belt DODGE RAM SRT-10 2006 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1160 of 5267

When Monitored:

Any time the engine is running, and the adaptive numerator has been successfully updated.

Set Condition:

When more than a 1% misfire rate is measured during two trips, or with a 6% to 30% misfire rate during one

trip.

Possible Causes

(K342) ASD RELAY OUTPUT CIRCUIT

(K14) INJECTOR CONTROL CIRCUIT

(K133) COIL CONTROL CIRCUIT

IGNITION WIRE

SPARK PLUG

IGNITION COIL

FUEL PUMP INLET STRAINER PLUGGED

RESTRICTED FUEL SUPPLY LINE

FUEL PUMP MODULE

FUEL PRESSURE LEAK DOWN

FUEL INJECTOR

ENGINE MECHANICAL

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.CYLINDER MIS-FIRE CONDITION ACTIVE

Engine running.

Observe the WHICH CYLINDER IS MISFIRING screen for at least one minute on the scan tool.

Isthereamisfirepresentatthistime?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.VISUAL INSPECTION

NOTE: Anything that affects the speed of the crankshaft can cause a misfireDTC.

NOTE: When a Misfire is detected for a particular cylinder, the PCM will shut down that cylinders Injector

Control circuit.

- Visually inspect the engine for any of the following conditions.

- Worn serpentine belt

- Binding Engine-Driven accessories: A/C Compressor, P/S Pump, Water pump.

- Misalignment of the Water pump, P/S Pump and A/C Compressor pulleys

- Corroded PCM power and ground circuits.

- Improper CKP, CMP, MAP, and TP Sensor mounting

- Poor connector/terminal to component connection. i.e., CKP sensor, Fuel Injector, Ign coil, etc.

- Vacuum leaks

- Restricted Air Induction system or Exhaust system.

Page 1169 of 5267

When Monitored:

Any time the engine is running, and the adaptive numerator has been successfully updated.

Set Condition:

When more than a 1% misfire rate is measured during two trips, or with a 6% to 30% misfire rate during one

trip.

Possible Causes

(K342) ASD RELAY OUTPUT CIRCUIT

(K38) INJECTOR CONTROL CIRCUIT

(K17) COIL CONTROL CIRCUIT

IGNITION WIRE

SPARK PLUG

IGNITION COIL

FUEL PUMP INLET STRAINER PLUGGED

RESTRICTED FUEL SUPPLY LINE

FUEL PUMP MODULE

FUEL PRESSURE LEAK DOWN

FUEL INJECTOR

ENGINE MECHANICAL

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.CYLINDER MIS-FIRE CONDITION ACTIVE

Engine running.

Observe the WHICH CYLINDER IS MISFIRING screen for at least one minute on the scan tool.

Isthereamisfirepresentatthistime?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.VISUAL INSPECTION

NOTE: Anything that affects the speed of the crankshaft can cause a misfireDTC.

NOTE: When a Misfire is detected for a particular cylinder, the PCM will shut down that cylinders Injector

Control circuit.

- Visually inspect the engine for any of the following conditions.

- Worn serpentine belt

- Binding Engine-Driven accessories: A/C Compressor, P/S Pump, Water pump.

- Misalignment of the Water pump, P/S Pump and A/C Compressor pulleys

- Corroded PCM power and ground circuits.

- Improper CKP, CMP, MAP, and TP Sensor mounting

- Poor connector/terminal to component connection. i.e., CKP sensor, Fuel Injector, Ign coil, etc.

- Vacuum leaks

- Restricted Air Induction system or Exhaust system.

Page 1178 of 5267

When Monitored:

Any time the engine is running, and the adaptive numerator has been successfully updated.

Set Condition:

When more than a 1% misfire rate is measured during two trips, or with a 6% to 30% misfire rate during one

trip.

Possible Causes

(K342) ASD RELAY OUTPUT CIRCUIT

(K58) INJECTOR CONTROL CIRCUIT

(K19) COIL CONTROL CIRCUIT

IGNITION WIRE

SPARK PLUG

IGNITION COIL

FUEL PUMP INLET STRAINER PLUGGED

RESTRICTED FUEL SUPPLY LINE

FUEL PUMP MODULE

FUEL PRESSURE LEAK DOWN

FUEL INJECTOR

ENGINE MECHANICAL

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.CYLINDER MIS-FIRE CONDITION ACTIVE

Engine running.

Observe the WHICH CYLINDER IS MISFIRING screen for at least one minute on the scan tool.

Isthereamisfirepresentatthistime?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.VISUAL INSPECTION

NOTE: Anything that affects the speed of the crankshaft can cause a misfireDTC.

NOTE: When a Misfire is detected for a particular cylinder, the PCM will shut down that cylinders Injector

Control circuit.

- Visually inspect the engine for any of the following conditions.

- Worn serpentine belt

- Binding Engine-Driven accessories: A/C Compressor, P/S Pump, Water pump.

- Misalignment of the Water pump, P/S Pump and A/C Compressor pulleys

- Corroded PCM power and ground circuits.

- Improper CKP, CMP, MAP, and TP Sensor mounting

- Poor connector/terminal to component connection. i.e., CKP sensor, Fuel Injector, Ign coil, etc.

- Vacuum leaks

- Restricted Air Induction system or Exhaust system.

Page 1187 of 5267

When Monitored:

Any time the engine is running, and the adaptive numerator has been successfully updated.

Set Condition:

When more than a 1% misfire rate is measured during two trips, or with a 6% to 30% misfire rate during one

trip.

Possible Causes

(K342) ASD RELAY OUTPUT CIRCUIT

(K26) INJECTOR CONTROL CIRCUIT

(K133) COIL CONTROL CIRCUIT

IGNITION WIRE

SPARK PLUG

IGNITION COIL

FUEL PUMP INLET STRAINER PLUGGED

RESTRICTED FUEL SUPPLY LINE

FUEL PUMP MODULE

FUEL PRESSURE LEAK DOWN

FUEL INJECTOR

ENGINE MECHANICAL

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.CYLINDER MIS-FIRE CONDITION ACTIVE

Engine running.

Observe the WHICH CYLINDER IS MISFIRING screen for at least one minute on the scan tool.

Isthereamisfirepresentatthistime?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.VISUAL INSPECTION

NOTE: Anything that affects the speed of the crankshaft can cause a misfireDTC.

NOTE: When a Misfire is detected for a particular cylinder, the PCM will shut down that cylinders Injector

Control circuit.

- Visually inspect the engine for any of the following conditions.

- Worn serpentine belt

- Binding Engine-Driven accessories: A/C Compressor, P/S Pump, Water pump.

- Misalignment of the Water pump, P/S Pump and A/C Compressor pulleys

- Corroded PCM power and ground circuits.

- Improper CKP, CMP, MAP, and TP Sensor mounting

- Poor connector/terminal to component connection. i.e., CKP sensor, Fuel Injector, Ign coil, etc.

- Vacuum leaks

- Restricted Air Induction system or Exhaust system.

Page 1196 of 5267

When Monitored:

Any time the engine is running, and the adaptive numerator has been successfully updated.

Set Condition:

When more than a 1% misfire rate is measured during two trips, or with a 6% to 30% misfire rate during one

trip.

Possible Causes

(K342) ASD RELAY OUTPUT CIRCUIT

(K28) INJECTOR CONTROL CIRCUIT

(K18) COIL CONTROL CIRCUIT

IGNITION WIRE

SPARK PLUG

IGNITION COIL

FUEL PUMP INLET STRAINER PLUGGED

RESTRICTED FUEL SUPPLY LINE

FUEL PUMP MODULE

FUEL PRESSURE LEAK DOWN

FUEL INJECTOR

ENGINE MECHANICAL

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.CYLINDER MIS-FIRE CONDITION ACTIVE

Engine running.

Observe the WHICH CYLINDER IS MISFIRING screen for at least one minute on the scan tool.

Isthereamisfirepresentatthistime?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.VISUAL INSPECTION

NOTE: Anything that affects the speed of the crankshaft can cause a misfireDTC.

NOTE: When a Misfire is detected for a particular cylinder, the PCM will shut down that cylinders Injector

Control circuit.

- Visually inspect the engine for any of the following conditions.

- Worn serpentine belt

- Binding Engine-Driven accessories: A/C Compressor, P/S Pump, Water pump.

- Misalignment of the Water pump, P/S Pump and A/C Compressor pulleys

- Corroded PCM power and ground circuits.

- Improper CKP, CMP, MAP, and TP Sensor mounting

- Poor connector/terminal to component connection. i.e., CKP sensor, Fuel Injector, Ign coil, etc.

- Vacuum leaks

- Restricted Air Induction system or Exhaust system.

Page 1205 of 5267

When Monitored:

Any time the engine is running, and the adaptive numerator has been successfully updated.

Set Condition:

When more than a 1% misfire rate is measured during two trips, or with a 6% to 30% misfire rate during one

trip.

Possible Causes

(K342) ASD RELAY OUTPUT CIRCUIT

(K115) INJECTOR CONTROL CIRCUIT

(K18) COIL CONTROL CIRCUIT

IGNITION WIRE

SPARK PLUG

IGNITION COIL

FUEL PUMP INLET STRAINER PLUGGED

RESTRICTED FUEL SUPPLY LINE

FUEL PUMP MODULE

FUEL PRESSURE LEAK DOWN

FUEL INJECTOR

ENGINE MECHANICAL

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.CYLINDER MIS-FIRE CONDITION ACTIVE

Engine running.

Observe the WHICH CYLINDER IS MISFIRING screen for at least one minute on the scan tool.

Isthereamisfirepresentatthistime?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.VISUAL INSPECTION

NOTE: Anything that affects the speed of the crankshaft can cause a misfireDTC.

NOTE: When a Misfire is detected for a particular cylinder, the PCM will shut down that cylinders Injector

Control circuit.

- Visually inspect the engine for any of the following conditions.

- Worn serpentine belt

- Binding Engine-Driven accessories: A/C Compressor, P/S Pump, Water pump.

- Misalignment of the Water pump, P/S Pump and A/C Compressor pulleys

- Corroded PCM power and ground circuits.

- Improper CKP, CMP, MAP, and TP Sensor mounting

- Poor connector/terminal to component connection. i.e., CKP sensor, Fuel Injector, Ign coil, etc.

- Vacuum leaks

- Restricted Air Induction system or Exhaust system.

Page 1214 of 5267

When Monitored:

Any time the engine is running, and the adaptive numerator has been successfully updated.

Set Condition:

When more than a 1% misfire rate is measured during two trips, or with a 6% to 30% misfire rate during one

trip.

Possible Causes

(K342) ASD RELAY OUTPUT CIRCUIT

(K116) INJECTOR CONTROL CIRCUIT

(K17) COIL CONTROL CIRCUIT

IGNITION WIRE

SPARK PLUG

IGNITION COIL

FUEL PUMP INLET STRAINER PLUGGED

RESTRICTED FUEL SUPPLY LINE

FUEL PUMP MODULE

FUEL PRESSURE LEAK DOWN

FUEL INJECTOR

ENGINE MECHANICAL

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.CYLINDER MIS-FIRE CONDITION ACTIVE

Engine running.

Observe the WHICH CYLINDER IS MISFIRING screen for at least one minute on the scan tool.

Isthereamisfirepresentatthistime?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.VISUAL INSPECTION

NOTE: Anything that affects the speed of the crankshaft can cause a misfireDTC.

NOTE: When a Misfire is detected for a particular cylinder, the PCM will shut down that cylinders Injector

Control circuit.

- Visually inspect the engine for any of the following conditions.

- Worn serpentine belt

- Binding Engine-Driven accessories: A/C Compressor, P/S Pump, Water pump.

- Misalignment of the Water pump, P/S Pump and A/C Compressor pulleys

- Corroded PCM power and ground circuits.

- Improper CKP, CMP, MAP, and TP Sensor mounting

- Poor connector/terminal to component connection. i.e., CKP sensor, Fuel Injector, Ign coil, etc.

- Vacuum leaks

- Restricted Air Induction system or Exhaust system.

Page 1228 of 5267

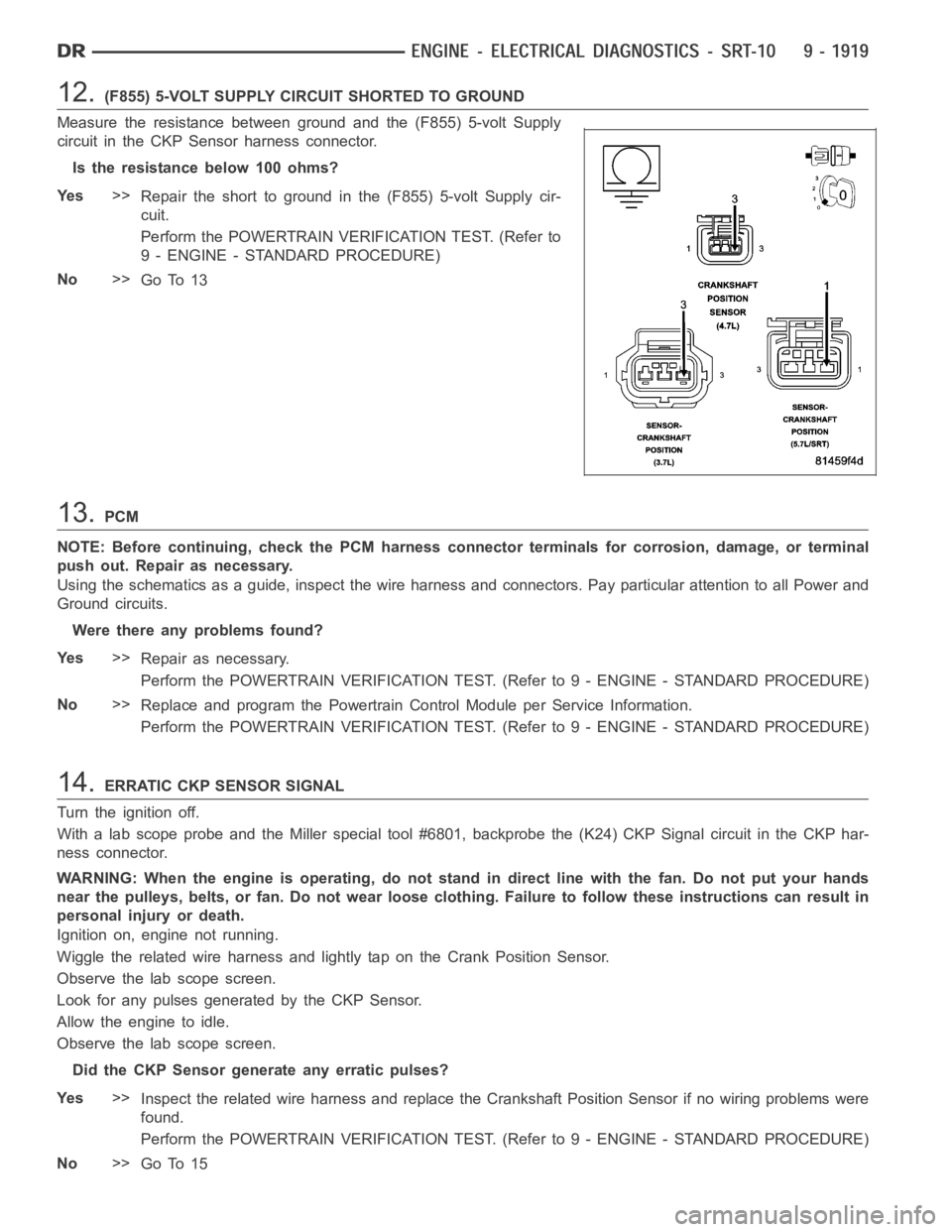

12.(F855) 5-VOLT SUPPLY CIRCUIT SHORTED TO GROUND

Measure the resistance between ground and the (F855) 5-volt Supply

circuit in the CKP Sensor harness connector.

Istheresistancebelow100ohms?

Ye s>>

Repair the short to ground in the (F855) 5-volt Supply cir-

cuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 13

13.PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

14.ERRATIC CKP SENSOR SIGNAL

Turn the ignition off.

With a lab scope probe and the Miller special tool #6801, backprobe the (K24) CKP Signal circuit in the CKP har-

ness connector.

WARNING: When the engine is operating, do not stand in direct line with the fan. Do not put your hands

near the pulleys, belts, or fan. Do notwear loose clothing. Failure to follow these instructions can result in

personal injury or death.

Ignition on, engine not running.

Wiggle the related wire harness and lightly tap on the Crank Position Sensor.

Observe the lab scope screen.

Look for any pulses generated by the CKP Sensor.

Allow the engine to idle.

Observe the lab scope screen.

Did the CKP Sensor generate any erratic pulses?

Ye s>>

Inspect the related wire harness and replace the Crankshaft Position Sensor if no wiring problems were

found.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 15

Page 1229 of 5267

15.ERRATIC CMP SIGNAL

Turn the ignition off.

With a lab scope probe and the Miller special tool #6801, backprobe the (K44) CMP Signal circuit in the CMP

harness connector.

WARNING: When the engine is operating, do not stand in direct line with the fan. Do not put your hands

near the pulleys, belts, or fan. Do notwear loose clothing. Failure to follow these instructions can result in

personal injury or death.

Ignition on, engine not running.

Wiggle the related wire harness and lightly tap on the Cam Position Sensor.

Observe the lab scope screen.

Look for any pulses generated by the CMP Sensor.

Allow the engine to idle.

Observe the lab scope screen.

Did the CMP Sensor generate any pulses?

Ye s>>

Inspect the related wire harness and replace the Camshaft Position Sensorif no wiring problems were

found.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Test complete, the conditions that set this DTC are not present at this time.

Page 1243 of 5267

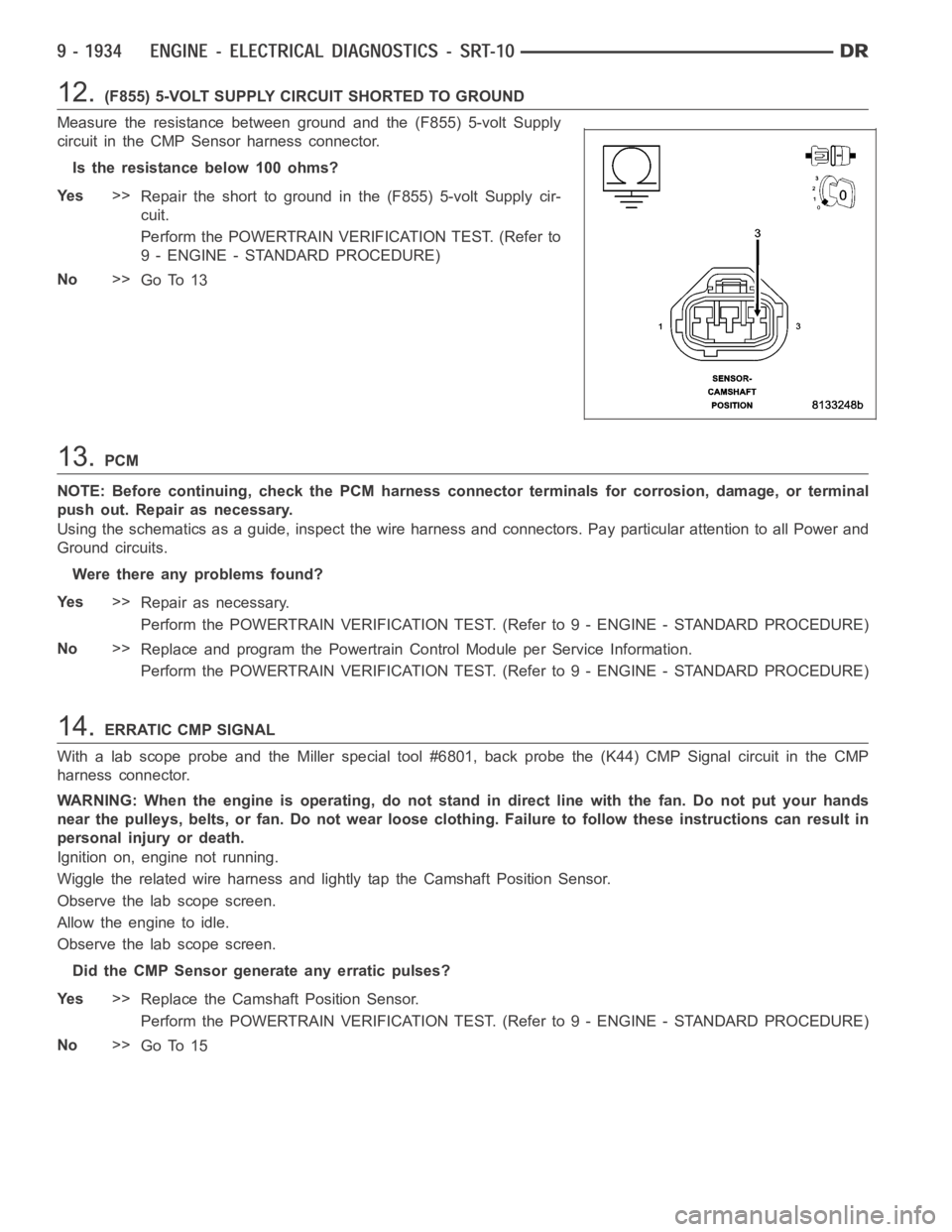

12.(F855) 5-VOLT SUPPLY CIRCUIT SHORTED TO GROUND

Measure the resistance between ground and the (F855) 5-volt Supply

circuit in the CMP Sensor harness connector.

Istheresistancebelow100ohms?

Ye s>>

Repair the short to ground in the (F855) 5-volt Supply cir-

cuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 13

13.PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace and program the Powertrain Control Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

14.ERRATIC CMP SIGNAL

With a lab scope probe and the Miller special tool #6801, back probe the (K44) CMP Signal circuit in the CMP

harness connector.

WARNING: When the engine is operating, do not stand in direct line with the fan. Do not put your hands

near the pulleys, belts, or fan. Do notwear loose clothing. Failure to follow these instructions can result in

personal injury or death.

Ignition on, engine not running.

Wiggle the related wire harness and lightly tap the Camshaft Position Sensor.

Observe the lab scope screen.

Allow the engine to idle.

Observe the lab scope screen.

Did the CMP Sensor generate any erratic pulses?

Ye s>>

Replace the Camshaft Position Sensor.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 15