belt DODGE RAM SRT-10 2006 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1244 of 5267

15.ERRATIC CKP SIGNAL

Turn the ignition off.

With a lab scope probe and the Miller special tool #6801, backprobe the (K24) CKP Signal circuit in the CKP har-

ness connector.

WARNING: When the engine is operating, do not stand in direct line with the fan. Do not put your hands

near the pulleys, belts, or fan. Do notwear loose clothing. Failure to follow these instructions can result in

personal injury or death.

Ignition on, engine not running.

Wiggle the related wire harness and lightly tap on the Crankshaft PositionSensor.

Observe the lab scope screen.

Allow the engine to idle.

Observe the lab scope screen.

Did the CKP Sensor generate any erratic pulses?

Ye s>>

Replace the Crankshaft Position Sensor.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Test complete, the conditions that set this DTC are not present at this time

Page 1345 of 5267

3.(K342) ASD CONTROL OUTPUT CIRCUIT

Turn the ignition off

Connect the C2 TIPM harness connector.

Ignition on, engine not running.

Back probe the C10 TIPM harness connector at the (K342) ASD Control Output circuit terminal and measure the

voltage on the (K342) ASD Control Output circuit.

Is the voltage above 10 volts?

Ye s>>

Go To 4

No>>

Go To 7

4.(K342) ASD CONTROL OUTPUT CIRCUIT VOLTAGE DROP TO THE FUEL INJECTORS

Turn the ignition off.

With a voltmeter, use Negative lead of the voltmeter along with terminal probe tool #6801, backprobe the (K342)

ASD Control Output circuit at a Fuel Injector harness connector.

With the Positive lead of the voltmeter along with terminal probe tool #6801, back probe the (K342) ASD Control

Output circuit at the C10 TIPM harness connector.

Start the engine and allow it to idle.

WARNING: When the engine is operating, do not stand in direct line with the fan. Do not put your hands

near the pulleys, belts, or fan. Do notwear loose clothing. Failure to follow these instructions can result in

personal injury or death.

Measure the voltage of the (K342) ASD Control Output circuit.

NOTE: Perform the test at every fuel injector.

Is the voltage above 0.001 of a volt (1.0mV) for any of the Fuel Injector ASD Control Output circuits?

Ye s>>

Repair the excessive resistance in the (K342) ASD Control Output circuit to the appropriate Fuel Injec-

tor.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 5

5.(K342) ASD CONTROL OUTPUT CIRCUIT VOLTAGE DRIP TO THE IGNITION COILS

Turn the Ignition off.

With a voltmeter, use Negative lead of the voltmeter along with terminal probe tool #6801, backprobe the (K342)

ASD Control Output circuit at a Ignition Coil harness connector.

With the Positive lead of the voltmeter along with terminal probe tool #6801, back probe the (K342) ASD Control

Output circuit at the C10 TIPM harness connector.

Start the engine and allow it to idle.

WARNING: When the engine is operating, do not stand in direct line with the fan. Do not put your hands

near the pulleys, belts, or fan. Do notwear loose clothing. Failure to follow these instructions can result in

personal injury or death.

Measure the voltage of the (K342) ASD Control Output circuit.

NOTE: Perform the test at every Ignition Coil.

Is the voltage above 0.001 of a volt (1.0mV) for any of the Ignition Coil ASD Control Output circuits?

Ye s>>

Repair the excessive resistance in the (K342) ASD Control Output circuit to the appropriate Ignition Coil.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 6

Page 1346 of 5267

6.PCM Turn the ignition off.

Disconnect C3 NGC harness connector.

CAUTION: Do not probe the PCM harness connectors. Probing the PCM harness connectors will damage

the PCM terminals resulting in poor terminal to pin connection. Install Miller Special Tool #8815 and #8815-1

to perform diagnosis.

With a voltmeter, use Negative lead of the voltmeter along with terminal probe tool #6801, probe the (K342) ASD

Control Output circuit at the appropriate terminals of special tool #8815.

With the Positive lead of the voltmeter along with terminal probe tool #6801, back probe the (K342) ASD Control

Output circuit at the C10 TIPM harness connector.

Start the engine and allow it to idle.

WARNING: When the engine is operating, do not stand in direct line with the fan. Do not put your hands

near the pulleys, belts, or fan. Do notwear loose clothing. Failure to follow these instructions can result in

personal injury or death.

Measure the voltage of the (K342) ASD Control Output circuit.

Is the voltage above 0.001 of a volt (1.0mV) for any of the Ignition Coil ASD Control Output circuits?

Ye s>>

Repair the excessive resistance in the (K342) ASD Control Output circuit tothePCM.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace and program the Powertrain Control Module in accordance with Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

7.TOTALLY INTEGRATED POWER MODULE

NOTE: Before continuing, check the TIPM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors.

Pay particular attention to allPower and voltage circuits.

Were any problems found?

Ye s>>

Repair as necessary.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Replace the Totally Integrated Power Module per Service Information.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 1410 of 5267

When Monitored:

Engine running or cranking.

Set Condition:

When the failure counter reaches 20 for 2 consecutive trips.

Possible Causes

GOOD TRIP EQUAL TO ZERO

CMP WIRE HARNESS INSPECTION

TONE WHEEL/PULSE RING INSPECTION

CKP WIRE HARNESS INSPECTION

TONE WHEEL/PULSE RING INSPECTION

CHECKING INTERMITTENT CKP SIGNAL WITH LAB SCOPE

CAMSHAFT POSITION SENSOR

CRANKSHAFT POSITION SENSOR

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

1.GOOD TRIP EQUAL TO ZERO

Ignition on, engine not running.

WARNING: When the engine is operating, do not stand in a direct line with thefan. Do not put your hand

near the pulleys, belts, or fan. Do not wear loose clothing.

With the scan tool, read DTCs and record the related Freeze Frame data.

Start the engine and run until operating temp is reached. (Closed Loop)

If the DTC does not return right away it may be necessary to test drive the vehicle to duplicate the DTC.

Does the P1391 return?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITIONSymptom (Diagnostic Procedure).

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.INTERMITTENT CAM POSITION SENSOR SIGNAL

Turn the ignition off.

With the scan tool as a Dual Channel Lab Scope and Miller special tool #6801,backprobe the (K44) CMP Signal

circuit in the CMP harness connector and PCM harness connector.

WARNING: When the engine is operating, do not stand in a direct line with thefan. Do not put your hand

near the pulleys, belts, or fan. Do not wear loose clothing.

Start the engine.

Observe the lab scope screen.

Are there any irregular or missing signals?

Ye s>>

Go To 3

No>>

Go To 6

Page 1411 of 5267

3.CMP WIRE HARNESS INSPECTION

Visually inspect the related wire harness. Look for any chafed, pierced, pinched, or partially broken wires.

Visually inspect the related wire harness connectors. Look for broken, bent, pushed out, or corroded terminals.

Make sure the Crankshaft Position Sensor and the Camshaft Position Sensorare properly installed and the mount-

ing bolt(s) are torqued to specification.

Refer to any TSB that may apply.

Were any of the above conditions present?

Ye s>>

Repair as necessary

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 4

4.TONE WHEEL/PULSE RING INSPECTION

Turn the ignition off.

Remove the Camshaft Position Sensor.

Inspect the Tone Wheel/Pulse Ring for damage, foreign material, or excessive movement.

Were any problems found?

Ye s>>

Repair or replace the Tone Wheel/Pulse Ring as necessary.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 5

5.CAMSHAFT POSITION SENSOR

If there are no possible causes remaining, view repair.

Repair

Replace the Camshaft Position Sensor.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

6.CHECKING CKP SIGNAL WITH THE SCAN TOOL LAB

Turn the ignition off.

With the scan tool as a Dual Channel Lab Scope and the Miller special tool #6801, backprobe the (K24) CKP Signal

circuit in the CKP harness connector and PCM harness connector.

WARNING: When the engine is operating, do not stand in a direct line with thefan. Do not put your hand

near the pulleys, belts, or fan. Do not wear loose clothing.

Start the engine.

Observe the lab scope screen.

Are there any irregular or missing signals?

Ye s>>

Go To 7

No>>

Go To 10

Page 1412 of 5267

7.CKP WIRE HARNESS INSPECTION

Visually inspect the related wire harness. Look for any chafed, pierced, pinched, or partially broken wires.

Visually inspect the related wire harness connectors. Look for broken, bent, pushed out, or corroded terminals.

Ensure the Crankshaft Position Sensor and the Camshaft Position Sensor are properly installed and the mounting

bolt(s) are torqued to specification.

Refer to any TSB that may apply.

Were any of the above conditions present?

Ye s>>

Repair as necessary

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 8

8.TONE WHEEL/FLEX PLATE INSPECTION

Remove the Crankshaft Position Sensor.

Inspect the Tone Wheel/Flex Plate slots for damage, foreign material, or excessive movement.

Were any problems found?

Ye s>>

Repair or replace the Tone Wheel/Flex Plate as necessary.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 9

9.CRANKSHAFT POSITION SENSOR

If there are no possible causes remaining, view repair.

Repair

Replace the Crankshaft Position Sensor.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

10.CHECKING CKP SIGNAL WITH LAB SCOPE

NOTE: The conditions that set this DTC are not present at this time. The following test may help in identi-

fying the intermittent condition.

Turn the ignition off.

With the scan tool as a Dual Channel Lab Scope and the Miller special tool #6801, backprobe the (K24) CKP Signal

circuit in the PCM harness connector and CKP harness connector.

WARNING: When the engine is operating, do not stand in a direct line with thefan. Do not put your hand

near the pulleys, belts, or fan. Do not wear loose clothing.

Start the engine.

Carefully wiggle the related wire harness and gently tap on the CKP sensor.

Compare the Channel 1 reading to the Channel 2 reading on the lab scope screen.

Both of the readings should be the same.

Were any of the above conditions present?

Ye s>>

Repair the wiring or connector concern.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .

Page 1414 of 5267

3.CKP CONNECTOR/HARNESS INSPECTION

NOTE: Visually inspect the Crankshaft Position Sensor and related wire harness connectors. Look for bro-

ken, bent, pushed out, or corroded terminals.

NOTE: Visually inspect the related wire harness. Look for any chafed, pierced, pinched, or partially broken

wires.

NOTE:VerifytheCrankPositionSensorisproperlyinstalled.

Were any problems found?

Ye s>>

Repair as necessary.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 4

4.TONE WHEEL/FLEX PLATE INSPECTION

Disconnect and remove the Crankshaft Position Sensor.

Inspect the tone wheel/flexplate slots for damage, foreign material, or excessive movement.

Is the tone wheel/flexplate free from defects?

Ye s>>

Go To 5

No>>

Repair/replace tone wheel/flex plate as necessary.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

5.CRANKSHAFT POSITION SENSOR l

With the scan tool lab scope probe and the Miller special tool #6801, back probe the (K24) CKP Signal circuit in the

PCM harness connector.

WARNING: WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A DIRECT LINEWITHTHE

FAN. DO NOT PUT YOUR HANDS NEAR THE PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING..

Start the engine and observe the lab scope screen for any erratic CKP Sensorpulses.

NOTE: Turn the ignition off before continuing.

Were any erratic Crank Position signals detected.

Ye s .>>

Replace the Crankshaft Position Sensor.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No.>>

Go To 6

6.PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

If there are no possible causes remaining, view repair.

Repair

Replace and program the Powertrain Control Module per Service Information.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 1440 of 5267

When Monitored:

With the ignition key on and the engine speed greater than 0 RPM.

Set Condition:

When the PCM regulates the generator field and there are no detected field problems, but the voltage output

does not decrease.

Possible Causes

(K20) GENERATOR FIELD CONTROL CIRCUIT SHORTED TO GROUND

GENERATOR FIELD COIL SHORTED TO GROUND

BATTERY TEMPERATURE SENSOR

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.CHARGING SYSTEM OPERATION

NOTE: Battery must be fully charged and be capable of passing a load test.

NOTE: Generator Belt tension and condition must be checked before continuing.

Ignition on, engine not running.

With the scan tool, read DTCs and the related Freeze Frame data then clear theDTCs.

With scan tool, actuate the Generator Field Driver.

With a 12-volt test light connected to ground, backprobe the (K20) Gen Field Control circuit in the back of Generator

Field harness connector.

Does the test light illuminate brightly and flash?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

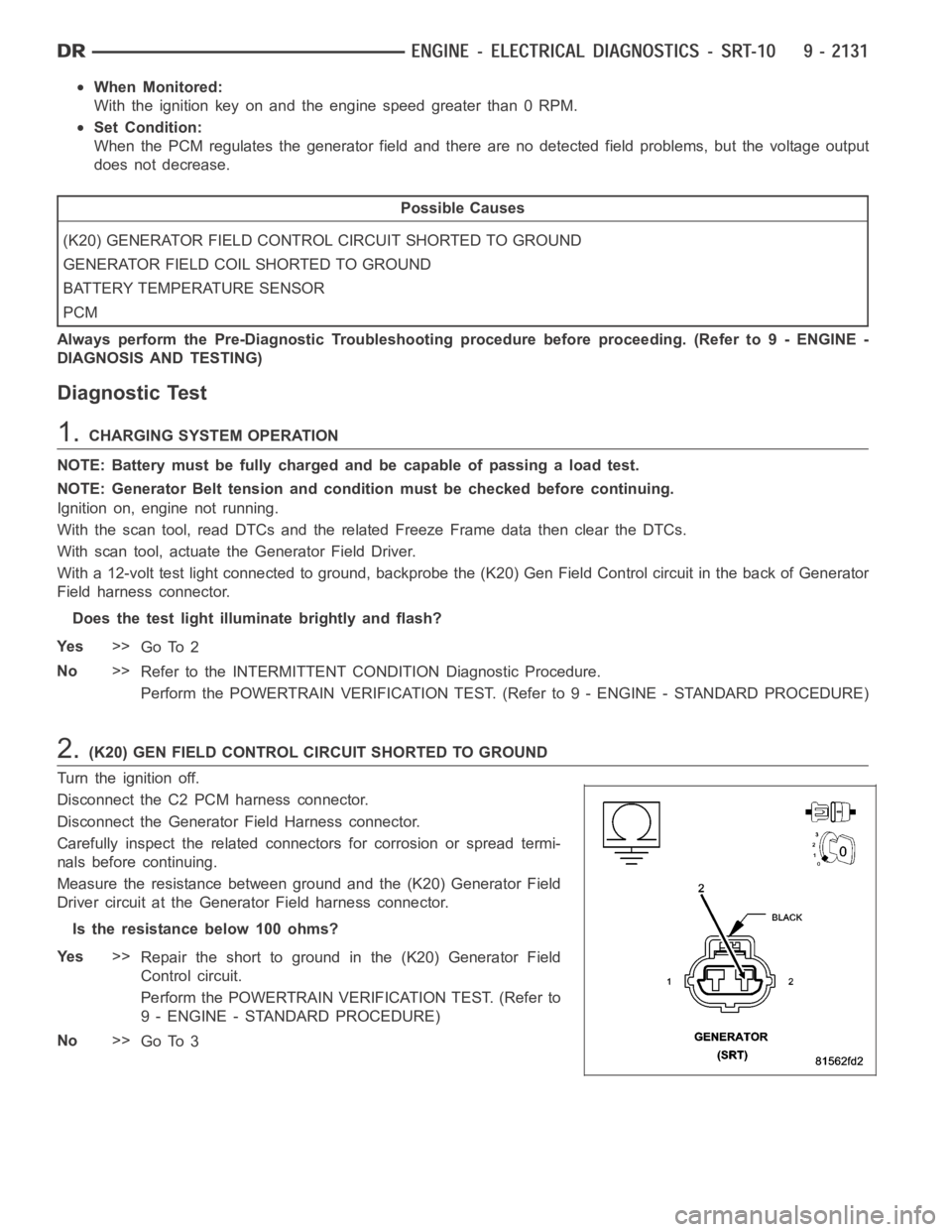

2.(K20) GEN FIELD CONTROL CIRCUIT SHORTED TO GROUND

Turn the ignition off.

Disconnect the C2 PCM harness connector.

Disconnect the Generator Field Harness connector.

Carefully inspect the related connectors for corrosion or spread termi-

nals before continuing.

Measure the resistance between ground and the (K20) Generator Field

Driver circuit at the Generator Field harness connector.

Istheresistancebelow100ohms?

Ye s>>

Repair the short to ground in the (K20) Generator Field

Control circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 3

Page 1451 of 5267

When Monitored:

With the ignition key on and the engine running over 1500 RPM after 25 seconds.

Set Condition:

When the PCM regulates the generator field and there are no detected field problems, but the voltage output

does not increase.

Possible Causes

BATTERY TEMPERATURE SENSOR

RESISTANCE IN THE BATTERY POSITIVE CIRCUIT

(K125) GENERATOR FIELD SOURCE CIRCUIT OPEN

RESISTANCE IN THE GENERATOR GROUND

(K125) GENERATOR FIELD SOURCE CIRCUIT SHORTED TO GROUND

(K20) GENERATOR FIELD CONTROL CIRCUIT OPEN

RESISTANCE IN THE GENERATOR FIELD COIL

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.CHARGING VOLTAGE BELOW 15.1 VOLTS

Turn the ignition off.

NOTE: Battery must be fully charged and capable of passing a battery load test.

NOTE: Generator Belt tension and condition must be checked before continuing.

NOTE: Inspect the vehicle for any aftermarket accessories that may exceedthe maximum Generator output.

WARNING: When the engine is operating, do not stand in direct line of the fan. Do not put your hands near

the pulley, belts, or fan. Do no wear loose clothing.

Start the engine.

Record all DTCs and the related Freeze Frame data.

With the scan tool, read the target charging voltage.

Is the target charging voltage above 15.1 volts?

Ye s>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 2

2.BATTERY TEMPERATURE SENSOR

Turn the ignition off.

NOTE: Generator Belt tension and condition must be checked before continuing.

Start the engine.

Allow the engine to reach normal operating temperature.

With the scan tool in sensors, read the Battery Temp Sensor value.

Using a Thermometer, measure under hood temperature.

Is the temperature within 10° F of Battery temperature?

Ye s>>

Go To 3

No>>

Replace the Battery Temperature Sensor.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 1452 of 5267

3.HIGH RESISTANCE IN THE BATTERY POSITIVE CIRCUIT

Ignition on, engine not running.

Measure the voltage between the Generator B+ Terminal and the Battery Positive Post.

WARNING: When the engine is operating, do not stand in direct line of the fan. Do not put your hands near

the pulley, belts, or fan. Do no wear loose clothing.

CAUTION: Make sure all wires are clear of the engine’s moving parts.

Start the engine.

Is the voltage above 0.4 of a volt?

Ye s>>

Repair the excessive resistance in the Battery Positive circuit between the Generator and Battery.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 4

4.RESISTANCE IN THE GENERATOR GROUND

Start the engine.

WARNING: When the engine is operating, do not stand in direct line of the fan. Do not put your hands near

the pulley, belts, or fan. Do no wear loose clothing.

Warm the engine to operating temperature.

CAUTION: Make sure all wires are clear of the engine’s moving parts.

Measure the voltage between the Generator case and Battery Negative Post.

Is the voltage above 0.1 of a volt?

Ye s>>

Repair the excessive resistance in the Generator Ground circuit between the Generator Case and Bat-

tery Negative side.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 5

5.(K125) GEN FIELD SOURCE CIRCUIT OPEN

Ignition on, engine not running.

Carefully inspect all connectors for corrosion or spread terminals before continuing.

With the scan tool actuate the Generator Field Driver.

While backprobing, measure the voltage on the (K125) Generator Field SourcecircuitatbackofGenerator.

Is the voltage above 10.0 volts?

Ye s>>

Go To 6

No>>

Repair the open in the (K125) Generator Field Source circuit.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)