DODGE RAM SRT-10 2006 Service Repair Manual

Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3371 of 5267

vehicles. Torque converter lock-up pressure is 120 psi for 3.7L/4.7L equipped vehicles and 125 psi for 5.7L

equipped vehicles.

UPSHIFT PRESSURES

ENGINE 1-2 2-3 2prime-3 3-4 2prime-4 2-5 3-5 4-5

5.7L150 125 125 135 135 135 135 135

3.7L/4.7L120 120 120 120 120 120 120 130

DOWNSHIFT PRESSURES

ENGINE 5-4 5-3 5-2 4-3 4-

2prime3-2 3-

2prime2prime-1 2-1 3-1

5.7L135 135 135 135 135 135 135 135 135 135

3.7L/

4.7L120 120 120 120 120 120 120 120 120 120

IN-GEAR PRESSURES

ENGINE122prime345NEUTRALREVERSE

5.7L160 135 135 135 135 135 120 250

3.7L/4.7L135 120 120 120 120 120 120 220

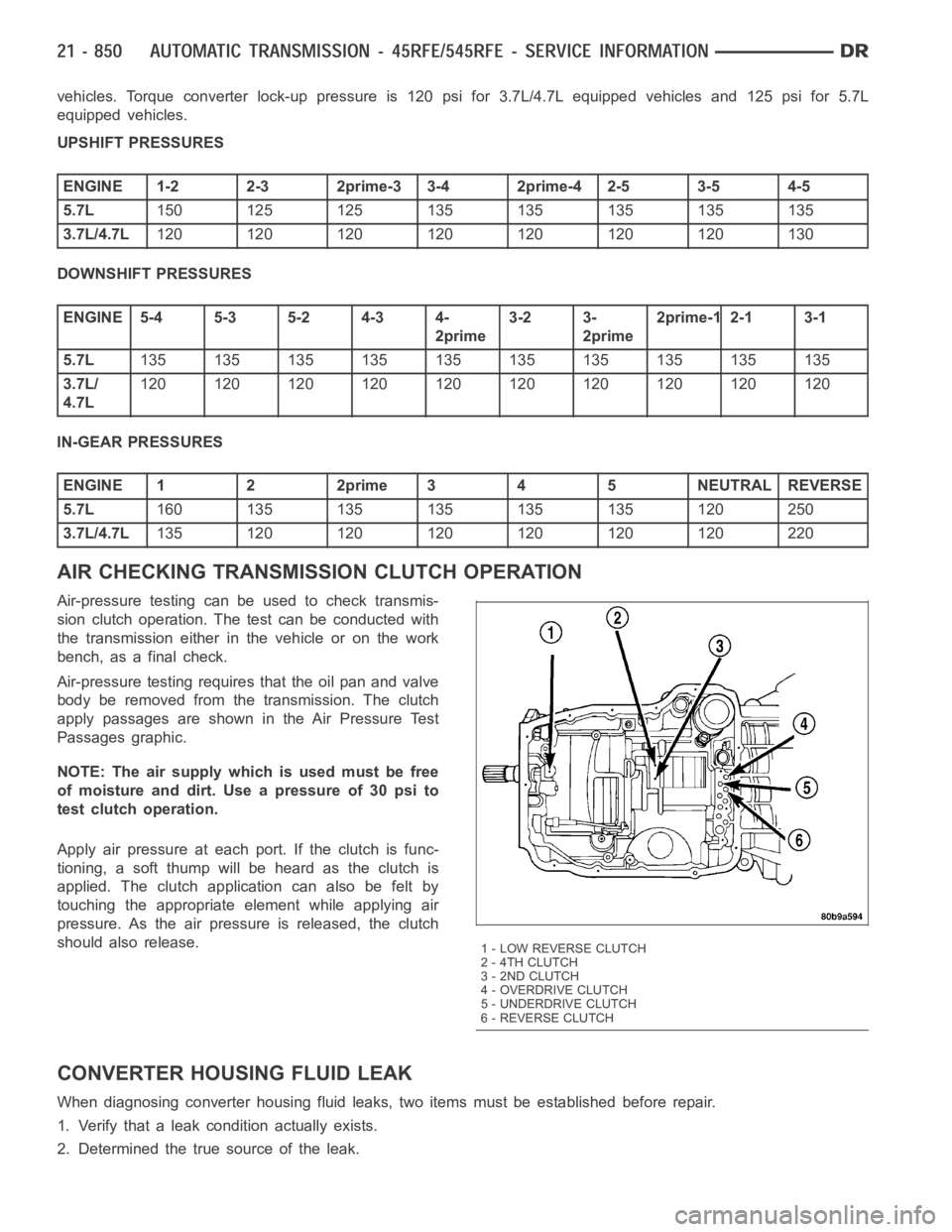

AIR CHECKING TRANSMISSION CLUTCH OPERATION

Air-pressure testing can be used to check transmis-

sion clutch operation. The test can be conducted with

the transmission either in the vehicle or on the work

bench, as a final check.

Air-pressure testing requires that the oil pan and valve

body be removed from the transmission. The clutch

apply passages are shown in the Air Pressure Test

Passages graphic.

NOTE: The air supply which is used must be free

ofmoistureanddirt.Useapressureof30psito

test clutch operation.

Apply air pressure at each port. If the clutch is func-

tioning, a soft thump will be heard as the clutch is

applied. The clutch application can also be felt by

touching the appropriate element while applying air

pressure. As the air pressure is released, the clutch

should also release.

CONVERTER HOUSING FLUID LEAK

When diagnosing converter housing fluid leaks, two items must be established before repair.

1. Verify that a leak condition actually exists.

2. Determined the true source of the leak.

1 - LOW REVERSE CLUTCH

2 - 4TH CLUTCH

3 - 2ND CLUTCH

4-OVERDRIVECLUTCH

5 - UNDERDRIVE CLUTCH

6 - REVERSE CLUTCH

Page 3372 of 5267

Some suspected converter housing fluid leaks may not be leaks at all. They may only be the result of residual fluid

in the converter housing, or excess fluid spilled during factory fill or fill after repair. Converter housing leaks have

several potential sources. Through careful observation, a leak source can be identified before removing the trans-

mission for repair. Torque converter seal leaks tend to move along the drive hub and onto the rear of the converter.

Pump cover seal leaks tend to run down the cover and the inside surface of thebellhousing.

Some leaks, or suspected leaks, may be particularly difficult to locate. If necessary, a Mopar

approved dye should

be used to locate and confirm a leak.

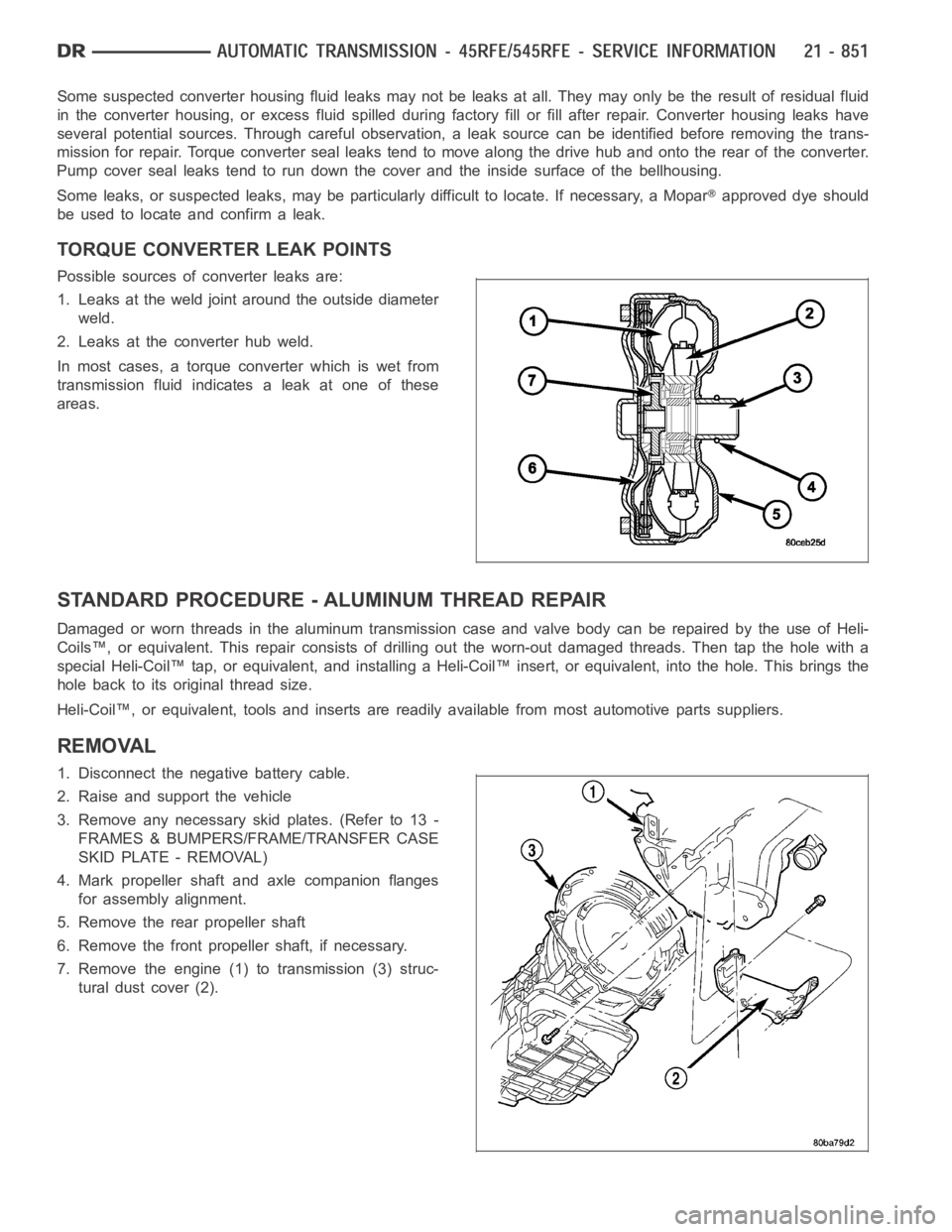

TORQUE CONVERTER LEAK POINTS

Possible sources of converter leaks are:

1. Leaks at the weld joint around the outside diameter

weld.

2. Leaks at the converter hub weld.

In most cases, a torque converter which is wet from

transmission fluid indicates a leak at one of these

areas.

STANDARD PROCEDURE - ALUMINUM THREAD REPAIR

DamagedorwornthreadsinthealuminumtransmissioncaseandvalvebodycanberepairedbytheuseofHeli-

Coils™, or equivalent. This repair consists of drilling out the worn-out damaged threads. Then tap the hole with a

special Heli-Coil™ tap, or equivalent, and installing a Heli-Coil™ insert, or equivalent, into the hole. This brings the

hole back to its original thread size.

Heli-Coil™, or equivalent, tools and inserts are readily available from most automotive parts suppliers.

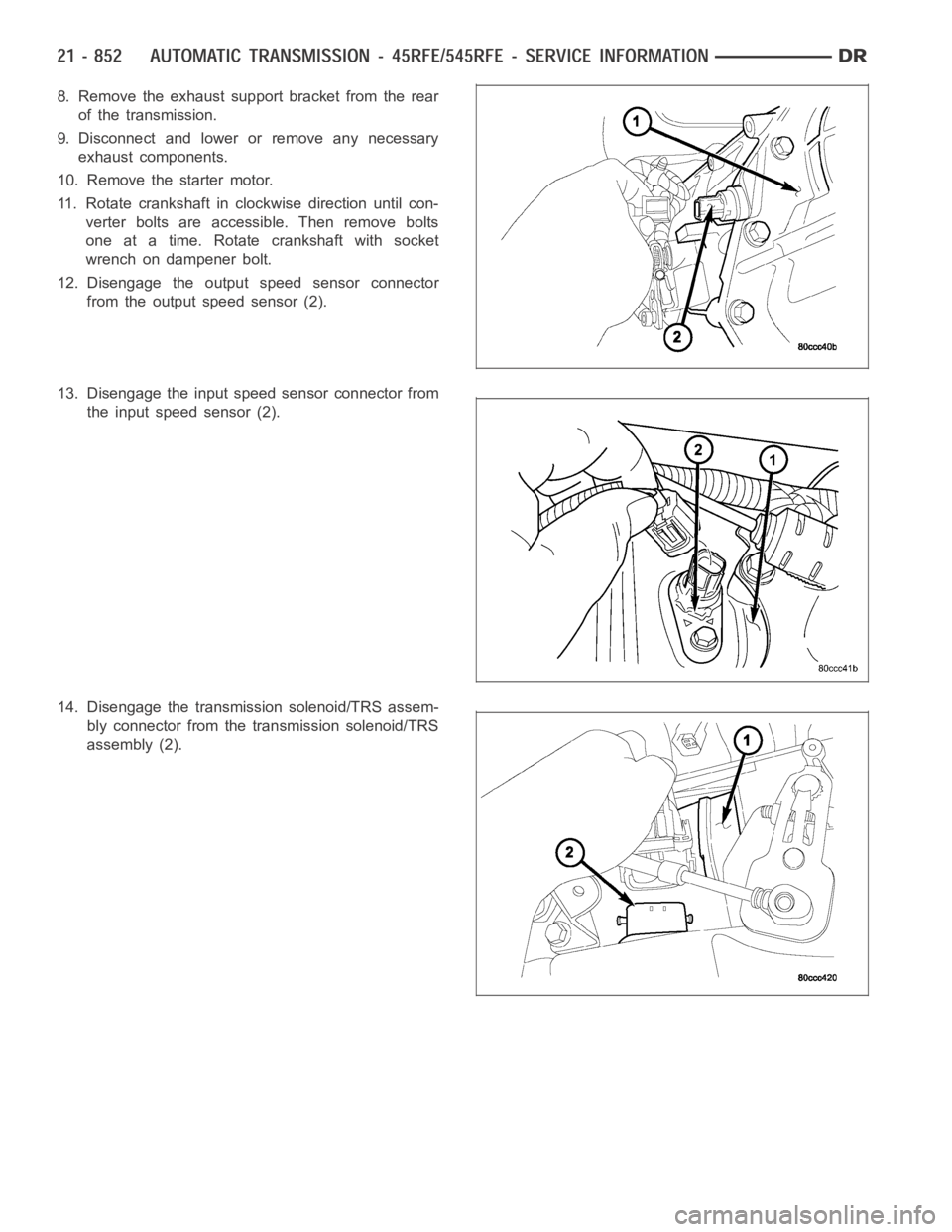

REMOVAL

1. Disconnect the negative battery cable.

2. Raise and support the vehicle

3. Remove any necessary skid plates. (Refer to 13 -

FRAMES & BUMPERS/FRAME/TRANSFER CASE

SKID PLATE - REMOVAL)

4. Mark propeller shaft and axle companion flanges

for assembly alignment.

5. Remove the rear propeller shaft

6. Remove the front propeller shaft, if necessary.

7. Remove the engine (1) to transmission (3) struc-

tural dust cover (2).

Page 3373 of 5267

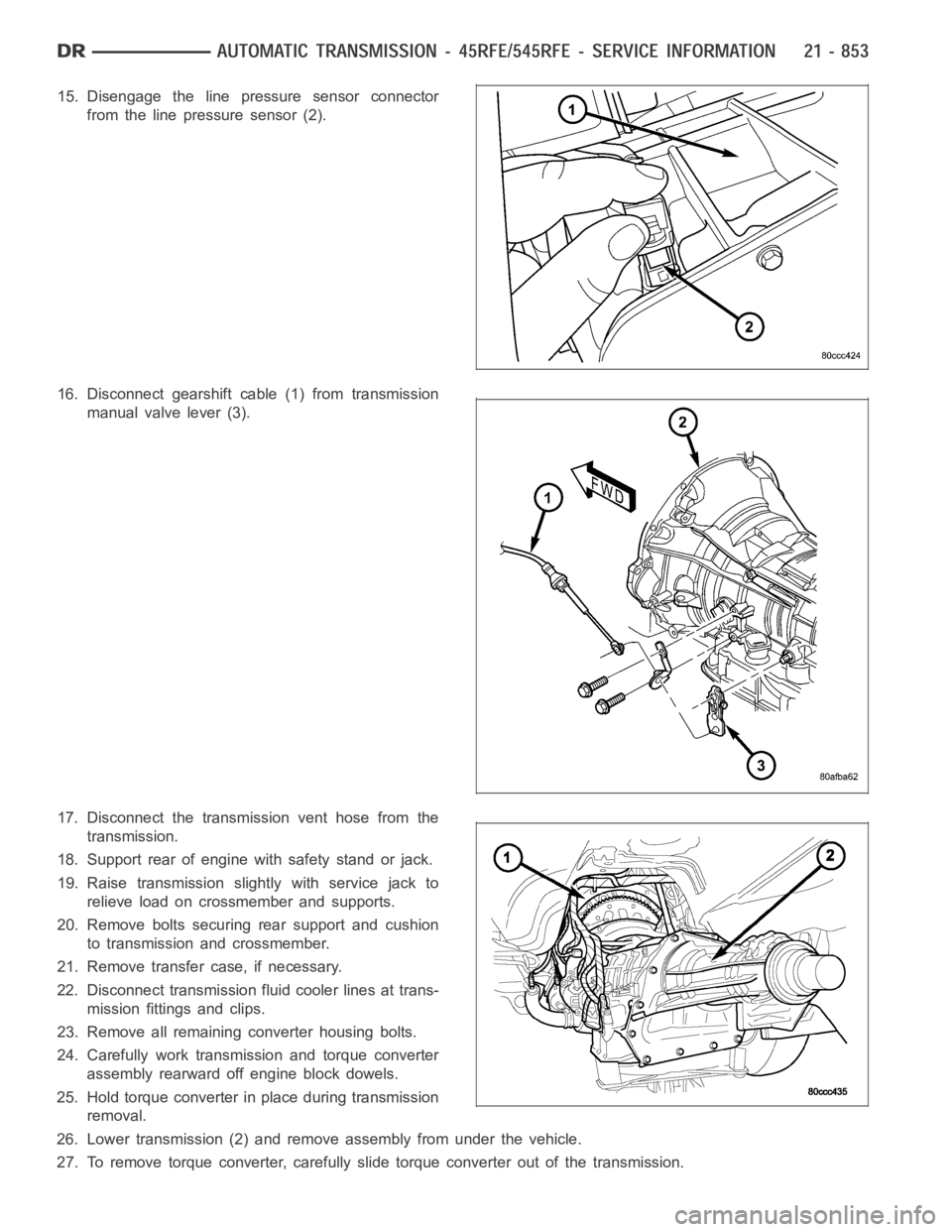

8. Remove the exhaust support bracket from the rear

of the transmission.

9. Disconnect and lower or remove any necessary

exhaust components.

10. Remove the starter motor.

11. Rotate crankshaft in clockwise direction until con-

verter bolts are accessible. Then remove bolts

one at a time. Rotate crankshaft with socket

wrench on dampener bolt.

12. Disengage the output speed sensor connector

from the output speed sensor (2).

13. Disengage the input speed sensor connector from

the input speed sensor (2).

14. Disengage the transmission solenoid/TRS assem-

bly connector from the transmission solenoid/TRS

assembly (2).

Page 3374 of 5267

15. Disengage the line pressure sensor connector

from the line pressure sensor (2).

16. Disconnect gearshift cable (1) from transmission

manual valve lever (3).

17. Disconnect the transmission vent hose from the

transmission.

18. Support rear of engine with safety stand or jack.

19. Raise transmission slightly with service jack to

relieve load on crossmember and supports.

20. Remove bolts securing rear support and cushion

to transmission and crossmember.

21. Remove transfer case, if necessary.

22. Disconnect transmission fluid cooler lines at trans-

mission fittings and clips.

23. Remove all remaining converter housing bolts.

24. Carefully work transmission and torque converter

assembly rearward off engine block dowels.

25. Hold torque converter in place during transmission

removal.

26. Lower transmission (2) and remove assembly from under the vehicle.

27. To remove torque converter, carefully slide torque converter out of the transmission.

Page 3375 of 5267

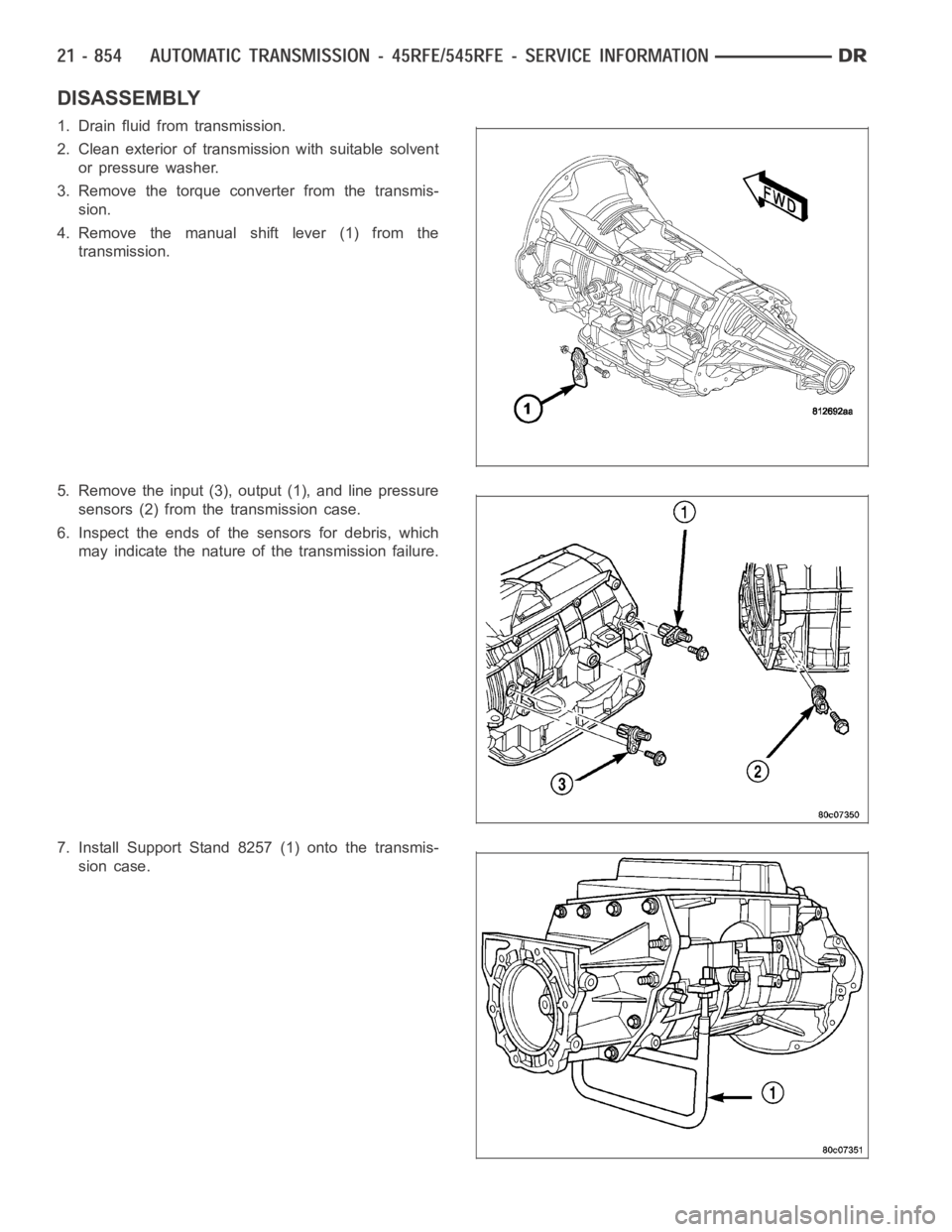

DISASSEMBLY

1. Drain fluid from transmission.

2. Clean exterior of transmission with suitable solvent

or pressure washer.

3. Remove the torque converter from the transmis-

sion.

4. Remove the manual shift lever (1) from the

transmission.

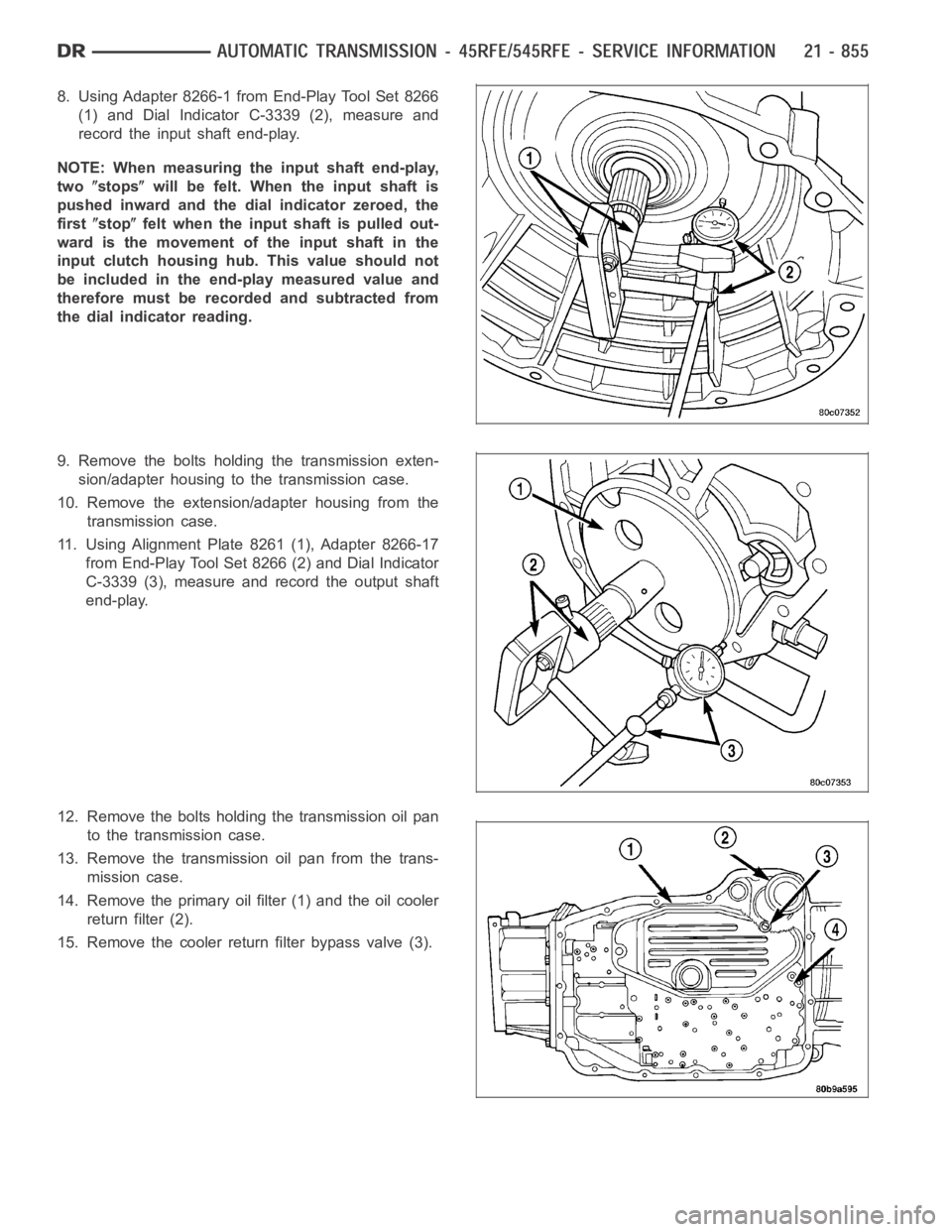

5. Remove the input (3), output (1), and line pressure

sensors (2) from the transmission case.

6. Inspect the ends of the sensors for debris, which

may indicate the nature of the transmission failure.

7. Install Support Stand 8257 (1) onto the transmis-

sion case.

Page 3376 of 5267

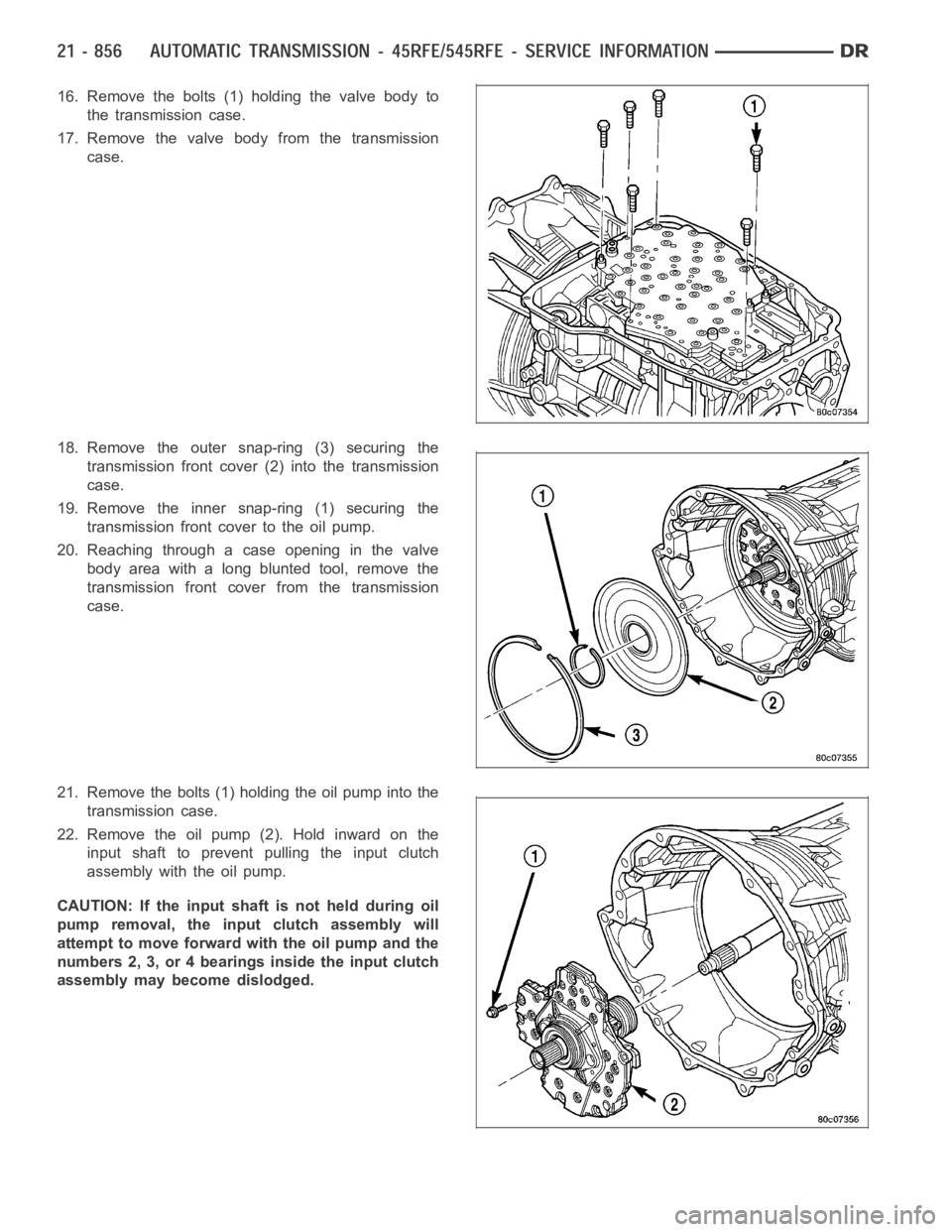

8. Using Adapter 8266-1 from End-Play Tool Set 8266

(1) and Dial Indicator C-3339 (2), measure and

record the input shaft end-play.

NOTE: When measuring the input shaft end-play,

two

stopswill be felt. When the input shaft is

pushed inward and the dial indicator zeroed, the

first

stopfelt when the input shaft is pulled out-

wardisthemovementoftheinputshaftinthe

input clutch housing hub. This value should not

be included in the end-play measured value and

therefore must be recorded and subtracted from

the dial indicator reading.

9. Remove the bolts holding the transmission exten-

sion/adapter housing to the transmission case.

10. Remove the extension/adapter housing from the

transmission case.

11. Using Alignment Plate 8261 (1), Adapter 8266-17

from End-Play Tool Set 8266 (2) and Dial Indicator

C-3339 (3), measure and record the output shaft

end-play.

12. Remove the bolts holding the transmission oil pan

to the transmission case.

13. Remove the transmission oil pan from the trans-

mission case.

14. Remove the primary oil filter (1) and the oil cooler

return filter (2).

15. Remove the cooler return filter bypass valve (3).

Page 3377 of 5267

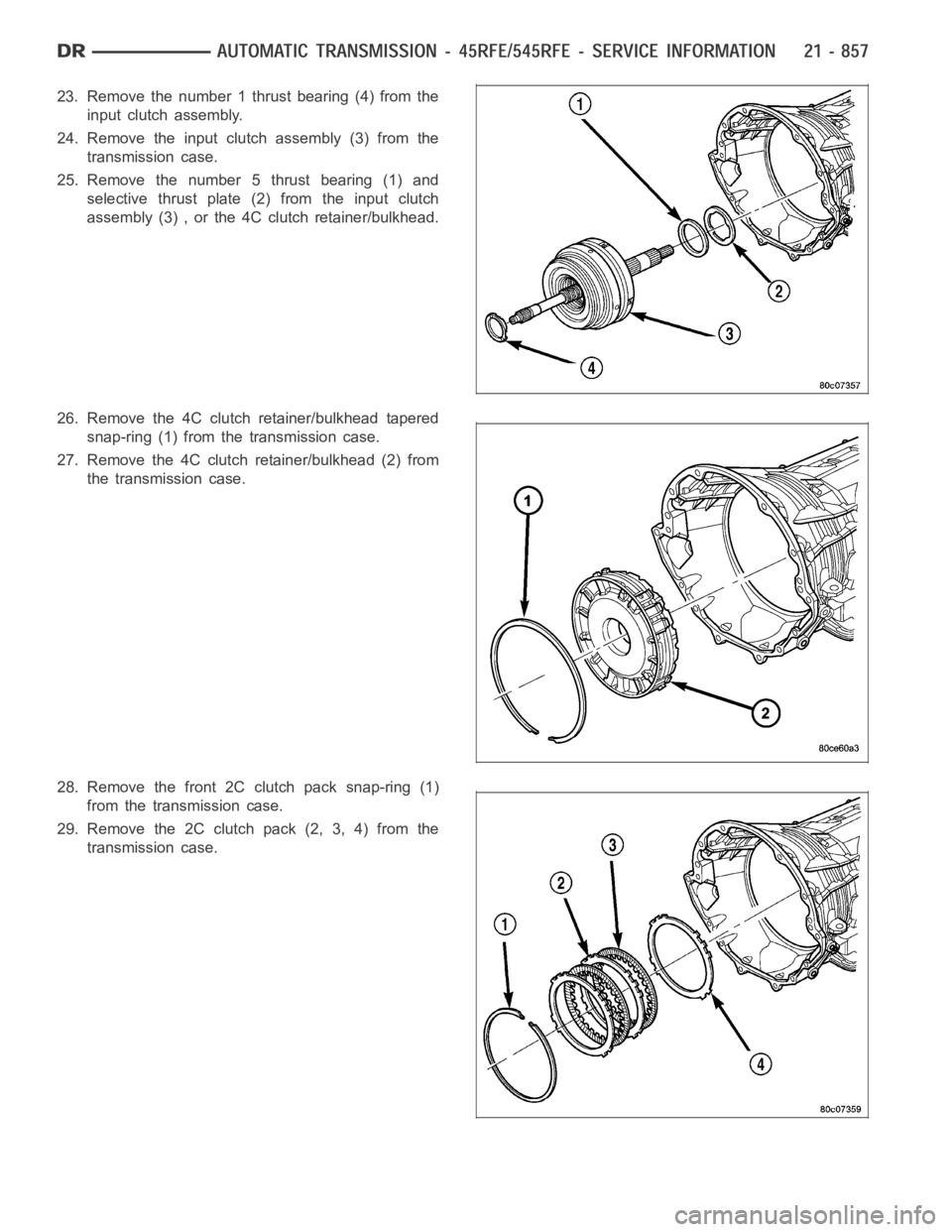

16. Remove the bolts (1) holding the valve body to

the transmission case.

17. Remove the valve body from the transmission

case.

18. Remove the outer snap-ring (3) securing the

transmission front cover (2) into the transmission

case.

19. Remove the inner snap-ring (1) securing the

transmission front cover to the oil pump.

20. Reaching through a case opening in the valve

body area with a long blunted tool, remove the

transmission front cover from the transmission

case.

21. Remove the bolts (1) holding the oil pump into the

transmission case.

22. Remove the oil pump (2). Hold inward on the

input shaft to prevent pulling the input clutch

assembly with the oil pump.

CAUTION: If the input shaft is not held during oil

pump removal, the input clutch assembly will

attempt to move forward with the oil pump and the

numbers 2, 3, or 4 bearings inside the input clutch

assembly may become dislodged.

Page 3378 of 5267

23. Remove the number 1 thrust bearing (4) from the

input clutch assembly.

24. Remove the input clutch assembly (3) from the

transmission case.

25. Remove the number 5 thrust bearing (1) and

selective thrust plate (2) from the input clutch

assembly (3) , or the 4C clutch retainer/bulkhead.

26. Remove the 4C clutch retainer/bulkhead tapered

snap-ring (1) from the transmission case.

27. Remove the 4C clutch retainer/bulkhead (2) from

the transmission case.

28. Remove the front 2C clutch pack snap-ring (1)

from the transmission case.

29. Remove the 2C clutch pack (2, 3, 4) from the

transmission case.

Page 3379 of 5267

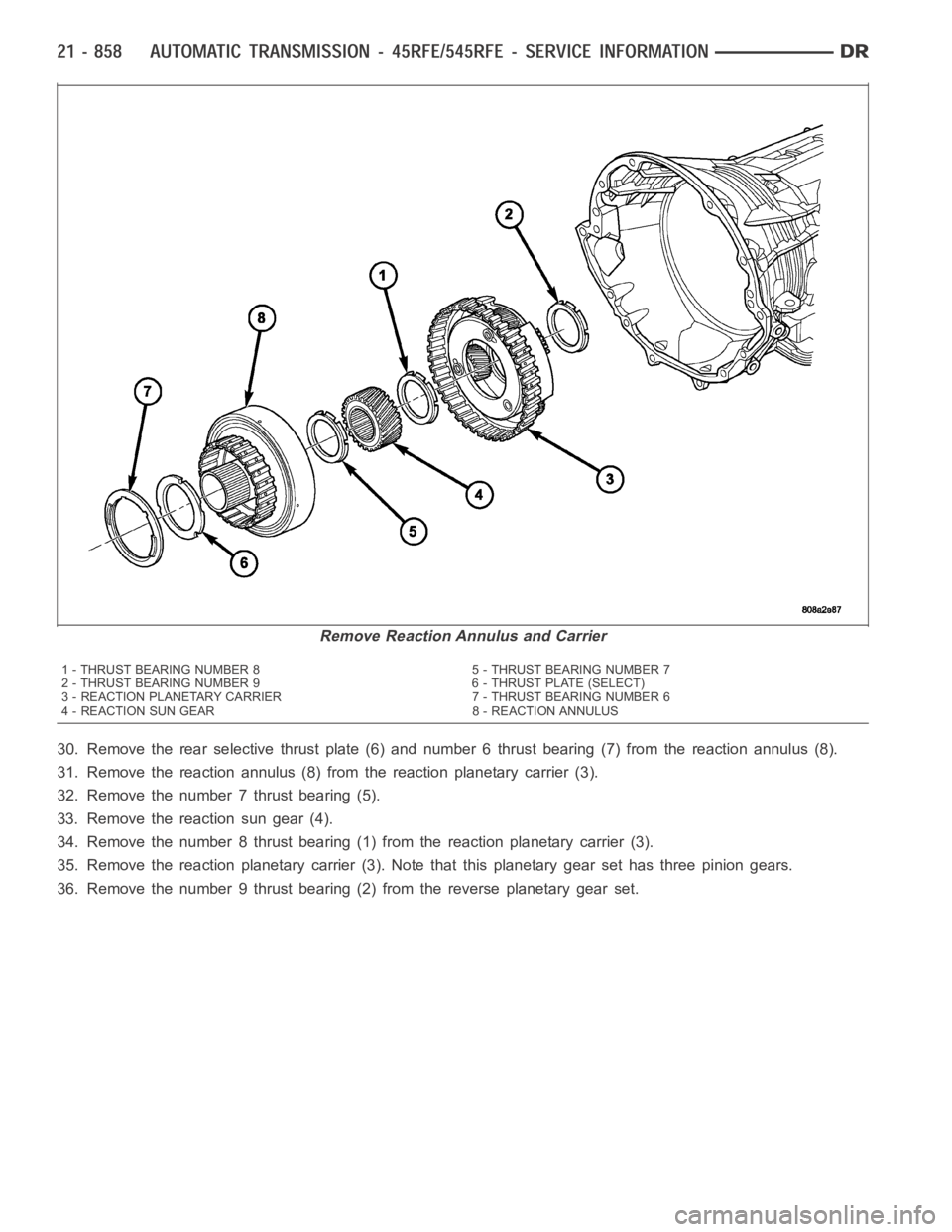

30. Remove the rear selective thrust plate (6) and number 6 thrust bearing (7) from the reaction annulus (8).

31. Remove the reaction annulus (8) from the reaction planetary carrier (3).

32. Remove the number 7 thrust bearing (5).

33. Remove the reaction sun gear (4).

34. Remove the number 8 thrust bearing (1) from the reaction planetary carrier (3).

35. Remove the reaction planetary carrier (3). Note that this planetary gear set has three pinion gears.

36. Remove the number 9 thrust bearing (2) from the reverse planetary gear set.

Remove Reaction Annulus and Carrier

1 - THRUST BEARING NUMBER 8 5 - THRUST BEARING NUMBER 7

2 - THRUST BEARING NUMBER 9 6 - THRUST PLATE (SELECT)

3 - REACTION PLANETARY CARRIER 7 - THRUST BEARING NUMBER 6

4 - REACTION SUN GEAR 8 - REACTION ANNULUS

Page 3380 of 5267

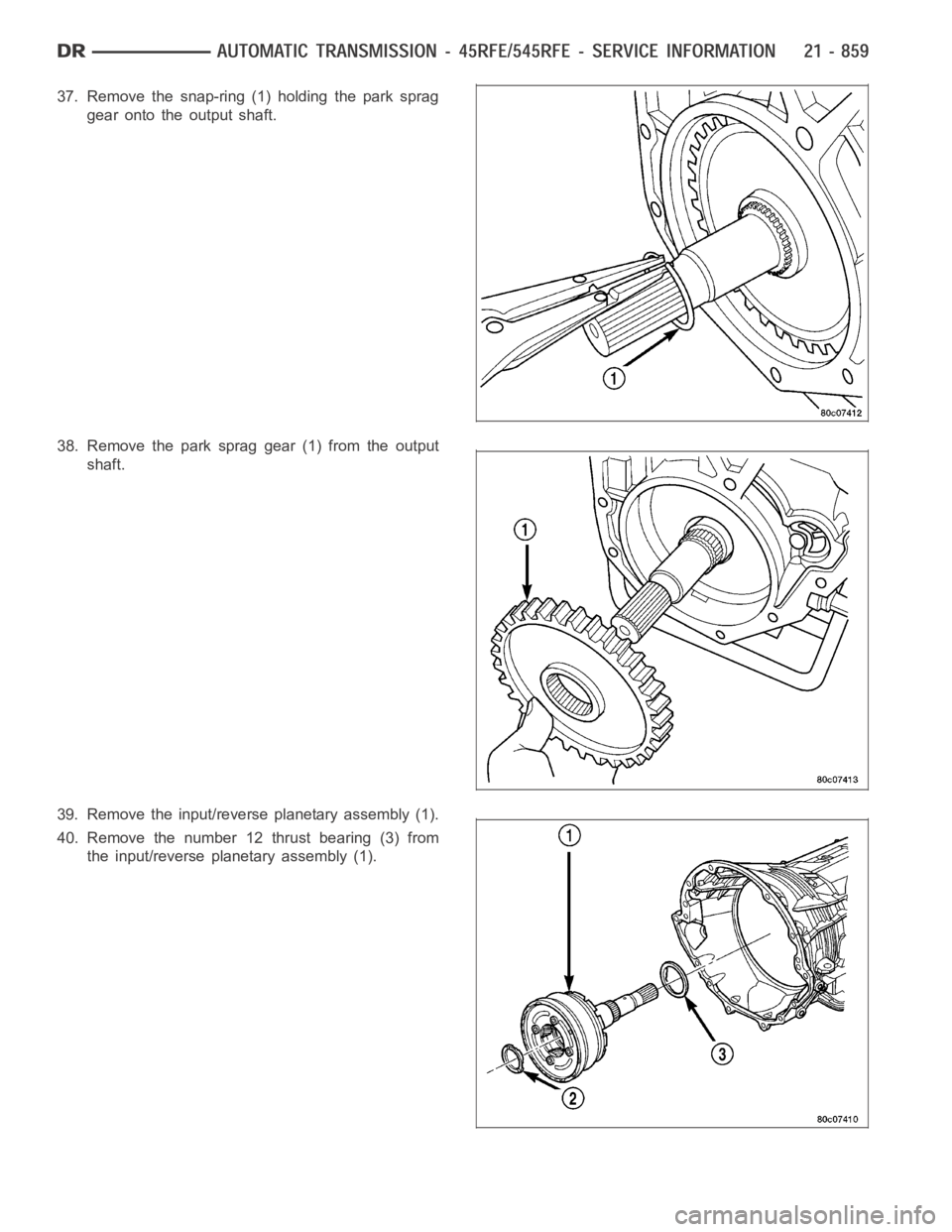

37. Remove the snap-ring (1) holding the park sprag

gear onto the output shaft.

38. Remove the park sprag gear (1) from the output

shaft.

39. Remove the input/reverse planetary assembly (1).

40. Remove the number 12 thrust bearing (3) from

the input/reverse planetary assembly (1).