maintenance DODGE RAM SRT-10 2006 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2227 of 5267

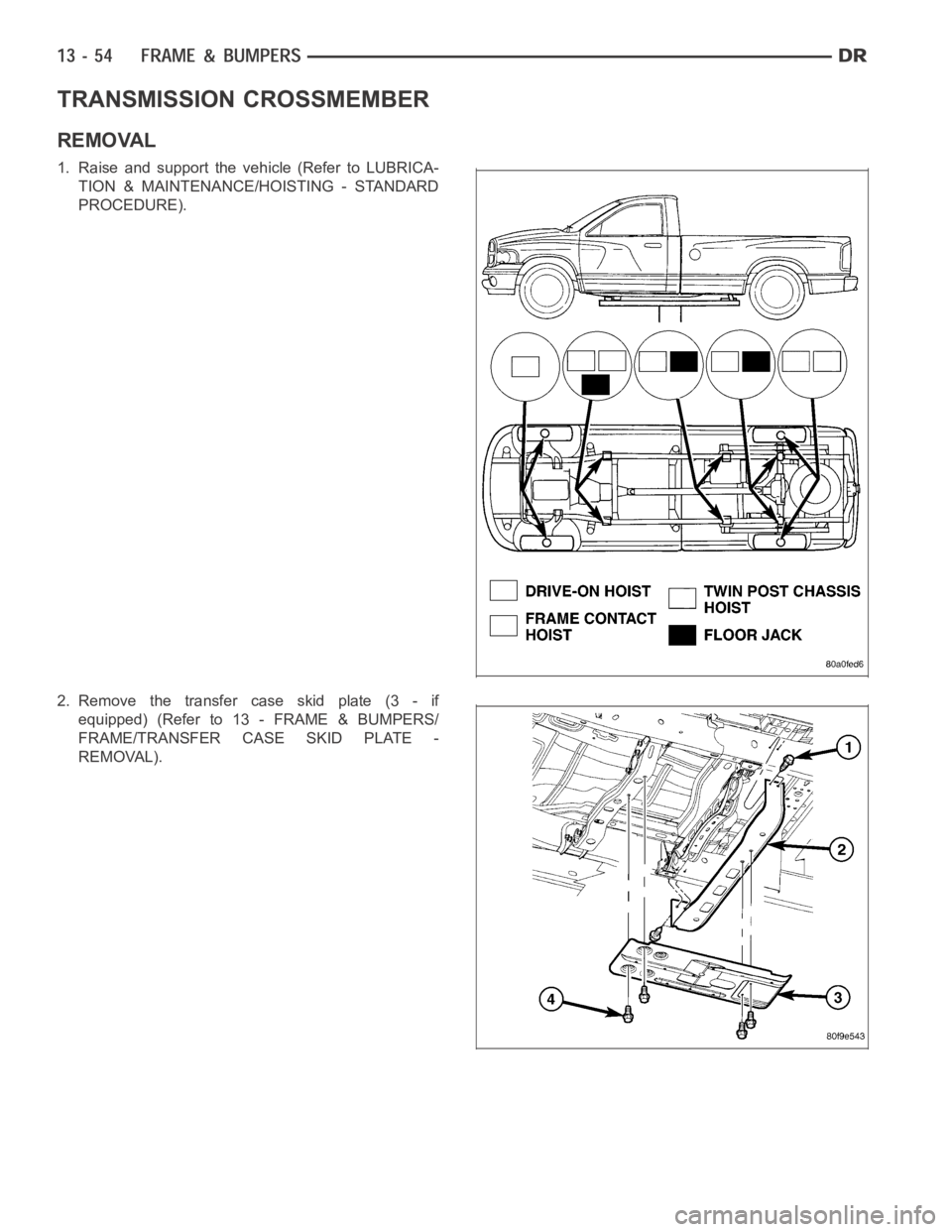

TRANSMISSION CROSSMEMBER

REMOVAL

1. Raise and support the vehicle (Refer to LUBRICA-

TION & MAINTENANCE/HOISTING - STANDARD

PROCEDURE).

2. Remove the transfer case skid plate (3 - if

equipped) (Refer to 13 - FRAME & BUMPERS/

FRAME/TRANSFER CASE SKID PLATE -

REMOVAL).

Page 2235 of 5267

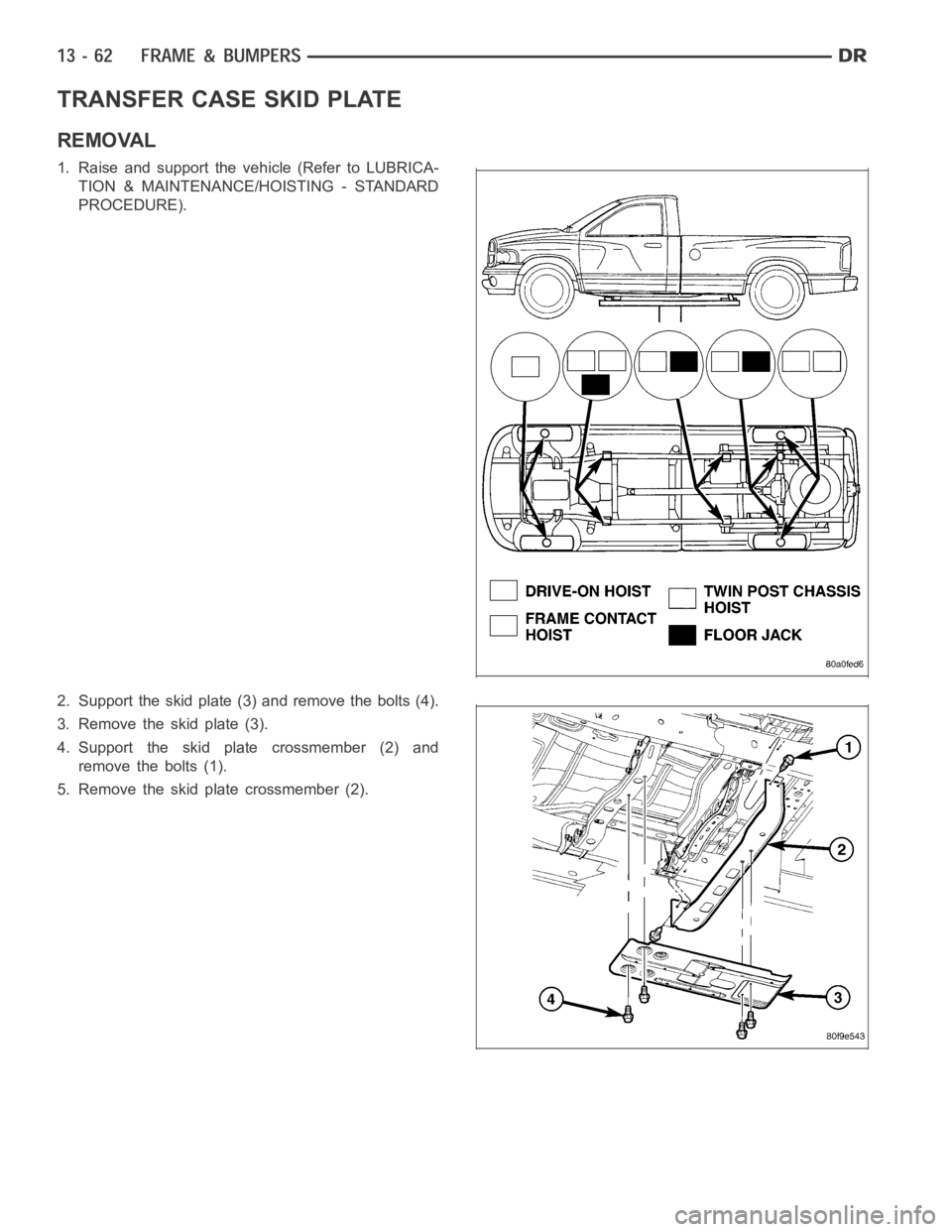

TRANSFER CASE SKID PLATE

REMOVAL

1. Raise and support the vehicle (Refer to LUBRICA-

TION & MAINTENANCE/HOISTING - STANDARD

PROCEDURE).

2. Support the skid plate (3) and remove the bolts (4).

3. Removetheskidplate(3).

4. Support the skid plate crossmember (2) and

remove the bolts (1).

5. Remove the skid plate crossmember (2).

Page 2241 of 5267

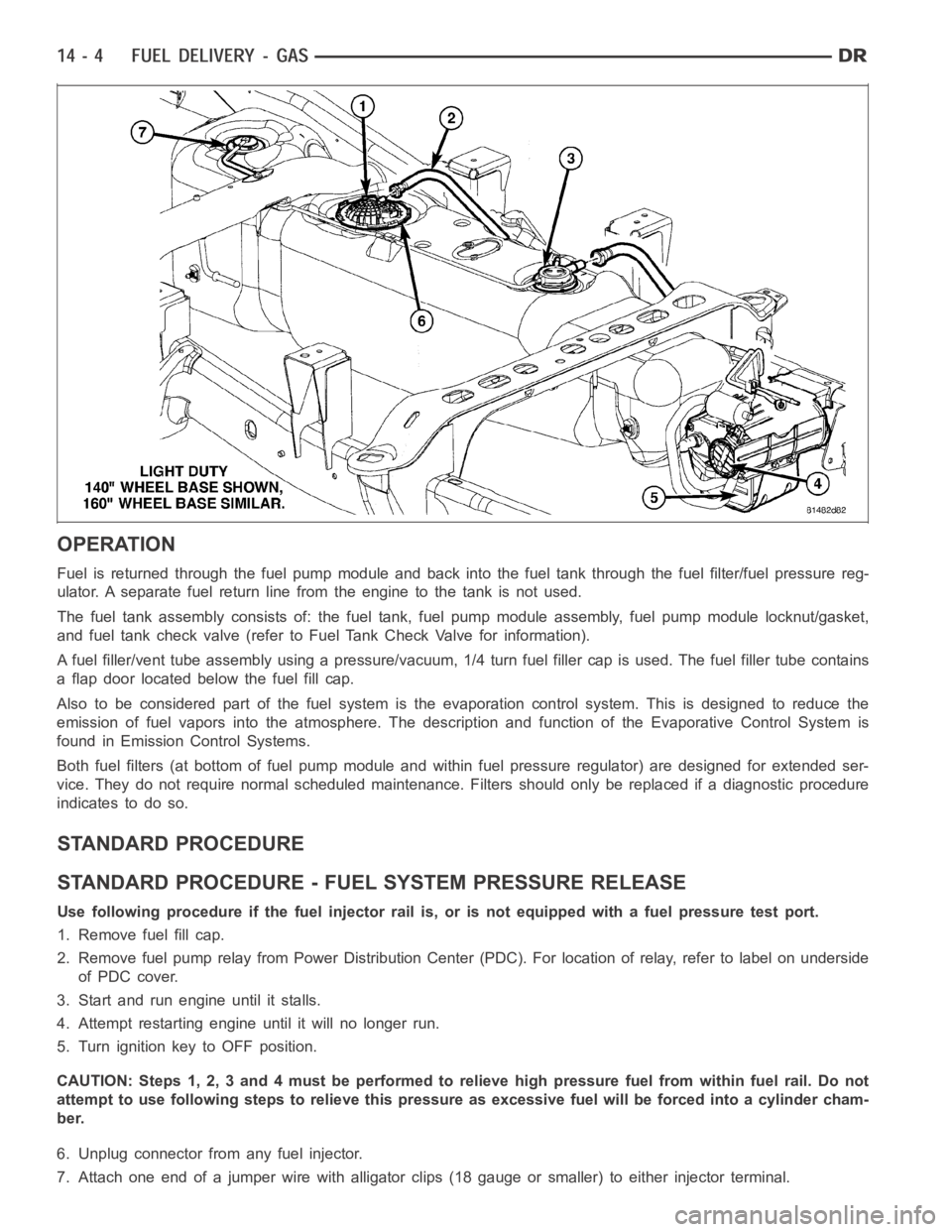

OPERATION

Fuel is returned through the fuel pump module and back into the fuel tank through the fuel filter/fuel pressure reg-

ulator. A separate fuel return line from the engine to the tank is not used.

The fuel tank assembly consists of: the fuel tank, fuel pump module assembly, fuel pump module locknut/gasket,

and fuel tank check valve (refer to Fuel Tank Check Valve for information).

A fuel filler/vent tube assembly using apressure/vacuum,1/4 turn fuel filler cap is used. The fuel filler tube contains

a flap door located below the fuel fill cap.

Also to be considered part of the fuelsystem is the evaporation control system. This is designed to reduce the

emission of fuel vapors into the atmosphere. The description and functionof the Evaporative Control System is

found in Emission Control Systems.

Both fuel filters (at bottom of fuel pump module and within fuel pressure regulator) are designed for extended ser-

vice. They do not require normal scheduled maintenance. Filters should only be replaced if a diagnostic procedure

indicates to do so.

STANDARD PROCEDURE

STANDARD PROCEDURE - FUEL SYSTEM PRESSURE RELEASE

Use following procedure if the fuel injector rail is, or is not equipped with a fuel pressure test port.

1. Remove fuel fill cap.

2. Remove fuel pump relay from Power Distribution Center (PDC). For location of relay, refer to label on underside

of PDC cover.

3. Start and run engine until it stalls.

4. Attempt restarting engine until it will no longer run.

5. Turn ignition key to OFF position.

CAUTION: Steps 1, 2, 3 and 4 must be performed to relieve high pressure fuel from within fuel rail. Do not

attempt to use following steps to relieve this pressure as excessive fuel will be forced into a cylinder cham-

ber.

6. Unplug connector from any fuel injector.

7. Attach one end of a jumper wire with alligator clips (18 gauge or smaller)to either injector terminal.

Page 2246 of 5267

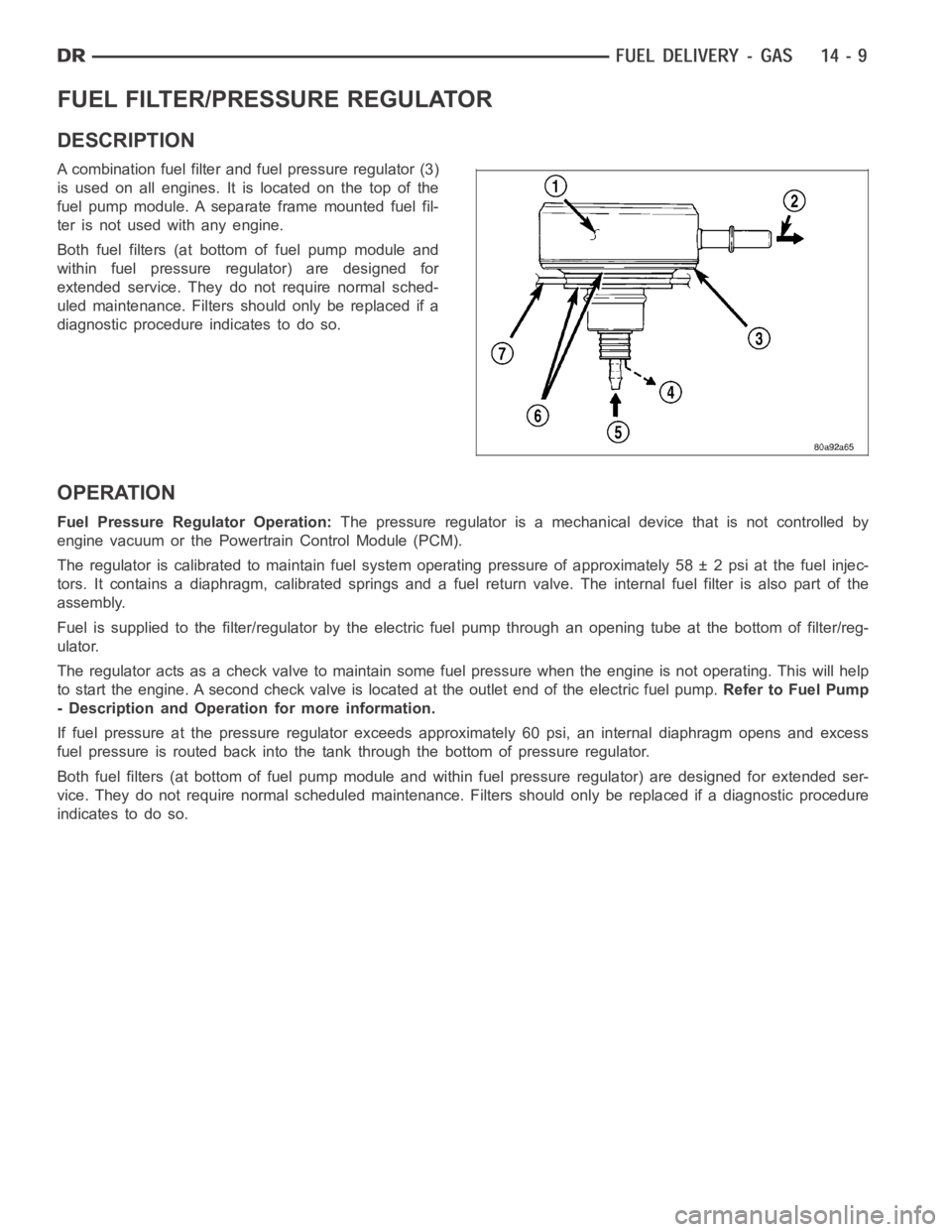

FUEL FILTER/PRESSURE REGULATOR

DESCRIPTION

A combination fuel filter and fuel pressure regulator (3)

is used on all engines. It is located on the top of the

fuel pump module. A separate frame mounted fuel fil-

ter is not used with any engine.

Both fuel filters (at bottom of fuel pump module and

within fuel pressure regulator) are designed for

extended service. They do not require normal sched-

uled maintenance. Filters should only be replaced if a

diagnostic procedure indicates to do so.

OPERATION

Fuel Pressure Regulator Operation:The pressure regulator is a mechanical device that is not controlled by

engine vacuum or the Powertrain Control Module (PCM).

The regulator is calibrated to maintain fuel system operating pressure ofapproximately 58 ± 2 psi at the fuel injec-

tors. It contains a diaphragm, calibrated springs and a fuel return valve.The internal fuel filter is also part of the

assembly.

Fuel is supplied to the filter/regulator by the electric fuel pump throughan opening tube at the bottom of filter/reg-

ulator.

The regulator acts as a check valve to maintain some fuel pressure when the engine is not operating. This will help

to start the engine. A second check valve is located at the outlet end of the electric fuel pump.Refer to Fuel Pump

- Description and Operation for more information.

If fuel pressure at the pressure regulator exceeds approximately 60 psi, an internal diaphragm opens and excess

fuel pressure is routed back into the tank through the bottom of pressure regulator.

Both fuel filters (at bottom of fuel pump module and within fuel pressure regulator) are designed for extended ser-

vice. They do not require normal scheduled maintenance. Filters should only be replaced if a diagnostic procedure

indicates to do so.

Page 2342 of 5267

FUEL DELIVERY - DIESEL

DESCRIPTION - DIESEL FUEL SYSTEM

WARNING: High-pressure fuel lines deliver diesel

fuel under extreme pressure from the injection

pump to the fuel injectors. This may be as high as

160,000 kpa (23,206 psi). Use extreme caution

when inspecting for high-pressure fuel leaks.

Inspect for high-pressure fuel leaks with a sheet of

cardboard. High fuel injection pressure can cause

personal injury if contact is made with the skin.

The fuel system used on the Cummins engine is an electronically controlled, Bosch HPCR (High-Pressure Common

Rail) system. The HPCR system consists of five main components:

Electric Fuel Transfer (lift) Pump Located in the Fuel Tank

Fuel Pump/Gear Pump (attached to fuel injection pump)

High-Pressure Fuel Injection Pump

Fuel Injection Rail

Fuel Injectors

Also to be considered as part of the overall fuel system are:

Accelerator Pedal

Air Cleaner Housing/Element

Check Valve Banjo Fitting at Rear of Cylinder Head

Fuel Connector Tubes

Fuel Drain Manifold (passage)

Fuel Drain Valve (at filter)

Fuel Filter/Water Separator

Fuel Heater

Fuel Heater Relay

Fuel Transfer Pump Relay

Fuel Level (gauge) Sending Unit

Fuel Pressure Limiting Valve

Fuel Tank

Fuel Tank Module (containing a fuel gauge sending unit, separate fuel filter located at bottom of tank module,

and fuel transfer pump)

Fuel Tank Filler/Vent Tube Assembly

Fuel Tank Filler Tube Cap

Fuel Tubes/Lines/Hoses

High-Pressure Fuel Injector Lines

In-Tank Fuel Filter (at bottom of fuel tank module)

Low-Pressure Fuel Supply Lines

Low-Pressure Fuel Return Lines

Overflow Valve

Quick-Connect Fuel Line Fittings

Accelerator Pedal Position Sensor (APPS) Located in Cab

Water Draining (maintenance)

Water-In-Fuel (WIF) Sensor

Screened Banjo Bolt (22)

The fuel injection pump supplies high pressure to the fuel rail independent of engine speed. This high pressure fuel

is then accumulated in the fuel rail. High pressure fuel is constantly supplied to the injectors by the fuel rail. The

Engine Control Module (ECM) controls the fueling and timing of the engine by actuating the injectors.

Page 2348 of 5267

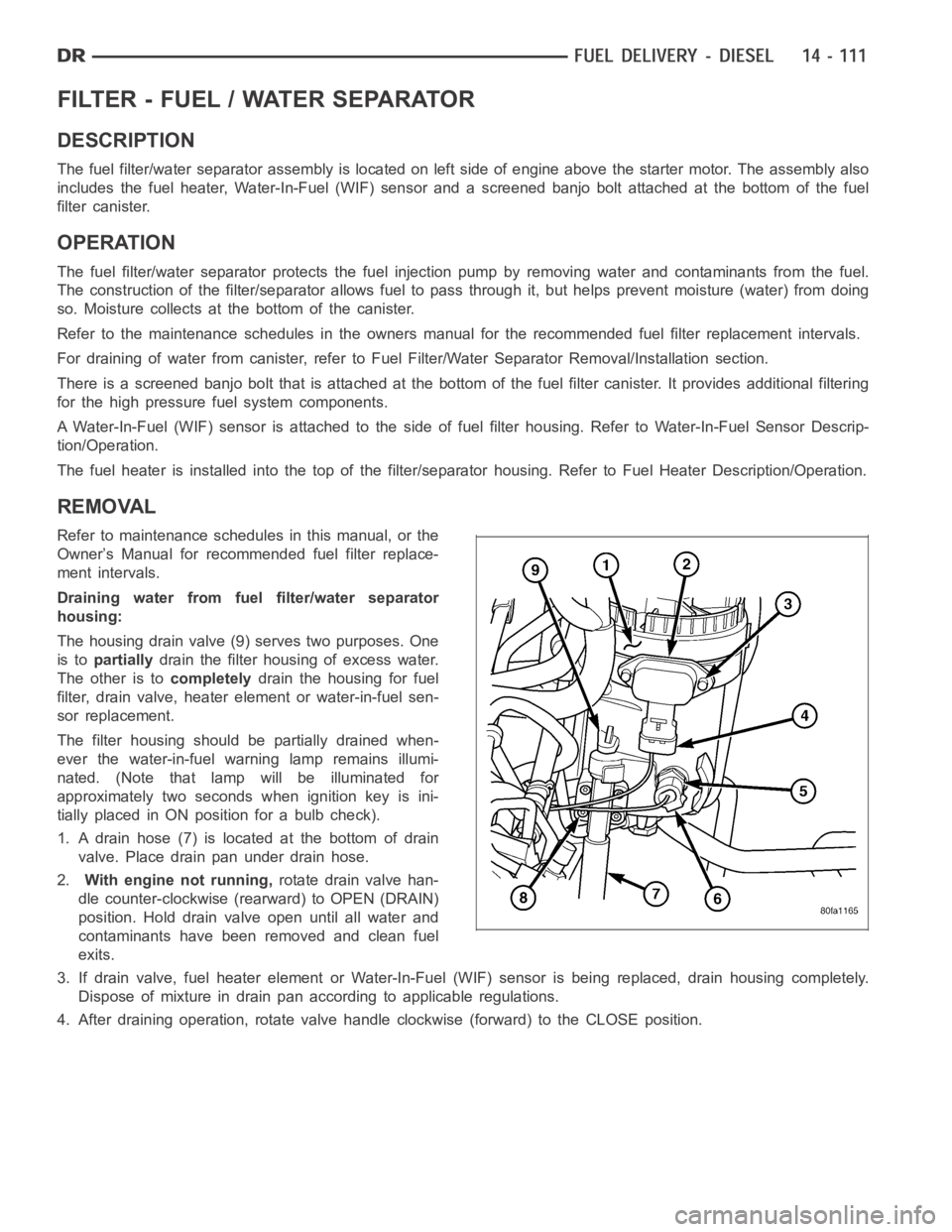

FILTER - FUEL / WATER SEPARATOR

DESCRIPTION

The fuel filter/water separator assembly is located on left side of engineabove the starter motor. The assembly also

includes the fuel heater, Water-In-Fuel (WIF) sensor and a screened banjobolt attached at the bottom of the fuel

filter canister.

OPERATION

The fuel filter/water separator protects the fuel injection pump by removing water and contaminants from the fuel.

The construction of the filter/separator allows fuel to pass through it, but helps prevent moisture (water) from doing

so. Moisture collects at the bottom of the canister.

Refer to the maintenance schedules in the owners manual for the recommended fuel filter replacement intervals.

For draining of water from canister, refer to Fuel Filter/Water SeparatorRemoval/Installation section.

There is a screened banjo bolt that is attached at the bottom of the fuel filter canister. It provides additional filtering

for the high pressure fuel system components.

A Water-In-Fuel (WIF) sensor is attached to the side of fuel filter housing. Refer to Water-In-Fuel Sensor Descrip-

tion/Operation.

The fuel heater is installed into the top of the filter/separator housing.Refer to Fuel Heater Description/Operation.

REMOVAL

Refer to maintenance schedules in this manual, or the

Owner’s Manual for recommended fuel filter replace-

ment intervals.

Draining water from fuel filter/water separator

housing:

The housing drain valve (9) serves two purposes. One

is topartiallydrain the filter housing of excess water.

The other is tocompletelydrain the housing for fuel

filter, drain valve, heater element or water-in-fuel sen-

sor replacement.

The filter housing should be partially drained when-

ever the water-in-fuel warning lamp remains illumi-

nated. (Note that lamp will be illuminated for

approximately two seconds when ignition key is ini-

tially placed in ON position for a bulb check).

1. A drain hose (7) is located at the bottom of drain

valve. Place drain pan under drain hose.

2.With engine not running,rotate drain valve han-

dle counter-clockwise (rearward) to OPEN (DRAIN)

position. Hold drain valve open until all water and

contaminants have been removed and clean fuel

exits.

3. If drain valve, fuel heater element or Water-In-Fuel (WIF) sensor is being replaced, drain housing completely.

Dispose of mixture in drain pan according to applicable regulations.

4. After draining operation, rotate valve handle clockwise (forward) to the CLOSE position.

Page 2350 of 5267

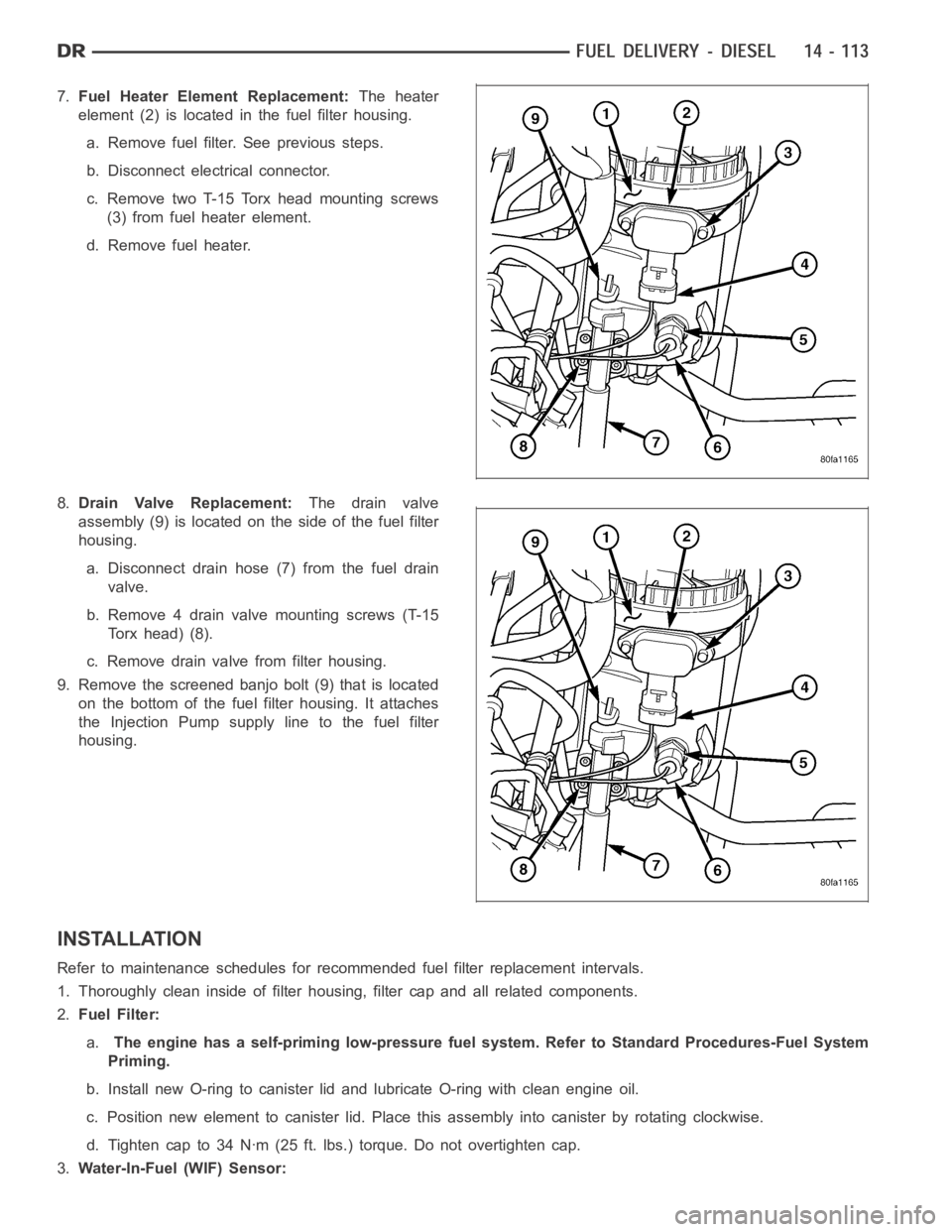

7.Fuel Heater Element Replacement:The heater

element (2) is located in the fuel filter housing.

a. Remove fuel filter. See previous steps.

b. Disconnect electrical connector.

c. Remove two T-15 Torx head mounting screws

(3) from fuel heater element.

d. Remove fuel heater.

8.Drain Valve Replacement:The drain valve

assembly (9) is located on the side of the fuel filter

housing.

a. Disconnect drain hose (7) from the fuel drain

valve.

b. Remove 4 drain valve mounting screws (T-15

Torx head) (8).

c. Remove drain valve from filter housing.

9. Remove the screened banjo bolt (9) that is located

on the bottom of the fuel filter housing. It attaches

the Injection Pump supply line to the fuel filter

housing.

INSTALLATION

Refer to maintenance schedules for recommended fuel filter replacement intervals.

1. Thoroughly clean inside of filter housing, filter cap and all related components.

2.Fuel Filter:

a.The engine has a self-priming low-pressure fuel system. Refer to StandardProcedures-Fuel System

Priming.

b. Install new O-ring to canister lid and lubricate O-ring with clean engine oil.

c. Position new element to canister lid. Place this assembly into canisterby rotating clockwise.

d. Tighten cap to 34 Nꞏm (25 ft. lbs.) torque. Do not overtighten cap.

3.Water-In-Fuel (WIF) Sensor:

Page 2472 of 5267

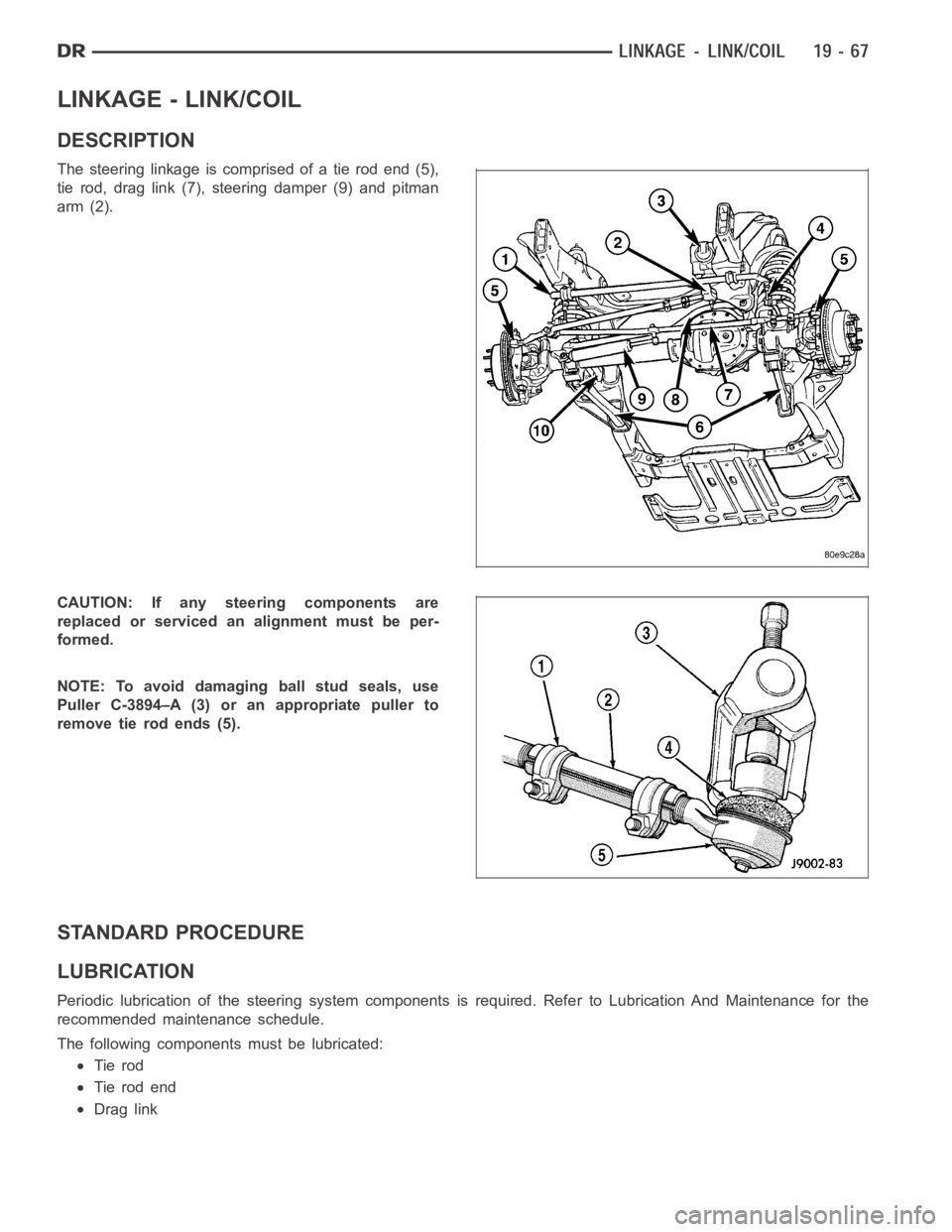

LINKAGE - LINK/COIL

DESCRIPTION

Thesteeringlinkageiscomprisedofatierodend(5),

tie rod, drag link (7), steering damper (9) and pitman

arm (2).

CAUTION: If any steering components are

replaced or serviced an alignment must be per-

formed.

NOTE: To avoid damaging ball stud seals, use

Puller C-3894–A (3) or an appropriate puller to

remove tie rod ends (5).

STANDARD PROCEDURE

LUBRICATION

Periodic lubrication of the steering system components is required. Refer to Lubrication And Maintenance for the

recommended maintenance schedule.

The following components must be lubricated:

Tie rod

Tie rod end

Drag link

Page 3432 of 5267

FLUID AND FILTER REPLACEMENT

For proper service intervals (Refer to LUBRICATION & MAINTENANCE/MAINTENANCE SCHEDULES - DESCRIP-

TION).

REMOVAL

1. Hoist and support vehicle on safety stands.

2. Place a large diameter shallow drain pan beneath the transmission pan.

3. Remove bolts holding front and sides of pan to transmission.

4. Loosen bolts holding rear of pan to transmission.

5. Slowly separate front of pan away from transmission allowing the fluid to drain into drain pan.

6. Hold up pan and remove remaining bolts holding pan to transmission.

7. While holding pan level, lower pan away from transmission.

8. Pour remaining fluid in pan into drain pan.

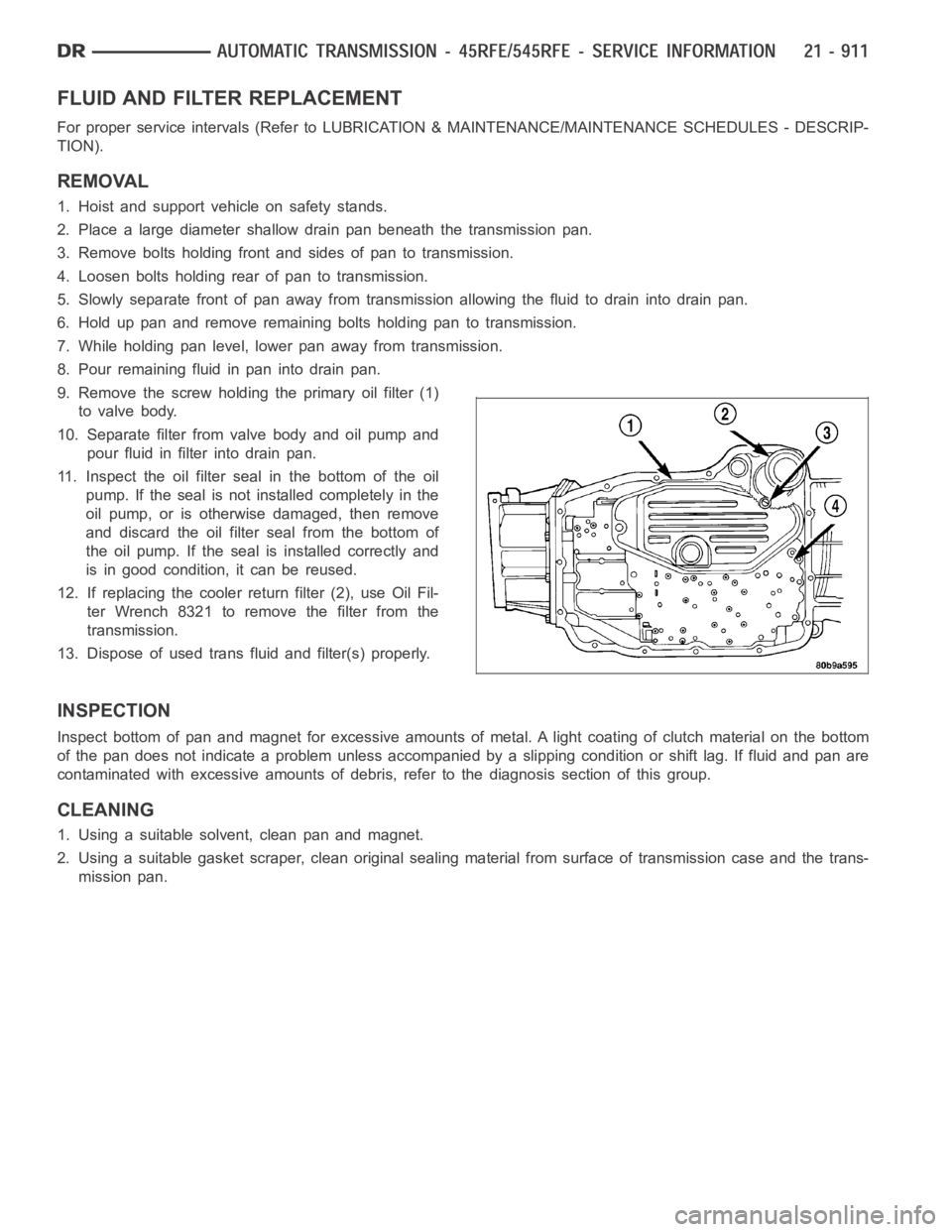

9. Remove the screw holding the primary oil filter (1)

to valve body.

10. Separate filter from valve body and oil pump and

pour fluid in filter into drain pan.

11. Inspect the oil filter seal in the bottom of the oil

pump. If the seal is not installed completely in the

oil pump, or is otherwise damaged, then remove

and discard the oil filter seal from the bottom of

the oil pump. If the seal is installed correctly and

is in good condition, it can be reused.

12. If replacing the cooler return filter (2), use Oil Fil-

ter Wrench 8321 to remove the filter from the

transmission.

13. Dispose of used trans fluid and filter(s) properly.

INSPECTION

Inspect bottom of pan and magnet for excessive amounts of metal. A light coating of clutch material on the bottom

of the pan does not indicate a problem unless accompanied by a slipping condition or shift lag. If fluid and pan are

contaminated with excessive amounts of debris, refer to the diagnosis section of this group.

CLEANING

1. Using a suitable solvent, clean pan and magnet.

2. Using a suitable gasket scraper, clean original sealing material from surface of transmission case and the trans-

mission pan.

Page 3876 of 5267

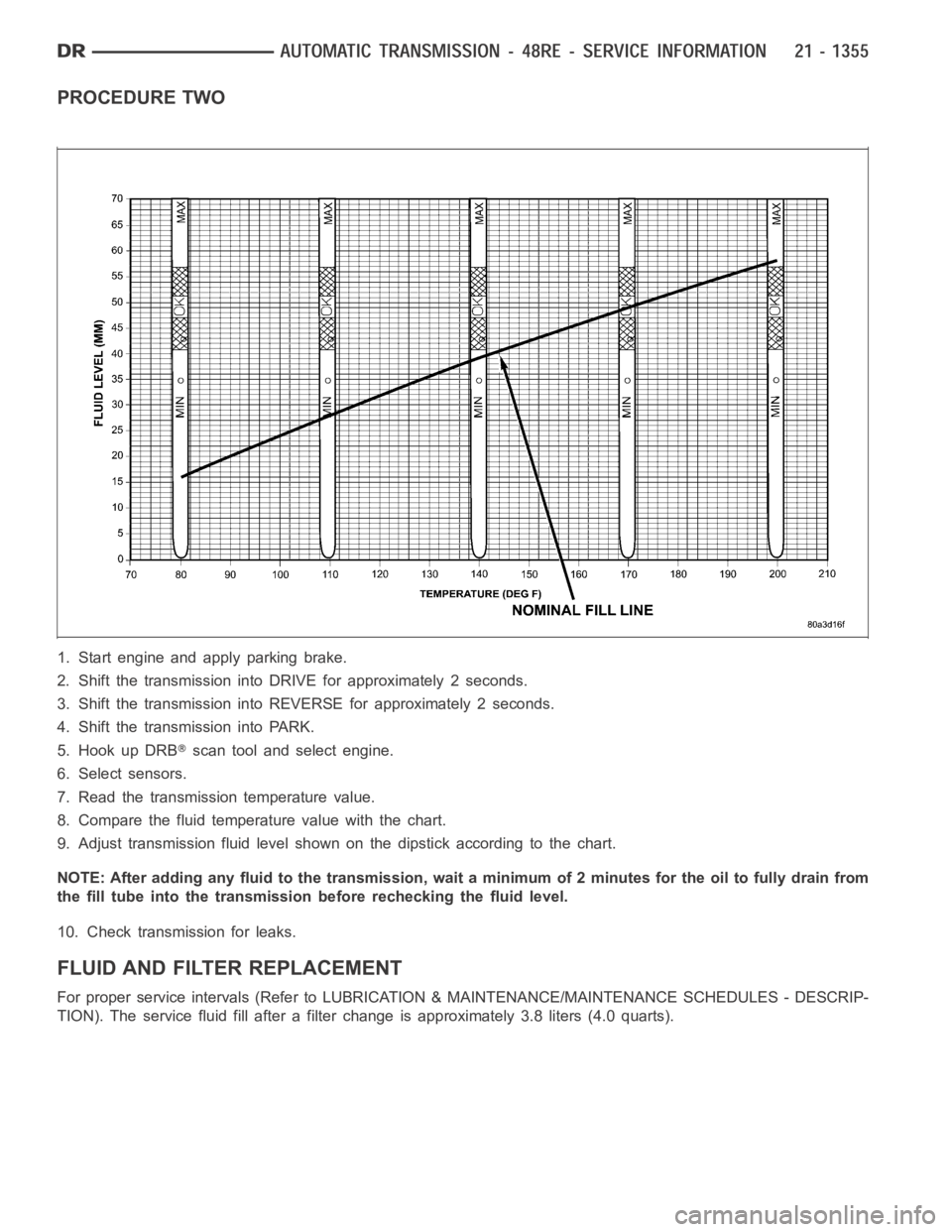

PROCEDURE TWO

1. Start engine and apply parking brake.

2. Shift the transmission into DRIVE for approximately 2 seconds.

3. Shift the transmission into REVERSE for approximately 2 seconds.

4. Shift the transmission into PARK.

5. Hook up DRB

scan tool and select engine.

6. Select sensors.

7. Read the transmission temperature value.

8. Compare the fluid temperature value with the chart.

9. Adjust transmission fluid level shown on the dipstick according to the chart.

NOTE: After adding any fluid to the transmission, wait a minimum of 2 minutes for the oil to fully drain from

the fill tube into the transmission before rechecking the fluid level.

10. Check transmission for leaks.

FLUID AND FILTER REPLACEMENT

For proper service intervals (Refer to LUBRICATION & MAINTENANCE/MAINTENANCE SCHEDULES - DESCRIP-

TION). The service fluid fill after a filter change is approximately 3.8 liters (4.0 quarts).