transmission DODGE RAM SRT-10 2006 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1579 of 5267

COVER-STRUCTURAL

DESCRIPTION

The structural dust cover is made of die cast aluminum and joins the lower half of the transmission bell housing to

the engine bedplate.

OPERATION

The structural cover provides additional powertrain stiffness and reduces noise and vibration.

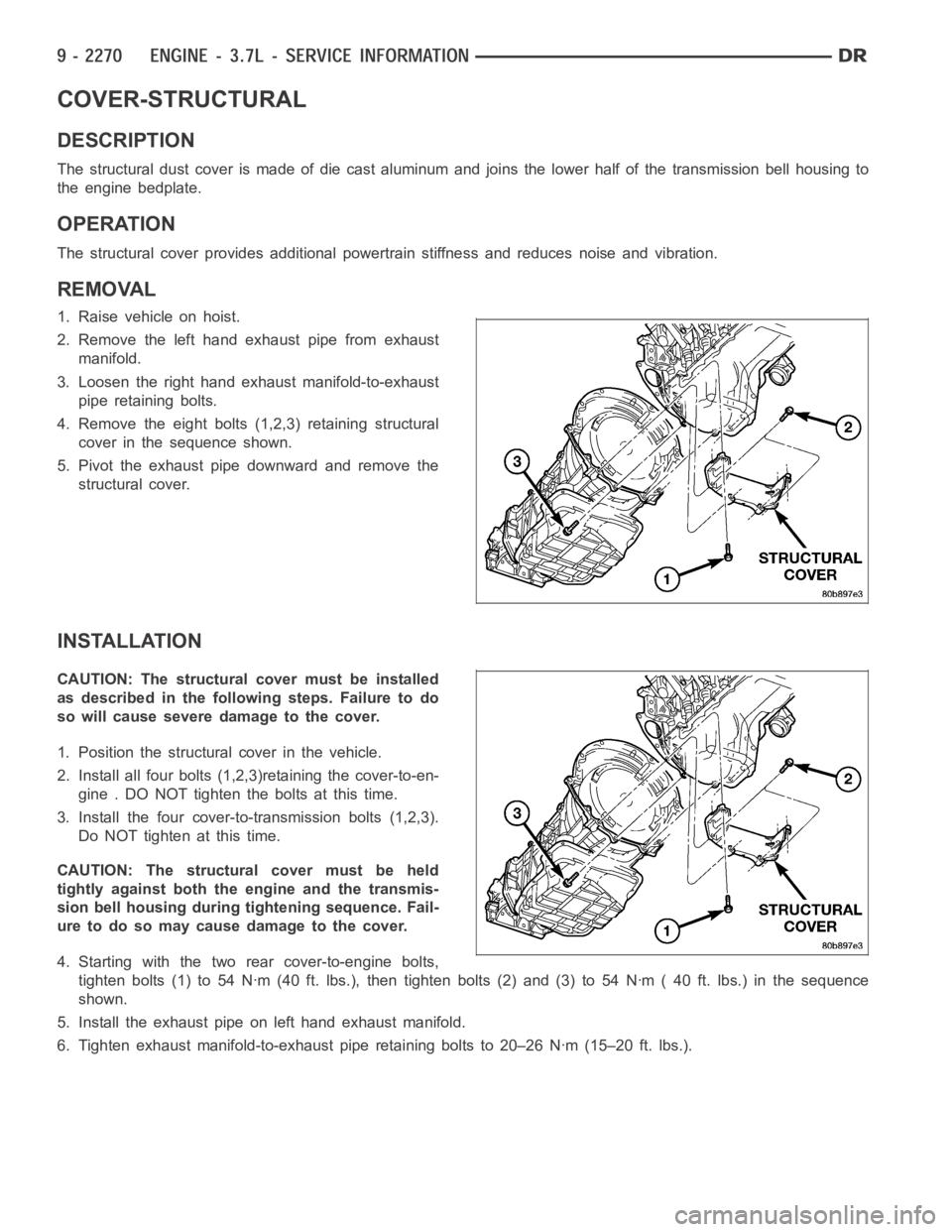

REMOVAL

1. Raise vehicle on hoist.

2. Remove the left hand exhaust pipe from exhaust

manifold.

3. Loosen the right hand exhaust manifold-to-exhaust

pipe retaining bolts.

4. Remove the eight bolts (1,2,3) retaining structural

cover in the sequence shown.

5. Pivot the exhaust pipe downward and remove the

structural cover.

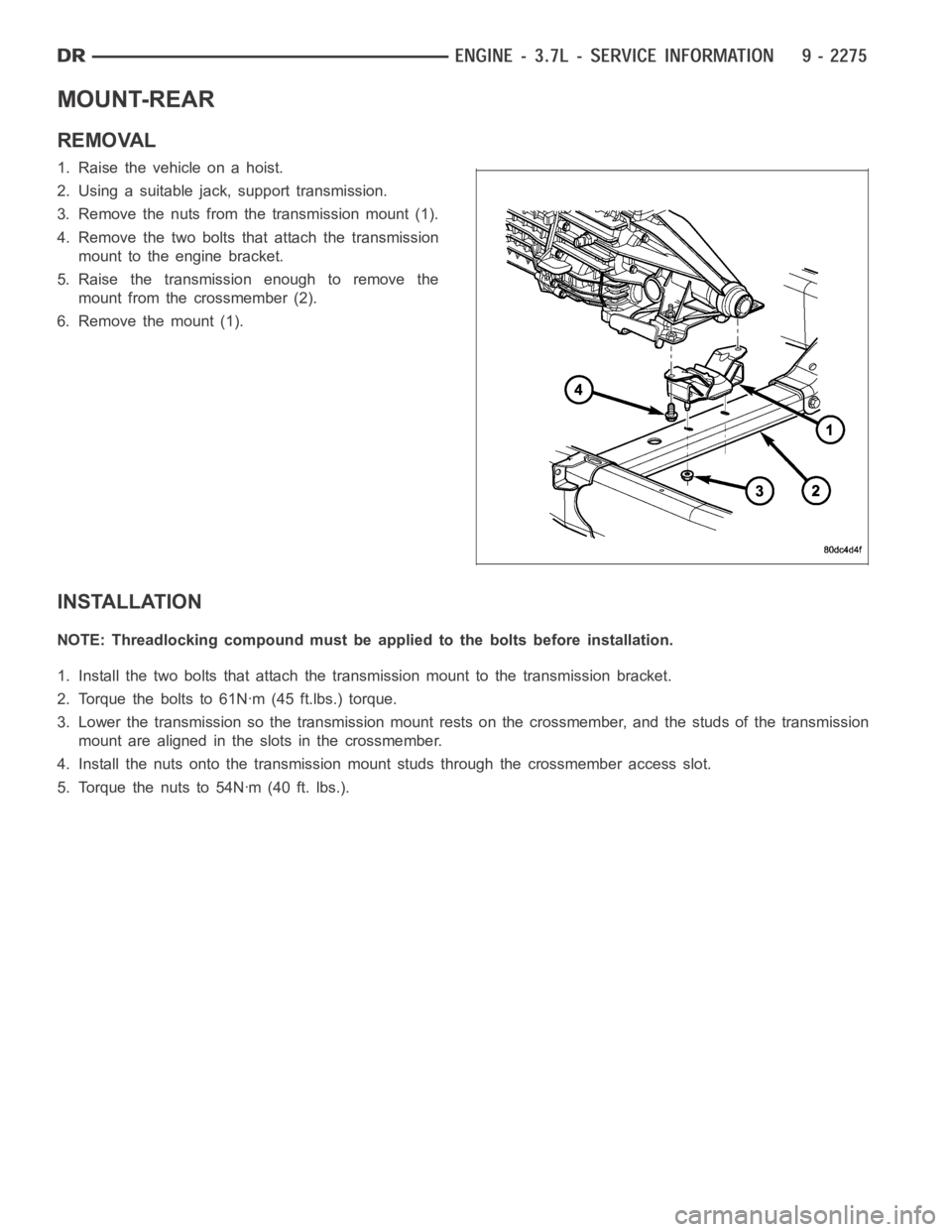

INSTALLATION

CAUTION: The structural cover must be installed

as described in the following steps. Failure to do

so will cause severe damage to the cover.

1. Position the structural cover in the vehicle.

2. Install all four bolts (1,2,3)retaining the cover-to-en-

gine . DO NOT tighten the bolts at this time.

3. Install the four cover-to-transmission bolts (1,2,3).

Do NOT tighten at this time.

CAUTION: The structural cover must be held

tightly against both the engine and the transmis-

sion bell housing during tightening sequence. Fail-

ure to do so may cause damage to the cover.

4. Starting with the two rearcover-to-engine bolts,

tighten bolts (1) to 54 Nꞏm (40 ft. lbs.), then tighten bolts (2) and (3) to 54Nꞏm ( 40 ft. lbs.) in the sequence

shown.

5. Install the exhaust pipe on left hand exhaust manifold.

6. Tighten exhaust manifold-to-exhaust pipe retaining bolts to 20–26 Nꞏm(15–20 ft. lbs.).

Page 1584 of 5267

MOUNT-REAR

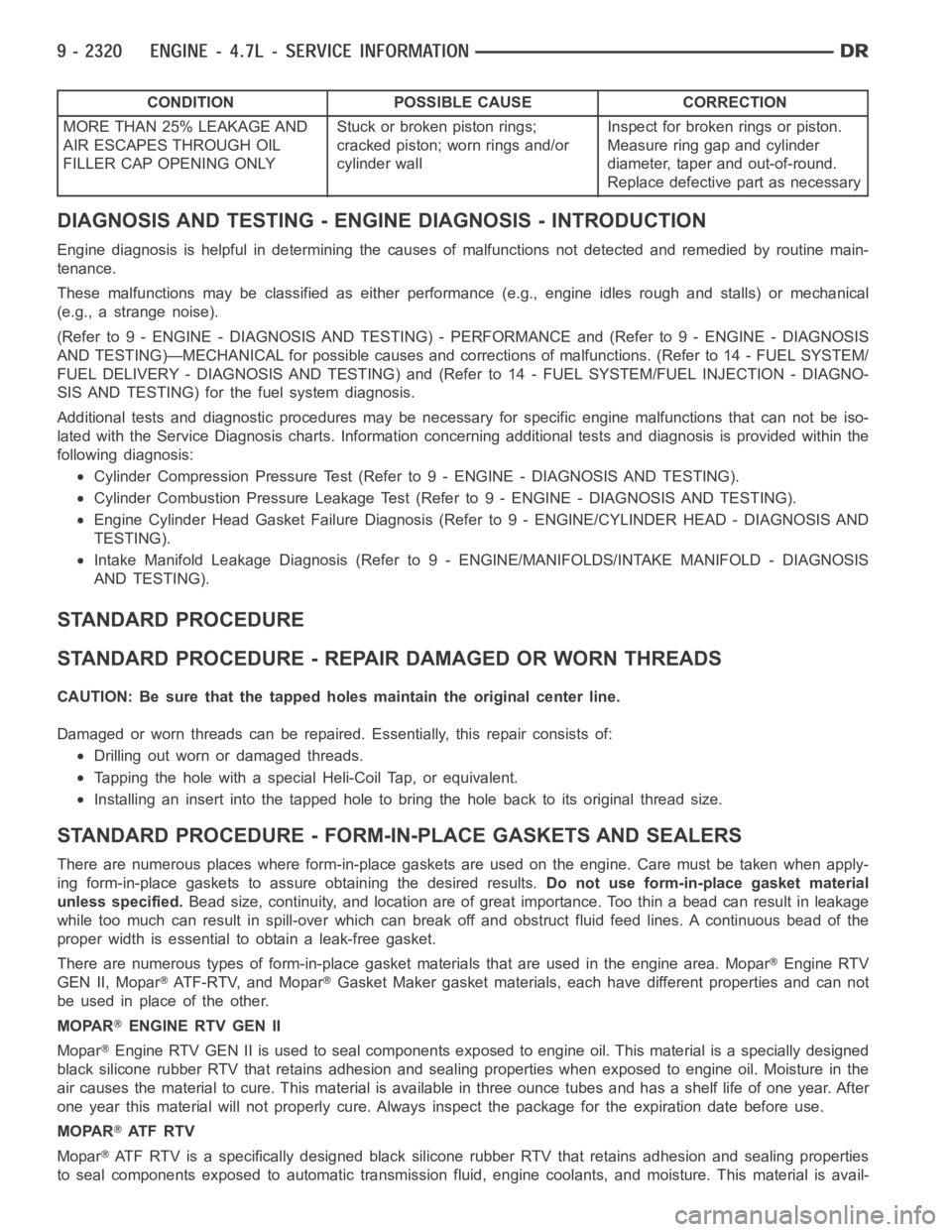

REMOVAL

1. Raise the vehicle on a hoist.

2. Using a suitable jack, support transmission.

3. Remove the nuts from the transmission mount (1).

4. Remove the two bolts that attach the transmission

mount to the engine bracket.

5. Raise the transmission enough to remove the

mount from the crossmember (2).

6. Remove the mount (1).

INSTALLATION

NOTE: Threadlocking compound must be applied to the bolts before installation.

1. Install the two bolts that attach the transmission mount to the transmission bracket.

2. Torque the bolts to 61Nꞏm (45 ft.lbs.) torque.

3. Lower the transmission so the transmission mount rests on the crossmember, and the studs of the transmission

mount are aligned in the slots in the crossmember.

4. Install the nuts onto the transmission mount studs through the crossmember access slot.

5. Torque the nuts to 54Nꞏm (40 ft. lbs.).

Page 1629 of 5267

CONDITION POSSIBLE CAUSE CORRECTION

MORE THAN 25% LEAKAGE AND

AIR ESCAPES THROUGH OIL

FILLER CAP OPENING ONLYStuckorbrokenpistonrings;

cracked piston; worn rings and/or

cylinder wallInspect for broken rings or piston.

Measure ring gap and cylinder

diameter, taper and out-of-round.

Replace defective part as necessary

DIAGNOSIS AND TESTING - ENGINE DIAGNOSIS - INTRODUCTION

Engine diagnosis is helpful in determining the causes of malfunctions notdetected and remedied by routine main-

tenance.

These malfunctions may be classified as either performance (e.g., engineidles rough and stalls) or mechanical

(e.g., a strange noise).

(Refer to 9 - ENGINE - DIAGNOSIS AND TESTING) - PERFORMANCE and (Refer to 9 - ENGINE - DIAGNOSIS

AND TESTING)—MECHANICAL for possible causes and corrections of malfunctions. (Refer to 14 - FUEL SYSTEM/

FUEL DELIVERY - DIAGNOSIS AND TESTING) and (Refer to 14 - FUEL SYSTEM/FUEL INJECTION - DIAGNO-

SIS AND TESTING) for the fuel system diagnosis.

Additional tests and diagnostic procedures may be necessary for specificengine malfunctions that can not be iso-

lated with the Service Diagnosis charts. Information concerning additional tests and diagnosis is provided within the

following diagnosis:

Cylinder Compression Pressure Test (Refer to 9 - ENGINE - DIAGNOSIS AND TESTING).

Cylinder Combustion Pressure LeakageTest (Refer to 9 - ENGINE - DIAGNOSISAND TESTING).

Engine Cylinder Head Gasket Failure Diagnosis (Refer to 9 - ENGINE/CYLINDER HEAD - DIAGNOSIS AND

TESTING).

Intake Manifold Leakage Diagnosis (Refer to 9 - ENGINE/MANIFOLDS/INTAKEMANIFOLD - DIAGNOSIS

AND TESTING).

STANDARD PROCEDURE

STANDARD PROCEDURE - REPAIR DAMAGED OR WORN THREADS

CAUTION: Be sure that the tapped holes maintain the original center line.

Damaged or worn threads can be repaired. Essentially, this repair consistsof:

Drilling out worn or damaged threads.

Tapping the hole with a special Heli-Coil Tap, or equivalent.

Installing an insert into the tapped hole to bring the hole back to its original thread size.

STANDARD PROCEDURE - FORM-IN-PLACE GASKETS AND SEALERS

There are numerous places where form-in-place gaskets are used on the engine. Care must be taken when apply-

ing form-in-place gaskets to assure obtaining the desired results.Do not use form-in-place gasket material

unless specified.Bead size, continuity, and location are of great importance. Too thin a bead can result in leakage

while too much can result in spill-overwhich can break off and obstruct fluid feed lines. A continuous bead of the

proper width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket materials that are used in the engine area. Mopar

Engine RTV

GEN II, Mopar

ATF-RTV, and MoparGasket Maker gasket materials, each have different properties and can not

be used in place of the other.

MOPAR

ENGINE RTV GEN II

Mopar

Engine RTV GEN II is used to seal components exposed to engine oil. This material is a specially designed

black silicone rubber RTV that retains adhesion and sealing properties when exposed to engine oil. Moisture in the

air causes the material to cure. This material is available in three ounce tubes and has a shelf life of one year. After

one year this material will not properly cure. Always inspect the package for the expiration date before use.

MOPAR

AT F R T V

Mopar

ATF RTV is a specifically designed black silicone rubber RTV that retains adhesion and sealing properties

to seal components exposed to automatic transmission fluid, engine coolants, and moisture. This material is avail-

Page 1631 of 5267

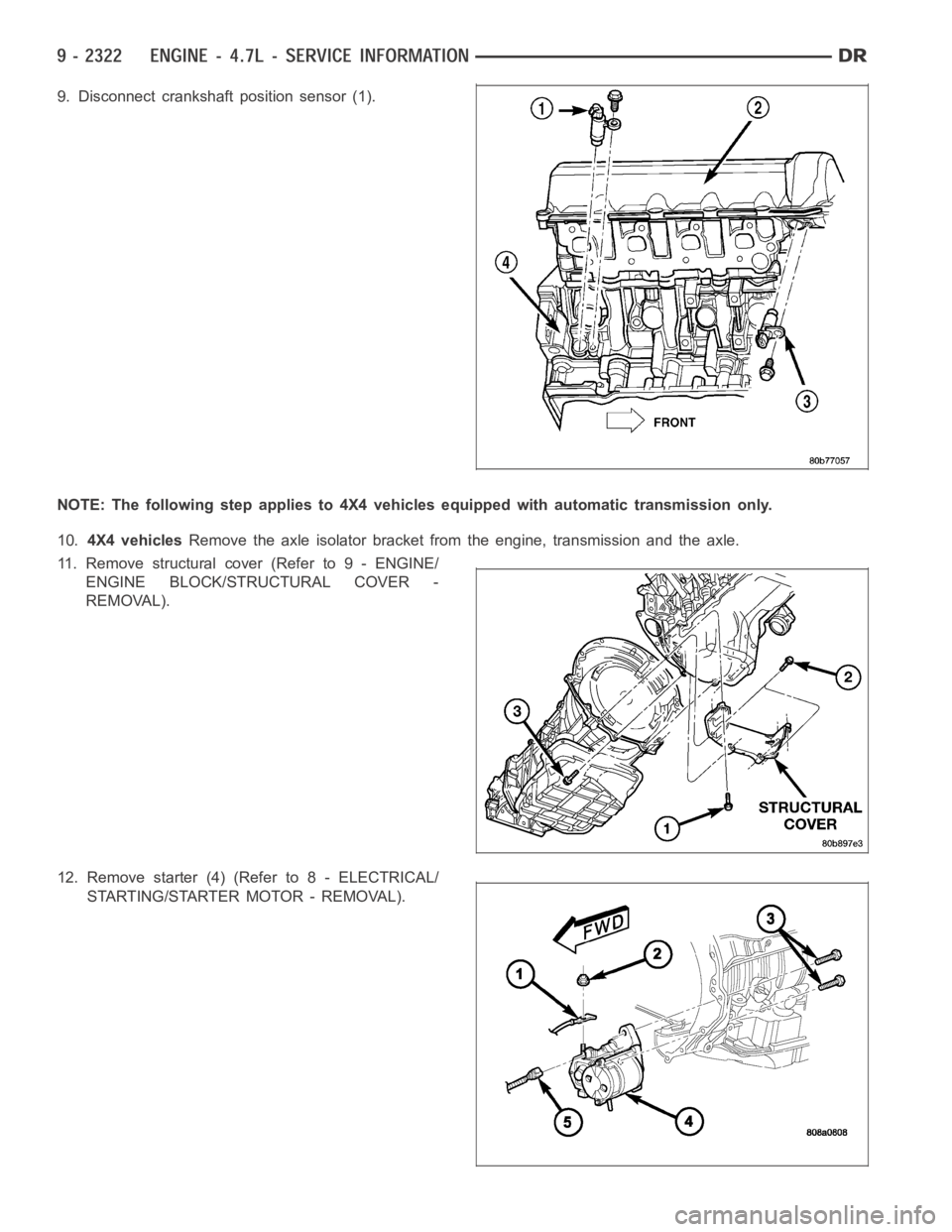

9. Disconnect crankshaft position sensor (1).

NOTE: The following step applies to 4X4vehicles equipped with automatic transmission only.

10.4X4 vehiclesRemove the axle isolator bracket from the engine, transmission and the axle.

11. Remove structural cover (Refer to 9 - ENGINE/

ENGINE BLOCK/STRUCTURAL COVER -

REMOVAL).

12. Remove starter (4) (Refer to 8 - ELECTRICAL/

STARTING/STARTER MOTOR - REMOVAL).

Page 1632 of 5267

13. Drain cooling system (Refer to 7 - COOLING - STANDARD PROCEDURE).

14. Remove torque converter bolts (Automatic Transmission Only).

15. Remove transmission to engine mounting bolts.

16. Disconnect the engine block heater power cable from the block heater, if equipped.

17. Lower vehicle.

18. Remove throttle body resonator assembly and air inlet hose.

19. Disconnect throttle and speed control cables.

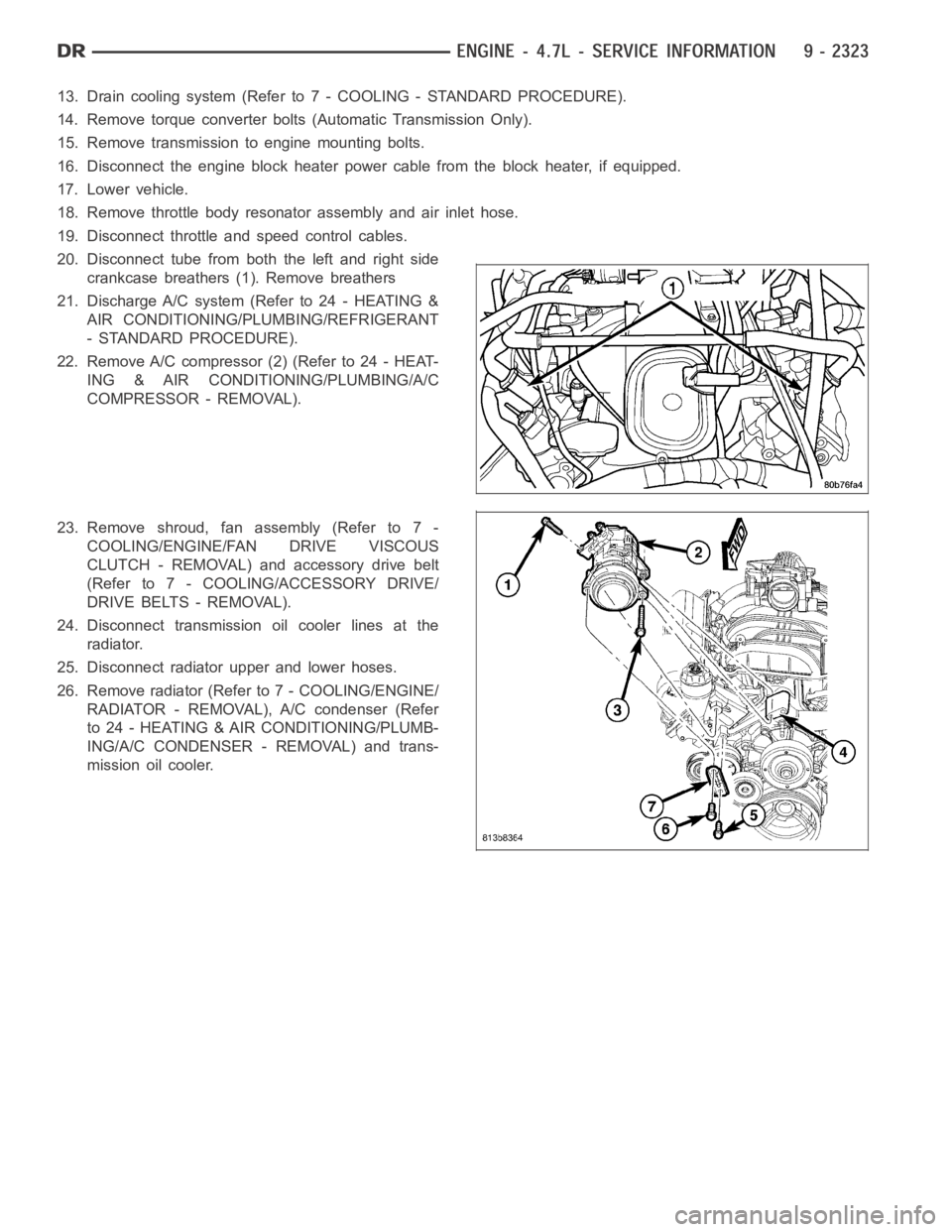

20. Disconnect tube from both the left and right side

crankcase breathers (1). Remove breathers

21. Discharge A/C system (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING/REFRIGERANT

- STANDARD PROCEDURE).

22. Remove A/C compressor (2) (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/A/C

COMPRESSOR - REMOVAL).

23. Remove shroud, fan assembly (Refer to 7 -

COOLING/ENGINE/FAN DRIVE VISCOUS

CLUTCH - REMOVAL) and accessory drive belt

(Refer to 7 - COOLING/ACCESSORY DRIVE/

DRIVE BELTS - REMOVAL).

24. Disconnect transmission oil cooler lines at the

radiator.

25. Disconnect radiator upper and lower hoses.

26. Remove radiator (Refer to 7 - COOLING/ENGINE/

RADIATOR - REMOVAL), A/C condenser (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMB-

ING/A/C CONDENSER - REMOVAL) and trans-

mission oil cooler.

Page 1635 of 5267

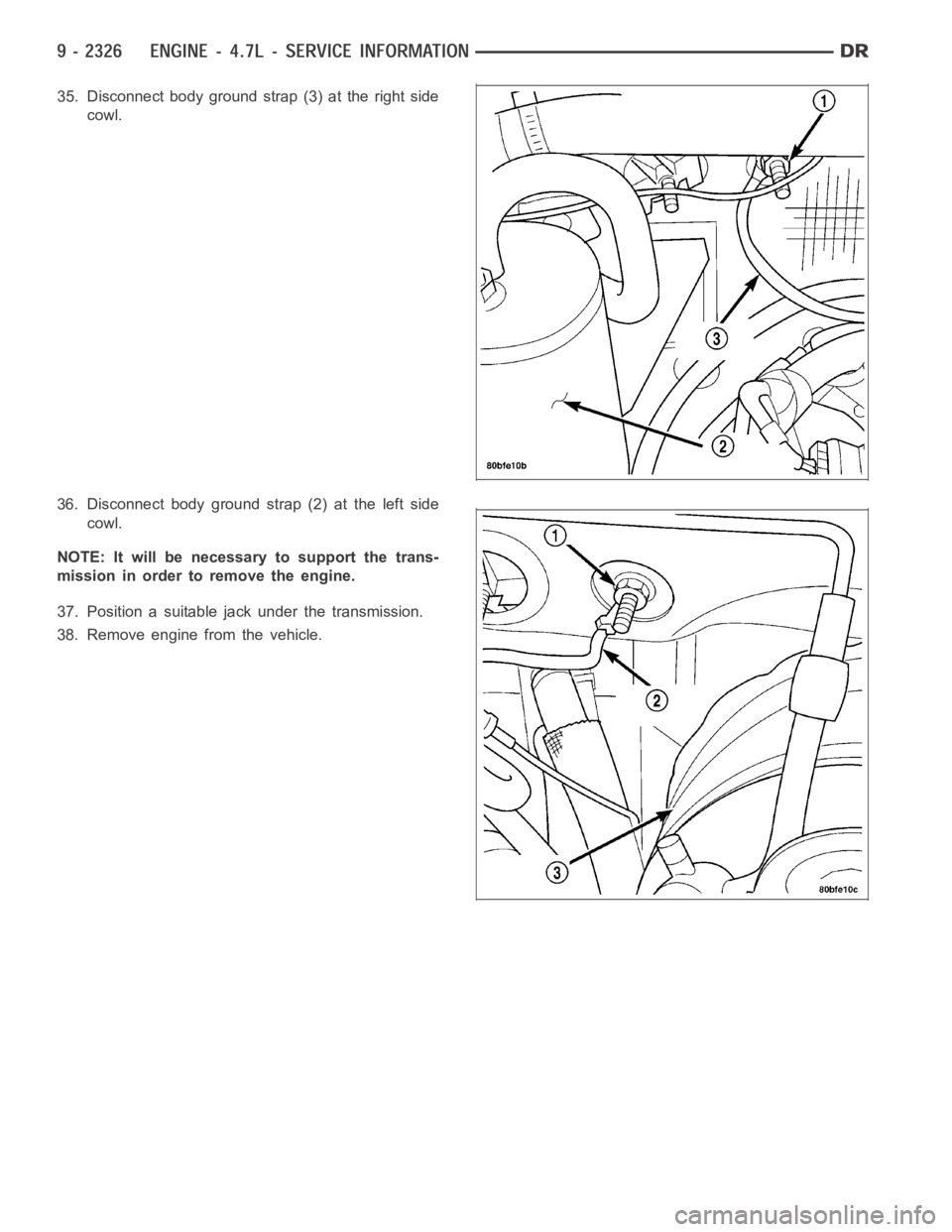

35. Disconnect body ground strap (3) at the right side

cowl.

36. Disconnect body ground strap (2) at the left side

cowl.

NOTE: It will be necessary to support the trans-

mission in order to remove the engine.

37. Position a suitable jack under the transmission.

38. Remove engine from the vehicle.

Page 1636 of 5267

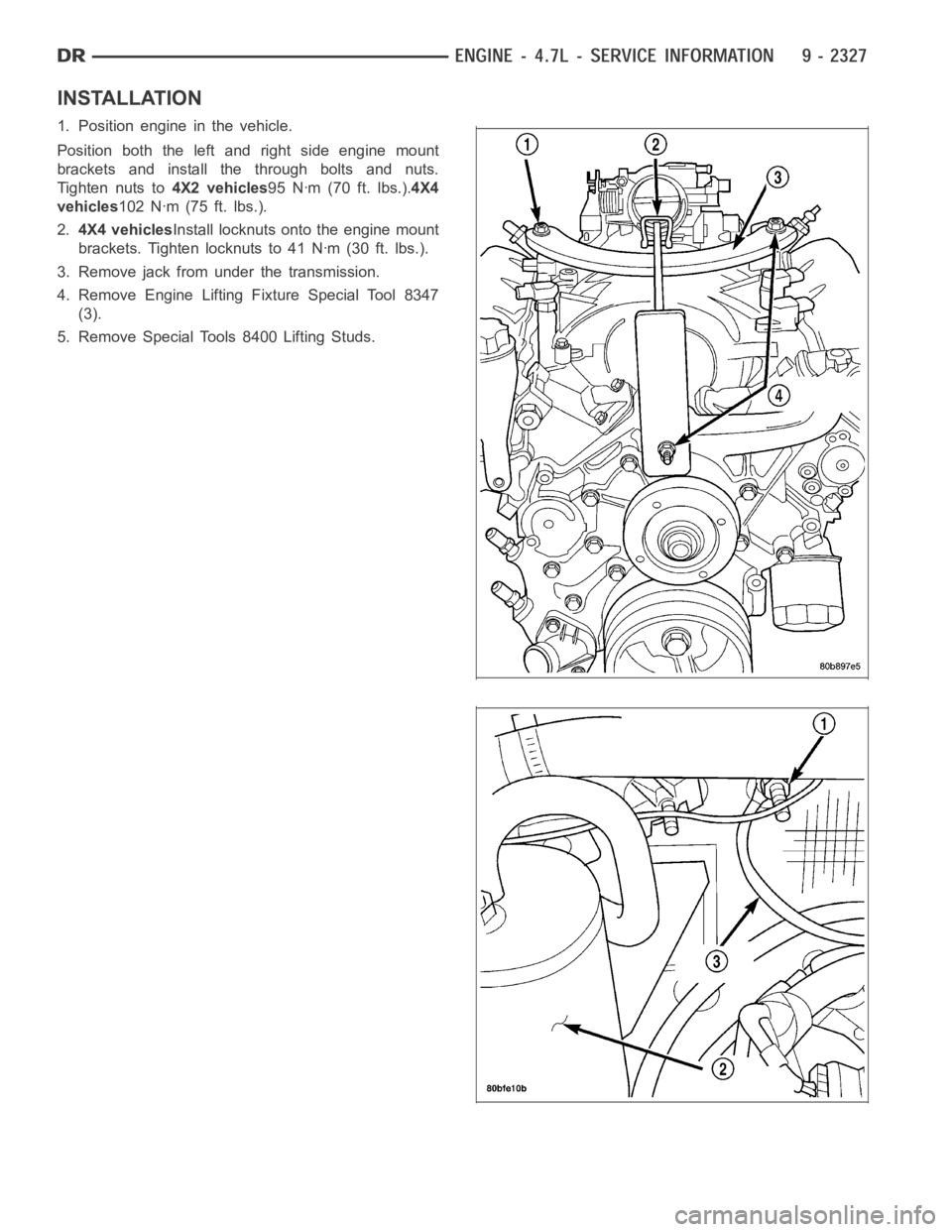

INSTALLATION

1. Position engine in the vehicle.

Position both the left and right side engine mount

brackets and install the through bolts and nuts.

Tighten nuts to4X2 vehicles95 Nꞏm (70 ft. lbs.).4X4

vehicles102Nꞏm(75ft.lbs.).

2.4X4 vehiclesInstall locknuts onto the engine mount

brackets. Tighten locknuts to 41 Nꞏm (30 ft. lbs.).

3. Remove jack from under the transmission.

4. Remove Engine Lifting Fixture Special Tool 8347

(3).

5. Remove Special Tools 8400 Lifting Studs.

Page 1638 of 5267

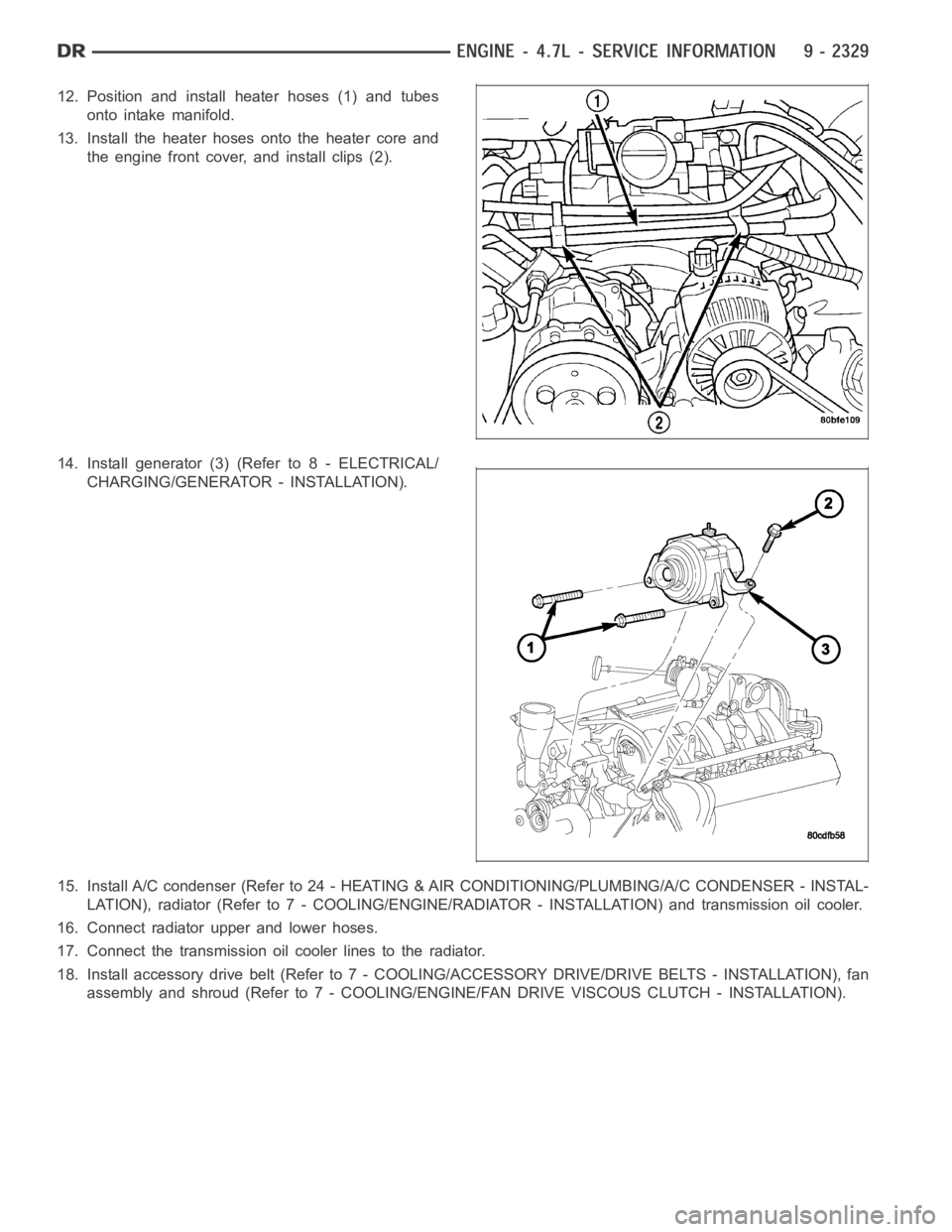

12. Position and install heater hoses (1) and tubes

onto intake manifold.

13. Install the heater hoses onto the heater core and

the engine front cover, and install clips (2).

14. Install generator (3) (Refer to 8 - ELECTRICAL/

CHARGING/GENERATOR - INSTALLATION).

15. Install A/C condenser (Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING/A/C CONDENSER - INSTAL-

LATION), radiator (Refer to 7 - COOLING/ENGINE/RADIATOR - INSTALLATION)and transmission oil cooler.

16. Connect radiator upper and lower hoses.

17. Connect the transmission oil cooler lines to the radiator.

18. Install accessory drive belt (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - INSTALLATION), fan

assembly and shroud (Refer to 7 - COOLING/ENGINE/FAN DRIVE VISCOUS CLUTCH- INSTALLATION).

Page 1639 of 5267

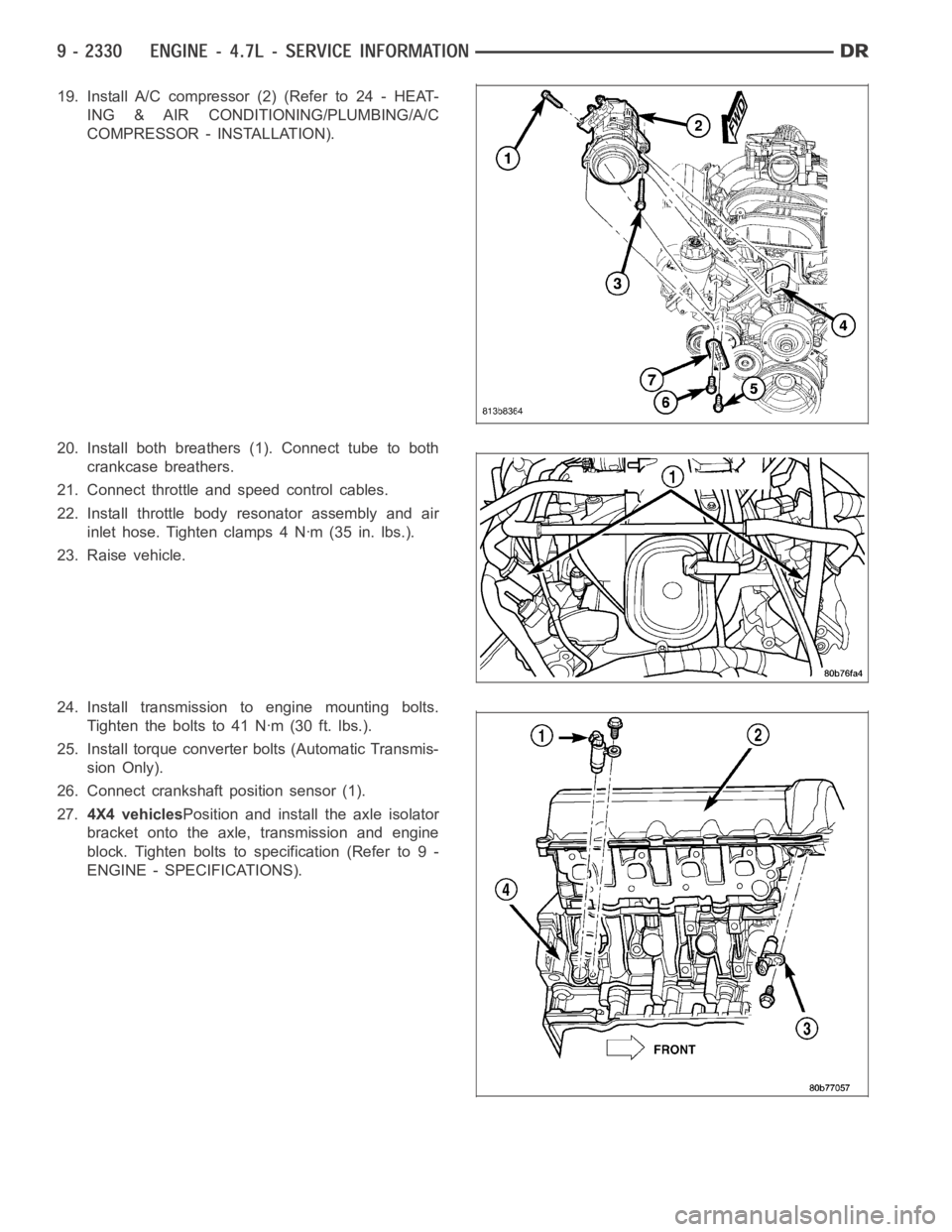

19. Install A/C compressor (2) (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/A/C

COMPRESSOR - INSTALLATION).

20. Install both breathers (1). Connect tube to both

crankcase breathers.

21. Connect throttle and speed control cables.

22. Install throttle body resonator assembly and air

inlet hose. Tighten clamps 4 Nꞏm (35 in. lbs.).

23. Raise vehicle.

24. Install transmission to engine mounting bolts.

Tighten the bolts to 41 Nꞏm (30 ft. lbs.).

25. Install torque converter bolts (Automatic Transmis-

sion Only).

26. Connect crankshaft position sensor (1).

27.4X4 vehiclesPosition and install the axle isolator

bracket onto the axle, transmission and engine

block. Tighten bolts to specification (Refer to 9 -

ENGINE - SPECIFICATIONS).

Page 1645 of 5267

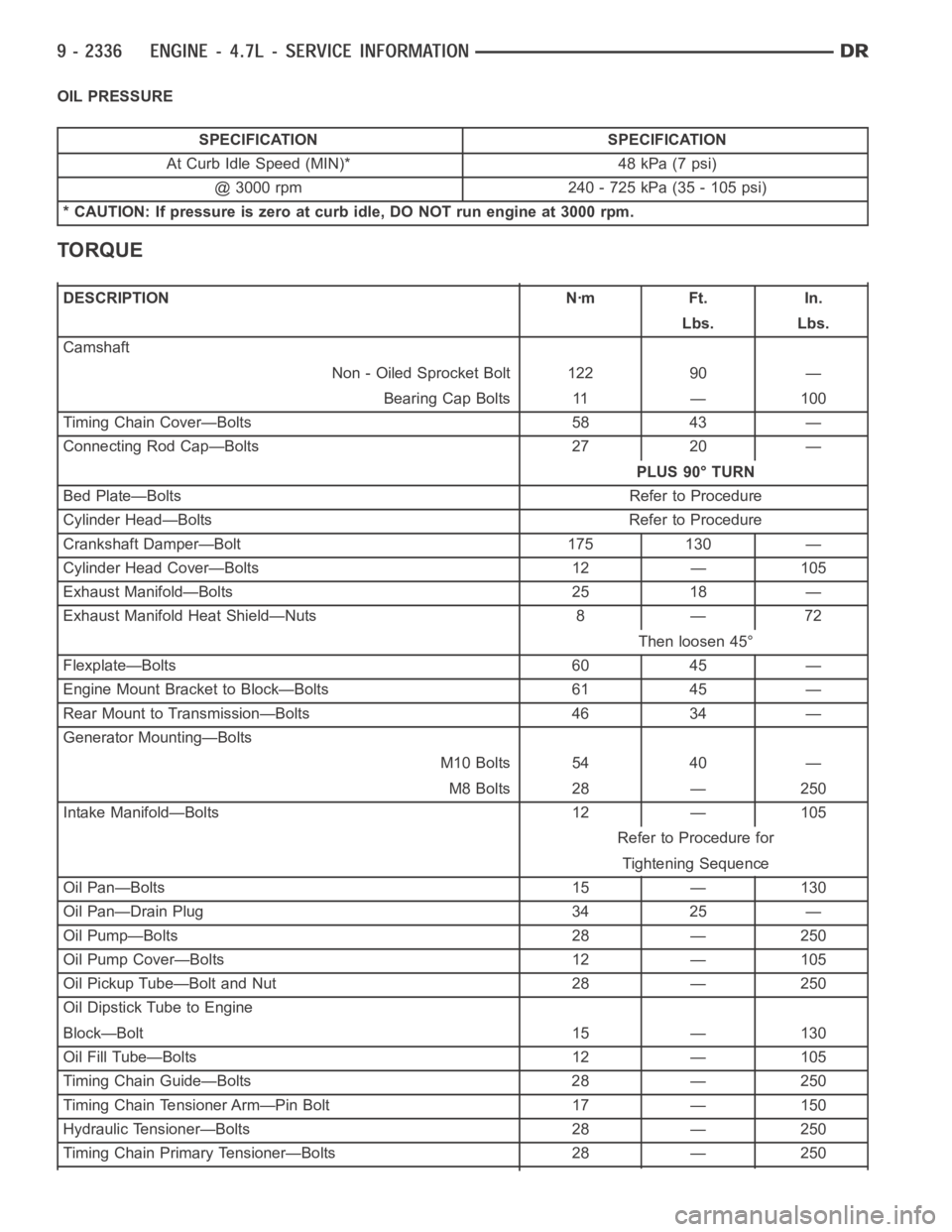

OIL PRESSURE

SPECIFICATION SPECIFICATION

At Curb Idle Speed (MIN)* 48 kPa (7 psi)

@ 3000 rpm 240 - 725 kPa (35 - 105 psi)

* CAUTION: If pressure is zero at curb idle, DO NOT run engine at 3000 rpm.

TORQUE

DESCRIPTION Nꞏm Ft. In.

Lbs. Lbs.

Camshaft

Non - Oiled Sprocket Bolt 122 90 —

Bearing Cap Bolts 11 — 100

Timing Chain Cover—Bolts 58 43 —

Connecting Rod Cap—Bolts 27 20 —

PLUS 90° TURN

Bed Plate—Bolts Refer to Procedure

Cylinder Head—Bolts Refer to Procedure

Crankshaft Damper—Bolt 175 130 —

Cylinder Head Cover—Bolts 12 — 105

Exhaust Manifold—Bolts 25 18 —

Exhaust Manifold Heat Shield—Nuts 8 — 72

Then loosen 45°

Flexplate—Bolts 60 45 —

Engine Mount Bracket to Block—Bolts 61 45 —

Rear Mount to Transmission—Bolts 46 34 —

Generator Mounting—Bolts

M10 Bolts 54 40 —

M8 Bolts 28 — 250

Intake Manifold—Bolts 12 — 105

Refer to Procedure for

Tightening Sequence

Oil Pan—Bolts 15 — 130

Oil Pan—Drain Plug 34 25 —

Oil Pump—Bolts 28 — 250

Oil Pump Cover—Bolts 12 — 105

Oil Pickup Tube—Bolt and Nut 28 — 250

Oil Dipstick Tube to Engine

Block—Bolt 15 — 130

Oil Fill Tube—Bolts 12 — 105

Timing Chain Guide—Bolts 28 — 250

Timing Chain Tensioner Arm—Pin Bolt 17 — 150

Hydraulic Tensioner—Bolts 28 — 250

Timing Chain Primary Tensioner—Bolts 28 — 250