DODGE RAM SRT-10 2006 Service Repair Manual

Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3221 of 5267

5.CHECK THE LINE PRESSURE SENSOR

Turn the ignition off to the lock position.

Disconnect the Transmission Simulator, Miller tool #8333 and reconnect all previously disconnected connectors.

Install the Line Pressure Adaptor, Miller tool #8259, and the Pressure Gauge, Miller tool #C-3293, 0 to 2000 kPa or

0to300psi.

Start the engine in park.

Monitor the line pressure readings of both the scan tool and the pressure gauge and compare the two readings.

Is the line pressure gauge reading within 34 kPa or 5 psi of the scan tool reading?

Ye s>>

Go To 6

No>>

Replace the Line Pressure Sensor per the Service Information.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

6.CHECK FOR A PLUGGED TRANSMISSION OIL FILTER

Turn the ignition off to the lock position.

Remove and inspect the Transmission Oil Pan for excessive debris per the Service Information.

Remove and inspect the Primary Oil Filter per the Service Information.

NOTE: Make sure the Primary Transmission Oil Filter and/or O-ring is not cracked or split.

Does the Oil Pan contain excessive debris and/or is the Primary Oil Filter cracked or plugged?

Ye s>>

Repair the plugged, cracked, or split Primary Transmission Oil Filter and/or O-ring. If the Primary Trans-

mission Oil Filter is plugged refer to the Service Information for the proper Hydraulic repair procedure.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Repair internal transmission and inspect the Transmission Oil Pump per the Service Information and

replace if necessary. If no problem is found, replace the Solenoid/TRS Assembly.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

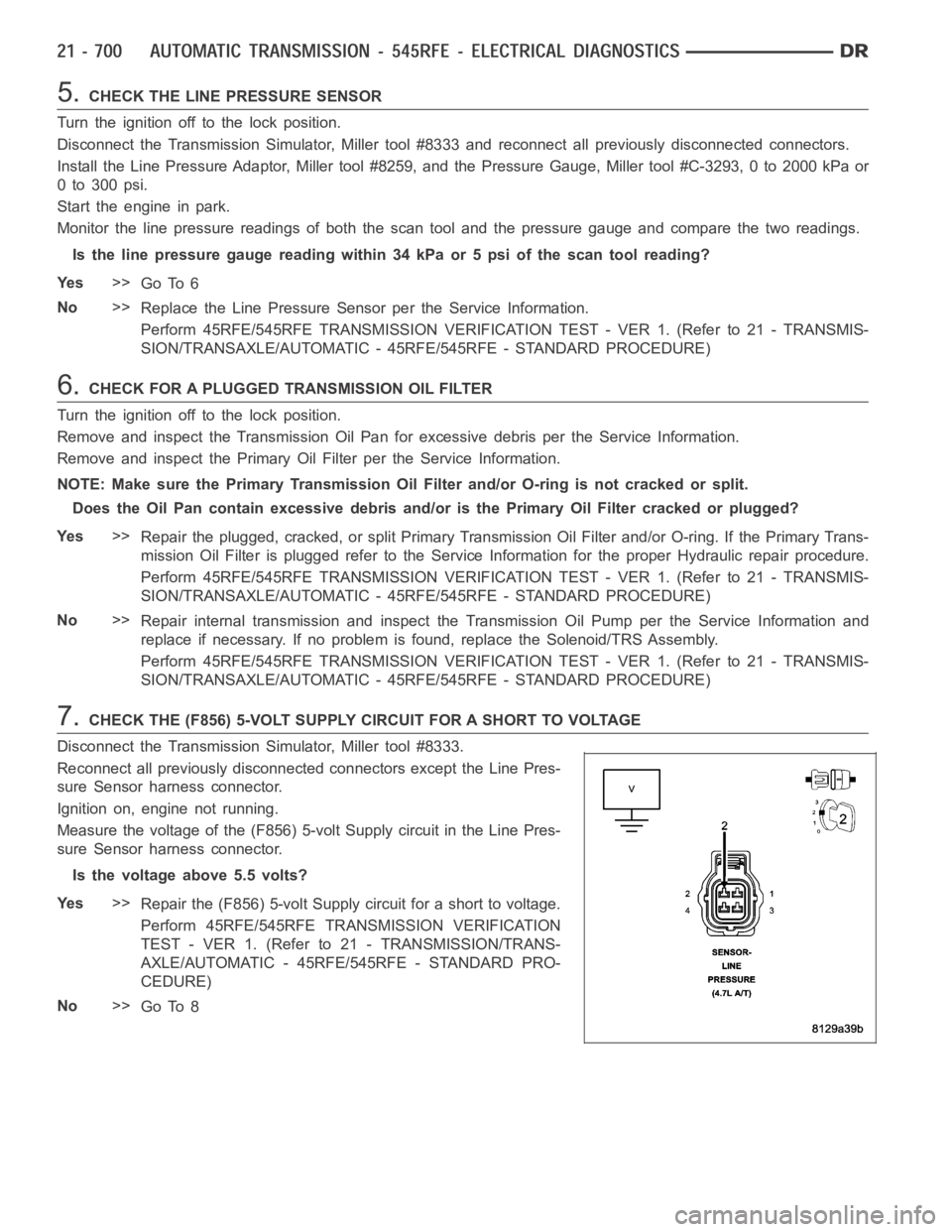

7.CHECK THE (F856) 5-VOLT SUPPLY CIRCUIT FOR A SHORT TO VOLTAGE

Disconnect the Transmission Simulator, Miller tool #8333.

Reconnect all previously disconnected connectors except the Line Pres-

sure Sensor harness connector.

Ignition on, engine not running.

Measure the voltage of the (F856) 5-volt Supply circuit in the Line Pres-

sure Sensor harness connector.

Is the voltage above 5.5 volts?

Ye s>>

Repair the (F856) 5-volt Supply circuit for a short to voltage.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

No>>

Go To 8

Page 3222 of 5267

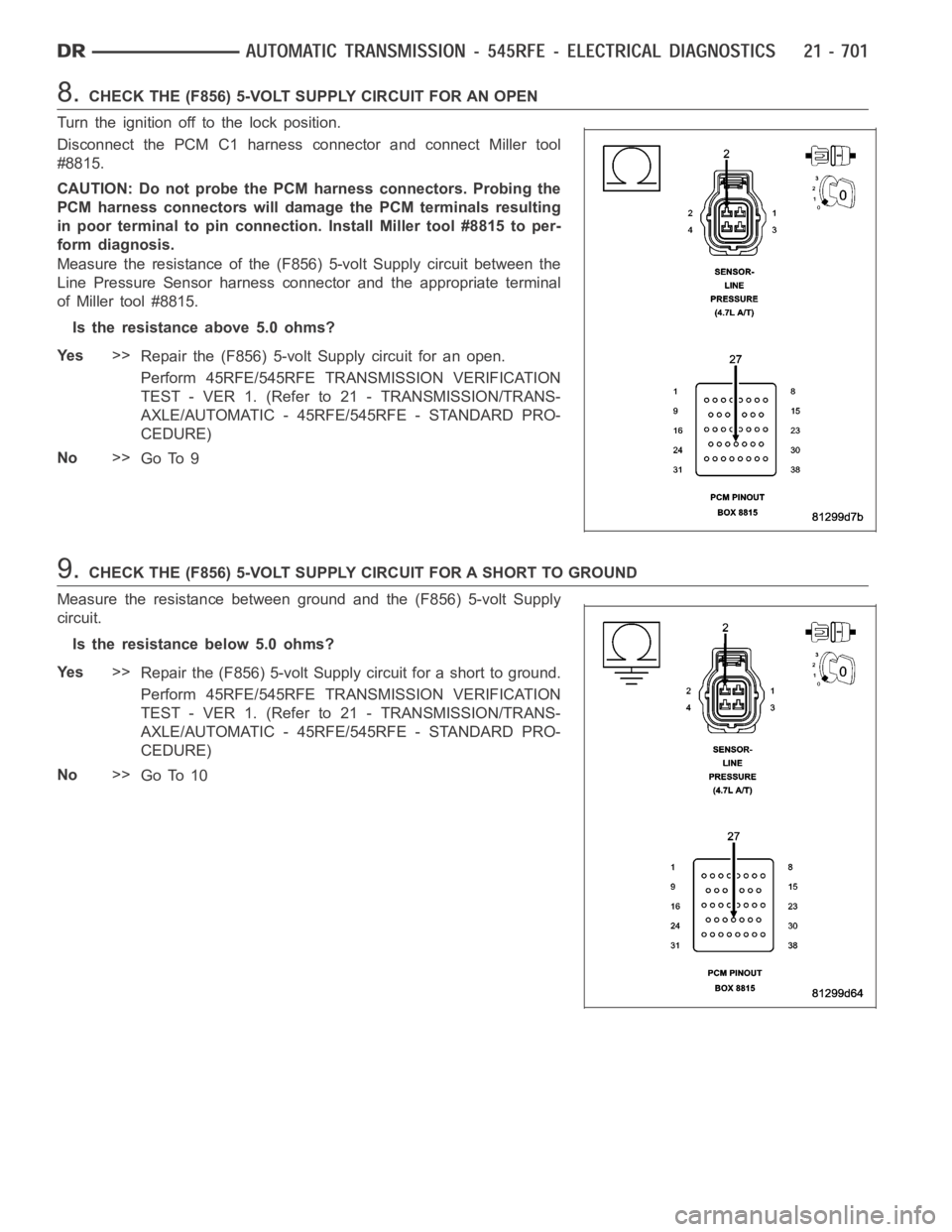

8.CHECK THE (F856) 5-VOLT SUPPLY CIRCUIT FOR AN OPEN

Turn the ignition off to the lock position.

Disconnect the PCM C1 harness connector and connect Miller tool

#8815.

CAUTION: Do not probe the PCM harness connectors. Probing the

PCM harness connectors will damage the PCM terminals resulting

in poor terminal to pin connection. Install Miller tool #8815 to per-

form diagnosis.

Measure the resistance of the (F856) 5-volt Supply circuit between the

Line Pressure Sensor harness connector and the appropriate terminal

of Miller tool #8815.

Is the resistance above 5.0 ohms?

Ye s>>

Repair the (F856) 5-volt Supply circuit for an open.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

No>>

Go To 9

9.CHECK THE (F856) 5-VOLT SUPPLY CIRCUIT FOR A SHORT TO GROUND

Measure the resistance between ground and the (F856) 5-volt Supply

circuit.

Is the resistance below 5.0 ohms?

Ye s>>

Repair the (F856) 5-volt Supply circuit for a short to ground.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

No>>

Go To 10

Page 3223 of 5267

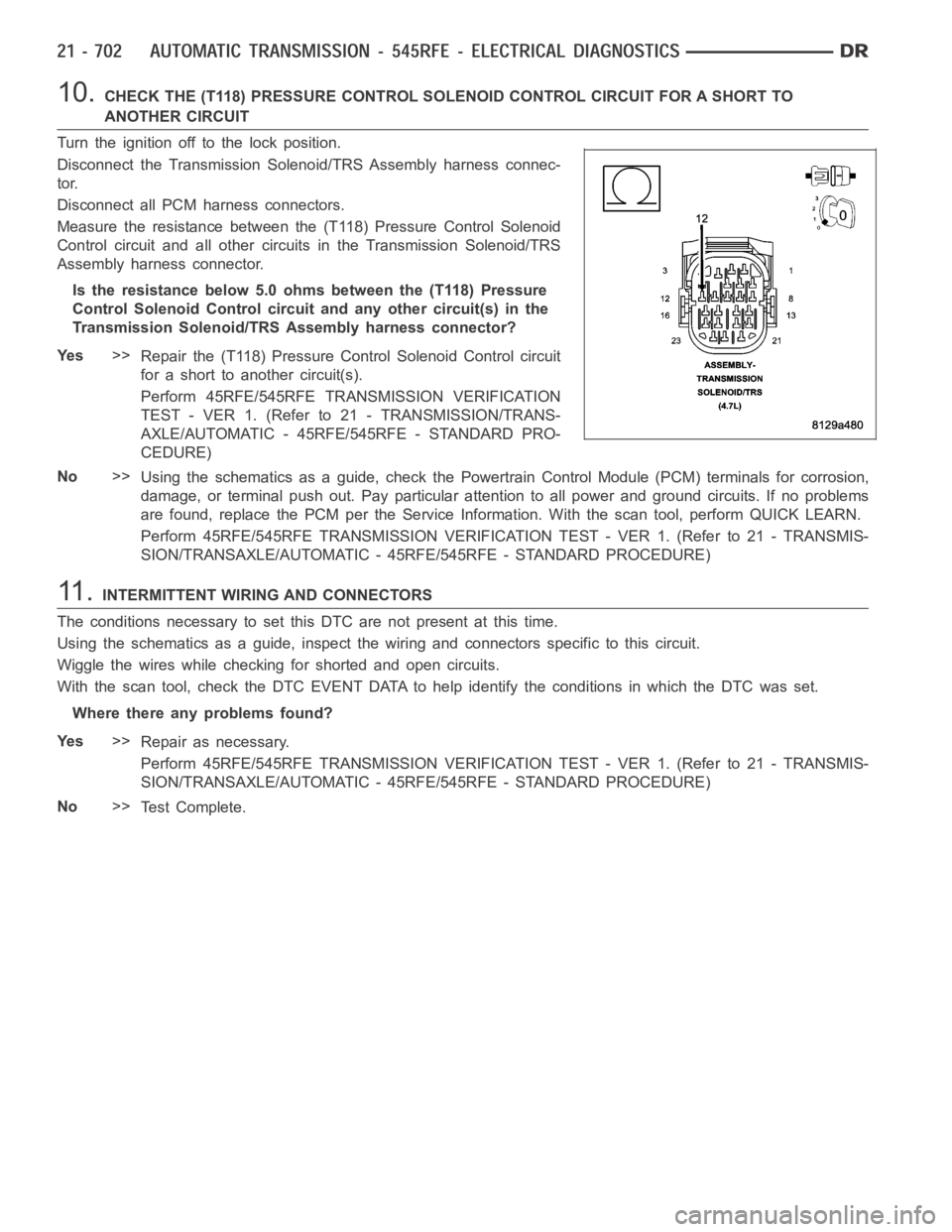

10.CHECK THE (T118) PRESSURE CONTROL SOLENOID CONTROL CIRCUIT FOR A SHORT TO

ANOTHER CIRCUIT

Turn the ignition off to the lock position.

Disconnect the Transmission Solenoid/TRS Assembly harness connec-

tor.

Disconnect all PCM harness connectors.

Measure the resistance between the (T118) Pressure Control Solenoid

Control circuit and all other circuits in the Transmission Solenoid/TRS

Assembly harness connector.

Is the resistance below 5.0 ohms between the (T118) Pressure

Control Solenoid Control circuit and any other circuit(s) in the

Transmission Solenoid/TRS Assembly harness connector?

Ye s>>

Repair the (T118) Pressure Control Solenoid Control circuit

for a short to another circuit(s).

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

No>>

Using the schematics as a guide, check the Powertrain Control Module (PCM)terminals for corrosion,

damage, or terminal push out. Pay particular attention to all power and ground circuits. If no problems

are found, replace the PCM per the Service Information. With the scan tool,perform QUICK LEARN.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

11 .INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specifictothiscircuit.

Wiggle the wires while checking for shorted and open circuits.

With the scan tool, check the DTC EVENT DATA to help identify the conditionsin which the DTC was set.

Where there any problems found?

Ye s>>

Repair as necessary.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .

Page 3224 of 5267

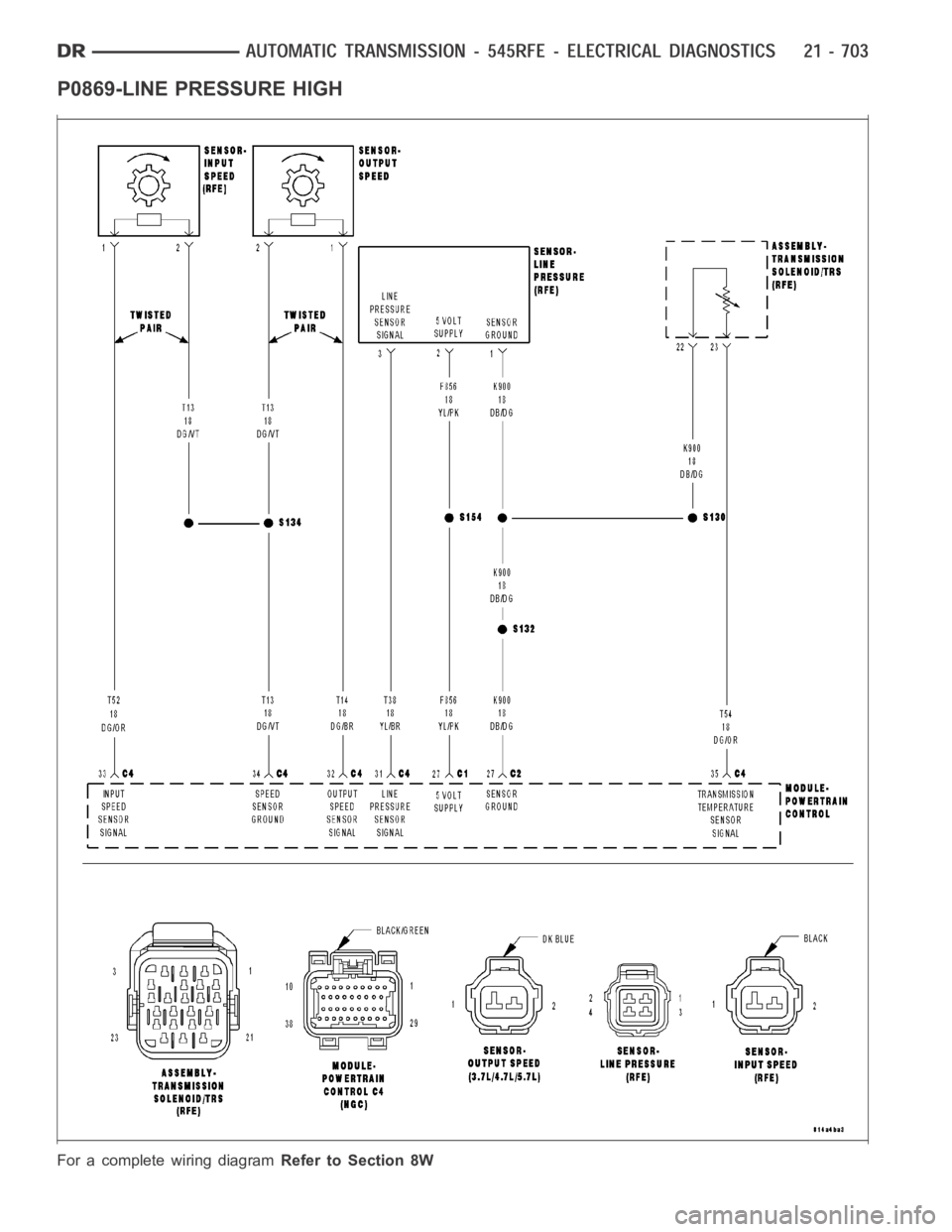

P0869-LINE PRESSURE HIGH

For a complete wiring diagramRefer to Section 8W

Page 3225 of 5267

When Monitored:

Continuously while driving in a forward gear.

Set Condition:

The PCM continuously monitors Actual Line Pressure. If the Actual Line Pressure reading is greater than the

highest Desired Line Pressure ever used in the current gear, while the Pressure Control Solenoid duty cycle is

at or near its maximum value (which should result in minimum line pressure), the DTC will set.

Possible Causes

(F856) 5-VOLT SUPPLY CIRCUIT OPEN

LINE PRESSURE SENSOR CONNECTION

(T118) PRESSURE CONTROL SOLENOID CONTROL CIRCUIT OPEN

(F856) 5-VOLT SUPPLY CIRCUIT SHORT TO GROUND

(T118) PRESSURE CONTROL SOLENOID CONTROL CIRCUIT SHORT TO GROUND

TRANSMISSION CONTROL RELAY OUTPUT CIRCUIT

LINE PRESSURE SENSOR

STUCK OR STICKING MAIN REGULATOR VALVE

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

Line pressure is measured by the Line Pressure Sensor (LPS) and regulationis achieved by changing the duty

cycle of the Pressure Control Solenoid (PCS) controlled by the Transmission Control System. (5% duty cycle =

solenoid off = Max line pressure, 62%duty cycle = solenoid on = Min line pressure). The Transmission Control

System calculates the desired line pressure based on inputs from both the engine and transmission.

The Transmission Control System calculates torque input to the transmission and uses it as the primary input to the

desired line pressure calculation. This is called Torque Based Line Pressure. In addition, the line pressure is set to

a preset level 827 or 931 kPa (120 or 135 psi) during shifts and in Park and Neutral to ensure consistent shift

quality. The desired line pressure is continuously being compared to the actual line pressure. If the actual line pres-

sure is consistently higher than the highest desired line pressure ever used in the current gear, the line pressure

high DTC P0869 will set.

Diagnostic Test

1.CHECKFORRELATEDDTC’S

With the scan tool, check for other Transmission DTC’s

Is the DTC P0932 or P0882 present also?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom.

No>>

Go To 2

2.CHECK IF THE DTC IS CURRENT

With the scan tool, check the STARTS SINCE SET counter for P0869.

Is the STARTS SINCE SET COUNTER 2 or less?

Ye s>>

Go To 3

No>>

Go To 10

Page 3226 of 5267

3.CHECK THE LINE PRESSURE SENSOR CONNECTION

Ignition on, engine not running.

With the scan tool, monitor the Transmission Line Pressure.

Firmly push the Line Pressure Sensor harness connector inward towards theTransmission.

Did the Line Pressure change to about 207 kPa or 30 psi when the sensor connector was pushed?

Ye s>>

Disconnect and properly reconnect the Line Pressure Sensor connector. Inspect terminals and repair as

necessary.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Go To 4

4.CHECK THE PCM AND WIRING

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator, Miller tool #8333.

With the Transmission Simulator select the

OFFposition on theInput/Output Speedswitch.

Ignition on, engine not running.

With the scan tool, monitor the Line Pressure during the following step.

Using the Transmission Simulator, set the rotary switch to each of the 3 line pressure positions.

NOTE: All three scan tool Line Pressure readings should be steady and ±14 kPa or 2.0 psi of the reading

specified on the Transmission Simulator.

Did the Line Pressure read within ±14 kPA or 2.0 psi in all three positions?

Ye s>>

Go To 5

No>>

Go To 6

5.CHECK THE LINE PRESSURE SENSOR CALIBRATION

Turn the ignition off to the lock position.

Disconnect the Transmission Simulator, Miller tool #8333 and reconnect all previously disconnected connectors.

Install the Line Pressure Adaptor,Miller tool #8259, and Pressure Gauge,Miller tool #C-3293, 0 to 2000 kPa or 0

to 300 psi.

Start the engine in park.

Monitor the Line Pressure readings on the scan tool and the pressure gauge.

Compare the Line Pressure readings between the scan tool and the pressure gauge.

Is the pressure gauge reading within 34 kPa or 5 psi of the scan tool reading?

Ye s>>

Repair the internal transmission and inspect the Transmission Oil Pump per the Service Information and

replace if necessary. If no problem is found, replace the Transmission Solenoid/TRS Assembly, possible

cause is a stuck Pressure Control Solenoid.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Replace the Line Pressure Sensor per the Service information.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Page 3227 of 5267

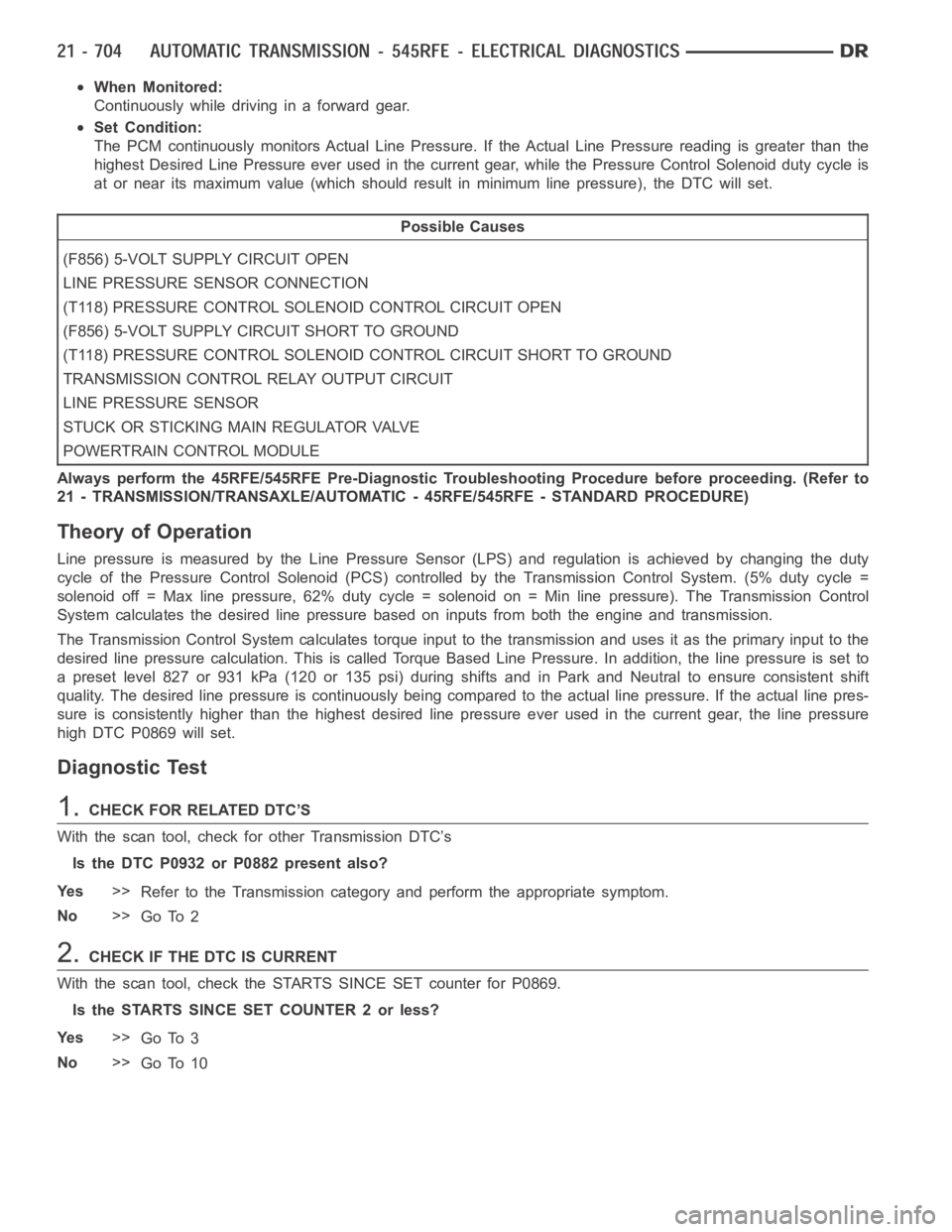

6.CHECK THE (T118) PRESSURE CONTROL SOLENOID CONTROL CIRCUIT FOR AN OPEN

Turn the ignition off to the lock position.

Disconnect the Transmission Simulator, Miller tool #8333.

Disconnect the Powertrain Control Module C4 harness connector.

CAUTION: Do not probe the PCM harness connectors. Probing the

PCM harness connectors will damage the PCM terminals resulting

in poor terminal to pin connection. Install Miller tool #8815 to per-

form diagnosis.

Measure the resistance of the (T118) Pressure Control Solenoid Control

circuit between the Solenoid/TRS Assembly harness connector and the

appropriate terminal of Miller tool #8815.

Is the resistance above 5.0 ohms?

Ye s>>

Repair the (T118) Pressure Control Solenoid Control circuit

for an open.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

No>>

Go To 7

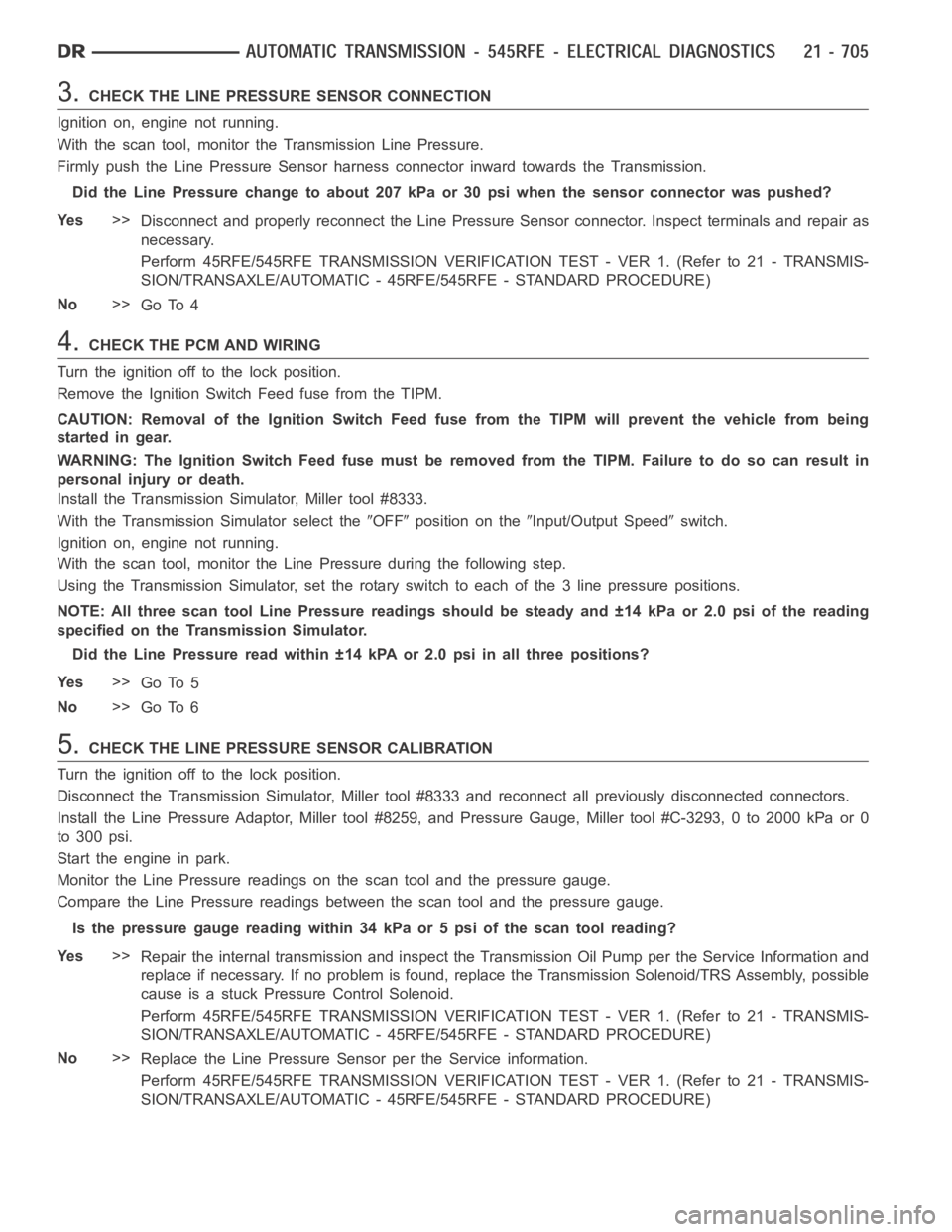

7.CHECK THE (T118) PRESSURE CONTROL SOLENOID CONTROL CIRCUIT FOR A SHORT TO GROUND

Measure the resistance between ground and the (T118) Pressure Con-

trol Solenoid Control circuit.

Is the resistance below 5.0 ohms?

Ye s>>

Repair the (T118) Pressure Control Solenoid Control circuit

for a short to ground.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

No>>

Go To 8

Page 3228 of 5267

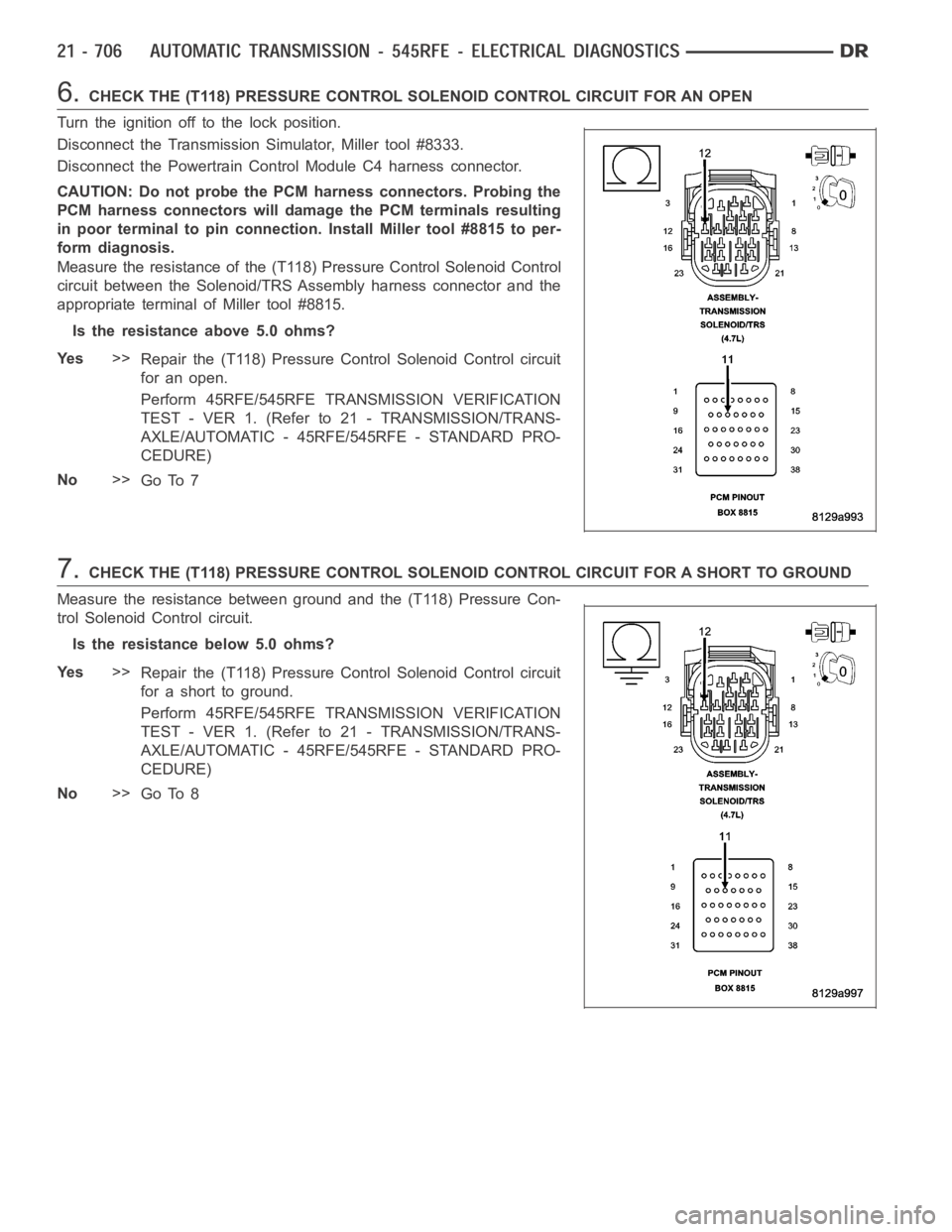

8.CHECK THE (F856) 5-VOLT SUPPLY CIRCUIT FOR AN OPEN

Measure the resistance of the (F856) 5-volt Supply circuit between the

Line Pressure Sensor harness connector and the appropriate terminal

of Miller tool #8815.

Is the resistance above 5.0 ohms?

Ye s>>

Repair the (F856) 5-volt Supply circuit for an open.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

No>>

Go To 9

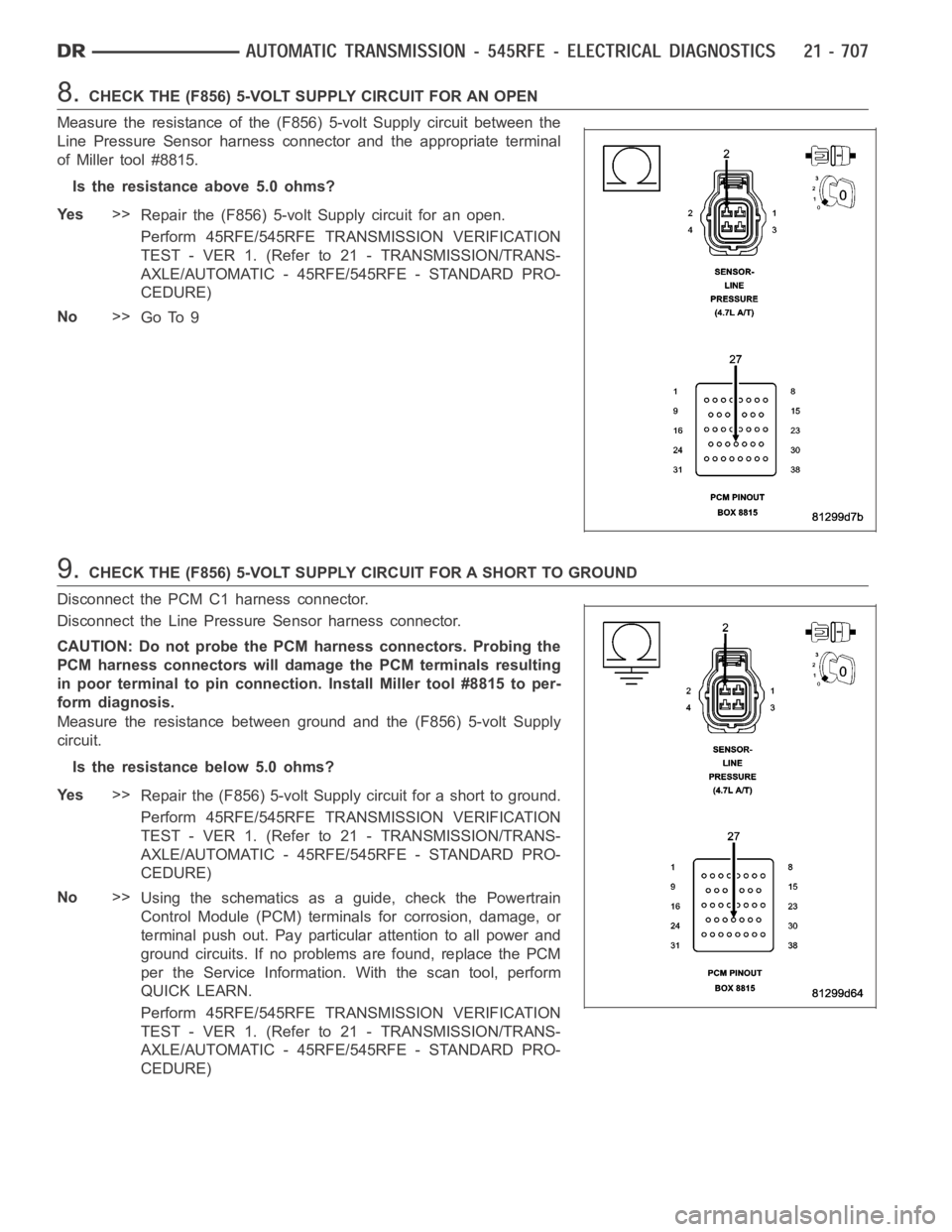

9.CHECK THE (F856) 5-VOLT SUPPLY CIRCUIT FOR A SHORT TO GROUND

Disconnect the PCM C1 harness connector.

Disconnect the Line Pressure Sensor harness connector.

CAUTION: Do not probe the PCM harness connectors. Probing the

PCM harness connectors will damage the PCM terminals resulting

in poor terminal to pin connection. Install Miller tool #8815 to per-

form diagnosis.

Measure the resistance between ground and the (F856) 5-volt Supply

circuit.

Is the resistance below 5.0 ohms?

Ye s>>

Repair the (F856) 5-volt Supply circuit for a short to ground.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

No>>

Using the schematics as a guide, check the Powertrain

Control Module (PCM) terminals for corrosion, damage, or

terminal push out. Pay particular attention to all power and

ground circuits. If no problems are found, replace the PCM

per the Service Information.With the scan tool, perform

QUICK LEARN.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

Page 3229 of 5267

10.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specifictothiscircuit.

Wiggle the wires while checking for shorted and open circuits.

With the scan tool, check the DTC EVENT DATA to help identify the conditionsin which the DTC was set.

Where there any problems found?

Ye s>>

Repair as necessary.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .

Page 3230 of 5267

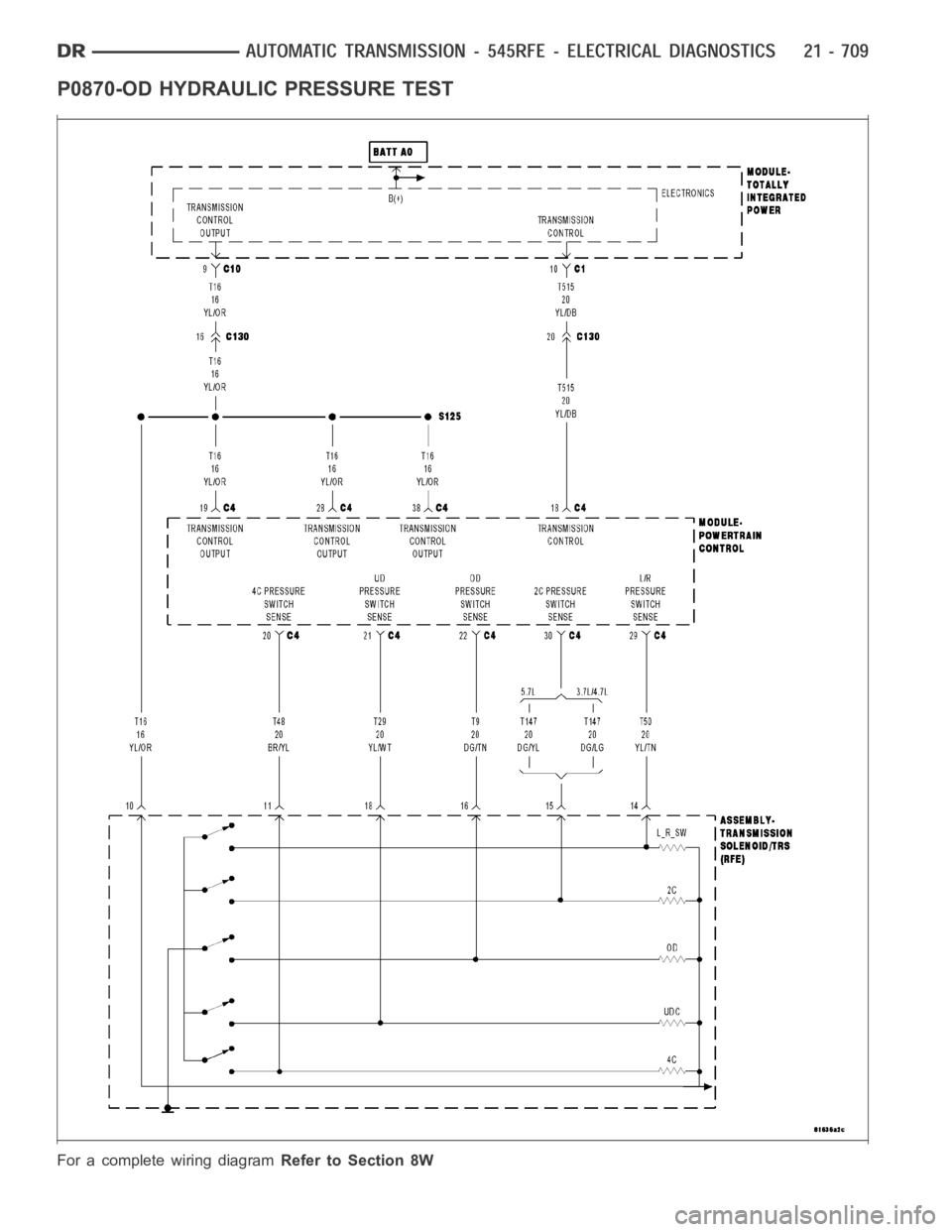

P0870-OD HYDRAULIC PRESSURE TEST

For a complete wiring diagramRefer to Section 8W