DODGE RAM SRT-10 2006 Service Repair Manual

Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3381 of 5267

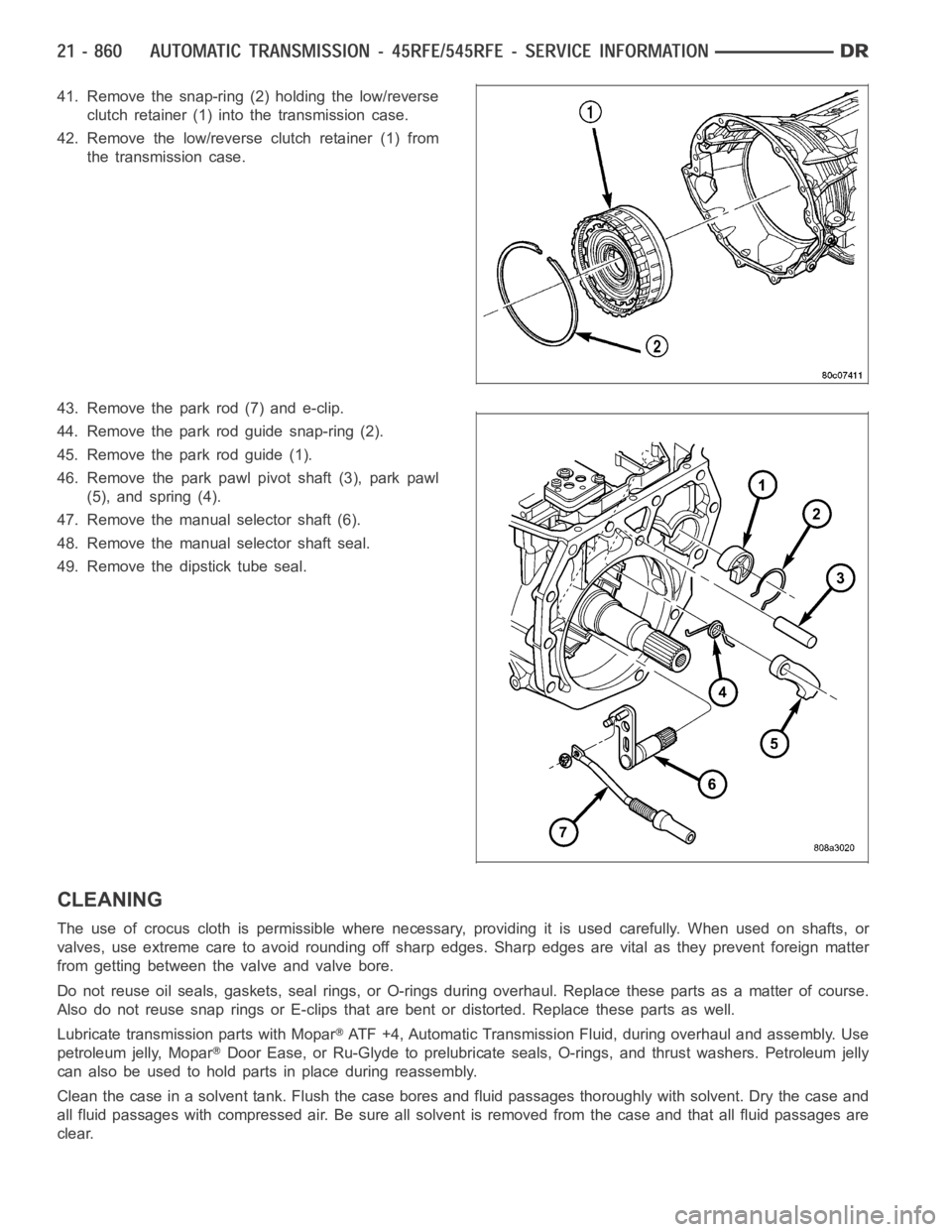

41. Remove the snap-ring (2) holding the low/reverse

clutch retainer (1) into the transmission case.

42. Remove the low/reverse clutch retainer (1) from

the transmission case.

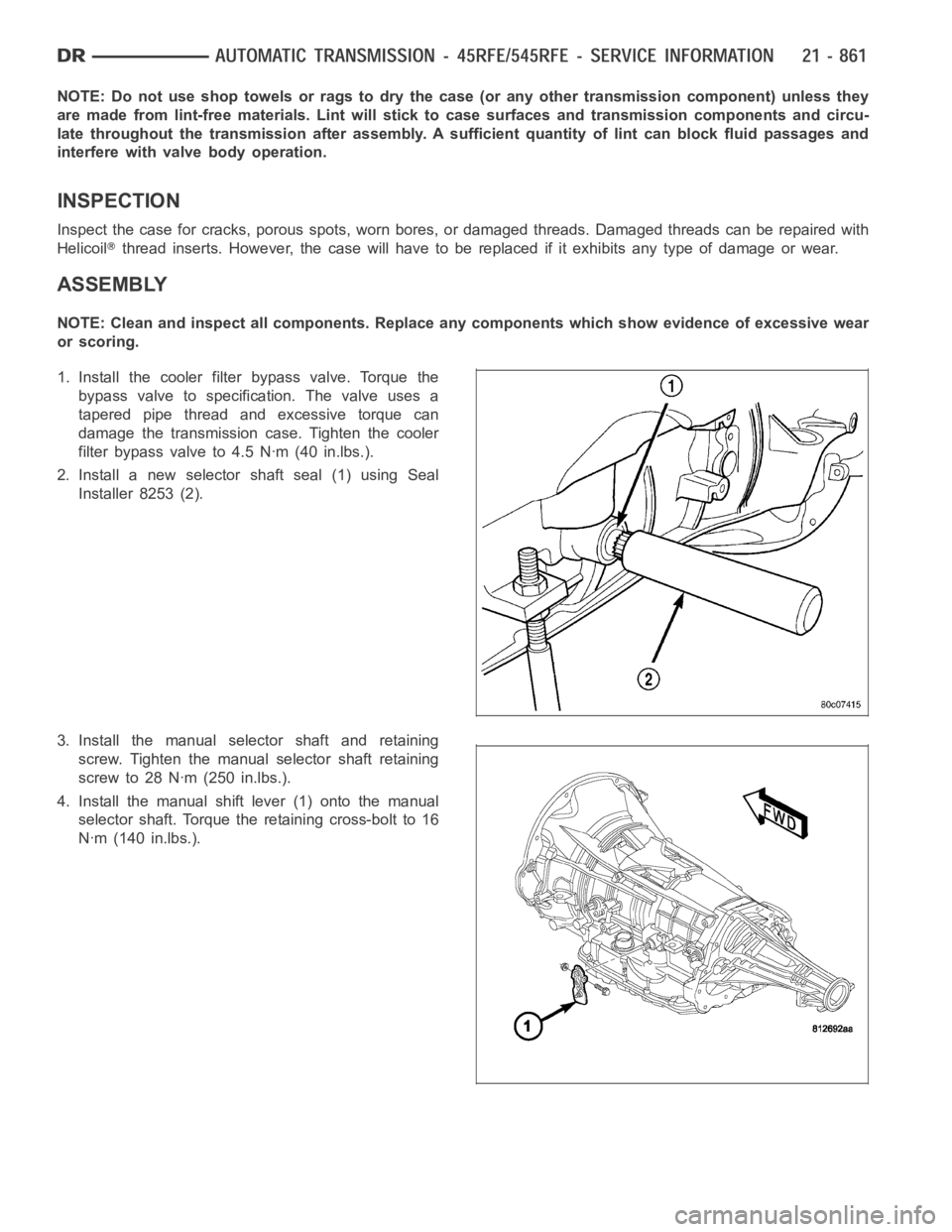

43. Remove the park rod (7) and e-clip.

44. Remove the park rod guide snap-ring (2).

45. Remove the park rod guide (1).

46. Remove the park pawl pivot shaft (3), park pawl

(5), and spring (4).

47. Remove the manual selector shaft (6).

48. Remove the manual selector shaft seal.

49. Remove the dipstick tube seal.

CLEANING

The use of crocus cloth is permissible where necessary, providing it is usedcarefully.Whenusedonshafts,or

valves, use extreme care to avoid rounding off sharp edges. Sharp edges arevital as they prevent foreign matter

from getting between the valve and valve bore.

Do not reuse oil seals, gaskets, seal rings, or O-rings during overhaul. Replace these parts as a matter of course.

Also do not reuse snap rings or E-clips that are bent or distorted. Replace these parts as well.

Lubricate transmission parts with Mopar

ATF +4, Automatic Transmission Fluid, during overhaul and assembly. Use

petroleum jelly, Mopar

Door Ease, or Ru-Glyde to prelubricate seals, O-rings, and thrust washers. Petroleum jelly

canalsobeusedtoholdpartsinplaceduringreassembly.

Clean the case in a solvent tank. Flush the case bores and fluid passages thoroughly with solvent. Dry the case and

all fluid passages with compressed air. Be sure all solvent is removed fromthe case and that all fluid passages are

clear.

Page 3382 of 5267

NOTE: Do not use shop towels or rags to dry the case (or any other transmission component) unless they

aremadefromlint-freematerials.Lintwillsticktocasesurfacesandtransmission components and circu-

late throughout the transmission after assembly. A sufficient quantity of lint can block fluid passages and

interfere with valve body operation.

INSPECTION

Inspect the case for cracks, porous spots, worn bores, or damaged threads.Damaged threads can be repaired with

Helicoil

thread inserts. However, the case will have to be replaced if it exhibits any type of damage or wear.

ASSEMBLY

NOTE: Clean and inspect all components. Replace any components which showevidence of excessive wear

or scoring.

1. Install the cooler filter bypass valve. Torque the

bypass valve to specification. The valve uses a

tapered pipe thread and excessive torque can

damage the transmission case. Tighten the cooler

filter bypass valve to 4.5 Nꞏm (40 in.lbs.).

2. Install a new selector shaft seal (1) using Seal

Installer 8253 (2).

3. Install the manual selector shaft and retaining

screw. Tighten the manual selector shaft retaining

screw to 28 Nꞏm (250 in.lbs.).

4. Install the manual shift lever (1) onto the manual

selector shaft. Torque the retaining cross-bolt to 16

Nꞏm (140 in.lbs.).

Page 3383 of 5267

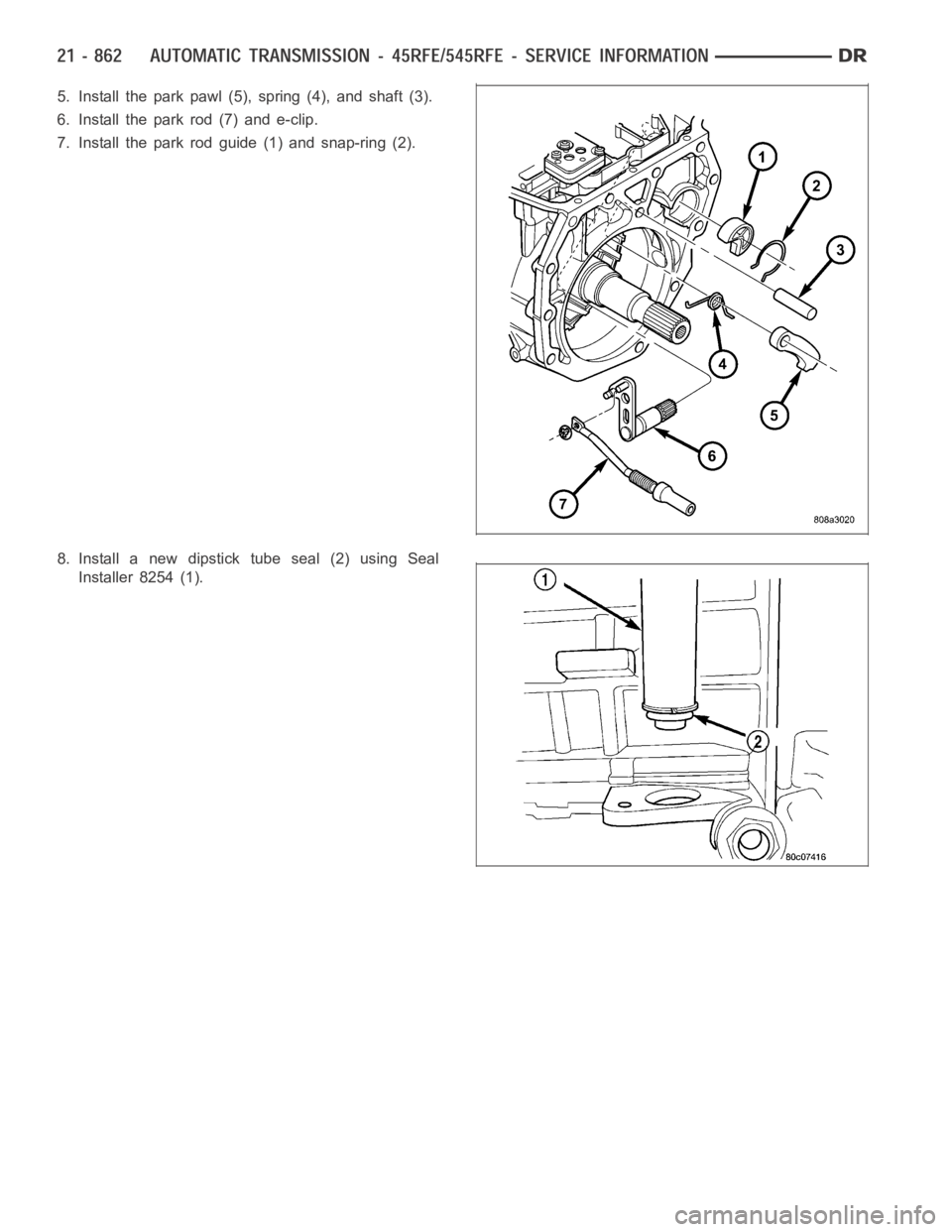

5. Install the park pawl (5), spring (4), and shaft (3).

6. Install the park rod (7) and e-clip.

7. Install the park rod guide (1) and snap-ring (2).

8. Install a new dipstick tube seal (2) using Seal

Installer 8254 (1).

Page 3384 of 5267

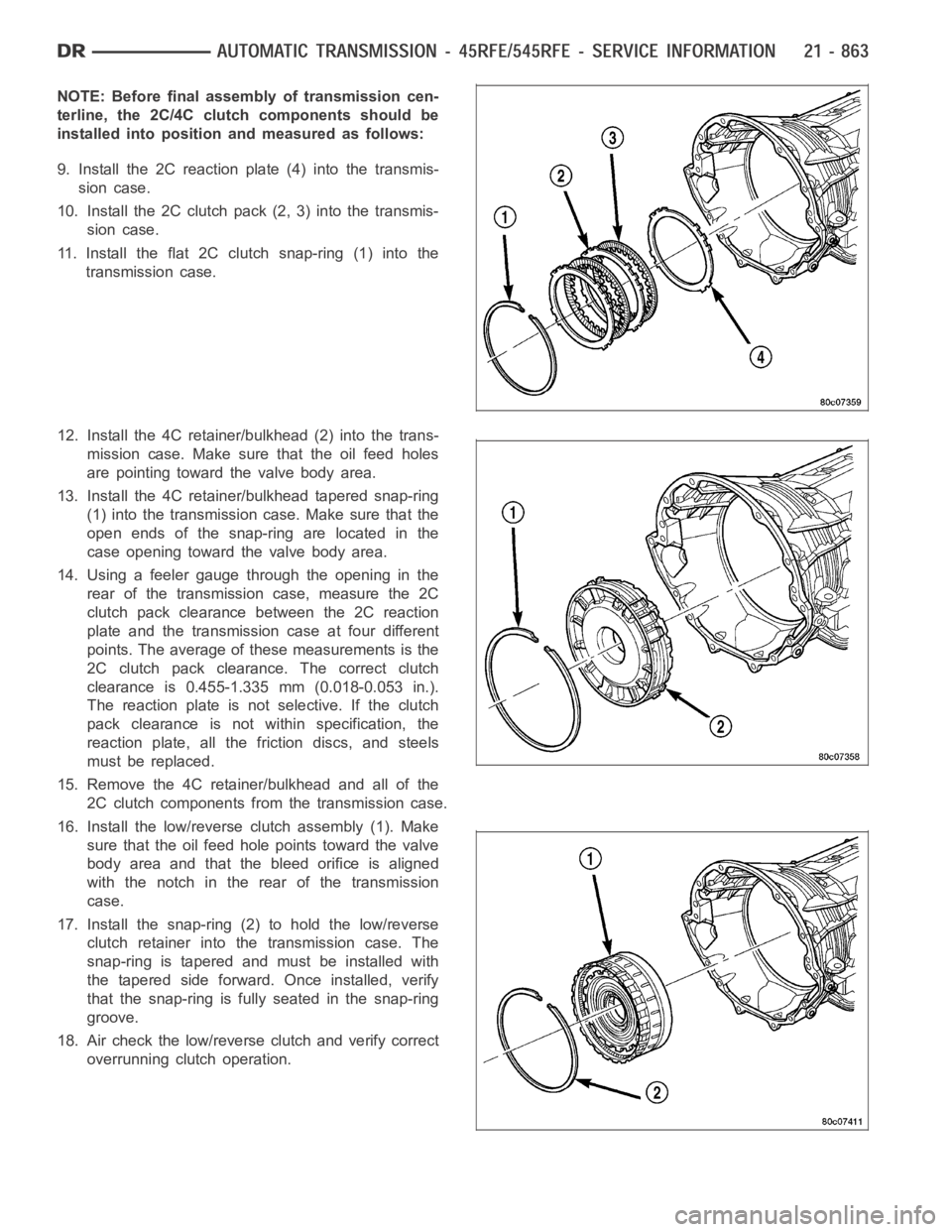

NOTE: Before final assembly of transmission cen-

terline, the 2C/4C clutch components should be

installed into position and measured as follows:

9. Install the 2C reaction plate (4) into the transmis-

sion case.

10. Install the 2C clutch pack (2, 3) into the transmis-

sion case.

11. Install the flat 2C clutchsnap-ring(1)intothe

transmission case.

12. Install the 4C retainer/bulkhead (2) into the trans-

mission case. Make sure that the oil feed holes

are pointing toward the valve body area.

13. Install the 4C retainer/bulkhead tapered snap-ring

(1) into the transmission case. Make sure that the

open ends of the snap-ring are located in the

case opening toward the valve body area.

14. Using a feeler gauge through the opening in the

rear of the transmission case, measure the 2C

clutch pack clearance between the 2C reaction

plate and the transmission case at four different

points. The average of these measurements is the

2C clutch pack clearance. The correct clutch

clearance is 0.455-1.335 mm (0.018-0.053 in.).

The reaction plate is not selective. If the clutch

pack clearance is not within specification, the

reaction plate, all the friction discs, and steels

must be replaced.

15. Remove the 4C retainer/bulkhead and all of the

2C clutch components from the transmission case.

16. Install the low/reverse clutch assembly (1). Make

sure that the oil feed hole points toward the valve

body area and that the bleed orifice is aligned

with the notch in the rear of the transmission

case.

17. Install the snap-ring (2) to hold the low/reverse

clutch retainer into the transmission case. The

snap-ring is tapered and must be installed with

the tapered side forward. Once installed, verify

that the snap-ring is fully seated in the snap-ring

groove.

18. Air check the low/reverse clutch and verify correct

overrunning clutch operation.

Page 3385 of 5267

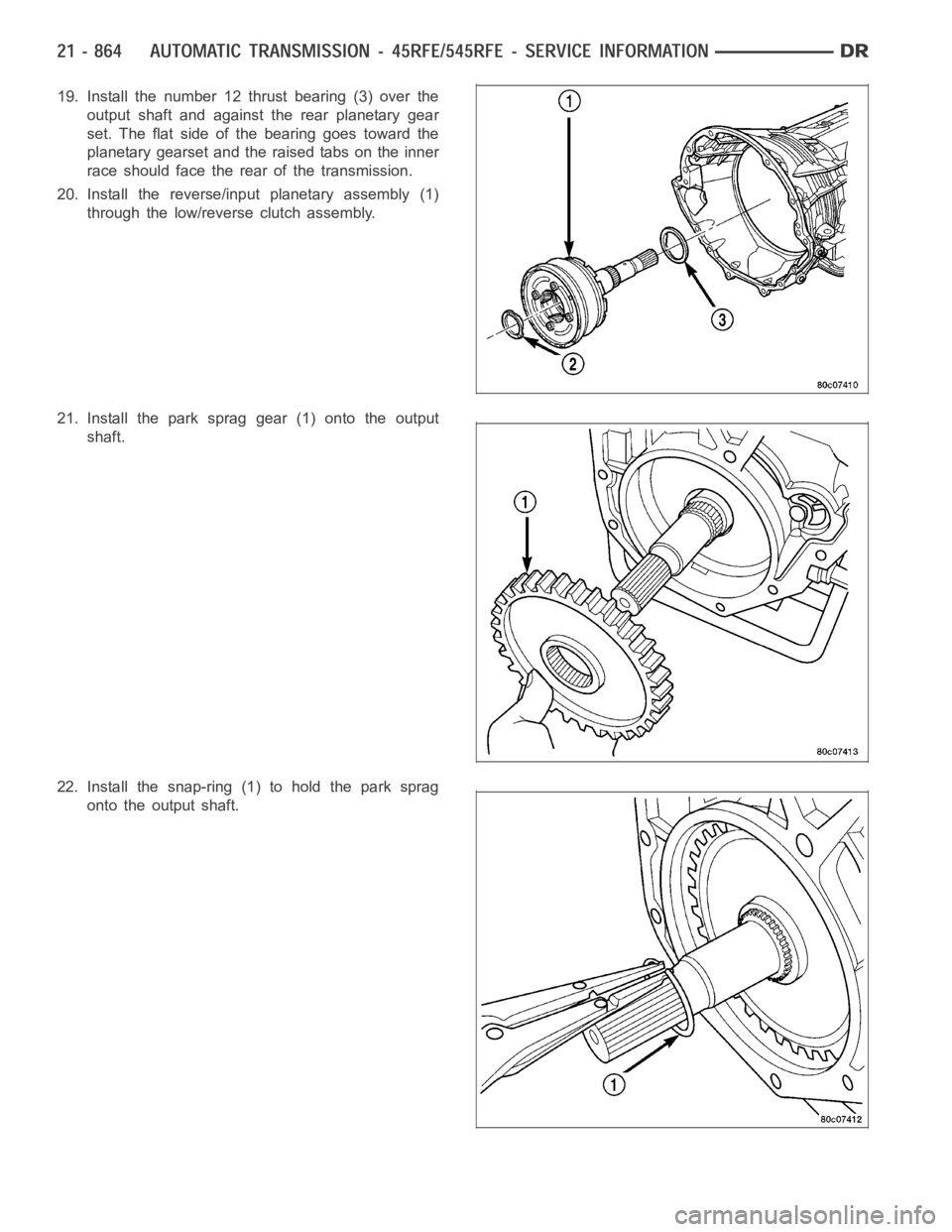

19. Install the number 12 thrust bearing (3) over the

output shaft and against the rear planetary gear

set. The flat side of the bearing goes toward the

planetary gearset and the raised tabs on the inner

race should face the rear of the transmission.

20. Install the reverse/input planetary assembly (1)

through the low/reverse clutch assembly.

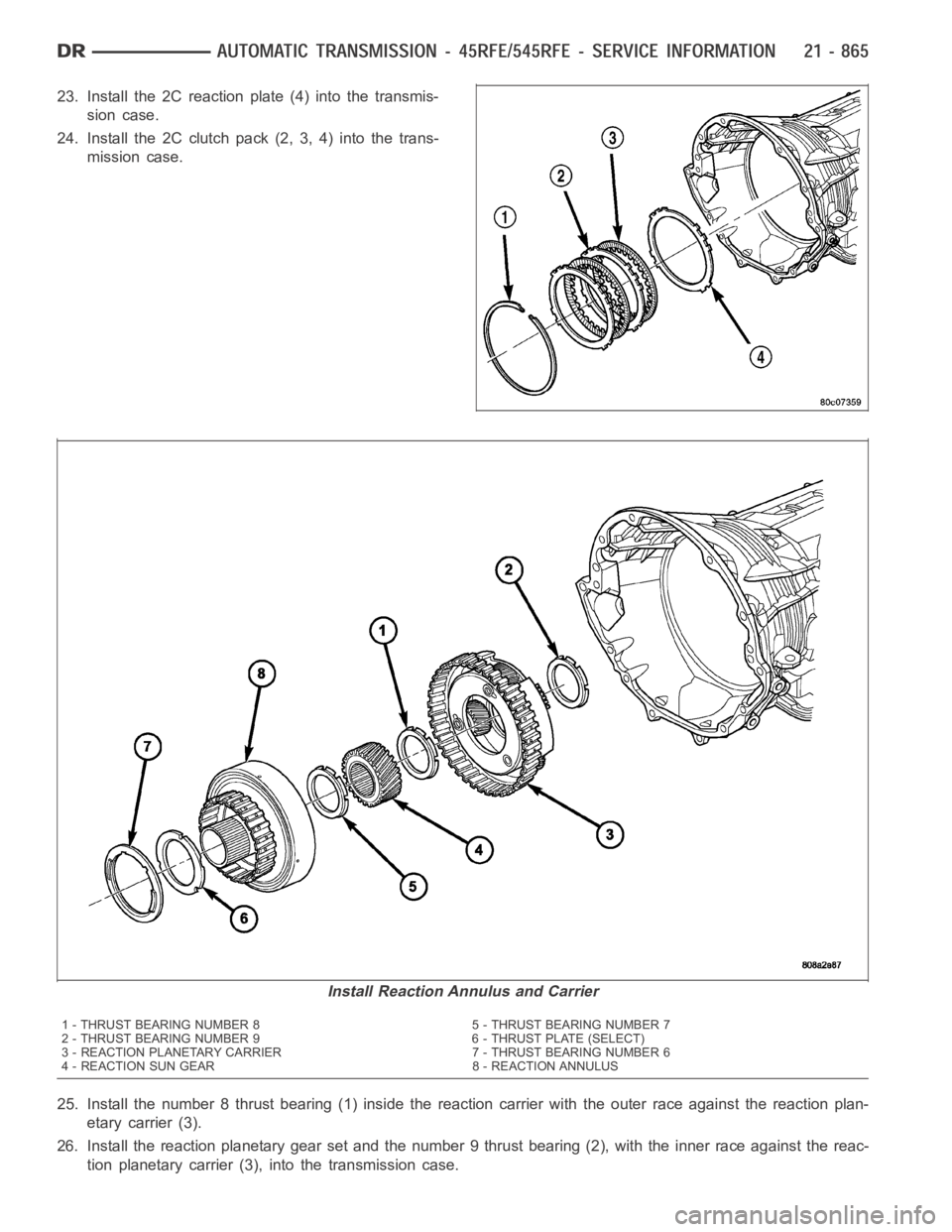

21. Install the park sprag gear (1) onto the output

shaft.

22. Install the snap-ring (1) to hold the park sprag

onto the output shaft.

Page 3386 of 5267

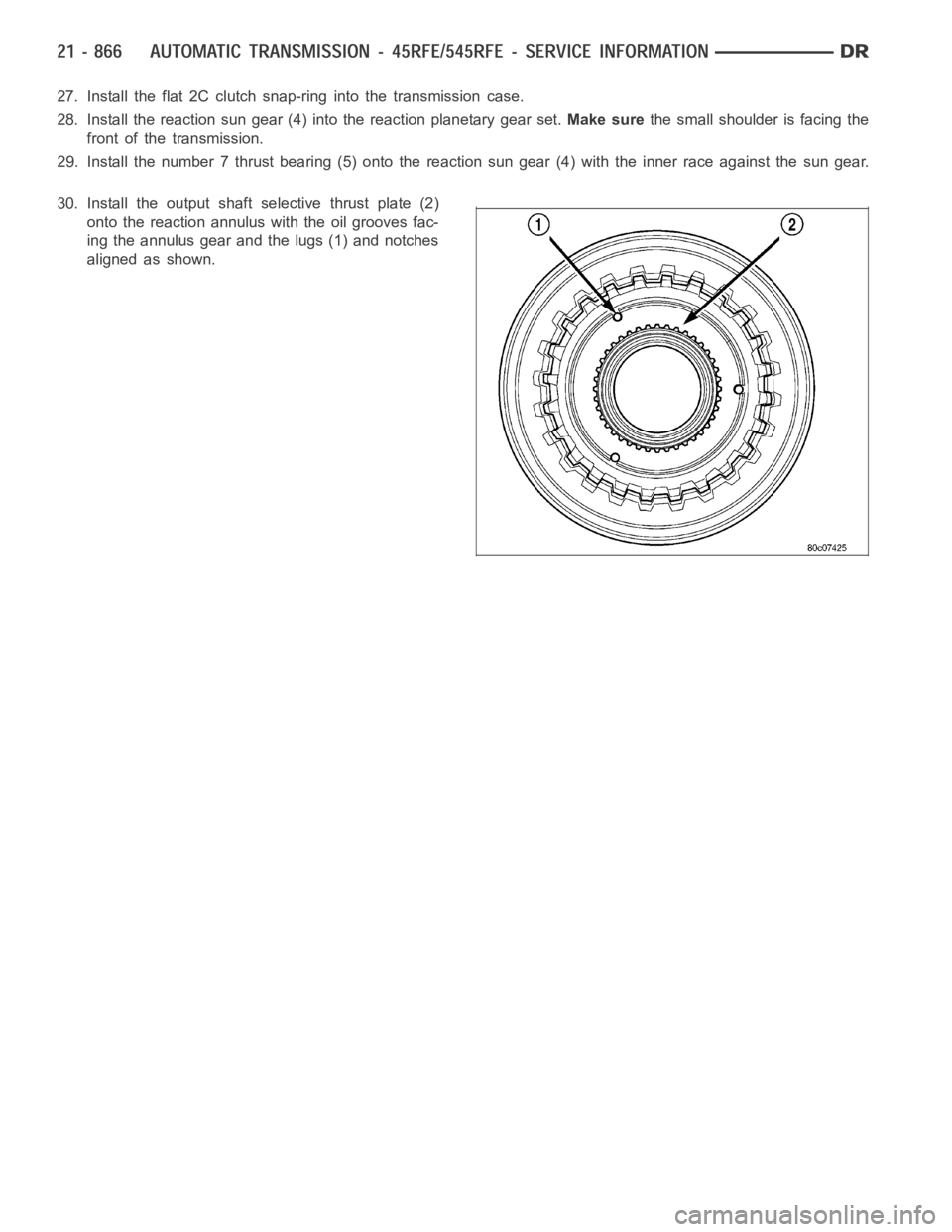

23. Install the 2C reaction plate (4) into the transmis-

sion case.

24. Install the 2C clutch pack (2, 3, 4) into the trans-

mission case.

25. Install the number 8 thrust bearing (1) inside the reaction carrier with the outer race against the reaction plan-

etary carrier (3).

26. Install the reaction planetary gear set and the number 9 thrust bearing(2), with the inner race against the reac-

tion planetary carrier (3), into the transmission case.

Install Reaction Annulus and Carrier

1 - THRUST BEARING NUMBER 8 5 - THRUST BEARING NUMBER 7

2 - THRUST BEARING NUMBER 9 6 - THRUST PLATE (SELECT)

3 - REACTION PLANETARY CARRIER 7 - THRUST BEARING NUMBER 6

4 - REACTION SUN GEAR 8 - REACTION ANNULUS

Page 3387 of 5267

27. Install the flat 2C clutch snap-ring into the transmission case.

28. Install the reaction sun gear (4) into the reaction planetary gear set.Make surethe small shoulder is facing the

front of the transmission.

29. Install the number 7 thrust bearing (5) onto the reaction sun gear (4) with the inner race against the sun gear.

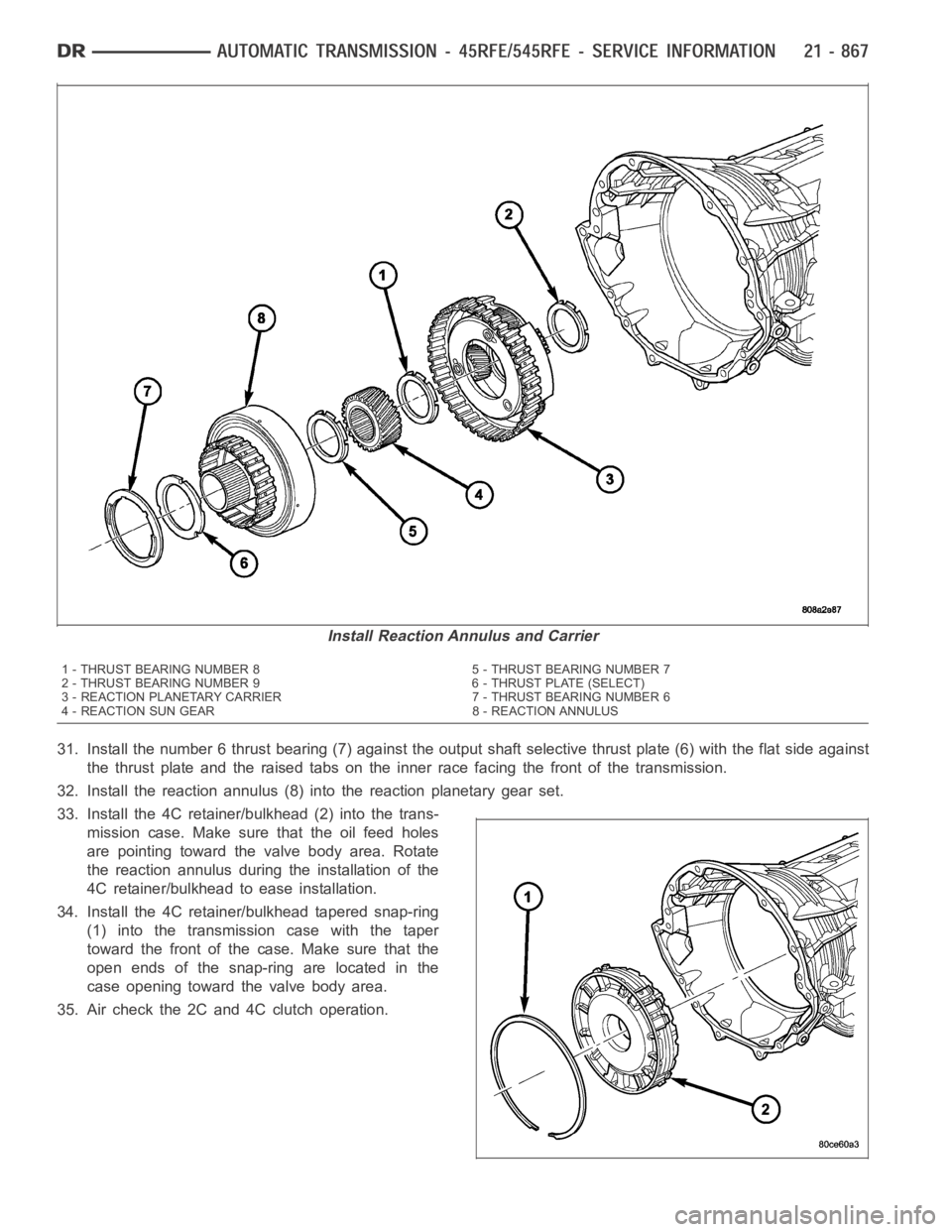

30. Install the output shaft selective thrust plate (2)

onto the reaction annulus with the oil grooves fac-

ing the annulus gear and the lugs (1) and notches

aligned as shown.

Page 3388 of 5267

31. Install the number 6 thrust bearing (7) against the output shaft selective thrust plate (6) with the flat side against

the thrust plate and the raised tabs on the inner race facing the front of thetransmission.

32. Install the reaction annulus (8) into the reaction planetary gear set.

33. Install the 4C retainer/bulkhead (2) into the trans-

mission case. Make sure that the oil feed holes

are pointing toward the valve body area. Rotate

the reaction annulus during the installation of the

4C retainer/bulkhead to ease installation.

34. Install the 4C retainer/bulkhead tapered snap-ring

(1) into the transmission case with the taper

toward the front of the case. Make sure that the

open ends of the snap-ring are located in the

case opening toward the valve body area.

35. Air check the 2C and 4C clutch operation.

Install Reaction Annulus and Carrier

1 - THRUST BEARING NUMBER 8 5 - THRUST BEARING NUMBER 7

2 - THRUST BEARING NUMBER 9 6 - THRUST PLATE (SELECT)

3 - REACTION PLANETARY CARRIER 7 - THRUST BEARING NUMBER 6

4 - REACTION SUN GEAR 8 - REACTION ANNULUS

Page 3389 of 5267

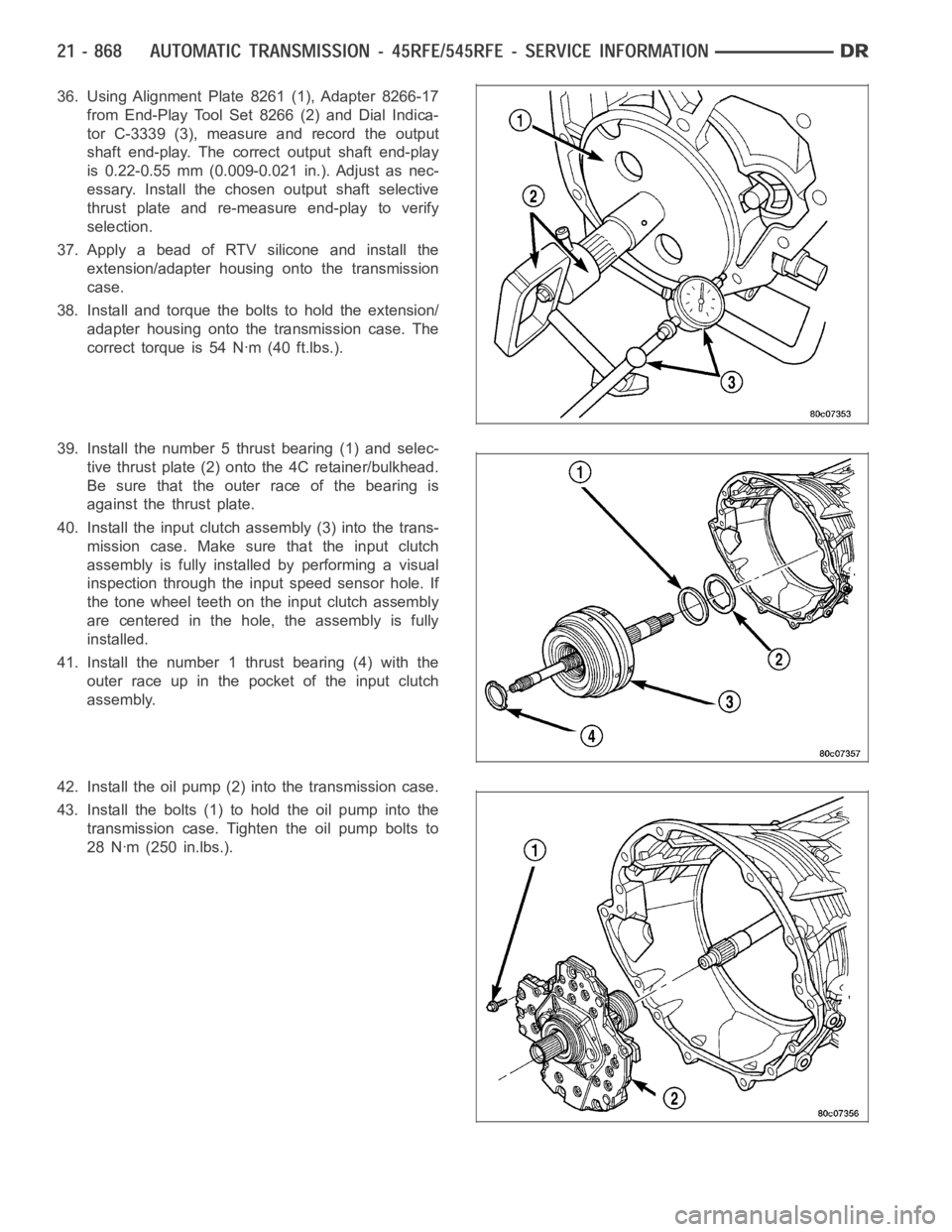

36. Using Alignment Plate 8261 (1), Adapter 8266-17

from End-Play Tool Set 8266 (2) and Dial Indica-

tor C-3339 (3), measure and record the output

shaft end-play. The correct output shaft end-play

is 0.22-0.55 mm (0.009-0.021 in.). Adjust as nec-

essary. Install the chosen output shaft selective

thrust plate and re-measure end-play to verify

selection.

37. Apply a bead of RTV silicone and install the

extension/adapter housing onto the transmission

case.

38. Install and torque the bolts to hold the extension/

adapter housing onto the transmission case. The

correct torque is 54 Nꞏm (40 ft.lbs.).

39. Install the number 5 thrust bearing (1) and selec-

tive thrust plate (2) onto the 4C retainer/bulkhead.

Be sure that the outer race of the bearing is

against the thrust plate.

40. Install the input clutch assembly (3) into the trans-

mission case. Make sure that the input clutch

assembly is fully installedbyperformingavisual

inspection through the input speed sensor hole. If

the tone wheel teeth on the input clutch assembly

are centered in the hole, the assembly is fully

installed.

41. Install the number 1 thrust bearing (4) with the

outer race up in the pocket of the input clutch

assembly.

42. Install the oil pump (2) into the transmission case.

43. Install the bolts (1) to hold the oil pump into the

transmission case. Tighten the oil pump bolts to

28 Nꞏm (250 in.lbs.).

Page 3390 of 5267

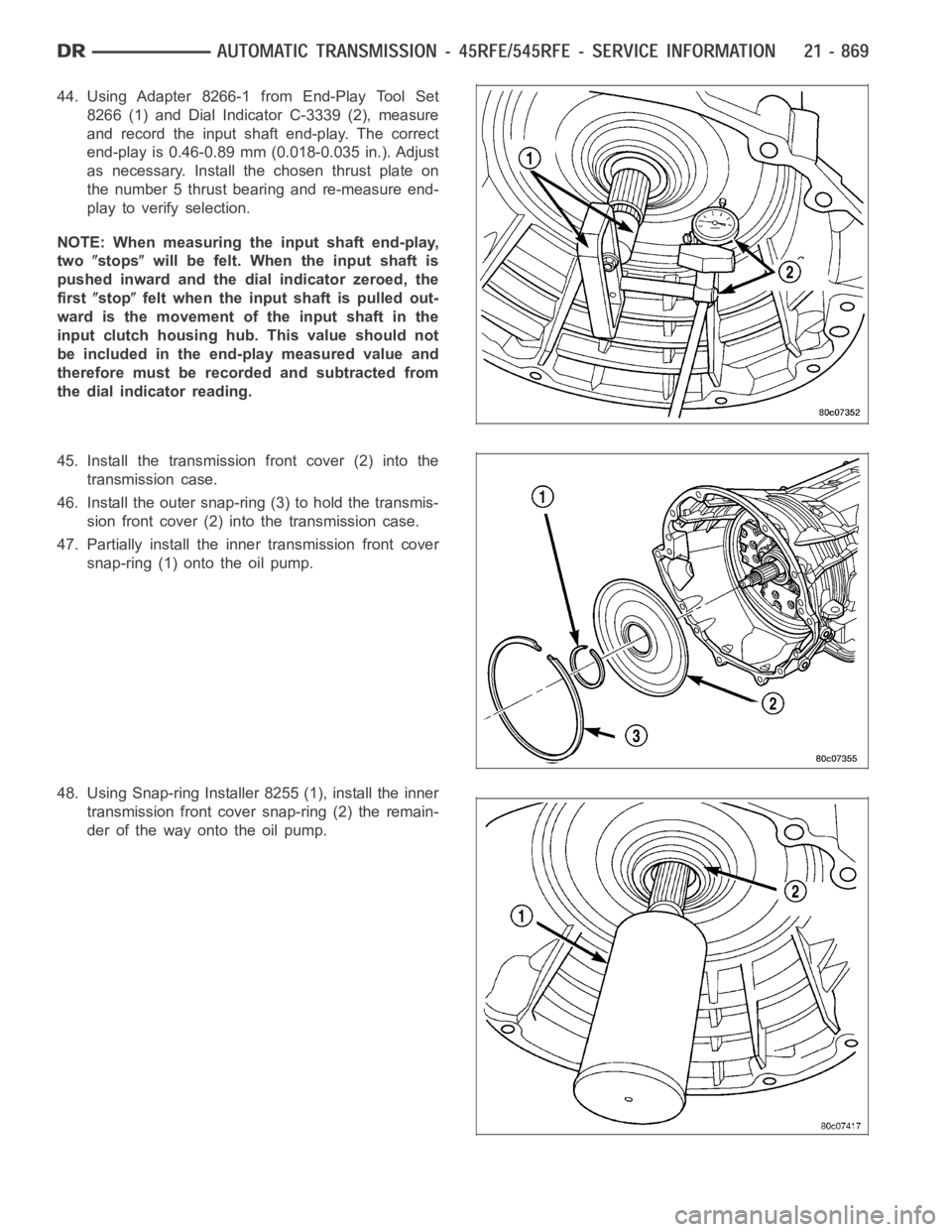

44. Using Adapter 8266-1 from End-Play Tool Set

8266 (1) and Dial Indicator C-3339 (2), measure

and record the input shaft end-play. The correct

end-play is 0.46-0.89 mm (0.018-0.035 in.). Adjust

as necessary. Install the chosen thrust plate on

the number 5 thrust bearing and re-measure end-

play to verify selection.

NOTE: When measuring the input shaft end-play,

two

stopswill be felt. When the input shaft is

pushed inward and the dial indicator zeroed, the

first

stopfelt when the input shaft is pulled out-

wardisthemovementoftheinputshaftinthe

input clutch housing hub. This value should not

be included in the end-play measured value and

therefore must be recorded and subtracted from

the dial indicator reading.

45. Install the transmission front cover (2) into the

transmission case.

46. Install the outer snap-ring (3) to hold the transmis-

sion front cover (2) into the transmission case.

47. Partially install the inner transmission front cover

snap-ring (1) onto the oil pump.

48. Using Snap-ring Installer 8255 (1), install the inner

transmission front cover snap-ring (2) the remain-

der of the way onto the oil pump.