transmission DODGE RAM SRT-10 2006 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1688 of 5267

ENGINE BLOCK

DESCRIPTION

The cylinder block is made of cast iron.The block is a closed deck design with the left bank forward. To provide

high rigidity and improved NVH an enhanced compacted graphite bedplate isbolted to the block. The block design

allows coolant flow between the cylinders bores, and an internal coolant bypass to a single poppet inlet thermostat

is included in the cast aluminum front cover.

STANDARD PROCEDURE - CYLINDER BORE HONING

Before honing, stuff plenty of clean shop towels under

the bores and over the crankshaft to keep abrasive

materials from entering the crankshaft area.

1. Used carefully, the Cylinder Bore Sizing Hone

C-823, equipped with 220 grit stones, is the best

tool for this job. In addition to deglazing, it will

reduce taper and out-of-round, as well as removing

light scuffing, scoring and scratches. Usually, a few

strokes will clean up a bore and maintain the

required limits.

CAUTION: DO NOT use rigid type hones to remove

cylinder wall glaze.

2. Deglazing of the cylinder walls may be done if the

cylinder bore is straight and round. Use a cylinder

surfacing hone, Honing Tool C-3501, equipped with

280 grit stones (C-3501-3810). about 20-60

strokes, depending on the bore condition, will be

sufficient to provide a satisfactory surface. Using

honing oil C-3501-3880, or a light honing oil, avail-

able from major oil distributors.

CAUTION: DO NOT use engine or transmission oil, mineral spirits, or kerosene.

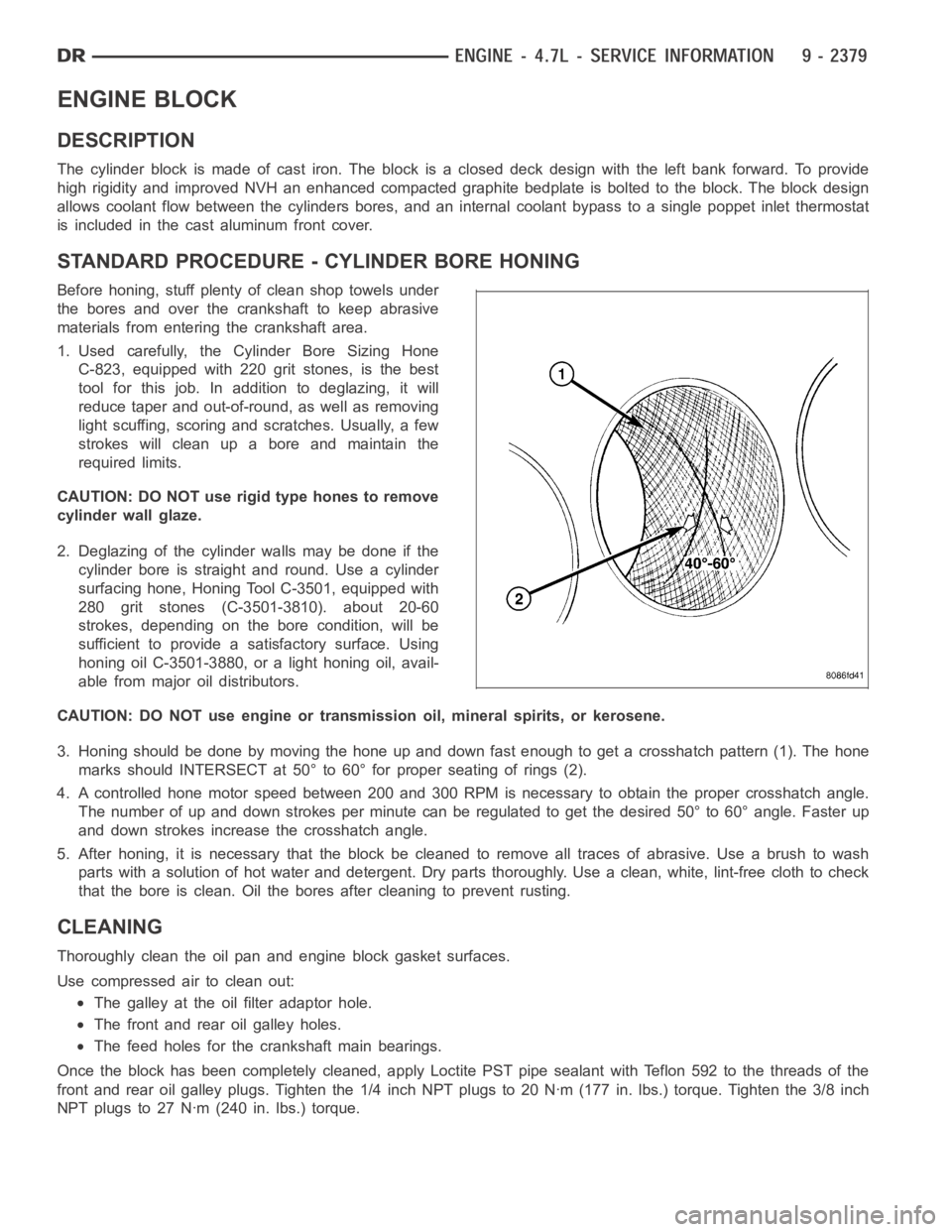

3. Honing should be done by moving the hone up and down fast enough to get a crosshatch pattern (1). The hone

marks should INTERSECT at 50° to 60° for proper seating of rings (2).

4. A controlled hone motor speed between 200 and 300 RPM is necessary to obtain the proper crosshatch angle.

The number of up and down strokes per minute can be regulated to get the desired 50° to 60° angle. Faster up

and down strokes increase the crosshatch angle.

5. After honing, it is necessary that the block be cleaned to remove all traces of abrasive. Use a brush to wash

parts with a solution of hot water and detergent. Dry parts thoroughly. Usea clean, white, lint-free cloth to check

that the bore is clean. Oil the bores after cleaning to prevent rusting.

CLEANING

Thoroughly clean the oil pan and engine block gasket surfaces.

Use compressed air to clean out:

The galley at the oil filter adaptor hole.

The front and rear oil galley holes.

The feed holes for the crankshaft main bearings.

Once the block has been completely cleaned, apply Loctite PST pipe sealantwith Teflon 592 to the threads of the

front and rear oil galley plugs. Tighten the 1/4 inch NPT plugs to 20 Nꞏm (177in. lbs.) torque. Tighten the 3/8 inch

NPT plugs to 27 Nꞏm (240 in. lbs.) torque.

Page 1700 of 5267

SEAL - CRANKSHAFT OIL - FRONT

REMOVAL

1. Disconnect negative cable from battery.

2. Remove accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

3. Remove A/C compressor mouning fasteners and

set aside.

4. Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

5. Remove upper radiator hose.

6. Disconnect electrical connector for fan mounted

inside radiator shroud.

7. Remove radiator shroud attaching fasteners.

NOTE: Transmission cooler line snaps into shroud

lower right hand corner.

8. Remove radiator cooling fan and shroud (Refer to

7 - COOLING/ENGINE/RADIATOR FAN -

REMOVAL).

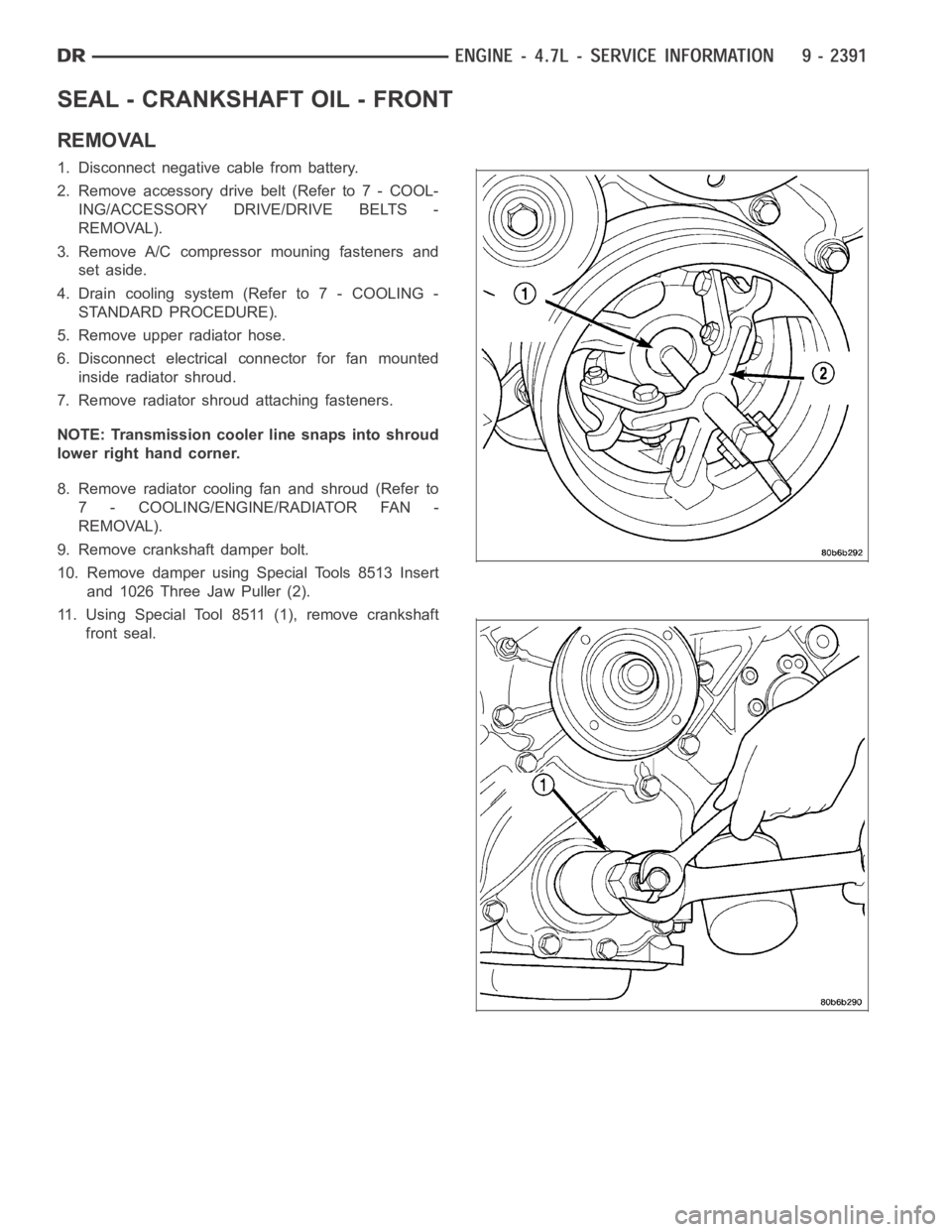

9. Remove crankshaft damper bolt.

10. Remove damper using Special Tools 8513 Insert

and 1026 Three Jaw Puller (2).

11. Using Special Tool 8511 (1), remove crankshaft

front seal.

Page 1703 of 5267

INSTALLATION

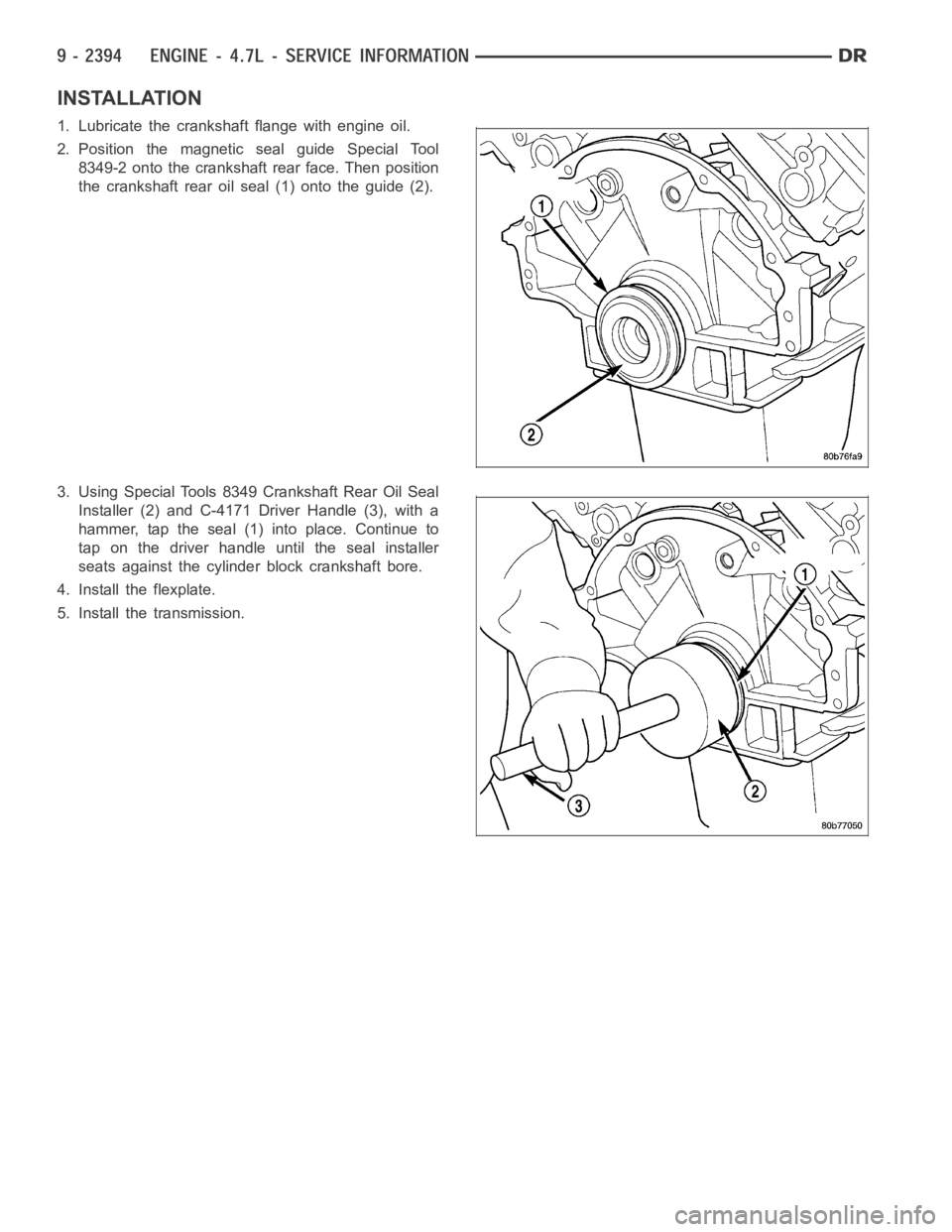

1. Lubricate the crankshaft flange with engine oil.

2. Position the magnetic seal guide Special Tool

8349-2 onto the crankshaft rear face. Then position

the crankshaft rear oil seal (1) onto the guide (2).

3. Using Special Tools 8349 Crankshaft Rear Oil Seal

Installer (2) and C-4171 Driver Handle (3), with a

hammer, tap the seal (1) into place. Continue to

tap on the driver handle until the seal installer

seats against the cylinder block crankshaft bore.

4. Install the flexplate.

5. Install the transmission.

Page 1704 of 5267

FLEX PLATE

REMOVAL

1. Remove the transmission. (Refer to 21 - TRANS-

MISSION/TRANSAXLE/AUTOMATIC - 45RFE/

545RFE - REMOVAL).

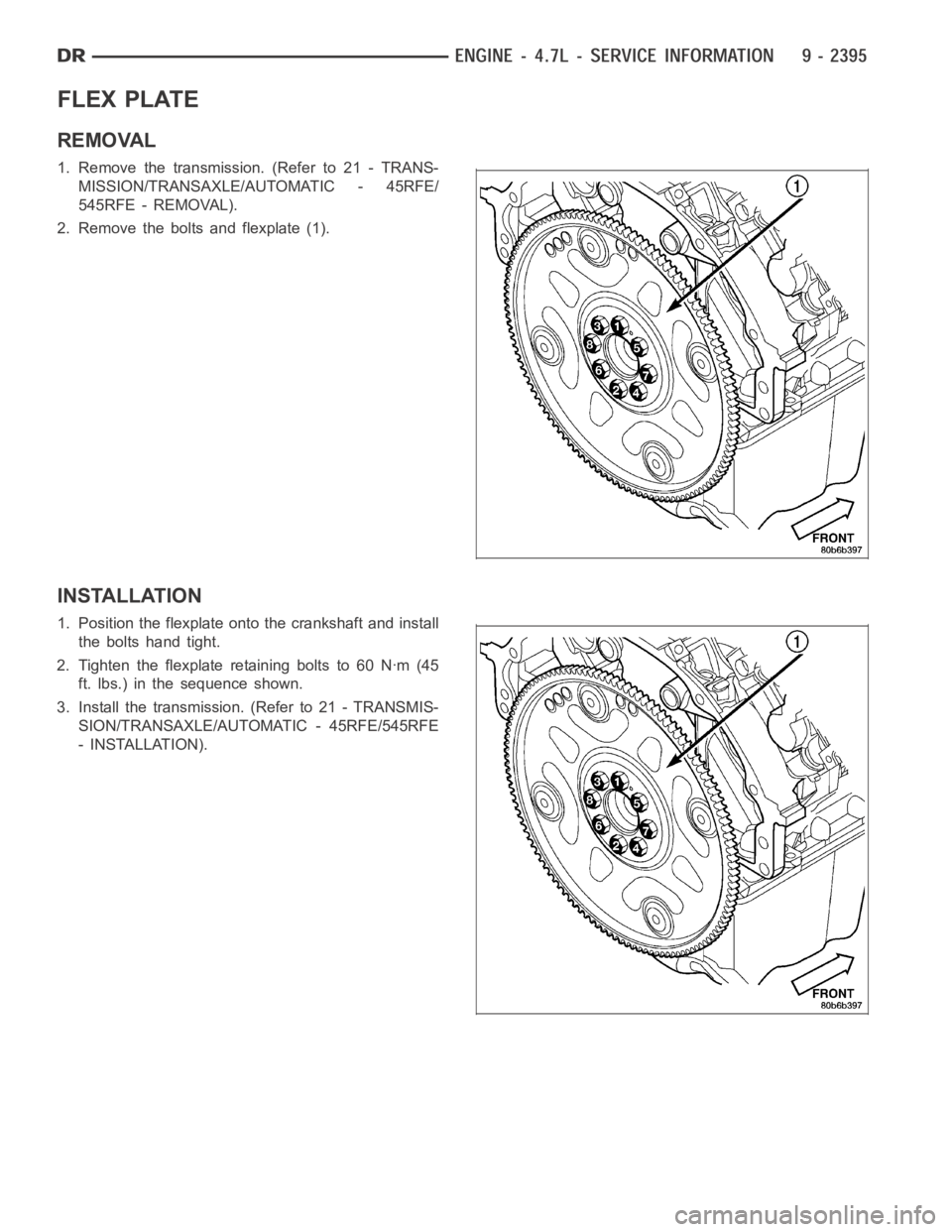

2. Remove the bolts and flexplate (1).

INSTALLATION

1. Position the flexplate ontothe crankshaft and install

the bolts hand tight.

2. Tighten the flexplate retaining bolts to 60 Nꞏm (45

ft. lbs.) in the sequence shown.

3. Install the transmission. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/AUTOMATIC - 45RFE/545RFE

- INSTALLATION).

Page 1712 of 5267

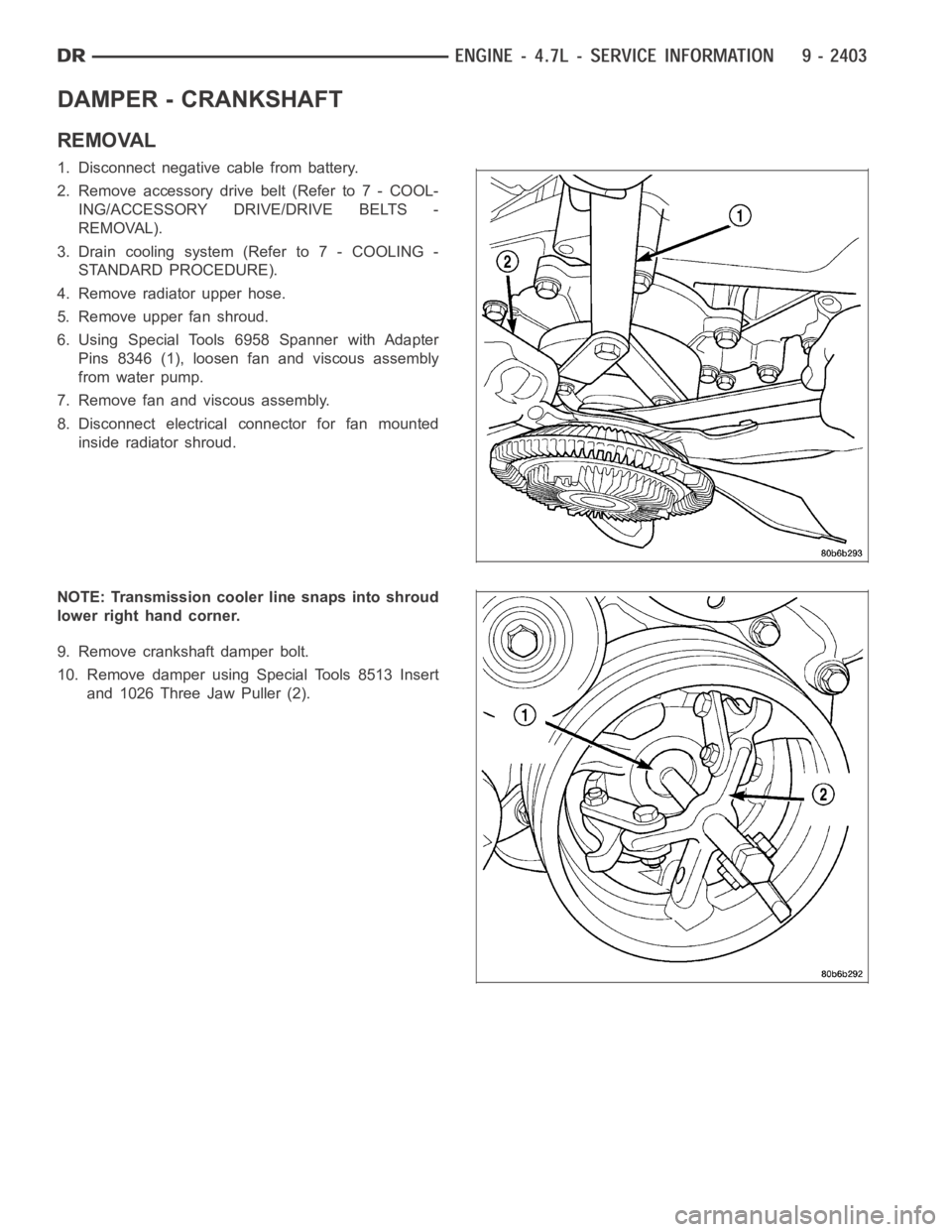

DAMPER - CRANKSHAFT

REMOVAL

1. Disconnect negative cable from battery.

2. Remove accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

3. Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

4. Remove radiator upper hose.

5. Remove upper fan shroud.

6. Using Special Tools 6958 Spanner with Adapter

Pins 8346 (1), loosen fan and viscous assembly

from water pump.

7. Remove fan and viscous assembly.

8. Disconnect electrical connector for fan mounted

inside radiator shroud.

NOTE: Transmission cooler line snaps into shroud

lower right hand corner.

9. Remove crankshaft damper bolt.

10. Remove damper using Special Tools 8513 Insert

and 1026 Three Jaw Puller (2).

Page 1714 of 5267

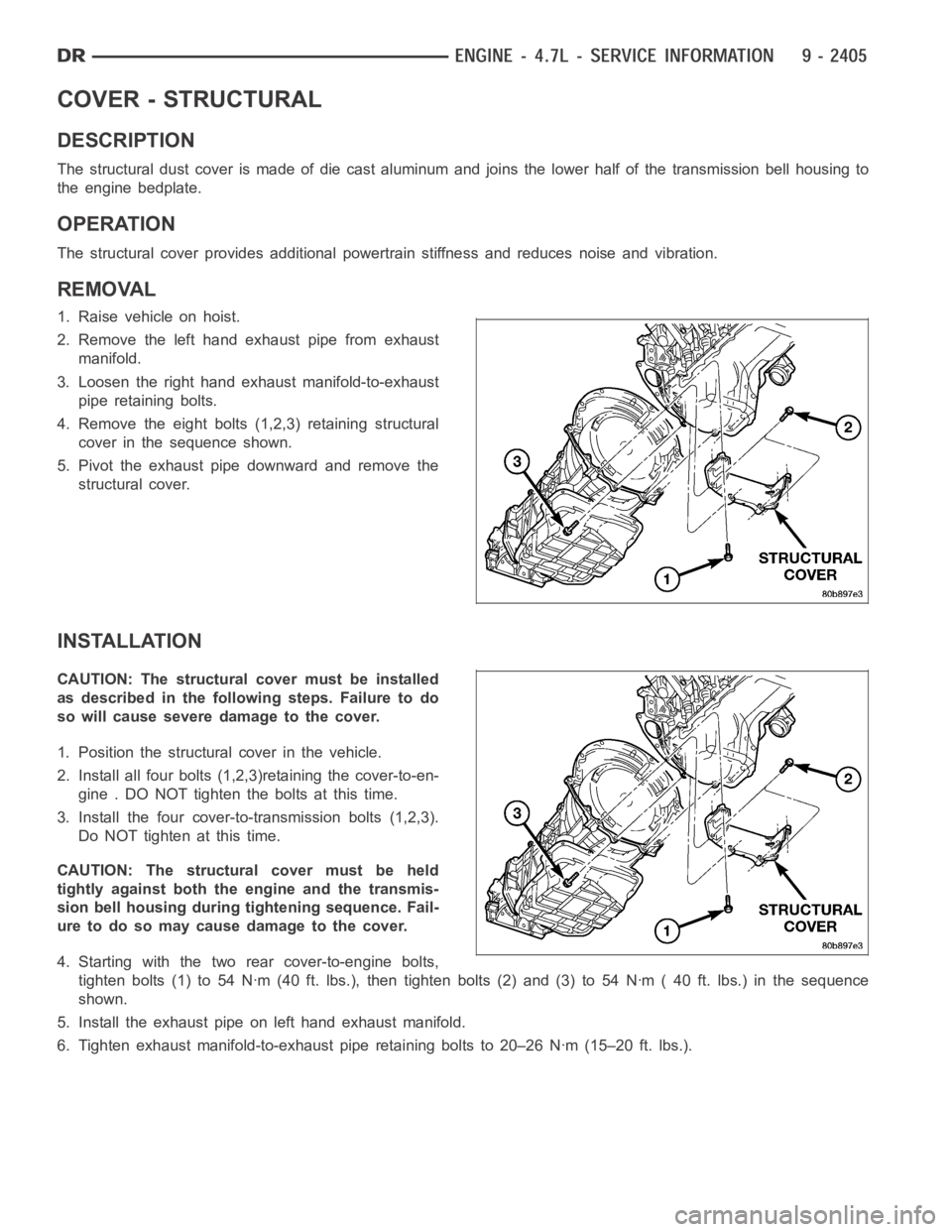

COVER - STRUCTURAL

DESCRIPTION

The structural dust cover is made of die cast aluminum and joins the lower half of the transmission bell housing to

the engine bedplate.

OPERATION

The structural cover provides additional powertrain stiffness and reduces noise and vibration.

REMOVAL

1. Raise vehicle on hoist.

2. Remove the left hand exhaust pipe from exhaust

manifold.

3. Loosen the right hand exhaust manifold-to-exhaust

pipe retaining bolts.

4. Remove the eight bolts (1,2,3) retaining structural

cover in the sequence shown.

5. Pivot the exhaust pipe downward and remove the

structural cover.

INSTALLATION

CAUTION: The structural cover must be installed

as described in the following steps. Failure to do

so will cause severe damage to the cover.

1. Position the structural cover in the vehicle.

2. Install all four bolts (1,2,3)retaining the cover-to-en-

gine . DO NOT tighten the bolts at this time.

3. Install the four cover-to-transmission bolts (1,2,3).

Do NOT tighten at this time.

CAUTION: The structural cover must be held

tightly against both the engine and the transmis-

sion bell housing during tightening sequence. Fail-

ure to do so may cause damage to the cover.

4. Starting with the two rearcover-to-engine bolts,

tighten bolts (1) to 54 Nꞏm (40 ft. lbs.), then tighten bolts (2) and (3) to 54Nꞏm ( 40 ft. lbs.) in the sequence

shown.

5. Install the exhaust pipe on left hand exhaust manifold.

6. Tighten exhaust manifold-to-exhaust pipe retaining bolts to 20–26 Nꞏm(15–20 ft. lbs.).

Page 1719 of 5267

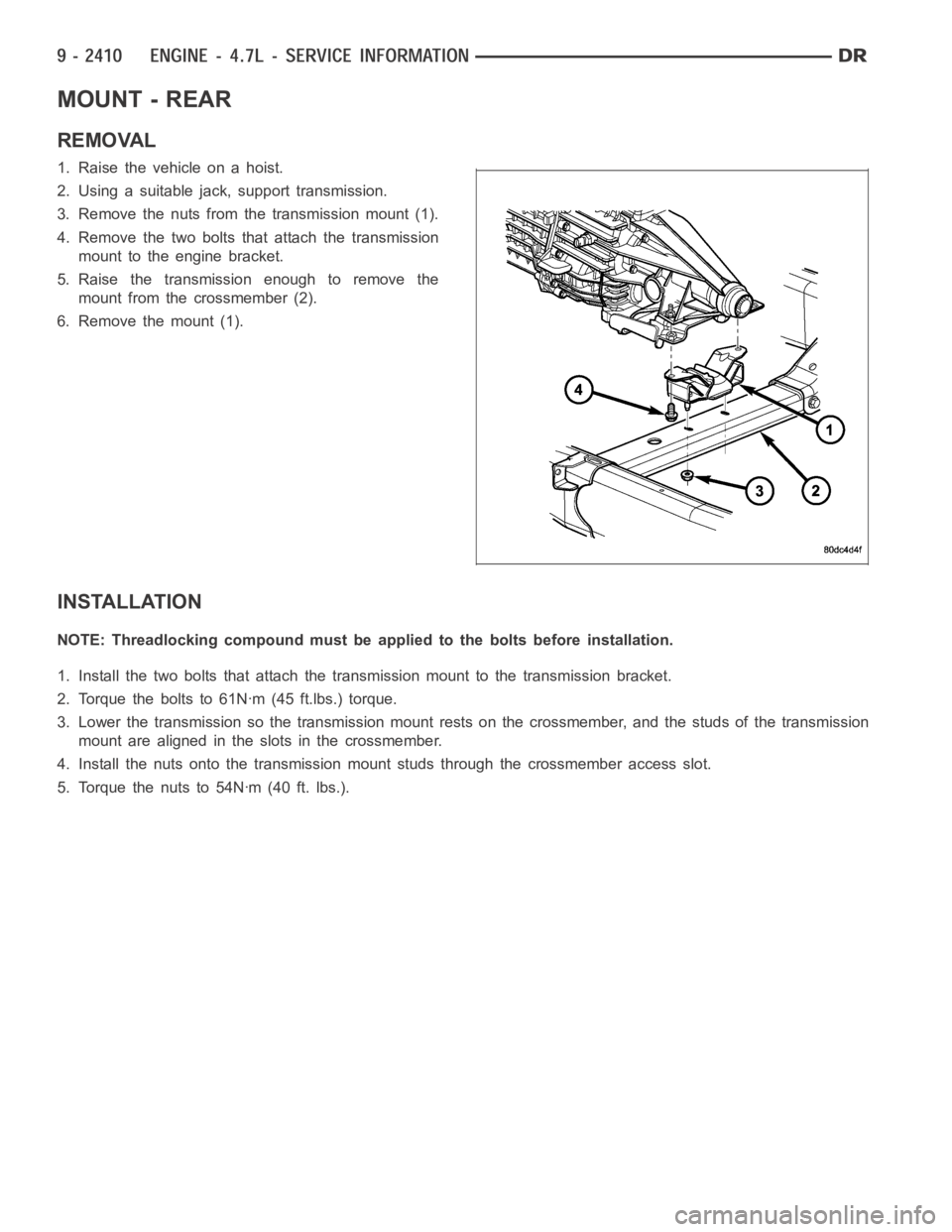

MOUNT - REAR

REMOVAL

1. Raise the vehicle on a hoist.

2. Using a suitable jack, support transmission.

3. Remove the nuts from the transmission mount (1).

4. Remove the two bolts that attach the transmission

mount to the engine bracket.

5. Raise the transmission enough to remove the

mount from the crossmember (2).

6. Remove the mount (1).

INSTALLATION

NOTE: Threadlocking compound must be applied to the bolts before installation.

1. Install the two bolts that attach the transmission mount to the transmission bracket.

2. Torque the bolts to 61Nꞏm (45 ft.lbs.) torque.

3. Lower the transmission so the transmission mount rests on the crossmember, and the studs of the transmission

mount are aligned in the slots in the crossmember.

4. Install the nuts onto the transmission mount studs through the crossmember access slot.

5. Torque the nuts to 54Nꞏm (40 ft. lbs.).

Page 1768 of 5267

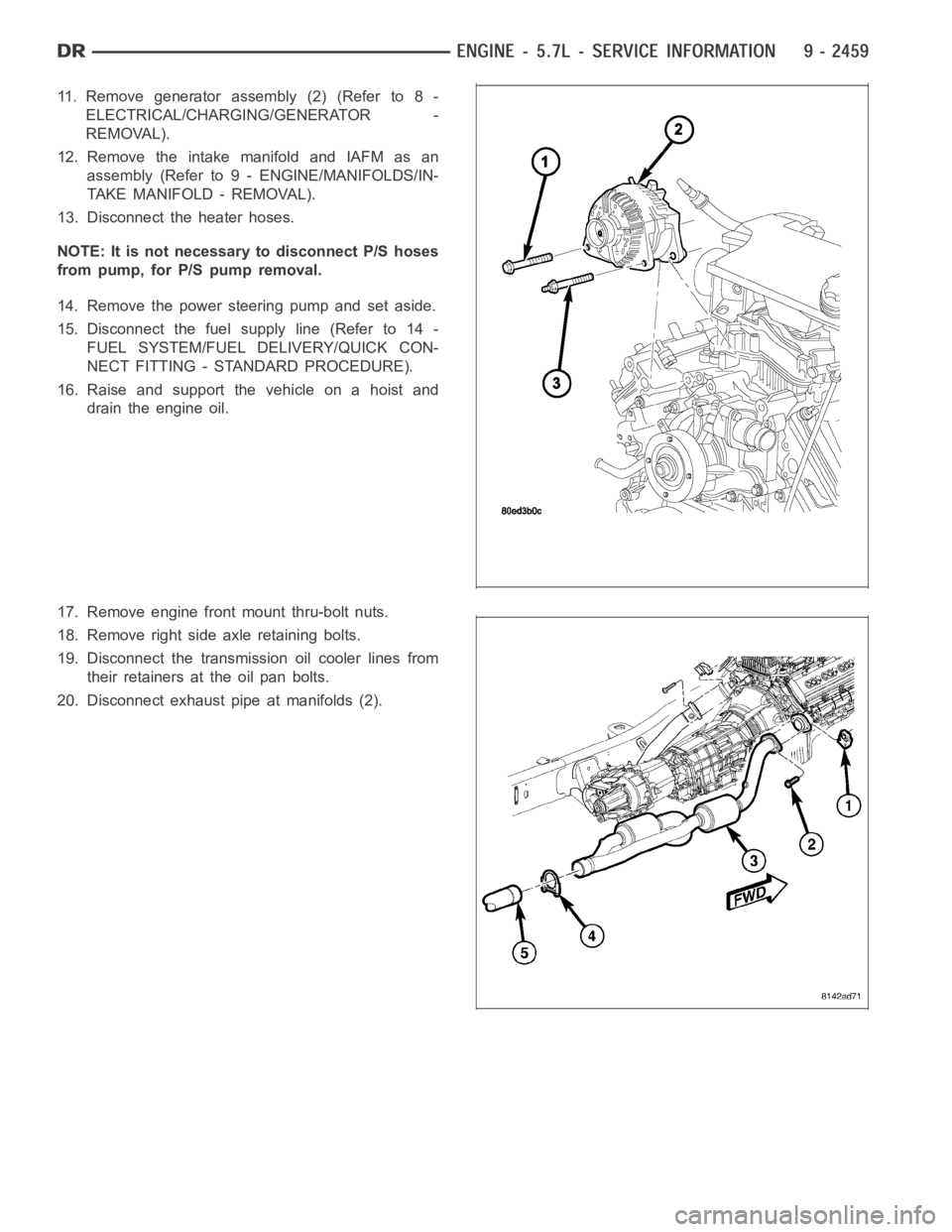

11. Remove generator assembly (2) (Refer to 8 -

ELECTRICAL/CHARGING/GENERATOR -

REMOVAL).

12. Remove the intake manifold and IAFM as an

assembly (Refer to 9 - ENGINE/MANIFOLDS/IN-

TAKE MANIFOLD - REMOVAL).

13. Disconnect the heater hoses.

NOTE: It is not necessary to disconnect P/S hoses

from pump, for P/S pump removal.

14. Remove the power steering pump and set aside.

15. Disconnect the fuel supply line (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/QUICK CON-

NECT FITTING - STANDARD PROCEDURE).

16. Raise and support the vehicle on a hoist and

drain the engine oil.

17. Remove engine front mount thru-bolt nuts.

18. Remove right side axle retaining bolts.

19. Disconnect the transmission oil cooler lines from

their retainers at the oil pan bolts.

20. Disconnect exhaust pipe at manifolds (2).

Page 1769 of 5267

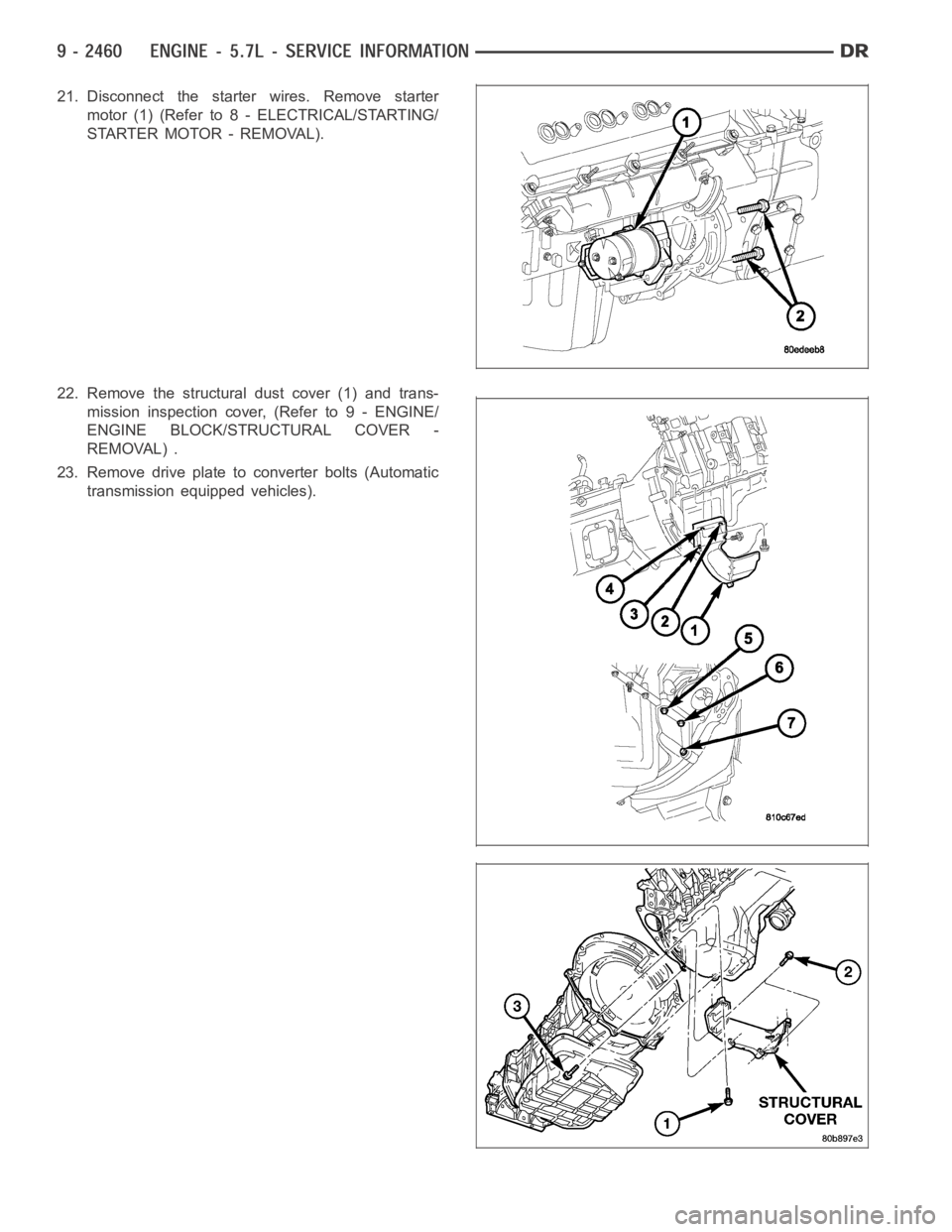

21. Disconnect the starter wires. Remove starter

motor (1) (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - REMOVAL).

22. Remove the structural dust cover (1) and trans-

mission inspection cover, (Refer to 9 - ENGINE/

ENGINE BLOCK/STRUCTURAL COVER -

REMOVAL) .

23. Remove drive plate to converter bolts (Automatic

transmission equipped vehicles).

Page 1770 of 5267

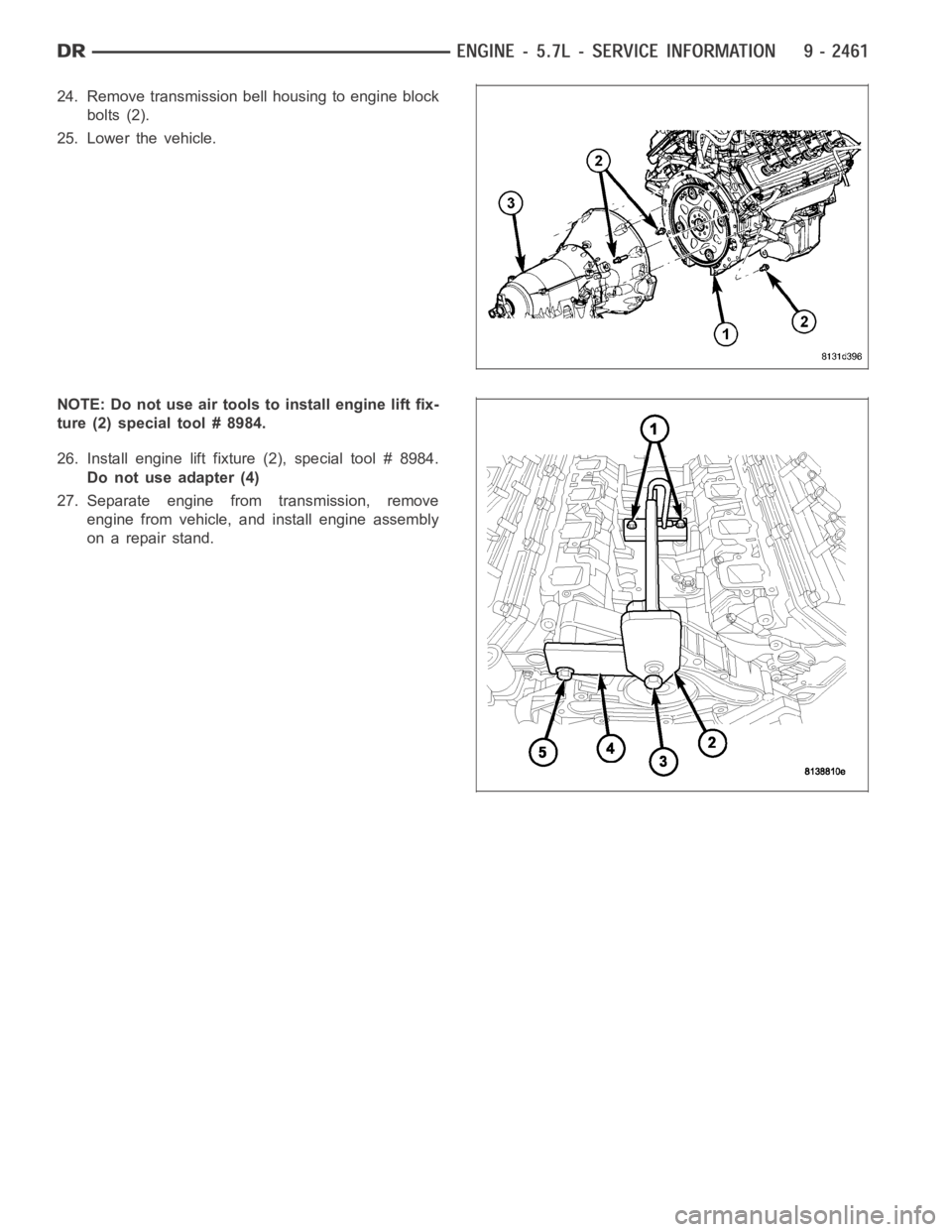

24. Remove transmission bell housing to engine block

bolts (2).

25. Lower the vehicle.

NOTE: Do not use air tools to install engine lift fix-

ture (2) special tool # 8984.

26. Install engine lift fixture (2), special tool # 8984.

Do not use adapter (4)

27. Separate engine from transmission, remove

engine from vehicle, and install engine assembly

on a repair stand.