belt DODGE RAM SRT-10 2006 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1541 of 5267

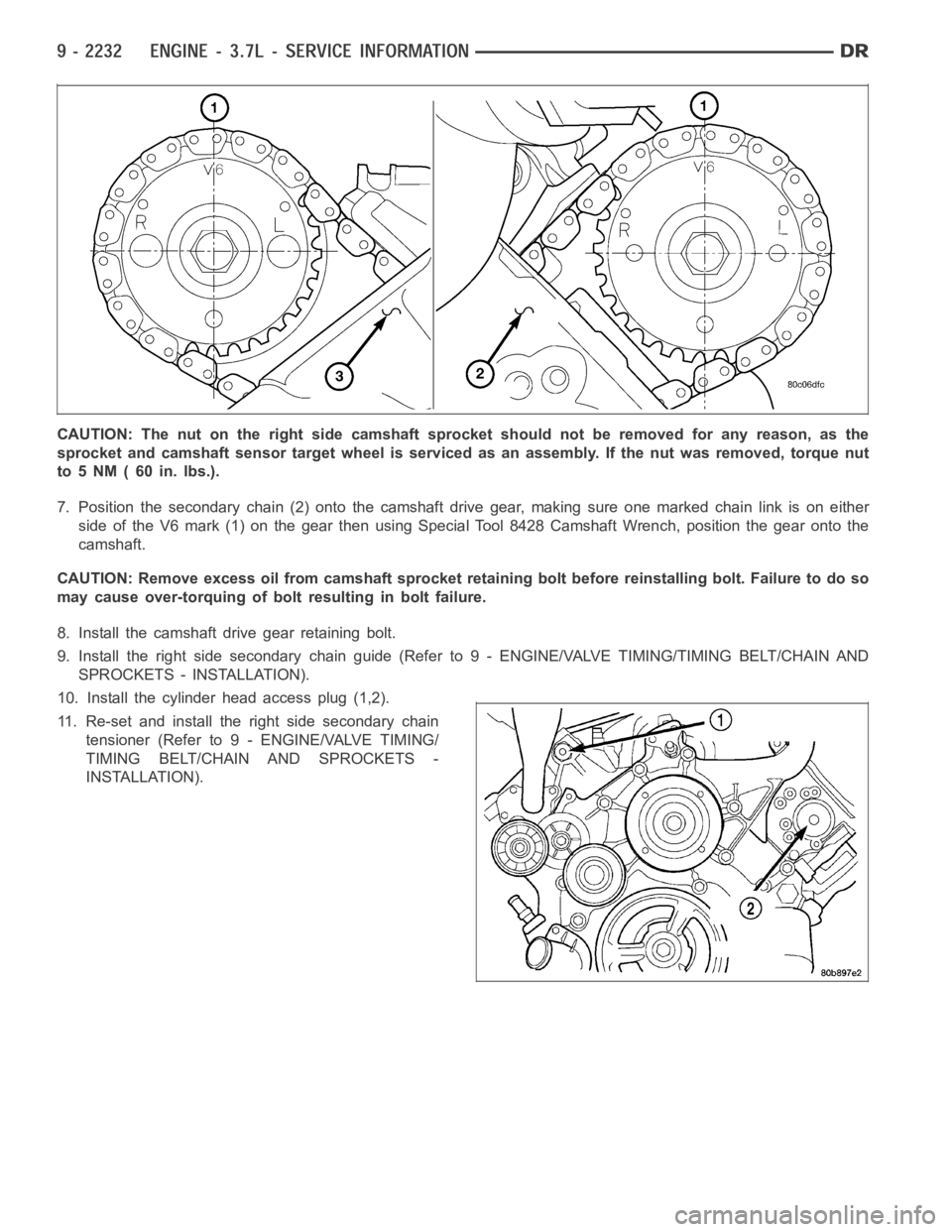

CAUTION: The nut on the right side camshaft sprocket should not be removed for any reason, as the

sprocket and camshaft sensor target wheel is serviced as an assembly. If the nut was removed, torque nut

to 5 NM ( 60 in. lbs.).

7. Position the secondary chain (2) onto the camshaft drive gear, making sure one marked chain link is on either

side of the V6 mark (1) on the gear then using Special Tool 8428 Camshaft Wrench, position the gear onto the

camshaft.

CAUTION: Remove excess oil from camshaft sprocket retaining bolt before reinstalling bolt. Failure to do so

may cause over-torquing of bolt resulting in bolt failure.

8. Install the camshaft drive gear retaining bolt.

9. Install the right side secondary chain guide (Refer to 9 - ENGINE/VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION).

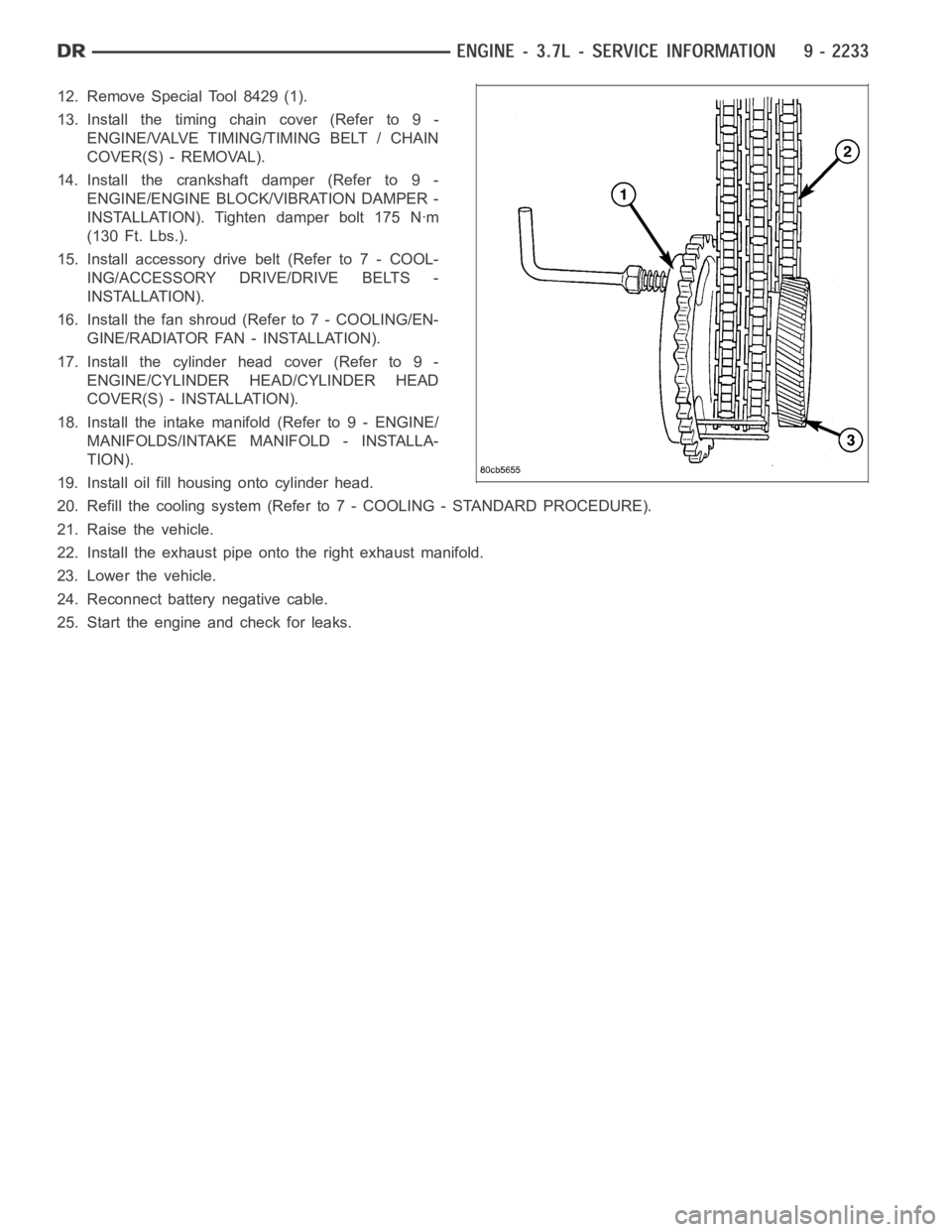

10. Install the cylinder head access plug (1,2).

11. Re-set and install the right side secondary chain

tensioner (Refer to 9 - ENGINE/VALVE TIMING/

TIMING BELT/CHAIN AND SPROCKETS -

INSTALLATION).

Page 1542 of 5267

12. Remove Special Tool 8429 (1).

13. Install the timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

14. Install the crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION). Tighten damper bolt 175 Nꞏm

(130 Ft. Lbs.).

15. Install accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

16. Install the fan shroud (Refer to 7 - COOLING/EN-

GINE/RADIATOR FAN - INSTALLATION).

17. Install the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

18. Install the intake manifold (Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD - INSTALLA-

TION).

19. Install oil fill housing onto cylinder head.

20. Refill the cooling system (Refer to 7 - COOLING - STANDARD PROCEDURE).

21. Raise the vehicle.

22. Install the exhaust pipe onto the right exhaust manifold.

23. Lower the vehicle.

24. Reconnect battery negative cable.

25. Start the engine and check for leaks.

Page 1548 of 5267

COVER - CYLINDER HEAD

REMOVAL

1. Disconnect battery negative cable.

2. Remove air cleaner assembly, resonator assembly and air inlet hose.

3. Drain cooling system, below the level of the heater hoses (Refer to 7 - COOLING - STANDARD PROCEDURE).

4. Remove accessory drive belt (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - REMOVAL).

5. Remove air conditioning compressor retaining bolts and move compressortotheleft.

6. Remove heater hoses.

7. Disconnect injector and ignition coil connectors.

8. Disconnect and remove positive crankcase ventilation (PCV) hose.

9. Remove oil fill tube.

10. Un-clip injector and ignition coil harness and move away from cylinderhead cover.

11. Remove right rear breather tube and filter assembly.

12. Remove cylinder head cover retaining bolts.

13. Remove cylinder head cover.

INSTALLATION

CAUTION: Do not use harsh cleaners to clean the cylinder head covers. Severedamagetocoversmay

occur.

NOTE: The gasket may be used again, provided no cuts, tears, or deformationhas occurred.

1. Clean cylinder head cover and both sealing surfaces. Inspect and replace gasket as necessary.

2. Tighten cylinder head cover bolts and double ended studs to 12 Nꞏm (105 in.lbs).

3. Install right rear breather tube and filter assembly.

4. Connect injector, ignition coil electrical connectors and harness retaining clips.

5. Install the oil fill tube.

6. Install PCV hose.

7. Install heater hoses.

8. Install air conditioning compressor retaining bolts.

9. Install accessory drive belt (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - INSTALLATION).

10. Fill Cooling system (Refer to 7 - COOLING - STANDARD PROCEDURE).

11. Install air cleaner assembly, resonator assembly and air inlet hose.

12. Connect battery negative cable.

Page 1562 of 5267

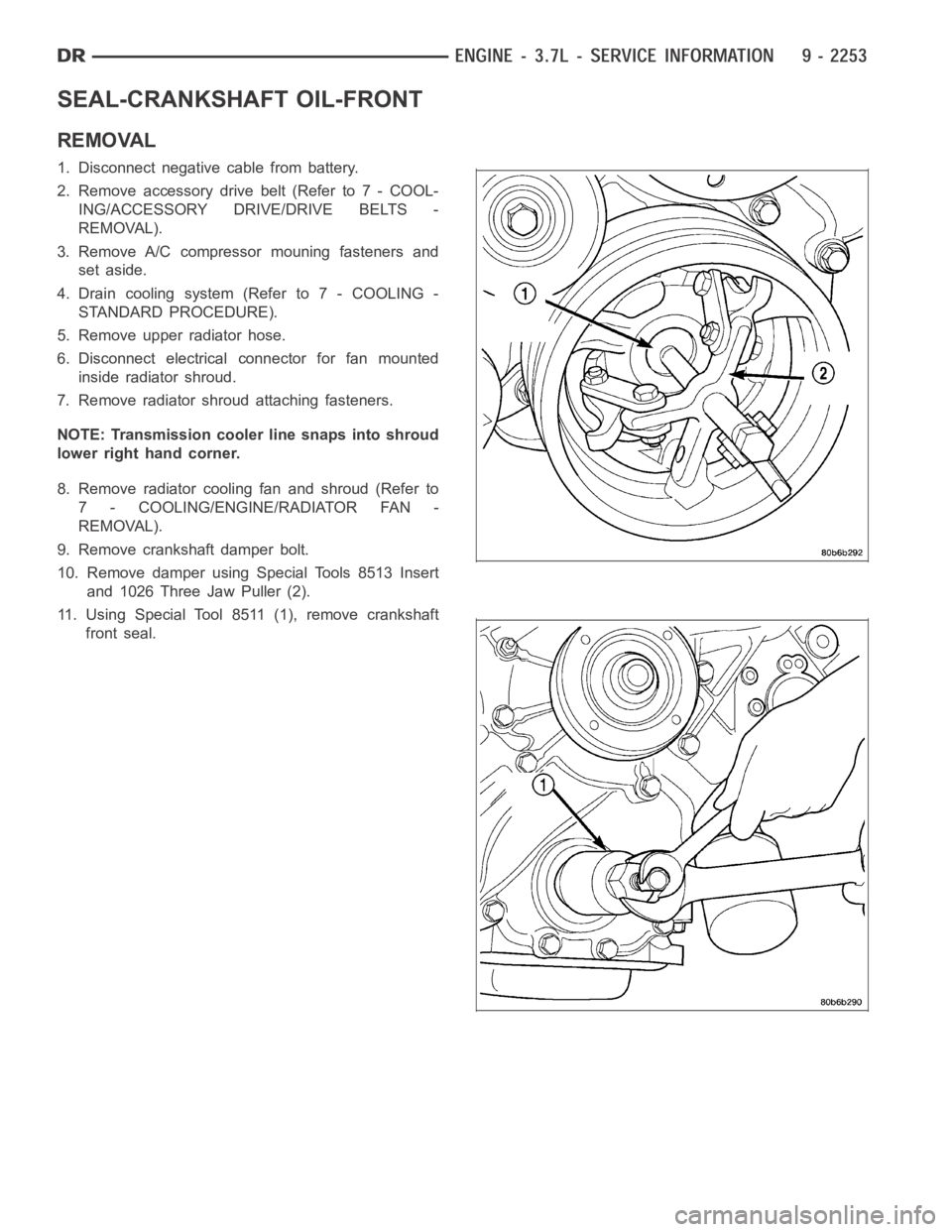

SEAL-CRANKSHAFT OIL-FRONT

REMOVAL

1. Disconnect negative cable from battery.

2. Remove accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

3. Remove A/C compressor mouning fasteners and

set aside.

4. Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

5. Remove upper radiator hose.

6. Disconnect electrical connector for fan mounted

inside radiator shroud.

7. Remove radiator shroud attaching fasteners.

NOTE: Transmission cooler line snaps into shroud

lower right hand corner.

8. Remove radiator cooling fan and shroud (Refer to

7 - COOLING/ENGINE/RADIATOR FAN -

REMOVAL).

9. Remove crankshaft damper bolt.

10. Remove damper using Special Tools 8513 Insert

and 1026 Three Jaw Puller (2).

11. Using Special Tool 8511 (1), remove crankshaft

front seal.

Page 1563 of 5267

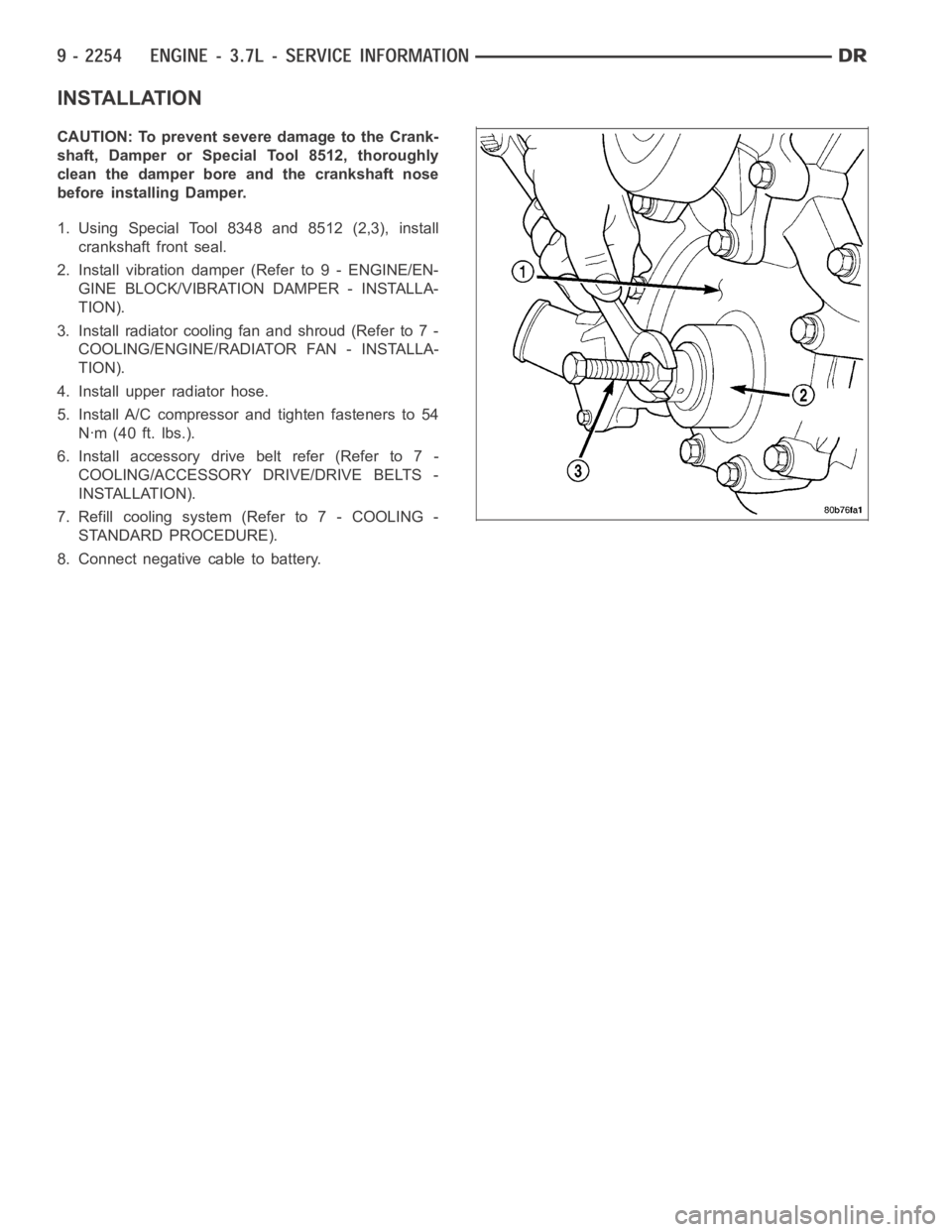

INSTALLATION

CAUTION: To prevent severe damage to the Crank-

shaft, Damper or Special Tool 8512, thoroughly

clean the damper bore and the crankshaft nose

before installing Damper.

1. Using Special Tool 8348 and 8512 (2,3), install

crankshaft front seal.

2. Install vibration damper (Refer to 9 - ENGINE/EN-

GINE BLOCK/VIBRATION DAMPER - INSTALLA-

TION).

3. Installradiatorcoolingfanandshroud(Referto7-

COOLING/ENGINE/RADIATOR FAN - INSTALLA-

TION).

4. Install upper radiator hose.

5. Install A/C compressor and tighten fasteners to 54

Nꞏm (40 ft. lbs.).

6. Install accessory drive belt refer (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

7. Refill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

8. Connect negative cable to battery.

Page 1571 of 5267

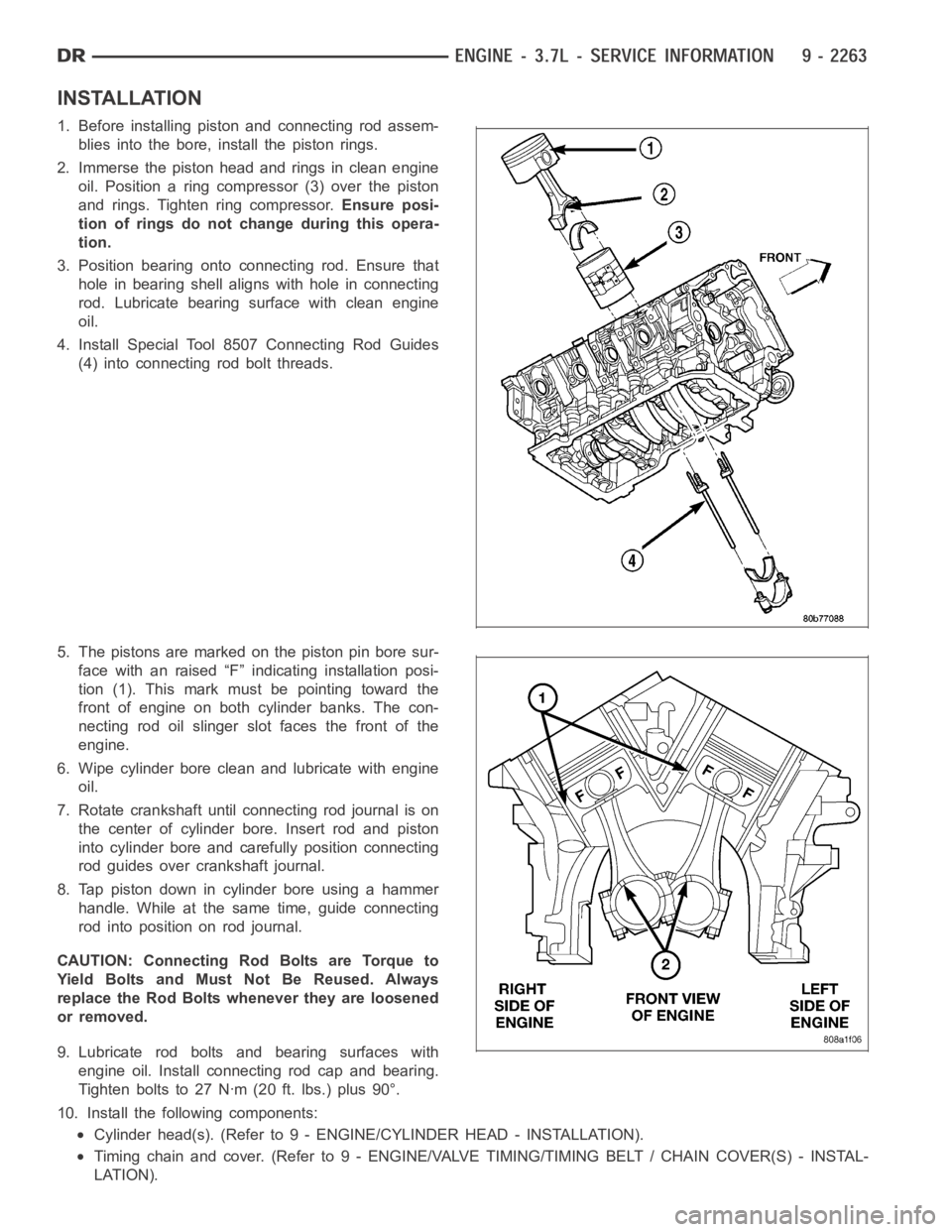

REMOVAL

1. Disconnect negative cable from battery.

2. Remove the following components:

Oil pan and gasket/windage tray (Refer to 9 - ENGINE/LUBRICATION/OIL PAN -REMOVAL).

Cylinder head covers (Refer to 9 - ENGINE/CYLINDER HEAD/CYLINDER HEAD COVER(S) - REMOVAL) and

(Refer to 9 - ENGINE/CYLINDER HEAD/CYLINDER HEAD COVER(S) - REMOVAL).

Timing chain cover (Refer to 9 - ENGINE/VALVE TIMING/TIMING BELT / CHAIN COVER(S) - REMOVAL).

Cylinder head(s) (Refer to 9 - ENGINE/CYLINDER HEAD - REMOVAL) and (Refer to 9 - ENGINE/CYLINDER

HEAD - REMOVAL).

3. If necessary, remove top ridge of cylinder bores with a reliable ridge reamer before removing pistons from cyl-

inder block.Be sure to keep tops of pistons covered during this operation.Pistons and connecting rods

must be removed from top of cylinder block. When removing piston and connecting rod assemblies from the

engine, rotate crankshaft so the each connecting rod is centered in cylinder bore.

CAUTION: DO NOT use a number stamp or a punch to mark connecting rods or caps,as damage to con-

necting rods could occur

NOTE: Connecting rods and bearing caps are not interchangeable and shouldbe marked before removing

to ensure correct reassembly.

4. Mark connecting rod and bearing cap positions using a permanent ink marker or scribe tool.

CAUTION: Care must be taken not to damage the fractured rod and cap joint face surfaces, as engine dam-

age may occur.

5. Remove connecting rod cap. Install Special Tool 8507 Connecting Rod Guides into the connecting rod being

removed. Remove piston from cylinder bore. Repeat this procedure for eachpiston being removed.

CAUTION: Care must be taken not to nick crankshaft journals, as engine damage may occur

6. Immediately after piston and connecting rod removal, install bearing cap on the mating connecting rod to prevent

damage to the fractured cap and rod surfaces.

CLEANING

CAUTION: DO NOT use a wire wheel or other abrasive cleaning devise to clean the pistons or connecting

rods. The pistons have a Moly coating, this coating must not be damaged.

1. Using a suitable cleaning solvent clean the pistons in warm water and towel dry.

2. Use a wood or plastic scraper to clean the ring land grooves.

CAUTION: DO NOT remove the piston pin from the piston and connecting rod assembly.

INSPECTION

Check the connecting rod journal for excessive wear, taper and scoring (Refer to 9 - ENGINE/ENGINE BLOCK/

CONNECTING ROD BEARINGS - STANDARD PROCEDURE).

Check the connecting rod for signs of twist or bending.

Check the piston for taper and elliptical shape before it is fitted into thecylinder bore (Refer to 9 - ENGINE/ENGINE

BLOCK/PISTON & CONNECTING ROD - STANDARD PROCEDURE).

Check the piston for scoring, or scraping marks in the piston skirts. Checkthe ring lands for cracks and/or deteri-

oration.

Page 1572 of 5267

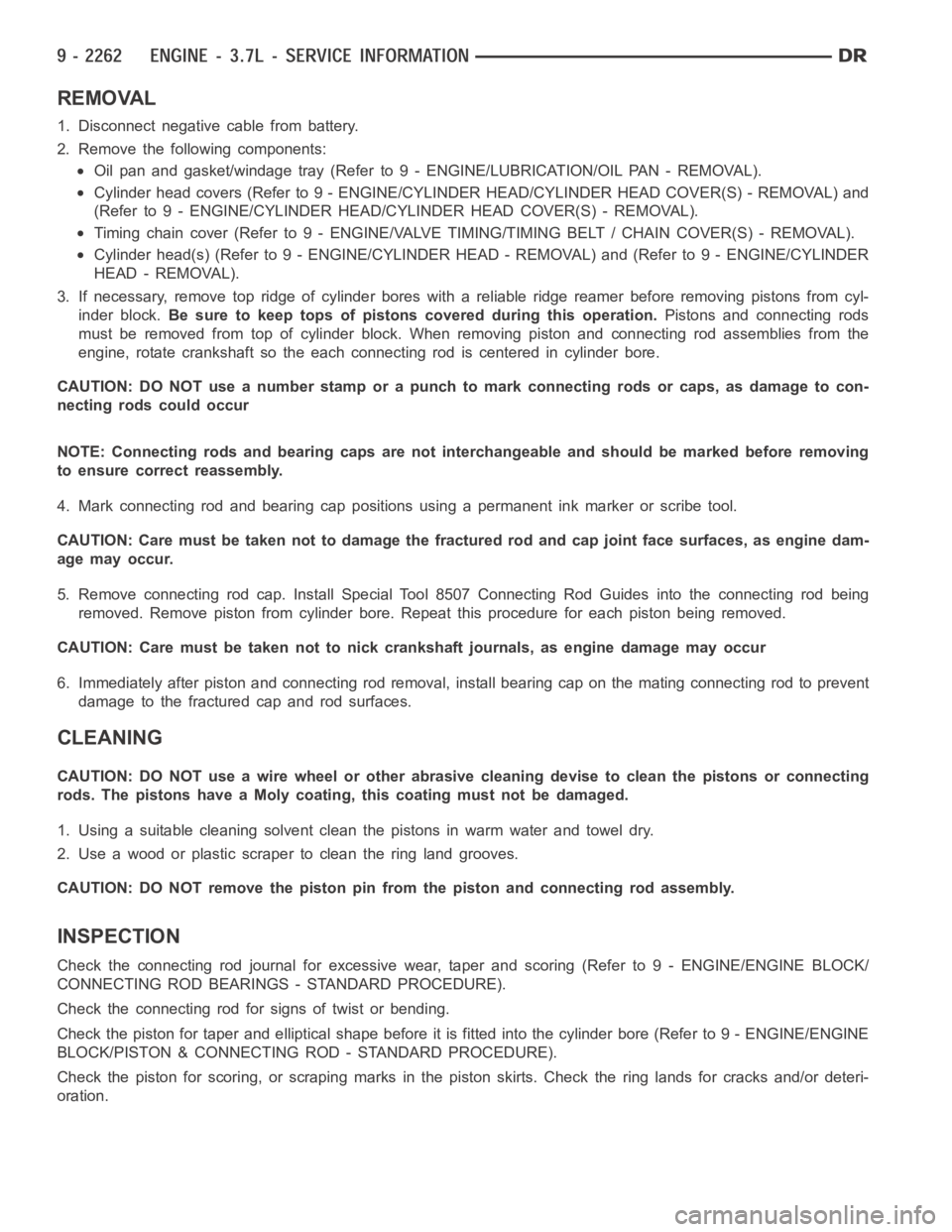

INSTALLATION

1. Before installing piston and connecting rod assem-

blies into the bore, install the piston rings.

2. Immerse the piston head and rings in clean engine

oil. Position a ring compressor (3) over the piston

and rings. Tighten ring compressor.Ensure posi-

tion of rings do not change during this opera-

tion.

3. Position bearing onto connecting rod. Ensure that

hole in bearing shell aligns with hole in connecting

rod. Lubricate bearing surface with clean engine

oil.

4. Install Special Tool 8507 Connecting Rod Guides

(4) into connecting rod bolt threads.

5. The pistons are marked on the piston pin bore sur-

face with an raised “F” indicating installation posi-

tion (1). This mark must be pointing toward the

front of engine on both cylinder banks. The con-

necting rod oil slinger slot faces the front of the

engine.

6. Wipe cylinder bore clean and lubricate with engine

oil.

7. Rotate crankshaft until connecting rod journal is on

the center of cylinder bore. Insert rod and piston

into cylinder bore and carefully position connecting

rod guides over crankshaft journal.

8. Tap piston down in cylinder bore using a hammer

handle. While at the same time, guide connecting

rodintopositiononrodjournal.

CAUTION: Connecting Rod Bolts are Torque to

Yield Bolts and Must Not Be Reused. Always

replace the Rod Bolts whenever they are loosened

or removed.

9. Lubricate rod bolts and bearing surfaces with

engine oil. Install connecting rod cap and bearing.

Tighten bolts to 27 Nꞏm (20 ft. lbs.) plus 90°.

10. Install the following components:

Cylinder head(s). (Refer to 9 - ENGINE/CYLINDER HEAD - INSTALLATION).

Timing chain and cover. (Refer to 9 - ENGINE/VALVE TIMING/TIMING BELT / CHAIN COVER(S) - INSTAL-

LATION).

Page 1577 of 5267

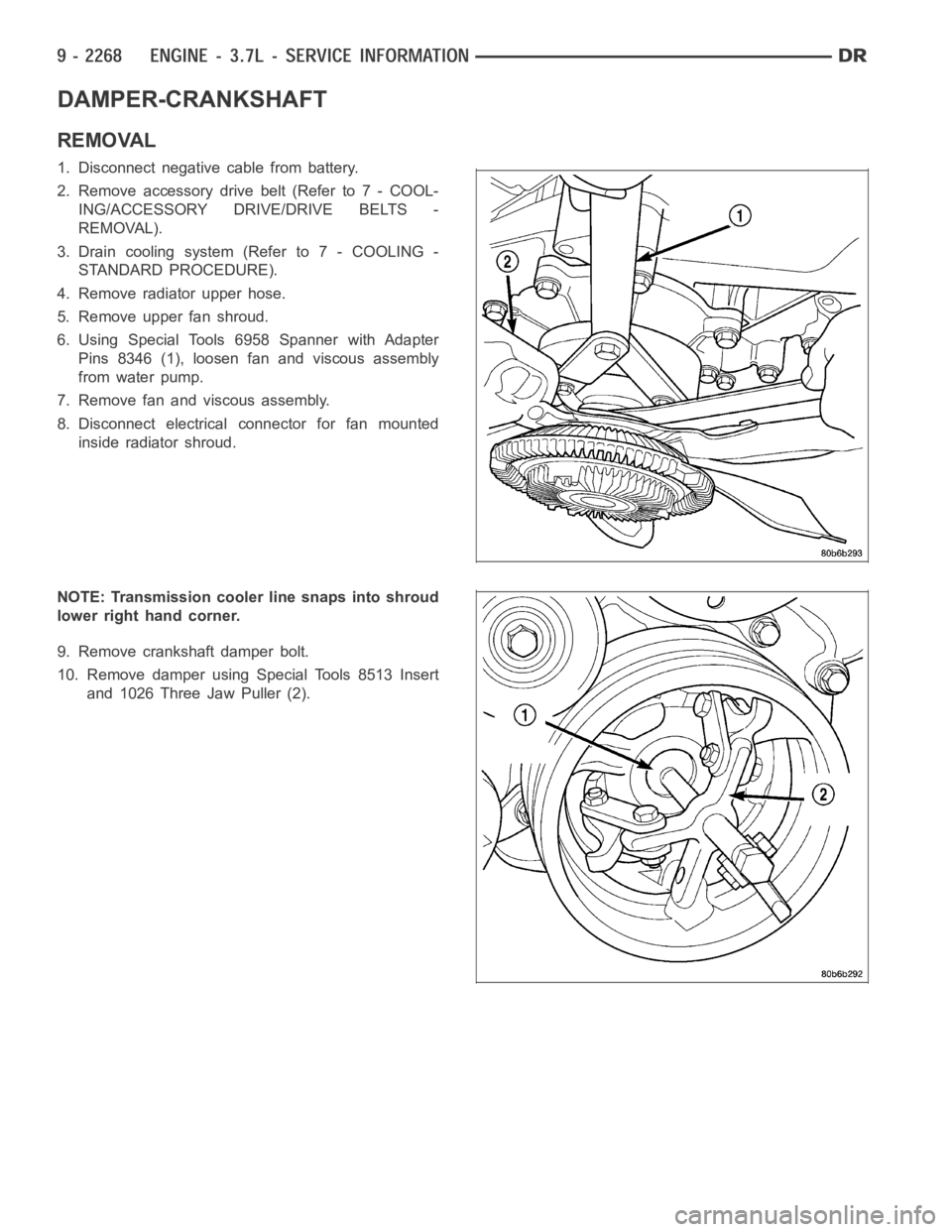

DAMPER-CRANKSHAFT

REMOVAL

1. Disconnect negative cable from battery.

2. Remove accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

3. Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

4. Remove radiator upper hose.

5. Remove upper fan shroud.

6. Using Special Tools 6958 Spanner with Adapter

Pins 8346 (1), loosen fan and viscous assembly

from water pump.

7. Remove fan and viscous assembly.

8. Disconnect electrical connector for fan mounted

inside radiator shroud.

NOTE: Transmission cooler line snaps into shroud

lower right hand corner.

9. Remove crankshaft damper bolt.

10. Remove damper using Special Tools 8513 Insert

and 1026 Three Jaw Puller (2).

Page 1578 of 5267

INSTALLATION

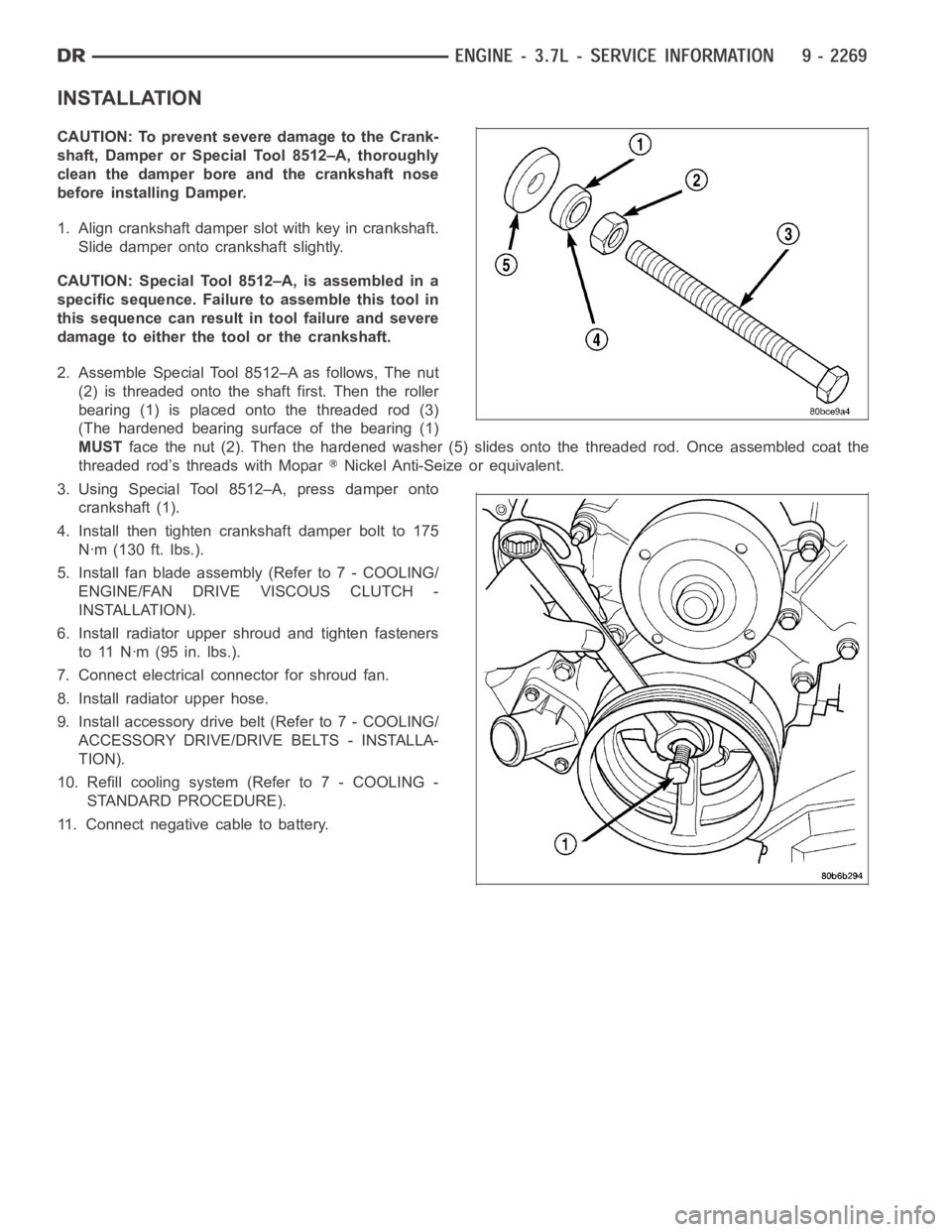

CAUTION: To prevent severe damage to the Crank-

shaft, Damper or Special Tool 8512–A, thoroughly

clean the damper bore and the crankshaft nose

before installing Damper.

1. Align crankshaft damper slot with key in crankshaft.

Slide damper onto crankshaft slightly.

CAUTION: Special Tool 8512–A, is assembled in a

specific sequence. Failure to assemble this tool in

this sequence can result in tool failure and severe

damage to either the tool or the crankshaft.

2. Assemble Special Tool 8512–A as follows, The nut

(2) is threaded onto the shaft first. Then the roller

bearing (1) is placed onto the threaded rod (3)

(The hardened bearing surface of the bearing (1)

MUSTface the nut (2). Then the hardened washer (5) slides onto the threaded rod.Once assembled coat the

threaded rod’s threads with Mopar

Nickel Anti-Seize or equivalent.

3. Using Special Tool 8512–A, press damper onto

crankshaft (1).

4. Install then tighten crankshaft damper bolt to 175

Nꞏm (130 ft. lbs.).

5. Install fan blade assembly (Refer to 7 - COOLING/

ENGINE/FAN DRIVE VISCOUS CLUTCH -

INSTALLATION).

6. Install radiator upper shroud and tighten fasteners

to 11 Nꞏm (95 in. lbs.).

7. Connect electrical connector for shroud fan.

8. Install radiator upper hose.

9. Install accessory drive belt (Refer to 7 - COOLING/

ACCESSORY DRIVE/DRIVE BELTS - INSTALLA-

TION).

10. Refill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

11. Connect negative cable to battery.

Page 1594 of 5267

PUMP-ENGINE OIL

REMOVAL

1. Remove the oil pan and pick-up tube (Refer to 9 - ENGINE/LUBRICATION/OILPA N - R E M O VA L ) .

2. Remove the timing chain cover (Refer to 9 - ENGINE/VALVE TIMING/TIMING BELT / CHAIN COVER(S) -

REMOVAL).

3. Remove the timing chains and tensioners (Refer to 9 - ENGINE/VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL).

4. Remove the four bolts, primary timing chain tensioner and the oil pump.

DISASSEMBLY

1. Remove oil pump cover screws and lift off cover plate.

2. Remove pump inner and outer rotors.

NOTE: Once the oil pressure relief valve, cup plug, and pin are removed, thepump assembly must be

replaced.

3. If it is necessary to remove the pressure relief valve, drive the roll pinfrom pump housing and remove cup plug,

spring and valve.

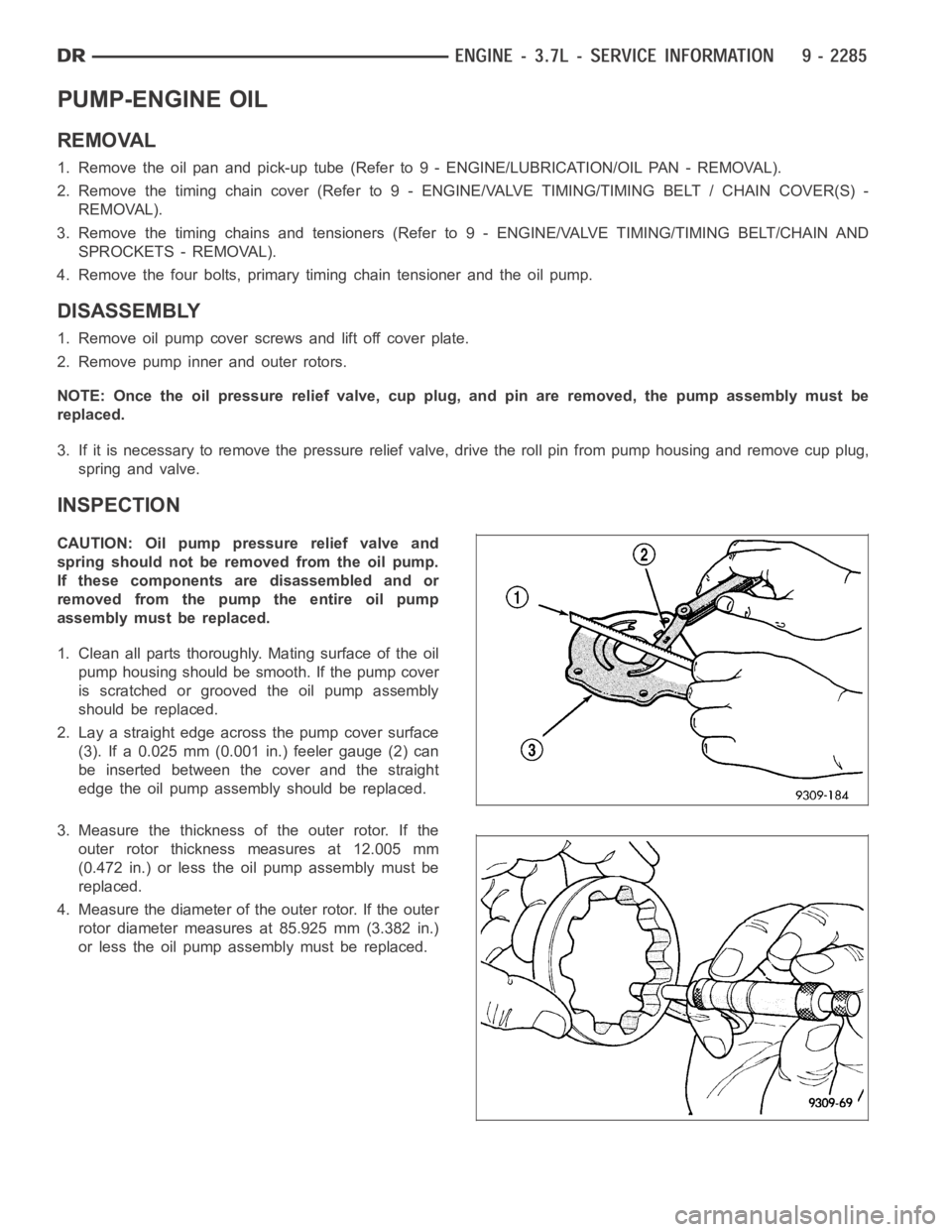

INSPECTION

CAUTION: Oil pump pressure relief valve and

spring should not be removed from the oil pump.

If these components are disassembled and or

removed from the pump the entire oil pump

assembly must be replaced.

1. Clean all parts thoroughly. Mating surface of the oil

pump housing should be smooth. If the pump cover

is scratched or grooved the oil pump assembly

should be replaced.

2. Lay a straight edge across the pump cover surface

(3). If a 0.025 mm (0.001 in.) feeler gauge (2) can

be inserted between the cover and the straight

edge the oil pump assembly should be replaced.

3. Measure the thickness of the outer rotor. If the

outer rotor thickness measures at 12.005 mm

(0.472 in.) or less the oil pump assembly must be

replaced.

4. Measure the diameter of the outer rotor. If the outer

rotor diameter measures at 85.925 mm (3.382 in.)

or less the oil pump assembly must be replaced.