DODGE RAM SRT-10 2006 Service Repair Manual

RAM SRT-10 2006

DODGE

DODGE

https://www.carmanualsonline.info/img/12/56917/w960_56917-0.png

DODGE RAM SRT-10 2006 Service Repair Manual

Page 2638 of 5267

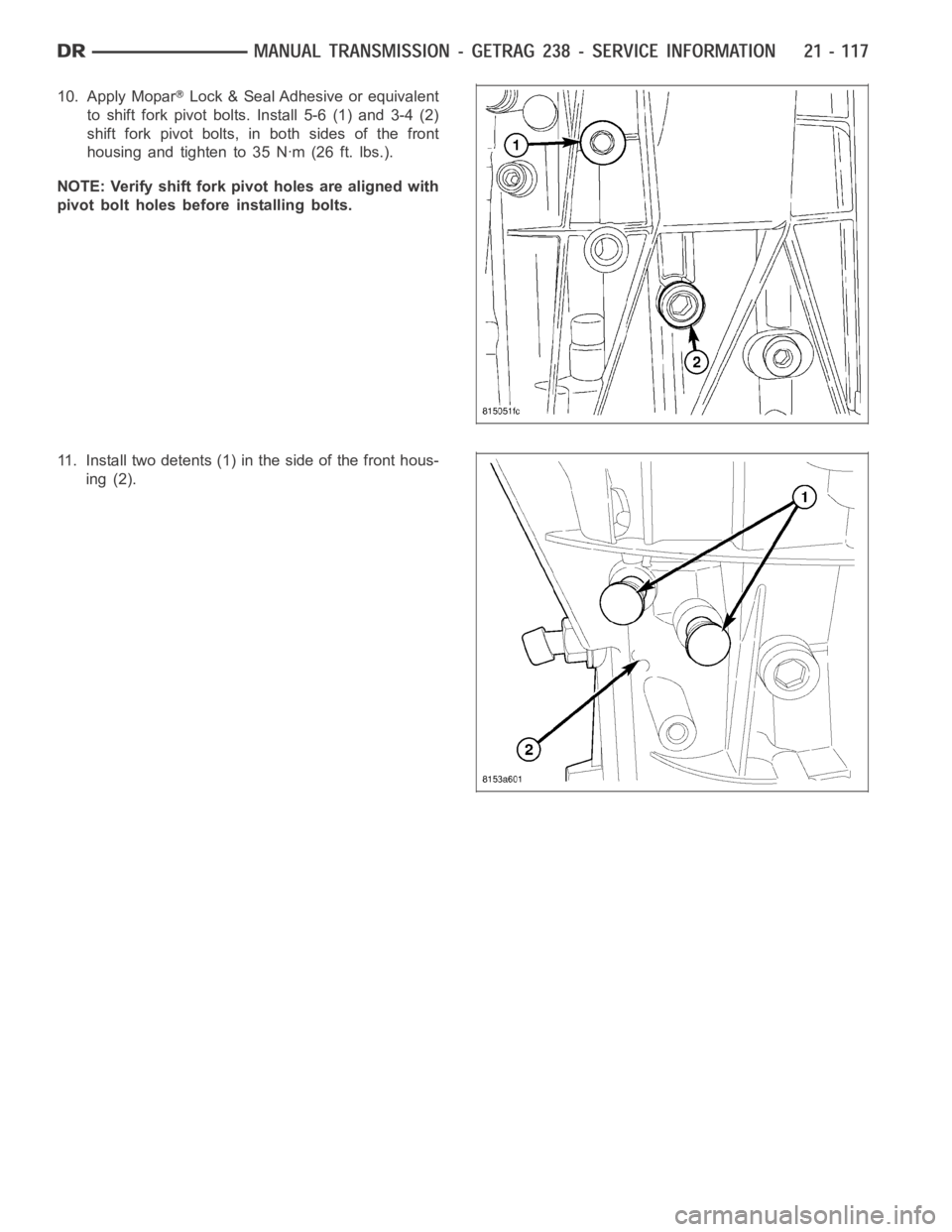

10. Apply MoparLock & Seal Adhesive or equivalent

to shift fork pivot bolts. Install 5-6 (1) and 3-4 (2)

shift fork pivot bolts, in both sides of the front

housing and tighten to 35 Nꞏm (26 ft. lbs.).

NOTE: Verify shift fork pivot holes are aligned with

pivot bolt holes before installing bolts.

11. Install two detents (1) in the side of the front hous-

ing (2).

Page 2640 of 5267

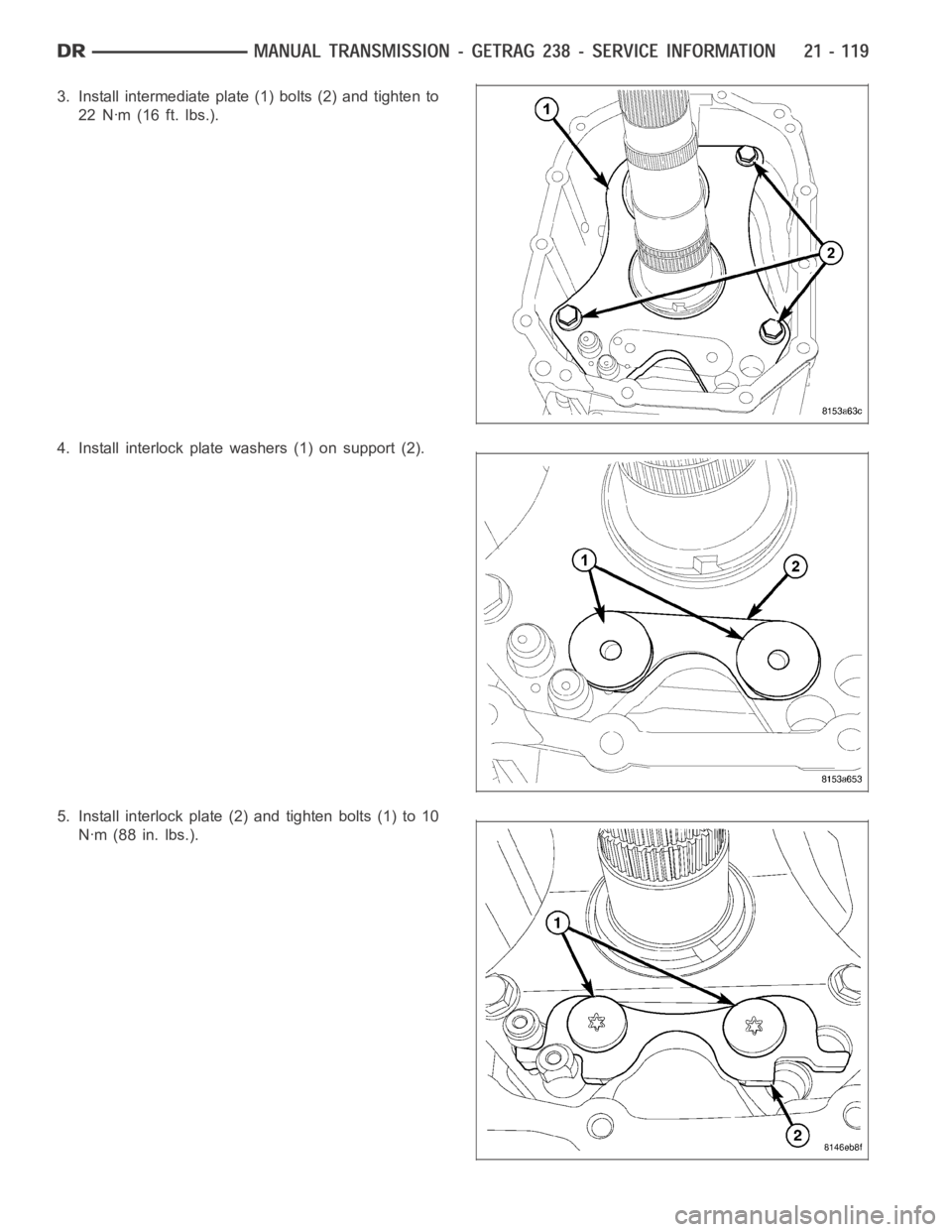

3. Install intermediate plate (1) bolts (2) and tighten to

22 Nꞏm (16 ft. lbs.).

4. Install interlock plate washers (1) on support (2).

5. Install interlock plate (2) and tighten bolts (1) to 10

Nꞏm (88 in. lbs.).

Page 2642 of 5267

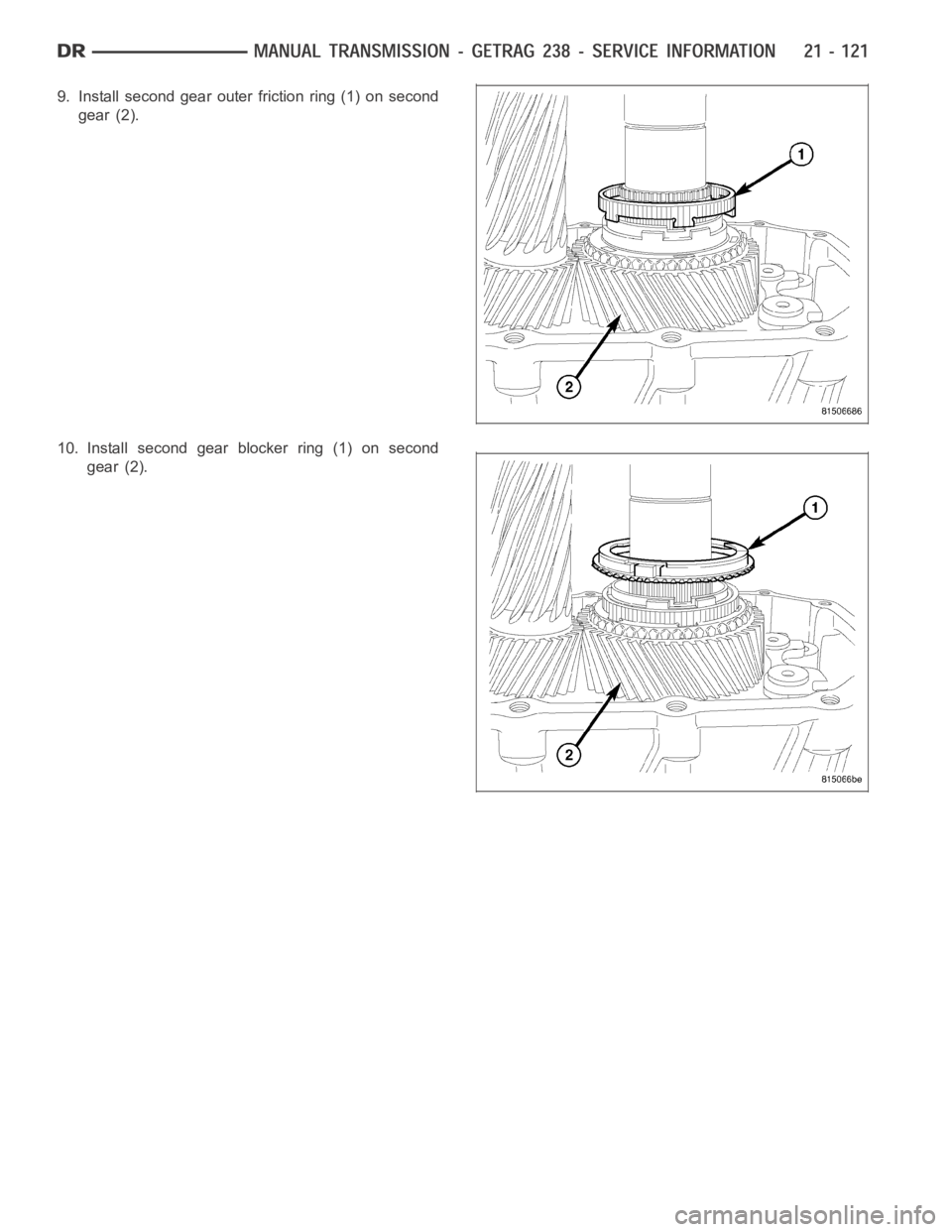

9. Install second gear outer friction ring (1) on second

gear (2).

10. Install second gear blocker ring (1) on second

gear (2).

Page 2643 of 5267

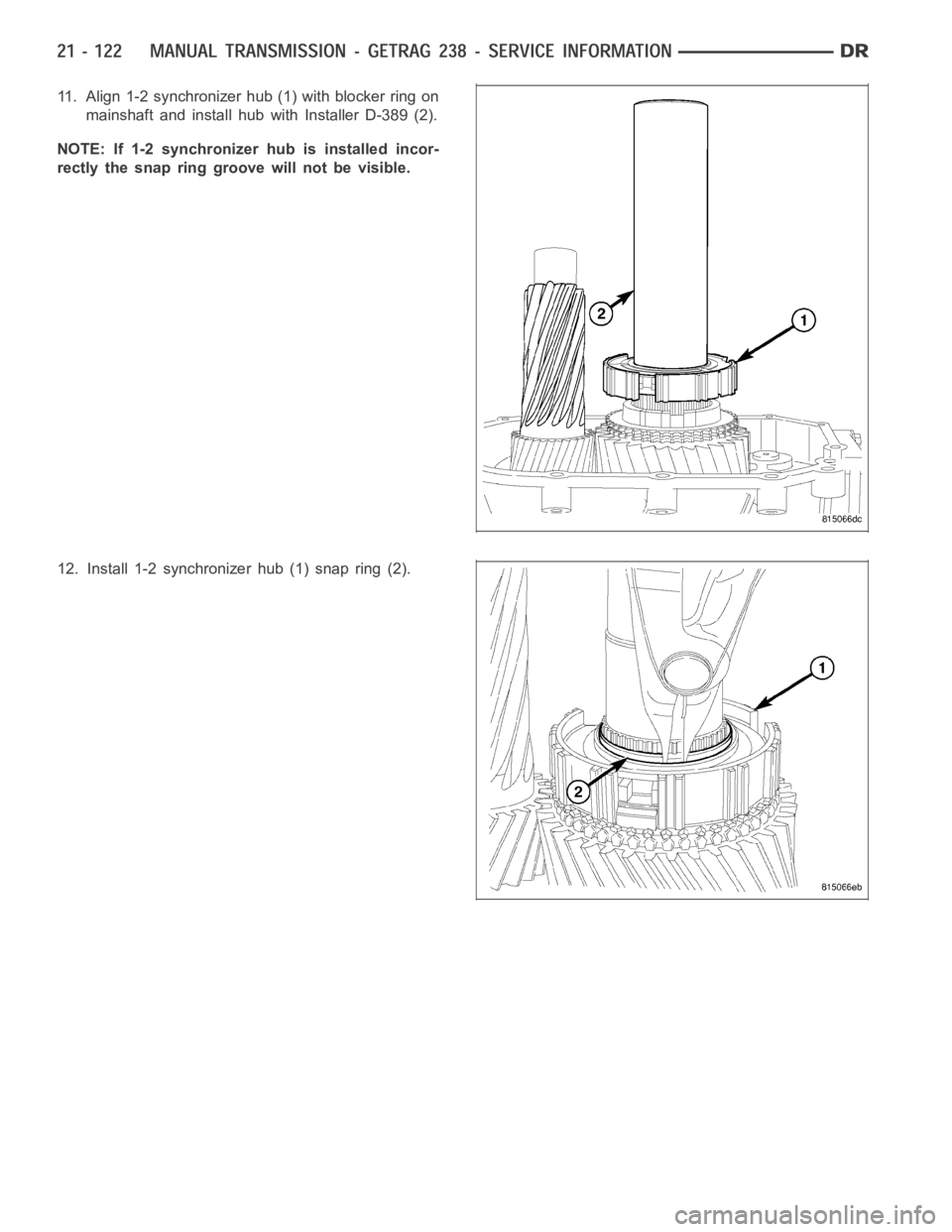

11. Align 1-2 synchronizer hub (1) with blocker ring on

mainshaft and install hub with Installer D-389 (2).

NOTE: If 1-2 synchronizer hub is installed incor-

rectly the snap ring groove will not be visible.

12. Install 1-2 synchronizer hub (1) snap ring (2).

Page 2644 of 5267

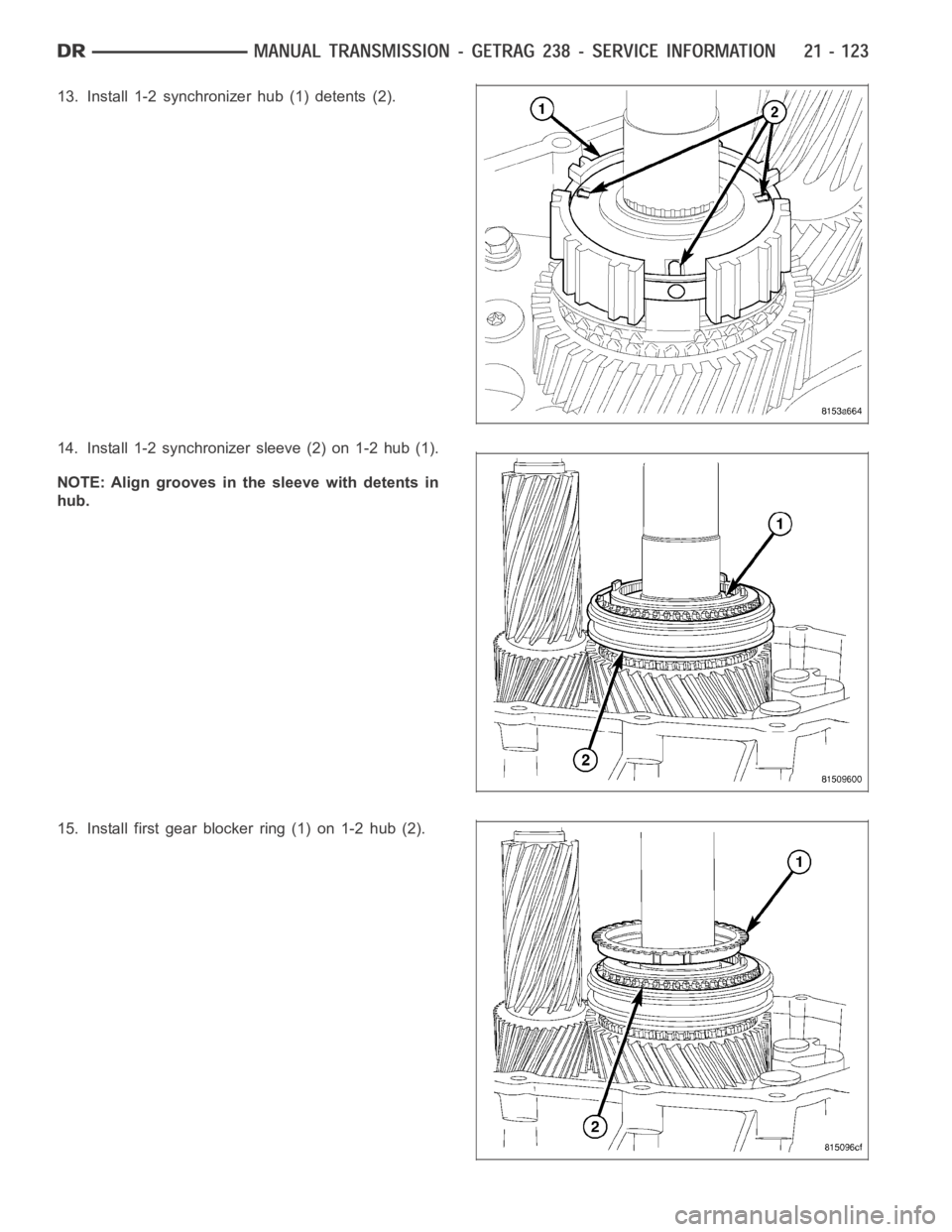

13. Install 1-2 synchronizer hub (1) detents (2).

14. Install 1-2 synchronizer sleeve (2) on 1-2 hub (1).

NOTE: Align grooves in the sleeve with detents in

hub.

15. Install first gear blocker ring (1) on 1-2 hub (2).

Page 2647 of 5267

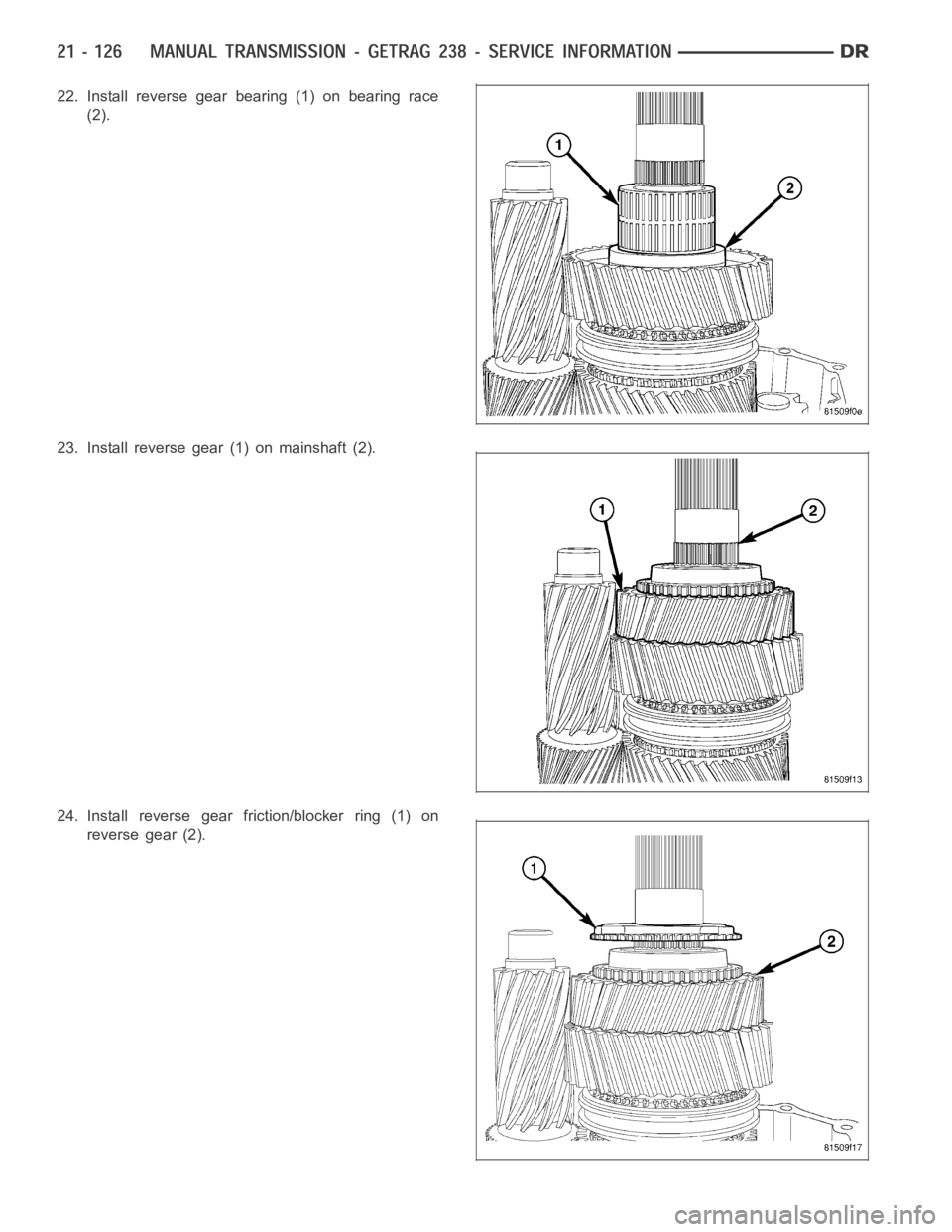

22. Install reverse gear bearing (1) on bearing race

(2).

23. Install reverse gear (1) on mainshaft (2).

24. Install reverse gear friction/blocker ring (1) on

reverse gear (2).

Page 2649 of 5267

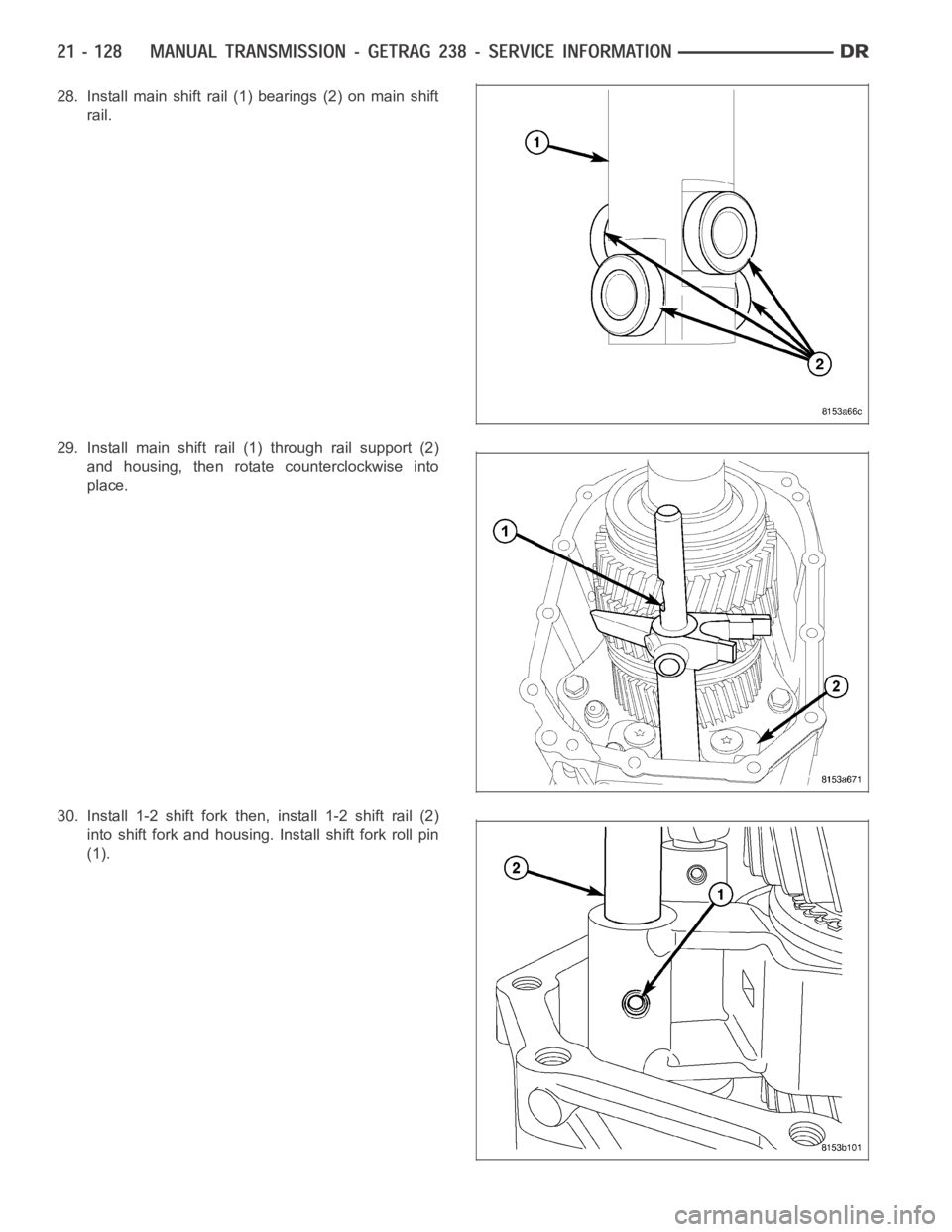

28. Install main shift rail (1) bearings (2) on main shift

rail.

29. Install main shift rail (1) through rail support (2)

and housing, then rotate counterclockwise into

place.

30. Install 1-2 shift fork then, install 1-2 shift rail (2)

into shift fork and housing. Install shift fork roll pin

(1).

Page 2655 of 5267

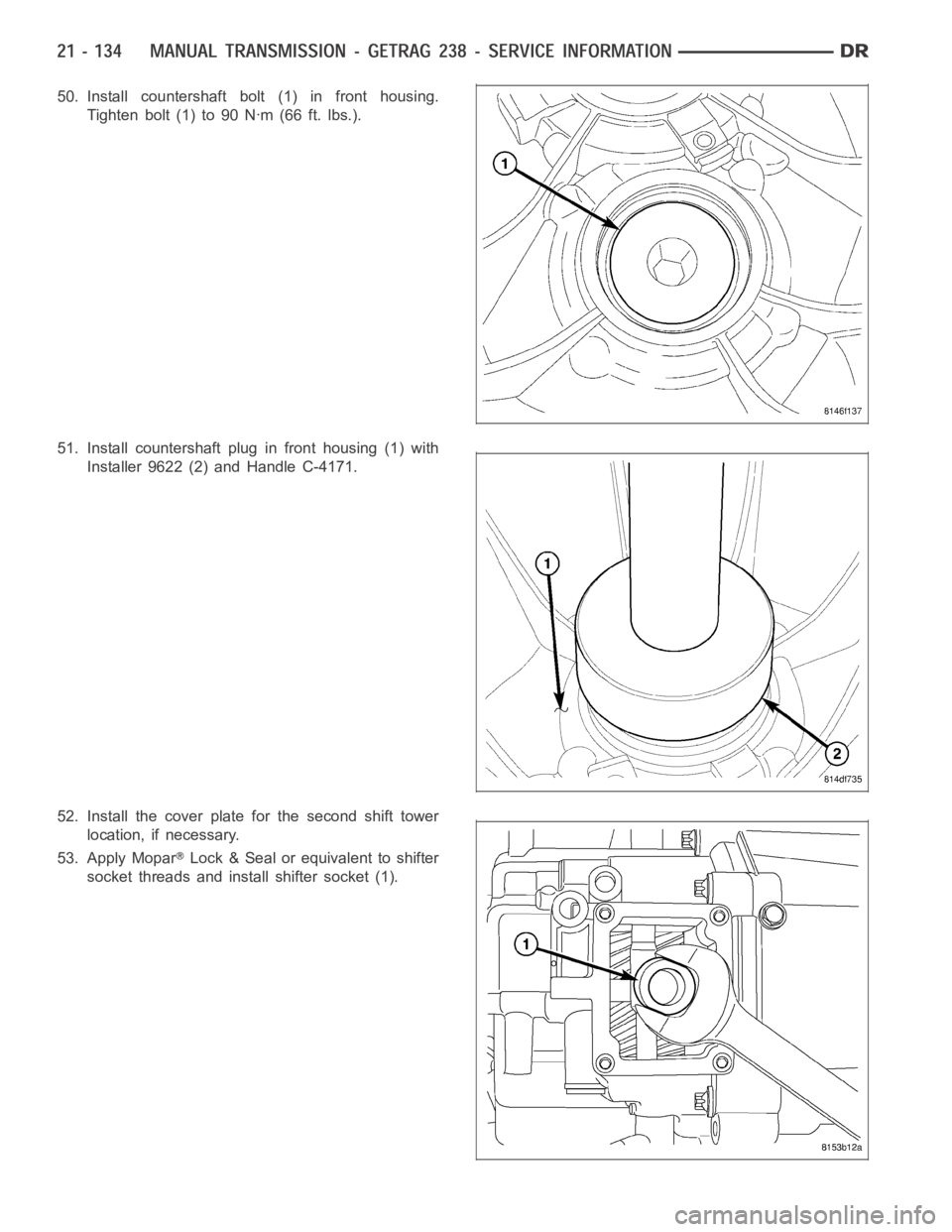

50. Install countershaft bolt (1) in front housing.

Tighten bolt (1) to 90 Nꞏm (66 ft. lbs.).

51. Install countershaft plug in front housing (1) with

Installer 9622 (2) and Handle C-4171.

52. Install the cover plate for the second shift tower

location, if necessary.

53. Apply Mopar

Lock & Seal or equivalent to shifter

socket threads and install shifter socket (1).

Page 2657 of 5267

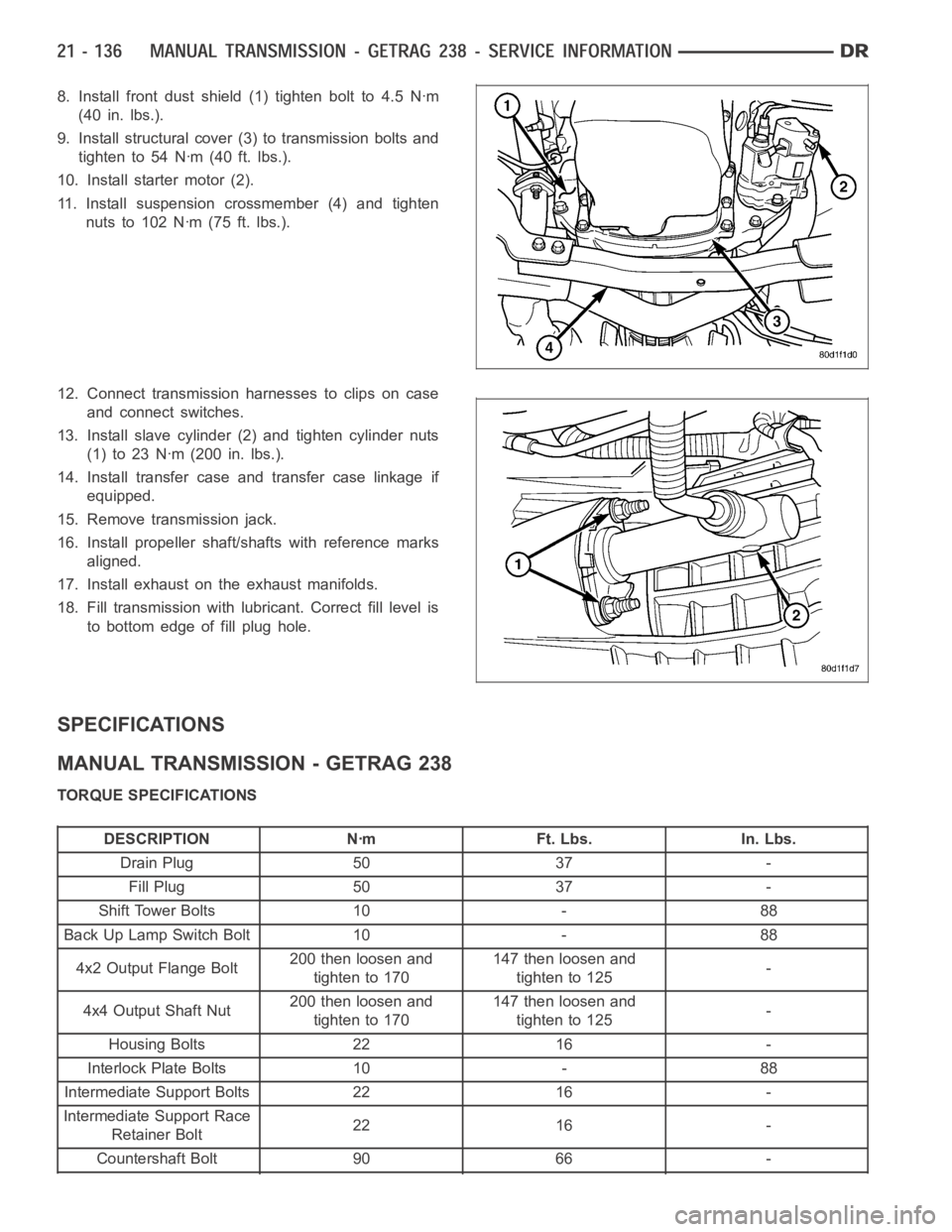

8. Install front dust shield (1) tighten bolt to 4.5 Nꞏm

(40 in. lbs.).

9. Install structural cover (3) to transmission bolts and

tighten to 54 Nꞏm (40 ft. lbs.).

10. Install starter motor (2).

11. Install suspension crossmember (4) and tighten

nuts to 102 Nꞏm (75 ft. lbs.).

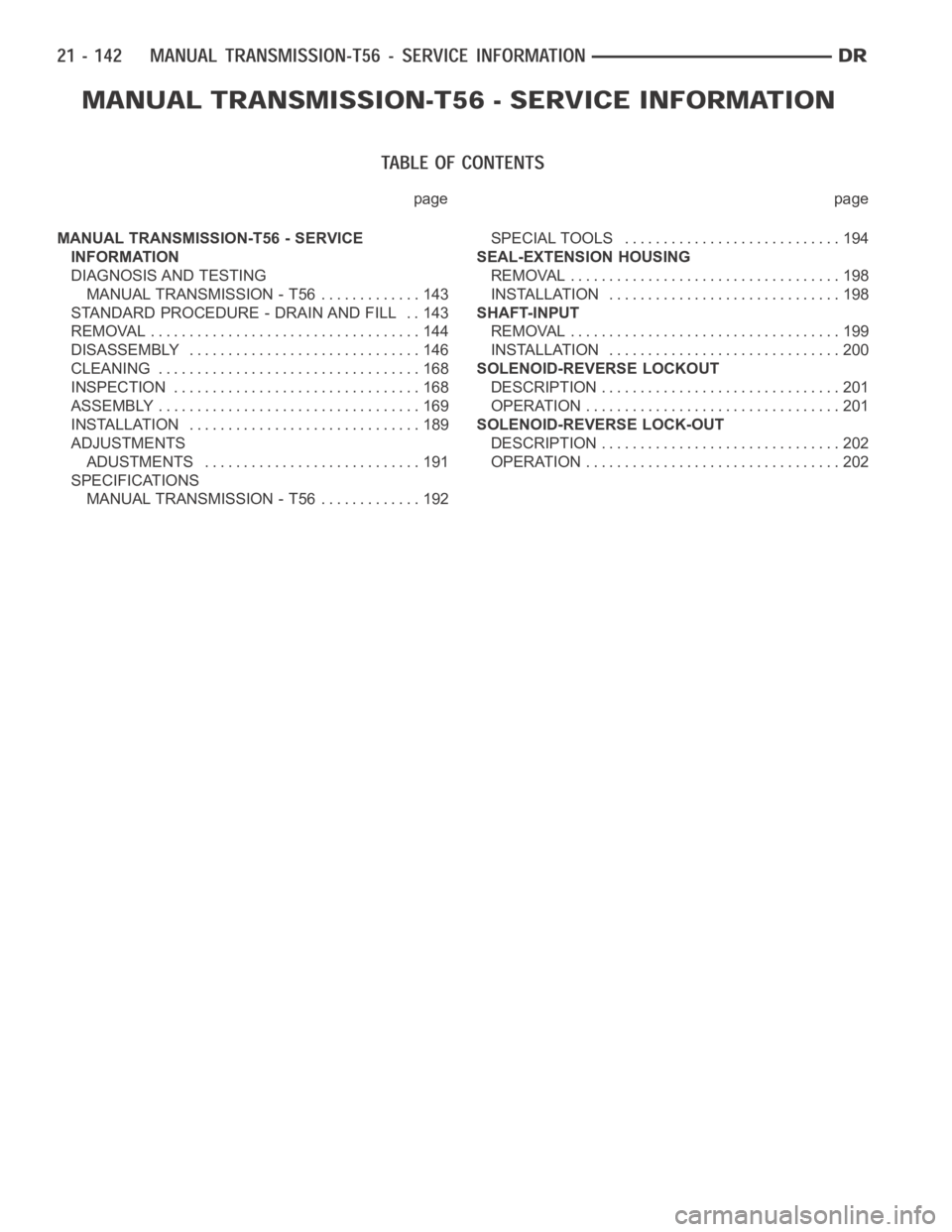

12. Connect transmission harnesses to clips on case

and connect switches.

13. Install slave cylinder (2) and tighten cylinder nuts

(1)to23Nꞏm(200in.lbs.).

14. Install transfer case and transfer case linkage if

equipped.

15. Remove transmission jack.

16. Install propeller shaft/shafts with reference marks

aligned.

17. Install exhaust on the exhaust manifolds.

18. Fill transmission with lubricant. Correct fill level is

to bottom edge of fill plug hole.

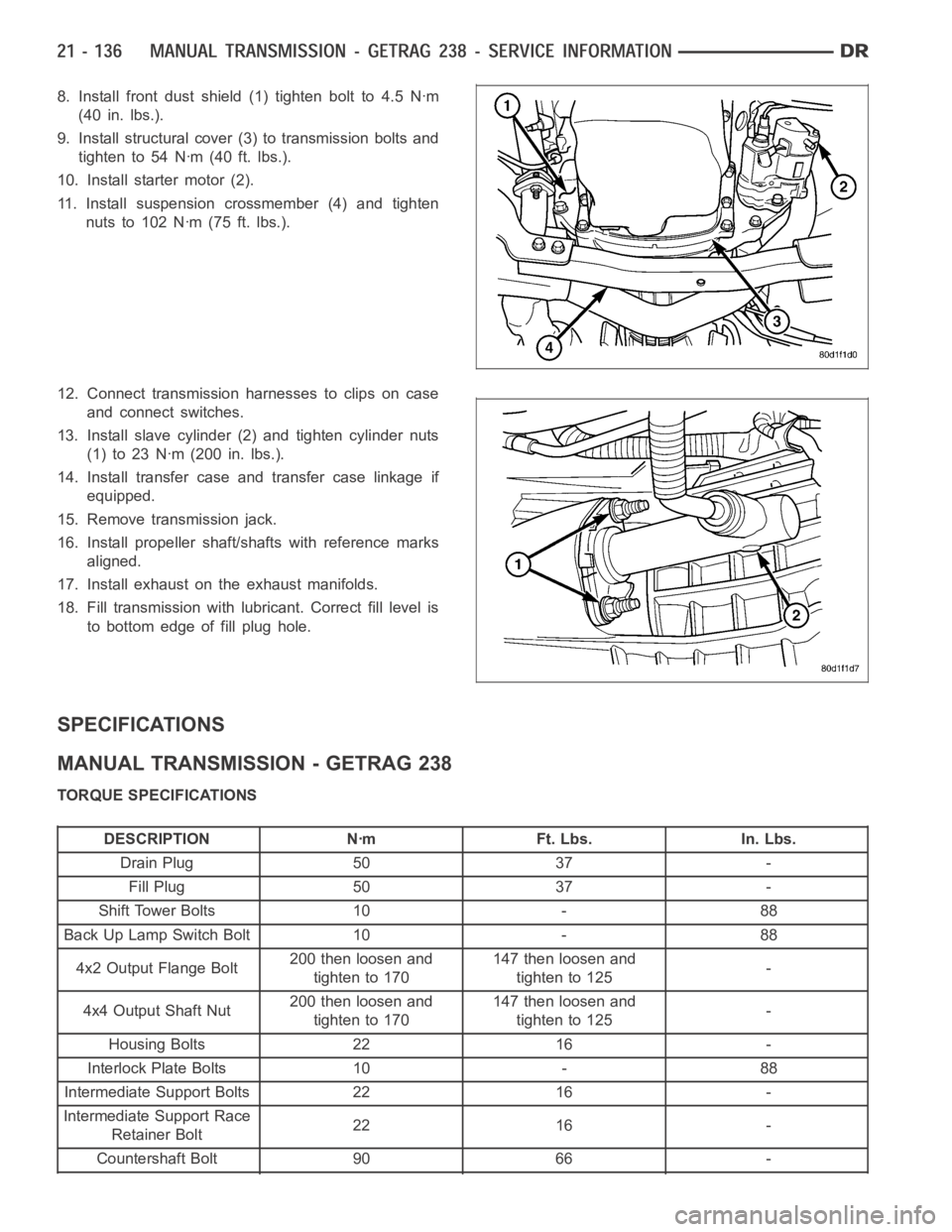

SPECIFICATIONS

MANUAL TRANSMISSION - GETRAG 238

TORQUE SPECIFICATIONS

DESCRIPTION Nꞏm Ft. Lbs. In. Lbs.

Drain Plug 50 37 -

Fill Plug 50 37 -

Shift Tower Bolts 10 - 88

Back Up Lamp Switch Bolt 10 - 88

4x2 Output Flange Bolt200 then loosen and

tighten to 170147 then loosen and

tighten to 125-

4x4 Output Shaft Nut200 then loosen and

tighten to 170147 then loosen and

tighten to 125-

Housing Bolts 22 16 -

Interlock Plate Bolts 10 - 88

Intermediate Support Bolts 22 16 -

Intermediate Support Race

Retainer Bolt22 16 -

Countershaft Bolt 90 66 -

Page 2663 of 5267

page page

MANUAL TRANSMISSION-T56 - SERVICE

INFORMATION

DIAGNOSIS AND TESTING

MANUAL TRANSMISSION - T56 ............. 143

STANDARD PROCEDURE - DRAIN AND FILL . . 143

REMOVAL ................................... 144

DISASSEMBLY .............................. 146

CLEANING .................................. 168

INSPECTION ................................ 168

ASSEMBLY .................................. 169

INSTALLATION .............................. 189

ADJUSTMENTS

ADUSTMENTS ............................ 191

SPECIFICATIONS

MANUAL TRANSMISSION - T56 ............. 192SPECIAL TOOLS ............................ 194

SEAL-EXTENSION HOUSING

REMOVAL ................................... 198

INSTALLATION .............................. 198

SHAFT-INPUT

REMOVAL ................................... 199

INSTALLATION .............................. 200

SOLENOID-REVERSE LOCKOUT

DESCRIPTION ............................... 201

OPERATION ................................. 201

SOLENOID-REVERSE LOCK-OUT

DESCRIPTION ............................... 202

OPERATION ................................. 202