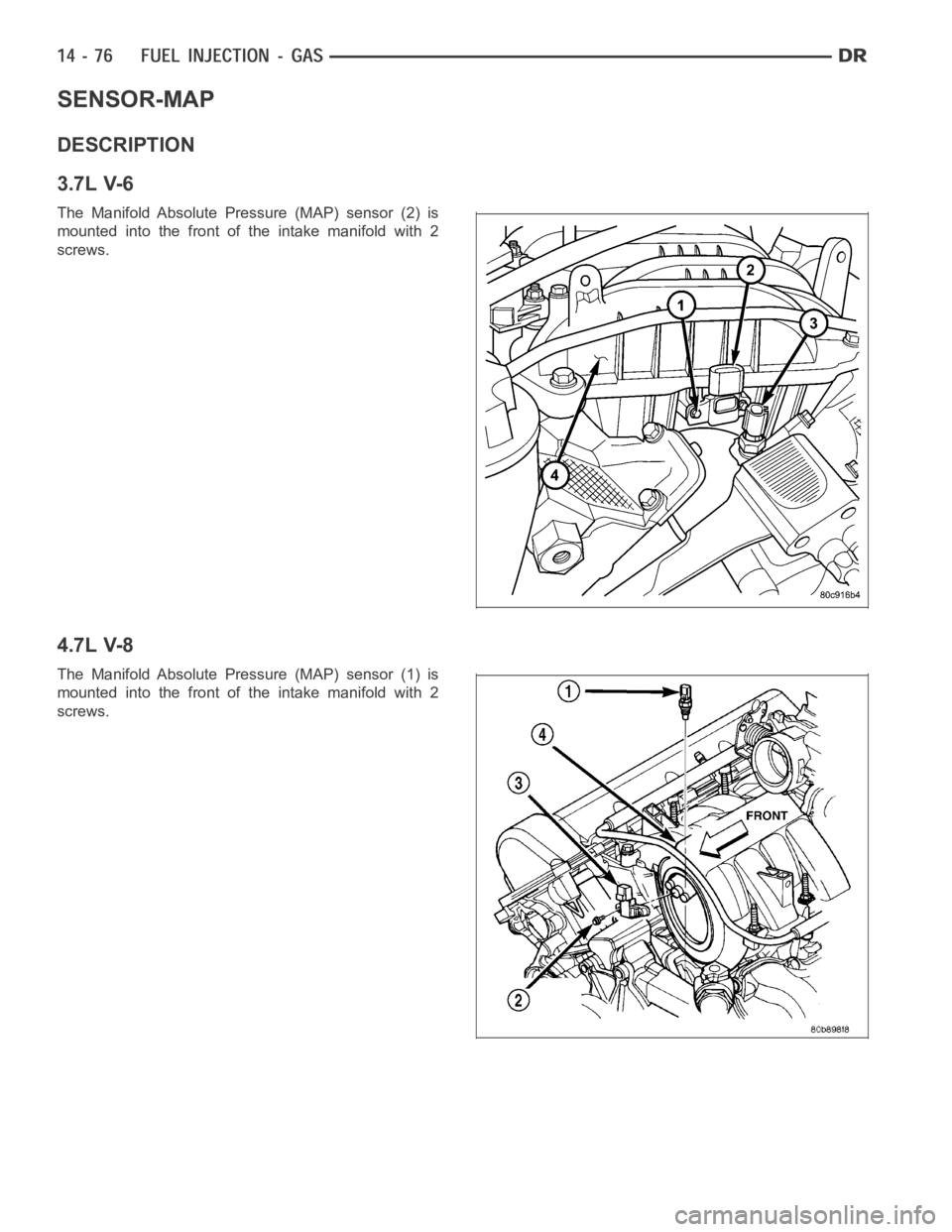

SENSOR-MAP

DESCRIPTION

3.7L V-6

The Manifold Absolute Pressure (MAP) sensor (2) is

mounted into the front of the intake manifold with 2

screws.

4.7L V-8

The Manifold Absolute Pressure (MAP) sensor (1) is

mounted into the front of the intake manifold with 2

screws.