DODGE RAM SRT-10 2006 Service Repair Manual

RAM SRT-10 2006

DODGE

DODGE

https://www.carmanualsonline.info/img/12/56917/w960_56917-0.png

DODGE RAM SRT-10 2006 Service Repair Manual

Page 2510 of 5267

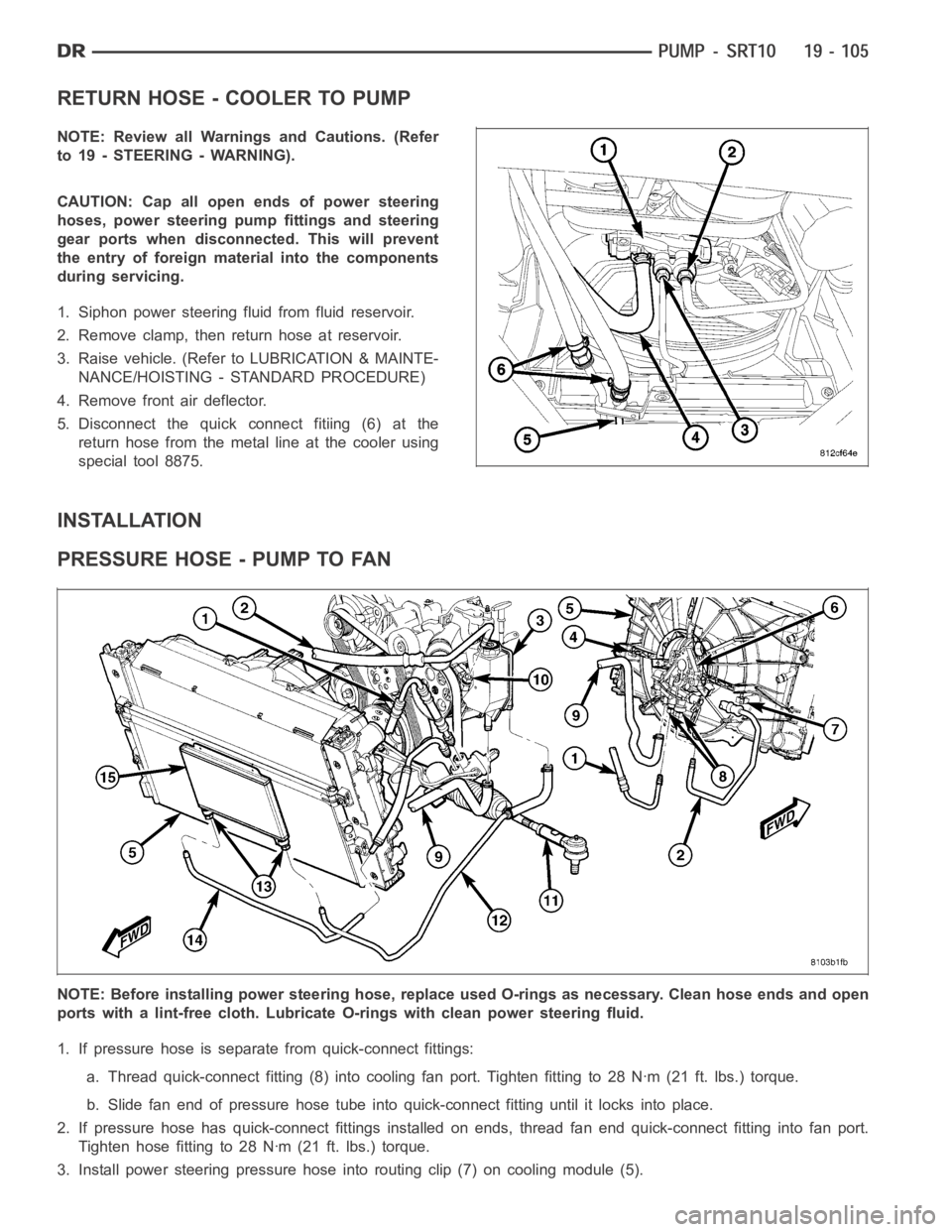

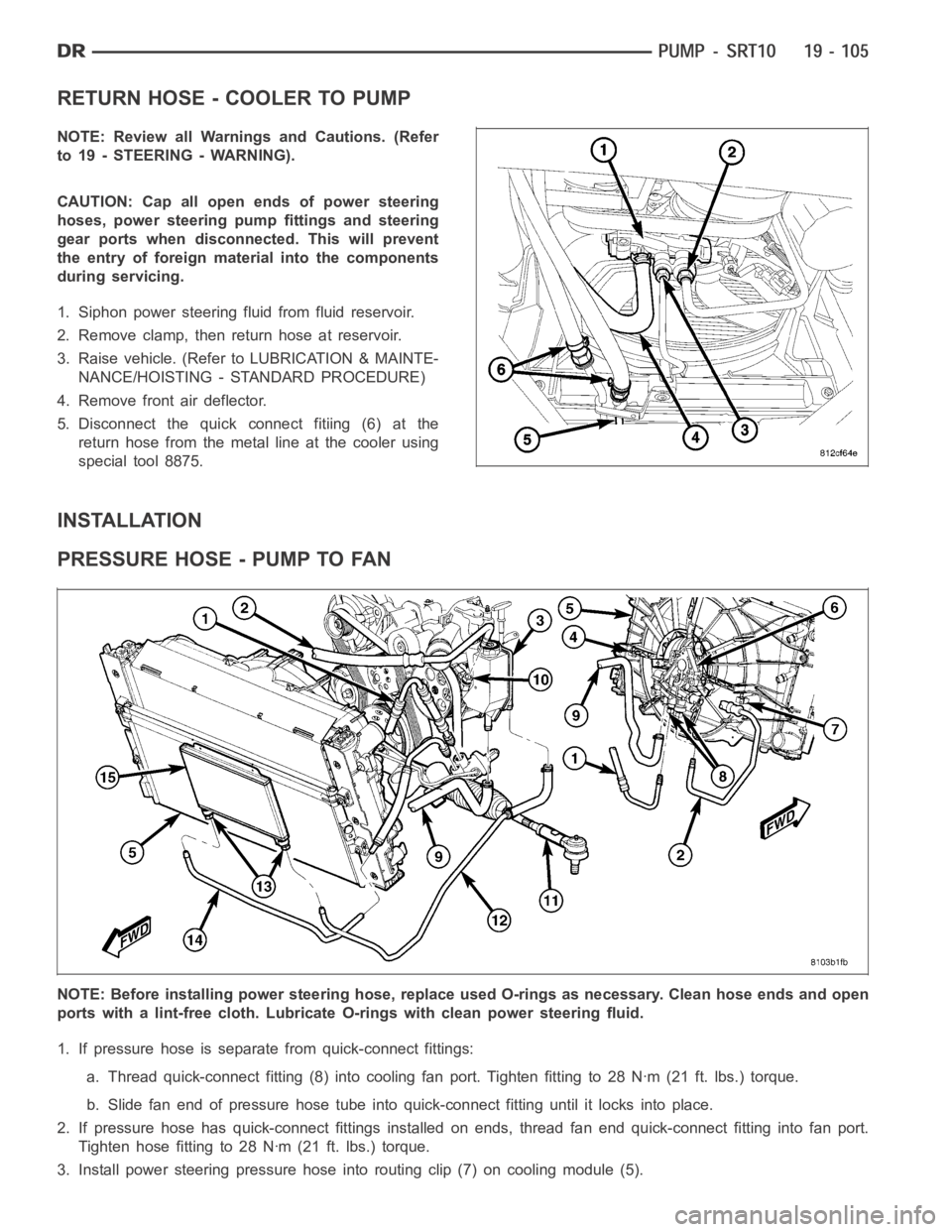

RETURN HOSE - COOLER TO PUMP

NOTE: Review all Warnings and Cautions. (Refer

to 19 - STEERING - WARNING).

CAUTION: Cap all open ends of power steering

hoses, power steering pump fittings and steering

gear ports when disconnected. This will prevent

the entry of foreign material into the components

during servicing.

1. Siphon power steering fluid from fluid reservoir.

2. Remove clamp, then return hose at reservoir.

3. Raise vehicle. (Refer to LUBRICATION & MAINTE-

NANCE/HOISTING - STANDARD PROCEDURE)

4. Remove front air deflector.

5. Disconnect the quick connect fitiing (6) at the

return hose from the metal line at the cooler using

special tool 8875.

INSTALLATION

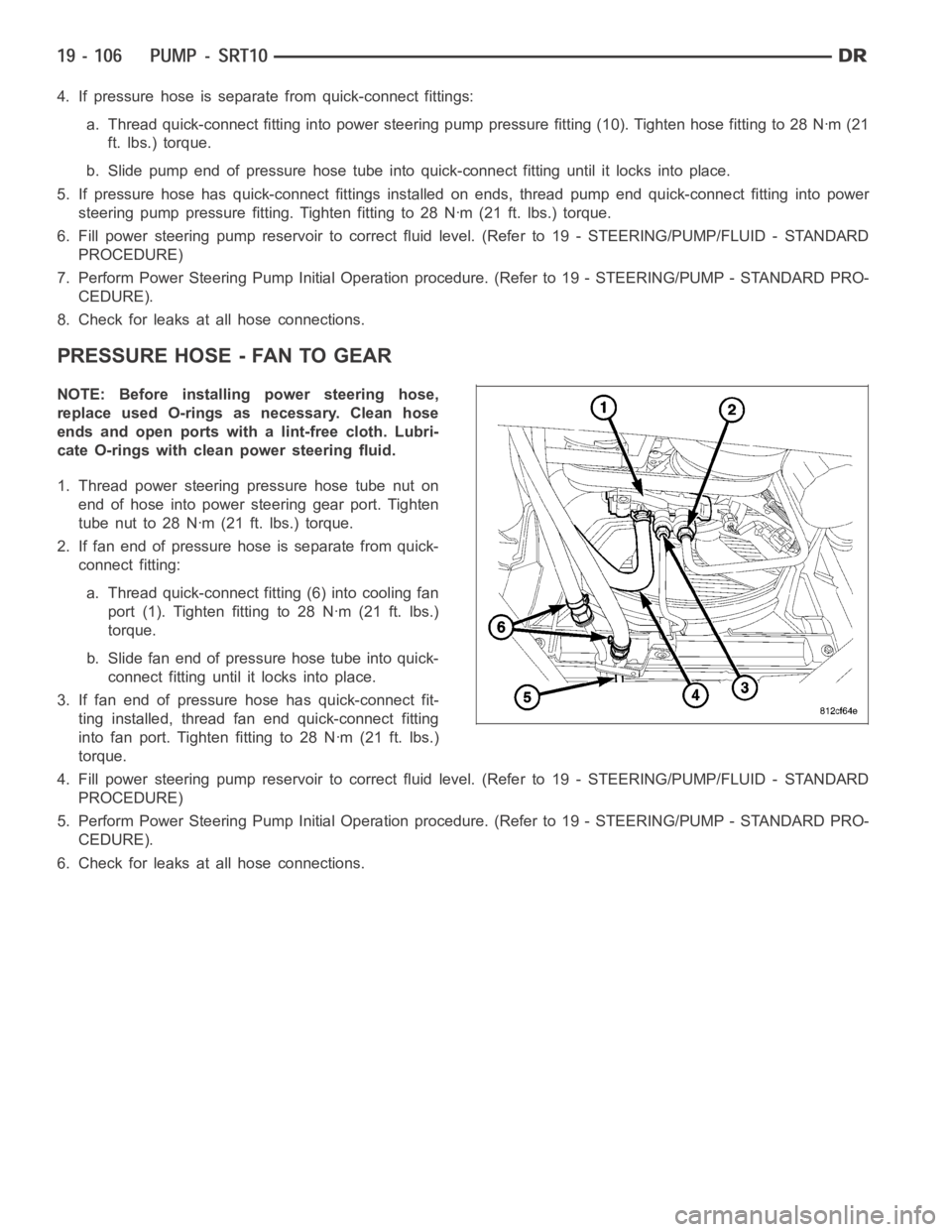

PRESSURE HOSE - PUMP TO FAN

NOTE: Before installing power steering hose, replace used O-rings as necessary. Clean hose ends and open

ports with a lint-free cloth. Lubricate O-rings with clean power steeringfluid.

1. If pressure hose is separate from quick-connect fittings:

a. Thread quick-connect fitting (8) into cooling fan port. Tighten fittingto28Nꞏm(21ft.lbs.)torque.

b. Slide fan end of pressure hose tube into quick-connect fitting until it locks into place.

2. If pressure hose has quick-connect fittings installed on ends, thread fan end quick-connect fitting into fan port.

Tighten hose fitting to 28 Nꞏm (21 ft. lbs.) torque.

3. Install power steering pressure hose into routing clip (7) on cooling module (5).

Page 2511 of 5267

4. If pressure hose is separate from quick-connect fittings:

a. Thread quick-connect fitting into power steering pump pressure fitting (10). Tighten hose fitting to 28 Nꞏm (21

ft. lbs.) torque.

b. Slide pump end of pressure hose tube into quick-connect fitting until itlocks into place.

5. If pressure hose has quick-connect fittings installed on ends, thread pump end quick-connect fitting into power

steering pump pressure fitting. Tighten fitting to 28 Nꞏm (21 ft. lbs.) torque.

6. Fill power steering pump reservoir to correct fluid level. (Refer to 19 -STEERING/PUMP/FLUID - STANDARD

PROCEDURE)

7. Perform Power Steering Pump Initial Operation procedure. (Refer to 19 -STEERING/PUMP - STANDARD PRO-

CEDURE).

8. Check for leaks at all hose connections.

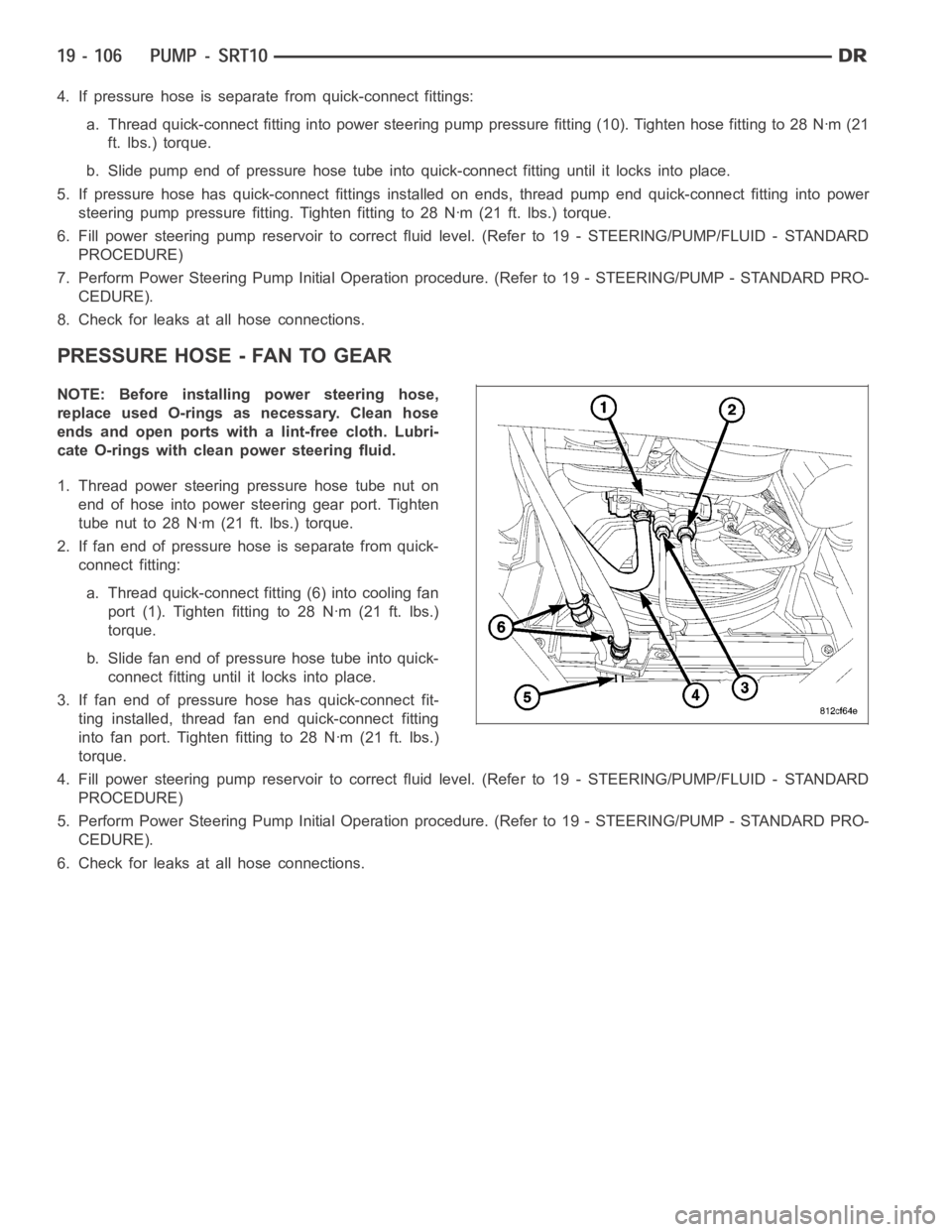

PRESSURE HOSE - FAN TO GEAR

NOTE: Before installing power steering hose,

replace used O-rings as necessary. Clean hose

ends and open ports with a lint-free cloth. Lubri-

cate O-rings with clean power steering fluid.

1. Thread power steering pressure hose tube nut on

end of hose into power steering gear port. Tighten

tube nut to 28 Nꞏm (21 ft. lbs.) torque.

2. If fan end of pressure hose is separate from quick-

connect fitting:

a. Thread quick-connect fitting (6) into cooling fan

port (1). Tighten fitting to 28 Nꞏm (21 ft. lbs.)

torque.

b. Slide fan end of pressure hose tube into quick-

connect fitting until it locks into place.

3. If fan end of pressure hose has quick-connect fit-

ting installed, thread fan end quick-connect fitting

into fan port. Tighten fitting to 28 Nꞏm (21 ft. lbs.)

torque.

4. Fill power steering pump reservoir to correct fluid level. (Refer to 19 -STEERING/PUMP/FLUID - STANDARD

PROCEDURE)

5. Perform Power Steering Pump Initial Operation procedure. (Refer to 19 -STEERING/PUMP - STANDARD PRO-

CEDURE).

6. Check for leaks at all hose connections.

Page 2514 of 5267

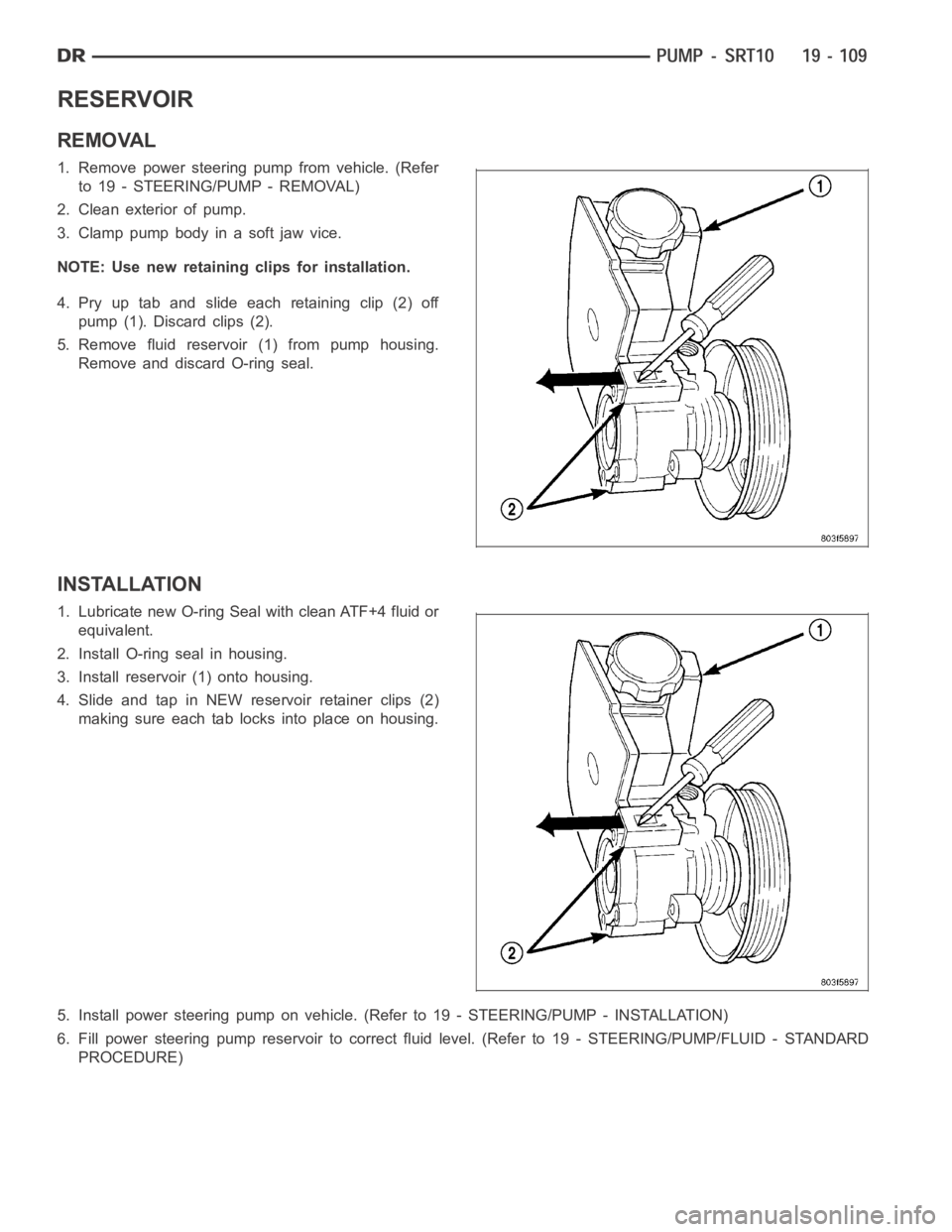

RESERVOIR

REMOVAL

1. Remove power steering pump from vehicle. (Refer

to 19 - STEERING/PUMP - REMOVAL)

2. Clean exterior of pump.

3. Clamp pump body in a soft jaw vice.

NOTE: Use new retaining clips for installation.

4. Pry up tab and slide each retaining clip (2) off

pump (1). Discard clips (2).

5. Remove fluid reservoir (1) from pump housing.

Remove and discard O-ring seal.

INSTALLATION

1. Lubricate new O-ring Seal with clean ATF+4 fluid or

equivalent.

2. Install O-ring seal in housing.

3. Install reservoir (1) onto housing.

4. Slide and tap in NEW reservoir retainer clips (2)

making sure each tab locks into place on housing.

5. Install power steering pump on vehicle. (Refer to 19 - STEERING/PUMP - INSTALLATION)

6. Fill power steering pump reservoir to correct fluid level. (Refer to 19 -STEERING/PUMP/FLUID - STANDARD

PROCEDURE)

Page 2527 of 5267

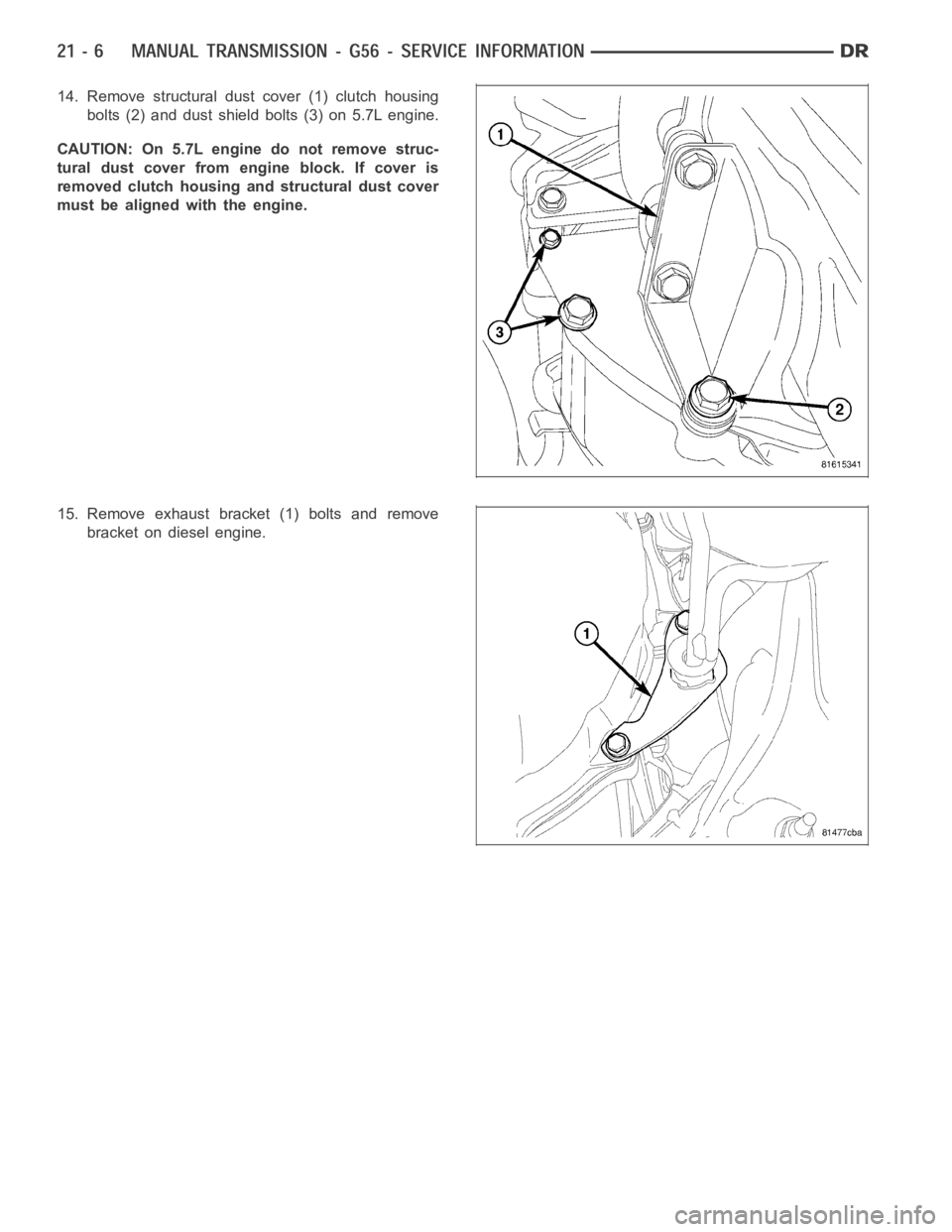

14. Remove structural dust cover (1) clutch housing

bolts (2) and dust shield bolts (3) on 5.7L engine.

CAUTION: On 5.7L engine do not remove struc-

tural dust cover from engine block. If cover is

removed clutch housing and structural dust cover

must be aligned with the engine.

15. Remove exhaust bracket (1) bolts and remove

bracket on diesel engine.

Page 2528 of 5267

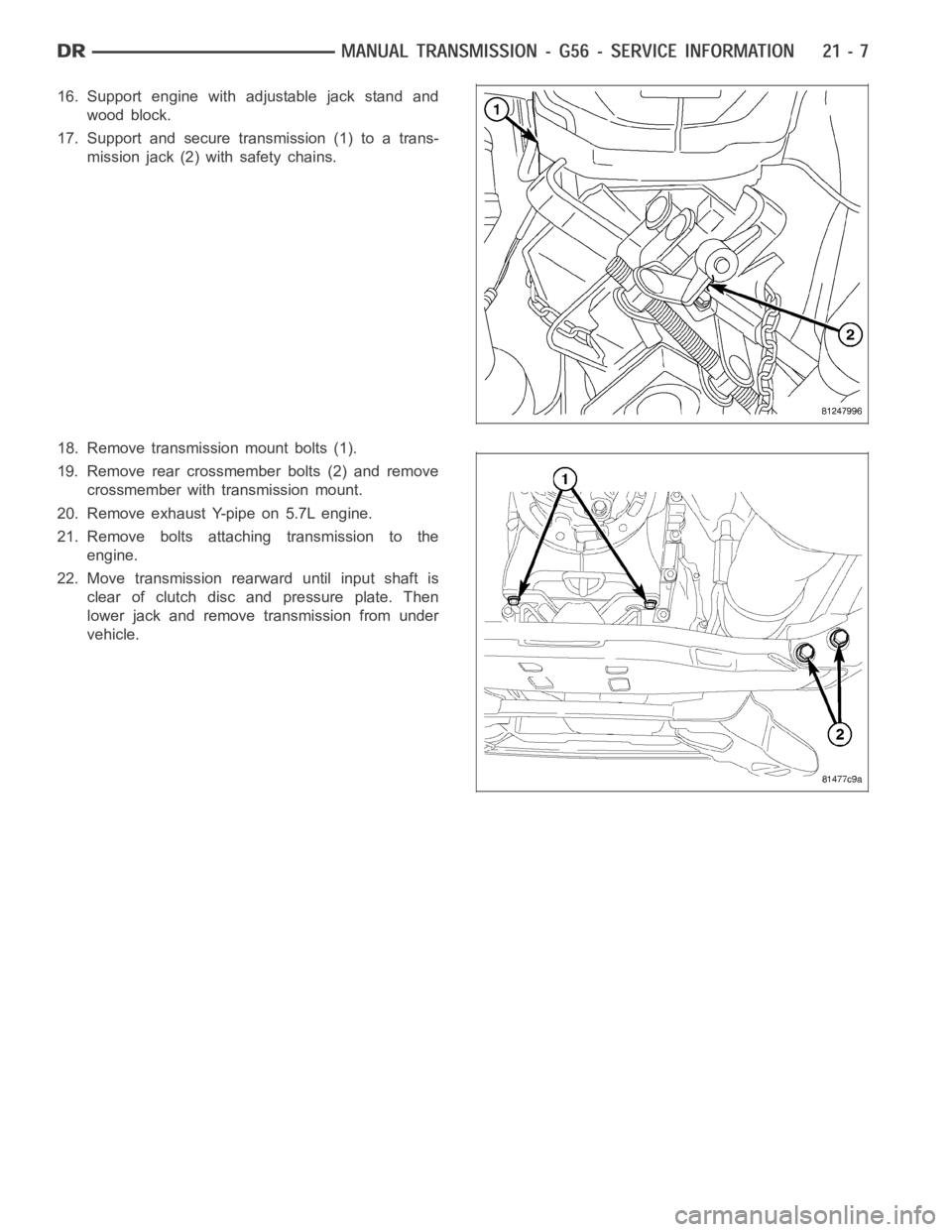

16. Support engine with adjustable jack stand and

wood block.

17. Support and secure transmission (1) to a trans-

mission jack (2) with safety chains.

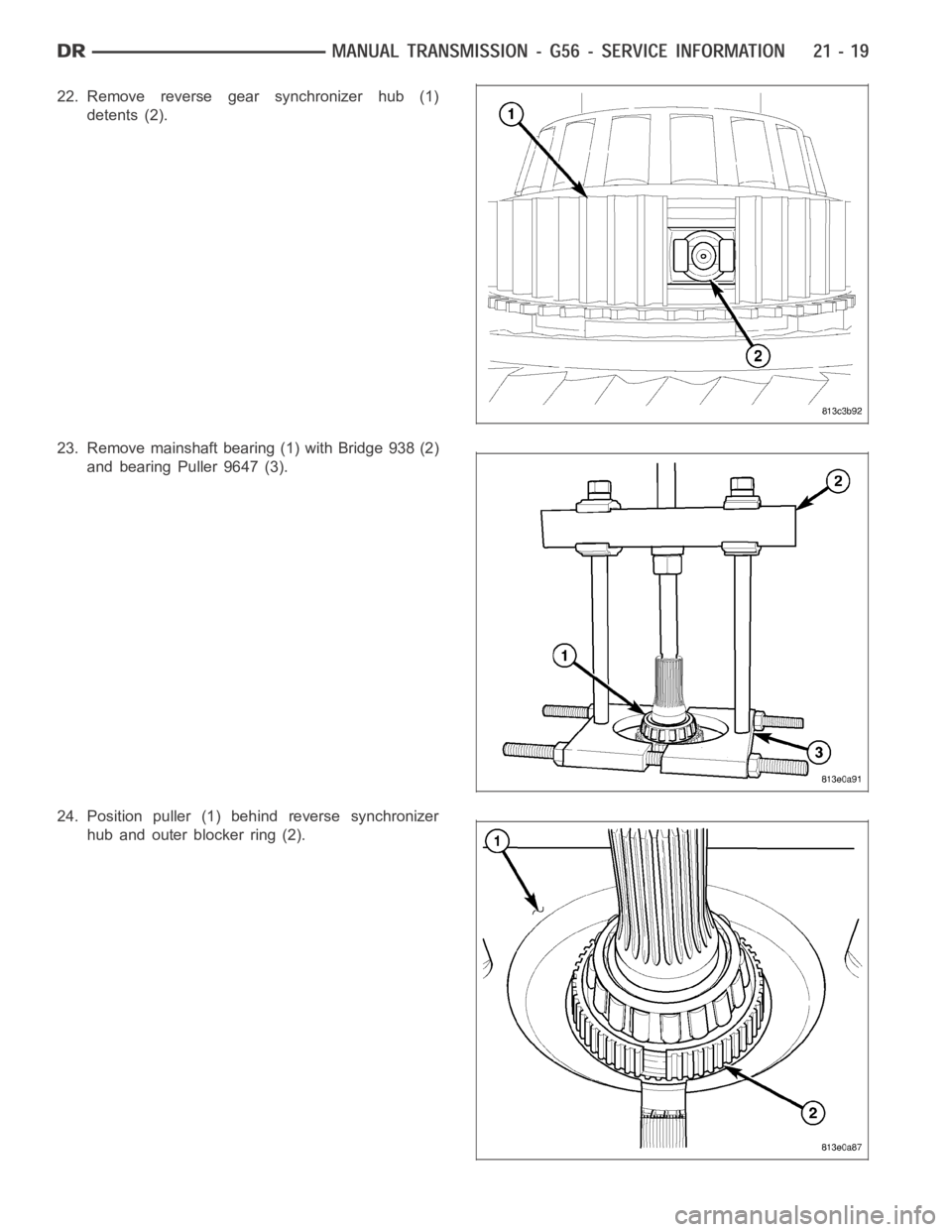

18. Remove transmission mount bolts (1).

19. Remove rear crossmember bolts (2) and remove

crossmember with transmission mount.

20. Remove exhaust Y-pipe on 5.7L engine.

21. Remove bolts attaching transmission to the

engine.

22. Move transmission rearward until input shaft is

clear of clutch disc and pressure plate. Then

lower jack and remove transmission from under

vehicle.

Page 2540 of 5267

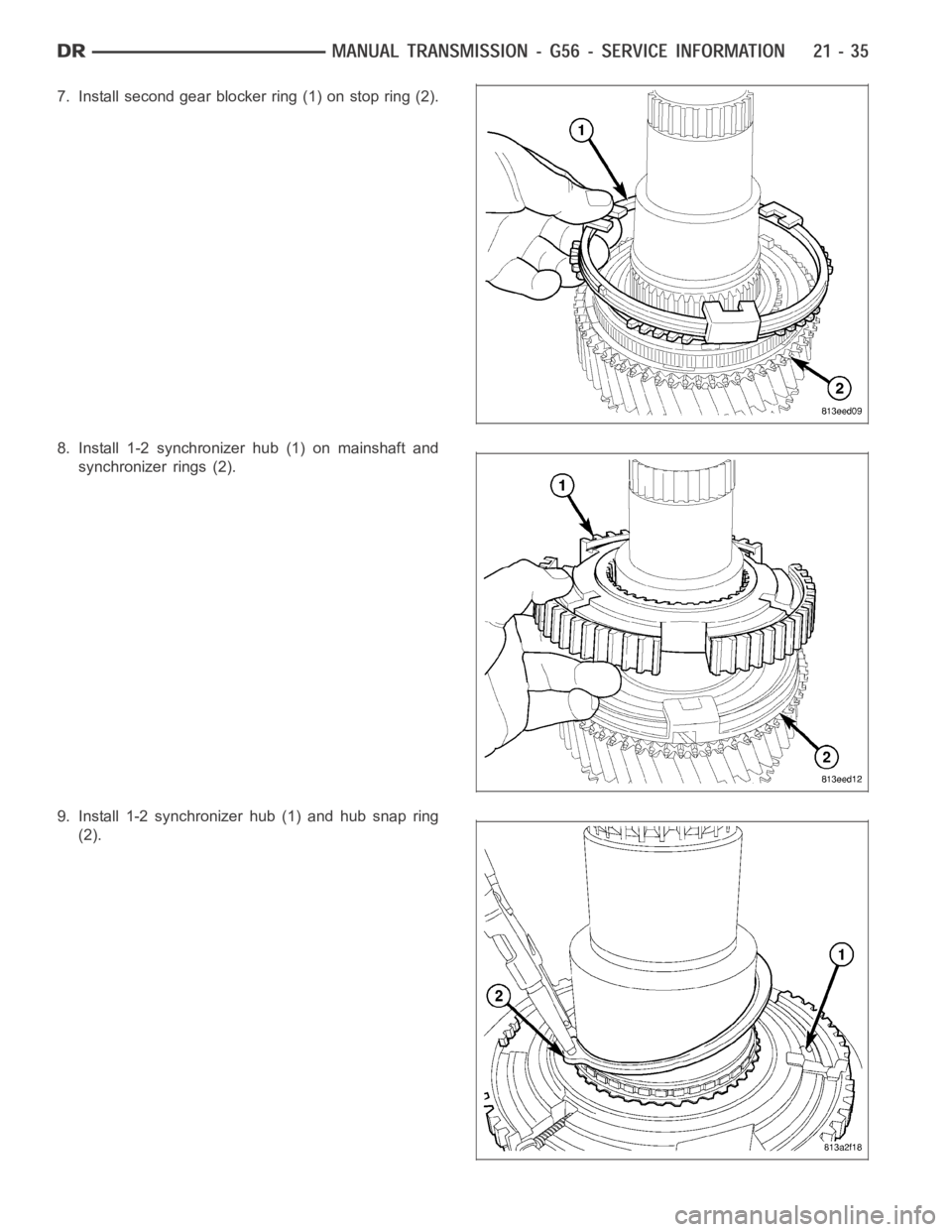

22. Remove reverse gear synchronizer hub (1)

detents (2).

23. Remove mainshaft bearing (1) with Bridge 938 (2)

and bearing Puller 9647 (3).

24. Position puller (1) behind reverse synchronizer

hub and outer blocker ring (2).

Page 2556 of 5267

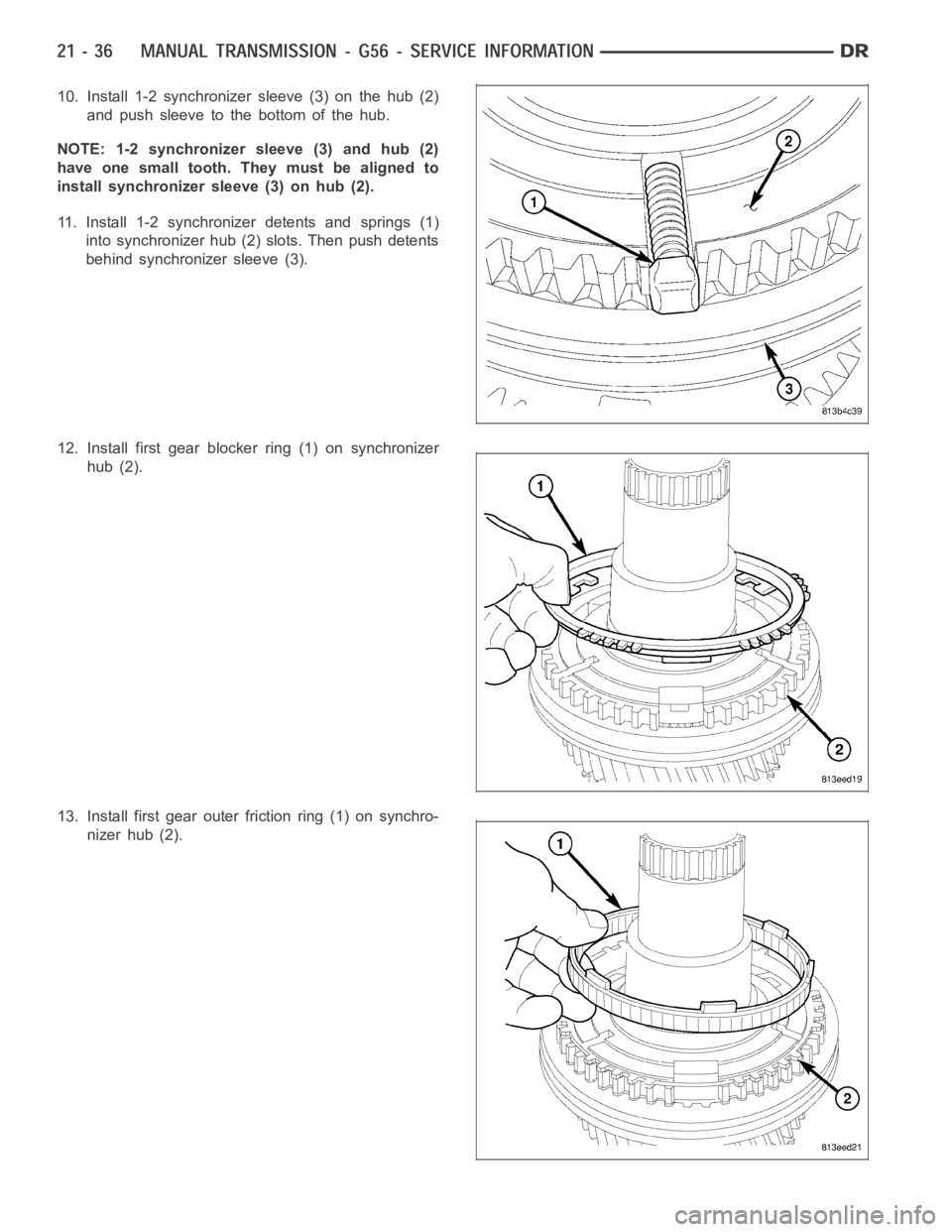

7. Install second gear blocker ring (1) on stop ring (2).

8. Install 1-2 synchronizer hub (1) on mainshaft and

synchronizer rings (2).

9. Install 1-2 synchronizer hub (1) and hub snap ring

(2).

Page 2557 of 5267

10. Install 1-2 synchronizer sleeve (3) on the hub (2)

and push sleeve to the bottom of the hub.

NOTE: 1-2 synchronizer sleeve (3) and hub (2)

have one small tooth. They must be aligned to

install synchronizer sleeve (3) on hub (2).

11. Install 1-2 synchronizer detents and springs (1)

into synchronizer hub (2) slots. Then push detents

behind synchronizer sleeve (3).

12. Install first gear blocker ring (1) on synchronizer

hub (2).

13. Install first gear outer friction ring (1) on synchro-

nizer hub (2).

Page 2560 of 5267

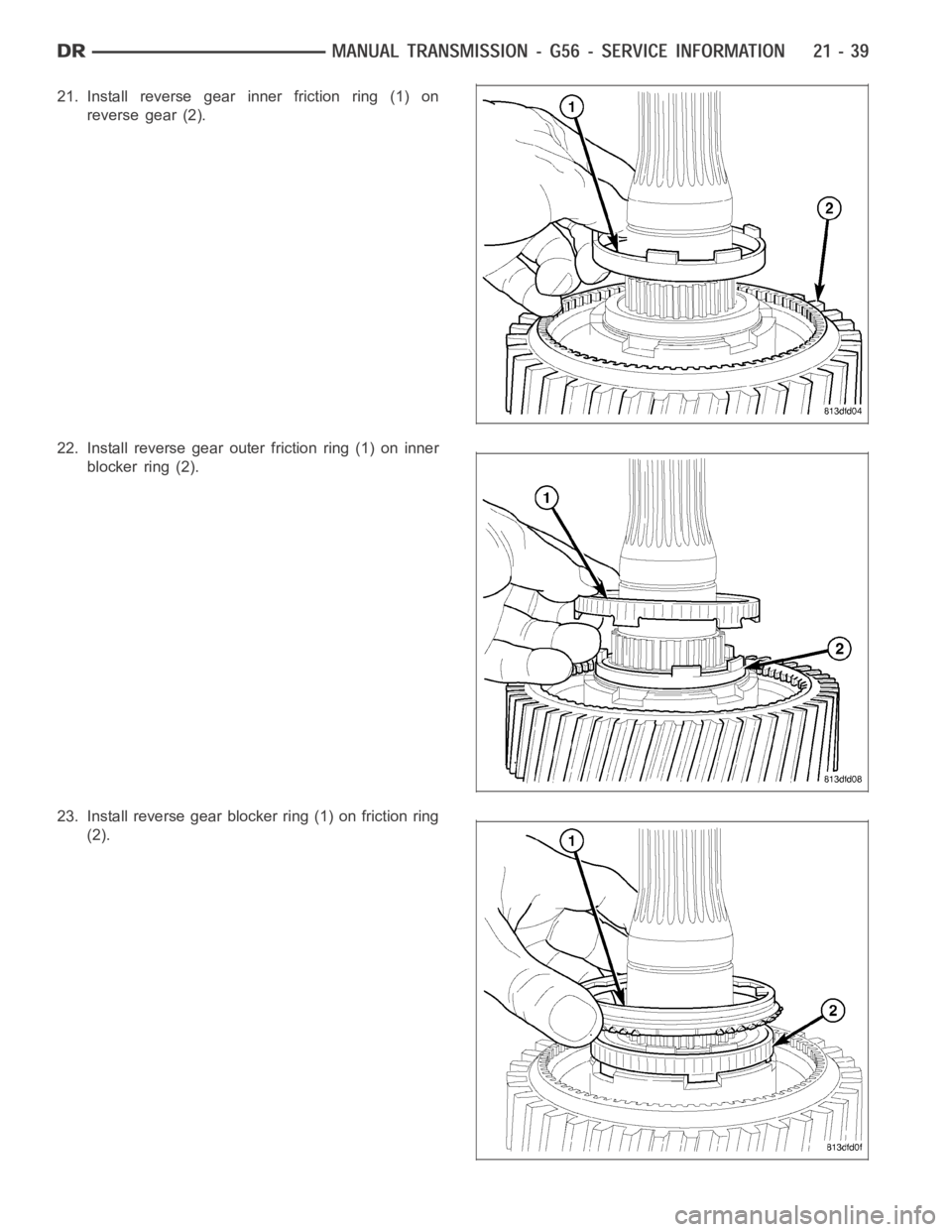

21. Install reverse gear inner friction ring (1) on

reverse gear (2).

22. Install reverse gear outer friction ring (1) on inner

blocker ring (2).

23. Install reverse gear blocker ring (1) on friction ring

(2).

Page 2564 of 5267

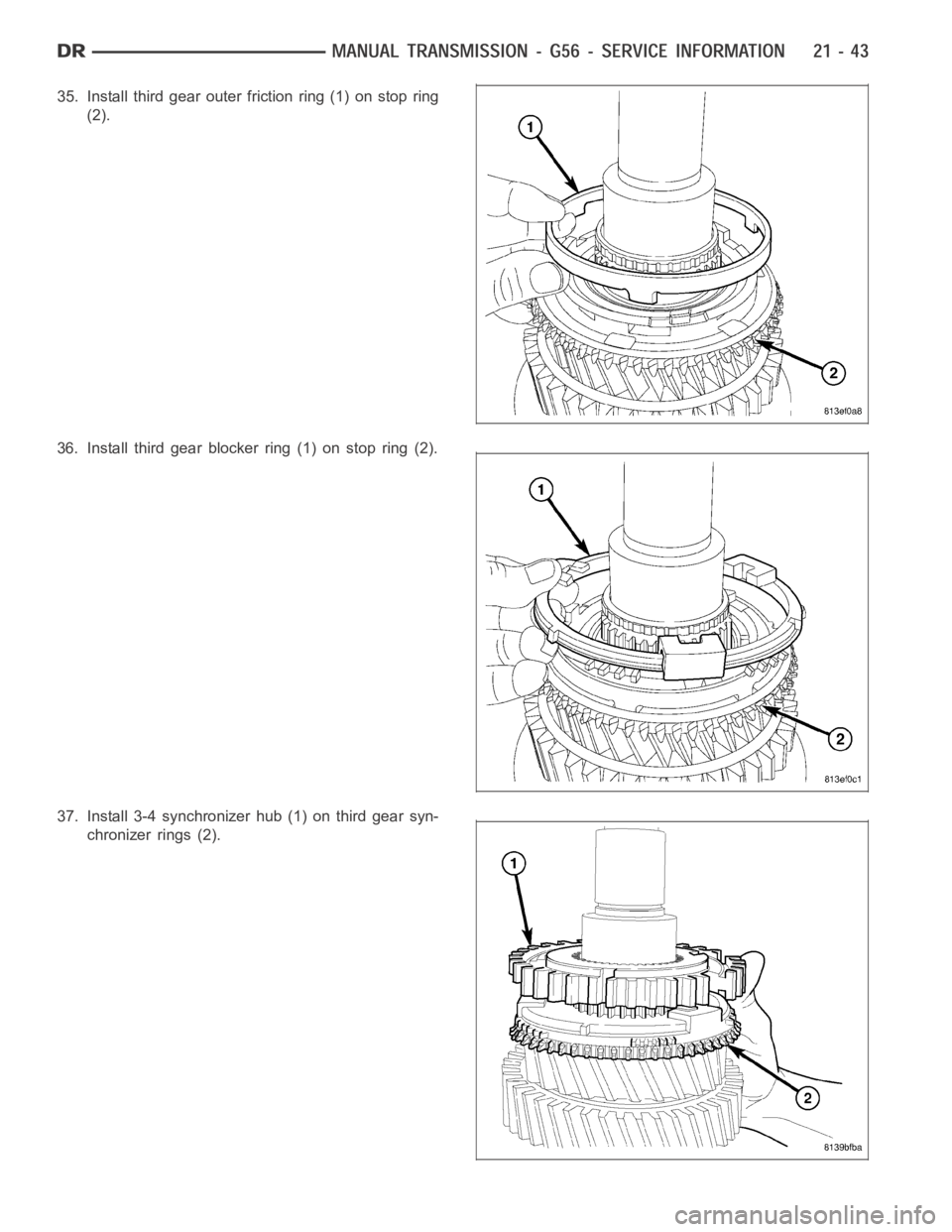

35. Install third gear outer friction ring (1) on stop ring

(2).

36. Install third gear blocker ring (1) on stop ring (2).

37. Install 3-4 synchronizer hub (1) on third gear syn-

chronizer rings (2).