coolant DODGE RAM SRT-10 2006 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 911 of 5267

page page

ENGINE - ELECTRICAL DIAGNOSTICS - SRT-10

DIAGNOSIS AND TESTING

PRE-DIAGNOSTIC TROUBLESHOOTING

PROCEDURE............................. 1606

INTERMITTENT CONDITION ............... 1607

P0031-O2 SENSOR 1/1 HEATER CIRCUIT

LOW..................................... 1608

P0032-O2 SENSOR 1/1 HEATER CIRCUIT

HIGH.................................... 1612

P0051-O2 SENSOR 2/1 HEATER CIRCUIT

LOW..................................... 1616

P0052-O2 SENSOR 2/1 HEATER CIRCUIT

HIGH.................................... 1620

P0071-AMBIENT/BATTERY TEMP SENSOR

PERFORMANCE.......................... 1624

P0107-MAP SENSOR VOLTAGE TOO LOW . 1629

P0108–MAP SENSOR VOLTAGE TOO HIGH . 1634

P0111-INTAKE AIR TEMP PERFORMANCE . . 1639

P0112-INTAKE AIR TEMP SENSOR

VOLTAGE TOO LOW...................... 1643

P0113-INTAKE AIR TEMPERATURE

SENSOR CIRCUIT HIGH.................. 1647

P0117-ENGINE COOLANT TEMPERATURE

SENSOR CIRCUIT LOW................... 1651

P0118-ENGINE COOLANT TEMP SENSOR

VOLTAGE TOO HIGH...................... 1655

P0121-TP SENSOR VOLTAGE DOES NOT

AGREE WITH MAP........................ 1659

P0122-THROTTLE POSITION SENSOR #1

VOLTAGE TOO LOW...................... 1667

P0123-THROTTLE POSITION SENSOR #1

VOLTAGE TOO HIGH...................... 1672

P0125-INSUFFICIENT COOLANT TEMP FOR

CLOSED-LOOP FUEL CONTROL........... 1677

P0131-O2 SENSOR 1/1 CIRCUIT VOLTAGE

TOO LOW................................ 1680

P0132-O2 SENSOR 1/1 CIRCUIT VOLTAGE

TOO HIGH............................... 1683

P0133-O2 SENSOR 1/1 SLOW RESPONSE . 1688

P0135-O2 SENSOR 1/1 HEATER

PERFORMANCE.......................... 1691

P0136-O2 SENSOR 1/2 HEATER CIRCUIT

MALFUNCTION........................... 1694

P0137-O2 SENSOR 1/2 CIRCUIT LOW ..... 1697

P0138-O2 SENSOR 1/2 CIRCUIT HIGH ..... 1701

P0139-O2 SENSOR 1/2 SLOW RESPONSE . 1706

P0141-O2 SENSOR 1/2 HEATER

PERFORMANCE.......................... 1709

P0151-O2 SENSOR 2/1 CIRCUIT LOW ..... 1713

P0152-O2 SENSOR 2/1 CIRCUIT HIGH ..... 1716

P0153-O2 SENSOR 2/1 SLOW RESPONSE . 1721P0155-O2 SENSOR 2/1 HEATER

PERFORMANCE.......................... 1724

P0157-O2 SENSOR 2/2 CIRCUIT VOLTAGE

TOO LOW................................ 1728

P0158-O2 SENSOR 2/2 CIRCUIT VOLTAGE

TOO HIGH............................... 1732

P0159-O2 SENSOR 2/2 SLOW RESPONSE . 1737

P0161-O2 SENSOR 2/2 HEATER

PERFORMANCE.......................... 1740

P0171-FUEL SYSTEM 1/1 LEAN ........... 1744

P0172-FUEL SYSTEM 1/1 RICH ............ 1751

P0174-FUEL SYSTEM 2/1 LEAN ........... 1757

P0175-FUEL SYSTEM 2/1 RICH ............ 1764

P0197-ENGINE OIL TEMPERATURE

SENSOR VOLTAGE TOO LOW............. 1770

P0198-ENGINE OIL TEMPERATURE

SENSOR VOLTAGE TOO HIGH............ 1773

P0201-FUEL INJECTOR 1 CIRCUIT ........ 1777

P0202-FUEL INJECTOR 2 CIRCUIT ........ 1781

P0203-FUEL INJECTOR 3 CIRCUIT ........ 1785

P0204-FUEL INJECTOR 4 CIRCUIT ........ 1789

P0205-FUEL INJECTOR 5 CIRCUIT ........ 1793

P0206-FUEL INJECTOR 6 CIRCUIT ........ 1797

P0207-FUEL INJECTOR 7 CIRCUIT ........ 1801

P0208-FUEL INJECTOR 8 CIRCUIT ........ 1805

P0209-FUEL INJECTOR 9 CIRCUIT ........ 1809

P0210-FUEL INJECTOR 10 CIRCUIT....... 1813

P0300-MULTIPLE CYLINDER MISFIRE ..... 1817

P0301-CYLINDER #1 MISFIRE ............. 1823

P0302-CYLINDER #2 MISFIRE ............. 1832

P0303-CYLINDER #3 MISFIRE ............. 1841

P0304-CYLINDER #4 MISFIRE ............. 1850

P0305-CYLINDER #5 MISFIRE ............. 1859

P0306-CYLINDER #6 MISFIRE ............. 1868

P0307-CYLINDER #7 MISFIRE ............. 1877

P0308-CYLINDER #8 MISFIRE ............. 1886

P0309-CYLINDER #9 MISFIRE ............. 1895

P0310-CYLINDER #10 MISFIRE ............ 1904

P0320–NO CANK REFERENCE SIGNAL AT

PCM..................................... 1913

P0325-KNOCK SENSOR 1 CIRCUIT ........ 1921

P0330-KNOCK SENSOR 2 CIRCUIT ........ 1925

P0340-CAMSHAFT POSITION SENSOR

CIRCUIT................................. 1929

P0352-IGNITION COIL #2 PRIMARY

CIRCUIT................................. 1936

P0353-IGNITION COIL #3 PRIMARY

CIRCUIT................................. 1940

P0354-IGNITION COIL #4 PRIMARY

CIRCUIT................................. 1944

Page 934 of 5267

When Monitored:

With the ignition on and no Battery Temperature Sensor Open or Short Faultspresent.

Set Condition:

After 5 warm cycles have occurred (coolant increases at least 22°C (40°F) to a minimum of 71°C (160°F) and

the odometer mileage has increased 196.6 miles and the Battery Temperature has changed less than 4°C

(7.2°F) change in temperature. One trip fault.

Possible Causes

GOOD TRIP EQUAL TO ZERO

(K25) BATTERY TEMP SIGNAL CIRCUIT SHORTED TO VOLTAGE

BATTERY TEMPERATURE SENSOR

RESISTANCE IN THE (K25) BATTERY TEMP SENSOR SIGNAL CIRCUIT

RESISTANCE IN THE (K900) SENSOR GROUND CIRCUIT

(K25) BATTERY TEMP SENSOR SIGNAL CIRCUIT SHORTED TO GROUND

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

1.GOOD TRIP EQUAL TO ZERO

Ignition on, engine not running.

With the scan tool, read DTCs and record the related Freeze Frame data.

Is the Good Trip Counter equal to zero?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Symptom. (Refer to 9 - ENGINE - DIAGNOSIS AND TEST-

ING)

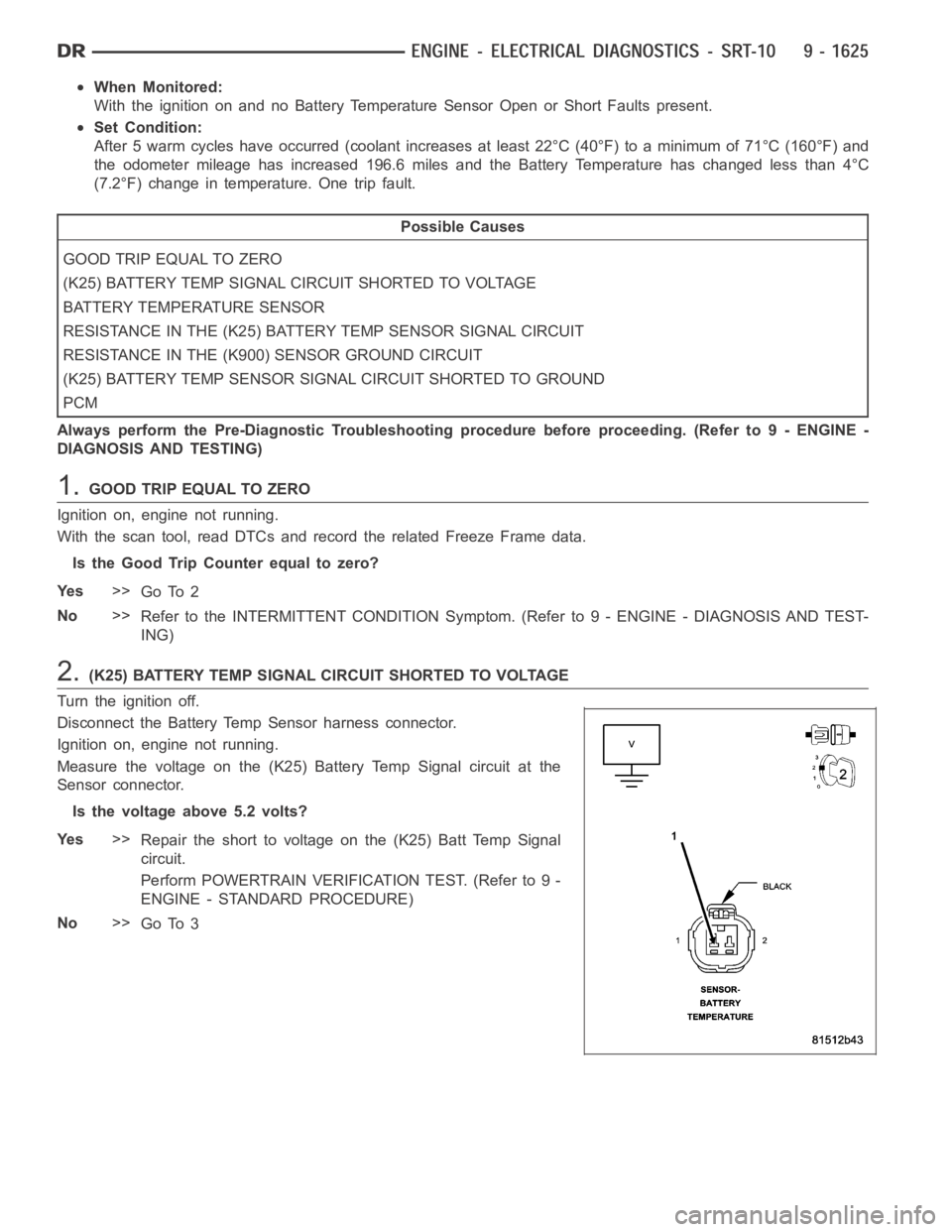

2.(K25) BATTERY TEMP SIGNAL CIRCUIT SHORTED TO VOLTAGE

Turn the ignition off.

Disconnect the Battery Temp Sensor harness connector.

Ignition on, engine not running.

Measure the voltage on the (K25) Battery Temp Signal circuit at the

Sensor connector.

Is the voltage above 5.2 volts?

Ye s>>

Repair the short to voltage on the (K25) Batt Temp Signal

circuit.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 -

ENGINE - STANDARD PROCEDURE)

No>>

Go To 3

Page 949 of 5267

When Monitored:

With the ignition on and no Intake Air Temperature Sensor open/shorted faults present.

Set Condition:

After 5 warm cycles have occurred (coolant increases at least 22°C (40°F) to a minimum of 71°C (160°F) and

the odometer mileage has increased 196.6 miles and the Intake Air Temperature has had less than 5°C (9°F)

change in temperature.

Possible Causes

RESISTANCE IN THE (K21) IAT SENSOR SIGNAL CIRCUIT

RESISTANCE IN THE (K900) SENSOR GROUND CIRCUIT

IAT SENSOR

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

1.GOOD TRIP EQUAL TO ZERO

Ignition on, engine not running.

With the scan tool, read DTCs and record the related Freeze Frame data.

Is the Good Trip Counter equal to zero?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Diagnostic Procedure. (Refer to 9 - ENGINE - DIAGNOSIS

AND TESTING)

2.IAT SENSOR VOLTAGE ABOVE 4.6 VOLTS

Turn the ignition off.

Disconnect the Intake Air Temperature Sensor harness connector.

Ignition on, engine not running.

With the scan tool, read the IAT voltage.

Is the voltage above 4.6 volts?

Ye s>>

Go To 3

No>>

Go To 5

Page 960 of 5267

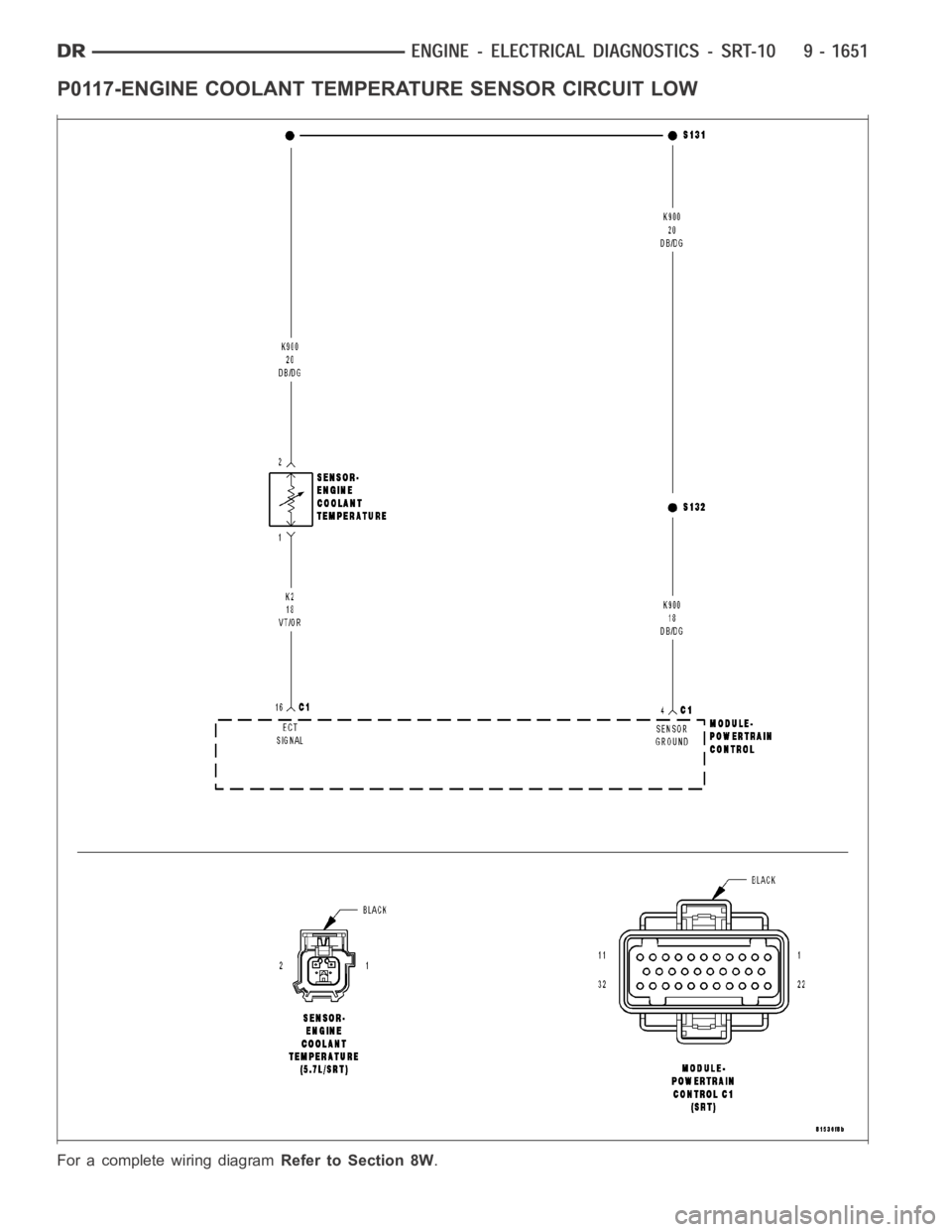

P0117-ENGINE COOLANT TEMPERATURE SENSOR CIRCUIT LOW

For a complete wiring diagramRefer to Section 8W.

Page 961 of 5267

Theory of Operation

The engine coolant temperature sensor is a negative temperature coefficient thermistor-type sensor whose resis-

tance varies inversely with temperature. At cold temperatures the sensorresistance is high so the voltage is high.

As the coolant temperature increases the resistance decreases and the voltage becomes low.

When Monitored:

With the ignition on. Battery voltage greater than 10.4 volts.

Set Condition:

The Engine Coolant Temperature (ECT) Signal circuit voltage at the PCM goes below 0.8 of a volt for more

than 3 seconds.

Possible Causes

(K2) ECT SIGNAL CIRCUIT SHORTED TO GROUND

(K2) ECT SIGNAL CIRCUIT SHORTED TO THE (K900) SENSOR GROUND CIRCUIT

ECT SENSOR

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ECT SENSOR VOLTAGE BELOW 1.0 OF A VOLT

Ignition on, engine not running.

With a scan tool, read the ECT voltage.

Is the voltage below 1.0 of a volt?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Symptom. (Refer to 9 - ENGINE - DIAGNOSIS AND TEST-

ING)

2.ECT SENSOR

Turn the ignition off.

Disconnect the ECT harness connector.

Ignition on, engine not running.

With a scan tool, read ECT voltage.

Is the voltage above 1.0 volt?

Ye s>>

Replace the ECT Sensor.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 3

Page 964 of 5267

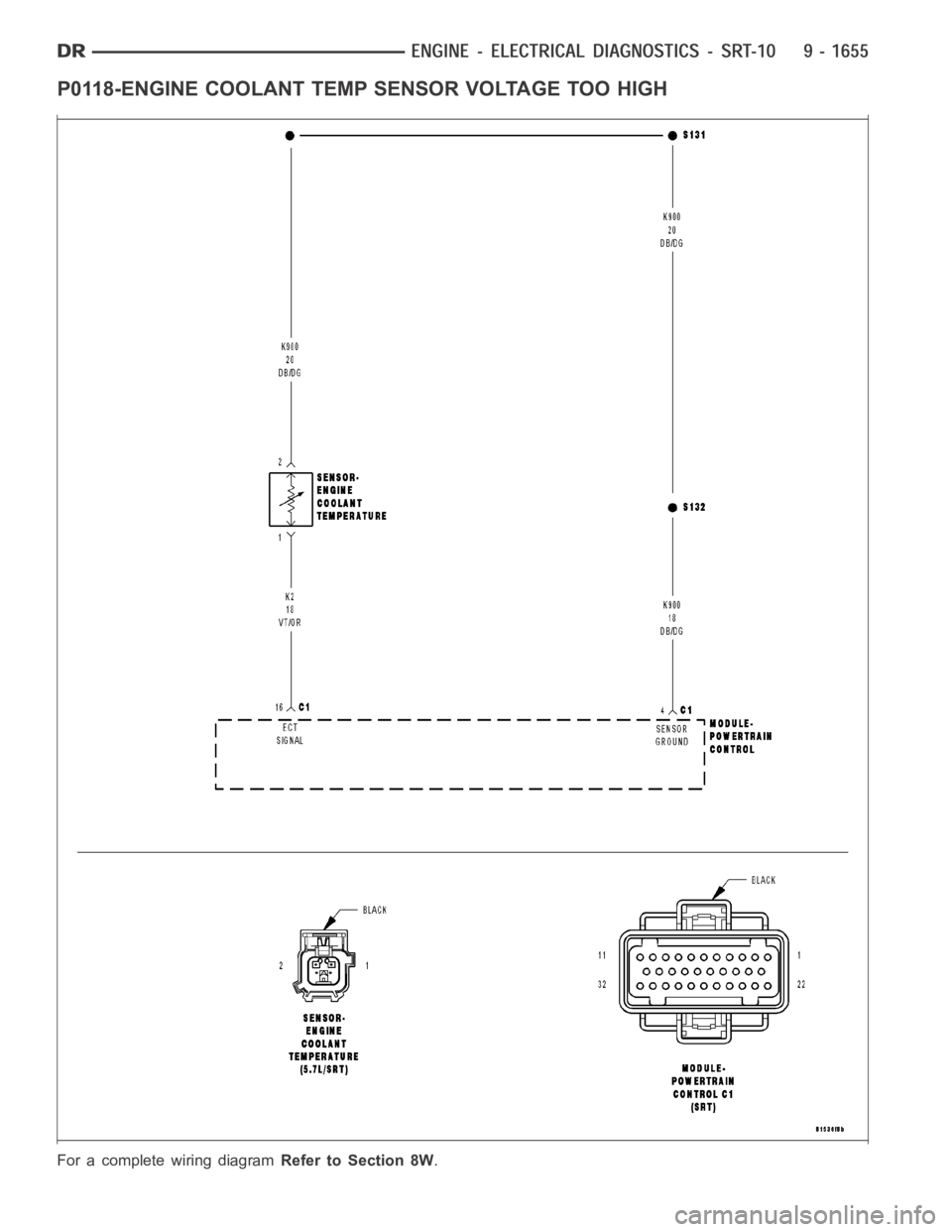

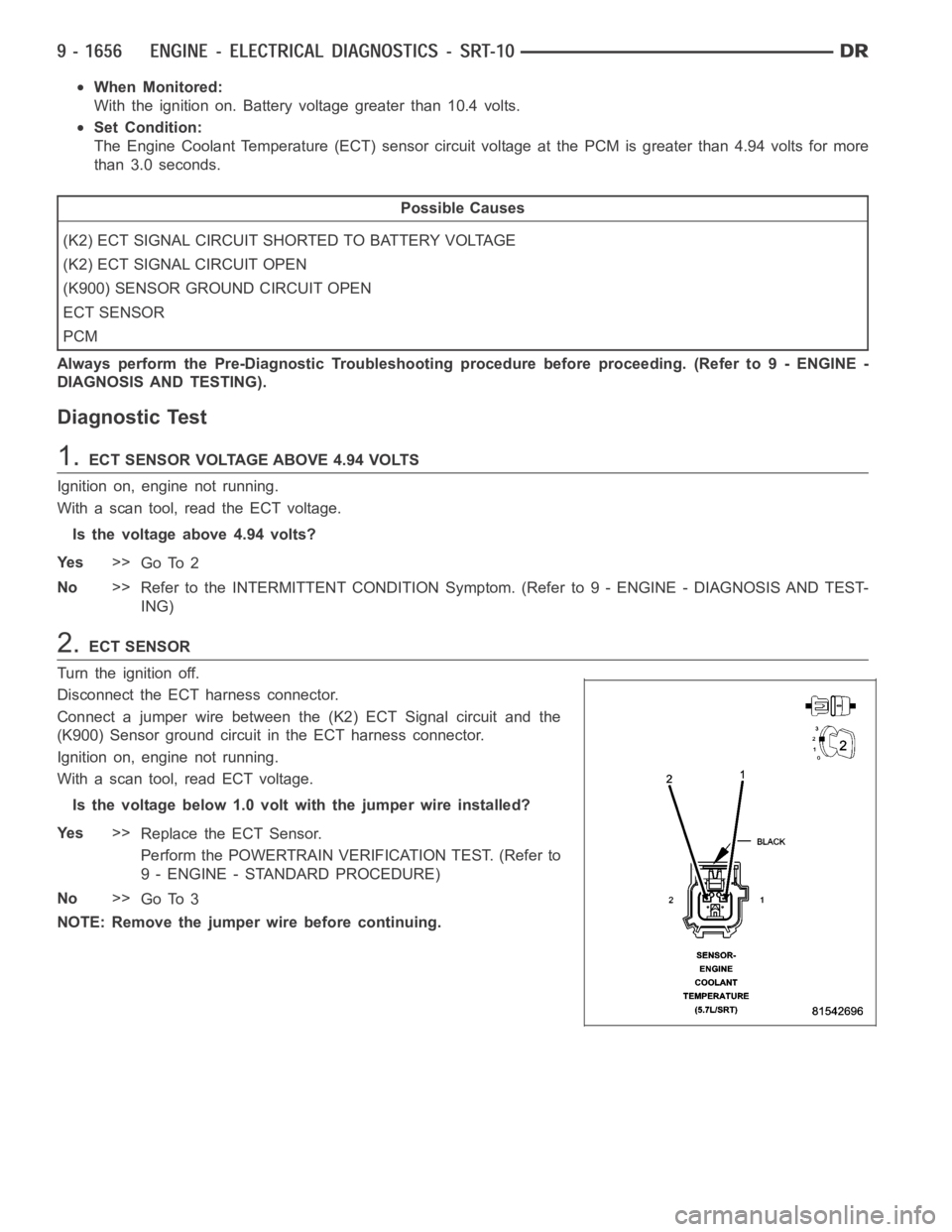

P0118-ENGINE COOLANT TEMP SENSOR VOLTAGE TOO HIGH

For a complete wiring diagramRefer to Section 8W.

Page 965 of 5267

When Monitored:

With the ignition on. Battery voltage greater than 10.4 volts.

Set Condition:

The Engine Coolant Temperature (ECT) sensor circuit voltage at the PCM is greater than 4.94 volts for more

than 3.0 seconds.

Possible Causes

(K2) ECT SIGNAL CIRCUIT SHORTED TO BATTERY VOLTAGE

(K2) ECT SIGNAL CIRCUIT OPEN

(K900) SENSOR GROUND CIRCUIT OPEN

ECT SENSOR

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.ECT SENSOR VOLTAGE ABOVE 4.94 VOLTS

Ignition on, engine not running.

With a scan tool, read the ECT voltage.

Is the voltage above 4.94 volts?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITION Symptom. (Refer to 9 - ENGINE - DIAGNOSIS AND TEST-

ING)

2.ECT SENSOR

Turn the ignition off.

Disconnect the ECT harness connector.

Connect a jumper wire between the (K2) ECT Signal circuit and the

(K900) Sensor ground circuit in the ECT harness connector.

Ignition on, engine not running.

With a scan tool, read ECT voltage.

Is the voltage below 1.0 volt with the jumper wire installed?

Ye s>>

Replace the ECT Sensor.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to

9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 3

NOTE: Remove the jumper wire before continuing.

Page 986 of 5267

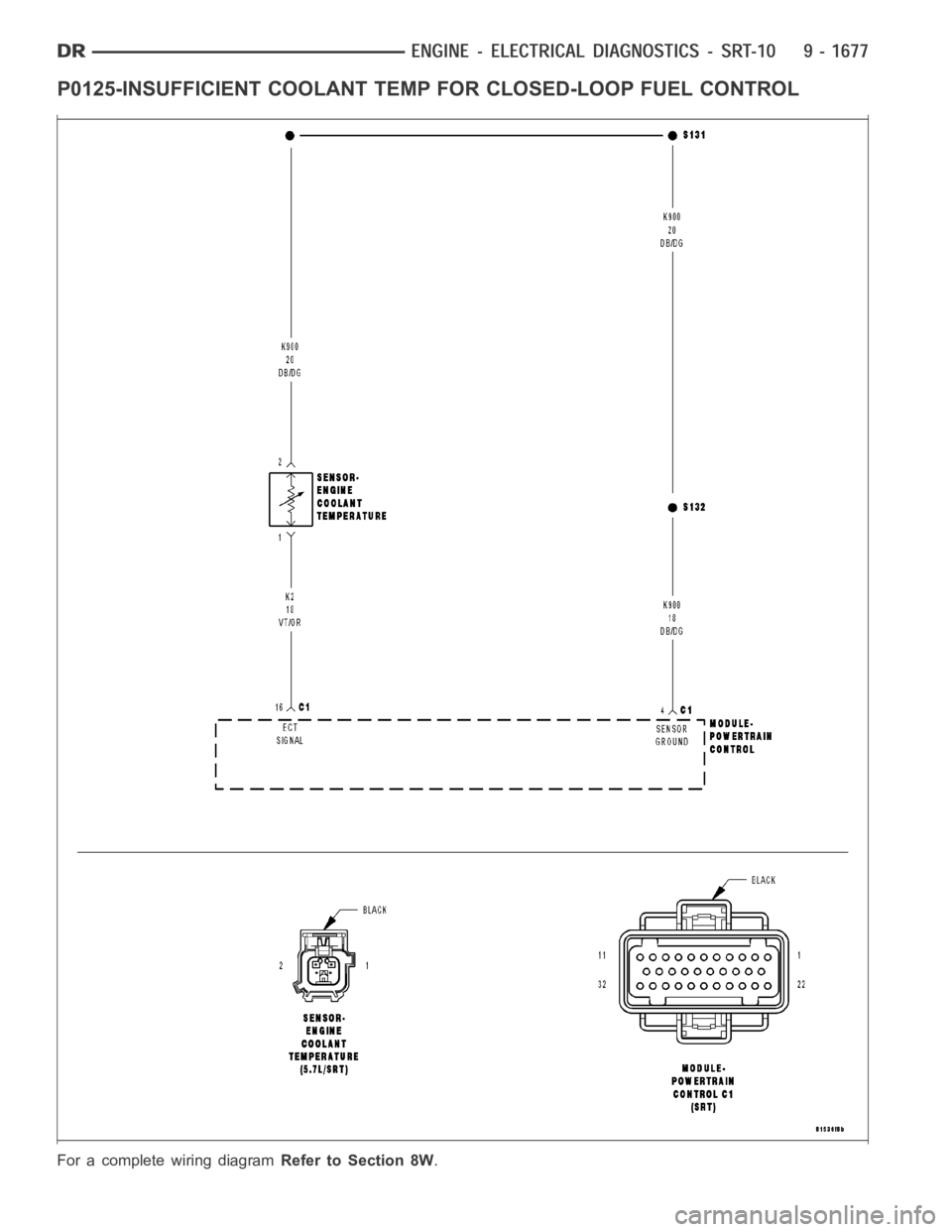

P0125-INSUFFICIENT COOLANT TEMP FOR CLOSED-LOOP FUEL CONTROL

For a complete wiring diagramRefer to Section 8W.

Page 987 of 5267

Theory of Operation

The engine coolant temperature sensor is a negative temperature coefficient thermistor-type sensor whose resis-

tance varies inversely with temperature. At cold temperatures the sensorresistance is high so the voltage is high.

As the coolant temperature increases the resistance decreases and the voltage becomes low. The INSUFFICIENT

COOLANT TEMP FOR CLOSED-LOOP FUEL CONTROL determines if the engine coolant temperature will reach

theclosedloopfuelingcontroltemperaturelimitinaregulatedtimeafterstart.

When Monitored:

With battery voltage greater than 10.4 volts and after engine is started.

Set Condition:

The engine temperature does not go above -10°C (15°F). Failure time depends on start-up coolant tempera-

ture and ambient temperature. (i.e. 2 minutes for a start temp of -10°C (15°F) or up to 10 minutes for a vehicle

with a start-up temp of -28°C (5°F). Two Trip Fault. Three good trips to turnoff the MIL.

Possible Causes

LOW COOLANT LEVEL

THERMOSTAT

ECT SENSOR

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.CHECKING COOLANT LEVEL AND CONDITION

Ignition on, engine not running.

With a scan tool, read DTCs.

NOTE: If an Engine Coolant Temperature (ECT) DTC is set along with this code, diagnose the ECT DTC first.

NOTE: Inspect the ECT terminals and related PCM terminals. Make sure the terminals are free from corro-

sion and damage.

NOTE: The best way to diagnose this DTC is to allow the vehicle to sit overnight outside in order to have

a totally cold soaked engine.

NOTE: Extremely cold outside ambient temperatures may have caused this DTCtoset.

WARNING: Never open the cooling system when the engine is hot. The system isunder pressure. Extreme

burns or scalding may result. Failure to follow these instructions can result in personal injury or death.

Allow the engine to cool before opening the cooling system.

Inspect the coolant system for proper level and condition.

Is the coolant level and condition OK?

Ye s>>

Go To 2

No>>

Inspect the vehicle for a coolant leak, make the appropriate repairs, and add the correct amount of

coolant.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 988 of 5267

2.THERMOSTAT OPERATION

NOTE: This test works best if performed on a cold engine (cold soak)

Ignition on, engine not running.

With a scan tool, read the Eng Coolant Tmp Deg value. If the engine was allowed to sit overnight (cold soak), the

temperature value should be a sensible value that is somewhere close to theambient temperature.

NOTE: If engine coolant temperature is above 82°C (180°F), allow the engine to cool until 65°C (150°F) is

reached.

Start the Engine.

During engine warm-up monitor the Eng Coolant Tmp Deg value. The temp deg value change should be a smooth

transition from start up to normal operating temp 82°C (180°F). Also monitor the actual coolant temperature with a

thermometer.

NOTE: As the engine warms up to operating temperature, the actual coolant temperature (thermometer read-

ing) and the scan tool Eng Coolant Tmp Deg values should stay relatively close to each other.

Using the appropriate service information, determine the proper openingtemperature of the thermostat.

Did the thermostat open at the proper temperature?

Ye s>>

Go To 3

No>>

Replace the thermostat.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

3.ECT SENSOR OPERATION

Ignition on, engine not running.

With a scan tool, read the Eng Coolant Tmp Deg value. If the engine was allowed to sit overnight (cold soak), the

temperature value should be a sensible value that is somewhere close to theambient temperature.

NOTE: If engine coolant temperature is above 82°C (180°F), allow the engine to cool until 65°C (150°F) is

reached.

Start the Engine.

During engine warm-up monitor the Eng Coolant Tmp Deg value. The temp deg value change should be a smooth

transition from start up to normal operating temp 82°C (180°F). Also monitor the actual coolant temperature with a

thermometer.

NOTE: As the engine warms up to operating temperature, the actual coolant temperature (thermometer read-

ing) and the scan tools Eng Coolant Tmp Deg value should stay relatively close to each other.

Is the thermometer reading relatively close to the scan tool ECT reading?

Ye s>>

Te s t C o m p l e t e .

No>>

Replace the Engine Coolant Temperature Sensor.

Perform the POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)