DODGE RAM SRT-10 2006 Service Repair Manual

Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3331 of 5267

When Monitored:

Continuously when performing partial or full EMCC - PEMCC or FEMCC.

Set Condition:

If the transmission senses the L/R pressure switch closing while performing PEMCC or FEMCC. This DTC will

set after two unsuccessful attempts toperform PEMCC or FEMCC. This DTC cantake up to five minutes of

problem identification before illuminating the MIL.

Possible Causes

RELATED DTC P0841 PRESENT

LR PRESSURE SWITCH SENSE CIRCUIT OPEN

LR PRESSURE SWITCH SENSE CIRCUIT SHORT TO GROUND

SOLENOID SWITCH VALVE

POWERTRAIN CONTROL MODULE

INTERMITTENT WIRING AND CONNECTORS

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The Solenoid Switch Valve (SSV) controls the direction of the transmission fluid when the L/R Solenoid is energized.

The SSV will be in the downshifted position in 1st gear, thus directing the fluid to the L/R clutch circuit. In 2nd

through 5th gears, it will be in the upshifted position and directing the fluid into the torque converter clutch (TCC).

When in 2nd, 2nd Prime, 3rd, 4th, or 5th gear, the Torque Converter Clutch (TCC) can be engaged when certain

conditions are met. The TCC piston is electronically modulated by increasing the duty cycle of the L/R solenoid until

the torque converter slip difference (difference between engine and transmission input speed) is within 60 RPM.

Then the L/R solenoid isfully energized (FEMCC - 100% duty cycle). Torque converter slip is monitored in FEMCC

to ensure adequate clutch capacity.

Diagnostic Test

1.CHECKFORRELATEDDTCS

With the scan tool, check for other transmission DTCs.

Is the DTC P0841 present also?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom.

No>>

Go To 2

2.CHECK TO SEE IF DTC P1776 IS CURRENT

With the scan tool, Check the STARTS SINCE SET counter.

NOTE: NOTE: This counter only applies to the last DTC set.

Is the STARTS SINCE SET counter 2 or less?

Ye s>>

Go To 3

No>>

Go To 7

Page 3332 of 5267

3.CHECK THE PCM AND WIRING

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator, Miller tool #8333.

Ignition on, engine not running.

With the Transmission Simulator, turn the Pressure Switch selector switchtotheLRposition.

With the scan tool, monitor the LR Pressure Switch state while pressing thePressure Switch Test button on the

Transmission Simulator.

Did the state of the LR Pressure Switch change while pressing the Pressure Switch Test button?

Ye s>>

Go To 4

No>>

Go To 5

4.CHECK THE SOLENOID SWITCH VALVE

Remove the Valve Body per the Service Information.

Inspect the Solenoid Switch Valve and plugs for sticking in the bore and/orwear.

Were there any problems found?

Ye s>>

Clean and repair as necessary per the Service Information.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Go To 7

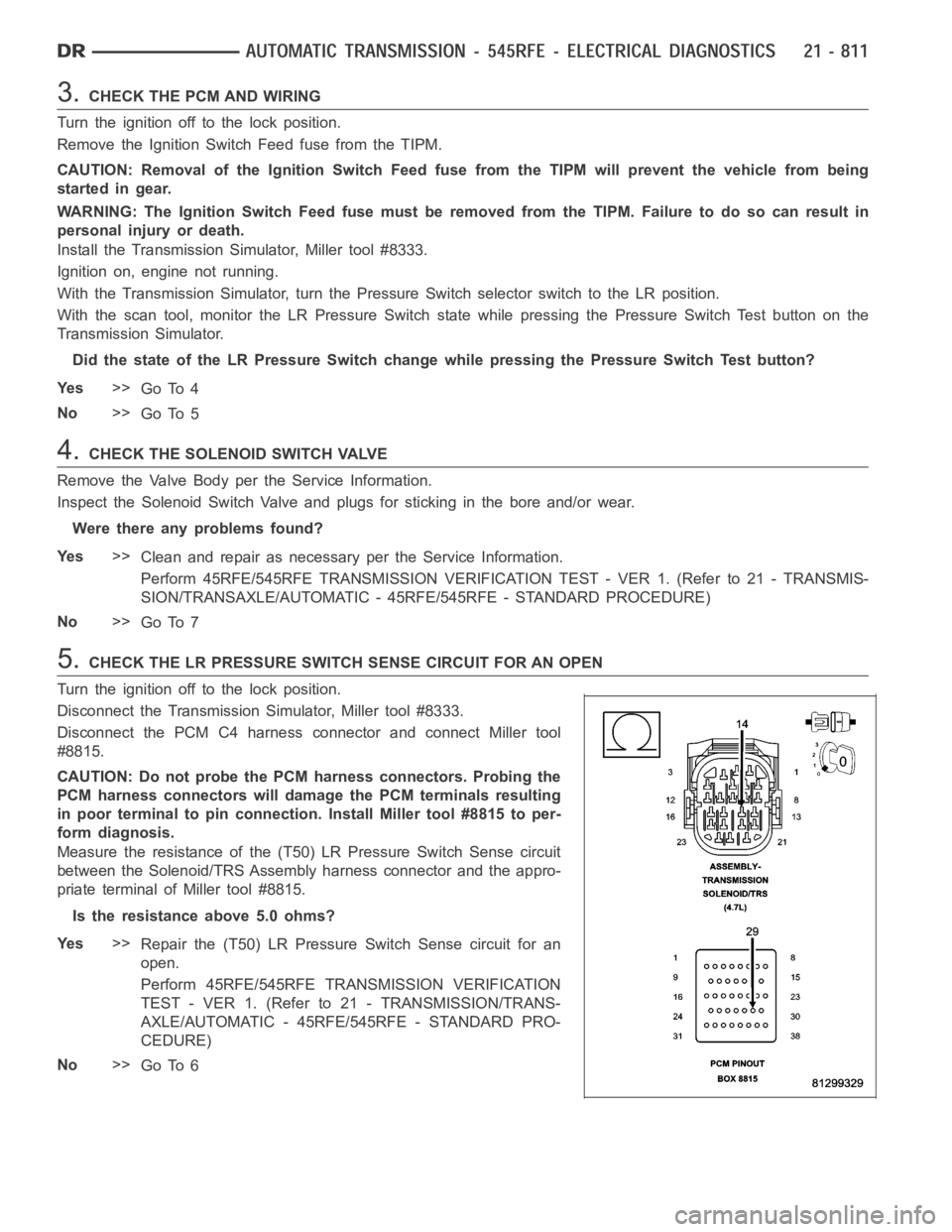

5.CHECK THE LR PRESSURE SWITCH SENSE CIRCUIT FOR AN OPEN

Turn the ignition off to the lock position.

Disconnect the Transmission Simulator, Miller tool #8333.

Disconnect the PCM C4 harness connector and connect Miller tool

#8815.

CAUTION: Do not probe the PCM harness connectors. Probing the

PCM harness connectors will damage the PCM terminals resulting

in poor terminal to pin connection. Install Miller tool #8815 to per-

form diagnosis.

Measure the resistance of the (T50) LR Pressure Switch Sense circuit

between the Solenoid/TRS Assembly harness connector and the appro-

priate terminal of Miller tool #8815.

Is the resistance above 5.0 ohms?

Ye s>>

Repair the (T50) LR Pressure Switch Sense circuit for an

open.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

No>>

Go To 6

Page 3333 of 5267

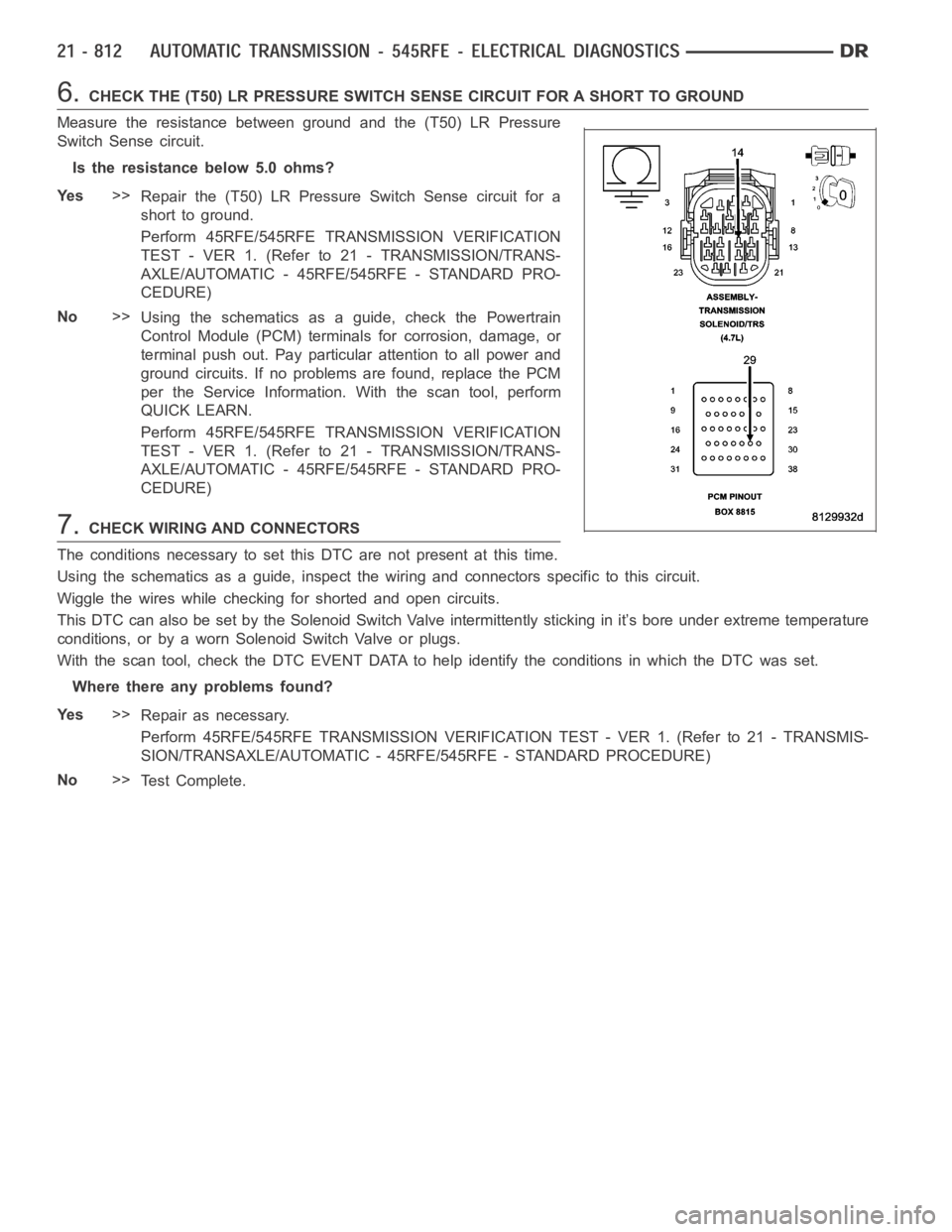

6.CHECK THE (T50) LR PRESSURE SWITCH SENSE CIRCUIT FOR A SHORT TO GROUND

Measure the resistance between ground and the (T50) LR Pressure

Switch Sense circuit.

Is the resistance below 5.0 ohms?

Ye s>>

Repair the (T50) LR Pressure Switch Sense circuit for a

short to ground.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

No>>

Using the schematics as a guide, check the Powertrain

Control Module (PCM) terminals for corrosion, damage, or

terminal push out. Pay particular attention to all power and

ground circuits. If no problems are found, replace the PCM

per the Service Information.With the scan tool, perform

QUICK LEARN.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

7.CHECK WIRING AND CONNECTORS

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specifictothiscircuit.

Wiggle the wires while checking for shorted and open circuits.

This DTC can also be set by the Solenoid Switch Valve intermittently sticking in it’s bore under extreme temperature

conditions, or by a worn Solenoid Switch Valve or plugs.

With the scan tool, check the DTC EVENT DATA to help identify the conditionsin which the DTC was set.

Where there any problems found?

Ye s>>

Repair as necessary.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .

Page 3334 of 5267

P1790-FAULT IMMEDIATELY AFTER SHIFT

For a complete wiring diagramRefer to Section 8W

When Monitored:

After a speed ratio error is stored.

Set Condition:

This DTC is set if the associated speed ratio DTC is stored within 1.3 seconds after a shift.

Possible Causes

FAULT AFTER SHIFT

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

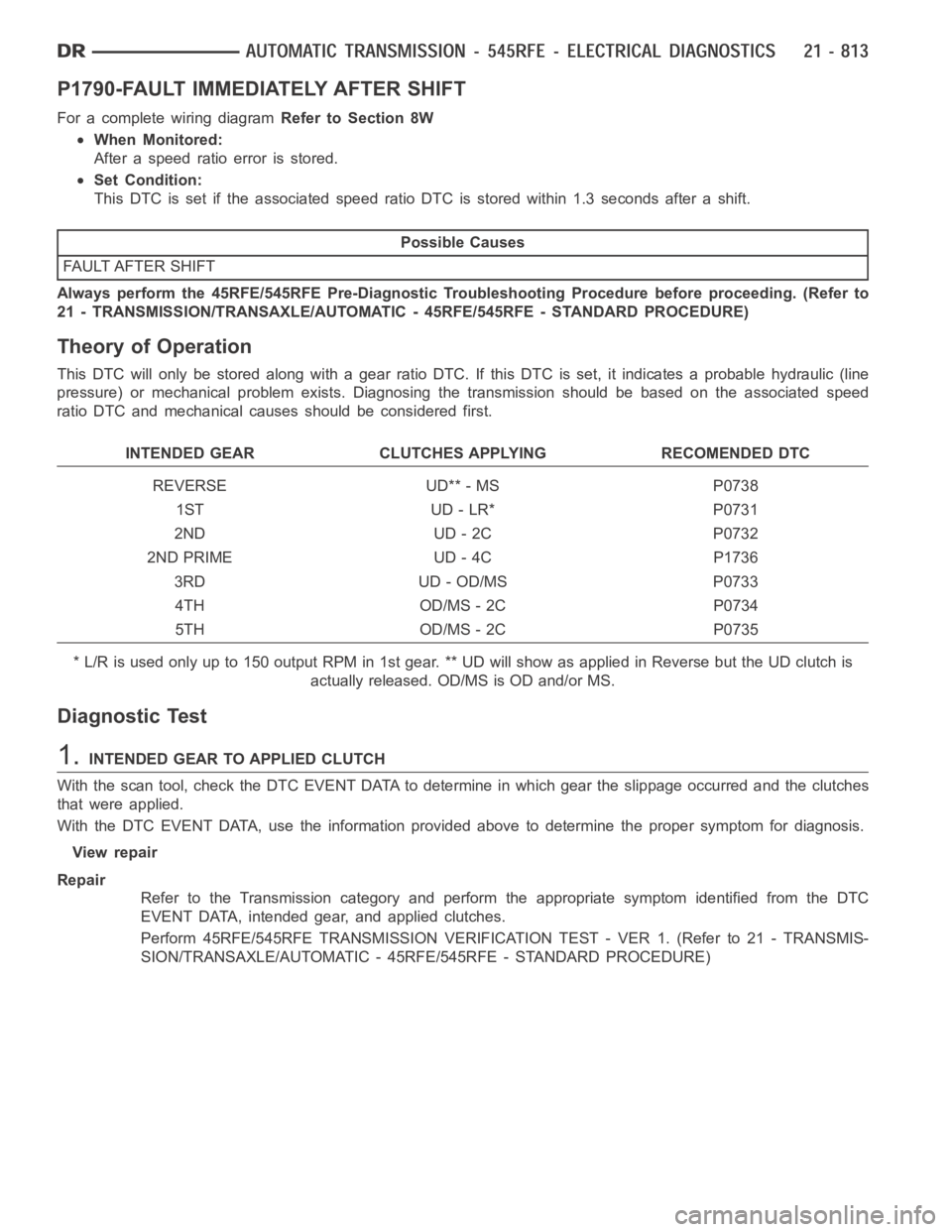

Theory of Operation

This DTC will only be stored along with a gear ratio DTC. If this DTC is set, itindicates a probable hydraulic (line

pressure) or mechanical problem exists. Diagnosing the transmission should be based on the associated speed

ratio DTC and mechanical causes should be considered first.

INTENDED GEAR CLUTCHES APPLYING RECOMENDED DTC

REVERSE UD** - MS P0738

1ST UD - LR* P0731

2ND UD - 2C P0732

2ND PRIME UD - 4C P1736

3RD UD - OD/MS P0733

4TH OD/MS - 2C P0734

5TH OD/MS - 2C P0735

* L/R is used only up to 150 output RPM in 1st gear. ** UD will show as applied inReversebuttheUDclutchis

actually released. OD/MS is OD and/or MS.

Diagnostic Test

1.INTENDED GEAR TO APPLIED CLUTCH

With the scan tool, check the DTC EVENT DATA to determine in which gear the slippage occurred and the clutches

that were applied.

WiththeDTCEVENTDATA,usetheinformationprovidedabovetodeterminethe proper symptom for diagnosis.

View repair

Repair

Refer to the Transmission category and perform the appropriate symptom identified from the DTC

EVENT DATA, intended gear, and applied clutches.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Page 3335 of 5267

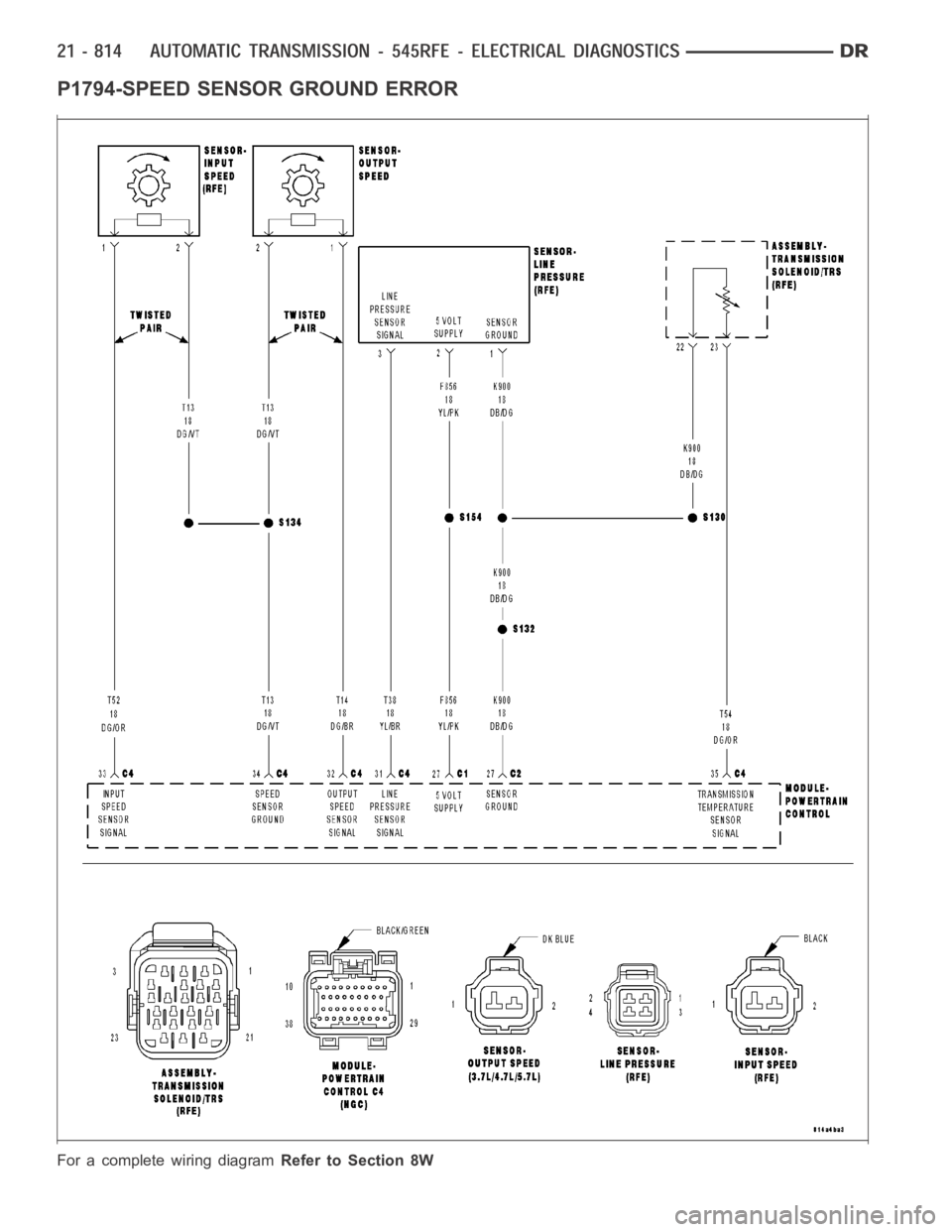

P1794-SPEED SENSOR GROUND ERROR

For a complete wiring diagramRefer to Section 8W

Page 3336 of 5267

When Monitored:

The gear ratio is monitored continuously while the Transmission is in gear.

Set Condition:

After a controller reset in neutral and a ratio of input to output, of 1 to 2. ThisDTCcantakeuptofiveminutes

of problem identification before illuminating the MIL.

Possible Causes

(T13) SPEED SENSOR GROUND CIRCUIT OPEN

(T13) SPEED SENSOR GROUND CIRCUIT SHORT TO GROUND

(T13) SPEED SENSOR GROUND CIRCUIT SHORT TO VOLTAGE

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting Procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The transmission system uses two speed sensors, one to measure input RPM and one to measure output RPM.

These inputs are essential for proper transmission operation. Therefore, the integrity of this data is verified through

the following checks:

1) When in gear, if the gear ratio does not compare to a known gear ratio, the corresponding in-gear trouble code

is set (DTCs P0731–36).

2) An excessive change in input or output speeds indicating signal intermittent which may result in the DTCs P0715

and/or P0720 to set.

3) If the common speed sensor ground circuit is lost, both sensor inputs will read the signal from the input speed

sensor at idle in neutral. Since the input speed sensor reads 60 teeth from the input clutch hub and the output

speed sensor reads 30 teeth from the park gear, the result is an apparent speed ratio of 1:2 and may cause the

DTC P1794 to set when at a stop.

Diagnostic Test

1.CHECK TO SEE IF DTC P1794 IS CURRENT

Engine Running, Shift lever in park.

With the scan tool, read the Transmission Output and Input Speed Sensor states.

Is the Output Speed Sensor reading twice the Input Speed Sensor reading?

Ye s>>

Go To 2

No>>

Go To 6

2.PCM AND WIRING

Turn the ignition off to the lock position.

Remove the Ignition Switch Feed fuse from the TIPM.

CAUTION: Removal of the Ignition Switch Feed fuse from the TIPM will prevent the vehicle from being

startedingear.

WARNING: The Ignition Switch Feed fuse must be removed from the TIPM. Failure to do so can result in

personal injury or death.

Install the Transmission Simulator, Miller tool 8333.

With the Transmission Simulator, set the Input/Output Speed selector switch to the

3000/1000position. Turn the

Input/Output Speed switch to

ON.

Ignition on, engine not running.

Page 3337 of 5267

With the scan tool, monitor the Input and Output Speed Sensor state.

Does the Input speed read 3000 RPM and the Output speed read 1000 RPM, within50 RPM?

Ye s>>

Go To 6

No>>

Go To 3

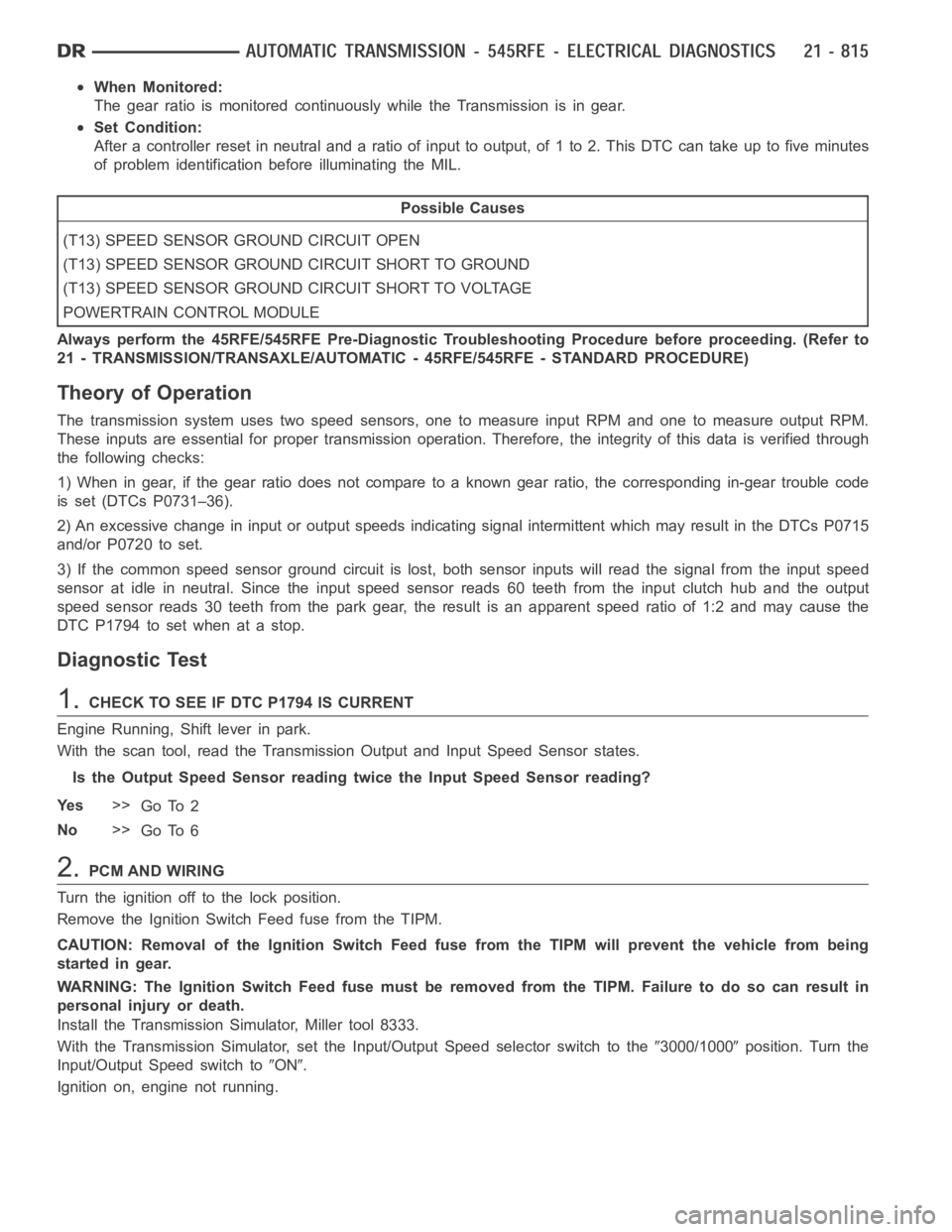

3.(T13) SPEED SENSOR GROUND CIRCUIT OPEN

Turn the ignition off to the lock position.

Disconnect the PCM C4 harness connector and connect Miller tool

#8815.

Disconnect the Transmission Simulator, Miller tool #8333.

CAUTION: Do not probe the PCM harness connectors. Probing the

PCM harness connectors will damage the PCM terminals resulting

in poor terminal to pin connection. Install Miller tool #8815 to per-

form diagnosis.

Measure the resistance of the (T13) Speed Sensor Ground circuit

between both Input and Output Speed Sensor harness connectors and

the appropriate terminalof Miller tool #8815 to the.

Is the resistance above 5.0 ohms on any of the above mea-

surements?

Ye s>>

Repair the (T13) Speed Sensor Ground circuit for an open.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

No>>

Go To 4

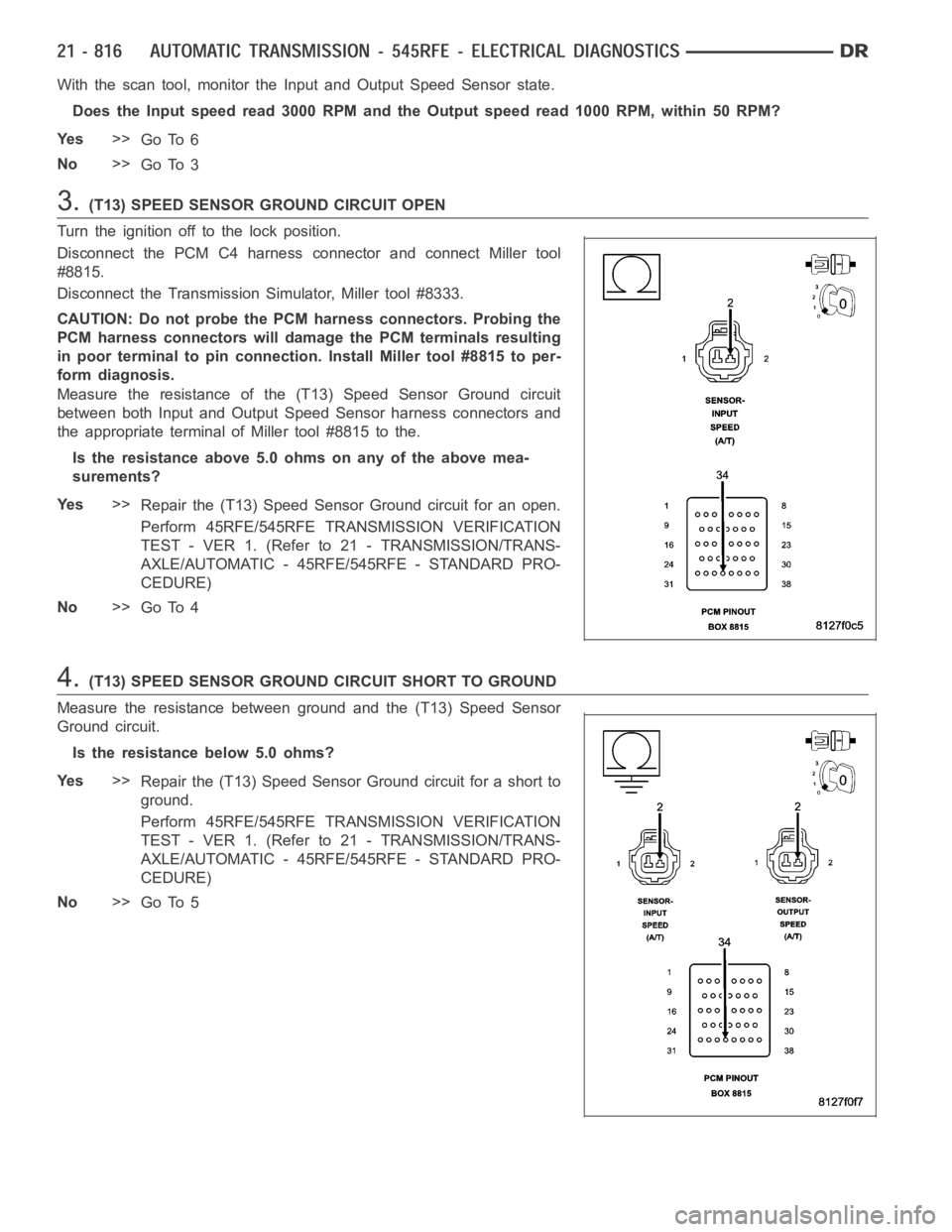

4.(T13) SPEED SENSOR GROUND CIRCUIT SHORT TO GROUND

Measure the resistance between ground and the (T13) Speed Sensor

Ground circuit.

Is the resistance below 5.0 ohms?

Ye s>>

Repair the (T13) Speed Sensor Ground circuit for a short to

ground.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

No>>

Go To 5

Page 3338 of 5267

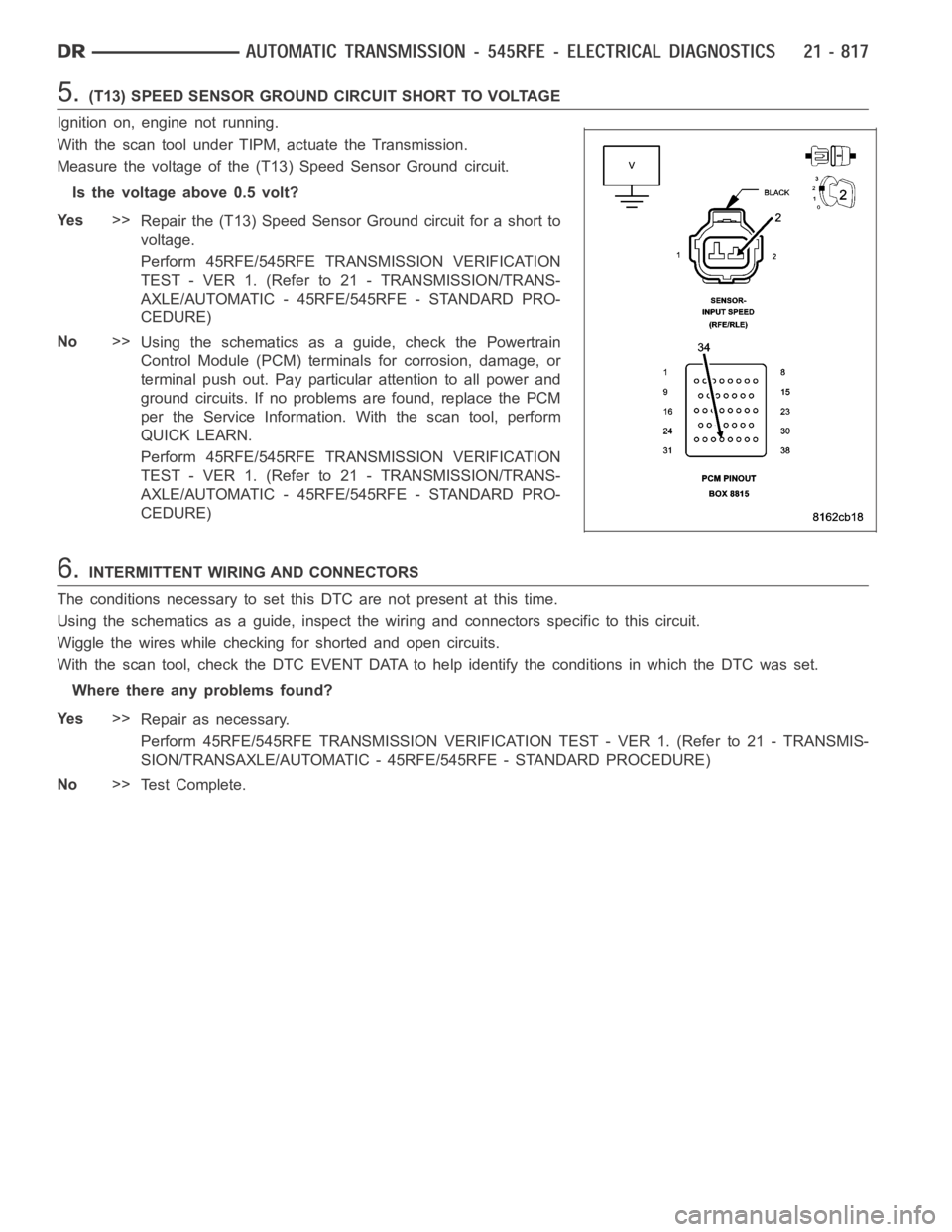

5.(T13) SPEED SENSOR GROUND CIRCUIT SHORT TO VOLTAGE

Ignition on, engine not running.

With the scan tool under TIPM, actuate the Transmission.

Measure the voltage of the (T13) Speed Sensor Ground circuit.

Is the voltage above 0.5 volt?

Ye s>>

Repair the (T13) Speed Sensor Ground circuit for a short to

voltage.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

No>>

Using the schematics as a guide, check the Powertrain

Control Module (PCM) terminals for corrosion, damage, or

terminal push out. Pay particular attention to all power and

ground circuits. If no problems are found, replace the PCM

per the Service Information.With the scan tool, perform

QUICK LEARN.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION

TEST - VER 1. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PRO-

CEDURE)

6.INTERMITTENT WIRING AND CONNECTORS

The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specifictothiscircuit.

Wiggle the wires while checking for shorted and open circuits.

With the scan tool, check the DTC EVENT DATA to help identify the conditionsin which the DTC was set.

Where there any problems found?

Ye s>>

Repair as necessary.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .

Page 3339 of 5267

P2700-INADEQUATE ELEMENT VOLUME LR

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Whenever the engine is running. The LR clutch volume index (CVI) is updatedduring a 3-1 or 2-1 manual

downshift with throttle angle below 5 degrees. Transmission temperaturemust be at least 43° C (110° F).

Set Condition:

When the LR clutch volume index (CVI) falls below 16.

Possible Causes

HYDRAULIC LEAK IN THE VALVE BODY

BROKEN L/R CLUTCH PISTON RETURN SPRING OR SPRING RETAINERS

BROKEN L/R ACCUMULATOR SPRING(S)

TRANSMISSION SOLENOID/TRS ASSEMBLY

POWERTRAIN CONTROL MODULE

Always perform the 45RFE/545RFE Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to

21 - TRANSMISSION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

Theory of Operation

The volumes of the transmission fluid needed to apply the friction elements are continuously monitored and learned

for adaptive controls. As the clutch friction material wears, the volume of fluid needed to apply the clutch increases.

Certain transmission mechanical problems can cause near-zero learned volumes resulting in setting a DTC. The

DTC will usually set with other DTC’s, which indicates an internal transmission problem.

Diagnostic Test

1.OTHER DTCS PRESENT

With the scan tool, check for other transmission DTCs.

Are there any Pressure Switch Sense circuit DTCs present also?

Ye s>>

Refer to the Transmission category and perform the appropriate symptom.

No>>

Go To 2

2.CHECKLRCLUTCHVOLUMEINDEX

With the scan tool, erase DTCs.

Start the engine and warm the transmission.

NOTE: The TRANS TEMP DEG must be at least 43° C or 110° F before performing thefollowing steps.

Drive the vehicle and perform at least ten 3-1 manual downshifts at closed throttle from speeds of about 32 Kmh or

20 MPH.

With the scan tool, read the LR CL VOL INDEX.

Is the LR CL VOL INDEX below 20?

Ye s>>

Go To 3

No>>

Go To 5

Page 3340 of 5267

3.L/R CLUTCH CIRCUIT LEAKS IN THE VALVE BODY

Turn the ignition off to the lock position.

Remove the transmission oil pan per the Service Information.

Remove the valve body per the service information.

Check condition of the L/R accumulator springs.

Look for possible leak paths into the L/R clutch hydraulics circuit withinthe valve body.

Were any problems found?

Ye s>>

Repair as necessary.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Go To 4

4.AIR CHECK L/R CLUTCH CIRCUITS

Perform an air check on the L/R Clutch circuit per the Service Information.

Watch and listen for L/R Clutch piston movement.

Does the L/R piston stroke and return properly?

Ye s>>

Replace the Transmission/TRS Solenoid Assembly per the service information. With the scan tool, per-

form Quick Learn.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Repair internal transmission as necessary. Pay attention to the components related to the L/R clutch. A

broken or weak L/R clutch return spring, Accumulator Spring, and/or dislocated snap ring could cause

this problem.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

5.VERIFY PCM OPERATION

NOTE: The TRANS TEMP DEG must be at least 43° C or 110° F before performing thefollowing steps.

Perform eight learnable starts. A learnable start is defined as follows: Start engine. From a standstill, accelerate

lightly to 80 Kmh or 50 MPH, then brake lightly to a stop. Turn off engine.

With the scan tool, record the CL VOL INDEX (CVI) for all clutches

With the scan tool, perform a BATTERY DISCONNECT.

With the scan tool, read the CVI’s and compare them to the readings recordedbefore the BATTERY DISCONNECT.

Are any of the CVI’s less than 5 or different than before the BATTERY DISCONNECT?

Ye s>>

Using the schematics as a guide, check the Powertrain Control Module (PCM)terminals for corrosion,

damage, or terminal push out. Pay particular attention to all power and ground circuits. If no problems

are found, replace the PCM per the Service Information. With the scan tool,perform QUICK LEARN.

Perform 45RFE/545RFE TRANSMISSION VERIFICATION TEST - VER 1. (Refer to 21- TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .