DODGE RAM SRT-10 2006 Service Repair Manual

Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 3821 of 5267

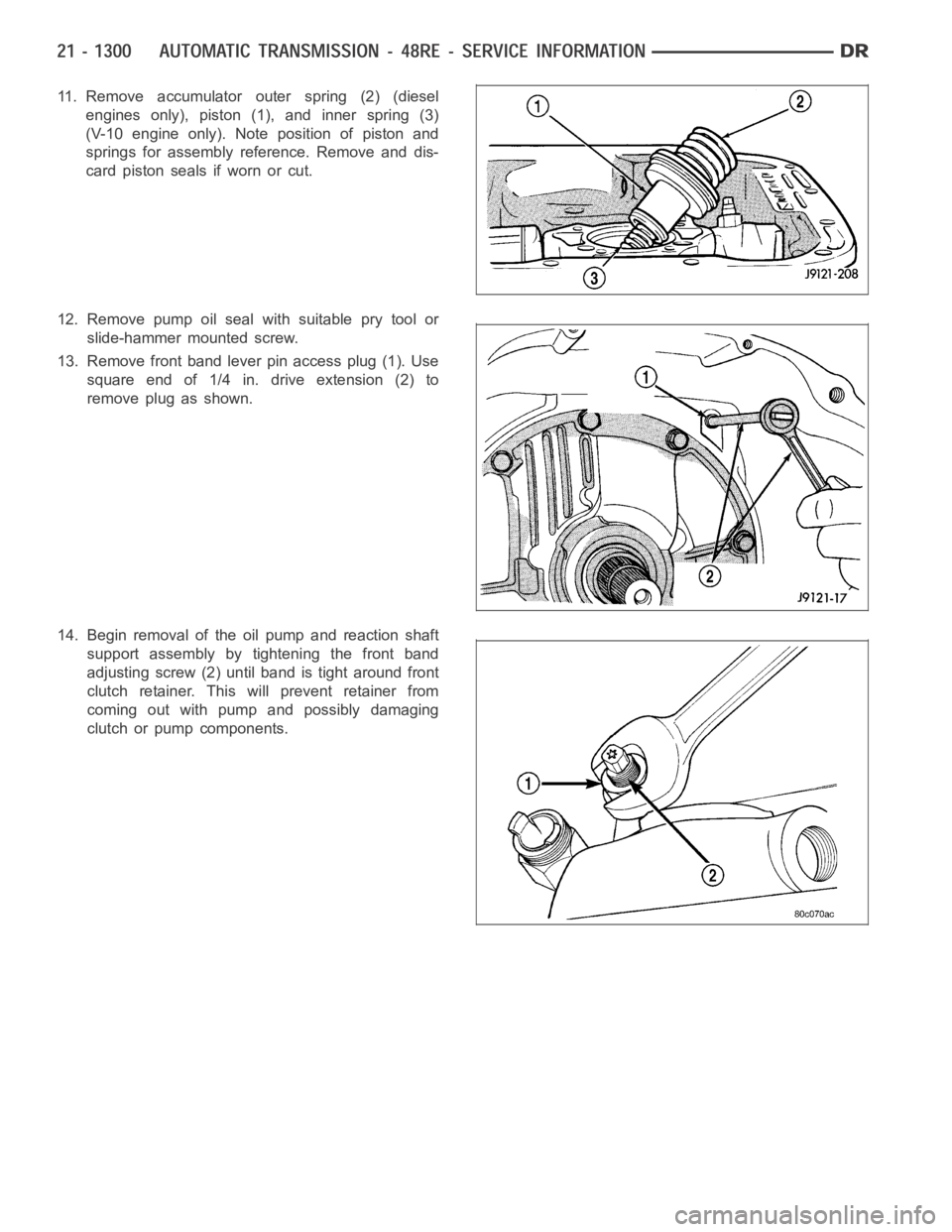

11. Remove accumulator outer spring (2) (diesel

engines only), piston (1), and inner spring (3)

(V-10 engine only). Note position of piston and

springs for assembly reference. Remove and dis-

card piston seals if worn or cut.

12. Remove pump oil seal with suitable pry tool or

slide-hammer mounted screw.

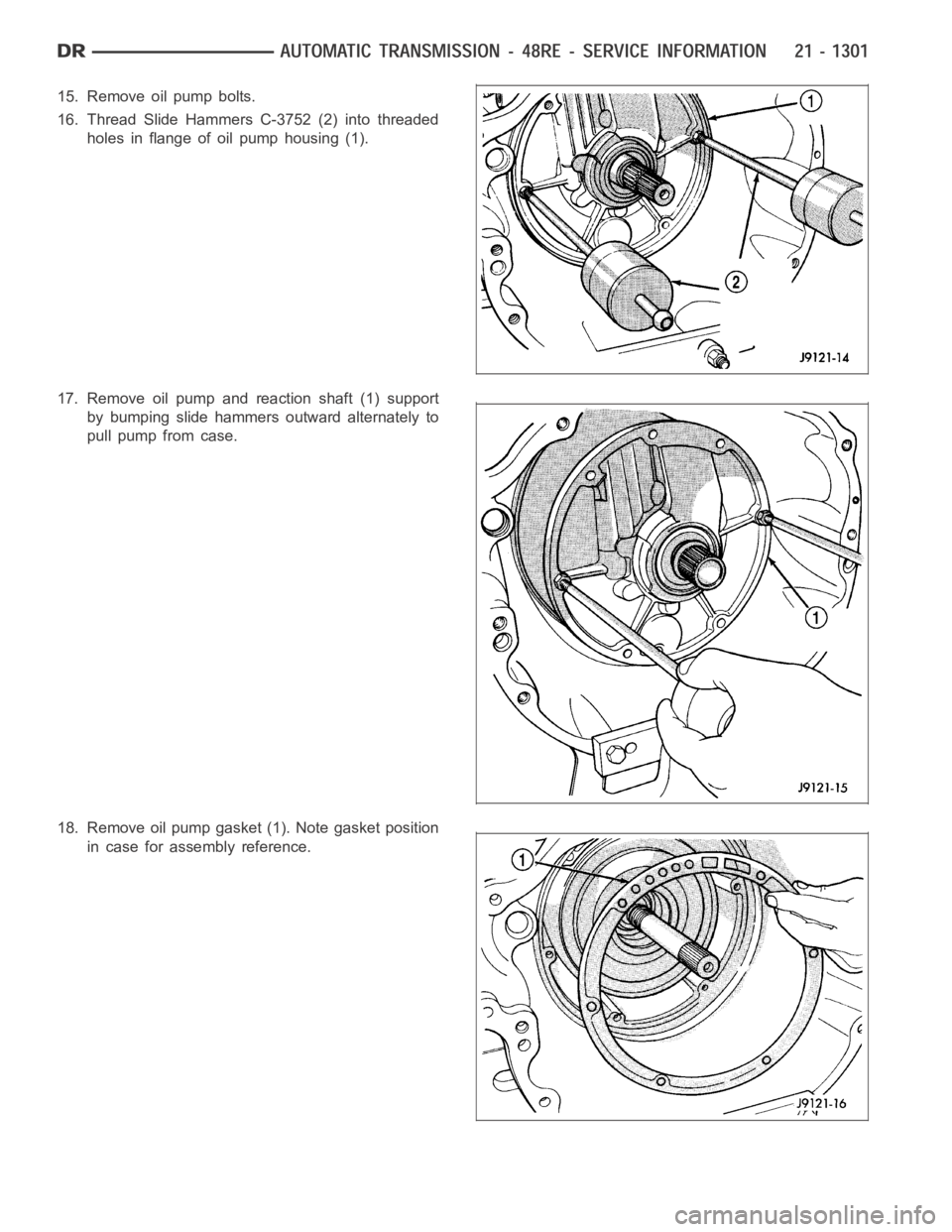

13. Remove front band lever pin access plug (1). Use

square end of 1/4 in. drive extension (2) to

remove plug as shown.

14. Begin removal of the oil pump and reaction shaft

support assembly by tightening the front band

adjusting screw (2) until band is tight around front

clutch retainer. This will prevent retainer from

coming out with pump and possibly damaging

clutch or pump components.

Page 3822 of 5267

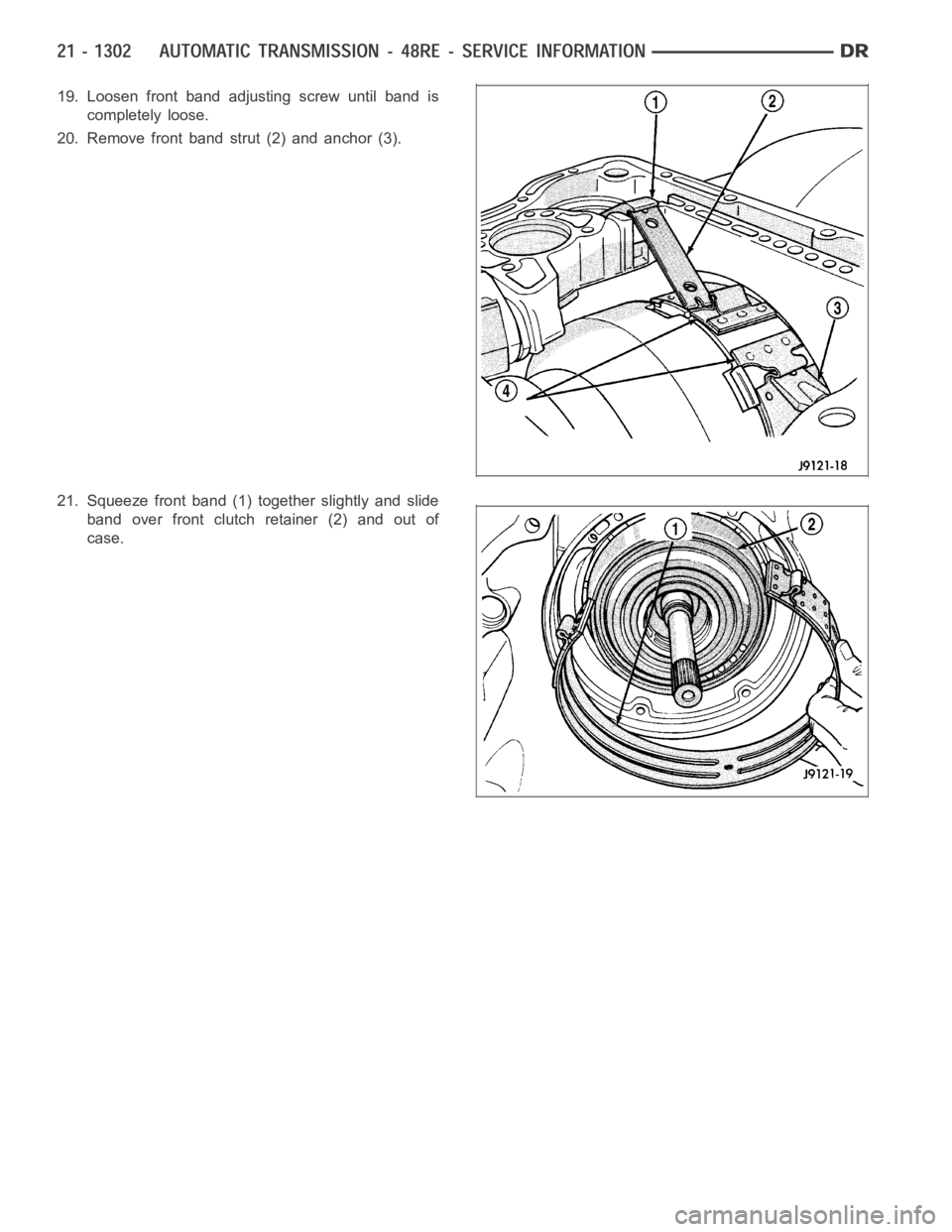

15. Remove oil pump bolts.

16. Thread Slide Hammers C-3752 (2) into threaded

holes in flange of oil pump housing (1).

17. Remove oil pump and reaction shaft (1) support

by bumping slide hammers outward alternately to

pull pump from case.

18. Remove oil pump gasket (1). Note gasket position

in case for assembly reference.

Page 3823 of 5267

19. Loosen front band adjusting screw until band is

completely loose.

20. Remove front band strut (2) and anchor (3).

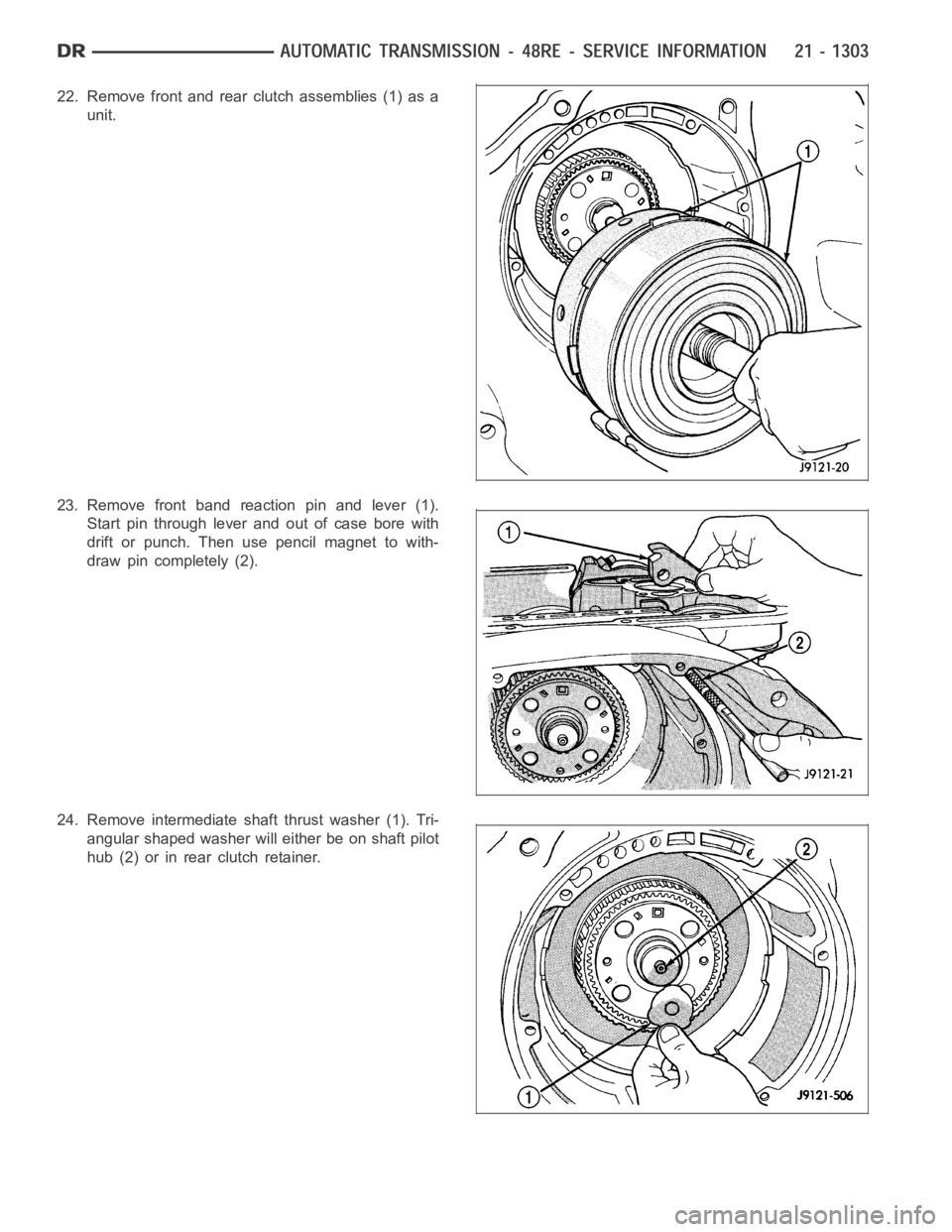

21. Squeeze front band (1) together slightly and slide

band over front clutch retainer (2) and out of

case.

Page 3824 of 5267

22. Remove front and rear clutch assemblies (1) as a

unit.

23. Remove front band reaction pin and lever (1).

Start pin through lever and out of case bore with

drift or punch. Then use pencil magnet to with-

draw pin completely (2).

24. Remove intermediate shaft thrust washer (1). Tri-

angular shaped washer will either be on shaft pilot

hub (2) or in rear clutch retainer.

Page 3825 of 5267

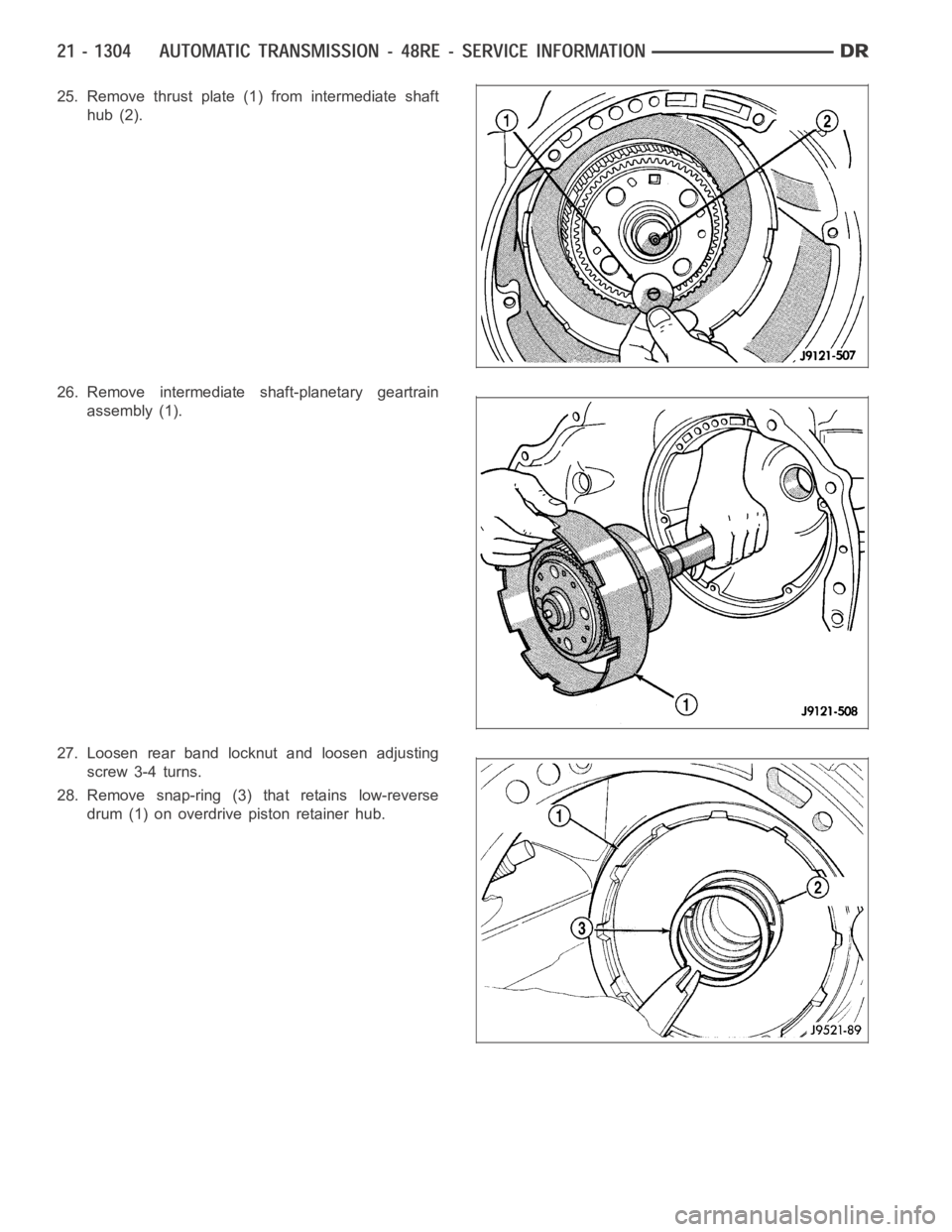

25. Remove thrust plate (1) from intermediate shaft

hub (2).

26. Remove intermediate shaft-planetary geartrain

assembly (1).

27. Loosen rear band locknut and loosen adjusting

screw 3-4 turns.

28. Remove snap-ring (3) that retains low-reverse

drum (1) on overdrive piston retainer hub.

Page 3826 of 5267

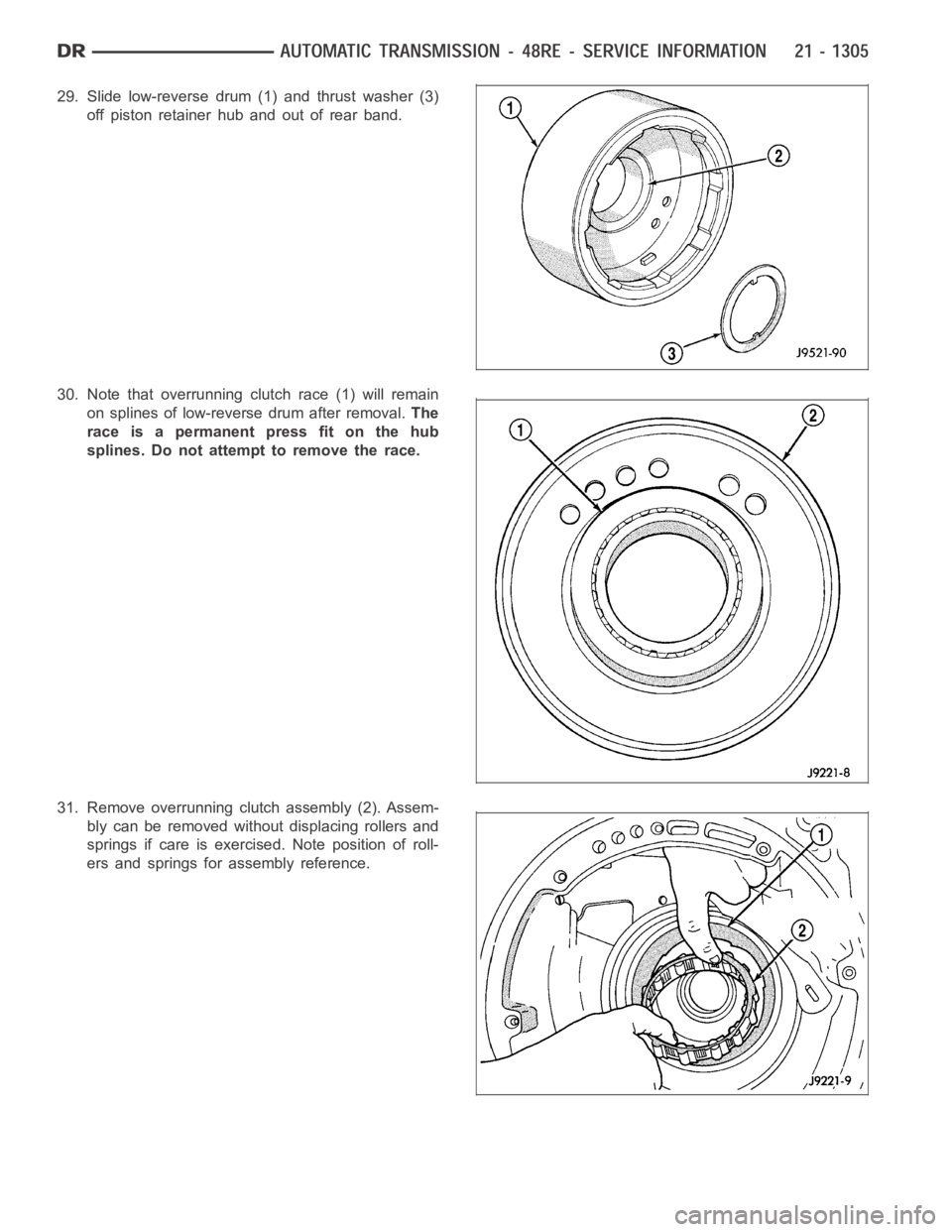

29. Slide low-reverse drum (1) and thrust washer (3)

off piston retainer hub and out of rear band.

30. Note that overrunning clutch race (1) will remain

on splines of low-reverse drum after removal.The

raceisapermanentpressfitonthehub

splines. Do not attempt to remove the race.

31. Remove overrunning clutch assembly (2). Assem-

bly can be removed without displacing rollers and

springs if care is exercised. Note position of roll-

ers and springs for assembly reference.

Page 3827 of 5267

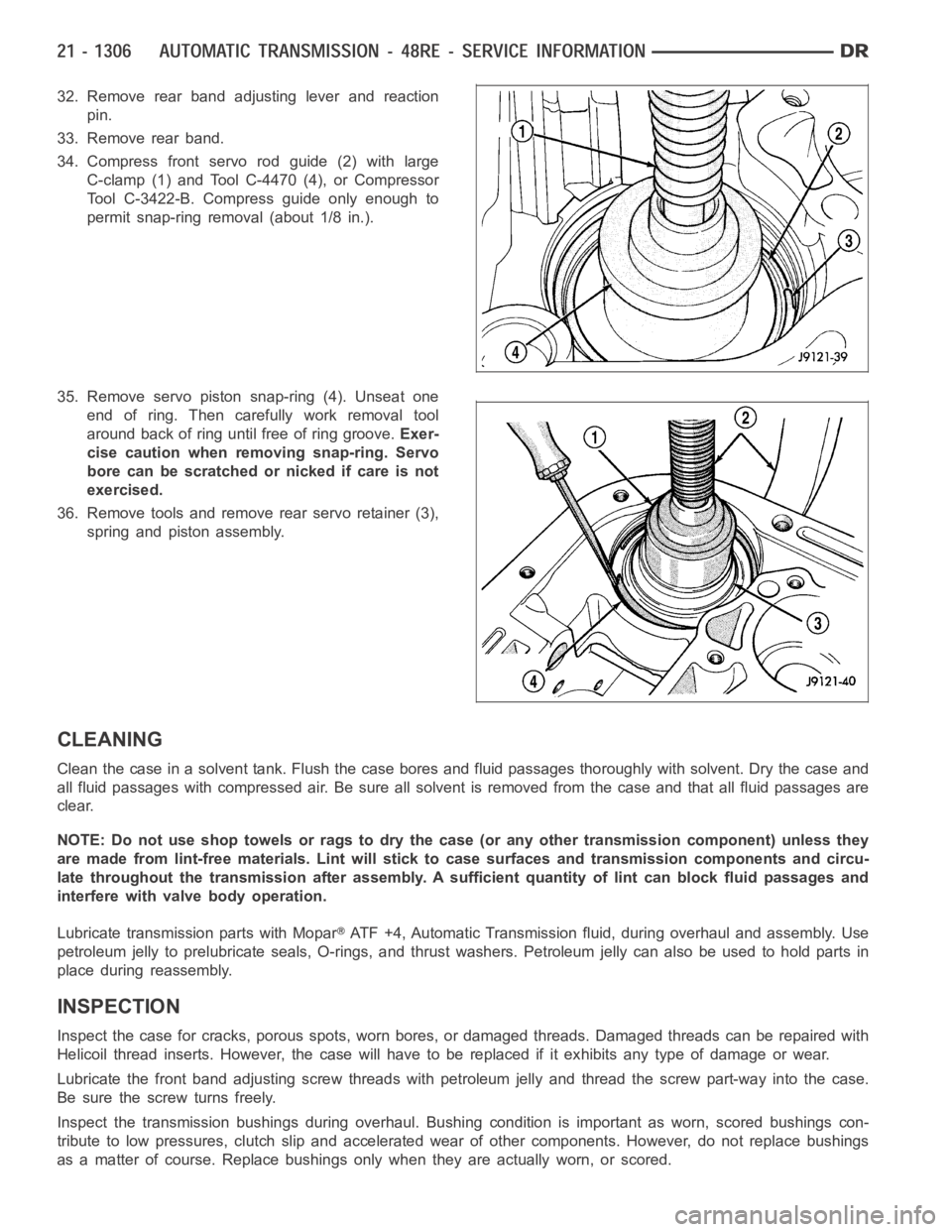

32. Remove rear band adjusting lever and reaction

pin.

33. Remove rear band.

34. Compress front servo rod guide (2) with large

C-clamp (1) and Tool C-4470 (4), or Compressor

Tool C-3422-B. Compress guide only enough to

permit snap-ring removal (about 1/8 in.).

35. Remove servo piston snap-ring (4). Unseat one

end of ring. Then carefully work removal tool

around back of ring until free of ring groove.Exer-

cise caution when removing snap-ring. Servo

bore can be scratched or nicked if care is not

exercised.

36. Remove tools and remove rear servo retainer (3),

spring and piston assembly.

CLEANING

Clean the case in a solvent tank. Flush the case bores and fluid passages thoroughly with solvent. Dry the case and

all fluid passages with compressed air. Be sure all solvent is removed fromthe case and that all fluid passages are

clear.

NOTE: Do not use shop towels or rags to dry the case (or any other transmission component) unless they

aremadefromlint-freematerials.Lintwillsticktocasesurfacesandtransmission components and circu-

late throughout the transmission after assembly. A sufficient quantity of lint can block fluid passages and

interfere with valve body operation.

Lubricate transmission parts with Mopar

ATF +4, Automatic Transmission fluid, during overhaul and assembly. Use

petroleum jelly to prelubricate seals, O-rings, and thrust washers. Petroleumjellycanalsobeusedtoholdpartsin

place during reassembly.

INSPECTION

Inspect the case for cracks, porous spots, worn bores, or damaged threads.Damaged threads can be repaired with

Helicoil thread inserts. However, the case will have to be replaced if it exhibits any type of damage or wear.

Lubricate the front band adjusting screw threads with petroleum jelly andthread the screw part-way into the case.

Be sure the screw turns freely.

Inspect the transmission bushings during overhaul. Bushing condition isimportant as worn, scored bushings con-

tribute to low pressures, clutch slipand accelerated wear of other components. However, do not replace bushings

as a matter of course. Replace bushings only when they are actually worn, orscored.

Page 3828 of 5267

The use of crocus cloth is permissible where necessary, providing it is usedcarefully.Whenusedonshafts,or

valves, use extreme care to avoid rounding off sharp edges. Sharp edges arevital as they prevent foreign matter

from getting between the valve and valve bore.

Do not reuse oil seals, gaskets, seal rings, or O-rings during overhaul. Replace these parts as a matter of course.

Also do not reuse snap rings or E-clips that are bent or distorted. Replace these parts as well.

ASSEMBLY

Do not allow dirt, grease, or foreign material to enter the case or transmission components during assembly. Keep

the transmission case and components clean. Also make sure the tools and workbench area used for reassembly

operations are equally clean.

Shop towels used for wiping off tools and your hands must be made fromlint freematerials. Lint will stick to trans-

mission parts and could interfere with valve operation or even restrict fluid passages.

Lubricate transmission clutch and gear components with Mopar

ATF +4 during reassembly. Soak clutch discs in

transmission fluid before installation.

Use petroleum jelly on piston seals and o-rings to ease installation. Petroleumjellycanalsobeusedtolubricate

and hold thrust washers and plates in position during assembly.

Do not use chassis grease, bearing grease, white grease, or similar lubricants on any part.These types of

lubricants can eventually block or restrict fluid passages and valve operation. Use petroleum jelly only.

Do not force parts into place. The transmission components and sub-assemblies are easily installed by hand when

properly aligned. If a part seems difficult to install, it is either misaligned or incorrectly assembled. Verify that thrust

washers, thrust plates and seal rings are correctly positioned.

The planetary geartrain, front/rear clutch assemblies and oil pump are all much easier to install when the transmis-

sion case is upright. Either tilt the case upward with wood blocks, or cut a hole in the bench large enough for the

intermediate shaft and rear support. Then lower the shaft and support intothe hole and support the rear of the case

directly on the bench.

FRONT/REAR SERVO

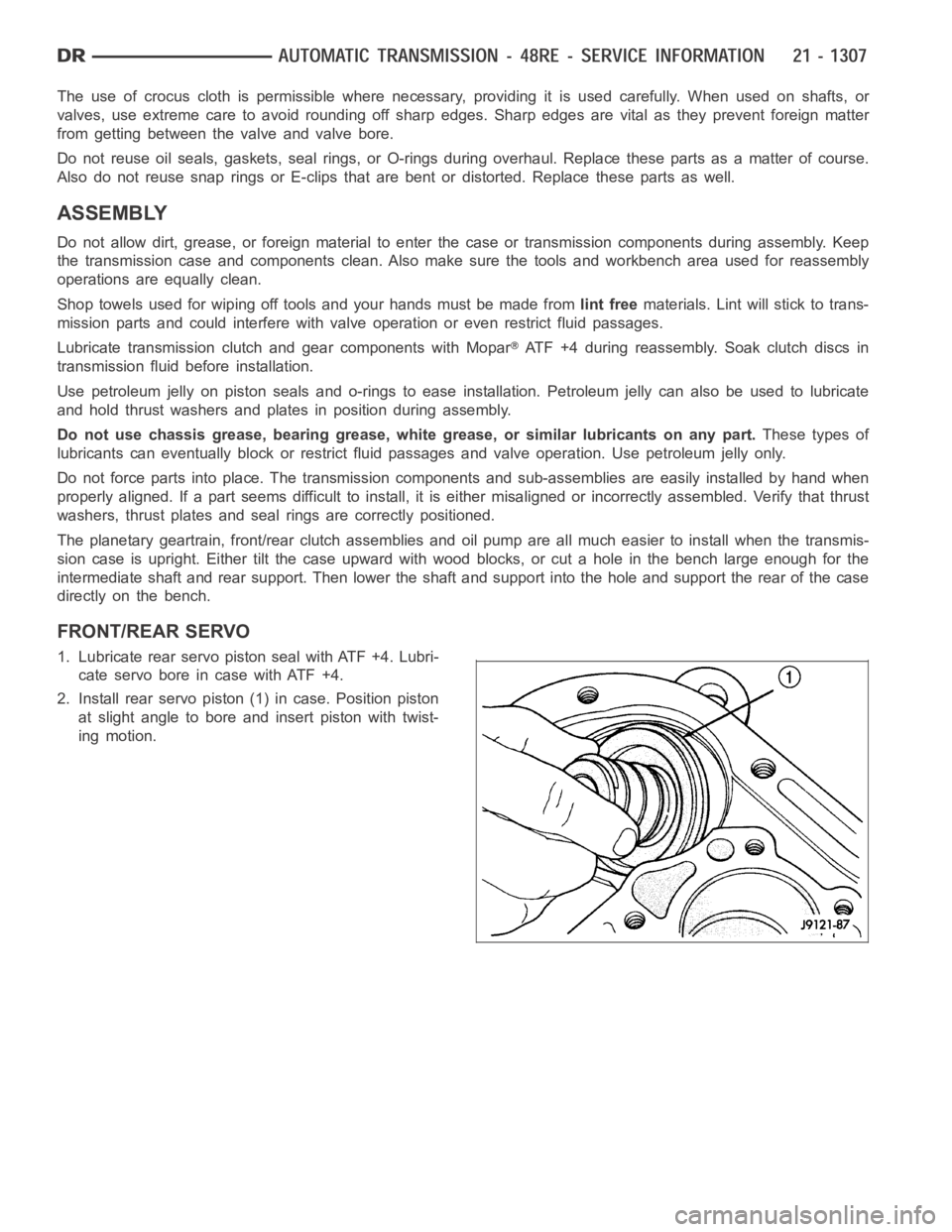

1. Lubricate rear servo piston seal with ATF +4. Lubri-

cateservoboreincasewithATF+4.

2. Install rear servo piston (1) in case. Position piston

at slight angle to bore and insert piston with twist-

ing motion.

Page 3829 of 5267

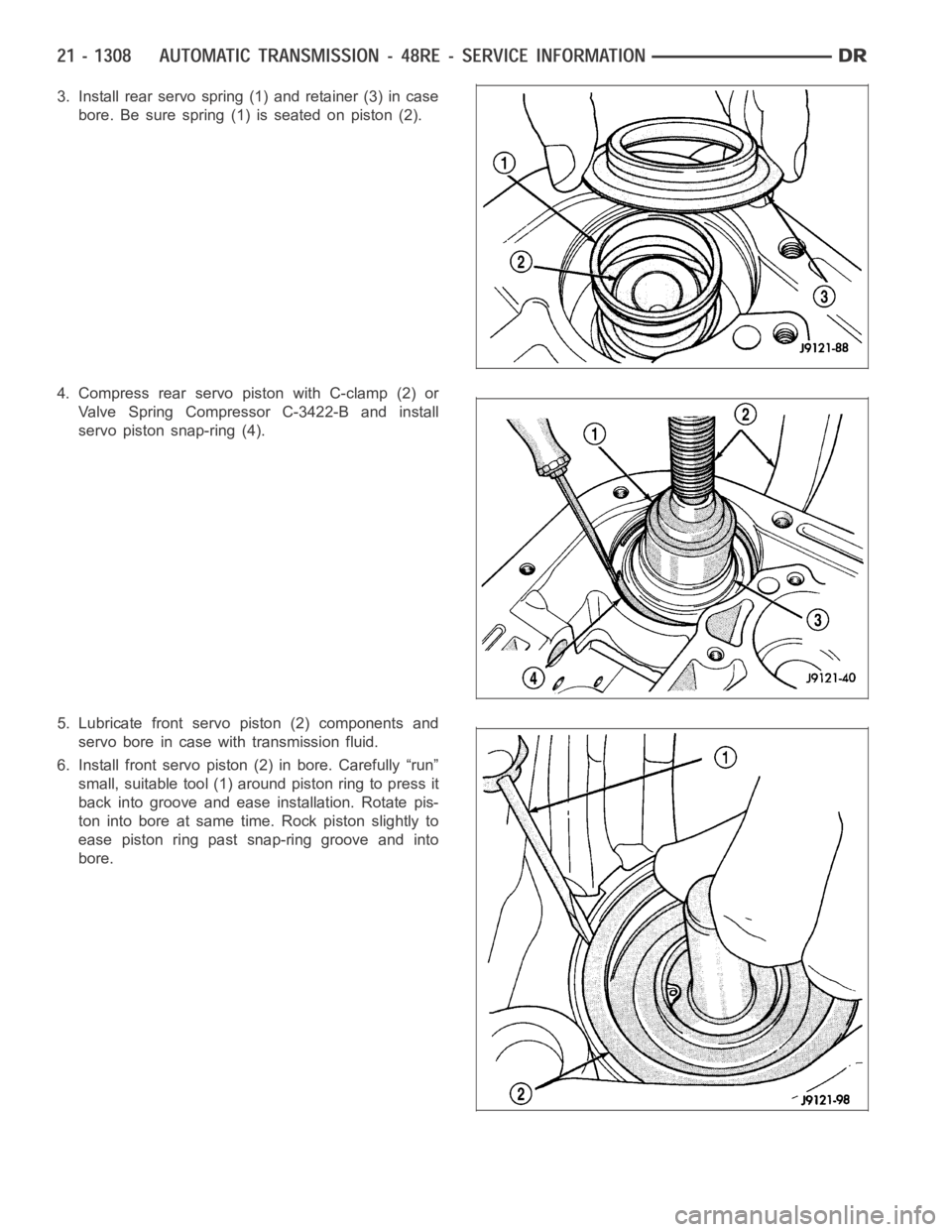

3. Install rear servo spring (1) and retainer (3) in case

bore. Be sure spring (1) is seated on piston (2).

4.CompressrearservopistonwithC-clamp(2)or

Valve Spring Compressor C-3422-B and install

servopistonsnap-ring(4).

5. Lubricate front servo piston (2) components and

servo bore in case with transmission fluid.

6. Install front servo piston (2) in bore. Carefully “run”

small, suitable tool (1) around piston ring to press it

back into groove and ease installation. Rotate pis-

tonintoboreatsametime.Rockpistonslightlyto

ease piston ring past snap-ring groove and into

bore.

Page 3830 of 5267

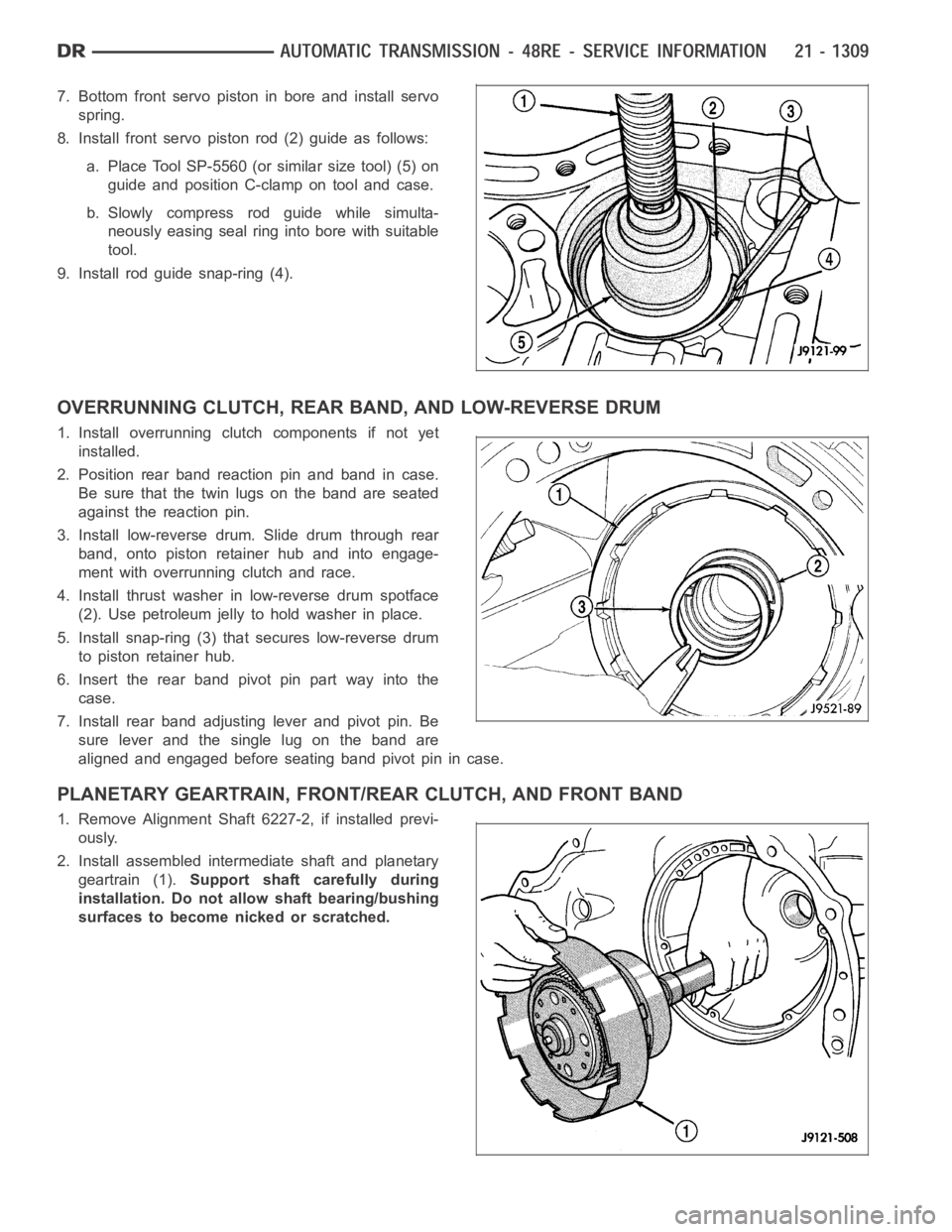

7. Bottom front servo piston in bore and install servo

spring.

8. Install front servo piston rod (2) guide as follows:

a. Place Tool SP-5560 (or similar size tool) (5) on

guide and position C-clamp on tool and case.

b. Slowly compress rod guide while simulta-

neously easing seal ring into bore with suitable

tool.

9. Install rod guide snap-ring (4).

OVERRUNNING CLUTCH, REAR BAND, AND LOW-REVERSE DRUM

1. Install overrunning clutch components if not yet

installed.

2. Position rear band reaction pin and band in case.

Be sure that the twin lugs on the band are seated

against the reaction pin.

3. Install low-reverse drum. Slide drum through rear

band, onto piston retainer hub and into engage-

ment with overrunning clutch and race.

4. Install thrust washer in low-reverse drum spotface

(2). Use petroleum jelly to hold washer in place.

5. Install snap-ring (3) that secures low-reverse drum

to piston retainer hub.

6. Insert the rear band pivot pin part way into the

case.

7. Install rear band adjusting lever and pivot pin. Be

sure lever and the single lug on the band are

aligned and engaged before seating band pivot pin in case.

PLANETARY GEARTRAIN, FRONT/REAR CLUTCH, AND FRONT BAND

1. Remove Alignment Shaft 6227-2, if installed previ-

ously.

2. Install assembled intermediate shaft and planetary

geartrain (1).Support shaft carefully during

installation. Do not allow shaft bearing/bushing

surfaces to become nicked or scratched.