DODGE RAM SRT-10 2006 Service Repair Manual

RAM SRT-10 2006

DODGE

DODGE

https://www.carmanualsonline.info/img/12/56917/w960_56917-0.png

DODGE RAM SRT-10 2006 Service Repair Manual

Trending: four wheel drive, load capacity, spark plugs, set clock, transmission, check engine, wheel size

Page 4291 of 5267

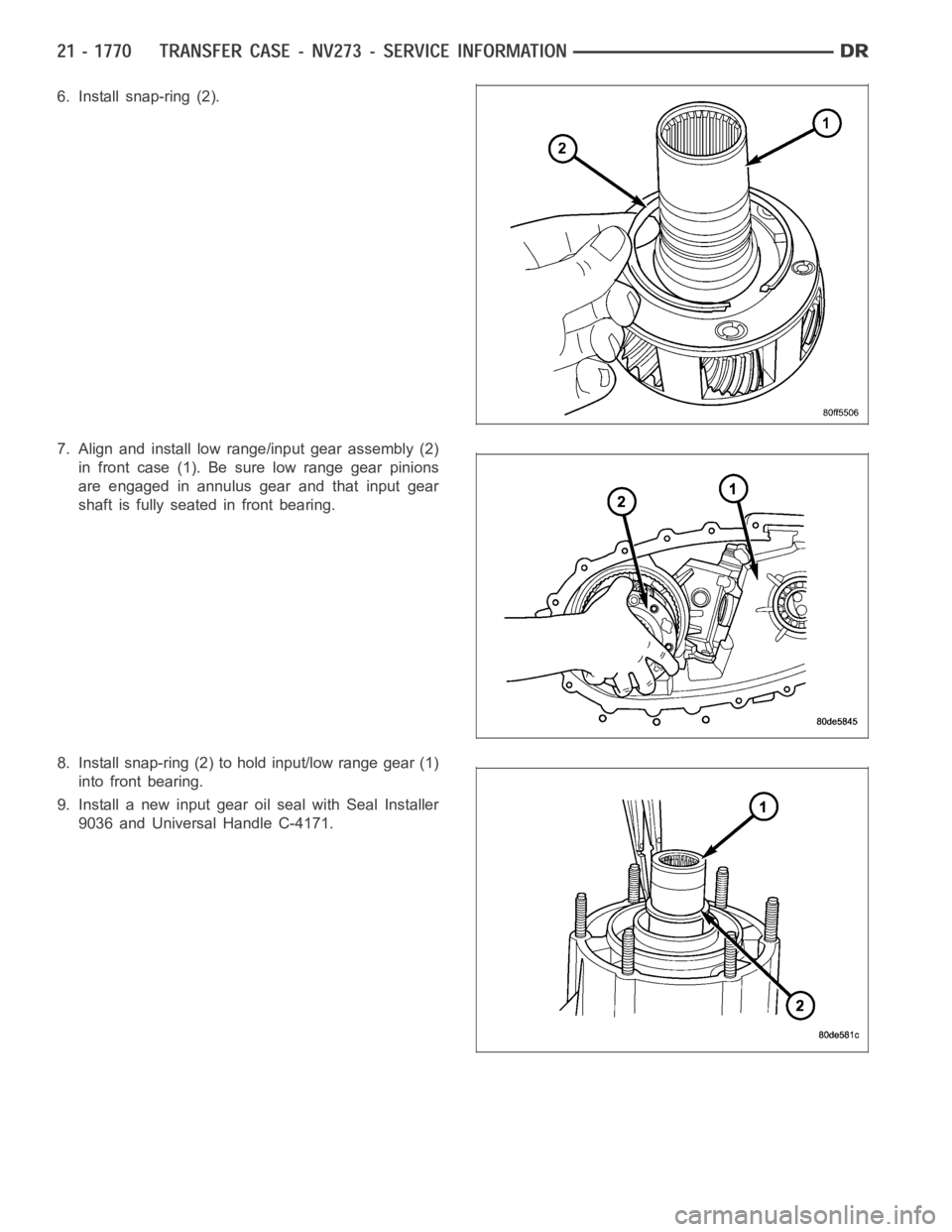

6. Install snap-ring (2).

7. Align and install low range/input gear assembly (2)

in front case (1). Be sure low range gear pinions

are engaged in annulus gear and that input gear

shaft is fully seated in front bearing.

8. Install snap-ring (2) to hold input/low range gear (1)

into front bearing.

9. Install a new input gear oil seal with Seal Installer

9036 and Universal Handle C-4171.

Page 4292 of 5267

SHIFT FORKS AND MAINSHAFT

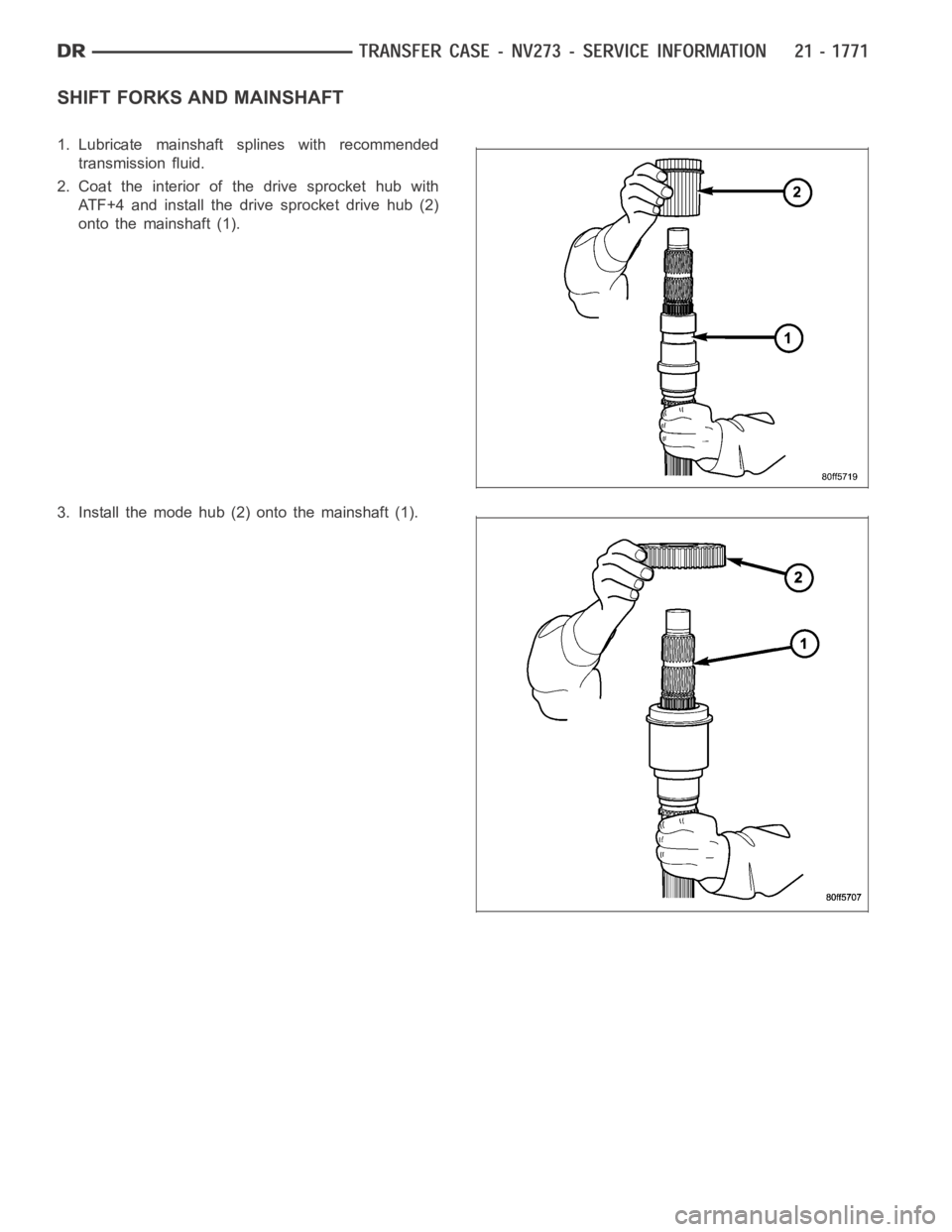

1. Lubricate mainshaft splines with recommended

transmission fluid.

2. Coat the interior of the drive sprocket hub with

ATF+4 and install the drive sprocket drive hub (2)

onto the mainshaft (1).

3. Install the mode hub (2) onto the mainshaft (1).

Page 4293 of 5267

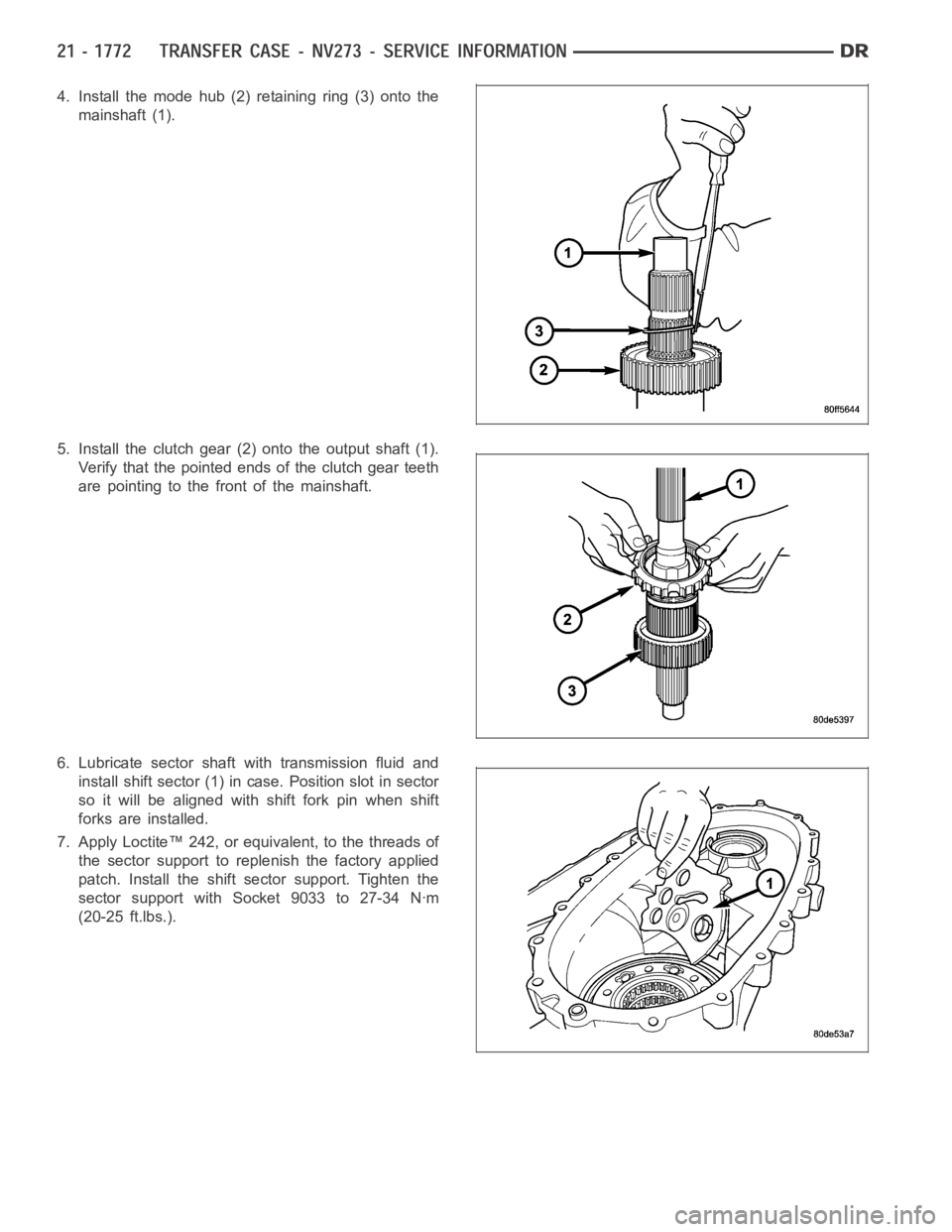

4. Install the mode hub (2) retaining ring (3) onto the

mainshaft (1).

5. Install the clutch gear (2) onto the output shaft (1).

Verify that the pointed ends of the clutch gear teeth

are pointing to the front of the mainshaft.

6. Lubricate sector shaft with transmission fluid and

install shift sector (1) in case. Position slot in sector

so it will be aligned with shift fork pin when shift

forks are installed.

7. Apply Loctite™ 242, or equivalent, to the threads of

the sector support to replenish the factory applied

patch. Install the shift sector support. Tighten the

sector support with Socket 9033 to 27-34 Nꞏm

(20-25 ft.lbs.).

Page 4294 of 5267

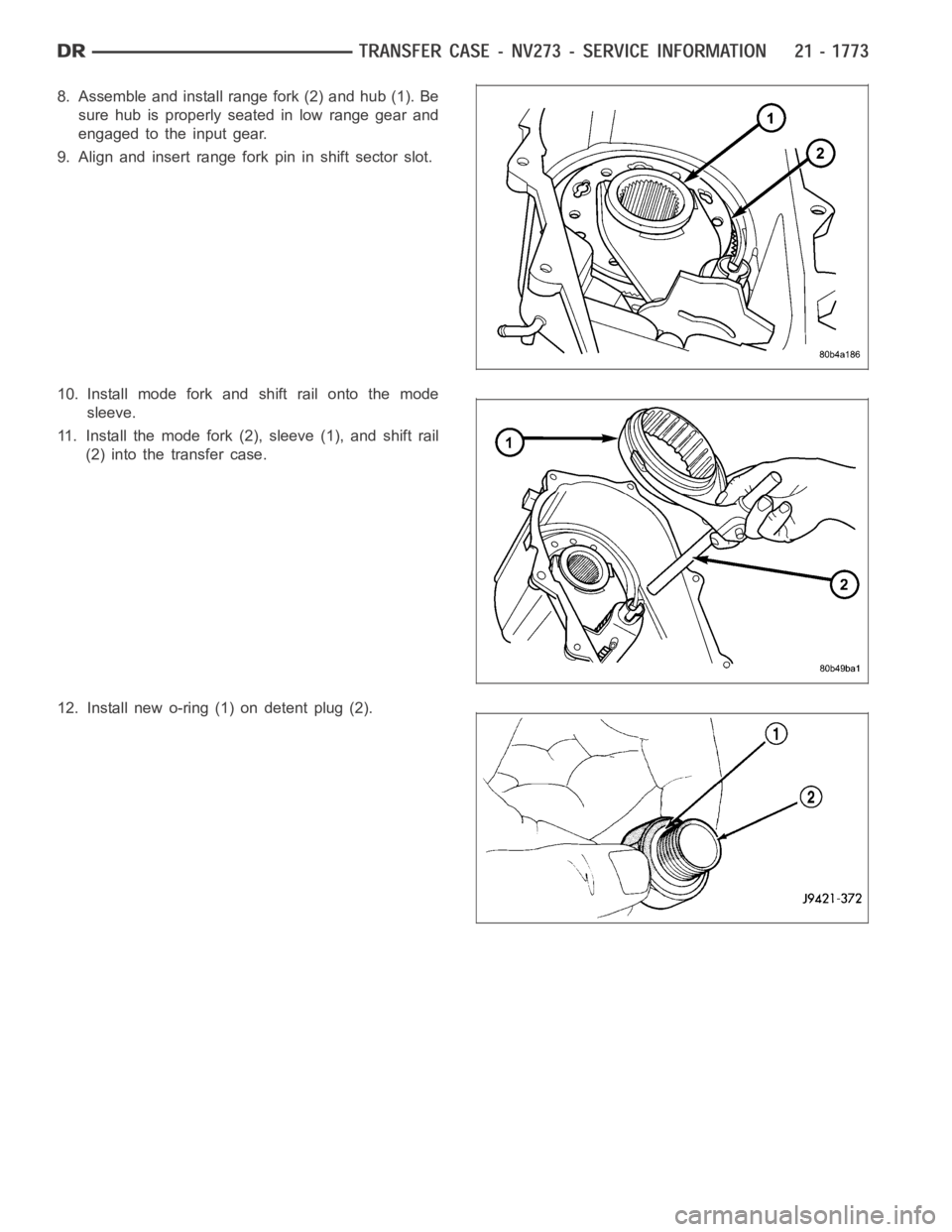

8. Assemble and install range fork (2) and hub (1). Be

sure hub is properly seated in low range gear and

engaged to the input gear.

9. Align and insert range fork pin in shift sector slot.

10. Install mode fork and shift rail onto the mode

sleeve.

11. Install the mode fork (2), sleeve (1), and shift rail

(2) into the transfer case.

12. Install new o-ring (1) on detent plug (2).

Page 4295 of 5267

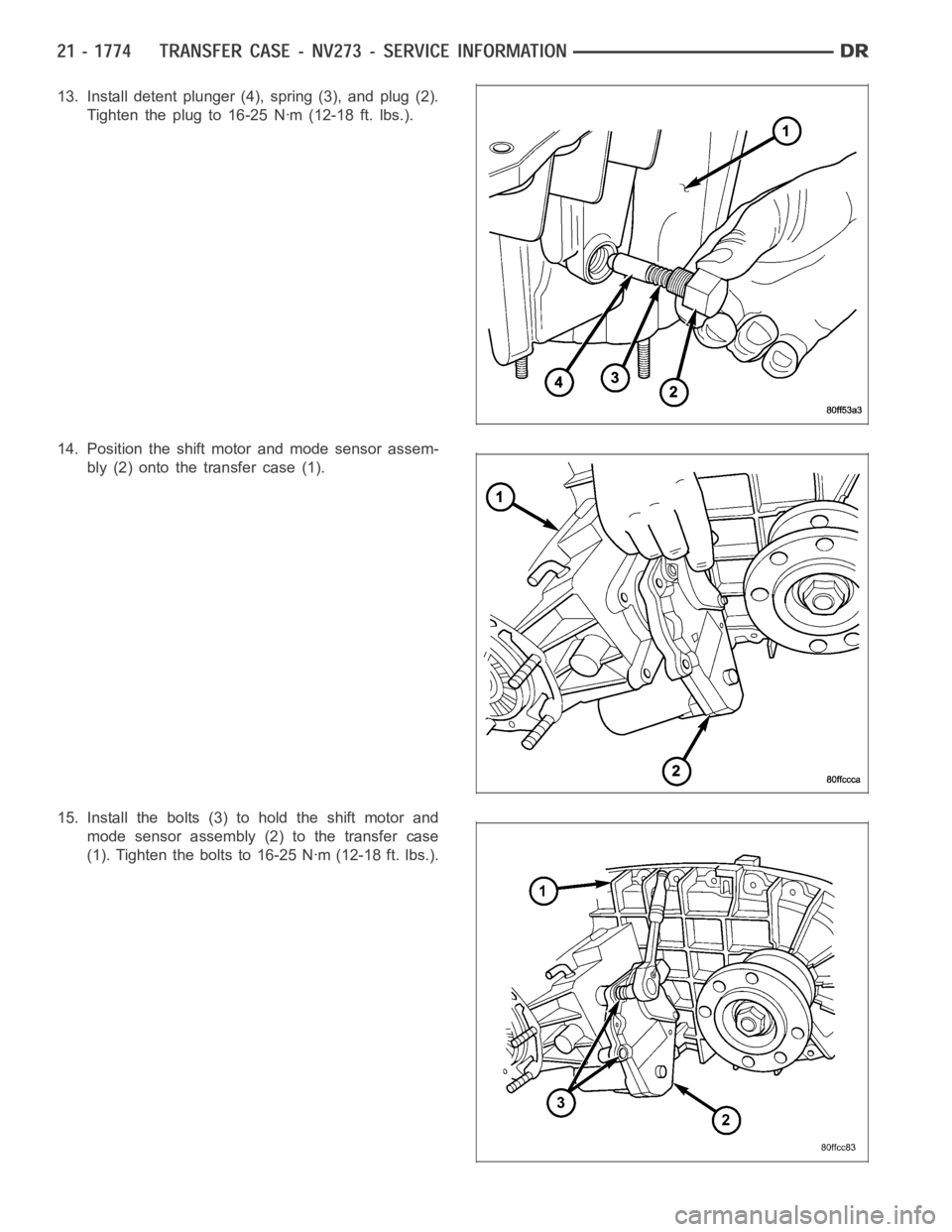

13. Install detent plunger (4), spring (3), and plug (2).

Tighten the plug to 16-25 Nꞏm (12-18 ft. lbs.).

14. Position the shift motor and mode sensor assem-

bly (2) onto the transfer case (1).

15. Install the bolts (3) to hold the shift motor and

mode sensor assembly (2) to the transfer case

(1). Tighten the bolts to 16-25 Nꞏm (12-18 ft. lbs.).

Page 4296 of 5267

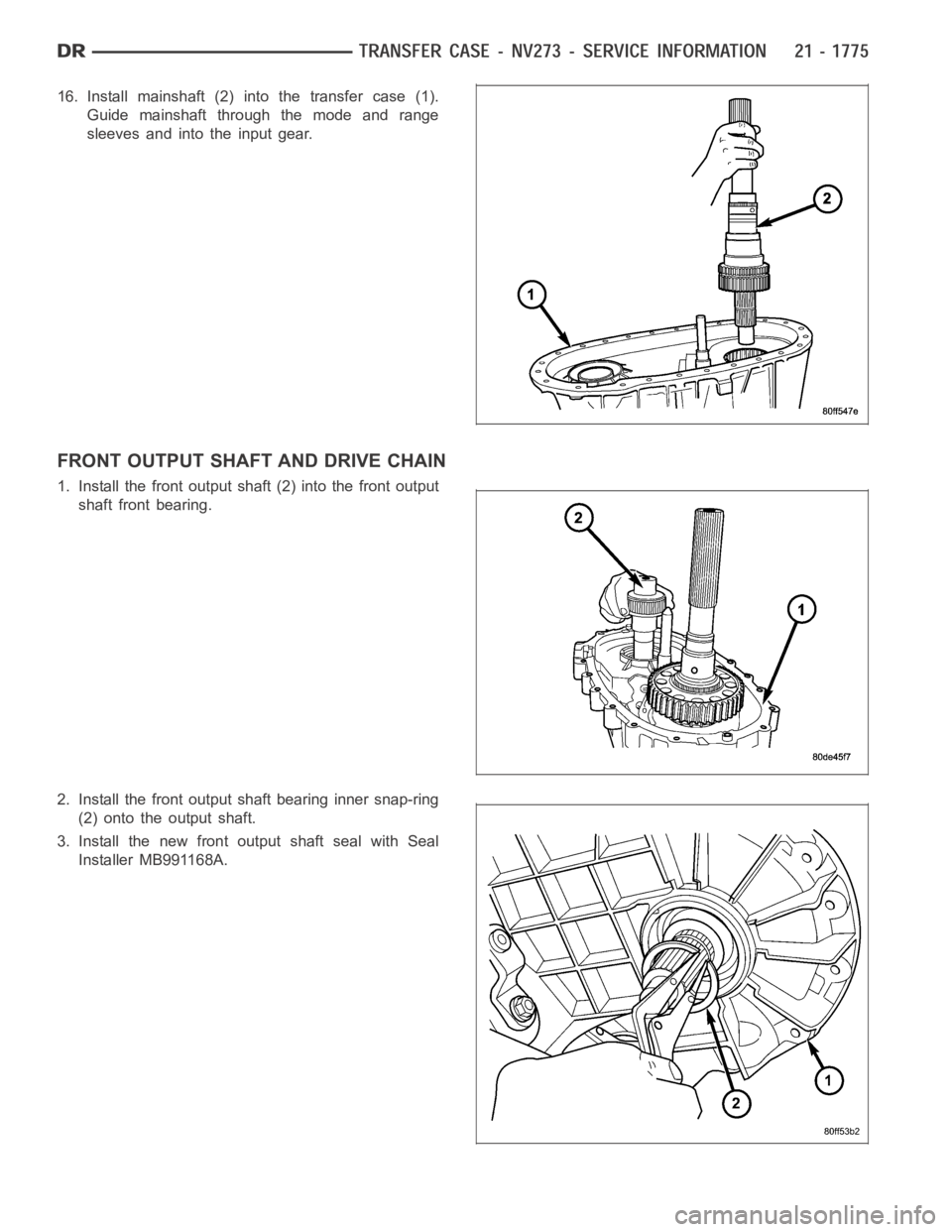

16. Install mainshaft (2) into the transfer case (1).

Guide mainshaft through the mode and range

sleeves and into the input gear.

FRONT OUTPUT SHAFT AND DRIVE CHAIN

1. Install the front output shaft (2) into the front output

shaft front bearing.

2. Install the front output shaft bearing inner snap-ring

(2) onto the output shaft.

3. Install the new front output shaft seal with Seal

Installer MB991168A.

Page 4297 of 5267

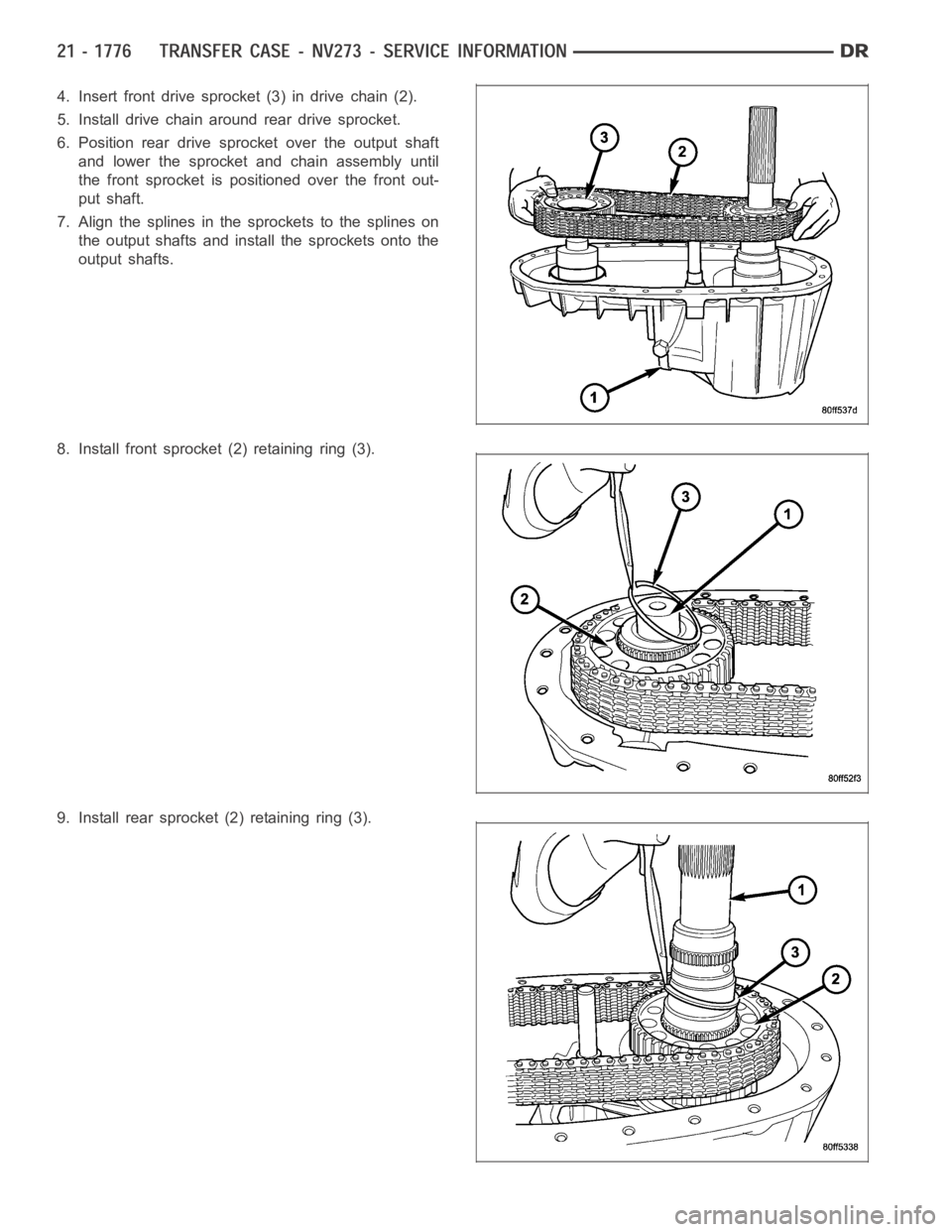

4. Insert front drive sprocket (3) in drive chain (2).

5. Install drive chain around rear drive sprocket.

6. Position rear drive sprocket over the output shaft

and lower the sprocket and chain assembly until

the front sprocket is positioned over the front out-

put shaft.

7. Align the splines in the sprockets to the splines on

the output shafts and install the sprockets onto the

output shafts.

8. Install front sprocket (2) retaining ring (3).

9. Install rear sprocket (2) retaining ring (3).

Page 4298 of 5267

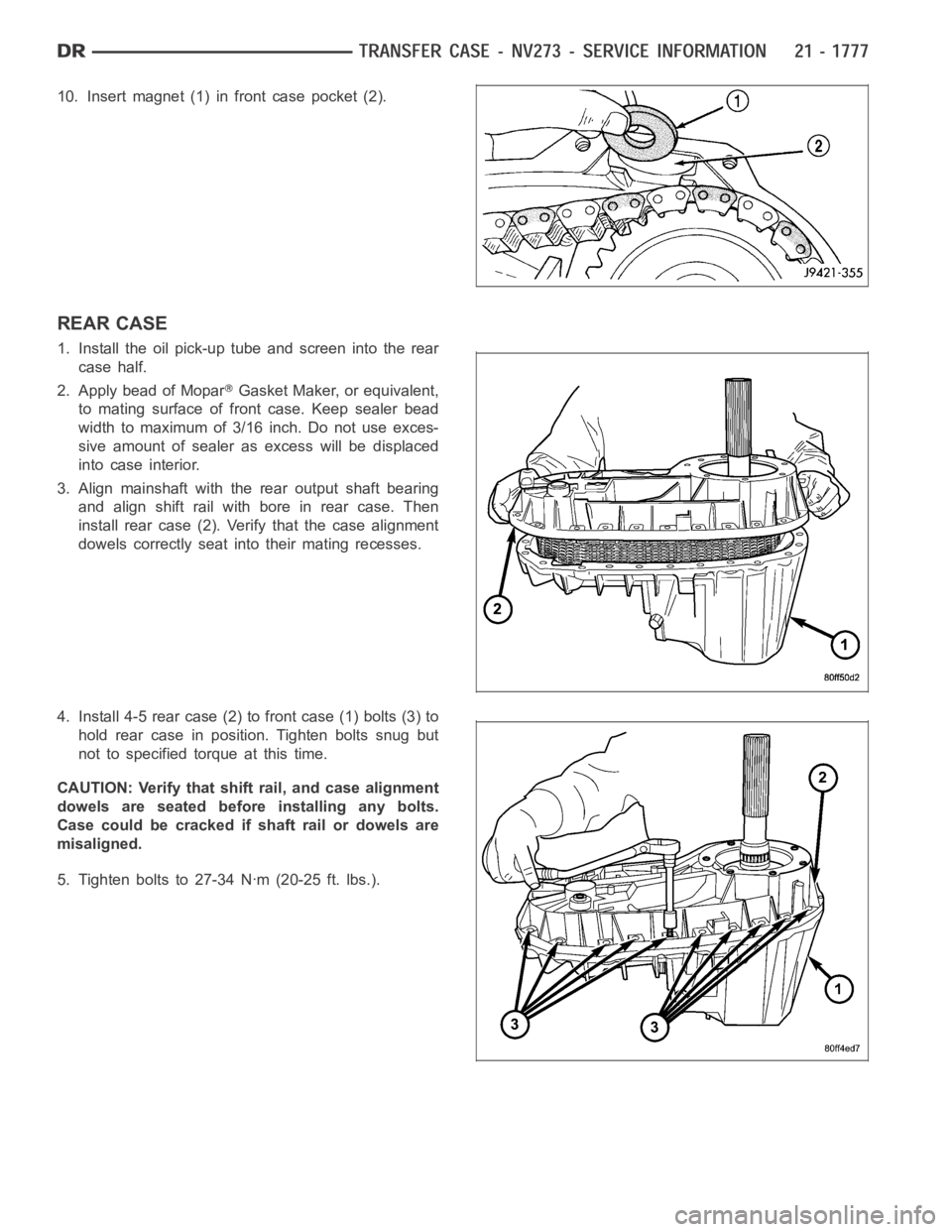

10. Insert magnet (1) in front case pocket (2).

REAR CASE

1. Install the oil pick-up tube and screen into the rear

case half.

2. Apply bead of Mopar

Gasket Maker, or equivalent,

to mating surface of front case. Keep sealer bead

width to maximum of 3/16 inch. Do not use exces-

sive amount of sealer as excess will be displaced

into case interior.

3. Align mainshaft with the rear output shaft bearing

and align shift rail with bore in rear case. Then

install rear case (2). Verify that the case alignment

dowels correctly seat into their mating recesses.

4. Install 4-5 rear case (2) to front case (1) bolts (3) to

hold rear case in position. Tighten bolts snug but

not to specified torque at this time.

CAUTION: Verify that shift rail, and case alignment

dowels are seated before installing any bolts.

Case could be cracked if shaft rail or dowels are

misaligned.

5. Tighten bolts to 27-34 Nꞏm (20-25 ft. lbs.).

Page 4299 of 5267

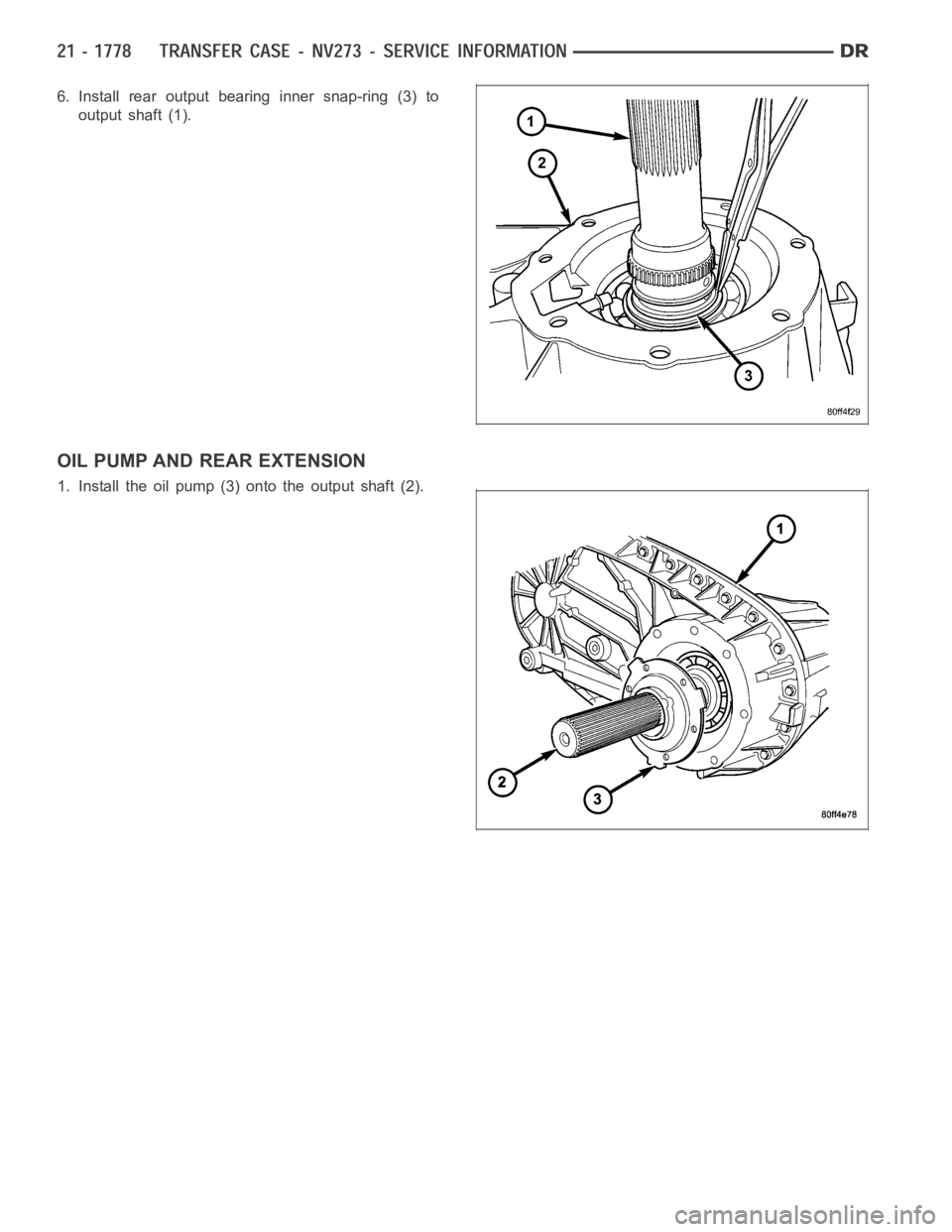

6. Install rear output bearing inner snap-ring (3) to

output shaft (1).

OIL PUMP AND REAR EXTENSION

1. Install the oil pump (3) onto the output shaft (2).

Page 4300 of 5267

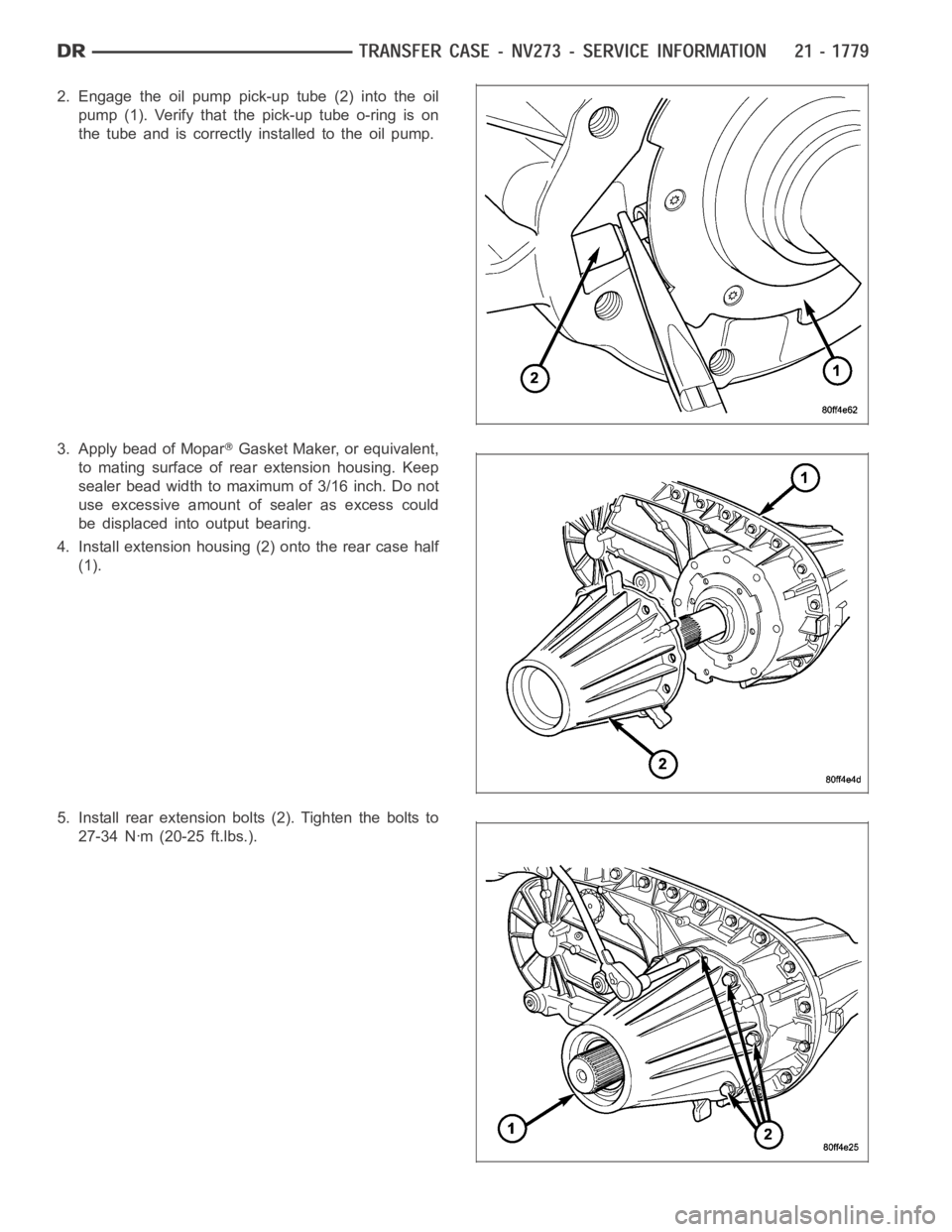

2. Engage the oil pump pick-up tube (2) into the oil

pump (1). Verify that the pick-up tube o-ring is on

the tube and is correctly installed to the oil pump.

3. Apply bead of Mopar

Gasket Maker, or equivalent,

to mating surface of rear extension housing. Keep

sealer bead width to maximum of 3/16 inch. Do not

use excessive amount of sealer as excess could

be displaced into output bearing.

4. Install extension housing (2) onto the rear case half

(1).

5. Install rear extension bolts (2). Tighten the bolts to

27-34 Nꞏm (20-25 ft.lbs.).

Trending: oil, coolant capacity, key, buttons, oil change, gearbox, set clock